Research and Application of Carbon Capture, Utilization, and Storage–Enhanced Oil Recovery Reservoir Screening Criteria and Method for Continental Reservoirs in China

Abstract

1. Introduction

2. Investigation of CCUS-EOR Reservoir Screening Criteria

2.1. CCUS-EOR Reservoir Screening Criteria outside China

2.2. CCUS-EOR Reservoir Screening Criteria in China

3. Optimization of CCUS-EOR Reservoir Screening Criteria in China

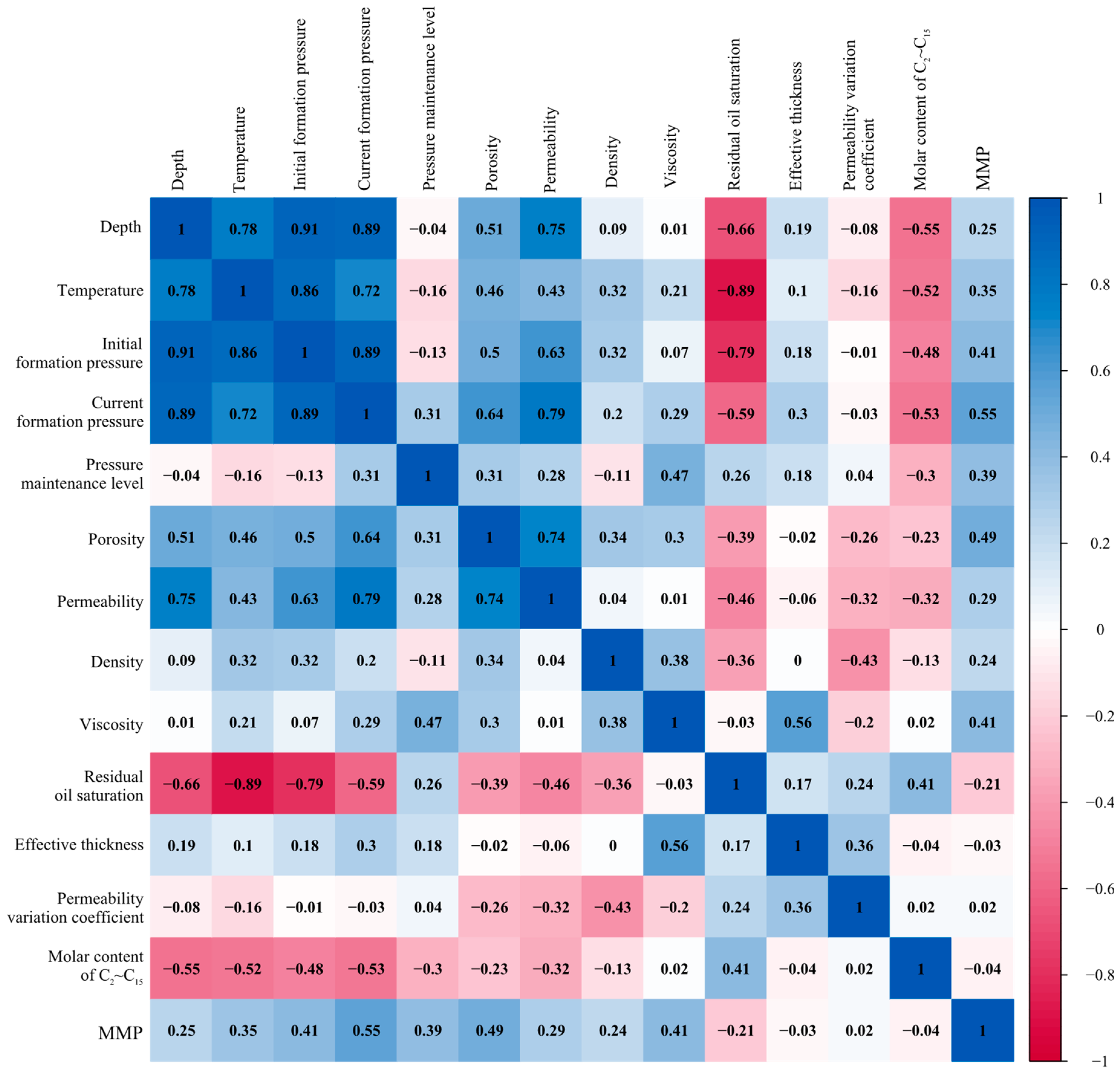

3.1. Pearson Correlation Analysis

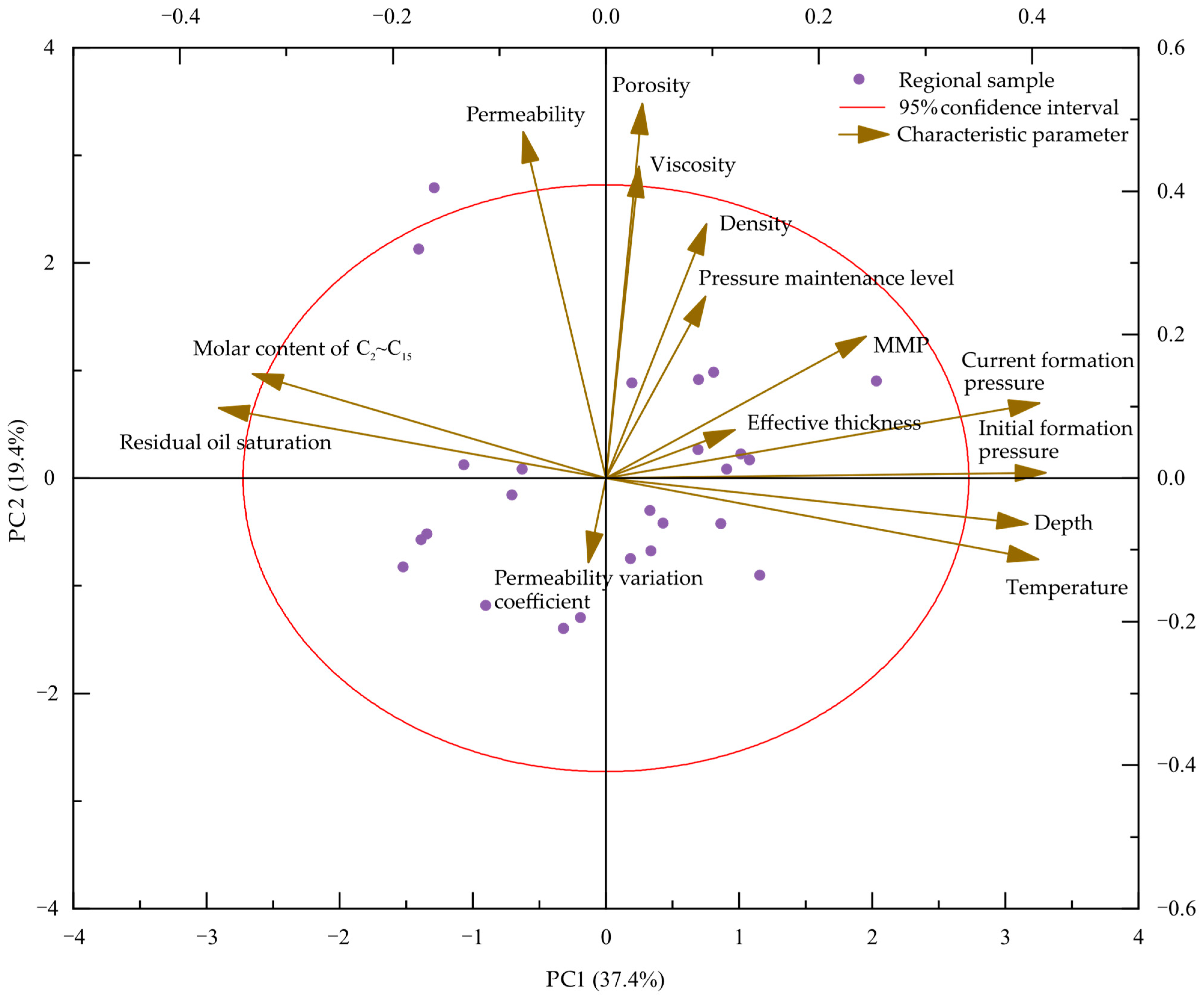

3.2. PCA of Screening Indices

- (1)

- Collect the data of parameters that influence CO2-EOR and assess the feasibility of PCA.

