Environmental Assessment of Hydrothermal Treatment of Wet Bio-Residues from Forest-Based and Agro-Industries into Intermediate Bioenergy Carriers

Abstract

1. Introduction

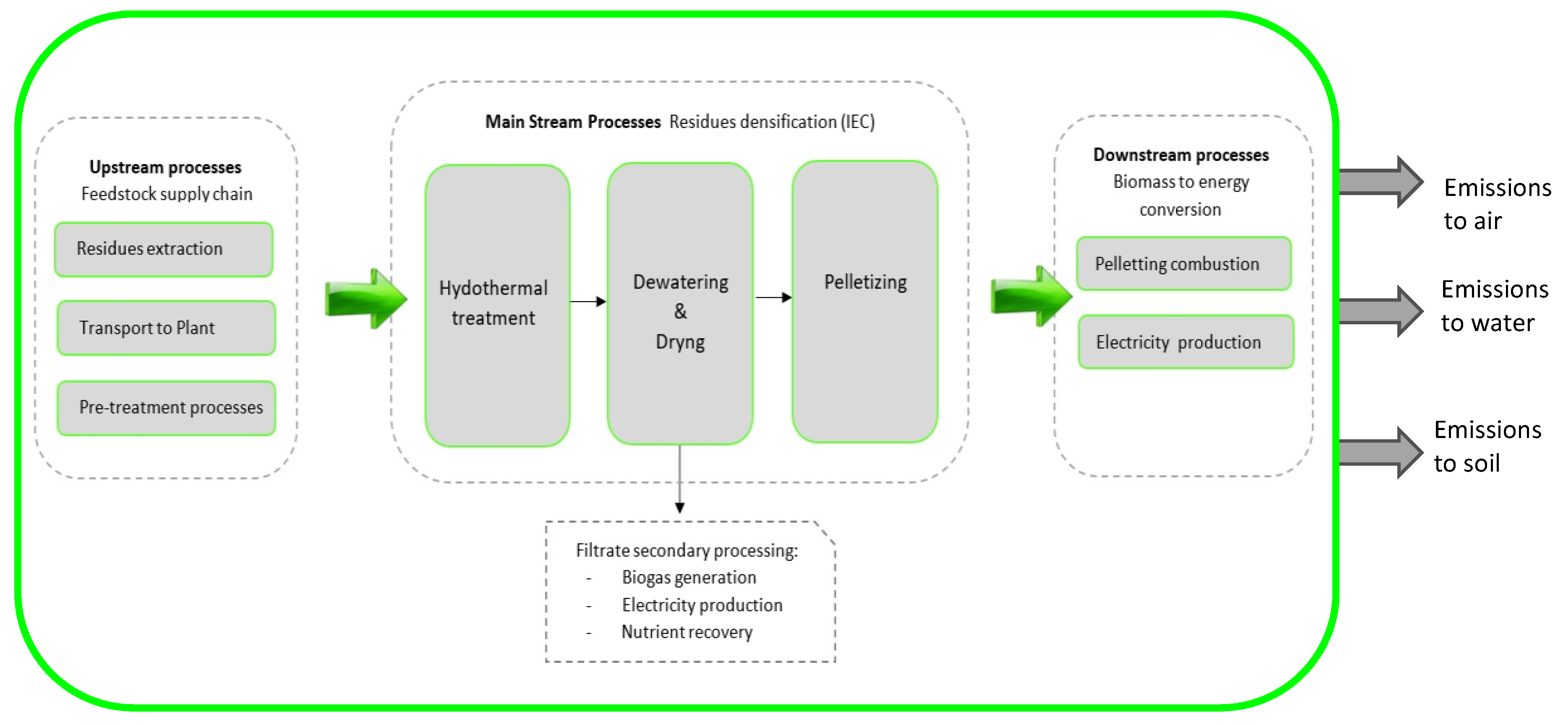

2. Materials and Methods

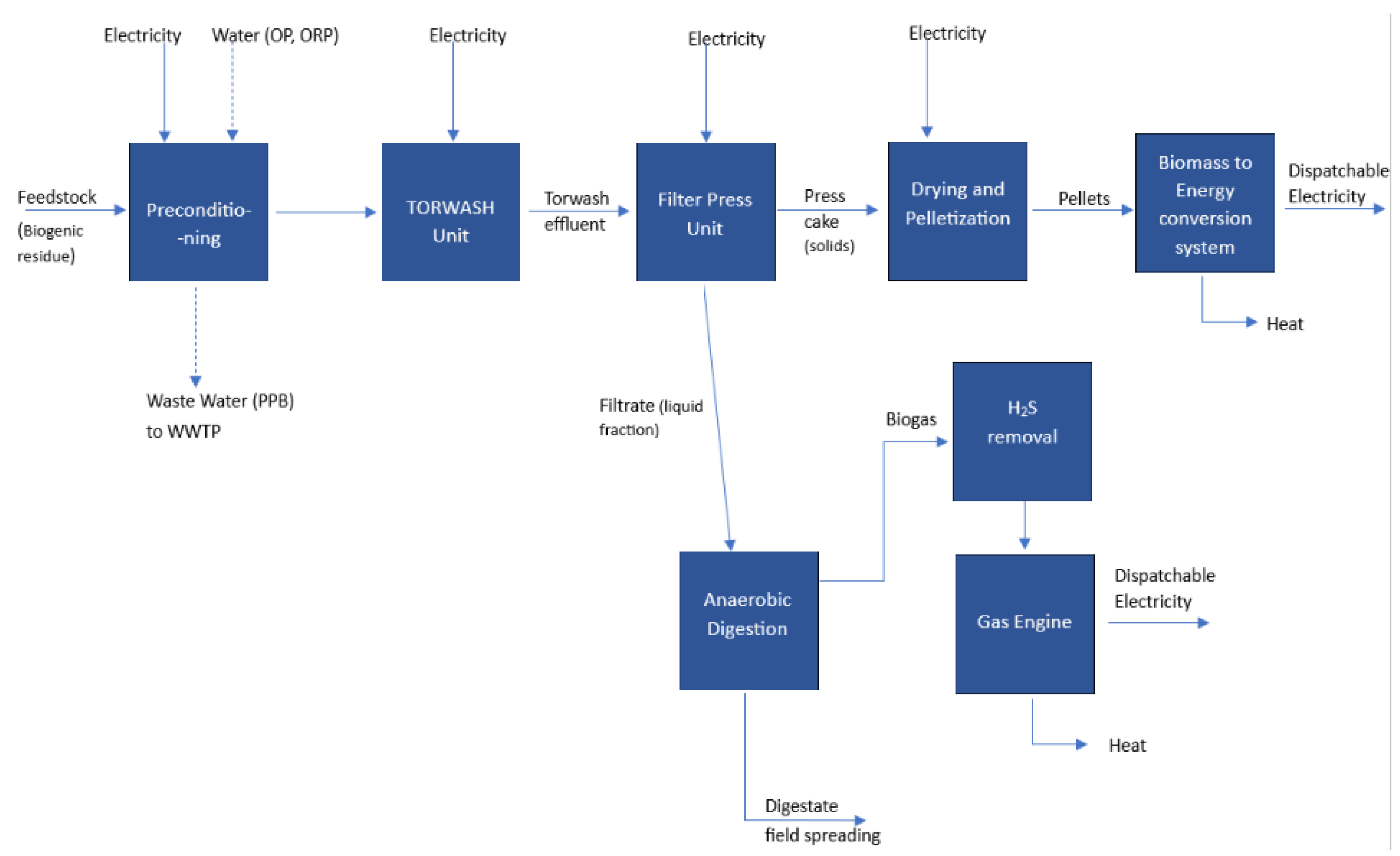

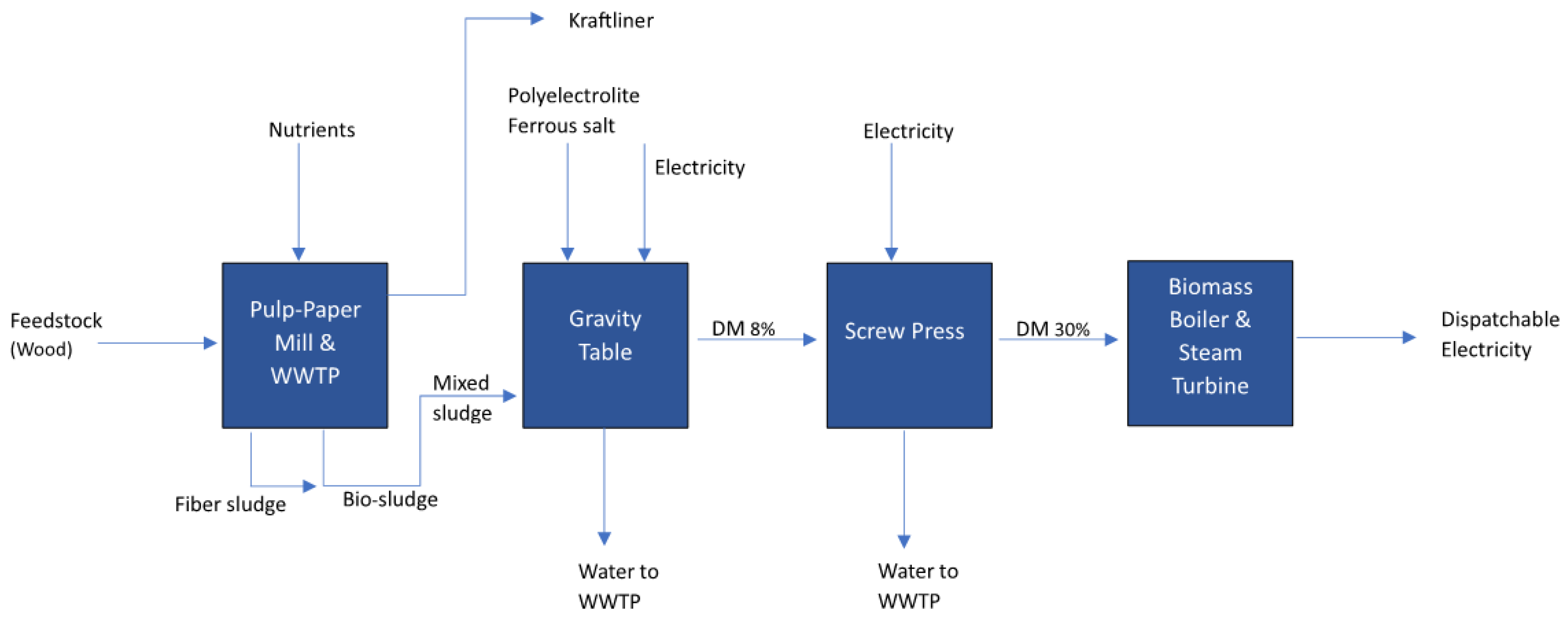

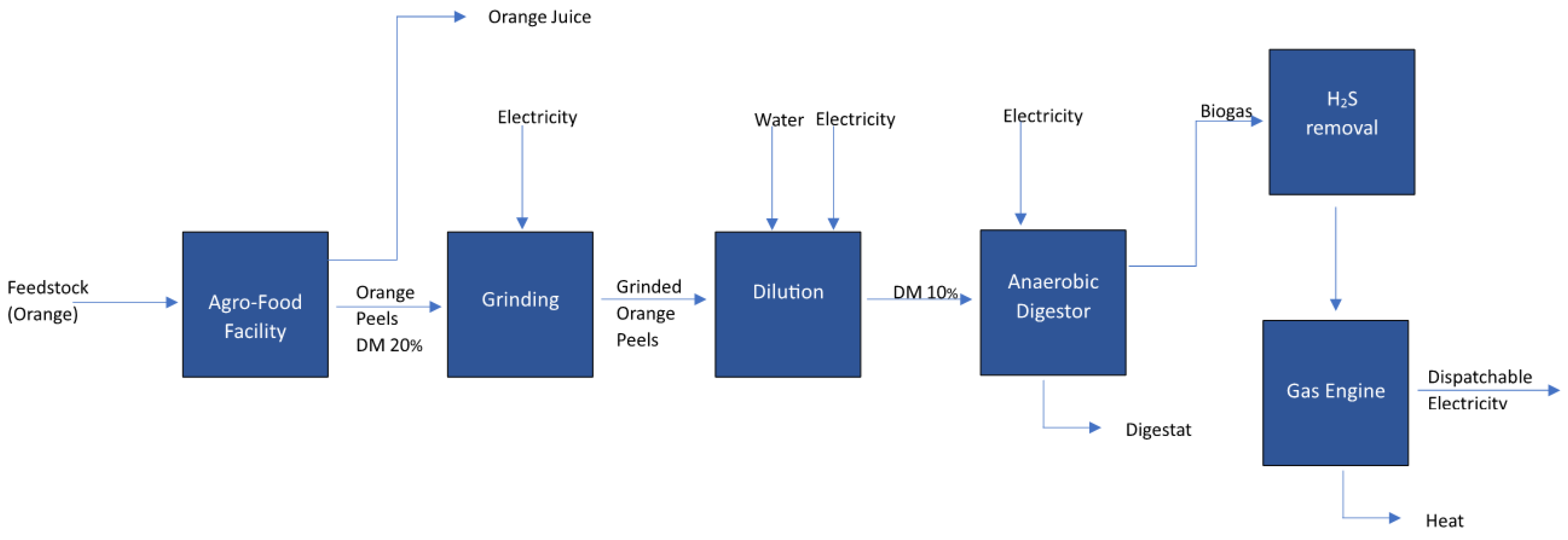

2.1. Case Studies Considered in the LCA for F-CUBED

2.2. Summary of the Reference Cases to which F-CUBED Is Compared to

- The wastewater treatment phase with a flow rate of 18 t/tADP representing an average value of the range 9–27 t/tADP valid for a plant capacity of about 650 ktADP/year, and an electricity consumption of 8 kWh/tADP, based on [29];

- The press cake feeding the biomass boiler was modelled with data collected in [31], setting the inputs of sodium hydroxide, ammonia, water for gas cleaning, and electricity requirement;

- The produced steam is converted into energy through a turbine characterised by a power efficiency of 20% and heat surplus to be used outside the system.

