A Layered Parallel Equaliser Based on Flyback Transformer Multiplexed for Lithium-Ion Battery System

Abstract

1. Introduction

- (1)

- The equaliser uses a layered equalisation mode to double the input voltage and improve equalisation efficiency. Additionally, the use of complementary PWM control with a dead band reduces switching loss, further improving equalisation efficiency.

- (2)

- The parallel equalisation mode is utilised to enable simultaneous charging or discharging of multiple batteries or battery units, resulting in a significant improvement in equalisation speed.

- (3)

- The equaliser employs flyback transformers as multiplexed energy storage elements, reducing both cost and size. The primary winding of the flyback transformer acts as an inductor in the first-layer equalisation, facilitating energy transfer between the two batteries. In the second-layer equalisation, the flyback transformer functions as an energy storage element, facilitating energy transfer between battery units through an energy transfer unit.

- (4)

- The equaliser has a modular design, allowing for the simple addition of equalisation modules as the number of batteries connected in series increases while maintaining the parameters within the equalisation module.

2. Proposed Equaliser

2.1. Structure of the Proposed Equaliser

2.2. Operating Principle of the Proposed Equaliser

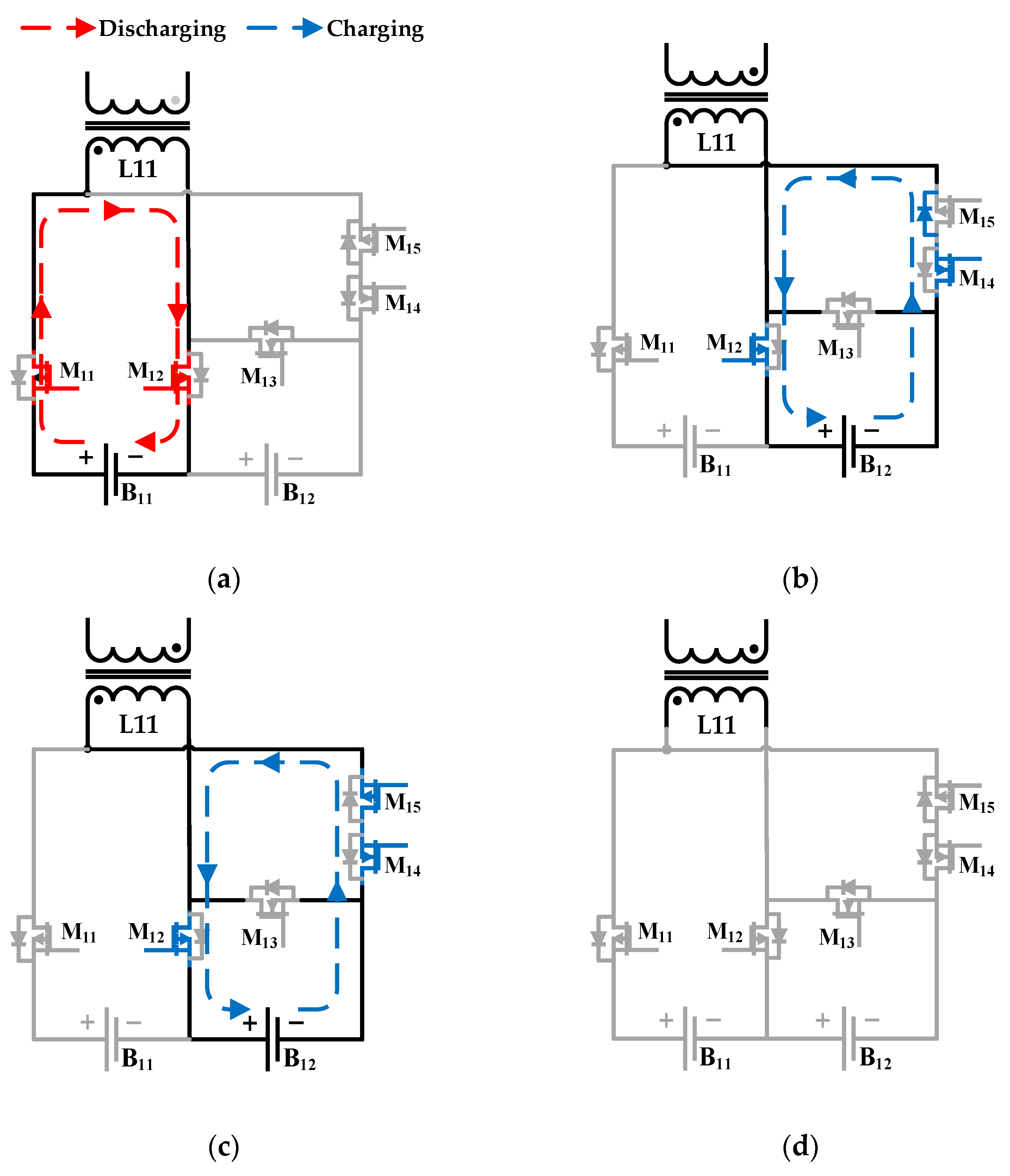

2.2.1. Operating Principle of the First-Layer Equalisation

