3.1. Overview of the Proposed System

This study integrates different technologies, with the aim to create a hydrogen, heat, and power combined production chain in the Aragónese province of Huesca in Spain, via a series of interdependent plants.

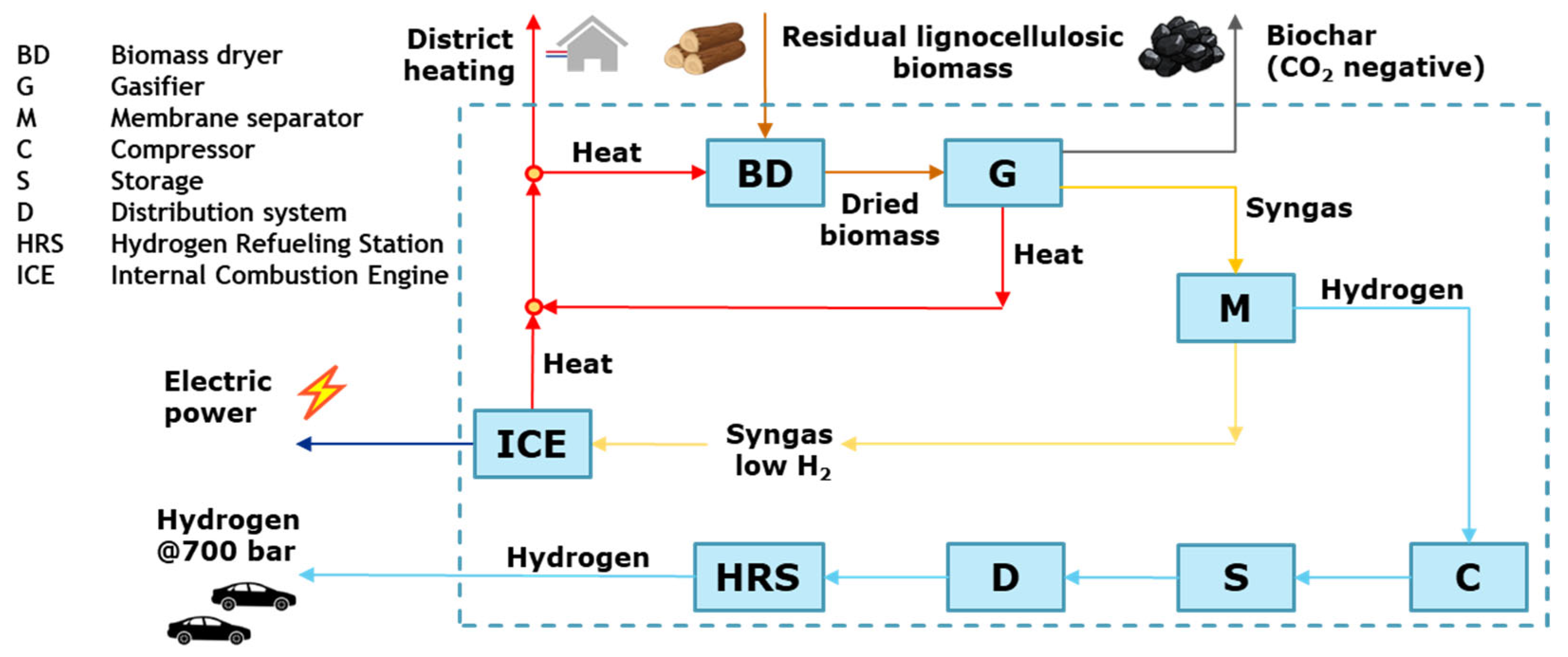

The modular basic plant is described in

Figure 2.

The feedstock used is lignocellulosic biomass from annual pruning of local crops in Aragón. This biomass is gasified in a series of downdraft commercial reactors, that allow carbon capture by producing biochar. The hydrogen contained in the syngas is extracted using Pd-based membranes and made available to a network of local hydrogen refueling stations.

The low-hydrogen-content residual syngas (retentate) is used in an ICE for the production of electricity which supplies a REC, contributing to the economic sustainability of the initiative, thanks to the Spanish shared energy valorization mechanism.

The waste heat from the process is valorized for heating some members of the REC and, in periods of the year with low residential heat requests, to dry biomass for consequent gasification. A series of HRSs in the province of Huesca, served by a stationary and mobile hydrogen storage system, allows us to create a network in the province and enable hydrogen mobility.