2.3. LCA Methodology for F-CUBED Production System Analysis

2.3.1. Goal and Scope Definition

2.3.2. Life Cycle Inventory

2.3.3. Life Cycle Impact Assessment

3. Results and Discussion

3.1. Life Cycle Inventory (LCI) Results

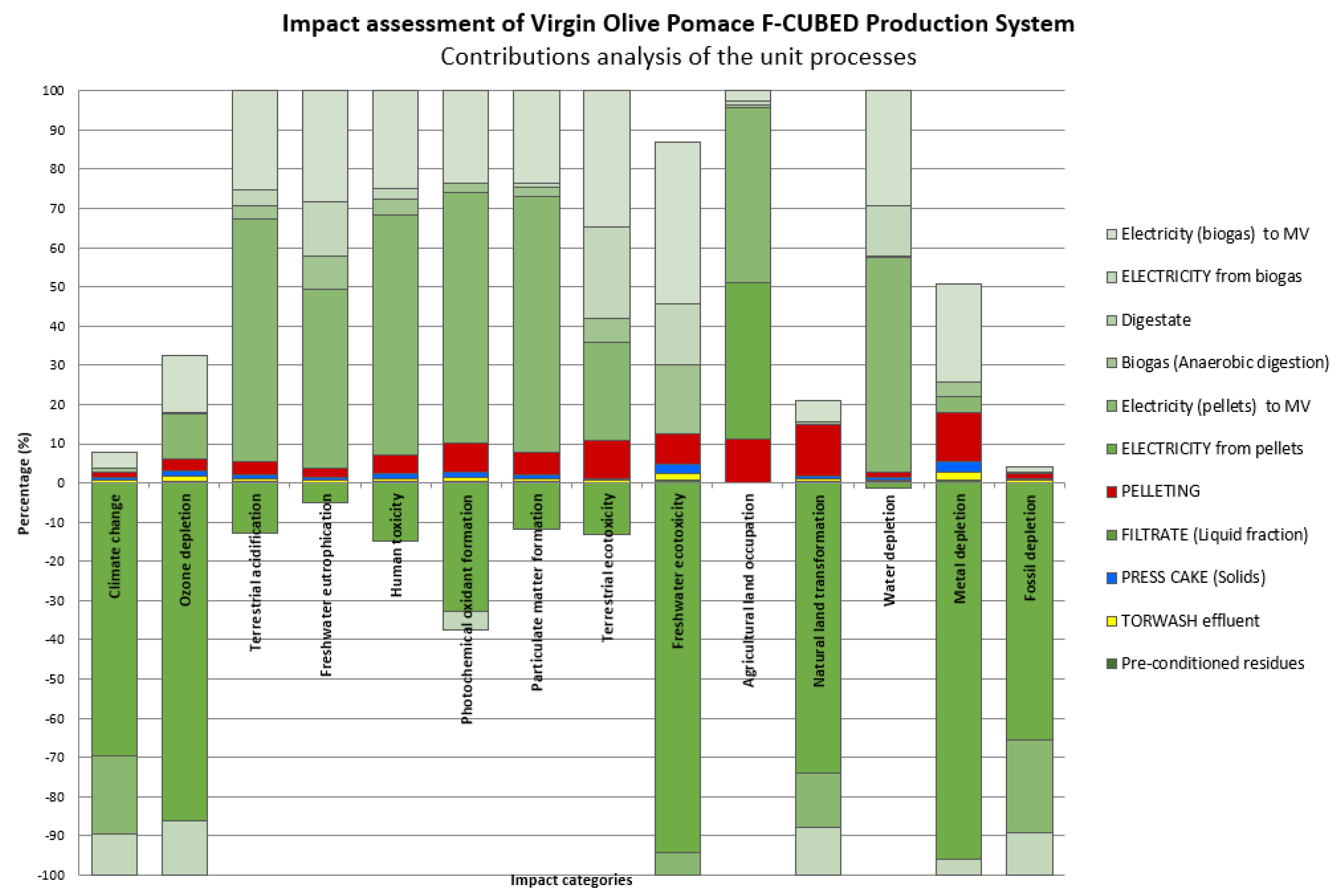

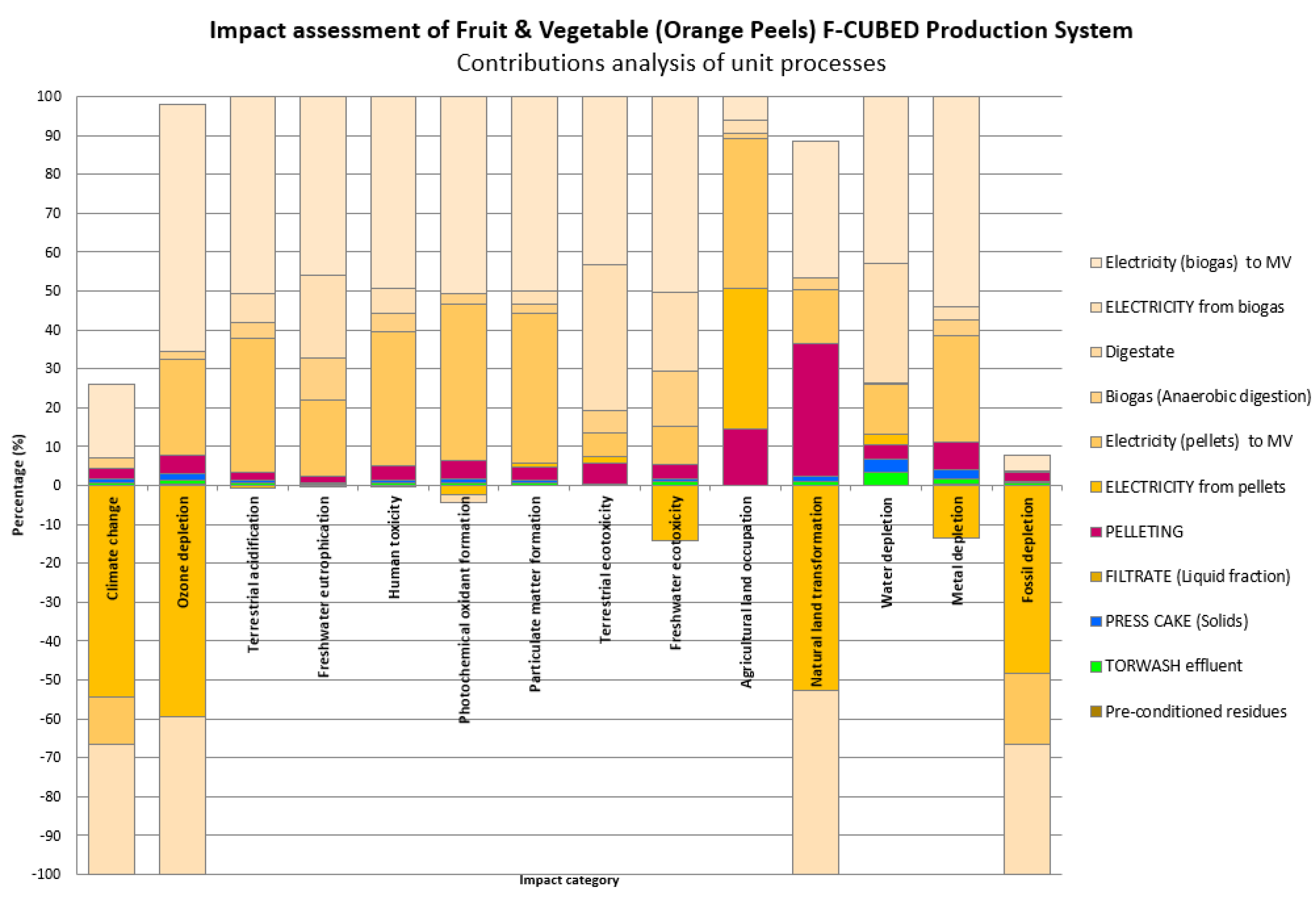

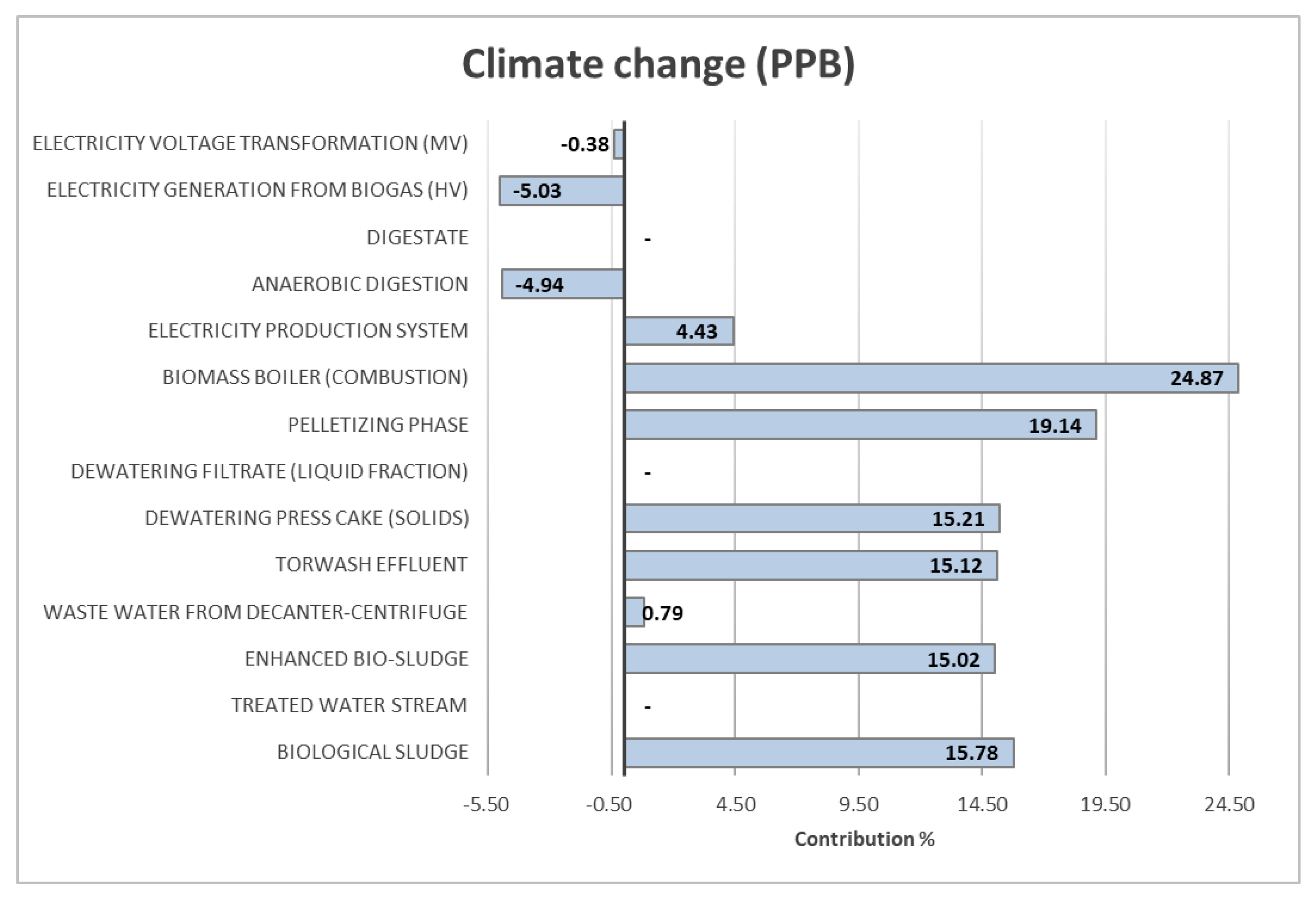

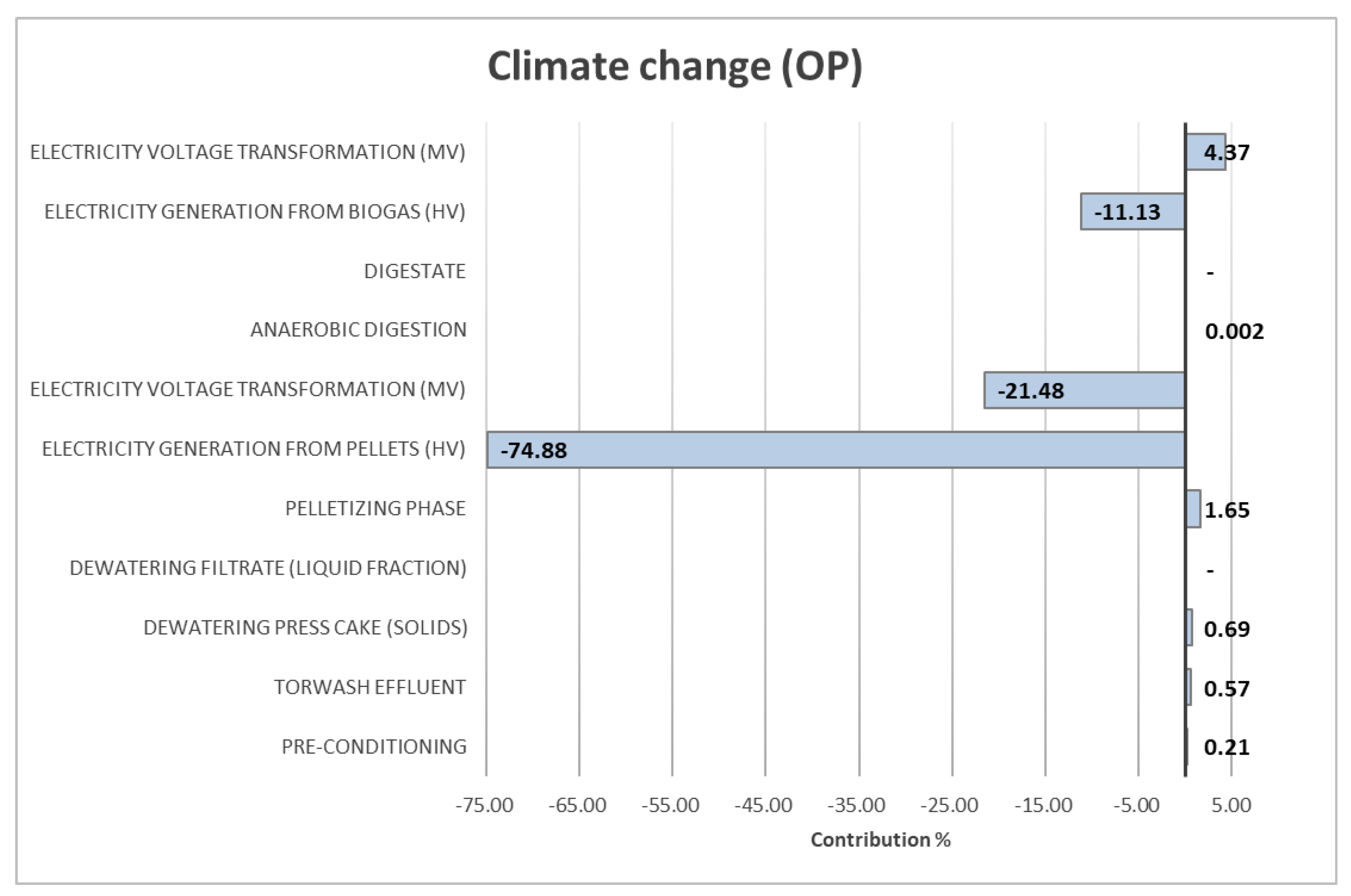

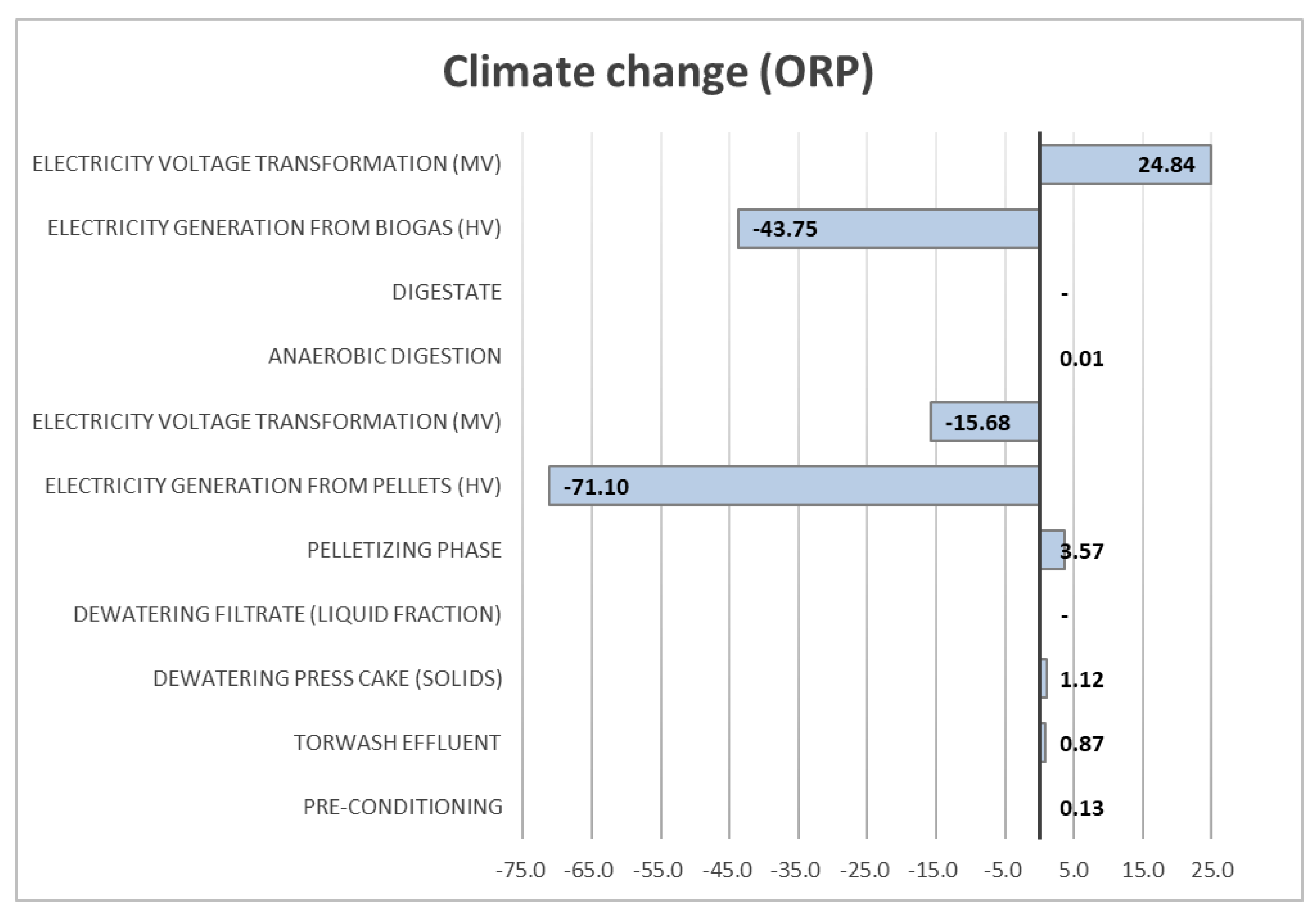

3.2. Life Cycle Impact Assessment (LCIA) Results

4. Conclusions, Outlook, and Limitations of the Study

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- EEA. The European Environment—State and Outlook 2020; Knowledge for Transition to a Sustainable Europe; Publications Office of the European Union: Luxembourg, 2019. [Google Scholar]

- European Parliament. Resolution on the Consequences of Drought, Fire, and Other Extreme Weather Phenomena: Increasing the EU’s Efforts to Fight Climate Change; European Parliament: Strasbourg, France, 2023.

- EEA. EEA Greenhouse Gases—Data Viewer. April 2023. Available online: https://www.eea.europa.eu/data-and-maps/data/data-viewers/greenhouse-gases-viewer (accessed on 23 August 2023).

- EEA. Trends and Projections in Europe 2022—EEA Report No 10/2022; Publications Office of the European Union: Luxembourg, 2022. [Google Scholar]

- European Parliament. Climate change in Europe: Facts and Figures. March 2023. Available online: https://www.europarl.europa.eu/news/en/headlines/society/20180703STO07123/climate-change-in-europe-facts-and-figures (accessed on 23 August 2023).

- Toscano, G.; Pizzi, A.; Pedretti, E.F.; Rossini, G.; Ciceri, G.; Martignon, G.; Duca, D. Torrefaction of Tomato Industry Residues. Fuel 2015, 143, 89–97. [Google Scholar] [CrossRef]

