Abstract

The objective of the article was to describe the importance of a good technically and economically planned process for purchasing a rail vehicle. Compliance with this process with safety standards and energy efficiency is crucial regarding effectiveness in the long-life cycle cost of a rail vehicle. Methods that were used focused on audit and document analysis. In the result based on a specific audit of a railway company, some non-compliances were found, and it was methodically proven that they are significant risk factors in terms of performing such processes in the future. Major conclusions regarded the importance of fulfilling legal requirements of SMS for purchase purposes, involvement of a safety engineer post in this process, and usage of technical feedback regarding previous operation of railway vehicles and operational findings from the past. The transport policy of the EU and other developed countries sets ambitious goals for reducing energy consumption in transportation activities, which is linked to the aim of reducing environmental burdens.

1. Introduction

Safety in rail transport represents one of the main criteria for the assessment of the functioning of a railway transport system and has a decisive effect on its efficiency, as well as on the wide-ranging concept of the quality of transport services. All parties involved (to a various extent) in railway transport-related activities utilise safety-related procedures and perform risk analyses related to this process. However, there are no available publications on engineering safety management (ESM) related to the purchase and operation of railway vehicles that would be helpful to railway engineering specialists (or to staff responsible for the modification of railway infrastructure sub-systems). Such procedures would vastly improve the safety and efficiency of the implemented technical solutions. This inevitably requires the consideration of aspects reaching beyond engineering issues and usually requires the participation of individuals without any technical knowledge [1].

It is important to consider the complexity of the issue of energy efficiency in electrified rail transport. The problem of energy efficiency is multidimensional and concerns not only factors shaping the level of energy consumption for traction purposes but also the selection of technical means ensuring efficient, energy-efficient vehicle designs, taking into account financially justified levels of investment and operating costs, rolling stock, infrastructure, traffic organisation, and transport. Finding an optimal solution should also consider the timetable, passenger comfort, traffic conditions on the route, and the durability and reliability of rail vehicles. This analysis serves as a starting point for further work on the energy efficiency of electrified rail transport, aiming to develop an energy optimisation algorithm [2,3,4,5,6,7,8,9,10,11,12].

In article [7], a review of existing technologies for both direct contact and wireless power transmission (PT) for Light Rail Vehicles (LRV) was conducted. Subsequently, an in-depth critical assessment of Inductive Power Transfer (IPT) and Capacitive Power Transfer (CPT) technologies for LRVs was carried out. The focus was particularly on presenting the feasibility and advantages of CPT for powering LRVs, emphasising its effectiveness in terms of power transmission capability, safety, and other factors. The following requirements for this power transmission system for LRVs were defined [5]:

- Performance: the system must effectively power a fully loaded LRV.

- Safety: the system must maintain a high level of safety during operation near pedestrian traffic and roads.

- Cost: the system must be cost-effective in both deployment and maintenance.

- Reliability: the system must be durable under continuous working conditions.

- Compatibility: the system must be compatible with various LRV chassis, brands, models, and capacities.

Keeping in mind the long-life cycle of railway vehicles, it is of the utmost importance that individuals in charge of this process possess proper knowledge and base their decisions on precise factors [8,9,10].

Any organisation acting as a railway operator must have a safety management system, which needs to be certified before being introduced into operation [5]. It must then act in accordance with this system’s requirements. The system should indicate whether a given risk is managed at an acceptable level. It should also indicate whether a process-based and systematic approach to safety management has been implemented to prove that the risk assessment of the organisation is still binding and valid [10,11]. A railway operator’s Safety Management System should define issues such as the following:

- The operator’s safety policy, as well as agreements and arrangements related to safety management;

- The risk management process;

- The change significance assessment process;

- The safety monitoring method;

- The methodology of implementation of the safety policy;

- The methodology of assurance of adequate competence of personnel for safety-related work.

In accordance with the regulation of the Commission (EU) No. 402/2013, the introduction of any changes to the railway system, which may be of a technical, maintenance, or organisational nature, should be analysed in terms of their impact on safety [9]. This analysis should be performed in accordance with criteria such as failure consequence, novelty used in implementing the change, complexity of change, monitoring, and reversibility of change.

If a change is considered insignificant, the keeping of adequate documentation to justify the undertaken decision will be sufficient. Otherwise, if a change is considered significant, a risk management process will be implemented.

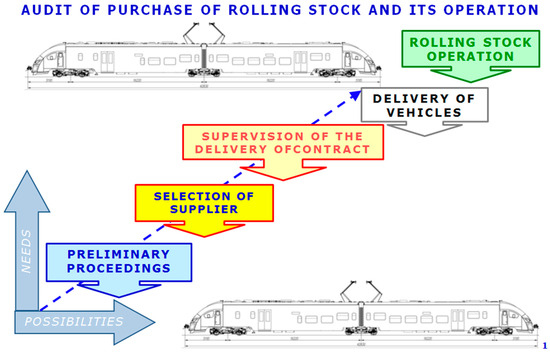

Persons responsible for the management of the organisation should ensure that, at any stage of the purchase or operation of a railway vehicle (Figure 1), the following criteria are met:

Figure 1.

