Study of a Novel Hybrid Refrigeration System, with Natural Refrigerants and Ultra-Low Carbon Emissions, for Air Conditioning

Abstract

1. Introduction

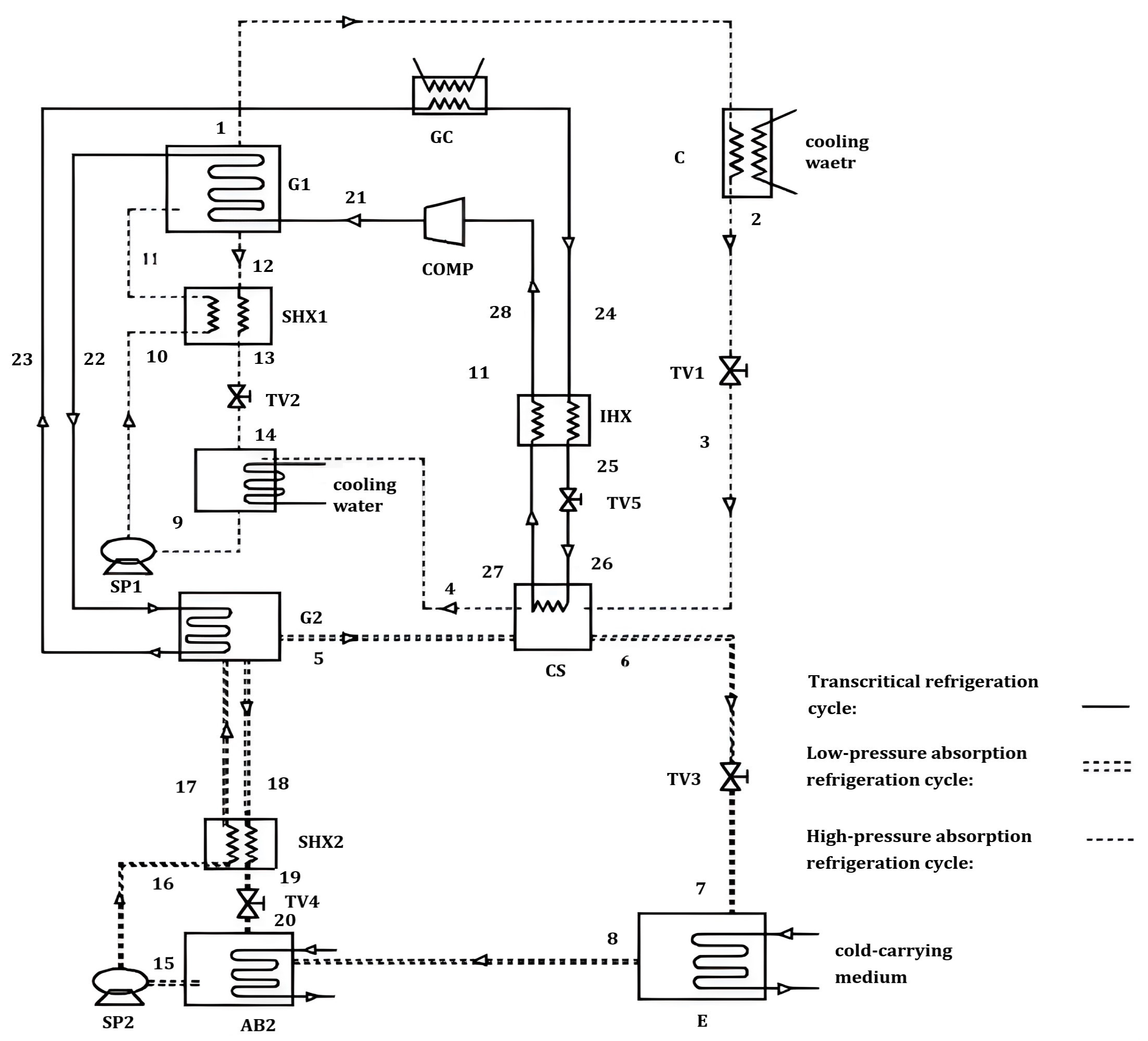

2. Descriptions of the CTTA System and Theoretical Model

2.1. Descriptions of the CTTA System

2.2. Construction of the Simulation Model

- The water vapor mass flow rates from G1 and G2 are equivalent to the mass flow rates from AB1 and AB2, respectively.

- The power consumption of the solution pumps is not factored into the analysis.

- All throttling processes are assumed to be isenthalpic.

- The outlet solution from the generator and absorber is saturated.

- The heat loss along the pipeline is disregarded.

- The pressure drop in the pipes and heat exchangers of the absorption subsystem is negligible.

- The isentropic efficiency of the compressor is taken as 0.8.

- The outlet solution temperature of the generator is the generation temperature and the outlet dilute solution temperature of the absorber is the absorption temperature.