- Oh, Y.-K.; Hwang, K.-R.; Kim, C.; Kim, J.; Lee, J.-S. Recent Developments and Key Barriers to Advanced Biofuels: A Short Review. Bioresour. Technol. 2018, 257, 320–333. [Google Scholar] [CrossRef] [PubMed]

- Aravani, V.; Sun, H.; Yang, Z.; Liu, G.; Wang, W.; Anagnostopoulos, G.; Syriopoulos, G.; Charisiou, N.; Goula, M.; Kornaros, M.; et al. Agricultural and Livestock Sector’s Residues in Greece & China: Comparative Qualitative and Quantitative Characterization for Assessing Their Potential for Biogas Production. Renew. Sustain. Energy Rev. 2022, 154, 111821. [Google Scholar] [CrossRef]

- Toscano, G.; Alfano, V.; Scarfone, A.; Pari, L. Pelleting Vineyard Pruning at Low Cost with a Mobile Technology. Energies 2018, 11, 2477. [Google Scholar] [CrossRef]

- E4tech. Advanced Drop-in Biofuels: UK Production Capacity Outlook to 2030; Final Report SPATS Work Package 1-045, PPRO 04/75/17; Department for Transport of UK Government: London, UK, 2017.

- EC. Sustainable and Optimal Use of Biomass for Energy in the EU beyond 2020—Final Report; DG Energy: Brussels, Belgium, 2017. [Google Scholar]

- Li, J.; Suvarna, M.; Li, L.; Pan, L.; Pérez-Ramírez, J.; Ok, Y.; Wang, X. A review of computational modeling techniques for wetwaste valorization: Research trends and future perspectives. J. Clean. Prod. 2022, 367, 133025. [Google Scholar] [CrossRef]

- Lachos-Perez, D.; Torres-Mayanga, P.; Abaide, E.; Zabot, G.; De Castilhos, F. Hydrothermal carbonization and Liquefaction: Differences, progress, challenges, and opportunities. Bioresour. Technol. 2022, 343, 126084. [Google Scholar] [CrossRef]

- Hussin, F.; Hazani, N.N.; Khalil, M.; Aroua, M.K. Environmental life cycle assessment of biomass conversionusing hydrothermal technology: A review. Fuel Process. Technol. 2023, 246, 107747. [Google Scholar] [CrossRef]