A REC, as a legal entity, manages the whole system, selling electricity exclusively to its members, and heat and hydrogen to its members or, anyhow, to someone in the territory where it is established.

Renewable electric power feeding the REC allows, in the simplified framework for Spanish regulation, a direct discount on the electric bill of REC’s members. The monthly savings on electric bills are supposed to fully devolve from members to the REC entity, to sustain hydrogen production for local transportation, using lignocellulosic biomass from local pruning in Aragón farming. As direct consequences of the REC implementation, local jobs will be generated; pruning, which is commonly a waste material, will be greatly valorized; and local pollution will be reduced by promoting the diffusion of zero-emission hydrogen vehicles and sustainable local district heating.

All these activities are in line with the REC general purposes: REC members under these hypotheses do not obtain any economic advantage.

3.2. Characterization of the Subsystems

Starting from the dried volume syngas composition of

Table 2, a deeper characterization of the gasifier and ICE is defined. It is considered, in the pruning, to be a content of carbon by weight of 50% and of hydrogen of 6% [

88]. The water content in the biomass after drying is set at 12%. Moreover, considering biochar production according to RESET specifications and an electrical efficiency of 95% for the MAN generator [

61], the engine efficiency is defined using the composition of syngas from a gasifier. The inferred value is 29.02%. It is aligned with the statement of Gobbato et al. [

61] considering the derating of efficiency in comparison with methane of a similar engine fed with syngas similar to this study.

With this assumption, the wet weight composition of syngas is also inferred, as described in

Table 5.

This composition is used to define specific heats of syngas to characterize the first heat exchangers and, without water, the compressor behavior (

Table 6). In fact, a complete drying of the syngas is foreseen after the first heat exchangers.

Atlas Copco HX&HN-15 is a double intercooled stage piston compressor. It is chosen for its compatibility with the syngas and for its oil-free functioning behavior. Moreover, it operates in the range of pressure and mass flow compliant with the size of the system. The technical datasheet is not sufficiently detailed for the simulation. According with general data from Atlas website [

53], isentropic adiabatic efficiency is inferred equal to 85.9% for each of the two stages of the compressor, using a well-known adiabatic isentropic mathematical model for the compressor.

A ratio between the heat power removed in the interstage refrigeration and the electrical power of the motor is also inferred equal to 0.6 to characterize the system energetic simulation. The electro-mechanical efficiency of the compressor is set equal to 85% according to Di Marcoberardino et al. [

40].

In the proposed scheme, the syngas is produced using an atmospheric downdraft gasifier, with a temperature at the exit of the gasifier of 600 °C, as declared by RESET. It is cooled down using a regenerative heat exchanger and a water–syngas heat exchanger. This cooling allows us to minimize the energy consumption of the syngas compression phase, required to bring the pressure from a value close to the atmosphere up to the value for hydrogen separation via Pd-based membranes.

The membranes can work at different pressure values [

40]. The value is chosen to optimize energy recovery via the downstream retentate expansion in the turbine.

Hydrogen permeation through Pd-based membranes is evaluated using Equation (3), considering a syngas temperature (T) of 500 °C, a retentate-side pressure ( of 14.58 bar, and a permeate-side pressure () of 0.2 bar.

Using these values in modelling evaluations, a membrane area of 5.16 m

2 is required to separate 50% of the hydrogen from the syngas: this percentage of removal is well explained and motivated as a consequence of engine constraints in the following

Section 3.3. Given the production cost of 5700 EUR/m

2, as reported in

Table 4, the cost of the membranes is estimated to be EUR 29,469. Since the amount of hydrogen separated is 89.8 kg/day, the specific cost of the membranes per unit of kg

H2 per day results in 328 EUR/(kg

H2/day).

Hydrogen is extracted using membranes that are connected to a vacuum pump (around 0.1 bar [

40]), and with other two stages it is compressed up to 200 bar. For the purpose of this study, it is important to define the total power of the extraction and compression system, based on the hydrogen mass flow rate. Spazzafumo and Raimondi [

75] stated that a rate of 0.376 (kg/h)/kW can be assumed as a ratio between the hydrogen flow rate and power for a small hydrogen compressor.