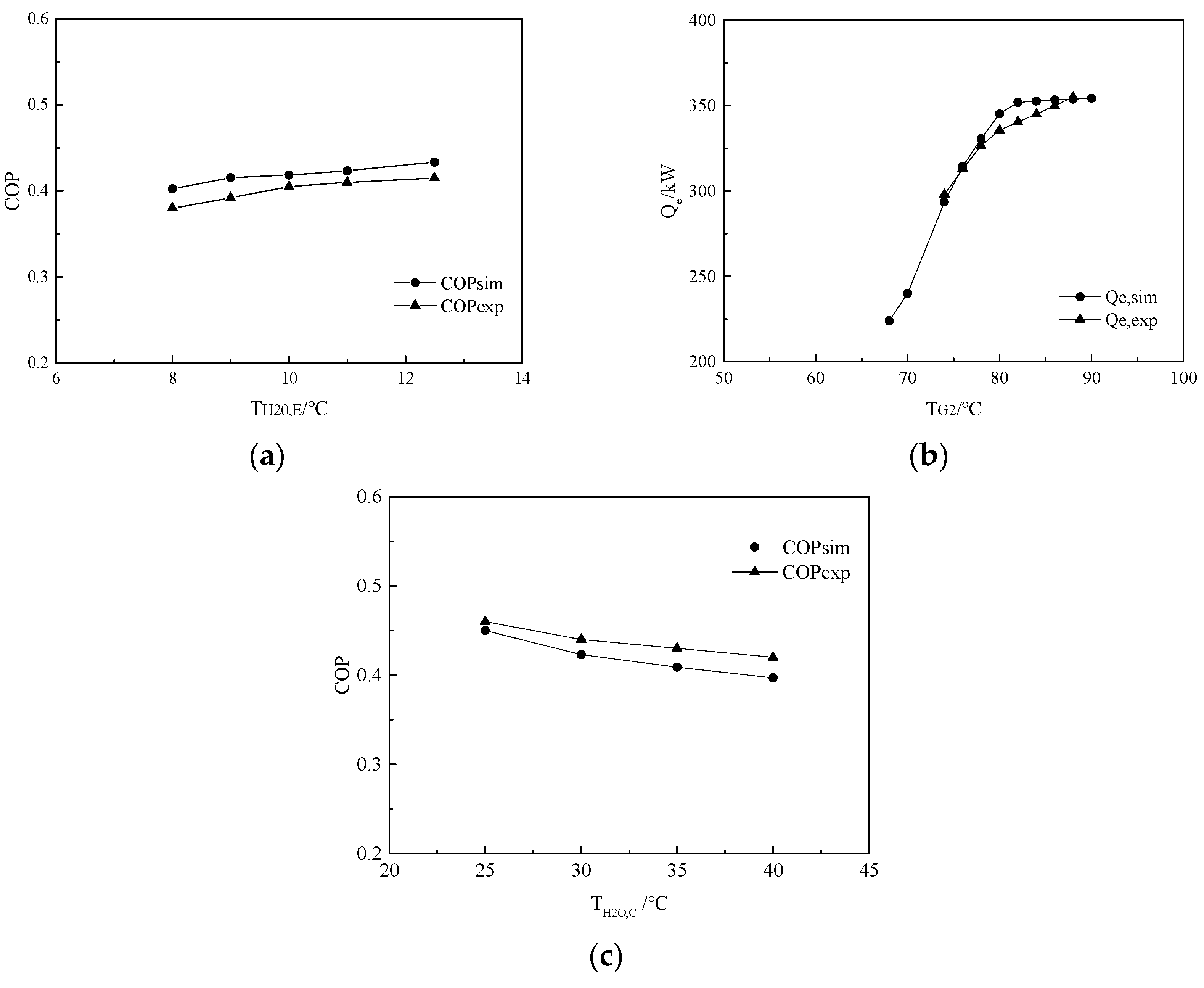

3. Validation of the Performance Simulation Model

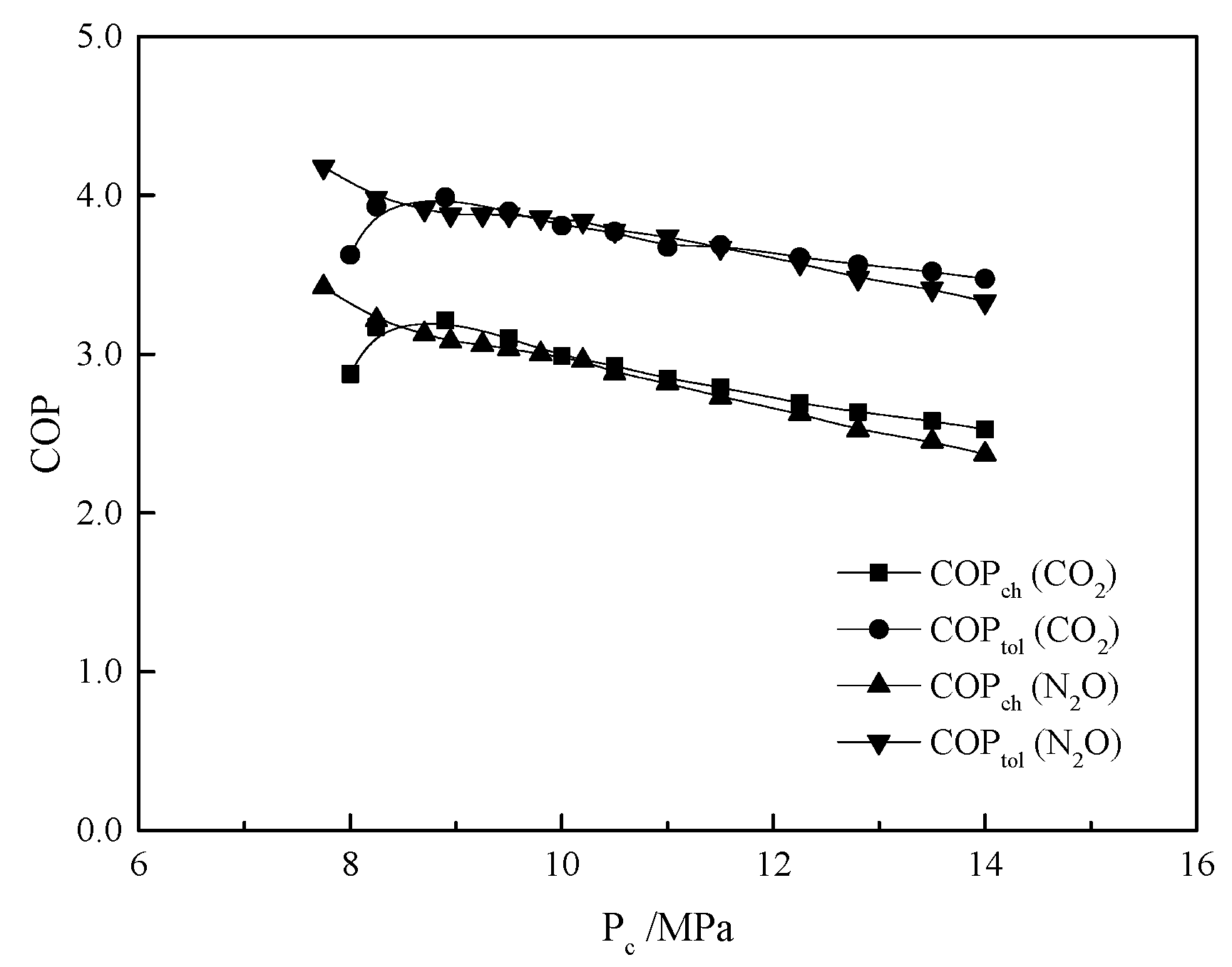

