Synergistic Hybrid Marine Renewable Energy Harvest System

Abstract

1. Introduction

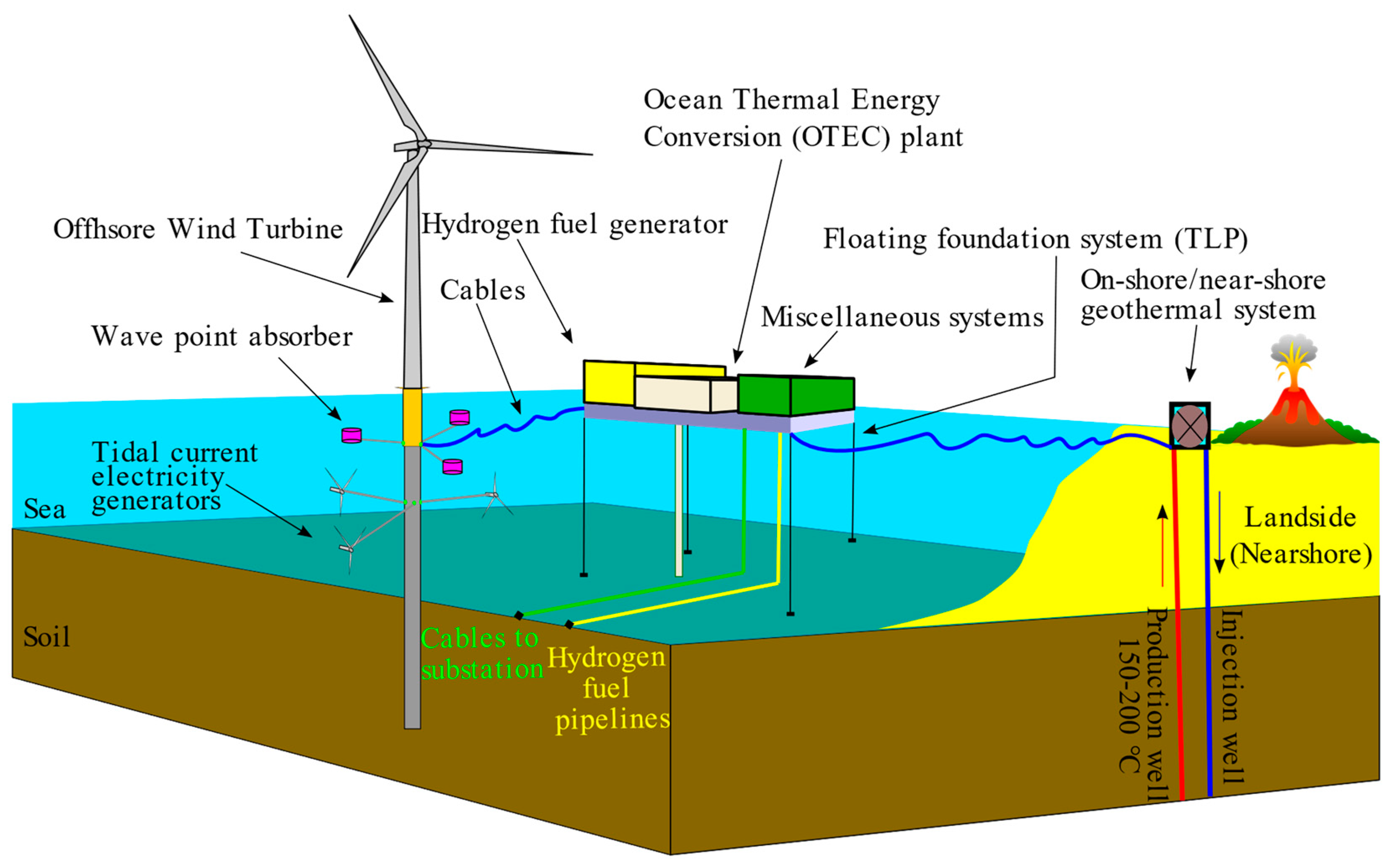

2. Marine Renewable Energy Harvest Devices and Energy Storage Technologies

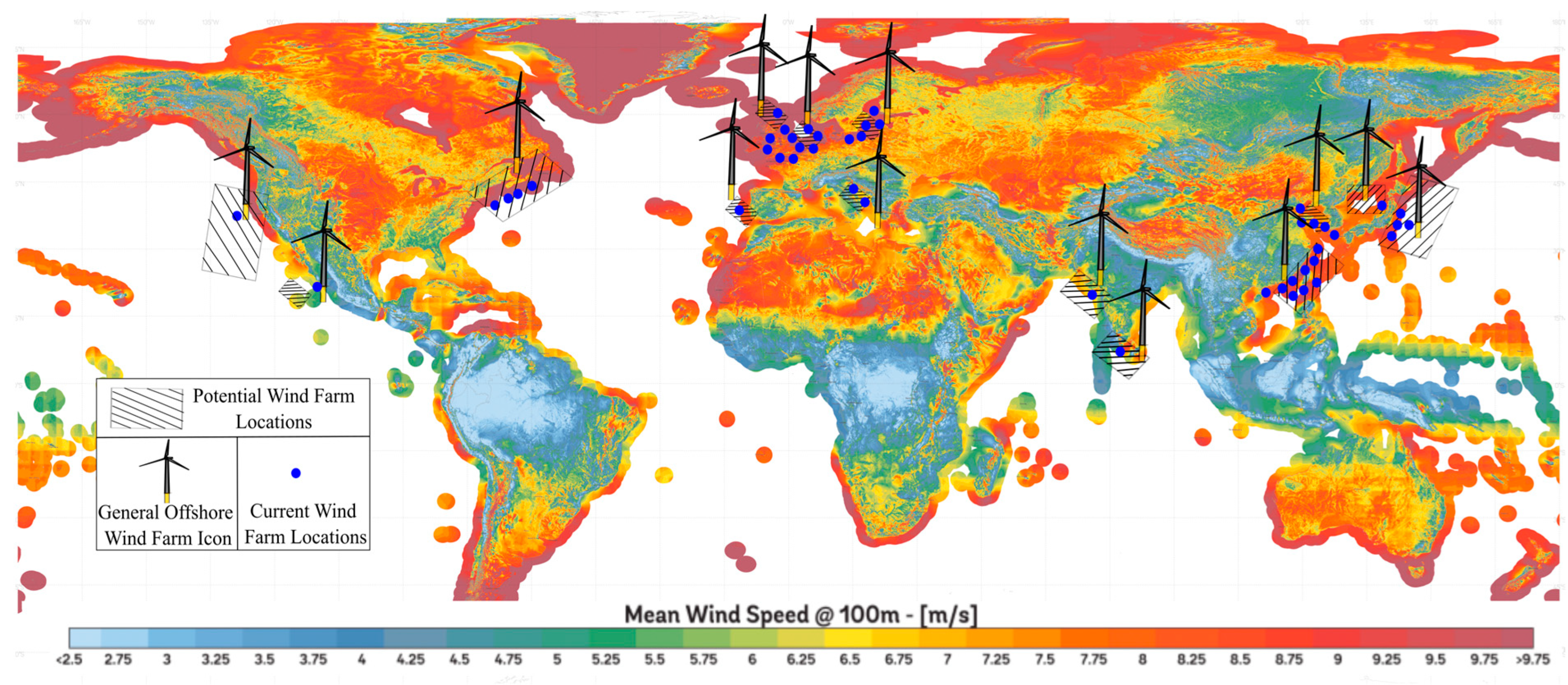

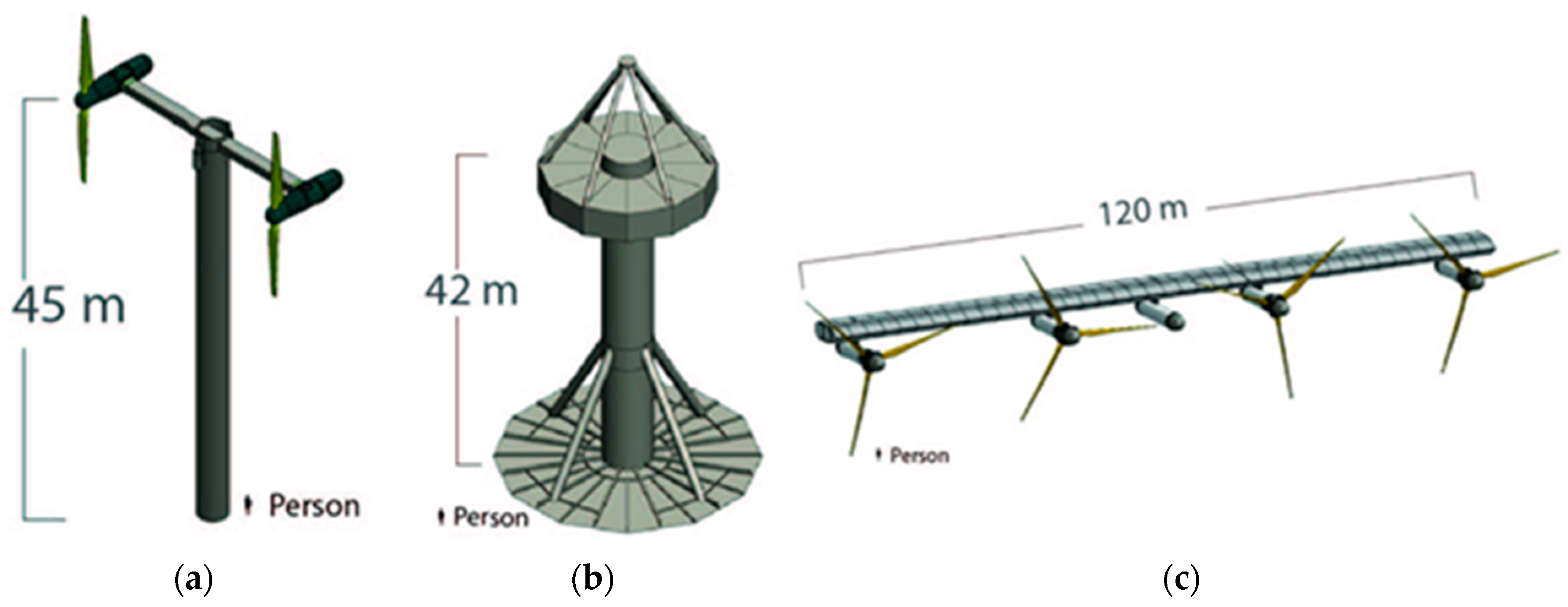

2.1. Offshore Wind Turbines (OWT)

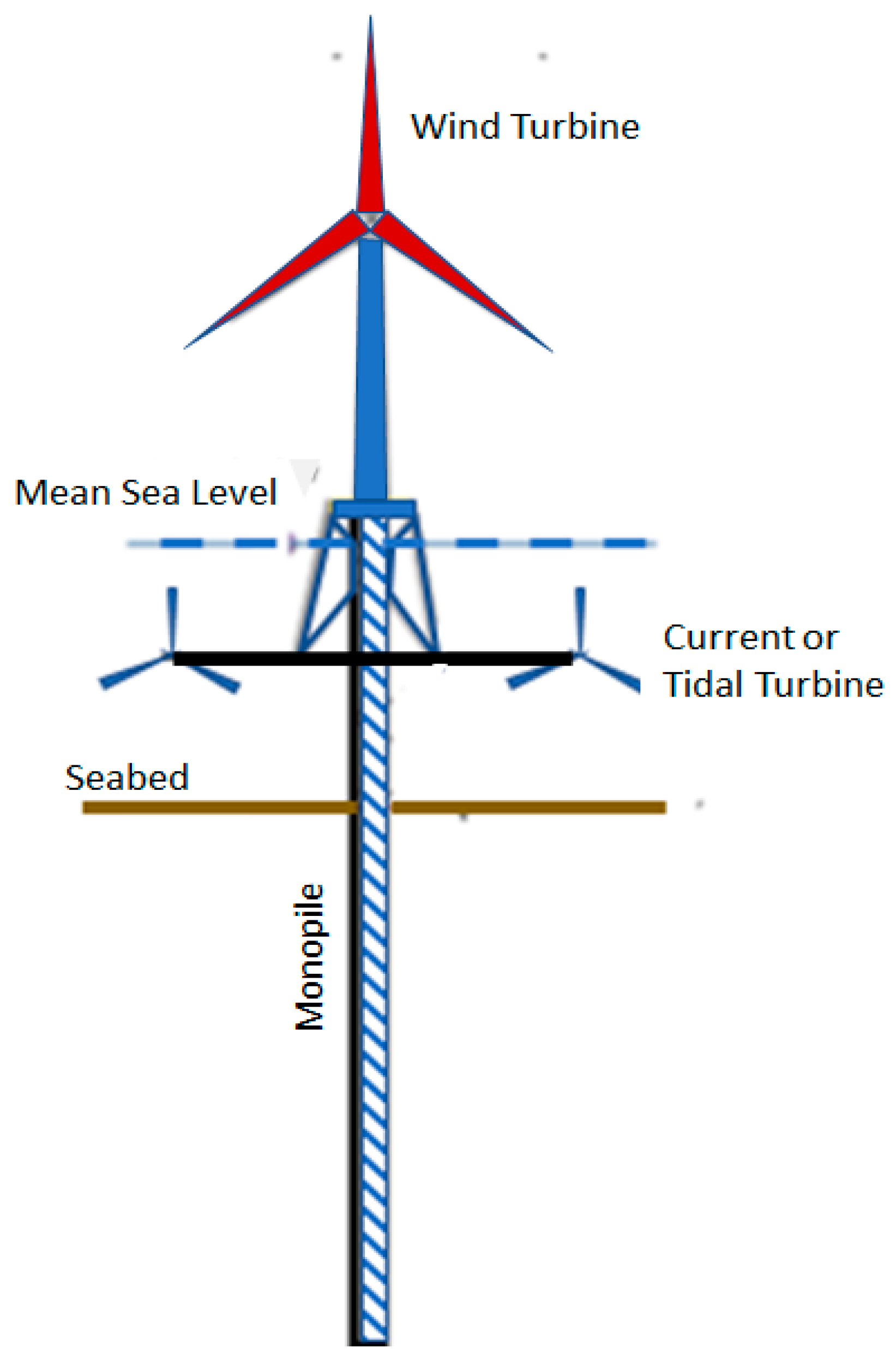

2.2. Marine Hydrokinetic (MHK) Energy Harvest Devices

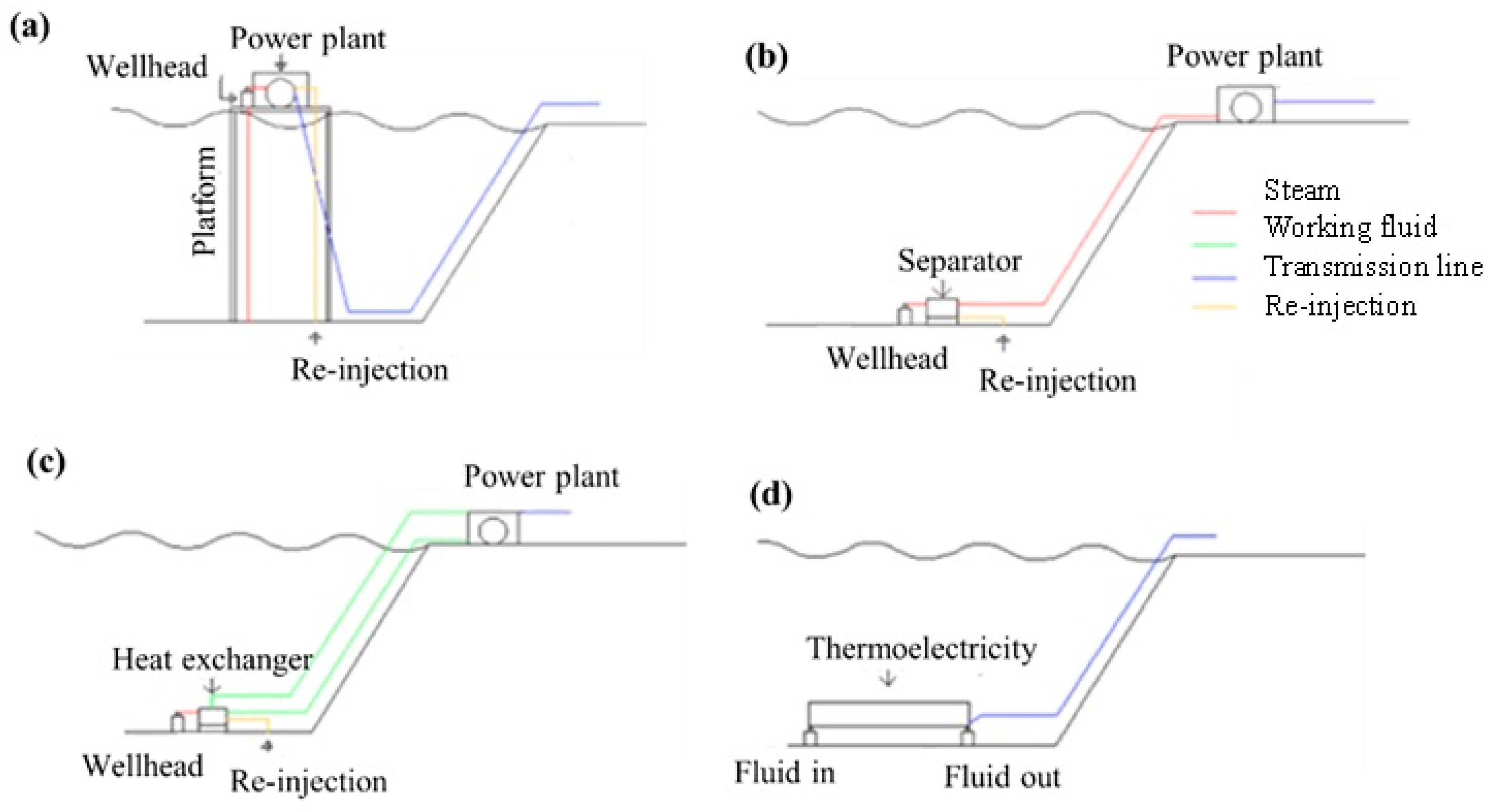