The hydrogen distribution system for automotive uses defined in this study concerns many hydrogen refueling stations in a large territorial area: the entire province of Huesca in the Aragón region. In this scenario, it is hypothesized to build not just a single gasification plant with an attached hydrogen refueling station but a series of plants like that described in

Figure 2 to create a mobility network throughout the province. The number of these plants is a result of the optimization of the storage and hydrogen logistic costs, as described below. To consider passenger cars as the intended use for the hydrogen represents the worst economic case respective to heavy duty vehicle utilization: the common level of hydrogen compression required for a passenger car (700 bar) entails a higher cost of installation than for a heavy duty vehicle (commonly 350 bar).

The major cities of the province of Huesca are taken into consideration as places for at least one plant and in particular those cities which represent a cumulative population of at least 50% of the inhabitants of the province.

Table 7 shows the biggest cities of the province with the number and percentage of inhabitant compared to the entire population of the province (224,264 inhabitants).

Considering that the gasification system is able to work for 7200 h a year [

36] and that it requires four maintenance stops during the year, around two weeks of break every three months are inferred as required for each plant. HRSs obviously also have to allow the refill of hydrogen vehicles when the own gasifier is shut down for maintenance. Each HRS dispenses hydrogen 261 day/year: Saturdays and Sundays are not considered as working days. Hydrogen storage is needed to manage the maintenance period. Limiting the storage is a way to decrease the capital cost: storage is always the most impactful cost in a hydrogen supply chain [

74]. A territorial network of gasification plants and HRSs is a way to minimize the capital cost of storage: hydrogen to feed each HRS when its own gasifier is off can be transported via a tube trailer from other running gasifiers as long as there are enough active ones to supply both its own refueling station and another one. Using this approach, it is not necessary to have a stationary storage in each HRS to manage the two weeks of maintenance of the gasifier; only a smaller one is needed to manage the peak hydrogen request on a working day (

wd) of a HRS in a year, from Monday to Friday (

days a year), compared to a continuous 24 h/7 days hydrogen production during the week (

days a year). For these reasons, each refueling station has both stationary and mobile hydrogen storage.

3.3. Constrains and Optimization for Sizing

The described case study includes regulatory and technical constrains and a range of values for technical parameters in which to find the optimal solution with a size of the territorial system that minimize the LCOH. The LCOH is defined from field to tank, which means that it includes all the activities from harvesting of biomass in the field to refueling of a hydrogen vehicle at 700 bar.

Figure 3 shows a flowchart summarizing the procedure for sizing and optimizing the system.

As mentioned, the Spanish regulation for a REC allows a simplified payment rule for a renewable power plant with a total energy output at most equal to 100 kW: a direct reduction in the bill due to contemporary produced and consumed energy in the REC and an economic compensation for energy exported and imported in the same month.

In the proposed plant, there are two systems that produce electricity: an ICE burning retentate and a turbine that expands retentate to partially recover compression energy. Their power output is indicated, respectively, as

and

. The consumption of electricity for syngas compressor

and for vacuum pump and hydrogen compressors

to store hydrogen at 200 bar defines the total electric output. All these facilities work simultaneously when the gasifier is running, without any variation in the load. The electricity requirements to boost hydrogen pressure at 900 bar for the fast refueling phase are not considered as a continuous need, due to intermittency of that operation. A constrain in the optimal sizing of the basic plant is that the sum of all powers previously considered is equal to 100 kW.

Based on Spazzafumo and Raimondi [

75], the minimal dimension of the REC is defined to assure that electricity produced in the REC

of 100 kW net power output is completely valorized, or as simultaneously consumption

(that is shared hourly inside the REC) or as economical balancing in each month of the year as exported

and imported

. In both cases there is a saving on the member’s bill. Both conditions can be summarized as follows:

considering values for

and

as in Equation (2).

This condition maximizes the saving on the bill of REC members, due to electric production in the REC. The size (number of members) of the REC is the unique independent variable: the shape of hourly consumption of the REC is based on lifestyle and seasons, and it is not easily changeable, and the power output is a constant technical constrain both when the gasifier is running and when it is in maintenance (equal to zero). Based on this consideration and on the assumptions described in

Section 2.8, the minimal and optimal size is a REC composed of 777 persons grouped into 370 electric domestic passive users. These users have to be at a maximum distance of 500 m from the generation plant to be considered in a single REC, according to the Spanish regulatory framework. Only a configuration inside a city can assure that condition: the Spanish countryside appears too sparsely populated. The monthly distribution of electricity of a modular basic plant in the REC is shown in

Figure 4.

