Risks and Challenges of Oversized Transport in the Energy Industry

Abstract

1. Introduction

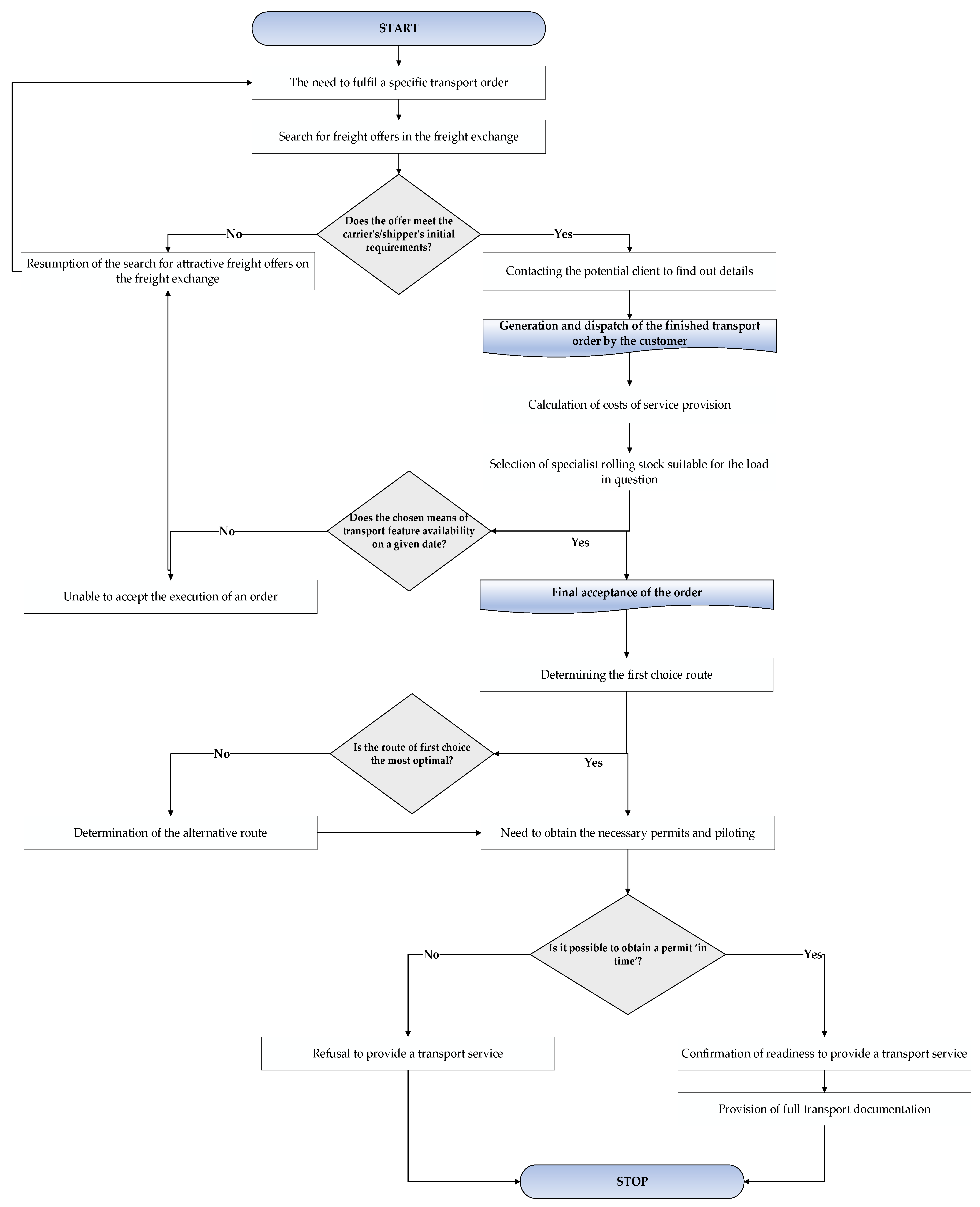

2. Materials and Methods

- Purpose and Scope Definition: The objective of the FMEA analysis was to identify, evaluate, and mitigate risks associated with the transport of oversized goods in Poland.

- Process Mapping: The logistics process was mapped using a flowchart, detailing the phases of transport and highlighting critical points.

- Risk Identification: Potential risks and obstacles were identified and categorized based on their causes and consequences (the employees who took part in the survey evaluated the individual criteria of the FMEA analysis—P, D, I; they also commented on the proposed 15 risks).

- Risk Assessment: Each risk was assigned a score for its probability of occurrence, importance in terms of transport feasibility, and detectability. These scores were used to calculate the overall risk value for each factor.

- Risk Evaluation: Risk assessment criteria were defined, enabling the classification of risks into acceptable, tolerable, or unacceptable categories.

- Corrective Actions: For risks deemed unacceptable, corrective actions and modifications were proposed to mitigate their impact and enhance the overall safety and efficiency of the transport process (corrective actions were identified through interviews with 11 companies in Poland).

- –

- Preparation—The work should start by defining all the processes performed by the organization, such as: transport execution, maintenance of vehicles and technical resources, documentation management, loading and unloading control. In each of these processes, possible risk areas should be analyzed and defined.