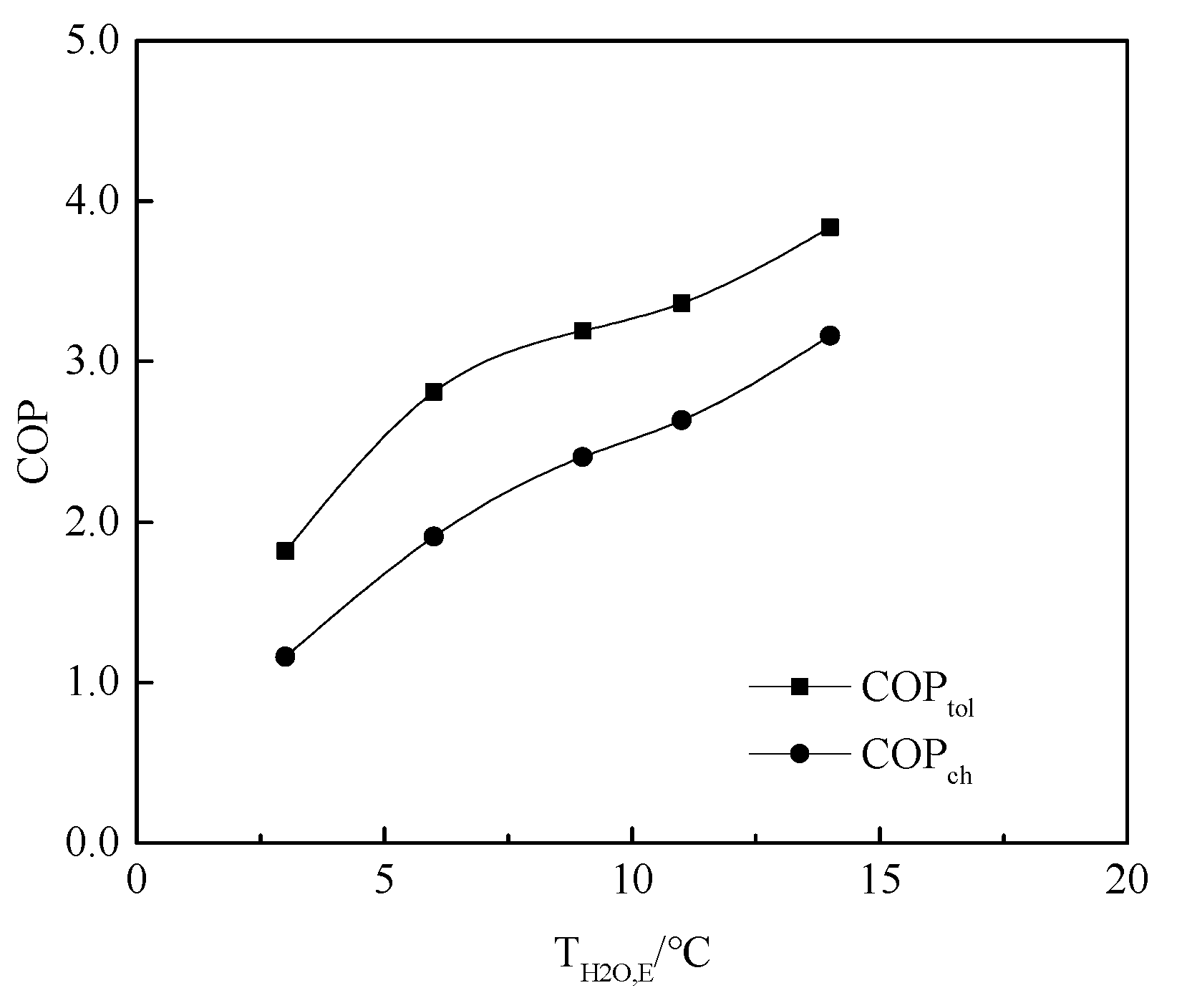

4. Results and Discussion

5. Conclusions

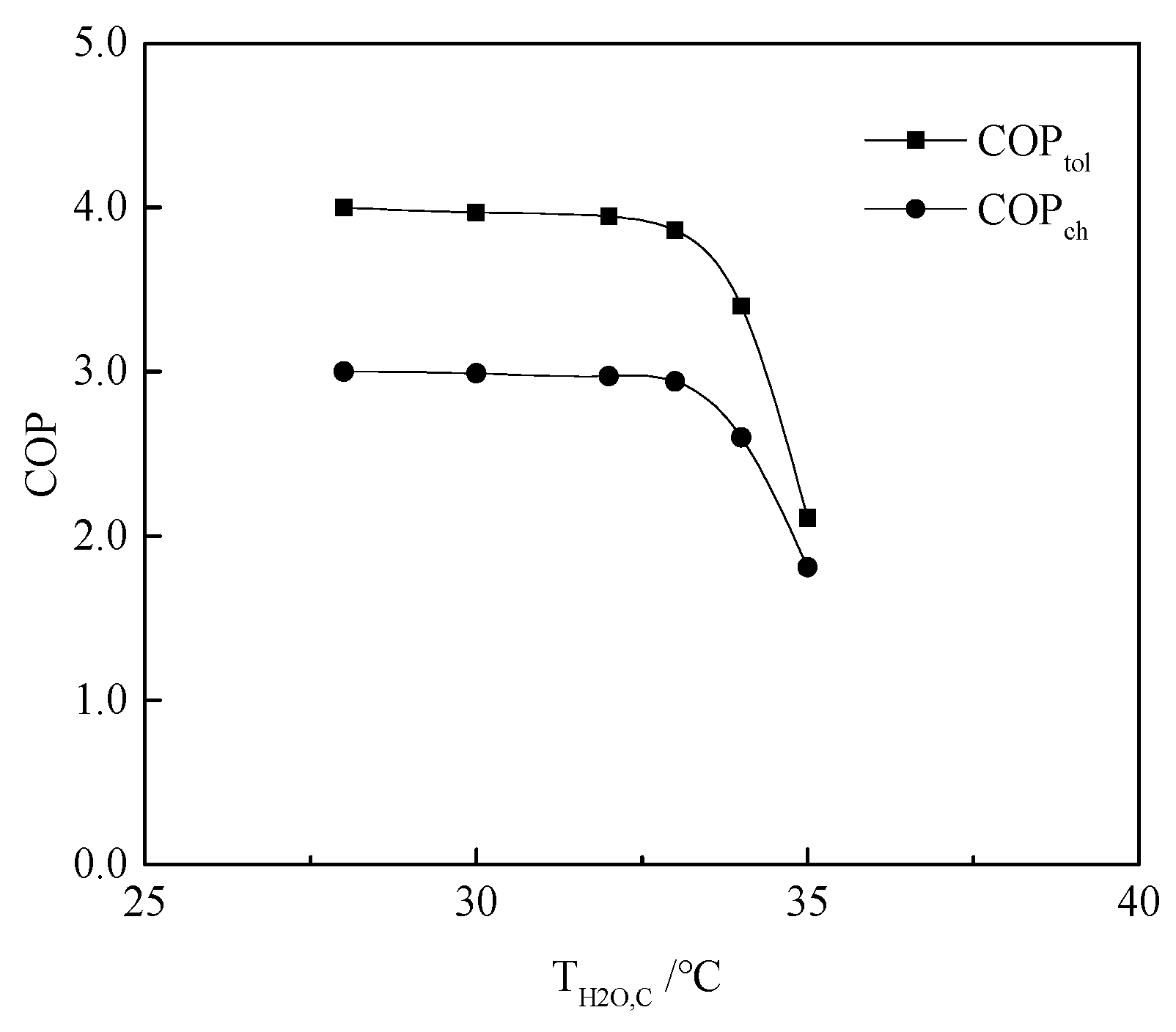

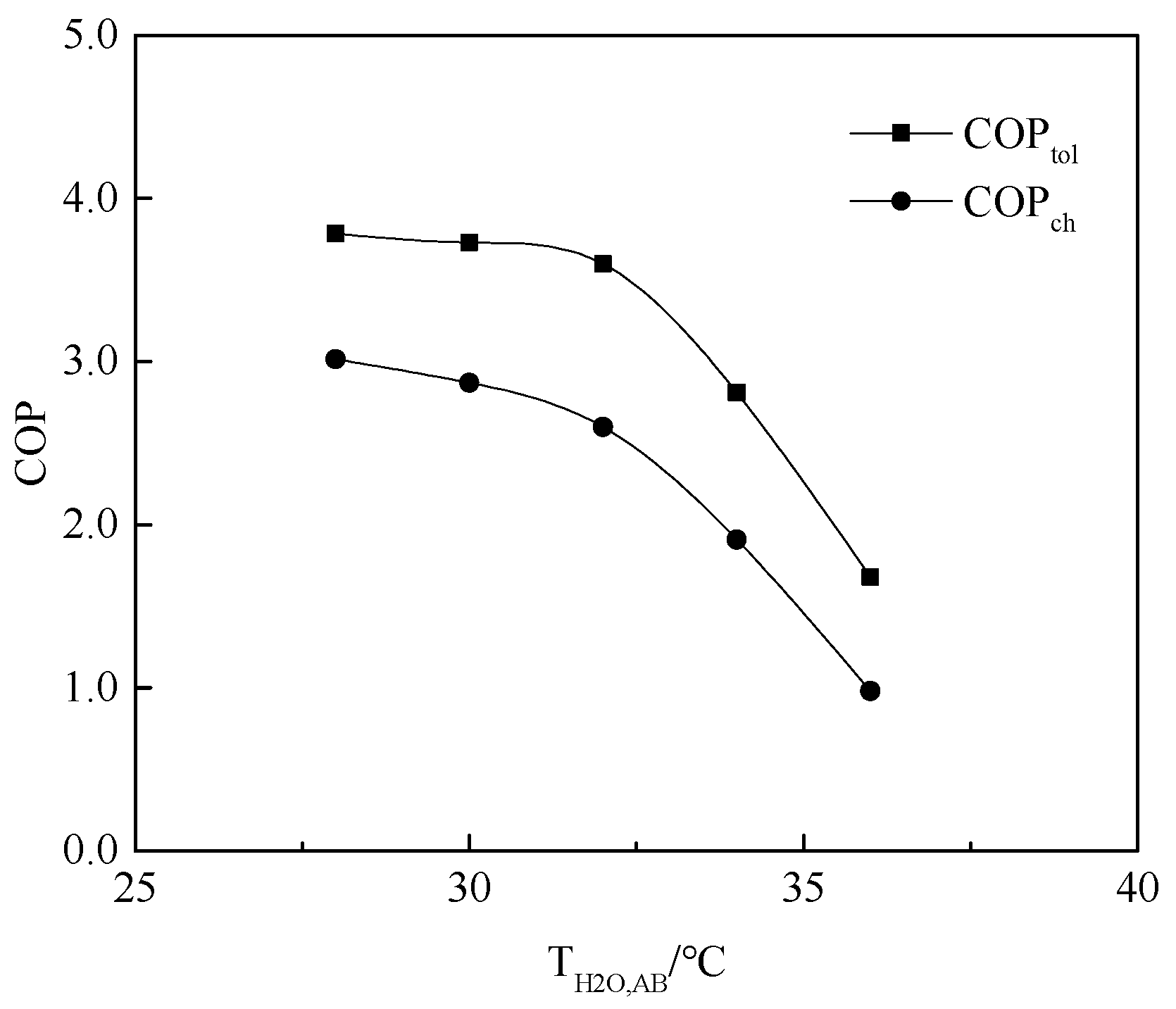