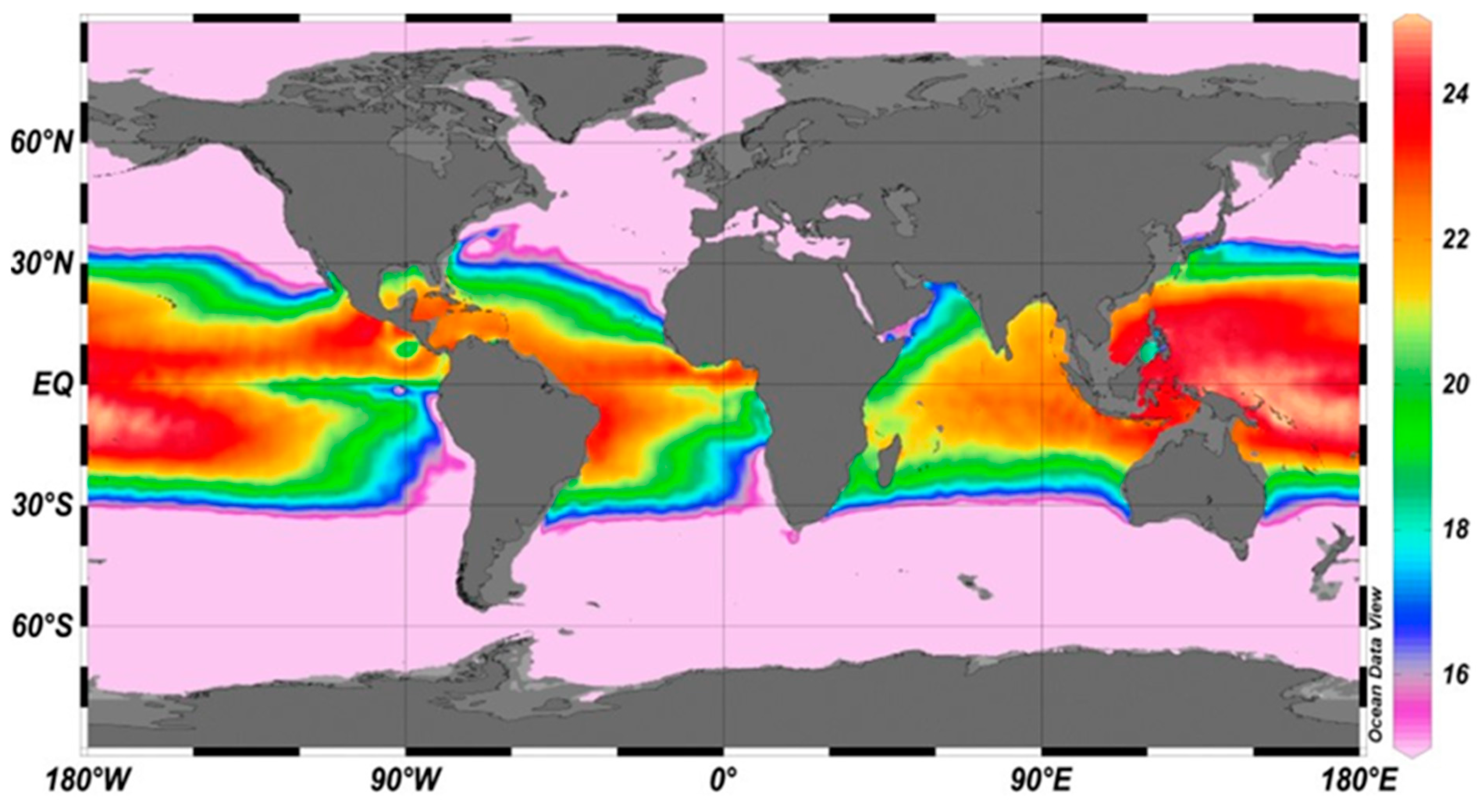

2.3. Marine Geothermal and Ocean Thermal Energy Conversion Technologies

- (a)

- Platform-based geothermal power plant where the geothermal fluids and re-injection fluids go through a pipeline from the seabed to the platform;

- (b)

- Land-based single-flash power plant and a separator located at the seabed;

- (c)

- Land-based binary power plant and a heat exchanger located at the seabed;

- (d)

- Underwater thermo-electricity power station.