2.2.2. Operating Principle of the Second-Layer Equalisation

3. Equalisation Strategy Design

4. Equalisation Experiment

4.1. Experimental Platform and Parameters

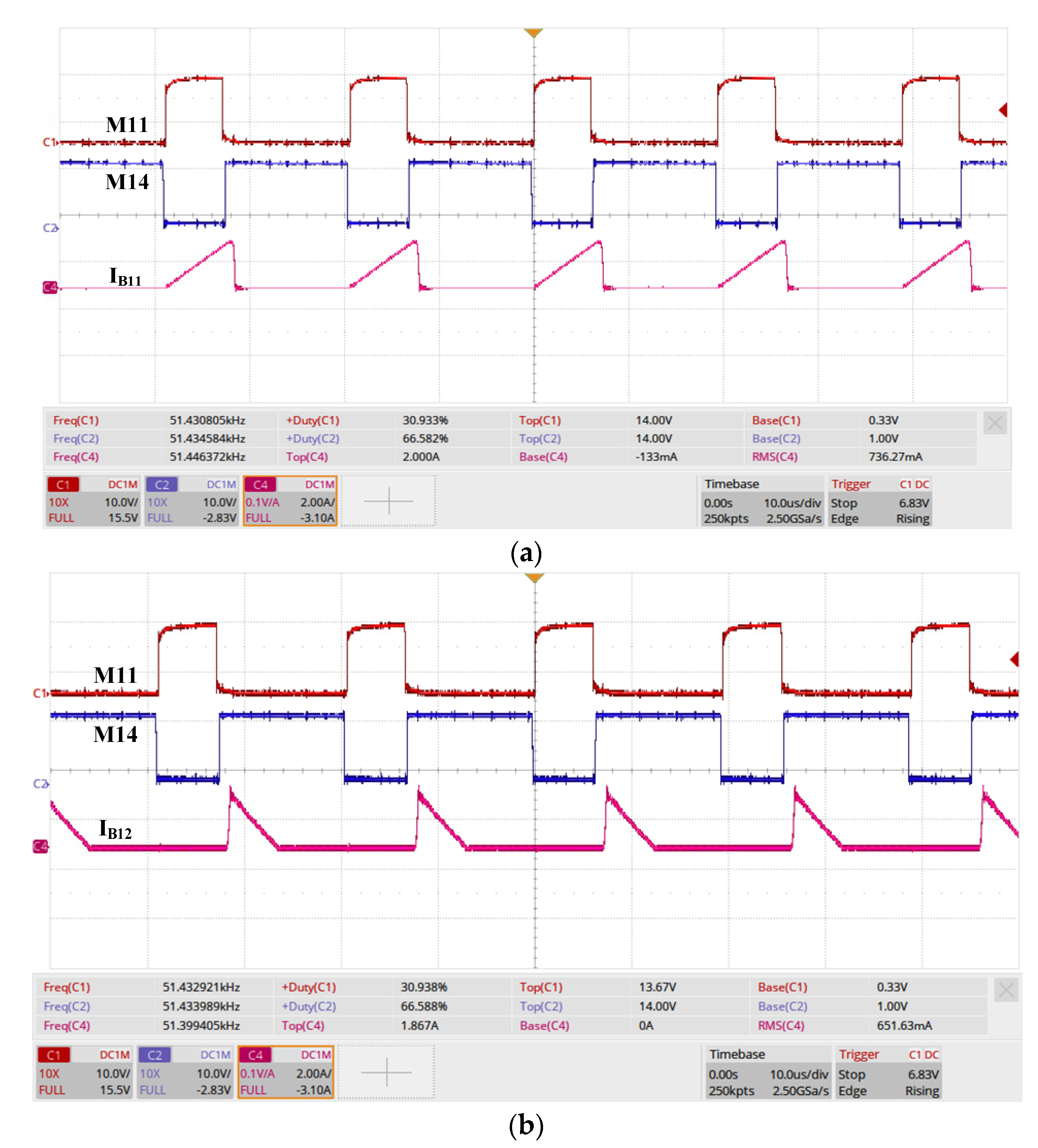

4.2. The First-Layer Equalisation Experiment

4.3. The Second-Layer Equalisation Experiment

4.4. Equalisation experiment results

5. Analysis of Experimental Results

5.1. Calculation of Equalisation Efficiency

5.1.1. Equalisation Efficiency of the First-Layer Equalisation

5.1.2. Equalisation Efficiency of the Second-Layer Equalisation

5.2. Comparison with Other Methods

6. Discussion

7. Conclusions

- High equalisation efficiency. The equaliser adopts a layered equalisation strategy. The first-layer equalisation targets a single battery and utilises a Buck-Boost circuit and complementary PWM driving method to prevent energy reflux. This approach results in low equalisation loss and high efficiency. The second-layer equalisation focuses on the battery unit and doubles the voltage to improve equalisation efficiency. This is achieved through a multi-winding transformer equalisation circuit. The first and second layer equalisation experiments resulted in an efficiency of 98.8% and 94.3%, respectively.

- Fast equalisation speed. The multi-objective parallel equalisation method is utilised by the equaliser. The first-layer equalisation ensures that equalisation within each battery cell does not interfere with each other. The more parallel equalisation targets there are, the