Techno-Economic and Environmental Analysis of a Sewage Sludge Alternative Treatment Combining Chemical Looping Combustion and a Power-to-Methane System

Abstract

1. Introduction

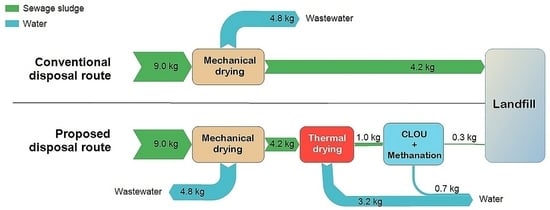

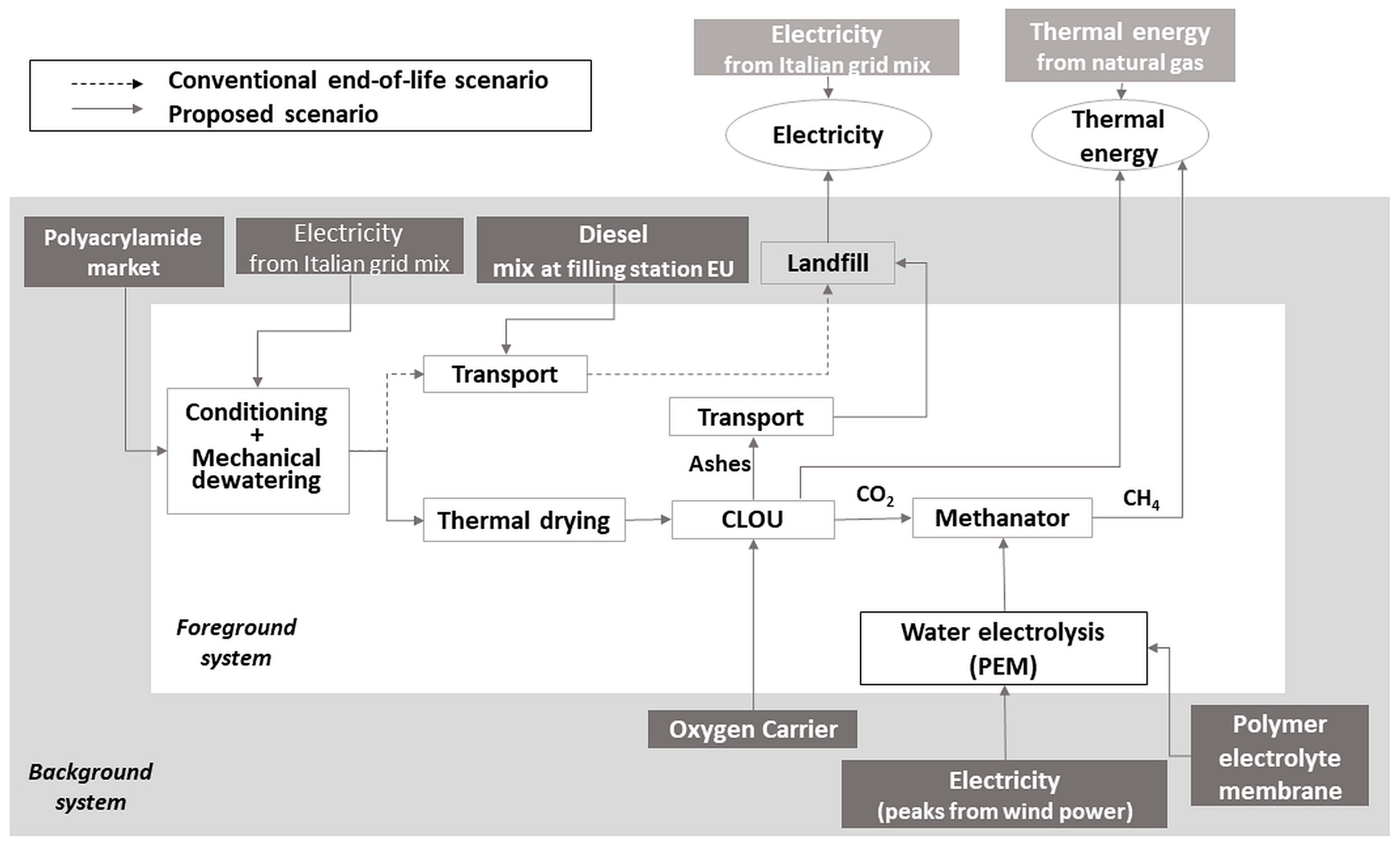

2. Materials and Methods

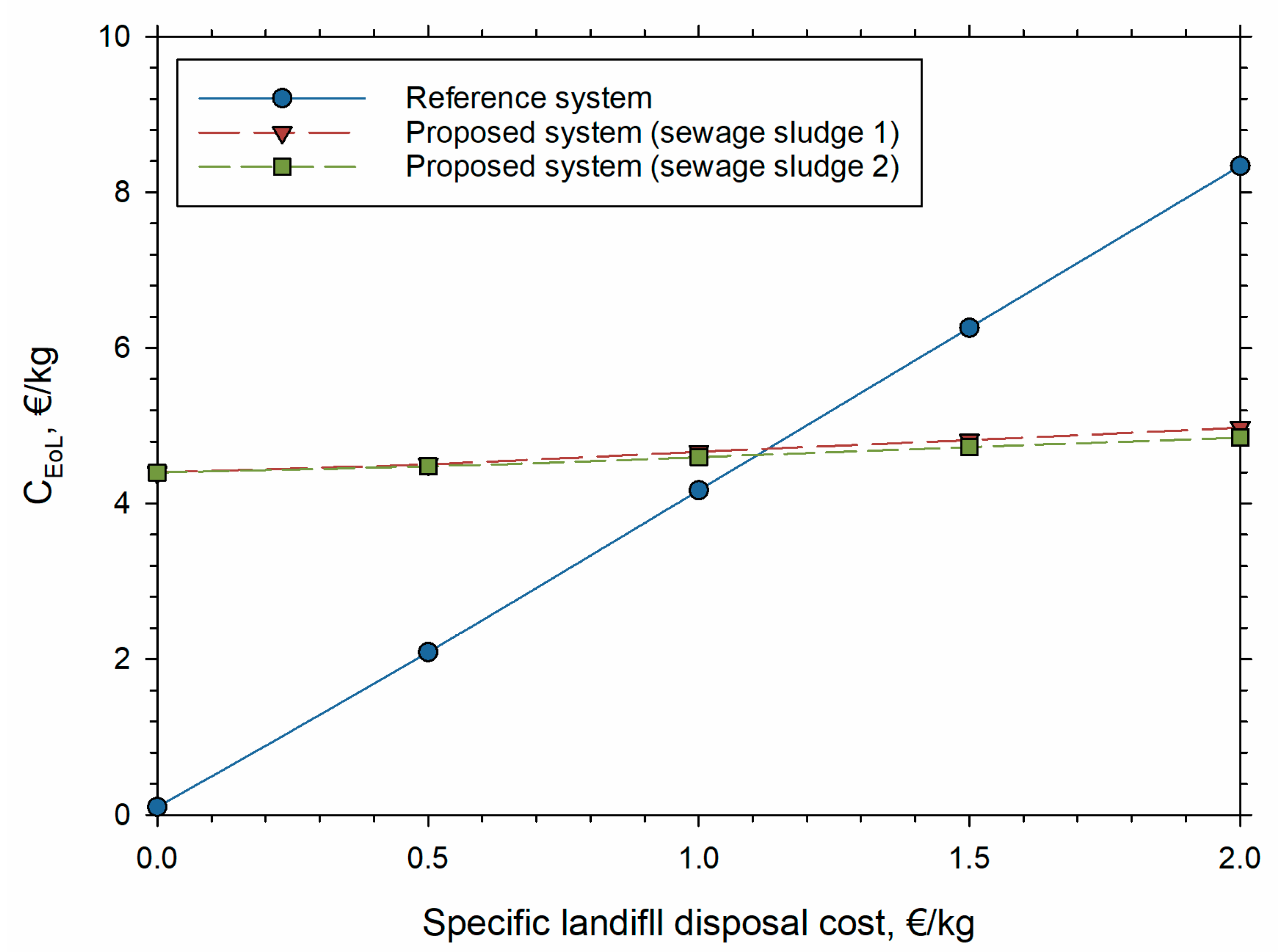

2.1. Economic Analysis

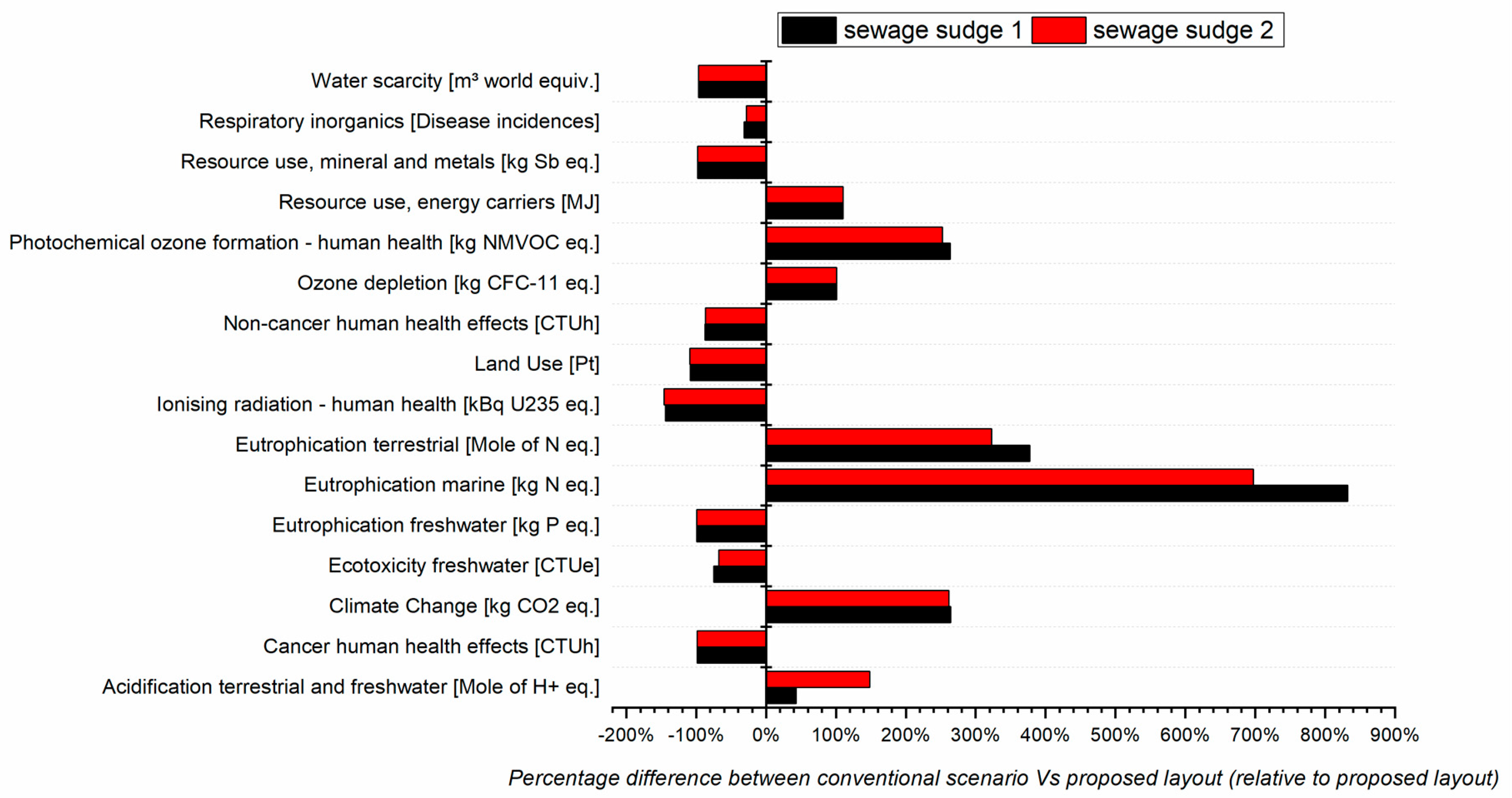

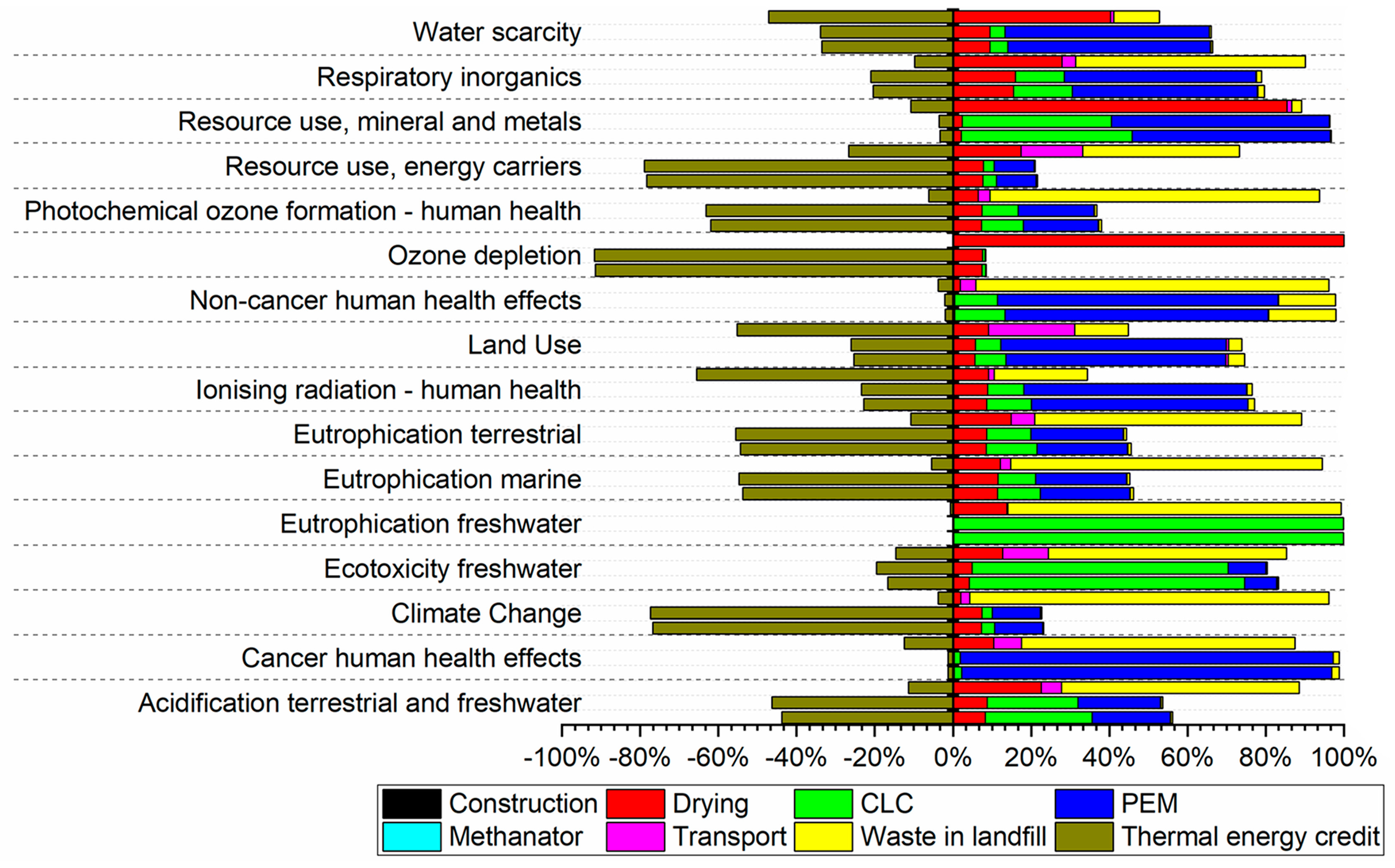

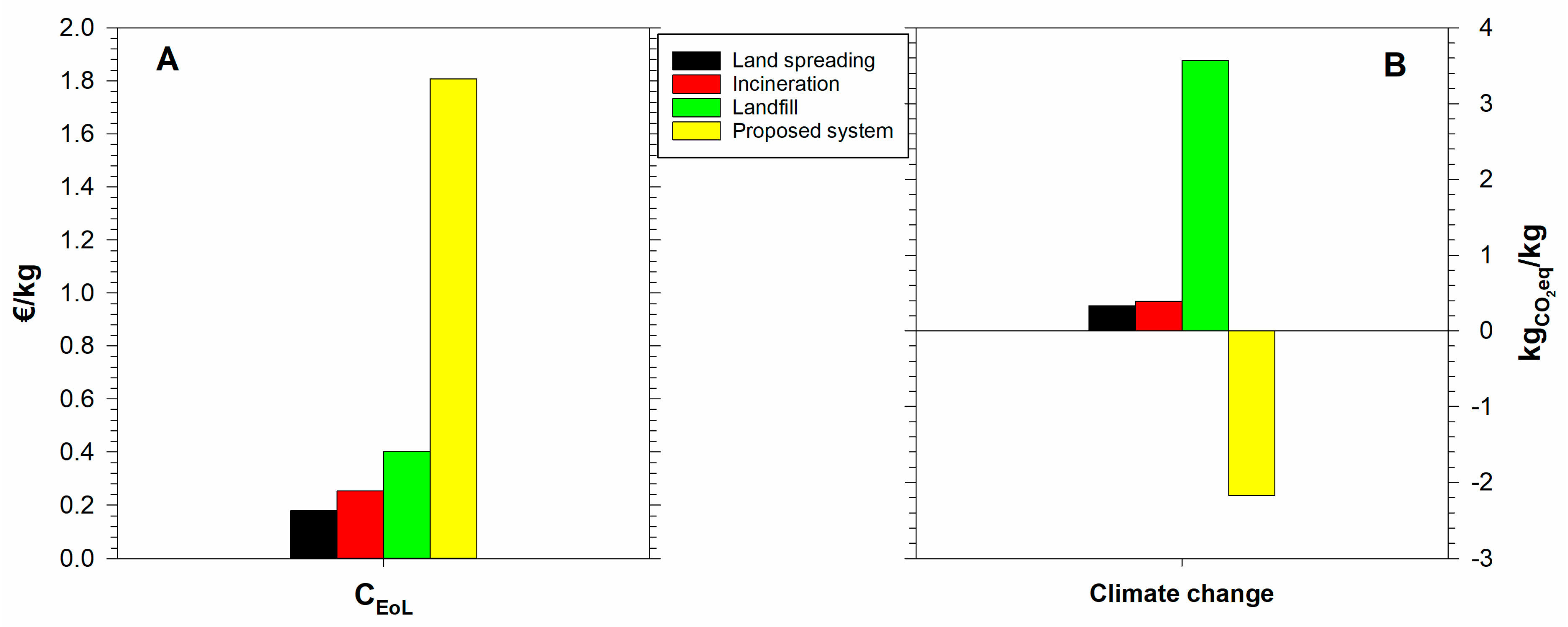

2.2. Life Cycle Assessment

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- FAO. Information System on Water and Agriculture; FAO: Rome, Italy.