The engagement of rail operators in the railway vehicle purchasing process.

- All employees are aware of any risks involved and are at all times conscious of any factors that may affect safety;

- All employees are ready to inform of any safety-related incidents and near misses (even if this is not convenient or may reveal any mistakes that were made), and the management actively reacts to this information;

- All employees understand what is considered acceptable behaviour, are reprimanded for their careless or intentional actions, and are encouraged to learn from their mistakes;

- The organisation is flexible enough to be able to effectively deal with abnormal/incorrect situations;

- The organisation draws conclusions from past experiences and uses these conclusions to improve safety.

An organisation responsible for the purchase of railway vehicles must ensure that all of its employees who perform actions that may affect safety have adequate competence and qualifications to perform these actions at every stage (Figure 1). The organisation should provide these employees with sufficient resources and authorisation needed for the performance of their duties and should monitor how these employees perform their duties. It should also define any requirements regarding the competencies and qualifications of employees who perform specific actions that may affect safety. The idea is that the organisation should determine which training, technical knowledge, skills, experience, and qualifications are needed for employees to decide what needs to be carried out to ensure an appropriate level of safety and to implement these actions correctly. If these requirements are met, we can expect, with a high level of probability, that the risk will be controlled entirely within acceptable standards, which are defined under the agreed methods for the management of this risk, and evidence demonstrating that requirements specified by these standards are met may be sufficient to demonstrate that the risk is under control [12].

Risk management activities are captured as a structured step-by-step process to identify, plan, and manage the risk of hazards during the planning and execution of the core project/process. The methods in question are the PMBoK Guide (Project Management Body of Knowledge) and PRINCE2 (PRojects IN Controlled Environments).

Taking into account the specifics of the railroad sector and the overall objectives of the rolling stock development project, it is necessary to identify risk-generating areas for which the identification of risks, assessment and valuation of risks (also with regard to changes made to the project during its implementation), planning and execution of preventive actions, and monitoring and control of risks should be carried out.

All activities in the process of managing risks associated with the implementation of the rolling stock development project should be carried out in accordance with the procedures adopted for this purpose, properly documented and supervised from the level of the company’s management.

The managers of the organisation, as the persons responsible under the national law for the technical safety of the purchased railway vehicle, require, in the course of the procurement–project (design, production, and operation) procedure, the development of an appropriate Engineering Safety Management (EMS) System, which should ensure effective implementation of the certification process prior to the commissioning of the vehicle for operation. The purpose of a railway vehicle purchasing project is therefore to ensure that the level of safety estimated during the process of the design, production, and testing will be possible to achieve in the course of everyday operation and will not bring them into conflict with the law as a result of any negligence during the implementation of any one of the phases of the project.

Therefore, before the purchase of railway vehicles by the rail operator, it is necessary to develop—in analogy to infrastructural projects—a methodology of supervision of safety levels during each phase of the purchase and operation of a railway vehicle (Figure 1), i.e., the following [13,14,15]:

- To establish an Engineering Safety Management System in accordance with the guidelines of standard PN-EN 50126-1:2018-02 [16] and other documentation, such as the Yellow Book [17];

- To record all decisions made in relation to safety;

- To establish the methodology of implementation of the ALARP (As Low As Reasonable Practicable) principle;

- To appoint an independent and competent specialist;

- To establish the Documentation of Engineering Safety Verification.

Railway Engineering Safety Management applies to the operational safety of railways and should assure their shareholders that the following criteria are met:

- Safety is evaluated by competent specialists using recognised methodologies of assessment [18].

- The project meets safety requirements defined by the shareholders.

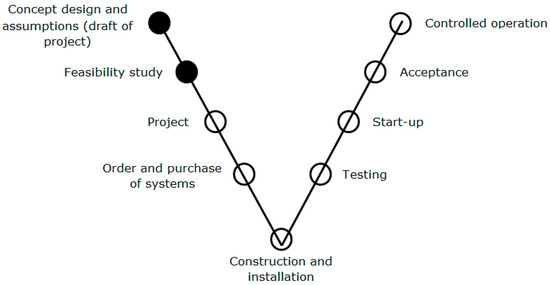

The Project Cycle (Figure 1), which is based on standard PN-EN 50126-1:2018-02, the Yellow Book, or other documents, should refer to actions that aim to ensure safety during all phases of this project and should be appropriate for each phase of the project and requires the following:

- The definition of the System Safety Assurance Plan;

- The implementation of risk assessment to demonstrate the safety of the system;

- The establishment of a hazard log for hazards identified using the risk assessment process, or in a different way, the definition of risk control/mitigation actions;

- The building of arguments to demonstrate the safety of the system and presenting them regularly to appropriate authorities (shareholders, railway safety inspectors, etc.)—dialogue v confrontation—Figure 2.