- (2)

- Normalize the data and calculate the covariance matrix to measure the correlation between the parameters.

- (3)

- Perform eigenvalue decomposition of the covariance matrix to obtain eigenvalues and corresponding eigenvectors.

- (4)

- Select the first few eigenvectors as the principal components and calculate their weights based on the magnitude of their eigenvalues.

- (5)

- Calculate the component scores by linearly combining the original variables with the selected principal components and their weights.

- (6)

- Determine the importance and weights of the parameters based on the component scores.

3.3. Results of CCUS-EOR Reservoir Screening Parameter Range and Weight

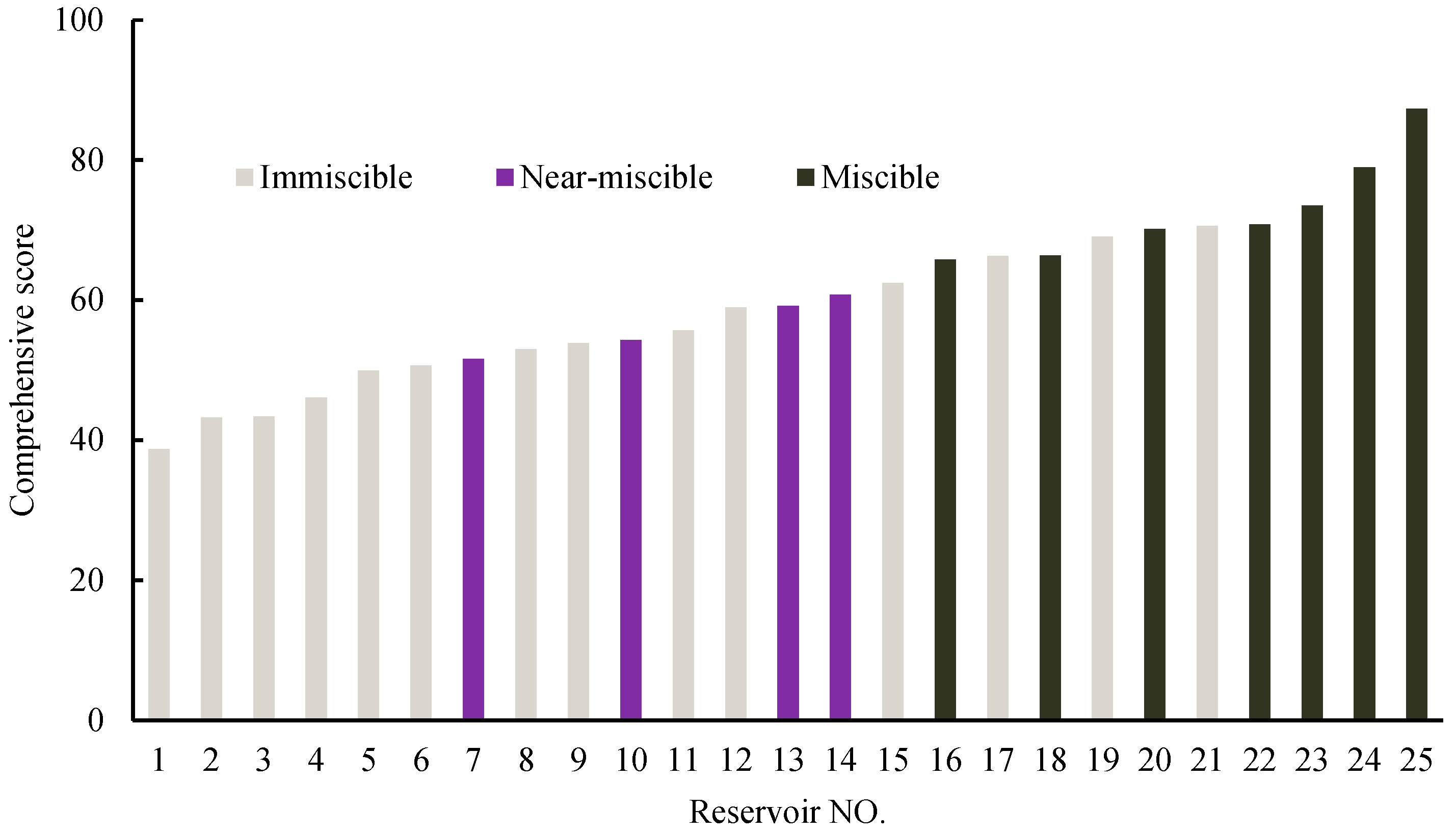

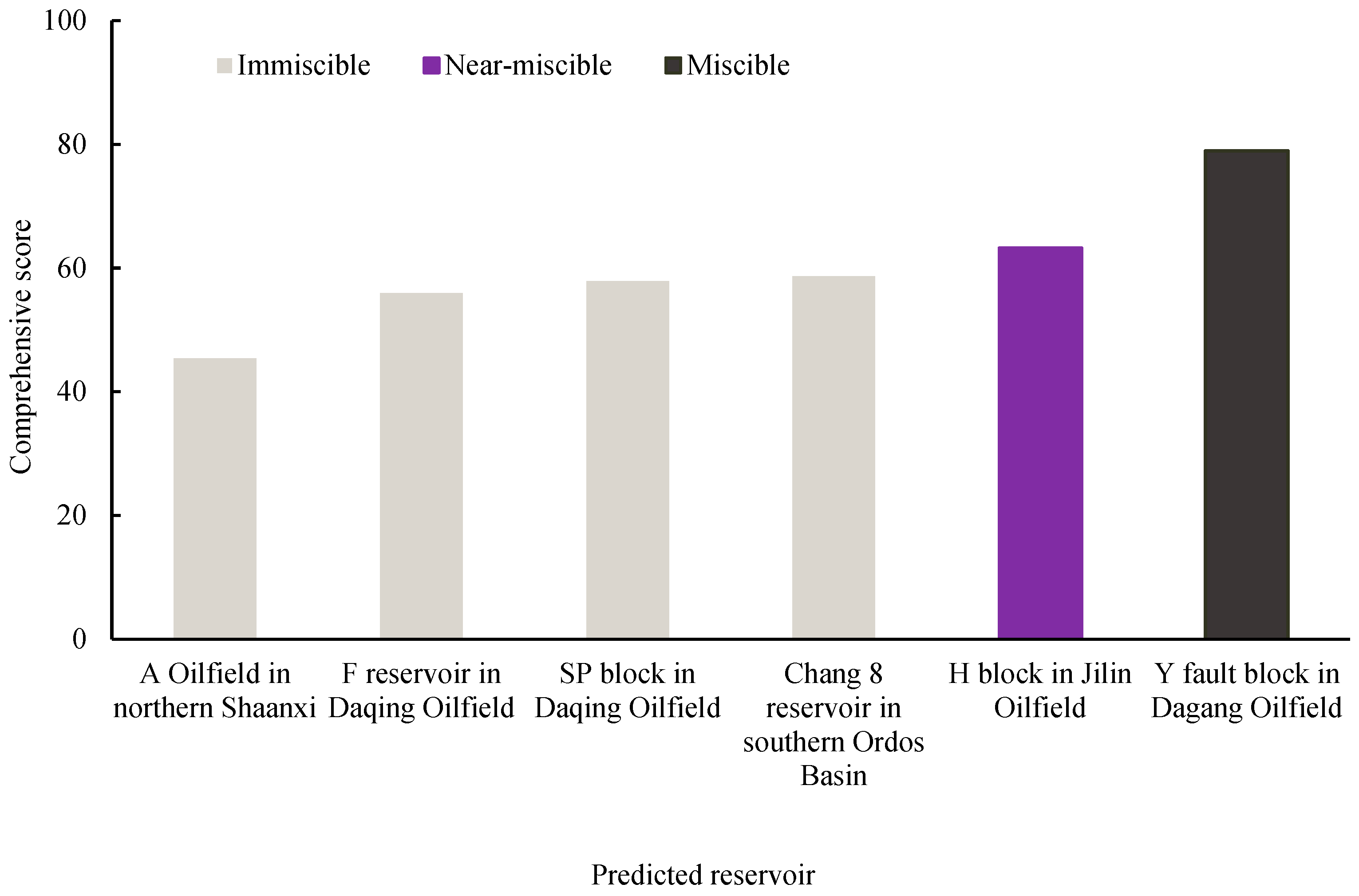

3.4. Application Cases

4. Conclusions and Prospect

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zou, C.; Zhao, Q.; Zhang, G.; Xiong, B. Energy Revolution: From a Fossil Energy Era to a New Energy Era. Nat. Gas Ind. B 2016, 3, 1–11. [Google Scholar] [CrossRef]