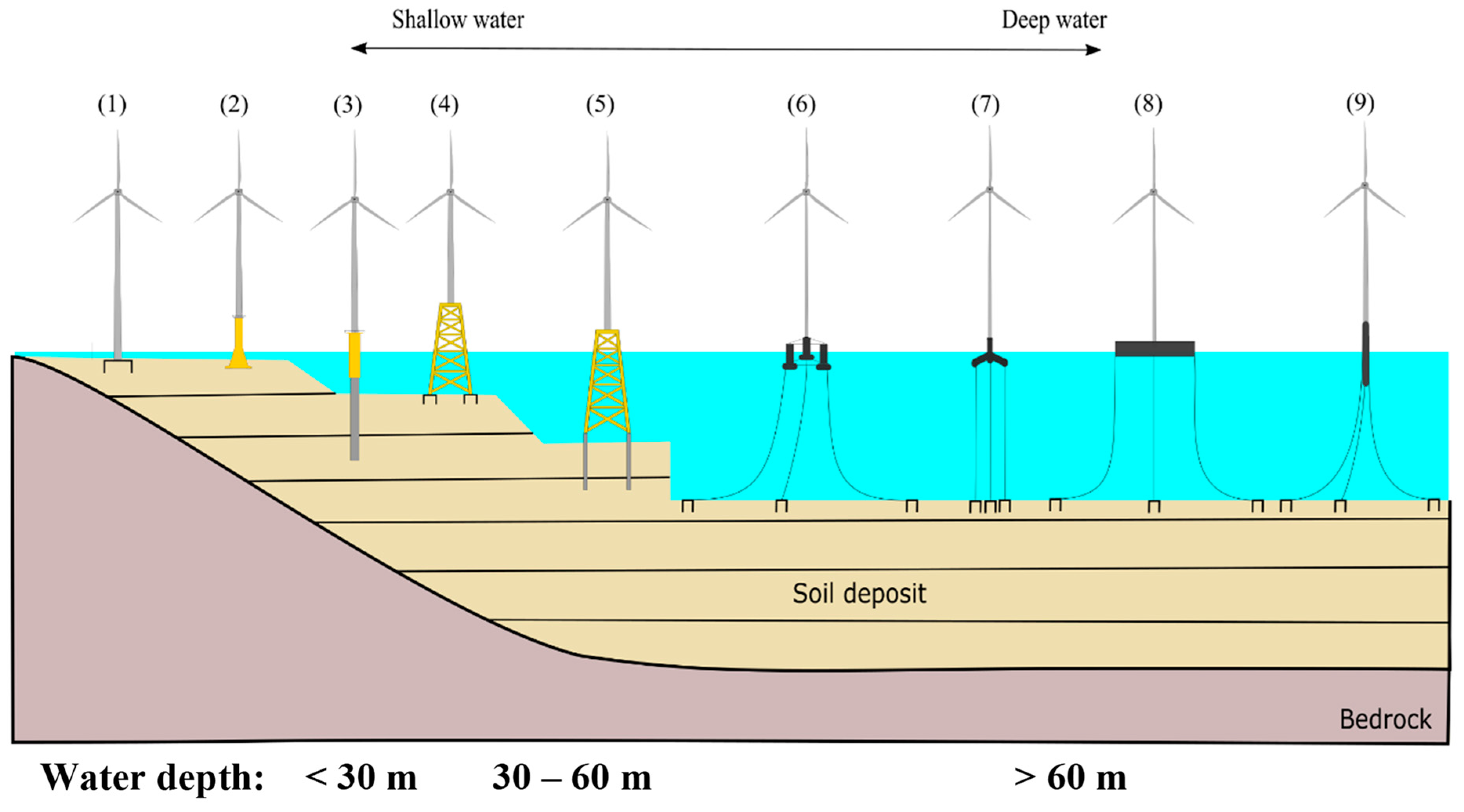

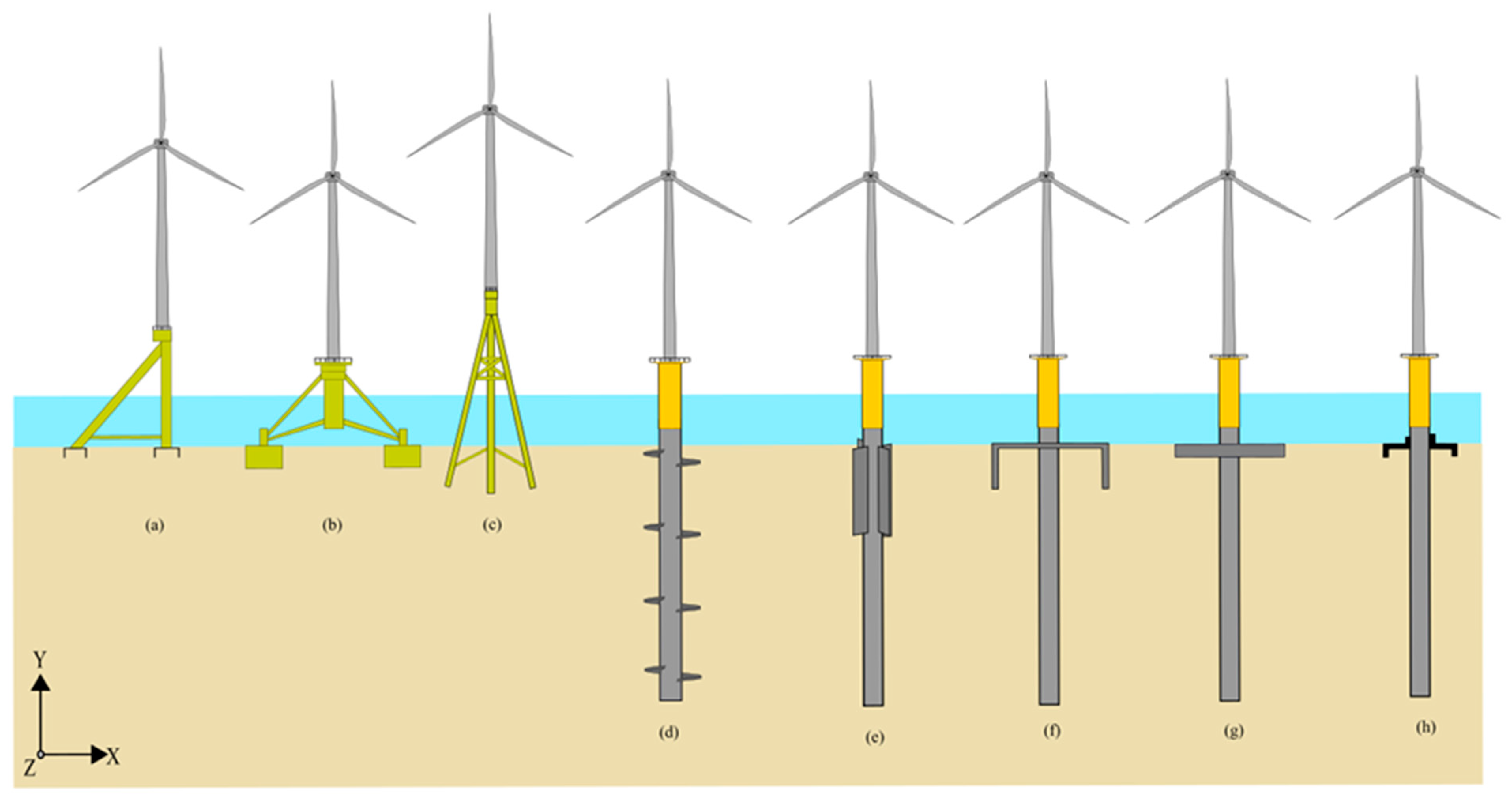

2.4. Foundation Support Systems for Energy Devices

2.4.1. Fixed-Based Foundations

2.4.2. Floating Foundations

2.5. Transmission Infrastructures

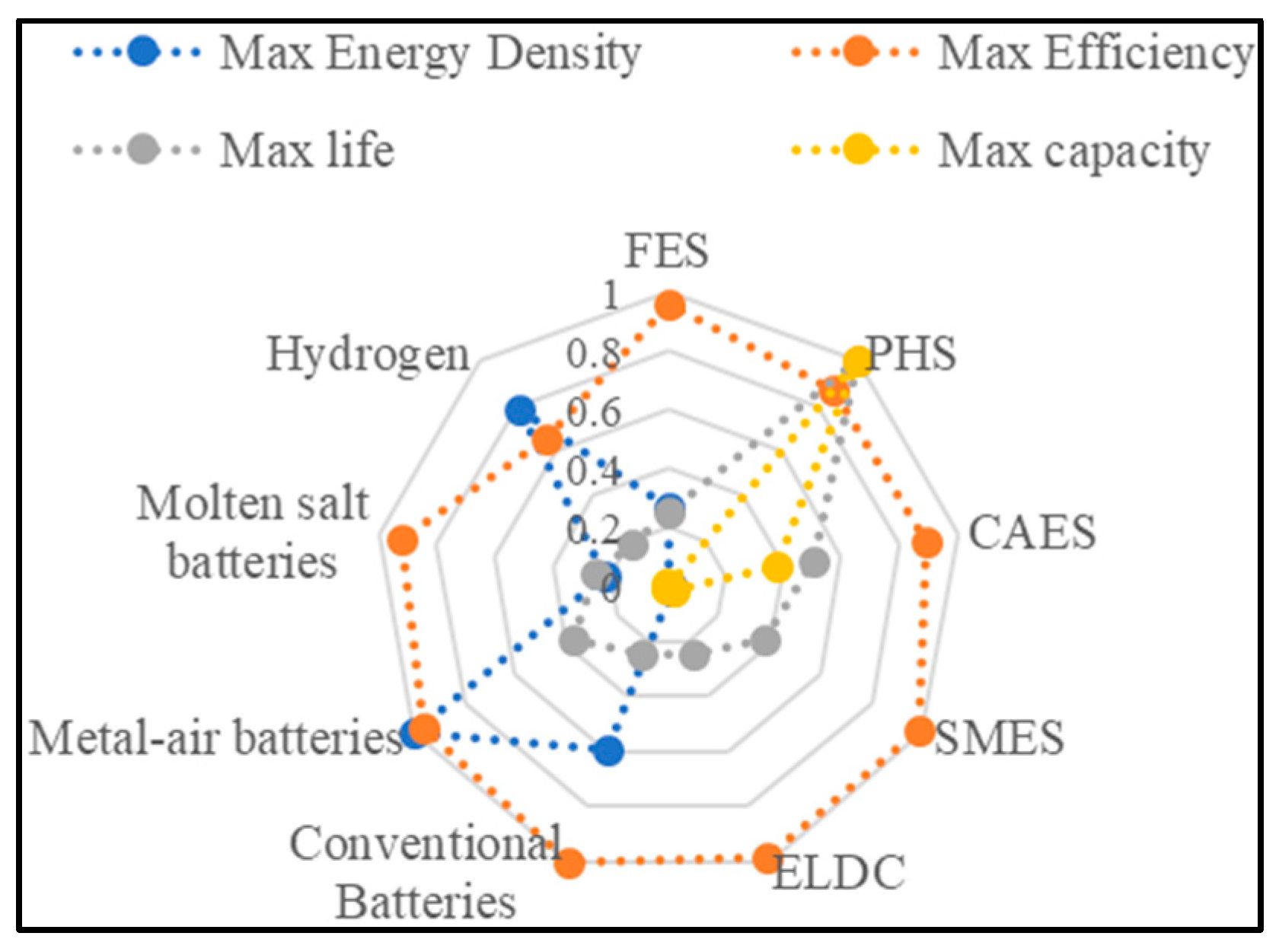

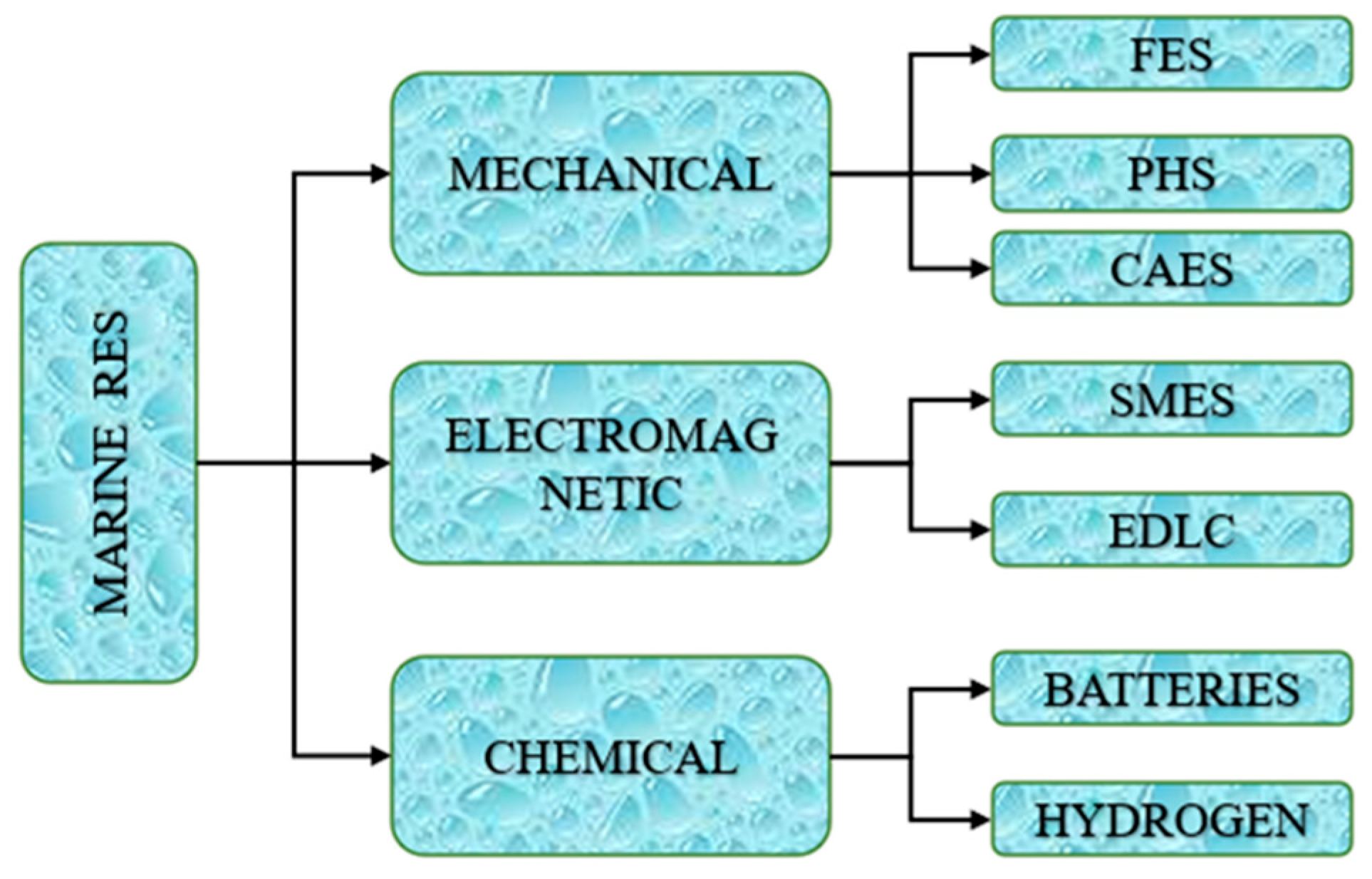

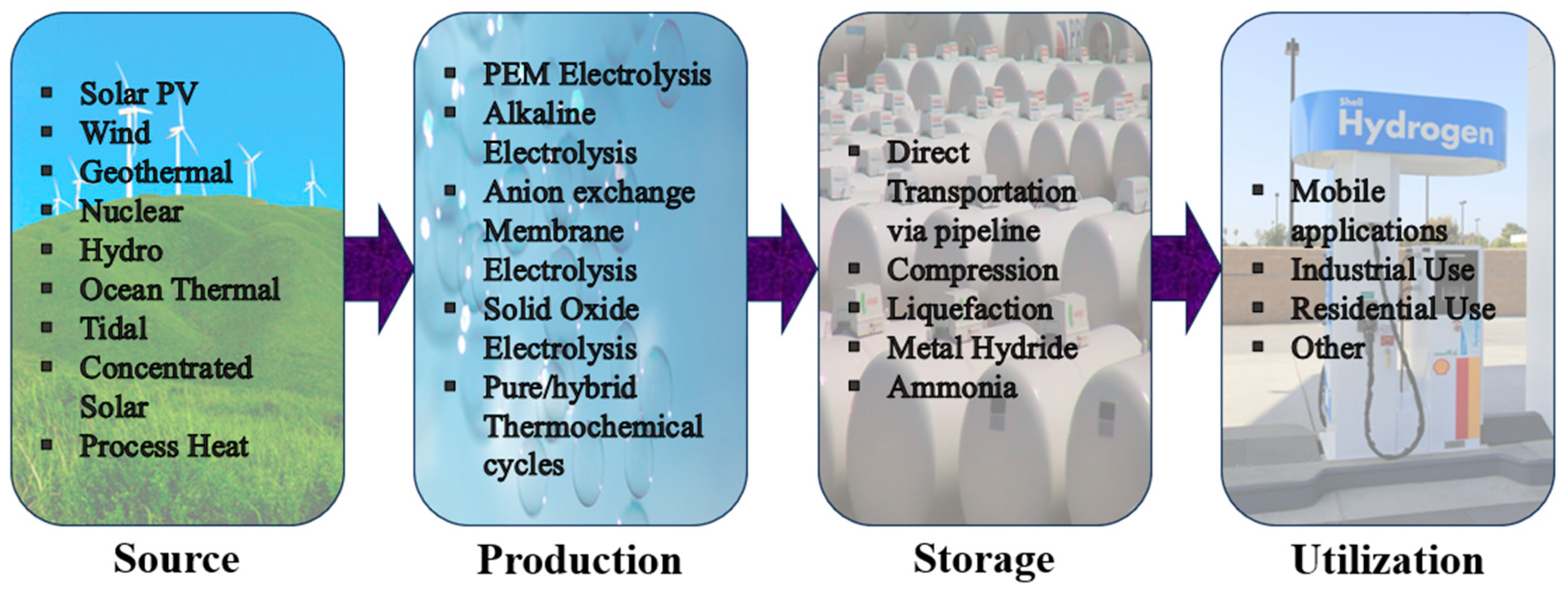