March, June, September, and December are the months with two weeks of shut off maintenance for the gasifier.

To optimize the harvesting of energy from retentate a turbine is considered in the study. Its efficiency depends on the inlet pressure [

55] that depends on the pressure needed by the membranes and generated by syngas compressor. Given the order of magnitude of flow rates of this study, considering an oil-free compression, the piston Atlas compressor is the best solution, so its outlet pressure defines the solution for the membrane and turbine performances and, consequently, turbine efficiency. The compressor ratio of the chosen Atlas compressor is 15 and, considering pressure drops, the pressure at the membrane is 14.58 bar and at the turbine is 14.3 bar. The temperature of the system is set by two constrains: the exit temperature from the gasifier (600 °C) and the maximum temperature endured by Pd-membranes (500 °C) to allow an acceptable long-life operation. The membrane lifetime chosen in this work is 10 years, since membranes are inside an empty tube and, thus, the conditions are not as extreme as in the fluidized bed. As reported in

Section 2.4, the fluidized bed membrane’s lifetime can be evaluated to be approximately 9 years. The value of 10 is chosen to be more conservative compared to the value of 15 years estimated for membranes in an empty tube from the literature. With the lifetime of 10 years, only one membrane replacement occurs in the expected 20-year operating period.

These constraints on pressure and temperature in the system define the energy consumption for syngas treatment to allow the membranes to work and also the capability of energy recovery of the syngas turbine: using the chosen solutions for gasification, compression, and Pd-membranes separation, there is no room for optimization via varying thermodynamic parameters.

The hydrogen removal percentage from syngas is a parameter to optimize: the higher the hydrogen removal rate, the greater the efficiency of the system. In the hypothesized scheme, the retentate powers an Internal Combustion Engine originally fed by natural gas. By depleting the syngas of the hydrogen removed from the membranes, the calorific value of retentate decreases: an excessive decrease in this value leads to engine malfunction. Two limits are defined: a retentate LHV at least equal to 3.8 MJ/Nm

3 [

59,

60] and an ICE derating power output in comparison to methane fed at most equal to 70% [

61]. Their variation based on different hydrogen removal percentages in a syngas dried stream are plotted in

Figure 5. Considering that the limit on the LHV is never reached for all percentage of hydrogen removal from 0% to 100%, 50% of hydrogen removal is the highest operable value, beyond which deration of the engine power does not allow reliable operation. This constrain means that the highest percentage of hydrogen removal is 50%.

With 50% of hydrogen removal, the weight composition of dry retentate is shown in

Table 8 and its specific heats and gas constant are indicated in the last row of

Table 3. The retentate LHV is equal to 4.45 MJ/Nm

3.

Previous constrains allow us to define the size of the single gasifier and coupled HRS: the proposed RESET gasification system PowerSkid 200+ is able to produce 520.3 Nm

3/h (585.5 kg/h) of dried syngas with a composition as described in

Table 6. It consumes 237 kg/h of pruning dried to a moisture composition of 10–15% (12% assumed) and compressed into briquettes. The system produces 16.6 kg/h of biochar. Pd-membranes extract a flow rate

equal to 89.9 kg/day of hydrogen (3.74 kg/h) over the 7200 h of annual activity. The optimal size of different machines is summarized in

Table 9 below.

The total electricity produced is 720 MWh/year with a shared electricity amount of 623.1 MWh/year. Exported electricity (out of REC) is 96.9 MWh/year and imported electricity 326.7 MWh/year: all exported electricity is compensated economically by value against the imported one. Total economic revenues from electricity are equal to 92,600 EUR/year considering that all savings from REC members are devolved to the REC. A different policy could be actuated, but, in the hypothesis of this study, all revenues are used to facilitate the hydrogen local supply and use chain for mobility.

The total thermal energy harvested from the ICE, compressor, and syngas treatment is equal to 3197 MWh/year (at least at 90 °C): with a 3350 h/year Spanish annual heating period, the heat used in the heating district is 1005 MWh/year (31% of harvested energy). That energy avails 99 flats of around 70 m2 each, producing an economical revenue of 91,000 EUR/year.

The single system consumes 1706 ton of pruning annually with a total annual cost of 143,600 EUR/year.