faster the entire battery system can be equalised. The second-layer equalisation module uses flyback transformers to parallel discharge or charge multiple battery units. It also enables simultaneous charging and discharging of multiple units, significantly increasing the speed of equalisation.

- Strong modularity. With an increase in the number of series-connected batteries, the hardware parameters of the equaliser remain unchanged. It is only necessary to adjust the number of corresponding equalisation modules according to needs, which greatly improves the equaliser’s scalability. The equaliser is suitable for a large-scale lithium-ion battery energy storage system.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Deng, J.; Bae, C.; Marcicki, J.; Masias, A.; Miller, T. Safety modelling and testing of lithium-ion batteries in electrified vehicles. Nat. Energy 2018, 3, 261–266. [Google Scholar] [CrossRef]

- Hannan, M.A.; Lipu, M.S.H.; Hussain, A.; Mohamed, A. A review of lithium-ion battery state of charge estimation and management system in electric vehicle applications: Challenges and recommendations (Review). Renew. Sustain. Energy Rev. 2017, 78, 834–854. [Google Scholar] [CrossRef]

- Zhao, Z.Y.; Hu, H.T.; He, Z.Y.; Iu, H.H.C.; Davari, P.; Blaabjerg, F. Power Electronics-Based Safety Enhancement Technologies for Lithium-Ion Batteries: An Overview from Battery Management Perspective. IEEE Trans. Power Electron. 2023, 38, 8922–8955. [Google Scholar] [CrossRef]