Figure 2. Life cycle of technical assets.

Figure 2. Life cycle of technical assets.

Building on previous considerations and general comments to assurance safety methods presented in the Yellow Book [17], i.e., the following:

- The planning of activities related to the Engineering Safety Management (ESM) System [18];

- The justification of approach to safety issues [19];

- The definition of safety requirements;

- The identification of roles and responsibilities;

- The identification of safety parameters and control of requirements.

Publication [20] demonstrates the results of an audit of a completed purchase and operation of a specific railway vehicle from the point of view of the Public Procurement Law and the implementation of the provisions of the railway law, where the supplier and safety requirements should be implemented—criterion C of appendix II to the Commission Regulation (EU) 1158/2010 [21]. The approach in Poland is generally to conform with the Public Procurement Law or with the Railway Transport Act, but in fact, both of these requirements have to be respected.

The primary research objective of the study was to present the legal status (in force in Poland) and the technical and organisational status of the rail vehicle purchase process with particular emphasis on safety and energy efficiency issues. For this purpose, the criteria and procedures for the purchase of rail vehicles used so far were analysed.

The primary implementation objective of the work described was the development by an interdisciplinary team of specialists of guidelines for a coherent process of rail vehicle procurement to be used by Polish local government institutions and rail carriers.

The primary social objective of the work was to improve the quality of travel and safety and minimise costs and energy.

This study used three research methods, i.e., a case study for a specific rail vehicle purchase, an analysis of documents related to the purchase, and observations and interviews with those implementing the purchases. For this research, data were used from a specific carrier implementing rail vehicle purchases over a period of several years.

2. Audit of a Completed Purchase and Operation of a Railway Vehicle from the Point of View of Railway Safety and Consumption of Electric Power

2.1. Case Study

In the context of the railway transport operator’s current and planned new vehicle purchases, a team of experts audited the previous purchase and operation of a specific manufacturer’s rail vehicle, from a railway safety perspective and operational requirements [21]. The purpose of this audit was also to develop a methodology and procedures for the purchase of railway vehicles to be used by the operator in the future. A team of specialists in the field of verification of contracts, agreements, purchasing documentation (ToR), and manufacturer’s acceptance documentation was appointed for the analysis of railway safety requirements [22,23]. This team also carried out an assessment of adequate compliance with the provisions of railway safety requirements of the below-mentioned documentation and evaluated compliance with the requirements included therein concerning the following:

- Purchase orders and contracts for the delivery of vehicles for the operator, signed with the Manufacturer;

- ToR documentation for the delivery of vehicles for the operator;

- Agreements and documentation of the requirements for delivery and commissioning of vehicles for the operator.

The analysed vehicle passed the entire public procurement process in accordance with Polish regulation, was approved by a research and certification body, and has been in operation for 2 years.

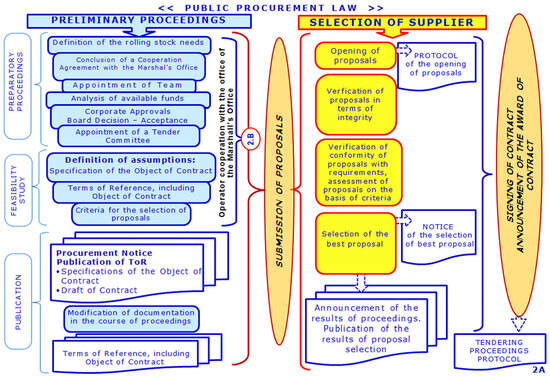

2.2. Tendering Procedure: Signing of Contract

The railway operator, representing a state company, was obliged to observe the Public Procurement Law during the purchase of vehicles. Although the analysis of the tendering process for the purchase of vehicles revealed its conformity with the law, the following reservations could be made from the point of view of the subject of safety:

- The operator’s documentation did not include any documentation regarding a system-based approach to the tender for railway vehicles (Figure 3).

Figure 3. Systematic approach to tendering for rail vehicles.

Figure 3. Systematic approach to tendering for rail vehicles. - There was no evident consideration of the problem of safety, i.e., no implementation of risk assessment to demonstrate the safety of the system.

- There was no indicated person responsible for safety.

- The “lowest price #short delivery time” criterion was chosen for the purposes of the vehicle purchasing and rolling stock supplier selection process (in the form of a tendering procedure). This allows the manufacturer (rolling stock supplier) to assume a dominating position with respect to the railway operator, who urgently needs to commission the vehicles in order to immediately put them into service, which is often carried out at the expense of care and diligence during the acceptance process, and thus at the expense of safety.

- In fact, the above criterion represents a cause for the breach of declared rolling stock delivery deadlines, while the extension of warranty periods (even up to several years) without providing a free and immediate (efficient) supply of spare components and parts (e.g., windows, pantographs, controllers, control devices, pneumatic fittings, shock absorbers, engines, wheelsets, etc.) places the employer in an unfavourable position against the manufacturer (the dependency of the operator on the supplier).