- Roy, P.; Mohanty, A.K.; Misra, M. Prospects of Carbon Capture, Utilization and Storage for Mitigating Climate Change. Environ. Sci. Adv. 2023, 2, 409–423. [Google Scholar] [CrossRef]

- Karnauskas, K.B.; Miller, S.L.; Schapiro, A.C. Fossil Fuel Combustion Is Driving Indoor CO2 toward Levels Harmful to Human Cognition. GeoHealth 2020, 4, e2019GH000237. [Google Scholar] [CrossRef]

- Kumar, N.; Augusto Sampaio, M.; Ojha, K.; Hoteit, H.; Mandal, A. Fundamental Aspects, Mechanisms and Emerging Possibilities of CO2 Miscible Flooding in Enhanced Oil Recovery: A Review. Fuel 2022, 330, 125633. [Google Scholar] [CrossRef]

- Kulp, S.A.; Strauss, B.H. New Elevation Data Triple Estimates of Global Vulnerability to Sea-Level Rise and Coastal Flooding. Nat. Commun. 2019, 10, 4844. [Google Scholar] [CrossRef]

- Rignot, E. Sea Level Rise from Melting Glaciers and Ice Sheets Caused by Climate Warming above Pre-Industrial Levels. Phys.–Uspekhi 2022, 65, 1129–1138. [Google Scholar]

- Yao, J.; Han, H.; Yang, Y.; Song, Y.; Li, G. A Review of Recent Progress of Carbon Capture, Utilization, and Storage (CCUS) in China. Appl. Sci. 2023, 13, 1169. [Google Scholar] [CrossRef]

- Di Stasi, C.; Renda, S.; Greco, G.; González, B.; Palma, V.; Manyà, J.J. Wheat-Straw-Derived Activated Biochar as a Renewable Support of Ni-CeO2 Catalysts for CO2 Methanation. Sustainability 2021, 13, 8939. [Google Scholar] [CrossRef]

- Dieterich, V.; Buttler, A.; Hanel, A.; Spliethoff, H.; Fendt, S. Power-to-Liquid via Synthesis of Methanol, DME or Fischer–Tropsch-Fuels: A Review. Energy Environ. Sci. 2020, 13, 3207–3252. [Google Scholar] [CrossRef]

- Yuan, S.; Ma, D.; Li, J.; Zhou, T.; Ji, Z.; Han, H. Progress and Prospects of Carbon Dioxide Capture, EOR-Utilization and Storage Industrialization. Pet. Explor. Dev. 2022, 49, 955–962. [Google Scholar] [CrossRef]

- Ateka, A.; Rodriguez-Vega, P.; Ereña, J.; Aguayo, A.T.; Bilbao, J. A Review on the Valorization of CO2. Focusing on the Thermodynamics and Catalyst Design Studies of the Direct Synthesis of Dimethyl Ether. Fuel Process Technol. 2022, 233, 107310. [Google Scholar] [CrossRef]

- Huang, J.; Chen, Q.; Zhong, P. National Assesment Report on Development of Carbon Capture Utilization and Storage Technology in China; Science Press: Beijing, China, 2021. [Google Scholar]

- Liu, Z.; Gao, M.; Zhang, X.; Liang, Y.; Guo, Y.; Liu, W.; Bao, J. CCUS and CO2 Injection Field Application in Abroad and China: Status and Progress. Geoenergy Sci. Eng. 2023, 229, 212011. [Google Scholar] [CrossRef]

- Yan, L.; Hu, J.; Fang, Q.; Xia, X.; Lei, B.; Deng, Q. Eco-Development of Oil and Gas Industry: CCUS-EOR Technology. Front. Earth Sci. 2023, 10, 1063042. [Google Scholar] [CrossRef]

- Gozalpour, F.; Ren, S.R.; Tohidi, B. CO2 Eor and Storage in Oil Reservoir. Oil Gas Sci. Technol. 2005, 60, 537–546. [Google Scholar] [CrossRef]

- Hill, L.B.; Li, X.; Wei, N. CO2-EOR in China: A Comparative Review. Int. J. Greenh. Gas Control 2020, 103, 103173. [Google Scholar] [CrossRef]

- Al-Shargabi, M.; Davoodi, S.; Wood, D.A.; Rukavishnikov, V.S.; Minaev, K.M. Carbon Dioxide Applications for Enhanced Oil Recovery Assisted by Nanoparticles: Recent Developments. ACS Omega 2022, 7, 9984–9994. [Google Scholar] [CrossRef]

- Huang, T.; Zhou, X.; Yang, H.; Liao, G.; Zeng, F. CO2 Flooding Strategy to Enhance Heavy Oil Recovery. Petroleum 2017, 3, 68–78. [Google Scholar] [CrossRef]

- Ampomah, W.; Balch, R.; Cather, M.; Rose-Coss, D.; Dai, Z.; Heath, J.; Dewers, T.; Mozley, P. Evaluation of CO2 Storage Mechanisms in CO 2 Enhanced Oil Recovery Sites: Application to Morrow Sandstone Reservoir. Energy Fuels 2016, 30, 8545–8555. [Google Scholar] [CrossRef]

- Kuuskraa, V.; Ferguson, R. Storing CO2 with Enhanced Oil Recovery; National Energy Technology Laboratory: Washington, DC, USA, 2008. [Google Scholar]

- Bachu, S. Identification of Oil Reservoirs Suitable for CO2 -EOR and CO2 Storage (CCUS) Using Reserves Databases, with Application to Alberta, Canada. Int. J. Greenh. Gas Control 2016, 44, 152–165. [Google Scholar] [CrossRef]

- Wang, G.; Zheng, X.; Zhang, Y.; Lü, W.; Wang, F.; Yin, L. A New Screening Method of Low Permeability Reservoirs Suitable for CO2 Flooding. Pet. Explor. Dev. 2015, 42, 390–396. [Google Scholar] [CrossRef]

- Mahjour, S.K.; Faroughi, S.A. Risks and Uncertainties in Carbon Capture, Transport, and Storage Projects: A Comprehensive Review. Gas Sci. Eng. 2023, 119, 205117. [Google Scholar] [CrossRef]

- Geffen, T.M. Improved Oil Recovery Could Help Ease Energy Shortage. World Oil 1973, 177, 84. [Google Scholar]

- Lewin, S. The Potential and Economics of Enhanced Oil Recovery. In Report US FEA Contract Np; CO-03-50222-000; FEA: Washington, DC, USA, 1976; p. 274. [Google Scholar]

- Council, N.P. Enhanced Oil Recovery—An Analysis of the Potential for Enhanced Oil Recovery from Known Fields in the United States–1976–2000; National Petroleum Council: Washington, DC, USA, 1976. [Google Scholar]

- McRee, B.C. CO2: How It Works, Where It Works. Pet. Eng. 1977, 52, 63. [Google Scholar]

- Iyoho, A.W. Selecting Enhanced Oil Recovery Processes. World OilUnited States 1978, 187, 6. Available online: https://www.osti.gov/biblio/6293850 (accessed on 22 August 2023).