- Christensen, T.; Damgaard, A.; Levis, J.; Zhao, Y.; Björklund, A.; Arena, U.; Barlaz, M.; Starostina, V.; Boldrin, A.; Astrup, T.; et al. Application of LCA modelling in integrated wastemanagement. Waste Manag. 2020, 118, 313–322. [Google Scholar] [CrossRef]

- Medina-Martos, E.; Istrate, I.; Villamil, J.; Gálvez-Martos, J.; Dufour, J.; Mohedano, A. Techno-economic and life cycle assessment of an integrated hydrothermal carbonization system for sewage sludge. J. Clean. Prod. 2020, 277, 122930. [Google Scholar] [CrossRef]

- Mendecka, B.; Di Ilio, G.; Lombardi, L. Thermo-fluid dynamic and kinetic modeling of hydrothermal carbonization of olive pomace in a batch reactor. Energies 2020, 13, 4142. [Google Scholar] [CrossRef]

- Benavente, V.; Fullana, A.; Berge, N. Life cycle analysis of hydrothermal carbonization of olive mill waste: Comparison with current management approaches. J. Clean. Prod. 2017, 142, 2637–2648. [Google Scholar] [CrossRef]

- Mayer, F.; Bhandari, R.; Gath, S. Life cycle assessment on the treatment of organic waste streams by anaerobic digestion, hydrothermal carbonization and incineration. Waste Manag. 2021, 130, 93–106. [Google Scholar] [CrossRef] [PubMed]

- Zijlstra, D.; Cobussen-Pool, E.; Slort, D.; Visser, M.; Nanou, P.; Pels, J.; Wray, H. Development of a Continuous Hydrothermal Treatment Process for Efficient Dewatering of Industrial Wastewater Sludge. Processes 2022, 10, 2702. [Google Scholar] [CrossRef]

- Shah, S.; Dijkstra, J.; Wray, H. Process evaluation of mild hydrothermal carbonization to convert wet biomass residue streams into intermediate bioenergy carriers. Biomass Bioenergy 2023. submitted. [Google Scholar] [CrossRef]

- Zijlstra, D.; Visser, M.; Cobussen-Pool, E.; Slort, D.; Nanou, P.; Pels, J.; Wray, H. Continuous hydrothermal carbonization of olive pomace and orange peels for the production of pellets as an intermediate energy carrier. Sustainability. submitted.