- Ghaeminezhad, N.; Ouyang, Q.; Hu, X.S.; Xu, G.T.; Wang, Z.S. Active Cell Equalization Topologies Analysis for Battery Systems: A Systematic Review. IEEE Trans. Power Electron. 2021, 36, 9119–9135. [Google Scholar] [CrossRef]

- Izadi, Y.; Beiranvand, R. A Comprehensive Review of Battery and Supercapacitor Cells Voltage-Equalizer Circuits. IEEE Trans. Power Electron. 2023, 38, 15671–15692. [Google Scholar] [CrossRef]

- Shang, Y.L.; Zhu, C.; Fu, Y.H.; Mi, C.C. An Integrated Heater Equalizer for Lithium-Ion Batteries of Electric Vehicles. IEEE Trans. Ind. Electron. 2019, 66, 4398–4405. [Google Scholar] [CrossRef]

- Ye, Y.M.; Cheng, K.W.E.; Fong, Y.C.; Xue, X.D.; Lin, J.J. Topology, Modeling, and Design of Switched-Capacitor-Based Cell Balancing Systems and Their Balancing Exploration. IEEE Trans. Power Electron. 2017, 32, 4444–4454. [Google Scholar] [CrossRef]

- Lee, S.; Noh, G.; Ha, J.I. Reconfigurable Power Circuits to Series or Parallel for Energy-Balanced Multicell Battery Pack. IEEE Trans. Ind. Electron. 2023, 70, 3641–3651. [Google Scholar] [CrossRef]

- Shang, Y.L.; Cui, N.X.; Duan, B.; Zhang, C.H. Analysis and Optimization of Star-Structured Switched-Capacitor Equalizers for Series-Connected Battery Strings. IEEE Trans. Power Electron. 2018, 33, 9631–9646. [Google Scholar] [CrossRef]

- Wang, S.; Yang, S.; Yang, W.; Wang, Y. A New Kind of Balancing Circuit with Multiple Equalization Modes for Serially Connected Battery Pack. IEEE Trans. Ind. Electron. 2021, 68, 2142–2150. [Google Scholar] [CrossRef]

- Ding, X.F.; Zhang, D.H.; Cheng, J.W.; Wang, B.B.; Chai, Y.M.; Zhao, Z.H.; Xiong, R.; Luk, P.C.K. A Novel Active Equalization Topology for Series-Connected Lithium-ion Battery Systems. IEEE Trans. Ind. Appl. 2020, 56, 6892–6903. [Google Scholar] [CrossRef]

- Manjunath, K.; Kalpana, R.; Singh, B.; Kiran, R. A Two-Stage Module Based Cell-to-Cell Active Balancing Circuit for Series Connected Lithium-Ion Battery Packs. IEEE Trans. Energy Convers. 2023, 38, 2282–2297. [Google Scholar] [CrossRef]

- Wang, L.J.; Ke, J.Y.; Zhan, M.; Tian, A.N.; Jiang, J.C. Efficient and Fast Active Equalization Method for Retired Battery Pack Using Wide Voltage Range Bidirectional Converter and DBSCAN Clustering Algorithm. IEEE Trans. Power Electron. 2022, 37, 13824–13833. [Google Scholar]

- Peng, F.; Wang, H.; Yu, L. Analysis and Design Considerations of Efficiency Enhanced Hierarchical Battery Equalizer Based on Bipolar CCM Buck–Boost Units. IEEE Trans. Ind. Appl. 2019, 55, 4053–4063. [Google Scholar] [CrossRef]

- Liu, L.; Mai, R.; Xu, B.; Sun, W.; Zhou, W.; He, Z. Design of Parallel Resonant Switched-Capacitor Equalizer for Series-Connected Battery Strings. IEEE Trans. Power Electron. 2021, 36, 9160–9169. [Google Scholar] [CrossRef]