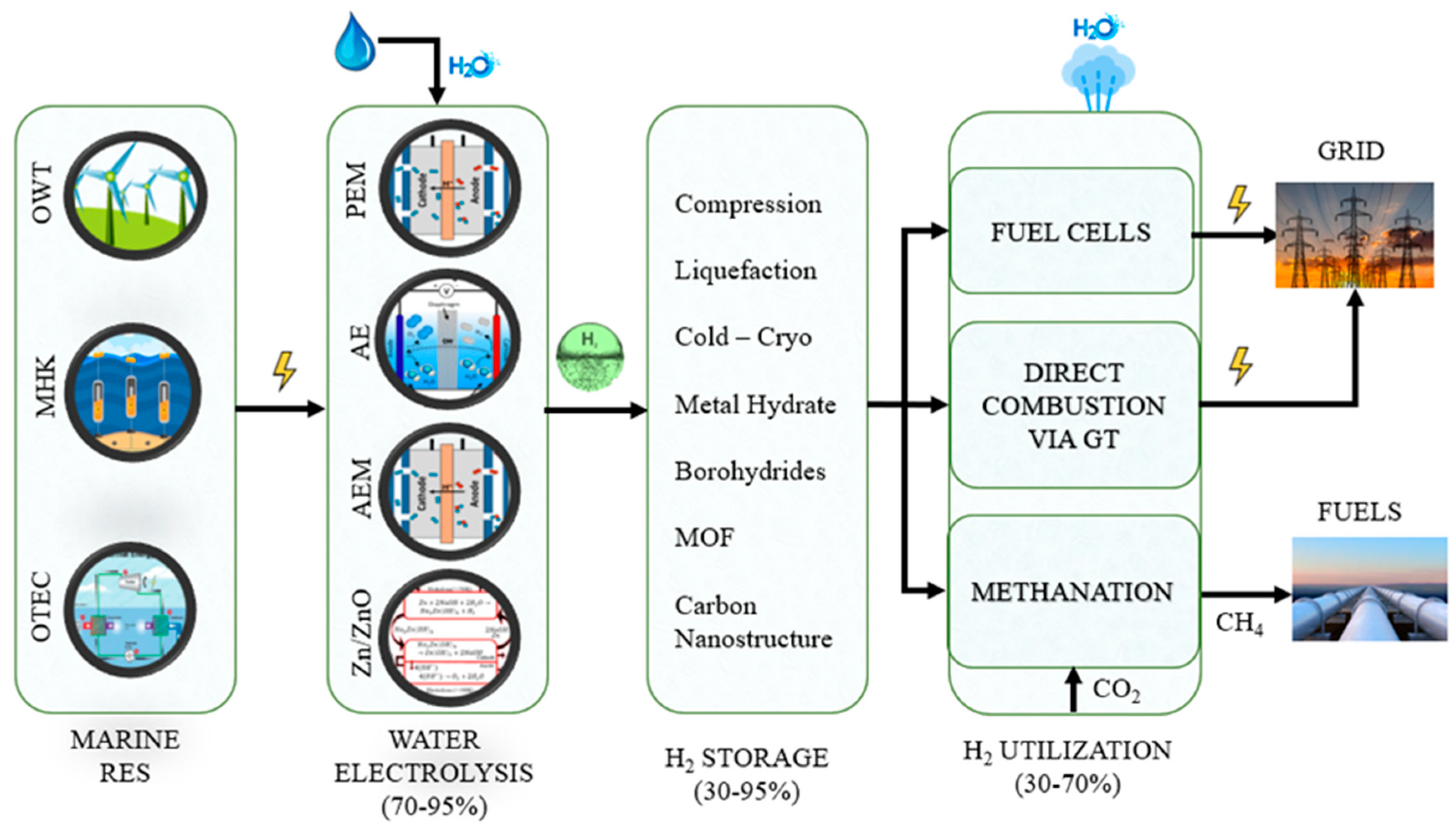

2.6. Green Energy Storage Technique

3. Site Selection Considerations Using Scoring Matrix System for Hybrid Energy Systems

- Offshore wind turbine;

- Wave energy converter;

- Tidal current converter;

- Geothermal energy;

- Ocean thermal energy conversion;

- Hydrogen generation.