- Bagheri, M.; Bauer, T.; Burgman, L.E.; Wetterlund, E. Fifty years of sewage sludge management research: Mapping researchers’ motivations and concerns. J. Environ. Manag. 2023, 325, 116412. [Google Scholar] [CrossRef]

- Eurostat. Eurostat—European Statistics, Database; European Commission: Brussels, Belgium, 2021. [Google Scholar]

- ISPRA. Rapporto Rifiuti Speciali, 2nd ed.; ISPRA: Rome, Italy, 2018. [Google Scholar]

- Mininni, G.; Mauro, E.; Piccioli, B.; Colarullo, G.; Brandolini, F.; Giacomelli, P. Production and characteristics of sewage sludge in Italy. Water Sci. Technol. 2019, 79, 619–626. [Google Scholar] [CrossRef]

- Buonocore, E.; Mellino, S.; De Angelis, G.; Liu, G.; Ulgiati, S. Life cycle assessment indicators of urban wastewater and sewage sludge treatment. Ecol. Indic. 2018, 94, 13–23. [Google Scholar] [CrossRef]

- Kacprzak, M.; Neczaj, E.; Fijałkowski, K.; Grobelak, A.; Grosser, A.; Worwag, M.; Rorat, A.; Brattebo, H.; Almås, Å.; Singh, B.R. Sewage sludge disposal strategies for sustainable development. Environ. Res. 2017, 156, 39–46. [Google Scholar] [CrossRef]