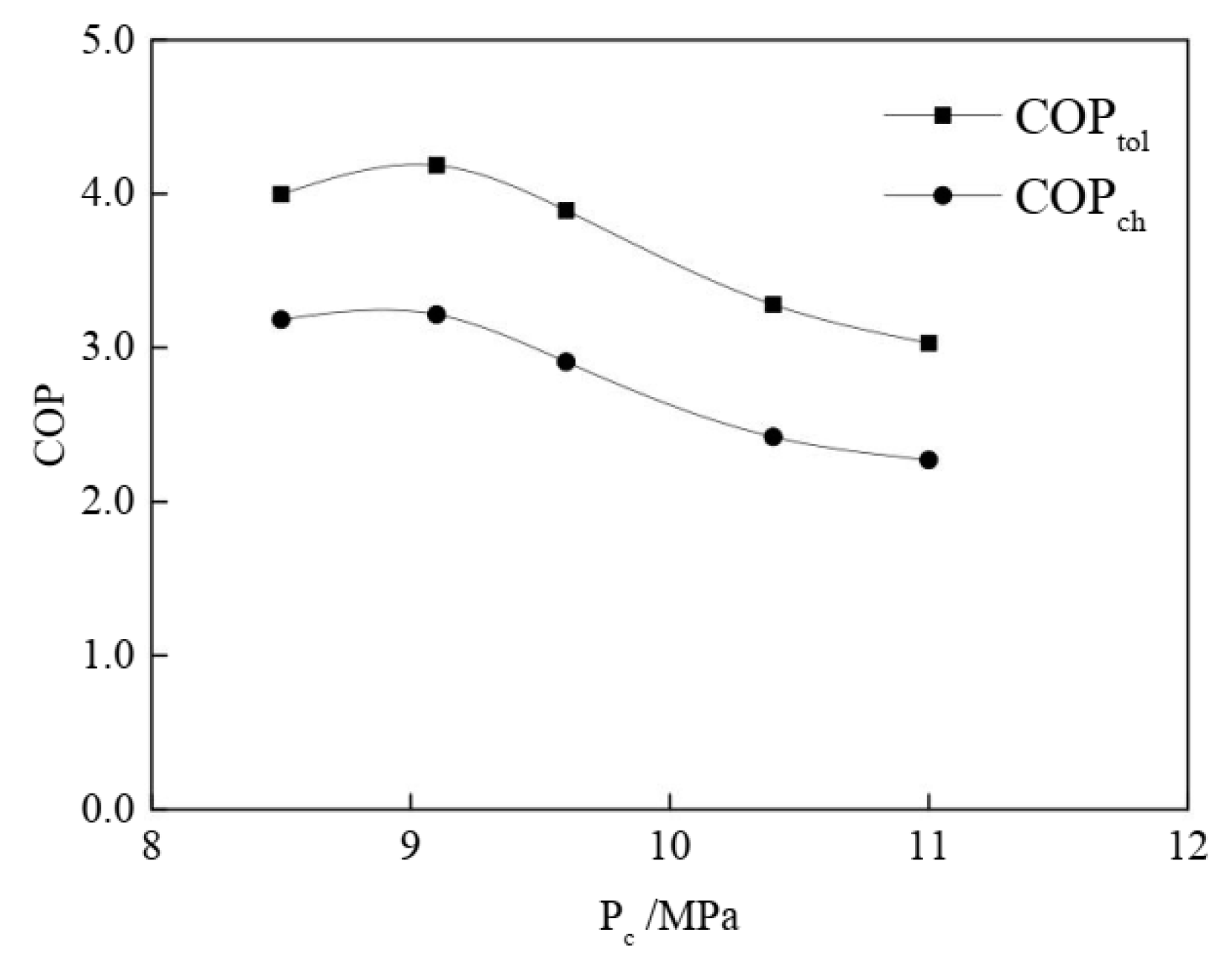

- Optimal values of Tm, TG2, Tair, and Pc exist for obtaining the maximum COPtol.