- The state of protection (level of protection) of the operator’s interests in the provisions of the contracts, agreements, purchasing documentation (ToR), and acceptance documentation related to third parties is insufficient, which also directly affects the level of safety.

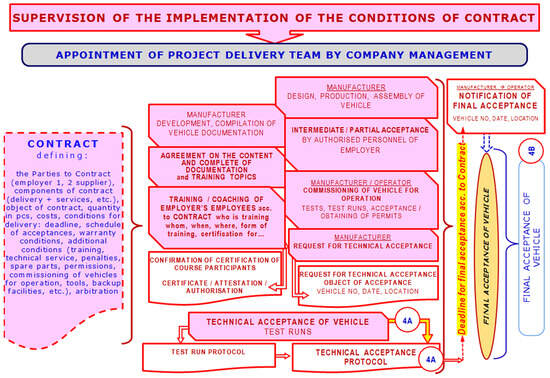

2.3. Supervision over the Implementation of Contractual Conditions until Final Acceptance

In order to ensure the implementation of contractual conditions, the railway operator appointed a team of 11 persons, which was overseen by the company vice-president. During the delivery of the contract, there were changes in the personnel of the team, as well as a change in the overseeing person. Although the team was appointed and was operational, the following reservations can be made with respect to safety issues:

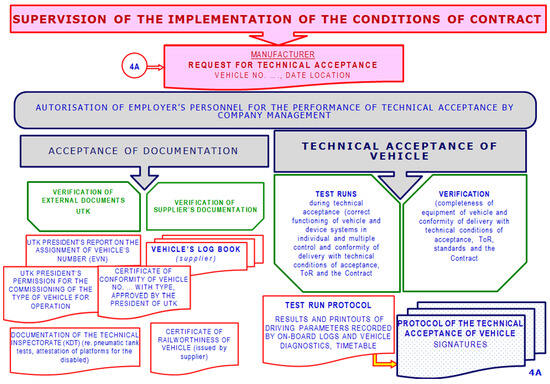

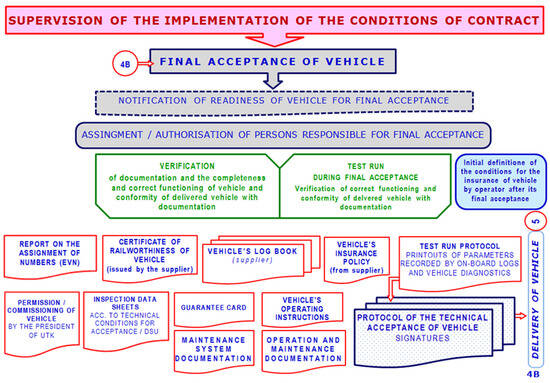

- The operator’s documentation does not include a system-based approach to the supervision of the delivery of the contract (Figure 4, Figure 5 and Figure 6).

Figure 4. Supervision of the implementation of the conditions of contract.

Figure 4. Supervision of the implementation of the conditions of contract. Figure 5. Supervision of the implementation of the conditions of contract—4A.

Figure 5. Supervision of the implementation of the conditions of contract—4A. Figure 6. Supervision of the implementation of the conditions of contract—4B.

Figure 6. Supervision of the implementation of the conditions of contract—4B. - There was no evident consideration of the problem of safety.

- There was no indicated person responsible for safety issues.

- There were no representatives of the field of safety in the team, e.g., related to training of train drivers.

- The content and completeness of documentation were not agreed upon.

- The subject of training courses was not agreed upon. The training/coaching of the operator’s employees was performed in accordance with the contract, but the issues of who was being trained, when, by whom, where, what the form of training is, what the certification is, etc., were not precisely answered or exercised.

- There was no confirmation of certification of the participants of the training certificate/attestation/authorisation.

- There were no intermediate/partial acceptances by authorised representatives of the Employer.

- There was no differentiation between a technical and final acceptance.

2.4. Delivery of Vehicles and Operation of Vehicles in the Warranty Period

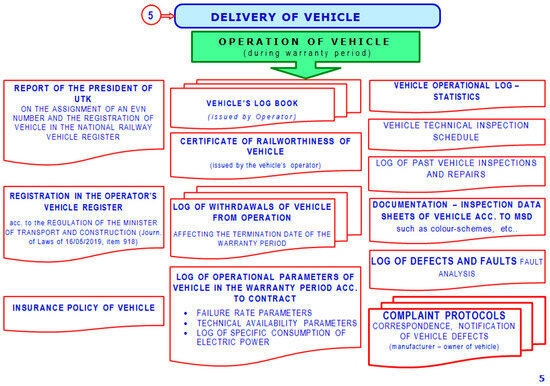

- The operator’s documentation does not contain any information regarding a system-based approach to the supervision of the delivery of the contract in terms of the delivery and operation of vehicles in the warranty period (Figure 7).