- Zhang, H.; Rigamonti, L.; Visigalli, S.; Turolla, A.; Gronchi, P.; Canziani, R. Environmental and economic assessment of electro-dewatering application to sewage sludge: A case study of an Italian wastewater treatment plant. J. Clean. Prod. 2019, 210, 1180–1192. [Google Scholar] [CrossRef]

- Migliaccio, R.; Brachi, P.; Montagnaro, F.; Papa, S.; Tavano, A.; Montesarchio, P.; Ruoppolo, G.; Urciuolo, M. Sewage Sludge Gasification in a Fluidized Bed: Experimental Investigation and Modeling. Ind. Eng. Chem. Res. 2021, 60, 5034–5047. [Google Scholar] [CrossRef]

- Niu, X.; Shen, L.; Jiang, S.; Gu, H.; Xiao, J. Combustion performance of sewage sludge in chemical looping combustion with bimetallic Cu-Fe oxygen carrier. Chem. Eng. J. 2016, 294, 185–192. [Google Scholar] [CrossRef]

- Bareschino, P.; Mancusi, E.; Urciuolo, M.; Paulillo, A.; Chirone, R.; Pepe, F. LCA and Feasibility Analysis of a Combined Chemical Looping Combustion and Power-to-Methane System for CO2 Capture and Utilization. Renew. Sustain. Energy Rev. 2020, 130, 109962. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: Geneva, Switzerland, 2006.