3.1. Data Definition

3.2. Data Evaluation and Decision-Making Criteria

4. Application of the Scoring Matrix at Triton Knoll Wind Farm

4.1. Triton Knoll Wind Farm, Site Data and Characteristics

4.2. Example of Use of Scoring Matrix

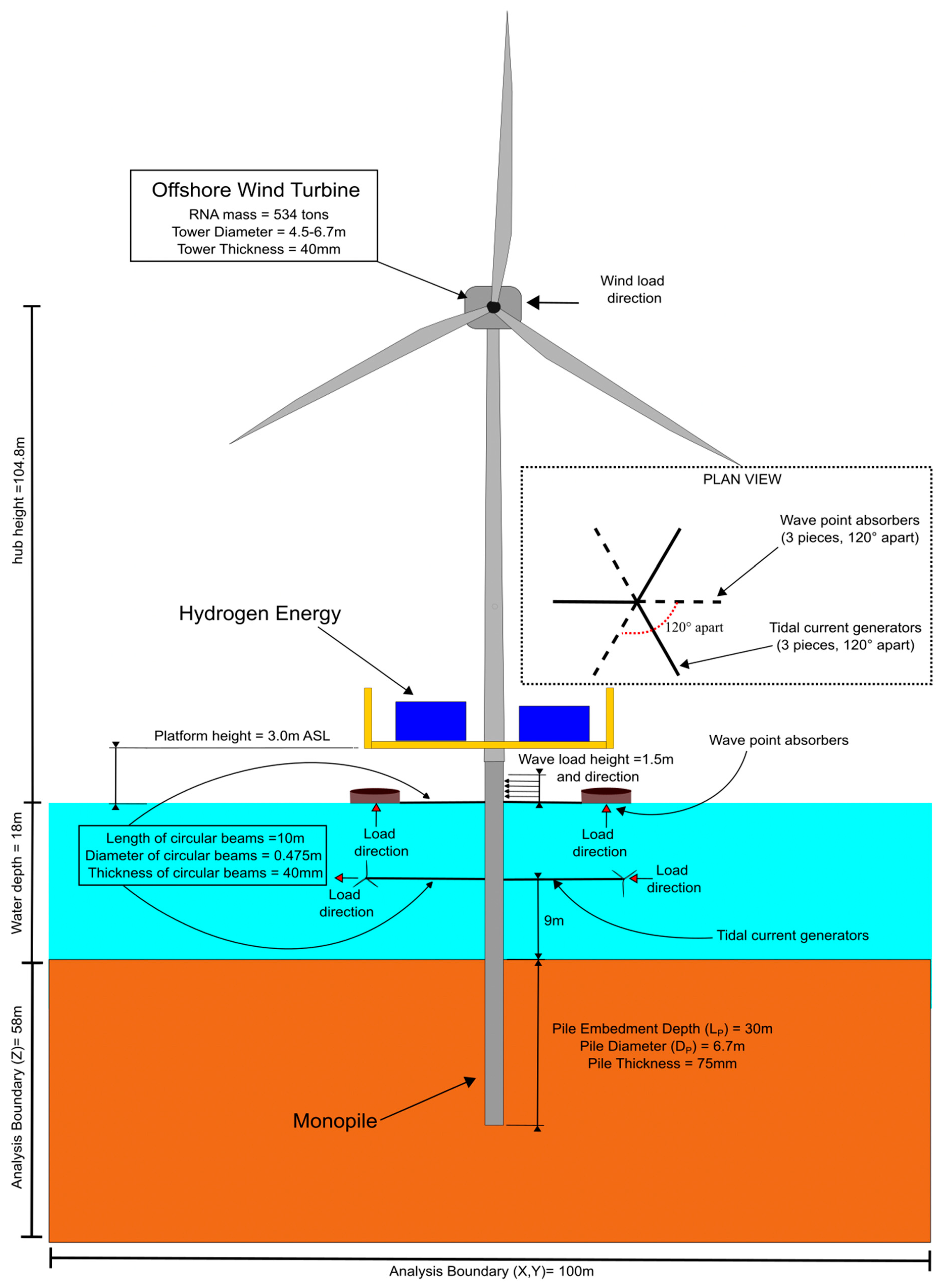

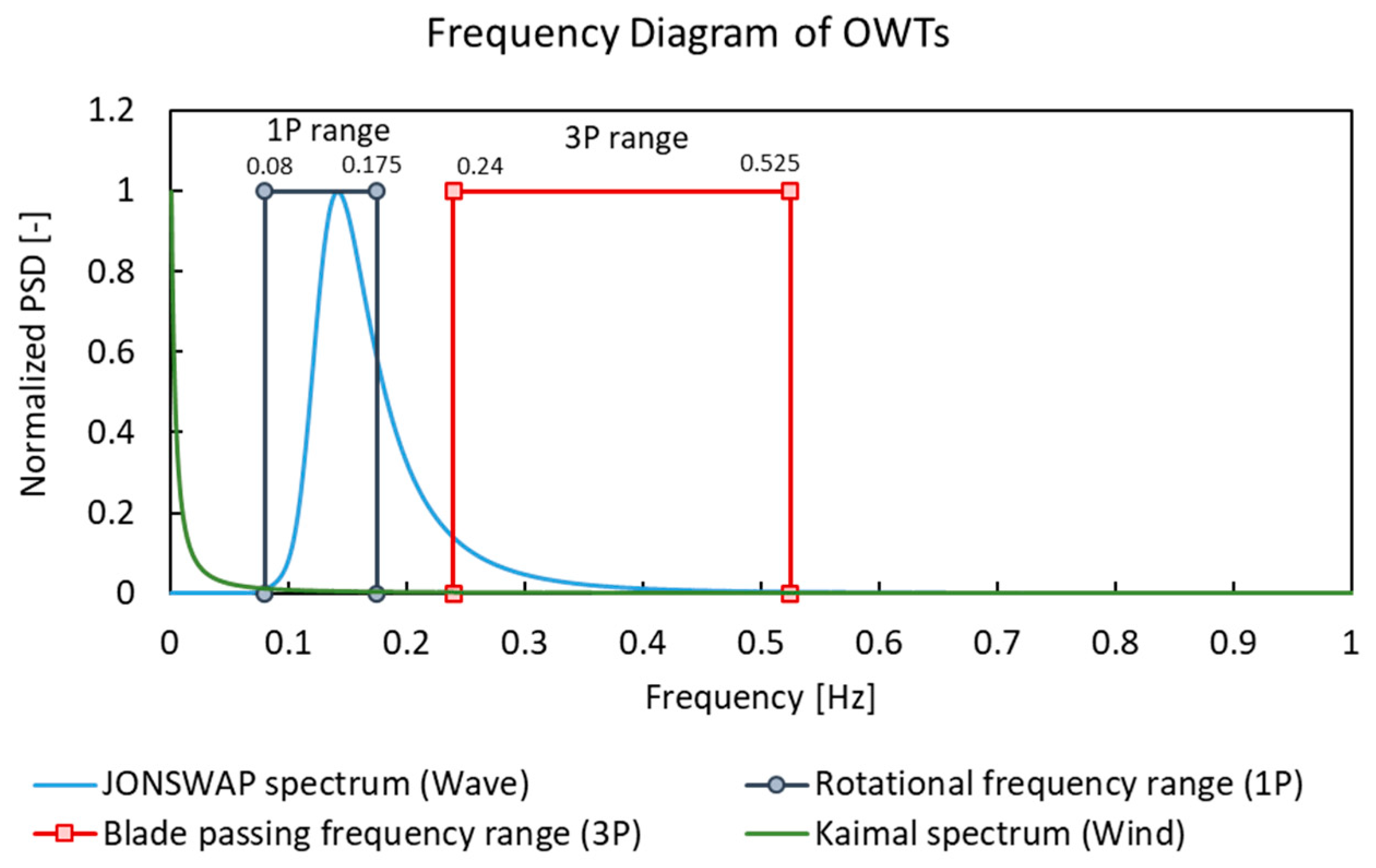

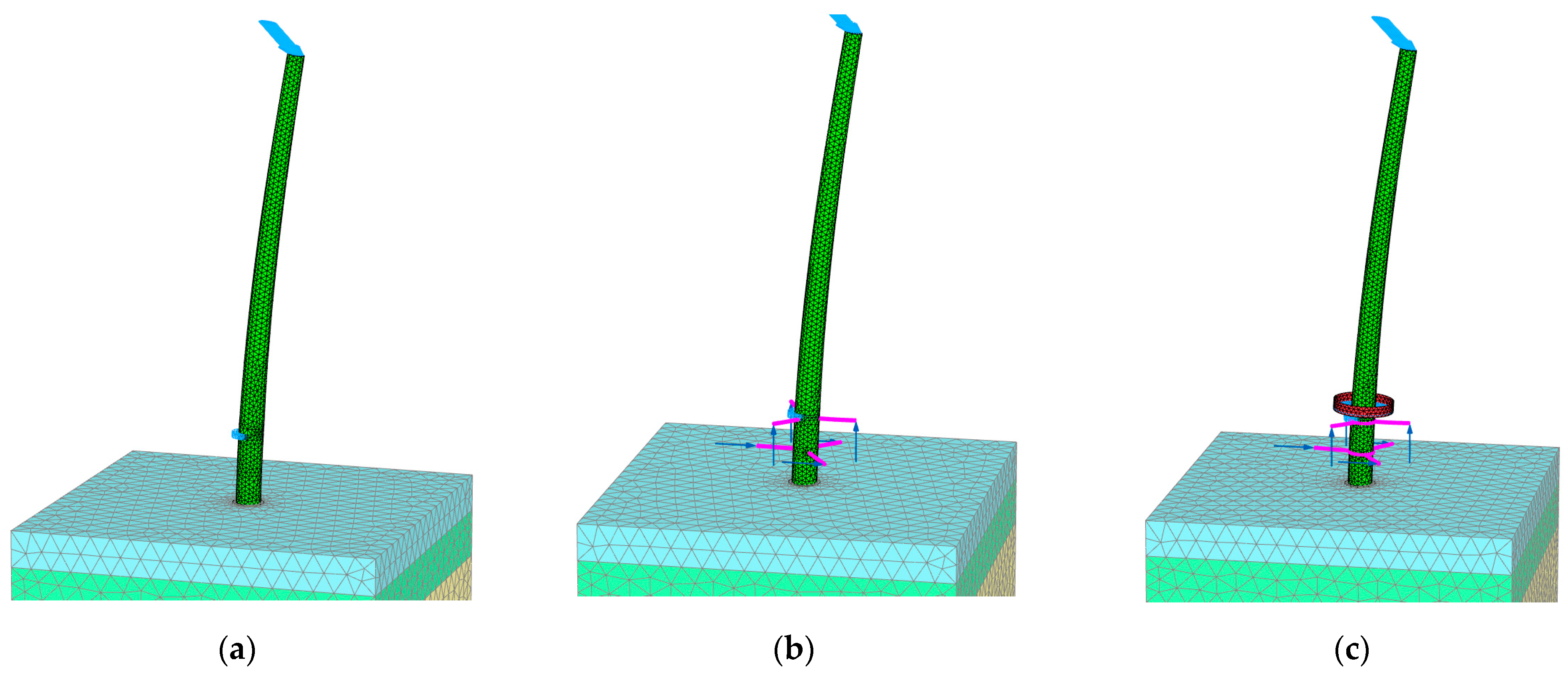

4.3. Modeling

5. Discussion and Conclusions

- It increases the energy yield per unit area of marine space and optimizes the use of available natural resources.