Figure 7. Systematic approaches to supervising the implementation of the contract for vehicle delivery and operation.

Figure 7. Systematic approaches to supervising the implementation of the contract for vehicle delivery and operation. - There are no adequate records of the vehicle’s contractual operational parameters during the warranty period, its failure rate {aw}, technical availability {gt}, its specific consumption of electric power, etc. A safety representative did not participate in these procedures.

- Defects or faults were not recorded adequately, and there was no adequate analysis or assessment of these defects or faults. A safety representative did not participate in these procedures.

3. Example of an Analysis of Defects Present during the Operation of a Railway Vehicle from the Safety Point of View

Analysis of Proceedings following the Damage of Vehicle K—003 (during the Warranty Period), on the Basis of Records in the Vehicle’s Log Book

Records from the P-003 Vehicle Board Book during the warranty period were selected for analysis. The quotation of records includes 46 driver annotations concerning the condition of vehicle P-003. The individual entries in the Log Book for Vehicle P-003 were not numbered by their authors in the designated “No.” column. During the above-mentioned period, train drivers assigned to operate vehicle P-003 reported the following:

- Nine (9) entries informing of good technical condition of the vehicle—without any remarks or faults, despite earlier entries reporting incorrect operation, defects, and faults, e.g., on 5, 8, 9, 10, 11, 12, and 16 October.

- In sixteen (16) entries, train drivers reported contradicting information, such as reporting the occurrence of defects and faults of specific components and systems, at the same time informing of the “good technical condition” of the vehicle, without any comments or reservations (annotations of “n/c” or “n/r” without any comments), despite previous (earlier) entries also informing of the occurrence of defects and faults,

- In eighteen (18) entries, train drivers reported defects and the occurrence of incorrect functioning of devices which did not compromise the further operation of the vehicle and allowed the operation of the vehicle to continue,

- In three (3) entries, train drivers reported incorrect functioning of devices, which were classified as defects that prevented further use of the vehicle and required it to be withdrawn from operation for repair due to being unsafe for operation. However, despite these entries, vehicle P-003 continued to be operated, i.e., the vehicle with the defects reported above was used to service more trains and continued to be used in its defective condition.

In accordance with the operator’s internal memo, information on defects was received in successive days by 21 persons from the company, including the directors and the safety representative, whose actions were merely limited to the recording of the vehicle’s defects for statistical purposes.

The value of the reliability index of the vehicle for the reported period was W = 0.99, whereas taking into consideration these defects, it would fall to W = 0.88, which would greatly affect the technical/operational, economic and safety parameters of the vehicle.

4. Example of Analysis concerning Power Supply Systems of Rail Vehicles

Most of the vehicles operated by the analysed carrier are equipped with energy meters, and it is possible to account for the actual consumption of electricity. Older vehicles are not equipped with meters. Due to the entry into force in 2018 of the TSI in terms of requirements for online electricity billing systems, market discernment should be carried out for their implementation, and a strategy should be developed for the carrier’s transition to this system for all rolling stock.

The rules for calculating the reliability index need to be revised. It was proposed to define the calculation algorithm as well as unit energy consumption in the form of a clear tabular algorithm in separate annexes, calculation rules.

Technical and energy analyses should take into account maintenance costs and the possibility of minimising the cost of the entire vehicle life cycle. The share of vehicle maintenance (27%) or traction electricity costs (10%) in the carrier’s operating costs is currently relatively high and should be reduced via optimisation measures. For example, the share of rolling stock maintenance costs (including employment costs) at another carrier remains at 6–7% of the company’s total operating costs and is indexed annually at the inflation rate.

5. General Comments on the Purchase and Operation of Railway Vehicles in Poland

The main reason for the occurrence of transgressions during the purchase and operation of railway vehicles in Poland is, above all, the low level of knowledge of operational/technical issues among persons responsible for the purchase of railway vehicles acting on behalf of the Voivodeship Marshall’s Office. This means that, despite significant expenses being spent on new or renovated rolling stock, in view of the absence of appropriate procedures, the railway market is supplied with vehicles with technical defects or inadequate design features, which generate unnecessary costs for the operation and maintenance of vehicles by their subsequent users.

The absence of common guidelines agreed upon between all local authorities and the rail operators, independent specialists, and the participation of manufacturers in the course of a technical dialogue means that the number of types, versions, sub-versions, and variants of railway vehicles used for the purposes of passenger transport, which have appeared on our tracks in recent years, is very large. This situation has already generated additional costs for the maintenance of single vehicles of a different design, which are often prototypes, which, in the event of a defect, have to wait for months to be repaired because of the absence of the damaged elements.