- Bareschino, P.; Mancusi, E.; Urciuolo, M.; Coppola, A.; Solimene, R.; Pepe, F.; Chirone, R.; Salatino, P. Modelling of a combined biomass CLC combustion and renewable-energy-based methane production system for CO2 utilization. Powder Technol. 2020, 373, 421–432. [Google Scholar] [CrossRef]

- Rönsch, S.; Schneider, J.; Matthischke, S.; Schlüter, M.; Götz, M.; Lefebvre, J.; Prabhakaran, P.; Bajohr, S. Review on methanation—From fundamentals to current projects. Fuel 2016, 166, 276–296. [Google Scholar] [CrossRef]

- Soleimani, S.; Lehner, M. Tri-Reforming of Methane: Thermodynamics, Operating Conditions, Reactor Technology and Efficiency Evaluation—A Review. Energies 2022, 15, 7159. [Google Scholar] [CrossRef]

- Brachi, P.; Bareschino, P.; Tregambi, C.; Pepe, F.; Urciuolo, M.; Ruoppolo, G.; Mancusi, E. Assessing the feasibility of an integrated CLC-methanation system using solar dried and torrefied biomasses as a feedstock. Fuel 2023, 331, 125951. [Google Scholar] [CrossRef]

- Gómez, L.; Martínez, I.; Navarro, M.V.; García, T.; Murillo, R. Sorption-enhanced CO and CO2 methanation (SEM) for the production of high purity methane. Chem. Eng. J. 2022, 440, 135842. [Google Scholar] [CrossRef]

- Ferrero, D.; Lanzini, A.; Santarelli, M.; Leone, P. A comparative assessment on hydrogen production from low- and high-temperature electrolysis. Int. J. Hydrogen Energy 2013, 38, 3523–3536. [Google Scholar] [CrossRef]

- Peters, M.S.; Timmerhaus, K.D.; West, R.E.; Timmerhaus, K.; West, R. Plant Design and Economics for Chemical Engineers; McGraw-Hill: New York, NY, USA, 2003. [Google Scholar]

- Lyngfelt, A.; Leckner, B. A 1000MWth boiler for chemical-looping combustion of solid fuels—Discussion of design and costs. Appl. Energy 2015, 157, 475–487. [Google Scholar] [CrossRef]

- Diglio, G.; Hanak, D.P.; Bareschino, P.; Mancusi, E.; Pepe, F.; Montagnaro, F.; Manovic, V. Techno-economic analysis of sorption-enhanced steam methane reforming in a fixed bed reactor network integrated with fuel cell. J. Power Sources 2017, 364, 41–51. [Google Scholar] [CrossRef]

- M.I.T., Pubblicazione del 9.luglio.2015 concernente i valori indicativi di riferimento dei costi di esercizio dell’impresa di autotrasporto per conto di terzi. 2015, 3.

- ISO 14044:2006/Amd 2:2020; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. ISO: Geneva, Switzerland; Amendment 2: London, UK, 2020.

- Deloitte Consulting. Energy Market Reform in Europe European Energy and Climate Policies: Achievements and Challenges to 2020 and Beyond; International Atomic Energy Agency: Vienna, Austria, 2020. [Google Scholar]

- Clift, R.; Doig, A.; Finnveden, G. The application of Life Cycle Assessment to Integrated Solid Waste Management. Part 1—Methodology. Process Saf. Environ. Prot. 2000, 78, 279–287. [Google Scholar] [CrossRef]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The ecoinvent database version 3 (Part I): Overview and methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Zhang, X.; Bauer, C.; Mutel, C.L.; Volkart, K. Life Cycle Assessment of Power-to-Gas: Approaches, system variations and their environmental implications. Appl. Energy 2017, 190, 326–338. [Google Scholar] [CrossRef]

- Mistry, M.; Gediga, J.; Boonzaier, S. Life cycle assessment of nickel products. Int. J. Life Cycle Assess. 2016, 21, 1559–1572. [Google Scholar] [CrossRef]

- Thorne, R.J.; Bouman, E.A.; Sundseth, K.; Aranda, A.; Czakiert, T.; Pacyna, J.M.; Pacyna, E.G.; Krauz, M.; Celińska, A. Environmental impacts of a chemical looping combustion power plant. Int. J. Greenh. Gas Control. 2019, 86, 101–111. [Google Scholar] [CrossRef]

- Fazio, S.; Castellani, V.; Sala, S.; Schau, E.; Secchi, M.; Zampori, L.; Diaconu, E. Supporting Information to the Characterisation Factors of Recommended EF Life Cycle Impact Assessment Method; JRC Technical Reports; New Models and Differences with ILCD Contents; European Commission: Brussels, Belgium, 2018. [Google Scholar] [CrossRef]

- Joint Research Centre. Product Environmental Footprint Category Rules Guidance, Version 6.3; Joint Research Centre: Brussels, Belgium, 2018. [Google Scholar]

- Hauschild, M.Z.; Rosenbaum, R.K.; Olsen, S.I. Life Cycle Assessment: Theory and Practice; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar] [CrossRef]