- The shadowing effect of multiple energy devices leads to milder loading and a minimization of environmental impact on the base structure.

- It optimizes the costs of installation, operation, and maintenance and reduces the costs of supporting infrastructures such as cable boxes and grid connectivity. This will lead to a reduction in the levelized cost of energy and benefit energy users.

- On-board hydrogen production addresses the intermittent production of marine energy and provides solutions to supply–demand balance.

- The new contributions of this paper are outlined below:

- The key factors to consider when developing the hybrid design are enumerated and the proposed new scoring matrix is proved to be effective for selecting viable energy resources to be incorporated into the hybrid system. This scoring matrix can be used in any marine site as the first step for hybrid system design.

- It is demonstrated that the hybrid system incorporating additional structures connecting wave point absorbers and current turbines to the main wind tower does not influence the wind tower structural integrity (<1% more deflection) or fatigue life significantly (6% increase in natural frequency). Some additional vertical load even reduced the structural deflections.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Azzellino, A.; Riefolo, L.; Lanfredi, C.; Vicinanza, D. Marine renewables: Exploring the opportunity for combining wind and wave energy. ENEA Special Issue Ocean energy: Ongoing reseach in Italy. Energ. Ambiente Innov. 2015, 43–51. [Google Scholar] [CrossRef]

- Astariz, S.; Perez-Collazo, C.; Abanades, J.; Iglesias, G. Hybrid wave and offshore wind farms: A comparative case study of co-located layouts. Int. J. Mar. Energy 2016, 15, 2–16. [Google Scholar] [CrossRef]

- Pérez-Collazo, C.; Greaves, D.; Iglesias, G. A review of combined wave and offshore wind energy. Renew. Sust. Energy Rev. 2015, 42, 141–153. [Google Scholar] [CrossRef]

- Astariz, S.; Perez-Collazo, C.; Abanades, J.; Iglesias, G. Towards the optimal design of a co-located wind-wave farm. Energy 2015, 84, 15–24. [Google Scholar] [CrossRef]

- Astariz, S.; Iglesias, G. Selecting optimum locations for co-located wave and wind energy farms. Part I: The Co-Location Feasibility index. Energy Convers. Manag. 2016, 122, 589–598. [Google Scholar] [CrossRef]

- Astariz, S.; Iglesias, G. Accessibility for operation and maintenance tasks in co-located wind and wave energy farms with non-uniformly distributed arrays. Energy Convers. Manag. 2015, 106, 1219–1229. [Google Scholar] [CrossRef]

- Goldschmidt, M.; Muskulus, M. Coupled Mooring Systems for Floating Wind Farms. Energy Procedia 2015, 80, 255–262. [Google Scholar] [CrossRef]

- Castro-Santos, L.; Martins, E.; Soares, C.G. Cost assessment methodology for combined wind and wave floating offshore renewable energy systems. Renew. Energy 2016, 97, 866–880. [Google Scholar] [CrossRef]

- Vo, L.; Jamaleddin, N.; Gabr, M.; Borden, R. Natural Frequency and Foundation Damping of Colocated and Hybrid Systems Sharing Wind Turbine Monopiles under Operational Conditions. Int. J. Geomech. 2024, 24, 04023259. [Google Scholar] [CrossRef]

- Zhang, W.J.; Ouyang, P.R.; Sun, Z.H. A novel hybridization design principle for intelligent mechatronics systems. In Proceedings of the 5th International Conference on the Advanced Mechatronics(ICAM2010): The Japan Society of Mechanical Engineers, Toyonaka, Japan, 4–6 October 2010. [Google Scholar] [CrossRef]

- Lee, J.; Zhao, F. Global Wind Report 2022; Global Wind Energy Council: Brussels, Belgium, 2022; pp. 1–154. [Google Scholar]

- Global Wind Atlas Version 3.0. 2018. Available online: https://globalwindatlas.info (accessed on 1 October 2021).

- Davis, N.N.; Badger, J.; Hahmann, A.N.; Hansen, B.O.; Mortensen, N.G.; Kelly, M.; Larsén, X.G.; Olsen, B.T.; Floors, R.; Lizcano, G.; et al. The Global Wind Atlas: A High-Resolution Dataset of Climatologies and Associated Web-Based Application. Bull. Am. Meteorol. Soc. 2023, 104, E1507–E1525. [Google Scholar] [CrossRef]

- Sun, H.; Yang, H.; Gao, X. Investigation into wind turbine wake effect on complex terrain. Energy 2023, 269, 126767. [Google Scholar] [CrossRef]

- Kilcher, L.; Fogarty, M.; Lawson, M. Marine Energy in the United States: An Overview of Opportunities. Golden, CO: National Renewable Energy Laboratory. NREL/TP-5700-78773. 2021. Available online: https://www.nrel.gov/docs/fy21osti/78773.pdf (accessed on 1 October 2021).

- Neary, V.S.; Lawson, M.; Previsic, M.; Copping, A.; Hallett, K.C.; LaBonte, A.; Rieks, J.; Murray, D. (Eds.) Methodology for Design and Economic Analysis of Marine Energy Conversion (MEC) Technologies. In Proceedings of the 2nd Marine Energy Technology Symposium, METS2014, Seattle, WA, USA, 15–17 April 2014. [Google Scholar]

- Kutasov, I.; Kagan, M. Procedures correct temperatures for deep offshore wells. Oil Gas J. 2002, 100, 56–61. [Google Scholar]

- Bu, X.; Ma, W.; Li, H. Geothermal energy production utilizing abandoned oil and gas wells. Renew. Energy 2012, 41, 80–85. [Google Scholar] [CrossRef]

- Prabowo, T.R.; Fauziyyah, F.; Suryantini Bronto, S. A new idea: The possibilities of offshore geothermal system in Indonesia marine volcanoes. IOP Conf. Ser. Earth Environ. 2017, 103, 12012. [Google Scholar] [CrossRef]

- Allahvirdizadeh, P. A review on geothermal wells: Well integrity issues. J. Clean Prod. 2020, 275, 124009. [Google Scholar] [CrossRef]

- Karason, B.; Gudjonsdottir, M.S.; Valdimarsson, P.; Thorolfsson, G. (Eds.) Utilization of Offshore Geothermal Resources for Power Production. In Proceedings of the Thirty-Eighth Workshop on Geothermal Reservoir Engineering, Stanford, CA, USA, 11–13 February 2013. [Google Scholar]

- Banerjee, A.; Chakraborty, T.; Matsagar, V. Evaluation of possibilities in geothermal energy extraction from oceanic crust using offshore wind turbine monopiles. Renew. Sust. Energy Rev. 2018, 92, 685–700. [Google Scholar] [CrossRef]

- Richter, A. Green Electricity from Heat under the Sea—Offshore Geothermal Energy; Think GeoEnergy: Reykjavík, Iceland, 2019. [Google Scholar]

- Atkins, D.; Audunsson, H. (Eds.) Exploration Techniques for Locating Offshore Geothermal Energy Near Iceland. In Proceedings of the Thirty-Eighth Workshop on Geothermal Reservoir Engineering, Stanford, CA, USA, 11–13 February 2013. [Google Scholar]

- Armani, F.B.; Paltrinieri, D. Perspectives of offshore geothermal energy in Italy. EPJ Web. Conf. 2013, 54, 2001. [Google Scholar] [CrossRef]

- Italiano, F.; Santis, A.D.; Favali, P.; Rainone, M.; Rusi, S.; Signanini, P. The Marsili Volcanic Seamount (Southern Tyrrhenian Sea): A Potential Offshore Geothermal Resource. Energies 2014, 7, 4068–4086. [Google Scholar] [CrossRef]

- Gonzalez-Fernández, A.; Neumann, F.; Negrete-Aranda, R.; Contreras, J.; Kretzschmar, T.; Batista-Cruz, R.Y.; Avilés-Esquivel, T.A.; Reyes Ortega, V.; Flores-Luna, C.F.; Gomez-Trevino, E.; et al. (Eds.) Conceptual Model for the Geothermal System of the Wagner Basin. In Proceedings of the American Geophysical Union Fall Meeting: American Geophysical Union, San Francisco, CA, USA, 11–15 December 2023. [Google Scholar]

- Faizal, M.; Bouazza, A.; Singh, R.M. An Overview of Ocean Thermal and Geothermal Energy Conversion Technologies and Systems. Int. J. Air-Conditioning Refrig. 2016, 24, 1630006. [Google Scholar] [CrossRef]

- Kim, H.-J.; Lee, H.-S.; Lim, S.-T.; Petterson, M. The Suitability of the Pacific Islands for Harnessing Ocean Thermal Energy and the Feasibility of OTEC Plants for Onshore or Offshore. Geosci. Process. 2021, 11, 407. [Google Scholar] [CrossRef]

- Vega, L.A. Ocean thermal energy conversion. In Encyclopedia of Sustainability Science and Technology, 6th ed.; ARCLER Press: Burlington, ON, Canada, 2012; pp. 7296–7328. [Google Scholar]

- Wu, Z.; Feng, H.; Chen, L.; Tang, W.; Shi, J.; Ge, Y. Constructal thermodynamic optimization for ocean thermal energy conversion system with dual-pressure organic Rankine cycle. Energy Convers. Manag. 2020, 210, 112727. [Google Scholar] [CrossRef]

- Ramachandran, A.; Shal, U.A.; Ramachandran, S. Finite Time Thermodynamic Investigation of a Solar-Boosted Irreversible OTEC, Smart Technologies for Energy. Environ. Sustain. Dev. 2022, 1, 849–859. [Google Scholar]

- Bhattacharya, S. Design of Foundations for Offshore Wind Turbines; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2019. [Google Scholar]

- Bhattacharya, S.; Lombardi, D.; Amani, S.; Aleem, M.; Prakhya, G.; Adhikari, S.; Aliyu, A.; Alexander, N.; Wang, Y.; Cui, L.; et al. Physical Modelling of Offshore Wind Turbine Foundations for TRL (Technology Readiness Level) Studies. J. Mar. Sci. Eng. 2021, 9, 589. [Google Scholar] [CrossRef]

- API. Recommended Practice for Planning, Designing and Constructing Fixed Offshore Platforms-Working Stress Design; American Petroleum Institute: Washington, DC, USA, 2007. [Google Scholar]

- IEC 61400-3-1:201; Wind Energy Generation Systems—Part 3-1: Design Requirements for Fixed Offshore Wind Turbines. International Electrotechnical Commission: Geneva, Switzerland, 2019.

- DNV. DNVGL-RP-C212: Offshore Soil Mechanics and Geotechnical Engineering. 2019. Available online: https://www.dnv.com/oilgas/download/dnv-rp-c212-offshore-soil-mechanics-and-geotechnical-engineering.html (accessed on 20 May 2022).

- Stehly, T.; Duffy, P. Cost of Wind Energy Review-NREL/TP-5000-81209; 2020; p. 1–77. Available online: https://www.nrel.gov/docs/fy23osti/84774.pdf (accessed on 28 September 2022).