- Toscano, G.; Feliciangeli, G.; Rossini, G.; Fabrizi, S.; Pedretti, E.F.; Duca, D. Engineered Solid Biofuel from Herbaceous Biomass Mixed with Inorganic Additives. Fuel 2019, 256, 115895. [Google Scholar] [CrossRef]

- IEA. How Biogas Can Support Intermittent Renewable Electricity. 2021. Available online: https://www.iea.org/articles/how-biogas-can-support-intermittent-renewable-electricity (accessed on 23 August 2023).

- UNI EN ISO 14040:2021; Gestione Ambientale—Valutazione del ciclo di vita—Principi e Quadro di Riferimento. ISO: Geneva, Switzerland, 2022.

- UNI EN ISO 14044:2021; Gestione Ambientale—Valutazione del ciclo di vita—Requisiti e Linee Guida. ISO: Geneva, Switzerland, 2023.

- Faubert, P.; Barnabé, S.; Bouchard, S.; Côté, R.; Villeneuve, C. Pulp and paper mill sludge management practices: What are the challenges to assess the impacts on greenhouse gas emissions? Resour. Conserv. Recycl. 2016, 108, 107–133. [Google Scholar] [CrossRef]

- Alonso-Fariñas, B.; Oliva, A.; Rodríguez-Galán, M.; Esposito, G.; García-Martín, J.; Rodríguez-Gutiérrez, G.; Serrano, A.; Fermoso, F. Environmental Assessment of Olive Mill Solid Waste Environmental Assessment of Olive Mill SolidWaste Pomace Oil Extraction. Processes 2020, 8, 626. [Google Scholar] [CrossRef]

- Suhr, M.; Klein, G.; Kourti, I.; Gonzalo, M.; Santonja, G.; Roudier, S.; Delgado, S. Best Available Techniques (BAT) Reference Document for the Production of Pulp, Paper and Board; European Commission, Joint Research Centre, Institute for Prospective Technological Studies: Luxembourg, 2015. [Google Scholar]

- Visigalli, S. Tecnologie di Disidratazione Meccanica, Corso di Formazione in Impianti Biologici di Depurazione, Modulo 4 Trattamento e Smaltimento Fanghi, 35°edizione; Politecnico di Milano: Milan, Italy, 2020. [Google Scholar]

- Neuwahl, F.; Cusano, G.; Benavides, G.; Holbrook, S.; Roudier, S. Best Available Techniques (BAT) Reference Document for Waste Incineration, Industrial Emissions Directive 2010/75/EU, Integrated Pollution Prevention and Control; JRC Science for Policy Report; Publications Office of the European Union: Luxembourg, 2019. [Google Scholar]

- Batuecas, E.; Tommasi, T.; Battista, F.; Negro, V.; Sonetti, G.; Viotti, P.; Fino, D.; Mancini, G. Life Cycle Assessment of waste disposal from olive oil production: Anaerobic digestion and conventional disposal on soil. J. Environ. Manag. 2019, 237, 94–102. [Google Scholar] [CrossRef]

- Shelford, T.; Gooch, C. Hydrogen Sulfide Removal from Biogas; Part 3A: Iron Sponge Basics; Northeast SARE: South Burlington, VT, USA, 2017. [Google Scholar]

- Zoair, A.; Attia, R.; Garbia, H.A.; Youssef, M. Utilization of Orange, Banana and Potato Peels in Formulating Functional Cupcakes and Crackers. J. Fd. Sci. Technol. 2016, 13, 11–18. [Google Scholar]

- Ortiz, D.; Batuecas, E.; Orrego, C.; Rodríguez, L.; Camelin, E.; Fino, D. Sustainable management of peel waste in the small-scale orange juice industries: Colombian case study. J. Clean. Prod. 2020, 265, 121587. [Google Scholar] [CrossRef]

- Curran, M. Life Cycle Assessment Handbook: A Guide for Environmentally Sustainable Products; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Ciroth, A.; Arvidsson, R. Life Cycle Inventory Analysis—Methods and Data; Springer: Berlin/Heidelberg, Germany, 2021. [Google Scholar]

- Rosenbaum, R.; Hauschild, M.; Boulay, A.-M.; Fantke, P.; Laurent, A.; Núñez, M.; Vieira, M. Life Cycle Impact Assessment in: Life Cycle Assessment; Springer: Berlin/Heidelberg, Germany, 2018; pp. 167–270. [Google Scholar]

- Huijbregts, M.; Steinmann, Z.; Elshout, P.; Stam, G.; Verones, F.; Vieira, M.; Hollander, A.; Zijp, M.; van Zelm, R. ReCiPe 2016 v1.1. A harmonized life cycle impact assessment method at midpoint and endpoint level. Report I: Characterization. RIVM/DMG, Bilthoven, the Netherlands, 2017. Report I: Characterization.

- Hosseinzadeh-Bandbafha, H.; Aghbashlo, M.; Tabatabaei, M. Life cycle assessment of bioenergy product systems: A critical review. e-Prime—Adv. Electr. Eng. Electron. Energy 2021, 265, 121587. [Google Scholar] [CrossRef]

- Scott, M.; Hendrickson, C.; Matthews, D. Life Cycle Assessment: Quantitative Approaches for Decisions that MATTER, Open Access Textbook; Carnegie Mellon University: Pittsburgh, PA, USA, 2014. [Google Scholar]

- Williams, E.; Weber, C.; Hawkins, T. Hybrid Framework for Managing Uncertainty in Life Cycle Inventories. J. Ind. Ecol. 2009, 13, 928–944. [Google Scholar] [CrossRef]

- Igos, E.; Benetto, E.; Meyer, R.; Baustert, P.; Othoniel, B. How to Treat Uncertainties in Life Cycle Assessment Studies? Int. J. Life Cycle Assess 2018, 24, 794–807. [Google Scholar] [CrossRef]

- Mahmood, A.; Varabuntoonvit, V.; Mungkalasiri, J.; Silalertruksa, T.; Gheewala, S. A Tier-Wise Method for Evaluating Uncertainty in Life Cycle Assessment. Sustainability 2022, 14, 13400. [Google Scholar] [CrossRef]

- Ghimire, A.; Gyawali, R.; Lens, P.; Lohani, S. Emerging Technologies and Biological Systems for Biogas Upgrading; Academic Press: Cambridge, MA, USA, 2021; pp. 295–320. [Google Scholar]

- Buratti, C.; Fantozzi, F. Life Cycle Assessment of biomass chains: Wood pellet from short rotation coppice using data measured on a real plant. Biomass Bioenergy 2010, 34, 1796–1804. [Google Scholar]

- IRENA. Solid biomass supply for heat and power: Technology brief. Int. Renew. Energy Agency 2018. [Google Scholar]

- Herrera, A.; D’Imporzano, G.; Zilio, M.; Pigoli, A.; Rizzi, B.; Meers, E.; Schouman, O.; Schepis, M.; Barone, F.; Giordano, A.; et al. Environmental Performance in the Production and Use of Recovered Fertilizers from Organic Wastes Treated by Anaerobic Digestion vs Synthetic Mineral Fertilizers. ACS Sustain. Chem. Eng. 2022, 10, 986–997. [Google Scholar] [CrossRef]

- Leone, A.; Romaniello, R.; Peri, G.; Tamborrino, A. Development of a new model of olives de-stoner machine: Evaluation of electric consumption and kernel characterization. Biomass Bioenergy 2015, 81, 108–116. [Google Scholar] [CrossRef]

- Nastri, A.; Ramieri, N.; Abdayem, R.; Marzadori, C.; Ciavatta, C. Olive pulp and its effluents suitability for soil amendment. J. Hazard. Mater. 2006, 138, 211–217. [Google Scholar] [CrossRef]

- Our World in Data. Global Change Data Lab. 2022. Available online: https://ourworldindata.org/grapher/carbon-intensity-electricity?tab=chart®ion=Europe&country=~SWE (accessed on 23 August 2023).