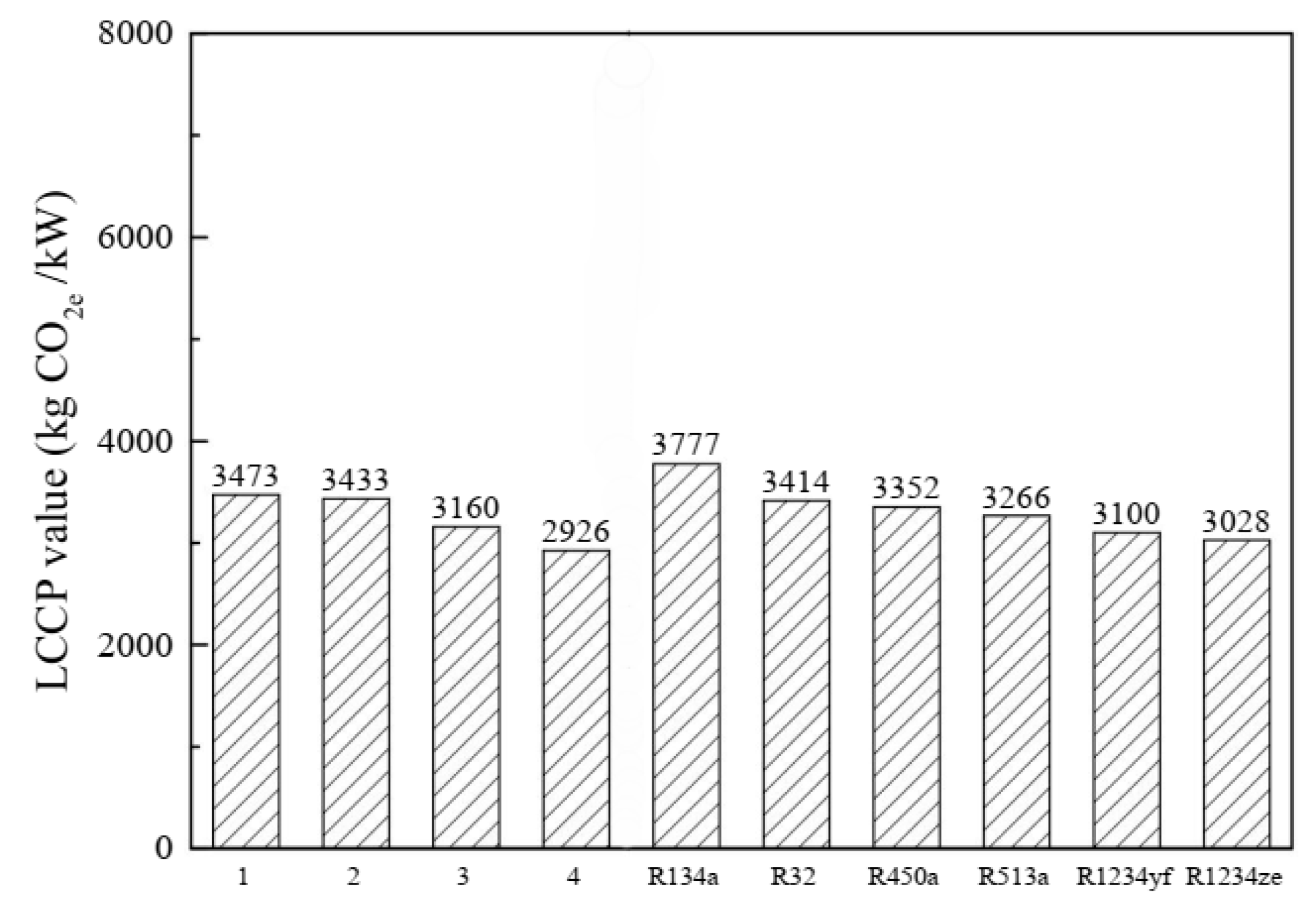

- The CTTA system has a notable improvement of 57.1% in COPtol, when compared to the BCT system.