- Carcoana, A.N. Enhanced Oil Recovery in Rumania. In Proceedings of the SPE Improved Oil Recovery Conference, Tulsa, OH, USA, 4–7 April 1982; SPE: Richardson, TX, USA, 1982; p. SPE-10699. [Google Scholar]

- Taber, J.J. Technical Screening Guides for the Enhanced Recovery of Oil. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Francisco, CA, USA, 5–8 October 1983; OnePetro: Richardson, TX, USA, 1983. [Google Scholar]

- Taber, J.J.; Martin, F.D.; Seright, R.S. EOR Screening Criteria Revisited—Part 1: Introduction to Screening Criteria and Enhanced Recovery Field Projects. SPE Reserv. Eng. 1997, 12, 189–198. [Google Scholar] [CrossRef]

- Taber, J.J.; Martin, F.D.; Seright, R.S. EOR Screening Criteria Revisited—Part 2: Applications and Impact of Oil Prices. SPE Reserv. Eng. 1997, 12, 199–206. [Google Scholar] [CrossRef]

- Rivas, O.; Embid, S.; Bolívar, F. Ranking Reservoirs for Carbon Dioxide Flooding Processes. SPE Adv. Technol. Ser. 1994, 2, 95–103. [Google Scholar] [CrossRef]

- Diaz, D.; Bassiouni, Z.; Kimbrell, W.; Wolcott, J. Screening Criteria for Application of Carbon Dioxide Miscible Displacement in Waterflooded Reservoirs Containing Light Oil. In Proceedings of the SPE Improved Oil Recovery Conference, Tulsa, OH, USA, 21–24 April 1996; SPE: Richardson, TX, USA, 1996; p. SPE-35431. [Google Scholar]

- Shaw, J.; Bachu, S. Screening, Evaluation, and Ranking of Oil Reservoirs Suitable for CO2-Flood EOR and Carbon Dioxide Sequestration. J. Can. Pet. Technol. 2002, 41, 9. [Google Scholar] [CrossRef]

- Bachu, S.; Shaw, J.C.; Pearson, R.M. Estimation of Oil Recovery and CO2 Storage Capacity in CO2 EOR Incorporating the Effect of Underlying Aquifers. In Proceedings of the SPE/DOE Symposium on Improved Oil Recovery, Tulsa, OH, USA, 17–21 April 2004. [Google Scholar]

- Algharaib, M. Potential Applications of CO2-EOR in the Middle East. In Proceedings of the All Days, Manama, Bahrain, 15–18 March 2009; SPE: Richardson, TX, USA, 2009; p. SPE-120231-MS. [Google Scholar]

- Wo, S.; Whitman, L.D.; Steidtmann, J.R. Estimates of Potential CO2 Demand for CO2 EOR in Wyoming Basins. In Proceedings of the All Days, Denver, CO, USA, 14–16 April 2009; SPE: Richardson, TX, USA, 2009; p. SPE-122921-MS. [Google Scholar]

- Aladasani, A.; Bai, B. Recent Developments and Updated Screening Criteria of Enhanced Oil Recovery Techniques. In Proceedings of the International Oil and Gas Conference and Exhibition in China, Beijing, China, 8–10 June 2010; OnePetro: Richardson, TX, USA, 2010. [Google Scholar]

- Al Adasani, A.; Bai, B. Analysis of EOR Projects and Updated Screening Criteria. J. Pet. Sci. Eng. 2011, 79, 10–24. [Google Scholar] [CrossRef]

- Gao, P.; Towler, B.; Pan, G. Strategies for Evaluation of the CO2 Miscible Flooding Process. In Proceedings of the Abu Dhabi International Petroleum Exhibition and Conference, Abu Dhabi, United Arab Emirates, 1–4 November 2010; SPE: Richardson, TX, USA, 2010; p. SPE-138786. [Google Scholar]

- Hajeri, S.A.; Negahban, S.; Al-Yafei, G.; Basry, A.A. Design and Implementation of the First CO2-EOR Pilot in Abu Dhabi, UAE. In Proceedings of the SPE EOR Conference at Oil & Gas West Asia, Muscat, Oman, 11–13 April 2010. [Google Scholar]

- NETL, N. Carbon Dioxide Enhanced Oil Recovery-Untapped Domestic Energy Supply and Long Term Carbon Storage Solution. Energy Lab 2010. Available online: https://netl.doe.gov/research/coal/energy-systems/gasification/gasifipedia/eor (accessed on 22 August 2023).

- Koottungal, L. 2014 Worldwide EOR Survey. Available online: https://www.ogj.com/drilling-production/production-operations/ior-eor/article/17210637/2014-worldwide-eor-survey (accessed on 22 August 2023).

- Verma, M.K. Fundamentals of Carbon Dioxide-Enhanced Oil Recovery (CO2-EOR): A Supporting Document of the Assessment Methodology for Hydrocarbon Recovery Using CO2-EOR Associated with Carbon Sequestration; U.S. Geological Survey: Reston, VA, USA, 2015. [Google Scholar]

- Yin, M. CO2 Miscible Flooding Application and Screening Criteria; Missouri University of Science and Technology: Rolla, MO, USA, 2015. [Google Scholar]

- Zhang, N.; Wei, M.; Bai, B. Statistical and Analytical Review of Worldwide CO2 Immiscible Field Applications. Fuel 2018, 220, 89–100. [Google Scholar] [CrossRef]

- Zhang, N.; Yin, M.; Wei, M.; Bai, B. Identification of CO2 Sequestration Opportunities: CO2 Miscible Flooding Guidelines. Fuel 2019, 241, 459–467. [Google Scholar] [CrossRef]

- Hares, R. Feasibility of CCUS to CO2-EOR in Alberta; University of Calgary: Calgary, AB, Canada, 2020; Volume 1. [Google Scholar]

- Qin, J. Application and Enlightenment of Carbon Dioxide Flooding in the United States of America. Pet. Explor. Dev. 2015, 42, 232–240. [Google Scholar] [CrossRef]

- Klins, M.A. Carbon Dioxide Flooding; Basic Mechanism and Project Design; Springer: Berlin/Heidelberg, Germany, 1984. [Google Scholar]

- GHG; IEA. CO2 Storage in Depleted Oilfields: Global Application Criteria for Carbon Dioxide Enhanced Oil Recovery. Chelten. Glos UK Prep. Adv. Resour. Int. Melzer Consult. 2009, 12. Available online: https://ieaghg.org/docs/General_Docs/Reports/2009-12.pdf (accessed on 22 August 2023).

- Song, Z.; Li, Y.; Song, Y. A Critical Review of CO2 Enhanced Oil Recovery in Tight Oil Reservoirs of North America and China. In Proceedings of the SPE/IATMI Asia Pacific Oil & Gas Conference and Exhibition, Bali, Indonesia, 29–31 October 2019. [Google Scholar]

- Guo, H.; Lyu, X.; Meng, E.; Xu, Y.; Zhang, M.; Fu, H.; Zhang, Y.; Song, K. CCUS in China: Challenges and Opportunities. In Proceedings of the SPE Improved Oil Recovery Conference, Virtual, 25–29 April 2022; OnePetro: Richardson, TX, USA, 2022. [Google Scholar]

- Xiong, Y. A Screening Candidate Reservoir for Gas in-Jection Way Based on Characteristic Parame-Ter’s Comprehensive Weight Optimizationmethod. J. Southwest Pet. Univ. Sci. Technol. Ed. 2004, 26, 22. [Google Scholar]

- Zeng, S.; Yang, Q.; Chen, J. Fuzzy Hierarchy Analysis-Based Selection of Oil Reservoirs for Gas Storage and Gas Injection. Henan Pet. 2005, 19, 40–46. [Google Scholar]

- Zheng, Y. Screening Method Based on Fuzzy Optimum for Gas Injection in Candidate Reservoir. J. Southwest Pet. Univ. Sci. Technol. Ed. 2005, 27, 44. [Google Scholar]

- Xiang, W.; Zhou, W.; Zhang, J.; Yang, G.; Jiang, W.; Sun, L.; Li, J. The Potential of CO2-EOR in China Offshore Oilfield. In Proceedings of the All Days, Perth, Australia, 20–22 October 2008; SPE: Richardson, TX, USA, 2008; p. SPE-115060-MS. [Google Scholar]

- Liang, Z.; Shu, W.; Li, Z.; Shaoran, R.; Qing, G. Assessment of CO2 EOR and Its Geo-Storage Potential in Mature Oil Reservoirs, Shengli Oilfield, China. Pet. Explor. Dev. 2009, 36, 737–742. [Google Scholar] [CrossRef]