- Liu, F.; Zou, R.; Liu, Y. An Any-Cell-to-Any-Cell Battery Equalizer Based on Half-Bridge LC Converter. IEEE Trans. Power Electron. 2023, 38, 4218–4223. [Google Scholar] [CrossRef]

- Wei, Z.; Wang, H.; Lu, Y.; Shu, D.; Ning, G.; Fu, M. Bidirectional Constant Current String-to-Cell Battery Equalizer Based on L2C3 Resonant Topology. IEEE Trans. Power Electron. 2022, 38, 666–677. [Google Scholar] [CrossRef]

- Noh, G.; Lee, J.; Ha, J.-I. Design and Analysis of Single-Inductor Power Converter for Both Battery Balancing and Voltage Regulation. IEEE Trans. Ind. Electron. 2022, 69, 2874–2884. [Google Scholar] [CrossRef]

- Reema, N.; Jagadanand, G.; Sasidharan, N.; Shreelakshmi, M.P. An Enhanced Coupled Inductor Based Voltage Equalizer for Matrix Connected Ultracapacitor Bank. IEEE Trans. Transp. Electrif. 2023, 9, 3328–3337. [Google Scholar] [CrossRef]

- Shang, Y.; Cui, N.; Duan, B.; Zhang, C. A Global Modular Equalizer Based on Forward Conversion for Series-Connected Battery Strings. IEEE J. Emerg. Sel. Top. Power Electron. 2018, 6, 1456–1469. [Google Scholar] [CrossRef]

- Guo, X.; Geng, J.; Liu, Z.; Xu, X.; Cao, W. A Flyback Converter-Based Hybrid Balancing Method for Series-Connected Battery System in Electric Vehicles. IEEE Trans. Veh. Technol. 2021, 70, 6626–6635. [Google Scholar] [CrossRef]

- Lee, K.M.; Lee, S.W.; Choi, Y.G.; Kang, B. Active Balancing of Li-Ion Battery Cells Using Transformer as Energy Carrier. IEEE Trans. Ind. Electron. 2017, 64, 1251–1257. [Google Scholar] [CrossRef]

- Shang, Y.; Xia, B.; Zhang, C.; Cui, N.; Yang, J.; Mi, C.C. An Automatic Equalizer Based on Forward–Flyback Converter for Series-Connected Battery Strings. IEEE Trans. Ind. Electron. 2017, 64, 5380–5391. [Google Scholar] [CrossRef]

- Narayanan, R.; Gangadharan, J.; Sasidharan, N.; Meleetil, P.S. A Novel Modularization Method for Voltage Equalization of Ultracapacitor Bank Using Coupled Inductor. IEEE Trans. Ind. Electron. 2024, 71, 3548–3558. [Google Scholar] [CrossRef]

- Wang, S.; Wang, Y.; Chen, G.; Wei, D.; Shang, Y. An Efficient and Compact Equalizer Based on Forward-Flyback Conversion for Large-Scale Energy Storage Systems. IEEE Trans. Transp. Electrif. 2023. early accessed. [Google Scholar] [CrossRef]

- Liu, L.; Xu, B.; Yan, Z.; Zhou, W.; Li, Y.; Mai, R.; He, Z. A Low-Cost Multiwinding Transformer Balancing Topology for Retired Series-Connected Battery String. IEEE Trans. Power Electron. 2021, 36, 4931–4936. [Google Scholar] [CrossRef]

- Fan, S.; Duan, J.; Sun, L.; Zhang, K. A Fast Modularized Multiwinding Transformer Balancing Topology for Series-Connected Super Capacitors. IEEE Trans. Power Electron. 2019, 34, 3255–3268. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, X.; Cui, Y.; Zou, J.; Yang, S. A MultiWinding Transformer Cell-to-Cell Active Equalization Method for Lithium-Ion Batteries with Reduced Number of Driving Circuits. IEEE Trans. Power Electron. 2016, 31, 4916–4929. [Google Scholar]