Storage of hydrogen is a key factor to allow continuous refueling of vehicles during maintenance stops of gasifiers: minimizing hydrogen storages via optimization of the time management of maintenance stops of gasifier is a key factor to decrease the capital cost of the territorial system proposed. For this purpose, considerations of hydrogen daily flow rates are needed in the running or maintenance mode of the gasifier and in the working or not working condition of the HRSs over the week (it is supposed that in the weekend HRSs are closed). A Pd-membrane hydrogen flow rate of 89.9 kg/day over the 7200 running hours produces a total mass of hydrogen per year of 26.97 ton/year in each gasifier.

The hydrogen flow rate dispensed in the HRS during weekdays

is bigger than the flow rate extracted from the membrane

, due to only five working days a week of the HRS. The hydrogen daily flow rate dispensed by a HRS during weekdays is as follows:

where

is the annual working day of the refueling station and

is the total mass of hydrogen produced per year by the membranes of a single plant.

From a balancing of mass in a week with gasifier running,

where

is the daily flow rate of hydrogen to be stored for the maintenance period, compared to

that is the hydrogen daily flow rate extracted using the membrane. Consequently, the daily flow rate of hydrogen to be stored for the maintenance period

can be inferred:

When the gasifier is shut down and the HRSs have to dispense hydrogen in daily refueling

, an amount of hydrogen has to be supplied by the running gasifiers, and the minimal number of required gasifiers

is

Consequently, a group of seven gasifiers (

) constitutes the optimal territorial system of a provincial hydrogen supply chain. As a result, each gasifier is equipped with a stationary storage

to manage the weekly operation and a mobile storage

to manage the maintenance of the gasifiers:

where

is the annual working day of the gasifier.

Considering the typical minimum inlet pressure for a booster hydrogen compressor [

89] and, consequently, a usage rate of the hydrogen stored in a cylinder of 200 bar of around 88%, each basic plant has to be equipped with a hydrogen storage of 140 kg for a stationary one and of 180 kg for a mobile one (results of ratio from results indicated in Equation (11) and 88% of the usage rate). One more mobile storage is necessary for managing logistics among the seven HRSs.

Considering the use of vehicles as stated, each HRS can serve 163 hydrogen passenger cars, consequently a total of 1141 hydrogen cars in the whole province.

A territorial system is summarized as in

Table 10 to have a uniform ratio over the cities between the number of RECs and total population of the cities, as well as for the number of hydrogen vehicle per 1000 inhabitants.

The total annual hydrogen production is 189 ton/year, consuming 11,900 ton/year of pruning; that is only around 4.5% of pruning annual production from the three most abundant cultivars in the region of Aragón.

3.5. Sensitivity and Further Development

The most prominent cost is the gasifier and ICE cost, which represents the highest part in the overall CAPEX for the whole plant. It is also affected by high variation, as stated in Figure 8.3 of the IRENA report [

77], in Europe in the range of 0–5 MW. A minimum value of 2800 EUR/kW can be considered the best realistic scenario.

Field pruning harvesting costs can be decreased: in normal cultivation operations, pruning on the ground must be treated using a passage of a mechanical means, which generates a cost for the farmer equivalent to the harvesting cost assumed in the scenario of this study (first row of

Table 1). Consequently, that value is a fixed operational cost for the farmer, which cannot be attributed to the valorization of the biomass like that described in the study. In view of this consideration, a lignocellulosic biomass harvesting and transformation cost of 44.1 EUR/ton can be inferred.

Considering only these two variations in economical parameters, a LCOH of 3.90 EUR/kg is obtained, with a minimum cost of hydrogen at the HRS (VAT included) of 4.72 EUR/kg, which is largely competitive with diesel. A total investment cost of EUR 11.02 million is required in this case.

Another margin for improvement lies in the valorization of harvested process heat. In fact, only around 30% of that heat is valorized in district heating: if the gasifier is installed near a SME operating with heating requests all year (i.e., laundry or dairy), this percentage could easily be raised to benefit the initiative.

Biochar valorization is not contemplated in this study: future studies could consider it as a revenue stream. Biochar valorization is a controversial matter due to its potential content of polycyclic aromatic hydrocarbons (PAHs). PAHs could be a risk for human health as well as the environment when biochar is used as soil amendment [

100], which is one of the most common valorization chains in an agricultural context. An industrial market opportunity for biochar could be reached, but a more detailed chemical analysis is necessary, which is out of the scope of this work.

All aspects that lead to a LCOH lower than the cost of diesel create the opportunity for a revenue for members of the REC, increasing the social acceptability of the initiative.