- Neary, V.S.; Lawson, M.; Previsic, M.; Copping, A.; Harllett, K.C.; Labonte, A.; Rieks, J.; Murray, D. Methodology for Design and Economic Analysis of Marine Energy Conversion (MEC) Technologies; Contract No.: SAND2014-9040; Sandia National Laboratories: Albuquerque, NM, USA, 2014.

- Weisser, D.; Garcia, R.S. Instantaneous wind energy penetration in isolated electricity grids: Concepts and review. Renew. Energy 2005, 30, 1299–1308. [Google Scholar] [CrossRef]

- Hameer, S.; van Niekerk, J.L. A review of large-scale electrical energy storage. Int. J. Energy Res. 2015, 39, 1179–1195. [Google Scholar] [CrossRef]

- Carmo, M.; Fritz, D.L.; Mergel, J.; Stolten, D. A comprehensive review on PEM water electrolysis. Int. J. Hydrogen Energy 2013, 38, 4901–4934. [Google Scholar] [CrossRef]

- Henkensmeier, D.; Najibah, M.; Harms, C.; Žitka, J.; Hnát, J.; Bouzek, K. Overview: State-of-the Art Commercial Membranes for Anion Exchange Membrane Water Electrolysis. J. Electrochem. Energy Convers. Storage 2021, 18, 024001. [Google Scholar] [CrossRef]

- El-Emam, R.S.; Ozcan, H.; Zamfirescu, C. Updates on promising thermochemical cycles for clean hydrogen production using nuclear energy. J. Clean. Prod. 2020, 262, 121424. [Google Scholar] [CrossRef]

- Horri, B.A.; Choolaei, M.; Chaudhry, A.; Qaalib, H. A highly efficient hydrogen generation electrolysis system using alkaline zinc hydroxide solution. Int. J. Hydrogen Energy 2019, 44, 72–81. [Google Scholar] [CrossRef]

- Rivard, E.; Trudeau, M.; Zaghib, K. Hydrogen Storage for Mobility: A Review. Materials 2019, 12, 1973. [Google Scholar] [CrossRef] [PubMed]

- von Colbe, J.B.; Ares, J.-R.; Barale, J.; Baricco, M.; Buckley, C.; Capurso, G.; Gallandat, N.; Grant, D.M.; Guzik, M.N.; Jacob, I.; et al. Application of hydrides in hydrogen storage and compression: Achievements, outlook and perspectives. Int. J. Hydrogen Energy 2019, 44, 7780–7808. [Google Scholar] [CrossRef]

- Sakintuna, B.; Lambaridarkrim, F.; Hirscher, M. Metal hydride materials for solid hydrogen storage: A review. Int. J. Hydrogen Energy 2007, 32, 1121–1140. [Google Scholar] [CrossRef]

- Sabihuddin, S.; Kiprakis, A.; Mueller, M. A Numerical and Graphical Review of Energy Storage Technologies. Energies 2014, 8, 172–216. [Google Scholar] [CrossRef]

- Costoya, X.; DeCastro, M.; Carvalho, D.; Arguilé-Pérez, B.; Gómez-Gesteira, M. Combining offshore wind and solar photovoltaic energy to stabilize energy supply under climate change scenarios: A case study on the western Iberian Peninsula. Renew. Sustain. Energy Rev. 2022, 157, 112037. [Google Scholar] [CrossRef]

- Zanuttigh, B.; Angelelli, E.; Kortenhaus, A.; Koca, K.; Krontira, Y.; Koundouri, P. A methodology for multi-criteria design of multi-use offshore platforms for marine renewable energy harvesting. Renew Energy 2016, 85, 1271–1289. [Google Scholar] [CrossRef]

- Bakhsh, T.T.; Monim, M.; Simpson, K.; Lapierre, T.; Dahl, J.; Rowe, J.; Spaulding, M.; Miller, J. Potential Earthquake, Landslide, Tsunami and Geo-Hazards for the U.S. Offshore Pacific Wind Farms. 2020. Available online: https://www.rpsgroup.com/imported-media/5565/potential-earthquake-landslide-tsunami-and-geohazards-for-the-us-offshore-pacific-wind-farms.pdf (accessed on 28 September 2022).

- Atlas of UK Marine Renewable Energy Resources. ABPmer. 2008. Available online: https://marine.gov.scot/data/atlas-uk-marine-renewable-energy-resources-2008-abpmer (accessed on 1 December 2021).

- Dalgic, Y.; Lazakis, I.; Turan, O. Vessel charter rate estimation for offshore wind O&M activities. In Developments in Maritime Transportation and Exploitation of Sea Resources; CRC Press: Boca Raton, FL, USA, 2013; pp. 899–907. [Google Scholar]

- Bhattacharya, S.; Amani, S.; Prabhakaran, A.; Macabuag, J. Hazard considerations in the vulnerability assessment of offshore wind farms in seismic zones. Earthq. Eng. Resil. 2022, 1, 88–109. [Google Scholar] [CrossRef]

- Beccario, C. earth.nullschool.net. 2022. Available online: https://earth.nullschool.net/about.html (accessed on 18 July 2022).

- Bir, G.S.; Lawson, M.J.; Li, Y. (Eds.) Structural Design of a Horizontal-Axis Tidal Current Turbine Composite Blade: Ocean Space Utilization, Ocean Renewable Energy; ASMEDC: New York, NY, USA, 2011; Volume 5. [Google Scholar]

- DiPippo, R. Geothermal Power Plants: Principles, Applications, Case Studies and Environmental Impact, 3rd ed.; Elsevier: Amsterdam, The Netherlands, 2012; 624p. [Google Scholar]

- Breede, K.; Dzebisashvili, K.; Liu, X.; Falcone, G. A systematic review of enhanced (or engineered) geothermal systems: Past, present and future. Geotherm. Energy 2013, 1, 4. [Google Scholar] [CrossRef]

- Cooper, A.; Garcia-Ibanez, J.; Gilbert, C.; Mack, S.; Mendiluce, X.M. A Methodology for a Decision Support Tool for a Tidal Stream Device: University of Strathclyde. 2014. Available online: https://www.esru.strath.ac.uk//EandE/Web_sites/13-14/Tidal/index.html (accessed on 1 December 2021).

- Yousefi, H.; Ehara, S.; Noorollahi, Y. (Eds.) Geothermal potential site selection using GIS in Iran. In Proceedings of the Thirty-Second Workshop on Geothermal Reservoir Engineering Stanford University, Standford, CA, USA, 22–24 January 2007. [Google Scholar]

- White, P. Site Selection for Geothermal Power Plants: Comprehensive Visualization of Geographical Data. 2021. Available online: https://www.dgi.com/blog/site-selection-geothermal-power-plants-comprehensive-visualization-geographical-data/ (accessed on 20 September 2022).

- Dugger, G.L.; Francis, E.J.; Avery, W.H. Technical and economic feasibility of Ocean Thermal Energy Conversion. Sol Energy 1978, 20, 259–274. [Google Scholar] [CrossRef]

- OpenStreetMap. Triton Knoll Offshore Wind Farm. 2024. Available online: https://en.wikipedia.org/wiki/Triton_Knoll#/map/0 (accessed on 15 February 2024).

- Craven, H. Decommissioning Programme for Triton Knoll Offshore Wind Farm. 2018. Available online: http://www.tritonknoll.co.uk/wp-content/uploads/2018/12/2505-TKN-CON-K-TA-0011_03_201812_TK-Decommissioning_consult.pdf (accessed on 1 October 2021).

- RWE. 2020. Available online: https://www.tritonknoll.co.uk (accessed on 2 December 2021).

- Plaxis. PLAXIS 3D Material Models Manual. 2019. Available online: https://communities.bentley.com/products/geotech-analysis/w/wiki/50826/manuals-archive---plaxis (accessed on 18 October 2022).

- da Silva, L.S.P.; Sergiienko, N.Y.; Cazzolato, B.; Ding, B. Dynamics of hybrid offshore renewable energy platforms: Heaving point absorbers connected to a semi-submersible floating offshore wind turbine. Renew. Energy 2022, 199, 1424–1439. [Google Scholar] [CrossRef]

- Rony, J.S.; Karmakar, D. Coupled Dynamic Analysis of Hybrid Offshore Wind Turbine and Wave Energy Converter. J. Offshore Mech. Arct. Eng. 2022, 144, 032002. [Google Scholar] [CrossRef]

- Arany, L.; Bhattacharya, S.; Macdonald, J.; Hogan, S.J. Design of monopiles for offshore wind turbines in 10 steps. Soil Dyn. Earthq Eng. 2017, 92, 126–152. [Google Scholar] [CrossRef]

| Number | Description | Maximum Score |

|---|---|---|

| Q.1 | Is the wind speed sufficient? | (20, 20) |

| Q.2 | Is the ground profile suitable for this specific foundation type? | (15, 10) |

| Q.3 | Is water depth suitable for the foundations type? | (10, 10) |

| Q.4 | Is the region less prone to earthquakes and fault ruptures? | (15, 10) |

| Q.5 | Is the location not protected as a Marine Protected Area (MPA) or Site of Special Scientific Interest (SSSI)? | (10, 10) |

| Q.6 | Distance to ports for the access to install facilities | (5, 5) |

| Q.7 | Distance to the national grid | (5, 5) |

| Q.8 | There are no obstructions to the RADARs | (5, 5) |

| Q.9 | There are no buried services around | (5, 10) |

| Q.10 | Is the wave height excess to cause damage or the wave period close to system natural frequency? | (5, 5) |

| Q.11 | Are there busy shipping routes? | (5, 10) |

| Number | Description | Maximum Score |

|---|---|---|

| Q.1 | Is the wave height sufficient and suitable? | (70, 70) |

| Q.2 | Is the wave period suitable? | (30, 30) |

| Number | Description | Maximum Score |

|---|---|---|

| Q.1 | Is the current speed above 0.5 m/s for consideration of energy production efficiency and below 6 m/s for structural stability? | (60, 60) |

| Q.2 | Is the minimum water depth greater than 15 m? | (40, 40) |

| Number | Description | Maximum Score |

|---|---|---|

| Q.1 | Are there volcanic rocks/volcanic mud in the area? | (10, 10) |

| Q.2 | Are there any active volcanoes in the region? | (10, 10) |

| Q.3 | Are there any active faults in the region? | (10, 10) |

| Q.4 | Are there any hot springs in the area? | (5, 5) |

| Q.5 | Are there any reported geothermal direct-use applications in the locality? | (5, 5) |

| Q.6 | Can you drill a borehole 150 m below the ground level? | (20, 20) |

| Q.7 | If any recorded subsurface temperature data are available, is the geothermal gradient above the average geothermal gradient (in excess of 30 °C/km)? | (15, 15) |

| Q.8 | Can the reservoir produce above 75 °C fluids with flow rates in excess of 1000 L/minute? | (15, 15) |

| Q.9 | Are there any offshore oil and gas platforms/offshore wells/pipelines available that could be potentially repurposed for geothermal applications? | (10, 10) |

| Number | Description | Maximum Score |

|---|---|---|

| Q.1 | Is the annual average temperature difference between the ocean surface and water at 1 km depth in excess of 18 °C? | (70, 70) |