- Nie, J.; Fu, R.; Cai, C.; Ma, J.; Shu, Z.; Ma, L. A High Efficiency Battery Equalizing Circuit Based on Half Bridge Topology with Multiport Transformer. IEEE Trans. Ind. Electron. 2024, 71, 2522–2532. [Google Scholar] [CrossRef]

| Parameters | Value | |

|---|---|---|

| Battery | Model | LS18650-10A |

| Nominal capacity | 2600 mAh | |

| Nominal voltage | 3.6 V | |

| MOSFET | Mij | TTD85N03AT (VDS = 10 V, ID = 85 A, RDS = 4.5 mΩ) |

| Transformer | N1:N2 | 1:1 |

| Lm | 21 μH | |

| Lk | 0.1 μH | |

| Equalisation start threshold (ε) | 0.1% | |

| Switching frequency of the first-layer equalisation (f1) | 50 kHz | |

| Switching frequency of the second-layer equalisation (f2) | 50 kHz | |

| Battery Number | SOC (%) | Voltage (V) | Battery Number | SOC (%) | Voltage (V) |

|---|---|---|---|---|---|

| B11 | 82.39 | 3.898 | B22 | 67.34 | 3.891 |

| B12 | 76.88 | 3.896 | B31 | 62.75 | 3.888 |

| B21 | 72.68 | 3.894 | B32 | 57.28 | 3.884 |

| Equalisers | Components | Equalisation Performance | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| M | D | L | C | T | Cost | Efficiency | Speed | Complexity | Volume | |

| [9] | 2N | 0 | 0 | N − 1 | 0 | L | 93.1% | L | M | L |

| [10] | 4N + 2 | 0 | N − 1 | 0 | 0 | H | 80% | M | H | M |

| [15] | 4N | 0 | N | N | 0 | H | 95.2% | L | H | L |

| [16] | 2N | 0 | 2N | N | N | H | 92% | M | H | H |

| [18] | 4N + 1 | 0 | 1 | 1 | 0 | M | 96.05% | L | H | L |

| [19] | N/2 | 0 | N/2 | 0 | 0 | M | / | M | H | M |

| [20] | N | 1 | N/2 | 0 | N/4 | L | 95.6% | M | L | H |

| [22] | 2N + 6 | 0 | 1 | 0 | 1 | M | 80.4% | L | M | L |

| [25] | 5/4N | 0 | 5/4N | 0 | N/4 | M | 93.15% | M | L | M |

| [28] | 2N | 0 | N | 0 | 1 | M | 70.14% | L | M | L |

| Proposed equaliser | 3N | 0 | 0 | 0 | N/2 | M | 98.8%/94.3% | H | M | M |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Wei, X.; Ai, J.; Yang, X. A Layered Parallel Equaliser Based on Flyback Transformer Multiplexed for Lithium-Ion Battery System. Energies 2024, 17, 754. https://doi.org/10.3390/en17030754

Liu H, Wei X, Ai J, Yang X. A Layered Parallel Equaliser Based on Flyback Transformer Multiplexed for Lithium-Ion Battery System. Energies. 2024; 17(3):754. https://doi.org/10.3390/en17030754

Chicago/Turabian StyleLiu, Hongrui, Xiangyang Wei, Junjie Ai, and Xudong Yang. 2024. "A Layered Parallel Equaliser Based on Flyback Transformer Multiplexed for Lithium-Ion Battery System" Energies 17, no. 3: 754. https://doi.org/10.3390/en17030754

APA StyleLiu, H., Wei, X., Ai, J., & Yang, X. (2024). A Layered Parallel Equaliser Based on Flyback Transformer Multiplexed for Lithium-Ion Battery System. Energies, 17(3), 754. https://doi.org/10.3390/en17030754