- The CTTA system has an equivalent carbon emission to the R134a system, which is 53.6% lower than the BCT system.

- Ultra-low carbon emissions could be obtained for the CTTA system, which could be reduced to 2926 kg CO2e/kW, a total 3.4% lower than the R1234ze(E) systems.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Nomenclature | Unit | Subscripts | ||

| Adp.GWP | GWP of atmospheric degradation product | kg CO2e/kg | 1,2,3 | State point |

| AEC | Annual energy consumption | kWh | a | Absorption system |

| Cr | Refrigerant charge | kg | ch | Conventional hybrid system |

| EM | Power plant emission factor | kg CO2e/kWh | exp | Experimental result |

| EOL | End-of-life refrigeration leakage | % | m | Intermedia |

| GWP | Global Warming Potential | kg CO2e/kg | sim | Simulation result |

| h | Enthalpy | kJ/kg | tol | Total |

| L | Average lifetime of equipment | year | Abbreviations | |

| M | Mass of unit | kg | AB | Absorber |

| MM | CO2e produced/material | kg CO2e/kg | BCT | Basic CO2 transcritical |

| Mass flow rate | kg/s | C | Condenser | |

| mr | Mass of recycle material | kg | COMP | Compressor |

| Q | Rated heat load | kW | CS | Condensing subcooler |

| Qe | Refrigeration capacity | kW | CTTA | CO2 transcritical/two-stage absorption |

| RM | CO2e produced/Recycled Material | kg CO2e/kg | E | Evaporator |

| RFM | Refrigerant manufacturing emissions | kg CO2e/kg | G | Generator |

| RFD | Refrigerant disposal emissions | kg CO2e/kg | GC | Gas cooler |

| T | Temperature | °C | GWP | Global warming potential |

| W | Input power | kW | IHX | Internal heat exchanger |

| LCCP | Life cycle climate performance | |||

| SHX | Solution heat exchanger | |||

| SP | Solution pump | |||

| TV | Throttling valve | |||

| DMS | Dedicated mechanical subrefrigeration |

References

- Li, J. Towards a low-carbon future in China’s building sector-A review of energy and climate models forecast. Energy Policy 2008, 36, 1736–1747. [Google Scholar] [CrossRef]

- Makhnatch, P.; Mota-Babiloni, A.; López-Belchí, A.; Khodabandeh, R. R450A and R513A as lower GWP mixtures for high ambient temperature countries: Experimental comparison with R134a. Energy 2019, 166, 223–235. [Google Scholar] [CrossRef]

- Li, Y.X.; Zhang, Z.Y.; De An, M.; Gao, D.; Yi, L.Y.; Hu, J.X. The estimated schedule and mitigation potential for hydrofluorocarbons phase-down in China. Adv. Clim. Chang. Res. 2019, 10, 174–180. [Google Scholar] [CrossRef]

- Lemmon, E.W.; Huber, M.L.; McLinden, M.O.; Bai, W. REFPROP, NIST Standard Reference Database 23; Version 9.1; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2013.

- Bhamidipati, A.; Pendyala, S.; Prattipati, R. Performance evaluation of multi pressure refrigeration system using R32. Mater. Today Proc. 2020, 28, 2405–2410. [Google Scholar] [CrossRef]

- Tanaka, K.; Higashi, Y. Thermodynamic properties of HFO-1234yf (2,3,3,3-tetrafluoropropene). Int. J. Refrig. 2010, 33, 474–479. [Google Scholar] [CrossRef]

- Navarro-Esbrí, J.; Molés, F.; Barragán-Cervera, Á. Experimental analysis of the internal heat exchanger influence on a vapour compression system performance working with R1234yf as a drop-in replacement for R134a. Appl. Therm. Eng. 2013, 59, 153–161. [Google Scholar] [CrossRef]

- Gaurav; Kumar, R. Computational energy and exergy analysis of R134a, R1234yf, R1234ze and their mixtures in vapour compression system. Ain Shams Eng. J. 2018, 9, 3229–3237. [Google Scholar] [CrossRef]

- Makhnatch, P.; Mota-Babiloni, A.; Khodabandeh, R. Experimental study of R450A drop-in performance in an R134a small capacity refrigeration unit. Int. J. Refrig. 2017, 84, 26–35. [Google Scholar] [CrossRef]

- International Institute of Refrigeration (IIR). Guideline for Life Cycle Climate Performance January 2016; International Institute of Refrigeration: Paris, France, 2016; pp. 1–26. [Google Scholar]

- Choi, S.; Oh, J.; Hwang, Y.; Lee, H. Life cycle climate performance evaluation (LCCP) on cooling and heating systems in South Korea. Appl. Therm. Eng. 2017, 120, 88–98. [Google Scholar] [CrossRef]

- Lee, H.; Troch, S.; Hwang, Y.; Radermacher, R. LCCP evaluation on various vapor compression cycle options and low GWP refrigerants. Int. J. Refrig. 2016, 70, 128–137. [Google Scholar] [CrossRef]

- Yu, B.; Yang, J.; Wang, D.; Shi, J.; Chen, J. An updated review of recent advances on modified technologies in transcritical CO2 refrigeration cycle. Energy. 2019, 189, 116147. [Google Scholar] [CrossRef]

- Wang, A.; Yin, X.; Fang, J.; Cao, F. Refrigerant Distributions and Dynamic Migration Characteristics of the Transcritical CO2 Air Conditioning System. Int. J. Refrig. 2021, 130, 233–241. [Google Scholar] [CrossRef]

- Song, Y.; Ye, Z.; Wang, Y.; Cao, F. The experimental verification on the optimal discharge pressure in a subcooler-based transcritical CO2 system for space heating. Energy Build. 2018, 158, 1442–1449. [Google Scholar] [CrossRef]

- Lawrence, N.; Elbel, S. Comparison of CO2 and R134a two-phase ejector performance for use in automotive air conditioning applications. SAE Tech. Pap. 2014, 1. [Google Scholar] [CrossRef]

- Tashtoush, B.; Megdouli, K.; Elakhdar, M.; Nehdi, E.; Kairouani, L. A comprehensive energy and exergoeconomic analysis of a novel transcritical refrigeration cycle. Processes 2020, 8, 758. [Google Scholar] [CrossRef]