An excessive number of the type series of existing vehicles represents a major obstacle for the operator in the context of the safe management of certification and authorisation of personnel directly involved with the safety of railway traffic, including train drivers, train managers and inspectors. This process will only be intensive because the demands faced by operators in terms of the assurance of conformity with safety procedures, especially in the context of Safety Management Systems operated by all operators, are systematically growing. The introduction of each new type of vehicle represents a very complex process, which involves training courses and authorisations for the entire personnel, as well as the renewal of these authorisations according to specific deadlines specified by appropriate regulations. This generates significant additional costs for the organisation of training courses, as well as additional supervision and control of the conformity of the actions of personnel assigned to operate a specific type of railway vehicle due to the possible occurrence of changes in the operation of a vehicle, e.g., as a result of a defect or the need to withdraw a certain type of vehicle for overhaul and the need to replace it with a different type of vehicle. The introduction of a new type or variant of rolling stock also requires the operator to carry out a complex and costly analysis process in accordance with the Commission Implementing Regulation (EU) No 402/2013 of 30 April 2013 on the common safety method for risk evaluation and assessment [24].

There is growing legal uncertainty about the way in which tenders for the purchase of railway vehicles are organised as a result of the lack of knowledge in terms of the requirements imposed on railway operators under the Directive (EU) 2016/798 of the European Parliament and of the Council of 11 May 2016 on railway safety [25].

These directives clearly define the principles of risk assessment and the implementation of Safety Management Systems by railway operators. These systems aim to ensure appropriate supervision of all types of risks related to the operation of a railway company, including provided maintenance services, supplies of materials, and the actions of their subcontractors. This supervision is usually provided by way of the performance of periodic audits of potential suppliers in order to verify their technical, economic, and organisational competence and to verify their compliance with safety requirements in view of adequate risk management.

Non-compliance with individually defined requirements in any Safety Management System of a railway operator means that the specific service, product, or element cannot be used unless it has successfully passed the supplier’s verification process, and the supplier himself must be listed as a qualified/recognised supplier. This situation is theoretically in contradiction to the Public Procurement Law, which requires all entities subject to this law, including the Voivodeship Marshal’s Office and the local railway operators, to organise open tenders. It is fair to say that none of the Voivodeship Marshal’s Offices, who act as suppliers (indirect suppliers, but nevertheless they are rolling stock suppliers) for railway operators, have been audited by any of the railway operators, which represents a breach of safety regulations and non-compliance with the Safety Management Systems approved by the President of the Railway Transport Authority (UTK).

Another major problem is the absence of a uniform, clear, and continuous compilation of the entire history of the operation and repair of railway vehicles. The dynamic growth of competitiveness in the field of passenger transport, short periods of availability of vehicles to operators, and frequent changes in their users mean that the operation of rolling stock by local operators is becoming increasingly dangerous.

Another problem is the lack of enforcement by the employers of penalties towards suppliers, resulting from the breach of conditions specified in the tenders. The reason for this is the absence of the correct registration and classification of the types of defects and repairs, as well as the reasons for their occurrence, in accordance with the principles of operation of vehicles. This way, the manufacturers, despite being financially responsible under the provisions of the tender for issues such as non-compliance with availability, reliability parameters, design errors, or minimum mileage of wheelsets from the first run, can avoid this responsibility and the cost of the elimination of these transgressions is borne by the operator, who is then reimbursed in the form of subsidies from the local government.

6. General Comments on Rail Vehicle Power Systems

It is a requirement for the vehicle manufacturer to test and document the results of tests under operating conditions (instead of computer simulations) to determine, for example, the following:

- -

- The permissible (maximum) power set for a vehicle of nominal weight with a load after one, two, or three traction motors have been taken out of service (e.g., after an inverter failure) when a smaller number of traction motors and inverters are involved in generating driving force and electrodynamic braking.

- -

- The permissible (maximum) time of vehicle standstill without power supply from the 3 kV traction network, i.e., to determine the maximum time of drawing energy to power systems (systems) from onboard sources (battery banks) during standstill (parking mode) in order to determine after what time the degree of discharge of onboard energy sources (battery banks) will allow procedures to ensure the safety of passengers.

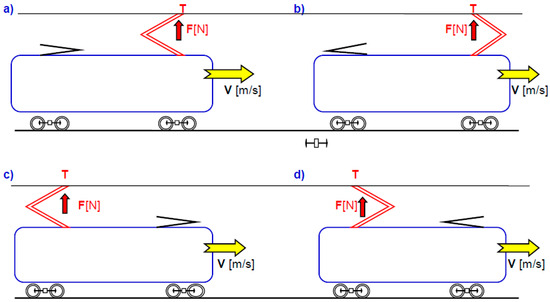

There is also a lack of unambiguous regulations taking into account the results of aerodynamic tests, depending on the speed and direction of travel, recommending the most favourable configuration of the pantograph in vehicles (Figure 8). Various configurations of the pantograph–catenary system not only affect the durability of the system but also have an impact on energy-related issues.

Figure 8.

Configurations of the pantograph in vehicles (a–d).