- Liao, X.; Gao, C.-N.; Wu, P.; Su, K.; Shangguan, Y. Assessment of CO2 EOR and Its Geo-Storage Potential in Mature Oil Reservoirs, Changqing Oil Field, China. In Proceedings of the Carbon Management Technology Conference; Carbon Management Technology Conference, Orlando, FL, USA, 7–9 February 2012. [Google Scholar]

- Wang, Y.; Jiao, Z.; Surdam, R.; Zhou, L.; Gao, R.; Chen, Y.; Luo, T.; Wang, H. A Feasibility Study of the Integration of Enhanced Oil Recovery (CO2 Flooding) with CO2 Storage in the Mature Oil Fields of the Ordos Basin, China. Energy Procedia 2013, 37, 6846–6853. [Google Scholar] [CrossRef]

- Jiao, Z.; Zhou, L.; Gao, R.; Luo, T.; Wang, H.; Wang, H.; McLaughlin, F.; Bentley, R.; Quillinan, S. Opportunity and Challenges of Integrated Enhanced Oil Recovery Using CO2 Flooding with Geological CO2 Storage in the Ordos Basin, China. Energy Procedia 2014, 63, 7761–7771. [Google Scholar]

- Wang, H.; Liao, X.; Dou, X.; Shang, B.; Ye, H.; Zhao, D.; Liao, C.; Chen, X. Potential Evaluation of CO2 Sequestration and Enhanced Oil Recovery of Low Permeability Reservoir in the Junggar Basin, China. Energy Fuels 2014, 28, 3281–3291. [Google Scholar] [CrossRef]

- He, L.; Shen, P.; Liao, X.; Gao, Q.; Wang, C.; Li, F. Study on CO2 EOR and Its Geological Sequestration Potential in Oil Field around Yulin City. J. Pet. Sci. Eng. 2015, 134, 199–204. [Google Scholar]

- Meng, X.; Zhou, H.B.; Luo, D.K. Screening, Assessing, and Sorting Chinese Oilfields for CO2-EOR Suitability and Potential Economic and Social Benefits. In Proceedings of the SPE Hydrocarbon Economics and Evaluation Symposium, Houston, TX, USA, 17–18 May 2016; SPE: Richardson, TX, USA, 2016; p. D021S008R005. [Google Scholar]

- Wang, X.; Yuan, Q.; Wang, S.; Zeng, F. The First Integrated Approach for CO2 Capture and Enhanced Oil Recovery in China. In Proceedings of the Carbon Management Technology Conference, Houston, TX, USA, 17–20 July 2017; CMTC: Long Beach, CA, USA, 2017; p. CMTC-486571. [Google Scholar]

- Yang, W.; Peng, B.; Liu, Q.; Wang, S.; Dong, Y.; Lai, Y. Evaluation of CO2 Enhanced Oil Recovery and CO2 Storage Potential in Oil Reservoirs of Bohai Bay Basin, China. Int. J. Greenh. Gas Control 2017, 65, 86–98. [Google Scholar] [CrossRef]

- He, Y.; Zhao, S.; Ji, B.; Liao, H.; Zhou, Y. Screening Method and Potential Evaluation for EOR by CO2 Flooding in Sandstone Reservoirs. Editor. Dep. Pet. Geol. Recovery Effic. 2020, 27, 140–145. [Google Scholar]

- Wang, P.-T.; Wu, X.; Ge, G.; Wang, X.; Xu, M.; Wang, F.; Zhang, Y.; Wang, H.; Zheng, Y. Evaluation of CO2 Enhanced Oil Recovery and CO 2 Storage Potential in Oil Reservoirs of Petroliferous Sedimentary Basin, China. Sci. Technol. Energy Transit. 2023, 78, 3. [Google Scholar] [CrossRef]

- Shen, P.; Liao, X. The Technology of Carbon Dioxide Stored in Geological Media and Enhanced Oil Recovery; The Press of the Petroleum Industry: Beijing, China, 2009. [Google Scholar]

- Hao, Y.; Bo, Q.; Chen, Y. Laboratory Investigation of CO2 Flooding. Pet. Explor. Dev. 2005, 2, 110–112. [Google Scholar]

- Cheng, J.C.; Lei, Y.; Zhu, W. Pilot Test on CO2 Flooding in Extra-Low Permeability Fuyu Oil Layer in Daqing Placanticline. Nat. Gas Geosci. 2008, 19, 402–409. [Google Scholar]

- Liu, W.; Chen, Z. Pilot Test on CO2 Flooding in Complex and Fault Block Small Reservoirs of North Jiangsu Oilfield. Nat. Gas Geosci. 2008, 147–149+645. [Google Scholar]

- Zhao, M.; Li, J.; Wang, Z. The Study on CO2 Immiscible Mechanism in Low Permeability Reservoir. Sci. Technol. Eng. 2011, 11, 1438–1440. [Google Scholar]

- Song, Z.; Li, Z.; Lai, F. Parameter Optimization and Effect Evaluation of CO2 Flooding after Water Flooding. J. Xian Shiyou Univ. Sci. Ed. 2012, 27, 42–47+4. [Google Scholar]

- Yang, T.; Yang, Z. Evaluation of Oil Displacement by CO2 at Fuyang Extralow Permeability Layer in Yushulin Oilfield. Sci. Technol. Rev. 2015, 33, 52–55. [Google Scholar]

- Li, X.; Cao, T. Effect Evaluation of CO2 Flooding in Low Permeability Reservoirs. Contemp. Chem. Ind. 2016, 45, 2339–2342. [Google Scholar]

- Sun, L.; Ji, M.; Zheng, J. EOR Feasibility of CO2 Flooding for Liubei Conglomerate Oil Reservoirs. Petro-Leum Geol. Oilfield Dev. Daqing 2016, 35, 123–127. [Google Scholar]

- Yang, H.; Wang, H.; Nan, Y.; Qu, Y. Suitability Evaluation of Enhanced Oil Recovery by CO2 Flooding. Lithol. Res.-Ervoirs 2017, 29, 140–146. [Google Scholar]

- Wang, S.; Tan, J.; Lei, X. CO2 Flooding Technology for Low Permeability Sandstone Reservoir of Changqing Oilfield; Xi’an Shiyou Unversity, Shaanxi Petroleum Society: Xi’an, China, 2018; pp. 2542–2553. [Google Scholar]

- Zhang, B.; Zhou, L.; He, X. A Laboratory Study on CO2 Injection of Chang 3 Reservoir of Weibei Oilfield in Ordos Basin. Pet. Geol. Eng. 2018, 32, 87–90+125. [Google Scholar]

- Cao, X.; Lyu, G.; Wang, J. Technology and Application of CO2 Flooding in Ultra-Low Permeability Beach-Bar Sand Reservoir. Reserv. Eval. Dev. 2019, 9, 41–46. [Google Scholar]

- Qi, C.; Li, R.; Zhu, S. Pilot Test on CO2 Flooding of Chang4+ 51 Oil Reservoir in Yougou Region of the Ordos Basin. Oil Drill. Prod. Technol. 2019, 41, 249–253. [Google Scholar]

- Zhao, X.; Yang, H.; Chen, L. Analysis of CO2 Flooding and Storage Potential of Chang6 Reservoir in Huaziping Area of Yanchang Oilfield. J. Xi’an Shiyou Univ. Nat. Sci. 2019, 34, 62–68. [Google Scholar]

- Jin, Z.; Wang, Z.; Mao, C. Dominant Mechanism and Application of CO2 Immiscible Flooding in M Block with Low Permeability. Reserv. Eval. Dev. 2020, 10, 68–74. [Google Scholar]

- Li, S.; Xia, Y.; Lan, J.; Ye, S.; Ma, X.; Zou, J.; Li, M. CO2 Flooding Experiment in the Chang-7 Tight Oil Reservoir of Ordos Basin. Sci. Technol. Eng. 2020, 20, 2251–2257. [Google Scholar]

- Ren, B. Analysis of CO2 Displacement Mechanism in the Third Member of Fujiang Formation in Zhangjiaduo Oilfield. Petrochem. Ind. Technol. 2020, 27, 97–98. [Google Scholar]

- Li, Y.; Zhang, D.; Fan, X.; Zhang, J.; Yang, R.; Ye, H. EOR of CO2 Flooding in Low-Permeability Sandy Conglomerate Reservoirs. Xinjiang Pet. Geol. 2022, 43, 59. [Google Scholar]