- Tenhumberg, N.; Büker, K. Ecological and Economic Evaluation of Hydrogen Production by Different Water Electrolysis Technologies. Chem. Ing. Tech. 2020, 92, 1586–1595. [Google Scholar] [CrossRef]

| Sewage Sludge 1 | Sewage Sludge 2 | ConventionalEnd of Life | |||

|---|---|---|---|---|---|

| 1 kg–10%wt water content into CLOU system | |||||

| Conditioning and mechanical drying | |||||

| Sewage sludge | kg | 9.00 | 9.00 | 9.00 | |

| Polyacrylamide | kg | 1.06 × 10−2 | 1.06 × 10−2 | 1.06 × 10−2 | |

| Electricity | kWh | 7.44 × 10−2 | 7.44 × 10−2 | 7.44 × 10−2 | |

| Thermal drying | |||||

| Energy | kWh | 2.36 | 2.36 | - | |

| CLOU | |||||

| OC | kg | 8.62 × 10−3 | 6.67 × 10−3 | - | |

| Air | kg | 3.86 | 3.86 | - | |

| Produced thermal energy | kWh | 2.59 | 2.68 | - | |

| PEM | |||||

| H2O | kg | 6.91 | 6.91 | - | |

| Renewable electricity | kWh | 1.79 | 1.79 | - | |

| MU | |||||

| CO2 produced in CLOU | kg | 2.11 | 2.11 | - | |

| H2 produced in PEM | kg | 3.84 × 10−1 | 3.84 × 10−1 | - | |

| Methane | kg | 7.37 × 10−1 | 7.37 × 10−1 | - | |

| Ni catalyst | kg | 1.47 × 10−5 | 1.47 × 10−5 | - | |

| Transport | |||||

| Cargo | kg | 3.15 × 10−1 | 2.50 × 10−1 | 4.17 | |

| Diesel | kg | 1.80 × 10−3 | 1.43 × 10−3 | 2.44 × 10−2 | |

| Single way | km | 3.00 × 102 | 3.00 × 102 | 3.00 × 102 | |

| Landfill | |||||

| Ash | kg | 3.06 × 10−1 | 2.43 × 10−1 | - | |

| OC spent | kg | 8.62 × 10−3 | 6.67 × 10−3 | - | |

| Catalyst | kg | 1.47 × 10−5 | 1.47 × 10−5 | - | |

| Sewage | kg | - | - | 4.17 | |

| Electricity | kWh | - | - | 9.66 × 10−1 | |

| Sewage Sludge 1 | Sewage Sludge 2 | Reference | |

|---|---|---|---|

| EUR/kg | EUR/kg | EUR/kg | |

| Conditioning and drying | |||

| Polyacrylamide | 1.48 × 10−2 | 1.48 × 10−2 | 1.48 × 10−2 |

| Mechanical drying | 5.36 × 10−3 | 5.36 × 10−3 | 5.36 × 10−3 |

| Thermal drying | 1.68 × 10−2 | 1.68 × 10−2 | - |

| CLOU system | |||

| Reactors | 2.77 × 10−2 | 2.77 × 10−2 | - |

| Cyclone | 6.49 × 10−3 | 6.49 × 10−3 | - |

| Compressors | 8.46 × 10−3 | 8.46 × 10−3 | - |

| OC (inventory) | 8.74 × 10−4 | 8.74 × 10−4 | - |

| Heat exchanger | 2.37 × 10−2 | 2.37 × 10−2 | - |

| OC (replacement) | 1.51 × 10−3 | 1.17 × 10−3 | - |

| Produced thermal energy | 1.21 × 10−1 | 1.21 × 10−1 | - |

| Electric energy | 2.46 × 10−3 | 2.46 × 10−3 | - |

| Hydrogen production system | |||

| PEM | 2.67 × 10−1 | 2.67 × 10−1 | - |

| Water | 1.34 × 10−2 | 1.34 × 10−2 | - |

| Electric energy | 4.83 | 4.83 | - |

| Methanation unit | |||

| Reactors | 4.36 × 10−2 | 4.36 × 10−2 | - |

| Compressors | 3.55 × 10−2 | 3.55 × 10−2 | - |

| Catalyst (inventory) | 1.40 × 10−2 | 1.40 × 10−2 | - |

| Methane | 4.00 × 10−1 | 4.00 × 10−1 | - |

| Catalyst (replacement) | 6.62 × 10−4 | 6.62 × 10−4 | - |

| Electric energy | 9.58 × 10−3 | 9.58 × 10−3 | - |

| Produced thermal energy | 2.20 × 10−2 | 2.20 × 10−2 | - |

| Transport | |||

| Diesel | 3.28 × 10−3 | 2.60 × 10−3 | 4.44 × 10−2 |

| Single way | 5.24 × 10−3 | 5.24 × 10−3 | 5.24 × 10−3 |

| Landfilling | |||

| Ash | 1.53 × 10−1 | 1.22 × 10−1 | - |

| OC spent | 4.31 × 10−3 | 3.34 × 10−3 | - |