The rapid technological advancement enables the use of energy-efficient solutions in rail transport. Unfortunately, they typically require significant investments in research, development, implementation, and organisational effort. As a result, they are gradually introduced, primarily in new rolling stock but also during the modernisation of rolling stock or rail transport routes. The effects, such as reduced energy consumption in rail systems, will be observed gradually and over a longer period. Therefore, it is essential to consider the energy-saving effect, for example, when calculating the life cycle cost (LCC) of rail rolling stock, typically used for 30 years or more [22].

Numerous transgressions have accumulated over the years on the railway rolling stock supply market, which must be unquestionably eliminated in the future.

7. Conclusions

The condition and safety of railway vehicles represent one of the main indicators for the assessment of the Polish transport system. Special attention must be given to long-term planning with the consideration of resources, climate change and spatial development, demographic, economic, and legal factors, as well as issues related to the maintenance and life cycle of vehicles. On the basis of the performed audit of the purchase and operation of a railway vehicle by the operator, from the point of view of the Public Procurement Law and the implementation of the provisions of the railway law, where the supplier and safety requirements should be implemented—criterion C of appendix II to the Commission Regulation (EU) 1158/2010—the following conclusions can be formulated:

- The absence in the documentation of any requirements for a system-based approach to the supervision of the delivery of a contract for the purchase of a vehicle has a profound impact on technical/operational, economic, and safety factors.

- Documentation for the delivery of a railway vehicle purchase contract must explicitly include a reference to safety issues and must specify a person responsible for safety issues.

- The delivery of a railway vehicle purchase contract should conform to safety levels defined by the shareholders. Safety should be evaluated by competent specialists using recognised methodologies of assessment.

- In previous works and publications, there has been a lack of a systematic approach to the issues of safety, energy efficiency, and operation from the tendering phase to the operation of rail vehicles.

- The management of the organisation should ensure that, at any stage of the process of purchase or operation of a railway vehicle, all employees are aware of any risks present during the performance of their professional duties and are at all times informed of any factors which may affect safety.

- The process of the purchase and operation of a railway vehicle, performed by the operator, conformed to the requirements of the Public Procurement Law but did not meet the provisions of the railway law, where the supplier and safety requirements should be implemented—criterion C of appendix II to the Commission Regulation (EU) 1158/2010.

- In the analysed railway company, there are many types of rail vehicles from various manufacturers, which significantly complicates their operation (usage and maintenance), increases procurement and operating costs, and reduces safety levels.

- The operator’s new methodology of the delivery of railway vehicle purchase contracts, established on the basis of the performed audit, allows him to assure his shareholders that safety issues will be assessed by competent specialists, with the use of recognised assessment methods.

- Actions aimed at energy efficiency primarily involve changes in traffic organisation and management, as well as the implementation of new technical solutions. These efforts have been ongoing worldwide for years, and the transport policy of the EU and other developed countries sets ambitious goals for reducing energy consumption in transportation activities, which is linked to the aim of reducing environmental burdens.

The rules for calculating the reliability index need to be revised. It is proposed that carriers define an algorithm for calculating vehicle reliability as well as unit energy consumption in the form of a clear tabular algorithm.

The strategic planning of the purchase of railway vehicles should cover purchase preparation, design and production, initial testing and decisions regarding major problems and risks for all stages, system configuration and the implementation of defined concepts. Long-term periods for the planning of railway projects, which are subject to detailed analysis once every few years, should be implemented.

Funding

This research received no external funding.

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The author declares no conflict of interest.

References

- Kour, R.; Aljumaili, M.; Karim, R.; Tretten, P. eMaintenance in railways: Issues and challenges in cybersecurity. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2019, 233, 1012–1022. [Google Scholar] [CrossRef]

- Szeląg, A. Zwiększanie efektywności energetycznej transportu szynowego. Technika Transportu Szynowego 2008, 14, 12–18. [Google Scholar]

- Jakubowski, A.; Jarzębowicz, L.; Karwowski, K.; Wilk, A. Efektywność energetyczna pojazdu szynowego w różnych warunkach obciążenia. Technika Transportu Szynowego 2018, 12, 44–48. [Google Scholar]

- Harrison, T.J.; Midgley, W.J.B.; Goodall, R.M.; Ward, C.P. Development and Control of a Rail Vehicle Model to Optimise Energy Consumption and Reduce Carbon Dioxide Emissions. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2021, 235, 1177. [Google Scholar] [CrossRef]

- Williams, K.J.; Wiseman, K.; Deilami, S.; Town, G.; Taghizadeh, F. A Review of Power Transfer Systems for Light Rail Vehicles: The Case for Capacitive Wireless Power Transfer. Energies 2023, 16, 5750. [Google Scholar] [CrossRef]

- Halkos, G.E.; Tsirivis, A.S. Sustainable Development of the European Electricity Sector: Investigating the Impact of Electricity Price, Market Liberalization and Energy Taxation on RES Deployment. Energies 2023, 16, 5567. [Google Scholar] [CrossRef]

- Raczyński, J. Czynniki decyzyjne w procesie zakupu taboru kolejowego. TTS Technika Transportu Szynowego 2007, 13, 38–45. [Google Scholar]