| Q.2 | Is it possible to integrate other thermal energy resources (i.e., solar/geothermal) to enhance the thermodynamic performance of the OTEC plant? | (10, 10) |

| Q.3 | Are there nearby hydrogen/ammonia production plants? | (10, 10) |

| Q.4 | Are there other demanding applications in the locality, such as heat, desalination, and chemical/metal production? | (10, 10) |

| Number | Description | Maximum Score |

|---|---|---|

| Q.1 | Is it close to the shoreline? | (25, 25) |

| Q.2 | Is there a transport route available? | (25, 25) |

| Q.3 | Is there fresh water available or a desalination facility available? | (25, 25) |

| Q.4 | Is the significant wave height not so excessive? | (25, 25) |

| Layer Depth | Soil Type | Su (kPa) | φ’ (°) | Gmax (MPa) | γ’ (kN/m3) |

|---|---|---|---|---|---|

| 0–10 m | Slightly sandy and gravelly clay | 200 | N/a | 60 | 10 |

| 10–23 m | Slightly fine to coarse sand | N/a | 35 | 55 | 10 |

| 23–47 m | Sandy clay | 250 | N/a | 75 | 10 |

| 47–58 | White chalk | 300 | N/a | 90 | 10 |

| Site ID | Dominant Wave Direction (°N) | Most Frequent Wave Height (m) and % of Total Record | Maximum Hs (m) and Associated Direction (°N) | Most Frequent Tm (s) and % of Total Record | Tp (s) and Associated Hs (m) |

|---|---|---|---|---|---|

| 107 (d1 and d2) | 345–15 | 0.0–0.5 (39%) | 2.0–2.5 (345–15) | 4.0–4.5 (30%) | 8.5–9.0 (0.0–0.5) |

| MN | 345–15 | 0.5–1.0 (41%) | 2.0–2.5 (165–195) | 4.5–5.0 (30%) | 8.0–8.5 (0.0–0.5) |

| SW | 15–45 | 0.0–0.5 (49%) | 2.0–2.5 (165–195) | 4.5–5.0 (33%) | 7.5–8.0 (0.0–0.5) |

| SW | 345–15 | 0.0–0.5 (41%) | 2.0–2.5 (345–15) | 4.5–5.0 (34%) | Recording error |

| Number | Parameter (Maximum Scores) | Wind Energy and Foundation Decision Making | |||||

|---|---|---|---|---|---|---|---|

| Bottom Fixed WT | Floating WT | ||||||

| Type of Foundation | GBS | Monopile | Jacket | Spar Buoy | Barge | TLP | |

| 1.1 | Is the wind speed sufficient? (20, 20) | 20 | 20 | 20 | 20 | 20 | 20 |

| 1.2 | Is the ground profile suitable for this specific foundation type? (15, 10) | 15 | 15 | 15 | 10 | 10 | 10 |

| 1.3 | Is water depth suitable for the foundations mentioned? (10, 10) | 0 | 10 | 5 | 0 | 0 | 0 |

| 1.4 | Is the region less prone to earthquakes and fault ruptures? (15, 10) | 15 | 15 | 15 | 10 | 10 | 10 |

| 1.5 | Is the location not protected as a Marine Protected Area (MPA) or Site of Special Scientific Interest (SSSI)? (10, 10) | 10 | 10 | 10 | 10 | 10 | 10 |

| 1.6 | Distance to ports for the access to install facilities (10, 10) | 5 | 5 | 5 | 5 | 5 | 5 |

| 1.7 | Distance to the national grid (5, 5) | 5 | 5 | 5 | 5 | 5 | 5 |

| 1.8 | There are no obstructions to the RADARs (5, 5) | 5 | 5 | 5 | 5 | 5 | 5 |

| 1.9 | There are no buried services around (5, 10) | 5 | 5 | 5 | 10 | 10 | 10 |

| 1.10 | Is the wave height excess to cause damage or is the wave period close to system natural frequency? (5, 5) | 5 | 5 | 5 | 5 | 5 | 5 |

| 1.11 | Are there busy shipping routes? (5, 10) | 5 | 5 | 5 | 10 | 10 | 10 |

| Decision-making score (main matrix) | 90% | 100% | 95% | 90% | 90% | 90% | |

| Wave Energy Converter (WEC) | Awarded Score | |

| 2.1 | Is the wave height sufficient and suitable? (70, 70) | 70 |

| 2.2 | Is the wave period suitable? (30, 30) | 30 |

| Decision-making score (local matrix) | 100% | |

| Tidal Current Turbines | Awarded score | |

| 3.1 | Is the current speed above 0.5 m/s for consideration of energy production efficiency and below 6 m/s for structural stability? (60, 60) | 60 |

| 3.2 | Is the minimum water depth greater than 15 m? (40, 40) | 40 |

| Decision-making score (local matrix) | 100% | |

| Geothermal Energy | Awarded score | |

| 4.1 | Are there volcanic rocks/volcanic mud in the area? (10, 10) | 0 |

| 4.2 | Are there any active volcanoes in the region? (10, 10) | 0 |

| 4.3 | Are there any active faults in the region? (10, 10) | 0 |

| 4.4 | Are there any hot springs in the area? (5, 5) | 0 |

| 4.5 | Are there any reported geothermal direct-use applications in the locality? (5, 5) | 0 |

| 4.6 | Can you drill a borehole 150 m below the ground level? (20, 20) | 20 |

| 4.7 | If any recorded subsurface temperature data are available, is the geothermal gradient above the average geothermal gradient (in excess of 30 °C/km)? (15, 15) | 0 |

| 4.8 | Can the reservoir produce above 75 °C fluids with flow rates in excess of 1000 L/minute? (15, 15) | 0 |

| 4.9 | Are there any offshore oil and gas platforms/offshore wells/pipelines available that could be potentially repurposed for geothermal applications? (10, 10) | 10 |

| Decision-making score (local matrix) | 30% | |

| Ocean Thermal Energy Storage (OTEC) | Awarded score | |

| 5.1 | Is the annual average temperature difference between the ocean surface and water at 1 km depth in excess of 18 °C? (70, 70) | 0 |

| 5.2 | Is it possible to integrate other thermal energy resources (i.e., solar/geothermal) to enhance the thermodynamic performance of the OTEC plant? (10, 10) | 10 |

| 5.3 | Are there nearby hydrogen/ammonia production plants? (10, 10) | 0 |

| 5.4 | Are there other demanding applications in the locality, such as heat, desalination, and chemical/metal production? (10, 10) | 10 |

| Decision-making score (local matrix) | 20% | |

| Hydrogen Energy | Awarded score | |

| 6.1 | Is it close to the shoreline? (25, 25) | 25 |

| 6.2 | Is there a transport route available? (25, 25) | 25 |

| 6.3 | Is there fresh water available or a desalination facility available? (25, 25) | 25 |

| 6.4 | Is the significant wave height not so excessive? (25, 25) | 10 |

| Decision-making score (local matrix) | 85% | |

| Input Parameter | Symbol | Unit | Value |

|---|---|---|---|

| Mass of RNA | mRNA | tons | 534 |

| Hub height | LT | m | 104.8 |

| Tower bottom diameter | Db | m | 6.7 |

| Tower top diameter | Dt | m | 4.5 |

| Average wall thickness | Tt | m | 0.04 |

| Tower Young’s modulus | ET | GPa | 210 |

| Tower weight | mT | tons | 558 |

| Monopile diameter | DP | m | 6.7 |

| Monopile embedment depth | Lp | m | 30.0 |

| Monopile wall thickness | TP | m | 0.075 |

| Monopile Young’s modulus | EP | GPa | 210 |

| Circular beam diameter | Db | m | 0.457 |

| Circular beam thickness | Tb | mm | 40 |

| Circular beam length | Lb | m | 10 |

| Outer and inner diameter of hydrogen production platform | - | m | 16.7/6.7 |

| Considerations | Abbreviation | Quantity |

|---|---|---|

| ULS Wind | Wind | 5.08 MN |

| ULS Wave | Wave | 3.618 MN |

| Self-Weight of Beams Connecting Tidal Current Turbines | ST | Steel section with the unit weight of 78.5 kN/m3 |

| Force on Tidal Current Turbines | FT | 60 kN |

| Self-Weight of Beams Connecting Wave Point Absorbers | SW | Steel section with the unit weight of 78.5 kN/m3 |

| Force on Wave Point Absorbers | FW | 60 kN |

| Hydrogen Energy Platform | HEP | 20 kPa |

| DLC | Load Configuration | Pile Head Lateral Displacement (m) | Maximum Displacement of Steel Beam (m) | Tower Top Lateral Displacement (m) | Natural Frequency (f1)-Hz |

|---|---|---|---|---|---|

| 1 | Wind+Wave | 0.168 | - | 2.652 | 0.217 |

| 2 | Wind+Wave+ST+SW | 0.1684 | 0.255 | 2.652 | 0.218 |

| 3 | Wind+Wave+ST+SW+FT | 0.1689 | 0.267 | 2.655 | 0.220 |

| 4 | Wind+Wave+ST+SW+FW | 0.1690 | 0.240 | 2.653 | 0.220 |

| 5 | Wind+Wave+ST+ SW+FW+FT | 0.1690 | 0.280 | 2.654 | 0.223 |

| DLC | Load Configuration | Pile Head Lateral Displacement (m) | Maximum Displacement of Steel Beam (m) | Tower Top Lateral Displacement (m) | Natural Frequency (f1)-Hz |

|---|---|---|---|---|---|

| 6 | Wind+Wave+ST+SW+HEP | 0.1667 | 0.218 | 2.637 | 0.227 |

| 7 | Wind+Wave+ST+SW+HEP+FT | 0.1667 | 0.241 | 2.637 | 0.229 |

| 8 | Wind+Wave+ST+SW+HEP+FW | 0.1673 | 0.219 | 2.640 | 0.229 |

| 9 | Wind+Wave+ST+SW+HEP+FW+FT | 0.1674 | 0.241 | 2.639 | 0.230 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, L.; Amani, S.; Gabr, M.; Kumari, W.G.P.; Ahmed, A.; Ozcan, H.; Horri, B.A.; Bhattacharya, S. Synergistic Hybrid Marine Renewable Energy Harvest System. Energies 2024, 17, 1240. https://doi.org/10.3390/en17051240

Cui L, Amani S, Gabr M, Kumari WGP, Ahmed A, Ozcan H, Horri BA, Bhattacharya S. Synergistic Hybrid Marine Renewable Energy Harvest System. Energies. 2024; 17(5):1240. https://doi.org/10.3390/en17051240

Chicago/Turabian StyleCui, Liang, Sadra Amani, Mohammed Gabr, Wanniarachchige Gnamani Pabasara Kumari, Aziz Ahmed, Hasan Ozcan, Bahman Amini Horri, and Subhamoy Bhattacharya. 2024. "Synergistic Hybrid Marine Renewable Energy Harvest System" Energies 17, no. 5: 1240. https://doi.org/10.3390/en17051240

APA StyleCui, L., Amani, S., Gabr, M., Kumari, W. G. P., Ahmed, A., Ozcan, H., Horri, B. A., & Bhattacharya, S. (2024). Synergistic Hybrid Marine Renewable Energy Harvest System. Energies, 17(5), 1240. https://doi.org/10.3390/en17051240