| Ni catalyst | 7.35 × 10−6 | 7.35 × 10−6 | - |

| Sewage | - | - | 2.09 |

| Produced electric energy | - | - | 6.52 × 10−2 |

| Total | |||

| TCRs + TCLs | 5.03 | 5.00 | 2.15 |

| Rs | 5.21 × 10−1 | 5.21 × 10−1 | 6.52 × 10−2 |

| CEoL | 4.51 | 4.48 | 2.09 |

| Sludge Transportation Scenario | Oxygen Carrier Replacement Ratio Scenario | Energy Consumption PEM Scenario | |||||||

|---|---|---|---|---|---|---|---|---|---|

| +5% | +10% | +25% | +5% | +10% | +25% | +5% | +10% | +25% | |

| variation (from baseline) | |||||||||

| Acidification terrestrial and freshwater | 0% | 0% | 0% | 10% | 21% | 52% | 8% | 16% | 40% |

| Cancer human health effects | 0% | 0% | 0% | 0% | 0% | 1% | 5% | 10% | 24% |

| Climate change | 0% | 0% | 0% | 0% | 1% | 2% | 1% | 2% | 6% |

| Ecotoxicity freshwater | 0% | 0% | 0% | 5% | 11% | 26% | 1% | 1% | 3% |

| Eutrophication freshwater | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% |

| Eutrophication marine | 0% | 0% | 1% | 5% | 10% | 26% | 15% | 29% | 74% |

| Eutrophication terrestrial | 0% | 0% | 1% | 6% | 11% | 28% | 13% | 26% | 65% |

| Ionising radiation–human health | 0% | 0% | 0% | 1% | 2% | 5% | 4% | 9% | 21% |

| Land use | 0% | 0% | 1% | 1% | 2% | 4% | 6% | 11% | 28% |

| Non-cancer human health effects | 0% | 0% | 0% | 1% | 1% | 3% | 3% | 7% | 17% |

| Ozone depletion | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% |

| Photochemical ozone formation–human health | 0% | 0% | 0% | 2% | 4% | 9% | 4% | 8% | 20% |

| Resource use, energy carriers | 0% | 0% | 0% | 0% | 1% | 2% | 1% | 2% | 4% |

| Resource use, mineral and metals | 0% | 0% | 0% | 2% | 5% | 12% | 3% | 5% | 14% |

| Respiratory inorganics | 0% | 0% | 0% | 1% | 2% | 6% | 4% | 8% | 20% |

| Water scarcity | 0% | 0% | 0% | 1% | 1% | 4% | 1% | 2% | 4% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bareschino, P.; Chirone, R.; Paulillo, A.; Tregambi, C.; Urciuolo, M.; Pepe, F.; Mancusi, E. Techno-Economic and Environmental Analysis of a Sewage Sludge Alternative Treatment Combining Chemical Looping Combustion and a Power-to-Methane System. Energies 2024, 17, 901. https://doi.org/10.3390/en17040901

Bareschino P, Chirone R, Paulillo A, Tregambi C, Urciuolo M, Pepe F, Mancusi E. Techno-Economic and Environmental Analysis of a Sewage Sludge Alternative Treatment Combining Chemical Looping Combustion and a Power-to-Methane System. Energies. 2024; 17(4):901. https://doi.org/10.3390/en17040901

Chicago/Turabian StyleBareschino, Piero, Roberto Chirone, Andrea Paulillo, Claudio Tregambi, Massimo Urciuolo, Francesco Pepe, and Erasmo Mancusi. 2024. "Techno-Economic and Environmental Analysis of a Sewage Sludge Alternative Treatment Combining Chemical Looping Combustion and a Power-to-Methane System" Energies 17, no. 4: 901. https://doi.org/10.3390/en17040901

APA StyleBareschino, P., Chirone, R., Paulillo, A., Tregambi, C., Urciuolo, M., Pepe, F., & Mancusi, E. (2024). Techno-Economic and Environmental Analysis of a Sewage Sludge Alternative Treatment Combining Chemical Looping Combustion and a Power-to-Methane System. Energies, 17(4), 901. https://doi.org/10.3390/en17040901