- Kulkarni, B.; Qazizadeh, A.; Berg, M.; Dirks, B.; Persson, I. Investigating the effect of the equivalent conicity function’s nonlinearity on the dynamic behaviour of a rail vehicle under typical service conditions. Veh. Syst. Dyn. 2022, 60, 3484–3503. [Google Scholar] [CrossRef]

- Konowrockia, R.; Kalinowskia, D.; Szolca, T.; Marczewski, A. Identification of safety hazards and operating conditions of the low-floor tram with independently rotating wheels with various drive control algorithms. Eksploatacja i Niezawodnosc–Maint. Reliab. 2021, 23, 21–33. [Google Scholar] [CrossRef]

- Alawad, H.; Kaewunruen, S.; An, M. A Deep Learning Approach towards Railway Safety Risk Assessment. IEEE Access 2020, 8, 102811–102832. [Google Scholar] [CrossRef]

- Andrews, J. A modelling approach to railway track asset management. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2013, 227, 56–73. [Google Scholar] [CrossRef]

- Wang, K.; Wang, Y. How AI Affects the Future Predictive Maintenance: A Primer of Deep Learning. In Advanced Manufacturing and Automation VII; Wang, K., Wang, Y., Strandhagen, J., Yu, T., Eds.; Springer Singapore: Singapore, 2018; pp. 1–9. [Google Scholar]

- BS EN 50126-2:2017; 50126 BSI Standards Publication Railway Applications—The Specification and Demonstration of Reliability, Availability, Maintainability and Safety (RAMS). The British Standards Institution: London, UK, 2017; National Page 25 of 28.

- Chen, C.; Wang, C.; Lua, N.; Jiang, B.; Xing, Y. A data-driven predictive maintenance strategy based on accurate failure prognostic. Eksploatacja I Niezawodnosc–Maint. Reliab. 2021, 23, 387–394. [Google Scholar] [CrossRef]

- Pordel, D.; Petersson, L.; Namin, S.; Rebola-Pardo, A. Modeling the cost and coverage of an ad-hoc asset management system based on existing fleet vehicles. In Proceedings of the 2015 IEEE Intelligent Vehicles Symposium (IV), Seoul, Republic of Korea, 28 June–1 July 2015; pp. 1068–1073. [Google Scholar]

- PN-EN 50126-1:2018-02; Zastosowania Kolejowe—Specyfikowanie i Wykazywanie Niezawodności, Dostępności, Podatności Utrzymaniowej i Bezpieczeństwa (RAMS)—Część 1: Proces Ogólny RAMS. Available online: https://sklep.pkn.pl/pn-en-50126-1-2018-02p.html (accessed on 19 January 2024).

- Engineering Safety Management (The Yellow Book) Fundamentals and Guidance; Rail Safety and Standards Board on behalf of the UK Rail Industry: London, UK, 2007; Volumes 1 and 2.

- Gola, A.; Pastuszak, Z.; Relich, M.; Sobaszek, Ł.; Szwarc, E. Scalability analysis of selected structures of a reconfigurable manufacturing system taking into account a reduction in machine tools reliability. Eksploatacja i Niezawodnosc–Maint. Reliab. 2021, 23, 242–252. [Google Scholar] [CrossRef]

- Sitarz, M. Analiza bezpieczeństwa przy zakupie pojazdów szynowych przez przewoźnika kolejowego. Materiały wewnętrzne niepublikowane 2019. [Google Scholar]

- Public Procurement Law. Regulation of 29 January 2004 (acc. to Art. 39 et seq.). J. Laws 2004, 1986, 2215. [Google Scholar]

- Commission Regulation (EU) No 1158/2010 of 9 December 2010 on a Common Safety Method for Assessing Compliance with the Requirements for Obtaining Railway Safety Certificates. Appendix II, Criterion C. Available online: https://eur-lex.europa.eu/legal-content/en/ALL/?uri=CELEX%3A32010R1158 (accessed on 19 January 2024).

- Aditya, P.; Uday, K. Maintenance performance measurement (MPM): Issues and challenges. J. Qual. Maint. Eng. 2006, 12, 239–251. [Google Scholar]

- Morant, A.; Karim, R.; Tretten, P.; Larsson-Kråik, P.O. Dependability improvement through configuration management—A study of railway signalling systems. Int. J. COMADEM 2013, 16, 31–40. [Google Scholar]

- Commission Implementing Regulation (EU) No 402/2013 of 30 April 2013 on a Common Safety Method for Risk Evaluation and Assessment and Repealing Regulation (EC) No 352/2009. Available online: https://eur-lex.europa.eu/legal-content/en/TXT/?uri=CELEX%3A32013R0402 (accessed on 19 January 2024).

- Directive (EU) 2016/798 of the European Parliament and of the Council of 11 May 2016 on Railway Safety. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32016L0798 (accessed on 19 January 2024).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).