- Statista. statista.com. Statista, Global Data and Business Intelligence Platform. 2022. Available online: https://www.statista.com/statistics/1013726/share-of-electricity-production-in-sweden-by-source/ (accessed on 23 August 2023).

- Our World in Data. Global Change Data Lab. 2022. Available online: https://ourworldindata.org/grapher/carbon-intensity-electricity?tab=chart®ion=Europe&country=~ESP (accessed on 23 August 2023).

- Our World in Data. Global Change Data Lab. 2022. Available online: https://ourworldindata.org/grapher/carbon-intensity-electricity?tab=chart®ion=Europe&country=~ITA (accessed on 23 August 2023).

| Biogenic Residue Stream | Object of Investigation | Description |

|---|---|---|

| Treatment of pulp and paper bio-sludge (DM 3.5%) | Reference case | Smurfit Kappa (SK) Kraftliner paper mill in Piteå, Sweden. The mill produces kraftliner as the main product. The wastewater streams from this mill are sent to the wastewater treatment plant (WWTP). |

| F-CUBED production system | Integration of the F-CUBED technology at the site of Smurfit Kappa (Piteå, Sweden) paper mill, for operational application with pulp and paper sludge (bio-sludge) as feedstock. Industrial scale operational scenario. | |

| Treatment of virgin olive pomace (DM 19.63%) | Reference case | APPO olive mill, in Sannicandro di Bari, Italy. In the mill, the cleaned olives are pressed for the extraction of the extra virgin olive oil. The olive pomace is sent to the AD reactor for biogas generation. |

| F-CUBED production system | Integration of the F-CUBED technology at the site of APPO olive mill, for operational application with virgin olive pomace as feedstock. Industrial scale operational scenario. | |

| Treatment of orange peel (DM 20%) | Reference case | Delafruit’s food processing plant, in Reus, Spain. In the plant, the fresh oranges are squeezed to obtain orange juice, which is used for different purposes. The orange peels are sent to the AD reactor for biogas generation. |

| F-CUBED production system | Integration of the F-CUBED technology at the site of Delafruit’s facility, for operational application with orange peels as feedstock. Industrial scale operational scenario. |

| Residue Stream | Input | Mass/Energy Flow Rate | Additional Information |

|---|---|---|---|

| Pulp and paper bio-sludge | Fiber sludge (DM 1.65%) | 3375 ton (db)/y | T—25 °C, P—1 atm |

| Bio-sludge (DM 3.5%) | 2250 ton (db)/y | T—25 °C, P—1 atm | |

| Polyelectrolyte (PE) | 25 ton/y | ||

| Ferrous salt solution | 170 ton/y | Added as 40% solution | |

| Nutrients added in WWTP | P—30 ton/y N—170 ton/y | P and N are added as an acid solution and urea salt respectively | |

| Yearly operating hours | 8600 h | F-CUBED partners information | |

| Virgin olive pomace | Olive pomace (DM 19.63%) | 9600 ton (ar)/y | T—15 °C, P—1 atm |

| Preparation of waste stream for AD | Dilution of stream to DM 9% | Heat to 30 °C for AD reactions | |

| BMP of olive pomace | 216 cm3 CH4/g volatile solids | ||

| Yearly operating hours | 960 h | F-CUBED partners information | |

| Orange peel | Orange peel waste stream (DM 20%) | 2300 ton (db)/y | T—15°C, P—1 atm |

| Preparation of waste stream for AD | Dilution of stream to DM 10% | Heat to 55 °C for AD reactions | |

| BMP of orange peel | 0.061 Nm3 CH4/kg volatile solids | ||

| Yearly operating hours | 3200 h | F-CUBED partners information |

| Impact Category | Abbreviation | Unit (Compartment) | Characterization Factor | Abbreviation |

|---|---|---|---|---|

| Climate change | CC | kg CO2 (air) | global warming potential | GWP |

| Ozone depletion | OD | kg CFC-11 (air) | ozone depletion potential | ODP |

| Terrestrial acidification | TA | kg SO2 (air) | terrestrial acidification potential | TAP |

| Freshwater eutrophication | FE | kg P (freshwater) | freshwater eutrophication potential | FEP |

| Marine eutrophication | ME | kg N (freshwater) | marine eutrophication potential | MEP |

| Human toxicity | HT | kg 14DCB (urban air) | human toxicity potential | HTP |

| Photochemical oxidant formation | POF | kg NMVOC (air) | photochemical oxidant formation potential | POFP |

| Particulate matter formation | PMF | kg PM10 (air) | particulate matter formation potential | PMFP |

| Terrestrial ecotoxicity | TET | kg 14 DCB (industrial soil) | terrestrial ecotoxicity potential | TETP |

| Freshwater ecotoxicity | FET | kg 14 DCB (freshwater) | freshwater ecotoxicity potential | FETP |

| Marine ecotoxicity | MET | kg 14 DCB (marine water) | marine ecotoxicity potential | METP |

| Ionising radiation | IR | kg U235 (air) | ionising radiation potential | IRP |

| Agricultural land occupation | ALO | m2yr (agricultural land) | agricultural land occupation potential | ALOP |

| Urban land occupation | ULO | m2yr (urban land) | urban land occupation potential | ULOP |

| Natural land transformation | NLT | m2 (natural land) | natural land transformation potential | NLTP |

| Water depletion | WD | m3 (water) | water depletion potential | WDP |

| Mineral depletion | MRD | kg Fe | mineral depletion potential | MDP |

| Fossil depletion | FD | kg oil | fossil depletion potential | FDP |

| Case Study | TORWASH® Electricity Consumption (kWh/tres) | Pellet MC (%) | Biogas LHV (MJ/kg) | Biological Sludge DM (%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Used | Min. | Max | Used | Min. | Max | Used | Min. | Max | Used | Min. | Max | |

| Pulp and paper sludge | 0.23 | 0.18 | 0.27 | 8 | 7 | 10 | - | - | - | 3.5 | 2.8 | 4.2 |

| Olive pomace | 10.87 | 8.69 | 13.04 | 8 | 6 | 10 | 17.31 | 13.85 | 20.77 | - | - | - |

| Orange peel | 27.98 | 22.38 | 33.57 | 8 | 6 | 10 | 15.79 | 12.63 | 18.95 | - | - | - |

| Impact Category | Unit | Pulp and Paper Bio-Sludge | Virgin Olive Pomace | Orange Peels |

|---|---|---|---|---|

| Climate change | kg CO2 eq./tres. | 1.79 × 101 | −1.29 × 103 | −1.30 × 103 |

| Ozone depletion | kg CFC−11 eq./tres | 4.88 × 10−6 | −6.50 × 10−5 | −4.88 × 10−6 |

| Terrestrial acidification | kg SO2 eq./tres | 2.02 × 10−1 | 2.99 × 10 | 1.35 × 101 |