- Liu, D. Research on Flood Law and Development Scheme of Sha NO3 Middle Reservoir in Fan 162 Block of Daluhu. Master’s Thesis, China University of Petroleum (East China), Qingdao, China, 2020. [Google Scholar]

- Li, Y. Laboratory Evaluation on EOR by CO2 Flooding in Ultra-Low Permeability Reservoirs of Changqing Oilfield. Master’s Thesis, Xi’an Shiyou University, Xi’an, China, 2019. [Google Scholar]

- Ren, D.; Wang, X.; Kou, Z.; Wang, S.; Wang, H.; Wang, X.; Tang, Y.; Jiao, Z.; Zhou, D.; Zhang, R. Feasibility Evaluation of CO2 EOR and Storage in Tight Oil Reservoirs: A Demonstration Project in the Ordos Basin. Fuel 2023, 331, 125652. [Google Scholar] [CrossRef]

- Cai, L. Research on the Mechanism CO2 Flooding on F Reservoir with Ultra-Low Permeability in Daqing. Master’s Thesis, Northeast Petroleum University, Daqing, China, 2016. [Google Scholar]

- Lyu, J. The Experimental Study on CO2 Flooding for Ultra-Low Permeability Reservoir in Chang 8 Oil-Baring Formation of Southern Erdos. Master’s Thesis, China University of Petroleum (East China), Qingdao, China, 2015. [Google Scholar]

- Li, M. Evaluation of the Impact of CO2 Injection for Enhanced Oil Recover in the Hei 79 Block of Jilin Oilfield. Master’s Thesis, Southwest Petroleum University, Chengdu, China, 2015. [Google Scholar]

- Luo, T. Research on Reservoir Characterization and Numerical Simulation of CO2 Enhanced Oil Recovery for Low Permeability Oil Reservoir in a Oilfield in Northern Shaanxi. Doctoral Dissertation, Northwest University, Xi’an, China, 2016. [Google Scholar]

- Dong, P. Research on Optimization of Reservoir Engineering Parameters in Deep-Buried Low-Permeability Reservoirs by CO2 Flooding. Master’s Thesis, China University of Petroleum (Beijing), Beijing, China, 2020. [Google Scholar]

- Zhang, L. Study on the Mechanism and Effect Evaluation of CO2 Gas Flooding Development. Master’s Thesis, Northeast Petroleum University, Daqing, China, 2023. [Google Scholar]

| Scholar/Institution | Area | Year | Depth (m) | Temperature (°C) | Pressure (MPa) | Porosity (%) | Permeability (mD) |

|---|---|---|---|---|---|---|---|

| Geffen [24] | United States | 1973 | >7.6 | ||||

| Lewin & Assoc [25] | United States | 1976 | >914 | >10.4 | |||

| NPC [26] | United States | 1976 | >701 | <121 | |||

| McRee [27] | United States | 1977 | >610 | >5 | |||

| Iyoho [28] | United States | 1978 | >762 | >10 | |||

| Carcoana [29] | Romania | 1982 | <3000 | <90 | >8 | >18 | >0.1 |

| Taber & Martin [30] | United States | 1983 | >610 | 8.3–32 | |||

| Klins [51] | United States | 1984 | >914 | >103 | |||

| Rivas [33] | Venezuela | 1994 | 54–93 | 0.1 ≤ P/M ≤ 1.3 | 9–33 | 18–2500 | |

| Diaz et al. [34] | United States | 1996 | 27–136 | 0.1 ≤ P/M ≤ 1.47 | 17.6–34 | 17–3485 | |

| Taber et al. [32] | World | 1997 | 762–1219 | >MMP | >5 | ||

| Bachu [35] | Canada | 2004 | 32–121 | 0.95 ≤ P/M | |||

| Alberta Research Council [52] | Canada | 2009 | >450 | 28–121 | >MMP and <Pf | ≥3 | ≥5 |

| Algharaib [37] | Middle East | 2009 | >600 | >30 | >MMP | ||

| Wo et al. [38] | United States | 2009 | >762 | >7 | >10 | ||

| NETL [43] | United States | 2010 | 610–2987 | <121 | >8.3–10.3 | >1–5 | |

| Aladasani [39] | World | 2010 | 457–4074 | 28–121 | 3–37 | 1.5–4500 | |

| Gao & Pan [41] | World | 2010 | >762 | >12 | >10 | ||

| Koottungal [44] | United States | 2014 | 487–3600 | 28–127 | 30 | 1–4500 | |

| Yin [46] | United States | 2015 | 350–3642 | 28–127 | 4–23.7 | >2 | |

| Bachu [21] | World | 2016 | 500–4100 | 28–127 | ≥MMP | 3–37 | |

| Zhang et al. [47] | World | 2018 | 426–2590 | 28–112 | 11.5–33 | 1.4–2750 | |

| Zhang et al. [48] | World | 2019 | >350 | <127 | ≥MMP | 3–37 | >0.1 |

| Hares [49] | Canada | 2020 | 500–1400 | 27–127 | ≥MMP |

| Scholar/Institution | Area | Year | Oil Density (g/cm3) | Oil Viscosity (cP, mPa·s) | Oil Saturation (%) | Net Thickness (m) | Oil Composition | Reservoir Dip Angle (°) |

|---|---|---|---|---|---|---|---|---|

| Geffen [24] | United States | 1973 | >7.6 | |||||

| Lewin & Assoc [25] | United States | 1976 | <0.88 | <3 | >25 | |||

| NPC [26] | United States | 1976 | <0.88 | <12 | >25 | |||

| McRee [27] | United States | 1977 | <0.89 | <10 | ||||

| Iyoho [28] | United States | 1978 | <0.85 | <5 | >25 | |||

| Carcoana [29] | Romania | 1982 | 0.8–0.88 | <10 | >25 | |||

| Taber & Martin [30] | United States | 1983 | <0.82 | <2 | >30 | <15 | ||

| Klins [51] | United States | 1984 | <0.9 | <15 | >30 | C5–C20 | ||

| Rivas [33] | Venezuela | 1994 | <0.88 | <12 | >25 | |||

| Diaz et al. [34] | United States | 1996 | 0.70–0.93 | 30–92 | 1.5–55 | 5–20 | ||

| Taber et al. [32] | World | 1997 | 0.79–0.91 | 8–80 | 1.5–53 | 0.03–64 | ||

| Bachu [35] | Canada | 2004 | 0.8–0.89 | 0.3–6 | 15–70 | C5–C12 | ||

| Alberta Research Council [52] | Canada | 2009 | 0.79–0.89 | >25 | ||||

| Algharaib [37] | Middle East | 2009 | 0.8–0.89 | ≤6 | ≥30 | |||

| Wo et al. [38] | United States | 2009 | <0.91 | <10 | >25 | |||

| NETL [43] | United States | 2010 | <0.92 | <10 | ||||

| Aladasani [39] | World | 2010 | <0.89 | ≤12 | >25–30 | |||

| Gao & Pan [41] | World | 2010 | 0.8–0.89 | <35 | 15–89 | |||

| Koottungal [44] | United States | 2014 | <0.89 | <10 | ||||

| Yin [46] | United States | 2015 | 0.8–0.89 | 0.4–6 | 5–50 | |||

| Bachu [21] | World | 2016 | <0.89 | <6 | >20 | 4.5–81 | ||

| Zhang et al. [47] | World | 2018 | 0.8–0.92 | 0.4–6 | ≥20 | |||

| Zhang et al. [48] | World | 2019 | 0.83–0.98 | 0.2–936 | 30–86 | 1.6–91 | ||

| Hares [49] | Canada | 2020 | 0.79–0.90 | <4 | >15 | 4.5–250 |

| Screening Parameter | Range |

|---|---|

| Depth (m) | 350–4100 |

| Temperature (°C) | 31–127 |

| Pressure (MPa) | 0.9 MMP ≤ P < Pf |

| Porosity (%) | 3–37 |

| Permeability (mD) | 0.1–4500 |

| Oil density (g/cm3) | 0.79–0.92 |

| Oil viscosity (cP, mPa·s) | 0.4–12 |

| Oil saturation (%) | ≥20 |

| Net thickness (m) | 1.5–250 |

| Oil composition | C5–C20 |

| Scholar/Institution | Year | Depth (m) | Temperature (°C) | Pressure (MPa) | Porosity (%) | Permeability (mD) |