- Megdouli, K.; Tashtoush, B.M.; Nahdi, E.; Elakhdar, M.; Kairouani, L.; Mhimid, A. Thermodynamic analysis of a novel ejector- cascade refrigeration cycles for freezing process applications and air-conditioning. Int. J. Refrig. 2016, 70, 108–118. [Google Scholar] [CrossRef]

- Liu, X.; Hu, Y.; Wang, Q.; Yao, L.; Li, M. Energetic, environmental and economic comparative analyses of modified transcritical CO2 heat pump system to replace R134a system for home heating. Energy 2021, 229, 120544. [Google Scholar] [CrossRef]

- Chan, W.M.; Leong, Y.T.; Foo, J.J.; Chew, I.M.L. Synthesis of energy efficient chilled and cooling water network by integrating waste heat recovery refrigeration system. Energy 2017, 141, 1555–1568. [Google Scholar] [CrossRef]

- Jain, V.; Sachdeva, G.; Kachhwaha, S.S. Comparative performance study and advanced exergy analysis of novel vapor compression-absorption integrated refrigeration system. Energy Convers. Manag. 2018, 172, 81–97. [Google Scholar] [CrossRef]

- Gibelhaus, A.; Fidorra, N.; Lanzerath, F.; Bau, U.; Köhler, J.; Bardow, A. Hybrid refrigeration by CO2 vapour compression cycle and water-based adsorption chiller: An efficient combination of natural working fluids. Int. J. Refrig. 2019, 103, 204–214. [Google Scholar] [CrossRef]

- He, Y.J.; Jiang, Y.Y.; Gao, N.; Chen, G.M.; Tang, L.M. Theoretical analyses of a new two- stage absorption-transcritical hybrid refrigeration system. Int. J. Refrig. 2015, 56, 105–113. [Google Scholar] [CrossRef]

- Klein, S.A. Engineering Equation Solver (EES) 1992–2014; F-Chart Software: Middleton, WI, USA, 2020. [Google Scholar]

- Herold, K.E. 99/01562 An analysis of the major variables impacting performance of absorption chillers and heat pumps. Fuel Energy Abstr. 1997, 40, 157. [Google Scholar] [CrossRef]

- Chen, X.; He, Y.; Wang, Y.; Chen, G. Analysis of a hybrid system of liquid desiccant and CO2 transcritical cycles. Int. J. Refrig. 2019, 105, 101–108. [Google Scholar] [CrossRef]

- Mcneely, L.A. Thermodynamic properties of aqueous solutions of lithium-bromide. ASHRAE Trans. 1979, 20, 54–55. [Google Scholar]

- Berlitz, T.; Plank, H.; Ziegler, F.; Kahn, R. An ammonia-water absorption refrigerator with a large temperature lift for combined heating and cooling. Int. J. Refrig. 1998, 21, 219–229. [Google Scholar] [CrossRef]

- Span, R.; Wagner, W. A new equation of state for carbon dioxide covering the fluid region from the triple-point temperature to 1100K at Pressures up to 800 MPa. J. Phys. Chem. Ref. Data. 1996, 6, 1509–1596. [Google Scholar] [CrossRef]

- Dai, Y. The Technology and Application of Lithium Bromide Absorption Refrigeration; Machinery Industry Press: Beijing, China, 1996. (In Chinese) [Google Scholar]

- Pitla, S.S.; Groll, E.A.; Ramadhyani, S. New correlation to predict the heat transfer coefficient in-tube cooling of supercritical CO2 in horizontal macro-tubes. Exp. Therm. Fluid Sci. 2002, 25, 887–895. [Google Scholar] [CrossRef]

- Huang, D.; Liang, Z.; Ding, G.; Zhang, C. Modeling and Performance Analysis of LFSN. J. Chem. Ind. Eng. 2002, 53, 832–836. [Google Scholar] [CrossRef]

- Agrawal, N.; Bhattacharyya, S. Non-adiabatic capillary tube flow of carbon dioxide in a transcritical heat pump cycle. Energy Convers. Manag. 2007, 48, 2491–2501. [Google Scholar] [CrossRef]

- Lockhart, R.; Martinelli, R. Proposed correlation of data for isothermal two-phase, two-component flow in pipes. Chem. Eng. Prog. Symp. Ser. 1949, 45, 39–48. [Google Scholar]

- Yunho, H.; Reinhard, R. Performance Measurement of CO2 Heat Exchangers. ASHRAE Trans. 2005, 111, 306–316. [Google Scholar]

- Boewe, D.; Bullard, C.; Yin, J.; Hrnjak, P. Contribution of internal heat exchanger to transcritical R744 cycle performance. ASHRAE Trans. 2001, 2, 189–198. [Google Scholar]

- Mohammadi, S.M.H. Theoretical investigation on performance improvement of a low-temperature transcritical carbon dioxide compression refrigeration system by means of an absorption chiller after-cooler. Appl. Therm. Eng. 2018, 138, 264–279. [Google Scholar] [CrossRef]

- Farsi, A.; Mohammadi, S.M.H.; Ameri, M. An efficient combination of transcritical CO2 refrigeration and multi-effect desalination: Energy and economic analysis. Energy Convers. Manag. 2016, 127, 561–575. [Google Scholar] [CrossRef]

- Yuan, Y.; Xianlong, W.; Yongjun, T. Performance investigation on double- lift LiBr absorption refrigerator in variable conditions. Cryogenics 2013, 193, 21–26. [Google Scholar]

- Zhang, F.Z.; Jiang, P.X.; Lin, Y.S.; Zhang, Y.W. Efficiencies of subcritical and transcritical CO2 inverse cycles with and without an internal heat exchanger. Appl. Therm. Eng. 2011, 31, 432–438. [Google Scholar] [CrossRef]

- Janković, Z.; Atienza, J.S.; Suárez, J.A.M. Thermodynamic and heat transfer analyses for R1234yf and R1234ze(E) as drop-in replacements for R134a in a small power refrigerating system. Appl. Therm. Eng. 2015, 80, 42–54. [Google Scholar] [CrossRef]

- Bolaji, B.O. Experimental study of R152a and R32 to replace R134a in a domestic refrigerator. Energy 2010, 35, 3793–3798. [Google Scholar] [CrossRef]

- Mendoza-Miranda, J.M.; Mota-Babiloni, A.; Ramírez-Minguela, J.J.; Muñoz-Carpio, V.D.; Carrera-Rodríguez, M.; Navarro-Esbrí, J.; Salazar-Hernández, C. Comparative evaluation of R1234yf, R1234ze(E) and R450A as alternatives to R134a in a variable speed reciprocating compressor. Energy 2016, 114, 753–766. [Google Scholar] [CrossRef]