| Freshwater eutrophication | kg P eq./tres | 2.89 × 10−1 | 3.49 × 10−1 | 1.31 × 101 |

| Human toxicity | kg 1.4-DB eq./tres | 1.46 × 101 | 1.50 × 102 | 6.56 × 102 |

| Photochemical oxidant formation | kg NMVOC/tres | 1.08 × 10−1 | 1.02 × 10 | 6.27 × 10 |

| Particulate matter formation | kg PM10 eq./tres | 7.89 × 10−2 | 9.29 × 10−1 | 4.59 × 10 |

| Terrestrial ecotoxicity | kg 1.4-DB eq./tres | −2.16 × 10−1 | 1.26 × 10−1 | 6.18 × 10−1 |

| Freshwater ecotoxicity | kg 1.4-DB eq./tres | 1.67 × 10 | −2.26 × 10 | 2.91 × 101 |

| Agricultural land occupation | m2a/tres | 6.36 × 101 | 1.60 × 103 | 3.09 × 103 |

| Natural land transformation | m2/tres | 9.08 × 10−3 | −1.24 × 10−1 | −2.24 × 10−2 |

| Water depletion | m3/tres | 1.45 × 10 | 2.56 × 101 | 7.52 × 101 |

| Metal depletion | kg Fe eq./tres | 3.84 × 10 | −6.17 × 10 | 4.67 × 101 |

| Fossil depletion | kg oil eq./tres | 4.43 × 10 | −4.99 × 102 | −6.27 × 102 |

| Impact Category | Unit | Pulp and Paper Bio-Sludge | Olive Pomace | Orange Peels | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| F-CUBED | RC | ECM (SE) | F-CUBED | RC | ECM (IT) | F-CUBED | RC | ECM (ES) | ||

| Climate change | kg CO2eq/kWhe | 1.13 × 10 | 3.33 × 10 | 4.50 × 10−2 | −6.29 × 10−1 | −1.68 × 10−1 | 3.72 × 10−1 | −2.50 × 10−1 | 6.64 × 10−2 | 2.17 × 10−1 |

| Ozone depletion | kg CFC-11eq/kWhe | 3.09 × 10−7 | 1.05 × 10−6 | 4.29 × 10−8 | −3.15 × 10−8 | 9.88 × 10−9 | 5.81 × 10−8 | −9.36 × 10−10 | 2.98 × 10−8 | 4.59 × 10−8 |

| Terrestrial acidification | kg SO2eq/kWhe | 1.28 × 10−2 | 2.18 × 10−2 | 1.55 × 10−4 | 1.45 × 10−3 | −2.49 × 10−3 | 1.66 × 10−3 | 2.58 × 10−3 | 1.61 × 10−3 | 2.12 × 10−3 |

| Freshwater eutrophication | kg P eq/kWhe | 1.83 × 10−2 | 1.65 × 10−1 | 2.30 × 10−5 | 1.69 × 10−4 | 1.01 × 10−3 | 1.27 × 10−4 | 2.51 × 10−4 | 4.38 × 10−4 | 1.23 × 10−4 |

| Human toxicity | Kg 1.4-DBeq/kWhe | 9.23 × 10−1 | 2.56 × 10 | 2.86 × 10−2 | 7.28 × 10−2 | −8.54 × 10−2 | 8.75 × 10−2 | 1.26 × 10−1 | 8.60 × 10−2 | 1.02 × 10−1 |

| Photochemical oxidant formation | kg NMVOC/kWhe | 6.85 × 10−3 | 1.12 × 10−2 | 1.42 × 10−4 | 4.92 × 10−4 | −6.61 × 10−4 | 1.01 × 10−3 | 1.20 × 10−3 | 9.26 × 10−4 | 1.23 × 10−3 |

| Particulate matter formation | kg PM10 eq/kWhe | 4.99 × 10−3 | 8.72 × 10−3 | 8.19 × 10−5 | 4.50 × 10−4 | −1.12 × 10−3 | 5.16 × 10−4 | 8.80 × 10−4 | 4.79 × 10−4 | 7.56 × 10−4 |

| Freshwater ecotoxicity | kg 1.4-DB eq/kWhe | 1.05 × 10−1 | 2.97 × 10−1 | 1.66 × 10−3 | −1.10 × 10−3 | −2.96 × 10−2 | 4.08 × 10−3 | 5.58 × 10−3 | 6.16 × 10−4 | 4.17 × 10−3 |

| Water depletion | m3/kWhe | 9.19 × 10−2 | 3.42 × 10−1 | 6.31 × 10−3 | 1.24 × 10−2 | −1.53 × 10−2 | 9.14 × 10−3 | 1.44 × 10−2 | −3.27 × 10−4 | 3.26 × 10−3 |

| Fossil depletion | kg oil eq/kWhe | 2.80 × 10−1 | 1.09 × 10 | 9.19 × 10−3 | −2.42 × 10−1 | −5.40 × 10−2 | 1.36 × 10−1 | −1.20 × 10−1 | 1.87 × 10−2 | 8.72 × 10−2 |

| Impact Category (Unit) | Pulp and Paper Bio-Sludge | Virgin Olive Pomace | Orange Peel |

|---|---|---|---|

| Climate change (kgCO2eq/t res.) | 17.91 | −1299 | −1301 |

| Particulate matter formation (kg PM10 eq./t res.) | 0.079 | 0.929 | 4.587 |

| Terrestrial acidification (kg SO2 eq/t res.) | 0.202 | 2.988 | 13.454 |

| Freshwater eutrophication (kg P eq/t res.) | 0.289 | 0.349 | 1.309 |

| Freshwater ecotoxicity (kg 1.4-DCB eq/t res.) | 1.667 | −2.262 | 29.113 |

| Human toxicity(kg 1.4-DCB eq/t res.) | 14.599 | 150.184 | 656.111 |

| KPI | Unit | RC PPB | F-CUBEDPPB | RC OP | F-CUBEDOP | RC ORP | F-CUBED ORP |

|---|---|---|---|---|---|---|---|

| Electricity production | kWh/tres. | 5.56 | 15.82 | 270.07 | 2.064.31 | 1.163.01 | 5.213.75 |

| Carbon footprint | kgCO2eq/kWhe | −2.36 | −4.56 | −0.17 | −0.63 | 0.07 | −0.25 |

| F-CUBED improvement | % | - | 93% | - | 274% | - | 476% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ugolini, M.; Recchia, L.; Wray, H.E.; Dijkstra, J.W.; Nanou, P. Environmental Assessment of Hydrothermal Treatment of Wet Bio-Residues from Forest-Based and Agro-Industries into Intermediate Bioenergy Carriers. Energies 2024, 17, 560. https://doi.org/10.3390/en17030560

Ugolini M, Recchia L, Wray HE, Dijkstra JW, Nanou P. Environmental Assessment of Hydrothermal Treatment of Wet Bio-Residues from Forest-Based and Agro-Industries into Intermediate Bioenergy Carriers. Energies. 2024; 17(3):560. https://doi.org/10.3390/en17030560

Chicago/Turabian StyleUgolini, Marco, Lucia Recchia, Heather E. Wray, Jan Wilco Dijkstra, and Pavlina Nanou. 2024. "Environmental Assessment of Hydrothermal Treatment of Wet Bio-Residues from Forest-Based and Agro-Industries into Intermediate Bioenergy Carriers" Energies 17, no. 3: 560. https://doi.org/10.3390/en17030560

APA StyleUgolini, M., Recchia, L., Wray, H. E., Dijkstra, J. W., & Nanou, P. (2024). Environmental Assessment of Hydrothermal Treatment of Wet Bio-Residues from Forest-Based and Agro-Industries into Intermediate Bioenergy Carriers. Energies, 17(3), 560. https://doi.org/10.3390/en17030560