|---|---|---|---|---|---|---|

| Xiong et al. [55] | 2004 | 5–25 | 1–1000 | |||

| Zeng et al. [56] | 2005 | 1200–2500 | 0.75 ≤ P/MMP ≤ 3 | >15 | >50 | |

| Zheng et al. [57] | 2005 | 800–3500 | 50–120 | 15–50 | 4–30 | 0.1–500 |

| Shen et al. [70] | 2009 | 800–3500 | 50–120 | 8–35 | ||

| Wang et al. [61] | 2013 | 200–2500 | 5–17 | 0.1–7 | ||

| Wang et al. [63] | 2014 | >600 | 32–120 | >1 | ||

| He et al. [64] | 2015 | 900–3000 | <90 | ≥MMP | <10 | |

| Meng et al. [65] | 2016 | 800–3500 | 50–120 | 8–35 | 4–30 | 0.1–500 |

| Yang et al. [67] | 2017 | 488–4074 | 28–127 | ≥MMP | 3–37 | |

| He et al. [68] | 2020 | >1000 | <120 | ≥MMP | >1 | |

| Wang et al. [69] | 2023 | 488–4074 | 28–127 | ≥MMP | 3–37 |

| Scholar/Institution | Year | Oil Density (g/cm3) | Oil Viscosity (cP, mPa·s) | Oil Saturation (%) | Net Thickness (m) | Permeability Variation Coefficient | Oil Composition | Reservoir Dip Angle (°) |

|---|---|---|---|---|---|---|---|---|

| Xiong et al. [55] | 2004 | 5–25 | 1–1000 | |||||

| Zeng et al. [56] | 2005 | <20 | 30–80 | |||||

| Zheng et al. [57] | 2005 | <0.88 | <8 | >30 | 3–20 | C1–C6 | 0–90 | |

| Shen et al. [70] | 2009 | <0.88 | <4 | >25 | <0.65 | >10 | ||

| Wang et al. [61] | 2013 | 0.795–0.9 | <10 | >25 | ||||

| Wang et al. [63] | 2014 | 0.73–0.86 | 1.3–9 | 40–56 | C5–C20 | |||

| He et al. [64] | 2015 | <0.92 | <188 | >20 | ||||

| Meng et al. [65] | 2016 | <0.90 | <10 | >30 | <0.75 | C2–C10 | ||

| Yang et al. [67] | 2017 | 0.79–0.92 | 1.5–12 | |||||

| He et al. [68] | 2020 | 0.4–6 | ≥26.5 | |||||

| Wang et al. [69] | 2023 | <0.876 | <10 | >30 | <0.75 |

| Scholar/Institution | Year | Depth (m) | Temperature (°C) | Pressure (MPa) | Porosity (%) |

|---|---|---|---|---|---|

| Shen et al. [70] | 2009 | 600–900 | |||

| Wang et al. [63] | 2014 | >550 | |||

| He et al. [64] | 2015 | >900 | |||

| Meng et al. [65] | 2016 | 600–900 | |||

| Yang et al. [67] | 2017 | 350–2590 | 28–92 | <MMP | 17–32 |

| He et al. [68] | 2020 | >600 | <120 | <0.8 MMP | |

| Wang et al. [69] | 2023 | 350–2591 | 28–92 | <MMP | 17–32 |

| Scholar/Institution | Year | Permeability (mD) | Oil Density (g/cm3) | Oil Viscosity (cP, mPa·s) | Oil Saturation (%) | Permeability Variation Coefficient |

|---|---|---|---|---|---|---|

| Shen et al. [70] | 2009 | 600–900 | ||||

| Wang et al. [63] | 2014 | >0.9 | 100–1000 | 30–70 | ||

| He et al. [64] | 2015 | 0.92–0.98 | <600 | |||

| Meng et al. [65] | 2016 | <0.99 | <600 | >30 | <0.75 | |

| Yang et al. [67] | 2017 | 0.92–0.98 | 100–1000 | |||

| He et al. [68] | 2020 | 0.6–592 | ≥30 | |||

| Wang et al. [69] | 2023 | >1 | <0.98 | <600 | >40 | <0.55 |

| Screening Index | Range | |

|---|---|---|

| Miscible and Near-Miscible Flooding | Immiscible Flooding | |

| Depth (m) | 600–3500 | >350 |

| Temperature (°C) | 28–127 | <120 |

| Pressure (MPa) | ≥0.8 MMP | <0.8 MMP |

| Porosity (%) | 3–37 | 17–32 |

| Permeability (mD) | >0.1 | |

| Oil density (g/cm3) | <0.92 | 0.92–0.99 |

| Oil viscosity (cP, mPa·s) | <20 | <1000 |

| Oil saturation (%) | >25 | >30 |

| Permeability variation coefficient | <0.75 | <0.75 |

| Oil composition | C2–C15 | |

| Reservoir dip angle (°) | >10 | |

| Study Area | Depth (m) | Temperature (°C) | Pressure (MPa) | Porosity (%) | Permeability (mD) | Oil Density (g/cm3) | Oil Viscosity (cP, mPa·s) |

|---|---|---|---|---|---|---|---|

| Daluhu Oilfield in Shengli Oil Area [71] | 3147 | 116 | 31.56 | ||||

| Fang 48 fault block [72] | 1699 | 85.9 | 20.4 | 14.5 | 1.4 | 0.815 | 6.6 |

| Taizhou formation in Caoshe Oilfield [73] | 3065 | 110 | 35.9 | <0.9 | |||

| Zhongnan fault block in Chujialou Oilfield [73] | 2962.9 | 28.943 | 21.3 | 241 | |||

| Well Shu 101 in Daqing Oilfield [74] | 108 | 22.05 | 0.78 | 2.8 | |||

| Dagang Oilfield [75] | 2700 | 27.21 | 19.04 | 300 | 0.88 | 6.59 | |

| Well Shu 101 in Yushulin Oilfield [76] | 2044 | 108 | 22.05 | 10.8 | 1.16 | 3.6 | |

| M Oilfield [77] | 2880 | 119.2 | 30.2 | 9 | 6.5 | 0.865 | 5.2 |

| Liubei block in Jidong Oilfield [78] | 2625 | 102 | 29.5 | 17.05 | 273 | 0.794 | 0.329 |

| Caoshe [79] | 3020 | 107 | 35.9 | 13.2 | 24.8 | 0.88 | 7 |

| Fumin [79] | 2090 | 76 | 20.9 | 12 | 854 | 0.82 | 2.4 |

| Sa II in Sanan Oilfield [79] | 1072 | 49 | 11.6 | 25.3 | 1165 | 0.86 | 8.6 |

| Sa I in Sanan Oilfield [79] | 1140 | 45 | 12.3 | 27.6 | 1628 | 0.87 | 9.8 |

| Jingbian [79] | 1590 | 47 | 12.3 | 12.8 | 0.9 | 0.86 | 2.5 |

| Huang 3 testing area in Changqing Oilfield [80] | 84 | 15.78 | 0.3–1 | 0.73 | 1.81 | ||

| Chang 3 reservoir in Weibei Oilfield [81] | 550 | 29.2 | 2.06 | 11.2 | 0.76 | 6.64 | |

| Gao 89-1 block in Shengli Oilfield [82] | 2900 | 42 | 9.18–14.7 | 0.29–4.92 | 0.86 | 11.83 | |

| Chang 4 + 5 reservoir in Wuqi Oilfield [83] | 60 | 15 | 12.8 | 0.78 | 0.78 | 2.38 | |

| Chang 6 formation in Yanchang Oilfield [84] | 46 | 8.9 | 7–12 | 0.94 | 0.79 | 3.4 | |

| M reservoir [85] | 2025 | 75 | 21.3 | 16.3 | 15.7 | 3.64 | |

| A block in CQ Oilfield [86] | 2200 | 75 | 18 | 9.8 | 0.07 | 0.825 | 8.73 |

| Fu3 member in Zhangjiaduo Oilfield [87] | 107 | 38 | 18.2 | 6.5 | 4.92 | ||

| Yan 2 block in Benbutu Oilfield [88] | 2550 | 95 | 186.27 | 12.2 | 9.8 | 0.64 | 0.68 |