- Llopis, R.; Sánchez, D.; Cabello, R.; Catalán-Gil, J.; Nebot-Andrés, L. Experimental analysis of R-450A and R-513A as replacements of R-134a and R-507A in a medium temperature commercial refrigeration system. Int. J. Refrig. 2017, 84, 52–66. [Google Scholar] [CrossRef]

| Characteristic | R744 | R744a | R134a | R32 | R1234yf | R1234ze(E) | R513a | R450a |

|---|---|---|---|---|---|---|---|---|

| ODP | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| GWP | 1 | 240 | 1300 | 675 | <1 | 4 | 572 | 547 |

| Critical temperature/°C | 31.0 | 36.4 | 101.1 | 78.4 | 94.7 | 109.4 | 94.9 | 104.5 |

| Critical pressure/MPa | 7.4 | 7.3 | 4.1 | 5.8 | 3.4 | 3.6 | 3.7 | 3.8 |

| Boiling point/°C | −78.5 | −88.5 | −26.1 | −51.6 | −29.5 | −19.0 | −29.8 | −23.4 |

| Standard safety classification | A1 | / | A1 | A2 | A2L | A2L | A1 | A1 |

| Parameter | Value | Unit |

|---|---|---|

| Inlet temperature of CO2 in G1 | 80 | °C |

| Inlet temperature of cooling water for condenser and absorber | 32 | °C |

| Inlet temperature of air | 32 | °C |

| Outlet temperature of chilled water | 9 | °C |

| Temperature at subcooler | 18 | °C |

| Condensing temperature | 35 | °C |

| Absorption temperature | 35 | °C |

| Evaporating temperature | 7 | °C |

| Discharged pressure | 9.7 | MPa |

| Component | Parameters |

|---|---|

| The CO2 subsystem | |

| COMP | the special piston compressor for CO2, Vth = 2.7 m3/h, rated input power: 3 kW, rated speed: 1450 rpm |

| GC | Fin-tube heat exchanger, diameter: 7 × 0.35 mm, fin thickness: 0.15 mm, fin pitch: 2 mm, tube spacing: 21 mm |

| IHX | Double tube heat exchanger, diameter: 6 × 0.5 mm, 10 × 1 mm |

| CS | Tube heat exchanger, diameter: 8 × 1 mm |

| The absorption subsystem | |

| G1 | Immersive serpentine coil heat exchanger, diameter: 8 × 1 mm |

| G2 | Immersive serpentine coil heat exchanger, diameter: 6 × 0.5 mm |

| E | Shell and tube heat exchanger, diameter: 8 × 1 mm |

| C | Shell and tube heat exchanger, diameter: 8 × 1 mm |

| AB1 | Shell and tube heat exchanger, diameter: 6 × 0.5 mm |

| AB2 | Shell and tube heat exchanger, diameter: 10 × 1 mm |

| SHX1 | Double tube heat exchanger, diameter: 8 × 1 mm |

| SHX2 | Double tube heat exchanger, diameter: 6 × 0.5 mm |

| CO2 | R134a | R32 | R450a | R513a | R1234yf | R1324ze(E) | |

|---|---|---|---|---|---|---|---|

| COP | 2.75 [40] | 6.00 [41] | 5.70 [42] | 5.64 [43] | 5.83 [44] | 5.22 [43] | 5.34 [43] |

| L (yr) | 15 | 15 | 15 | 15 | 15 | 15 | 15 |

| ALR (%) | 5 | 5 | 5 | 5 | 5 | 5 | 5 |

| EOL (%) | 15 | 15 | 15 | 15 | 15 | 15 | 15 |

| Adp. GWP (kg CO2e/kg) | 0 | 1.6 | / | / | / | 3.3 | / |

| EM (kg CO2e/kWh) | 0.973 | ||||||

| RFM (kg CO2e/kg) | 0 | 5 | 7.2 | 10 | 10 | 13.7 | 14 |

| Direct emission (kg CO2e/kW) | 2 | 1087 | 595 | 486 | 492 | 1 | 4 |

| Indirect emission (kg CO2e/kW) | 5786 | 2689 | 2832 | 2866 | 2774 | 3099 | 3024 |

| New CTTA System | COP Improvement (%) | LCCP Value (kg CO2e/kW) | Improvement, Compared to Traditional Refrigerant Systems (%) | ||||

|---|---|---|---|---|---|---|---|

| Potential Case | R134a | R32 | R1234yf | R1234ze(E) | |||

| 1 | Discharge pressure optimization [15] | 8.8 | 3473 | 8.0 | −1.7 | −12.0 | −14.7 |

| 2 | Refrigerant discharge optimization [14] | 10.1 | 3433 | 9.1 | −0.5 | −10.8 | −13.4 |

| 3 | Ejector expansion cycle [16] | 20.0 | 3160 | 16.3 | 7.4 | −1.9 | −4.4 |

| 4 | Ejector-csscade cycle [17] | 30.0 | 2926 | 22.5 | 14.3 | 5.6 | −3.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, Y.; Zheng, Y.; Zhao, J.; Chen, Q.; Zhang, L. Study of a Novel Hybrid Refrigeration System, with Natural Refrigerants and Ultra-Low Carbon Emissions, for Air Conditioning. Energies 2024, 17, 880. https://doi.org/10.3390/en17040880

He Y, Zheng Y, Zhao J, Chen Q, Zhang L. Study of a Novel Hybrid Refrigeration System, with Natural Refrigerants and Ultra-Low Carbon Emissions, for Air Conditioning. Energies. 2024; 17(4):880. https://doi.org/10.3390/en17040880

Chicago/Turabian StyleHe, Yijian, Yufu Zheng, Jianguang Zhao, Qifei Chen, and Lunyuan Zhang. 2024. "Study of a Novel Hybrid Refrigeration System, with Natural Refrigerants and Ultra-Low Carbon Emissions, for Air Conditioning" Energies 17, no. 4: 880. https://doi.org/10.3390/en17040880

APA StyleHe, Y., Zheng, Y., Zhao, J., Chen, Q., & Zhang, L. (2024). Study of a Novel Hybrid Refrigeration System, with Natural Refrigerants and Ultra-Low Carbon Emissions, for Air Conditioning. Energies, 17(4), 880. https://doi.org/10.3390/en17040880