| Area A in Tahe Oilfield [89] | 4600 | 110.5 | 128.5 | 21 | 733 | 2.89 | |

| North Xinghe block in Ansai Oilfield [90] | 1250 | 48 | 29.9 | 10.39 | 0.61 | 0.766 | 2.26 |

| Triassic Yanchang formation in Wuqi Oilfield [91] | 2000 | 72.8 | 18.5 | 6.1 | 3.44 | 0.78 | 2.03 |

| Study Area | Oil Saturation (%) | Effective Thickness (m) | Permeability Variation Coefficient/Heterogeneity | Oil Composition | Reservoir Dip Angle (°) | P/MMP | Miscible/Immiscible Flooding |

|---|---|---|---|---|---|---|---|

| Daluhu Oilfield in Shengli Oil Area [71] | C7+ | 1.21 | Miscible | ||||

| Fang 48 fault block [72] | 6.6 | 0.37 | Immiscible | ||||

| Taizhou formation in Caoshe Oilfield [73] | 30–50 | Relatively heterogeneous | >1 | Miscible | |||

| Zhongnan fault block in Chujialou Oilfield [73] | 35 | Highly heterogeneous | <1 | Immiscible | |||

| Well Shu 101 in Daqing Oilfield [74] | <1 | Immiscible | |||||

| Dagang Oilfield [75] | 10 | 0.5 | C11+ | 1.18 | Miscible | ||

| Well Shu 101 in Yushulin Oilfield [76] | 17.7 | C8–C25 | 2–4 | 0.68 | Immiscible | ||

| M Oilfield [77] | 1.12 | Miscible | |||||

| Liubei block in Jidong Oilfield [78] | C7+ | 0.98 | Near-miscible | ||||

| Caoshe [79] | 31 | 17 | 1.22 | Miscible | |||

| Fumin [79] | 36 | 6.1 | 0.96 | Near-miscible | |||

| Sa II in Sanan Oilfield [79] | 51.7 | 8.6 | 0.46 | Immiscible | |||

| Sa I in Sanan Oilfield [79] | 45.8 | 9.2 | 0.48 | Immiscible | |||

| Jingbian [79] | 48 | 12 | 0.52 | Immiscible | |||

| Huang 3 testing area in Changqing Oilfield [80] | Heterogeneous | C2–C10 | 0.98 | Near-miscible | |||

| Chang 3 reservoir in Weibei Oilfield [81] | 1.1 | 0.13 | Immiscible | ||||

| Gao 89-1 block in Shengli Oilfield [82] | 1.5 | Highly heterogeneous | 5–8 | 1.45 | Miscible | ||

| Chang 4 + 5 reservoir in Wuqi Oilfield [83] | 55 | 7.69 | 0.84 | Immiscible | |||

| Chang 6 formation in Yanchang Oilfield [84] | 42.2 | 14.1 | 0.62 | Immiscible | |||

| M reservoir [85] | Light components | 0.78 | Immiscible | ||||

| A block in CQ Oilfield [86] | Light components | 0.75 | Immiscible | ||||

| Fu3 member in Zhangjiaduo Oilfield [87] | 1.29 | Miscible | |||||

| Yan 2 block in Benbutu Oilfield [88] | 0.76 | Near-miscible | |||||

| Area A in Tahe Oilfield [89] | 15 | 0.74 | C2–C15 | 0.8 | 1.22 | Miscible | |

| North Xinghe block in Ansai Oilfield [90] | Highly heterogeneous | C2–C15 | 0.46 | Immiscible | |||

| Triassic Yanchang formation in Wuqi Oilfield [91] | C7+ | 1.00 | Miscible |

| Screening Parameter | PC1 | PC2 | PC3 | PC4 |

|---|---|---|---|---|

| Depth | 0.906 | −0.105 | −0.018 | 0.015 |

| Temperature | 0.929 | −0.186 | −0.048 | −0.149 |

| Initial formation pressure | 0.944 | 0.012 | −0.030 | −0.059 |

| Current formation pressure | 0.931 | 0.172 | 0.038 | 0.170 |

| Pressure maintenance level | 0.214 | 0.417 | 0.171 | 0.658 |

| Porosity | 0.078 | 0.860 | −0.241 | 0.157 |

| Permeability | −0.177 | 0.795 | −0.283 | 0.116 |

| Density | 0.217 | 0.584 | 0.053 | −0.561 |

| Viscosity | 0.071 | 0.716 | 0.417 | −0.377 |

| Residual oil saturation | −0.832 | 0.161 | 0.150 | 0.297 |

| Effective thickness | 0.277 | 0.111 | 0.857 | −0.148 |

| Permeability variation coefficient | −0.038 | −0.193 | 0.644 | 0.400 |

| Molar content of C2–C15 | −0.759 | 0.239 | 0.151 | −0.164 |

| MMP | 0.559 | 0.326 | −0.053 | 0.388 |

| PC1 | PC2 | PC3 | PC4 | |

|---|---|---|---|---|

| Variance contribution rate (%) | 37.414 | 19.372 | 11.037 | 10.215 |

| Normalized weight | 0.479 | 0.249 | 0.141 | 0.131 |

| Weight | Screening Index | Range | ||

|---|---|---|---|---|

| Miscible Flooding | Near-Miscible Flooding | Immiscible Flooding | ||

| 0.479 | Depth (m) | 2750–4600 | 2550–3050 | 1072–2963 |

| Temperature (°C) | 107–120 | 84–102.5 | 45–126 | |

| Initial formation pressure (MPa) | 27–50 | 18–30.5 | 7–42 | |

| Current formation pressure (MPa) | 23–48 | 14–22 | 5–26 | |

| Residual oil saturation (%) | 31–40 | 37–43 | 27–55 | |

| C2–C15 molar content (mol%) | 40–52 | 34–48 | 35–61 | |

| MMP | 23–40 | 16–30 | 14–55 | |

| 0.249 | Porosity (%) | 9–21 | 8–17 | 6–27.6 |

| Permeability (mD) | 1–735 | 0.5–273 | 0.05–1628 | |

| Oil density (g/cm3) | 0.8–0.88 | 0.64–0.83 | 0.77–0.87 | |

| Oil viscosity (cP, mPa·s) | 2.9–15.1 | 0.3–1.8 | 1.98–9.8 | |

| 0.141 | Average effective thickness (m) | 10–60 | 2–12 | 1.5–20 |

| Permeability variation coefficient | 0.34–0.96 | 0.72–0.8 | 0.7–0.9 | |

| 0.131 | Pressure maintenance level (%) | 77–97 | 64–86 | 56–110 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, J.; Gao, M.; Liu, Z.; Yu, H.; Liu, W.; Yin, H. Research and Application of Carbon Capture, Utilization, and Storage–Enhanced Oil Recovery Reservoir Screening Criteria and Method for Continental Reservoirs in China. Energies 2024, 17, 1143. https://doi.org/10.3390/en17051143

Cao J, Gao M, Liu Z, Yu H, Liu W, Yin H. Research and Application of Carbon Capture, Utilization, and Storage–Enhanced Oil Recovery Reservoir Screening Criteria and Method for Continental Reservoirs in China. Energies. 2024; 17(5):1143. https://doi.org/10.3390/en17051143

Chicago/Turabian StyleCao, Jinhong, Ming Gao, Zhaoxia Liu, Hongwei Yu, Wanlu Liu, and Hengfei Yin. 2024. "Research and Application of Carbon Capture, Utilization, and Storage–Enhanced Oil Recovery Reservoir Screening Criteria and Method for Continental Reservoirs in China" Energies 17, no. 5: 1143. https://doi.org/10.3390/en17051143

APA StyleCao, J., Gao, M., Liu, Z., Yu, H., Liu, W., & Yin, H. (2024). Research and Application of Carbon Capture, Utilization, and Storage–Enhanced Oil Recovery Reservoir Screening Criteria and Method for Continental Reservoirs in China. Energies, 17(5), 1143. https://doi.org/10.3390/en17051143