- –

- Hazard identification—At this stage, all possible hazards in the organization that may become apparent during the manufacture, realization or use (of the product/process) are identified. The hazard relationship effect cause is then determined for all types of identified hazards and the current control and monitoring methods used to detect the hazard or cause under consideration are identified.

- –

- Risk estimation—The aim of this step is to estimate the identified risks for the whole area. On a scale of 1–10, identify the factors contributing to the hazard and assign a risk number R to each hazard, which is the product of the three factors:whereR = P·D·I

- –

- R—risk of hazard occurrence,

- –

- P—probability of hazard occurrence,

- –

- D—possibility of identifying the hazard, and

- –

- I—effect of hazard.

3. Analysis of the Process of Organizing Oversized Transport

3.1. Freight Search in the Freight Exchange

3.2. Calculation of Costs of Service Provision

3.3. Selection of Specialist Rolling Stock Suitable for the Load in Question

3.4. Selection of the Optimum Basic Route and Alternative

3.5. Obtaining the Necessary Permits and Ordering the Pilotage on the Route

3.6. Implementation of the Transport Service

4. Analysis of Risk Factors Using the FMEA Method

- –

- Person/entity responsible for the defect—the person who takes possible responsibility for the fact that the hazard/obstacle has arisen,

- –

- Potential type of defect—the hazard or difficulty analyzed,

- –

- Potential effect of the defect—the listed effects of the individual impediment,

- –

- Potential causes—the listed causes of individual handicaps,

- –

- Column “P”—indicating on a scale of 1–10 the probability of a specific handicap occurring,

- –

- Column “I”—indicating on a scale of 1–10 the importance of a given impediment in the context of the possibility of carrying out transport,

- –

- Column “D”—indicating on a scale of 1–10 the detectability of a given obstacle,

- –

- Column “R”—which is the product of the above three coefficients (P, I, D) and characterizes the level of each identified risk, and

- –

- Corrective actions—proposed modifications to increase the level of safety of the entire service and to minimize the negative effects/risks.

- –

- Risk level legend discussed in the table:

- –

- Intolerable (red)—the probability of the occurrence of the difficulty and/or the significance in the context of the possibility of carrying out the transport is unacceptable. Modifications should be introduced to reduce the probability of the risk occurrence.

- –

- Tolerable (yellow)—if the risk has been classified in this category, the possibility of its occurrence and the consequences should be taken into account. It is necessary to take action to reduce it. If, despite this, the risk still remains at this level, it can be considered acceptable provided that it has been carefully analyzed.

- –

- Acceptable (green)—if the risk is in the green area, it is considered low (the probability of the threat occurrence is very small and/or the consequences are not too serious). However, it is still necessary to consider further risk reduction.

- Discrepancies between the actual dimensions of the cargo and the transport documentationCauses:

- (a)

- Measurement or assessment errors leading to inaccurate determination of the cargo dimensions by the sender.

Consequences:- (a)

- Inappropriate selection of the trailer, rendering it unsuitable for the actual dimensions of the cargo.

- (b)

- Increased difficulty in maneuvering the load during transportation.

- (c)

- Necessity for re-evaluation of critical points, objects, or locations along the route.

- 2.

- Potential accidents involving vehicles transporting oversized loadsCauses:

- (a)

- Reckless driving by a driver traveling immediately ahead of the vehicle carrying the oversized load. “Reckless driving” refers to a behavior that contradicts safe driving practices, exhibiting disregard for road safety.

- (b)

- Excessive speed, increasing the likelihood of losing control over the vehicle and creating hazardous conditions.

- (c)

- Non-compliance with traffic regulations, such as yielding right of way or adhering to instructions provided by pilot vehicles directing traffic at intersections during the transport of oversized cargo.

- (d)

- Failure to maintain a safe minimum distance between vehicles traveling in the same direction. In emergency situations requiring quick reflexes and sudden braking, this failure eliminates the driver’s ability to respond effectively.

- (e)

- Adverse weather conditions, reducing traction and impairing visibility, which may include obscured roads or other road users.

Consequences:- (a)

- Forced delays along the transport route, affecting the final delivery timeline of the cargo.

- (b)

- Necessity to change the planned route if the primary road becomes impassable for an extended period.

- (c)

- Requirement to maneuver the load strategically to create an emergency corridor (“life corridor”) for emergency vehicles.

- Potential Accident in Front of a Vehicle Transporting Oversized Cargo: Due to the nature of this risk and the presence of external factors such as road conditions and the behavior of other road users, its complete elimination is challenging. To minimize the consequences of such an event, the following solutions are proposed:

- Establishment of Alternative Routes: Defining a sufficient number of alternative routes allows for a quick response in the event of temporary impassability of the primary route. This enables the driver to independently adjust the route, avoiding delays and minimizing disruptions to road traffic [49,50].

- Implementation of a Collision Detection System: This system would integrate GPS data, satellite maps, and real-time road condition information. Its primary functions include: Continuous monitoring of the planned route; risk analysis for potential accidents based on historical data; automatic alerts in case of incidents occurring along the route; providing estimated delays and recommendations for rerouting or stopping at a safe location [51,52].

Adopting such solutions would enhance transport safety and mitigate the impact of unforeseen events on the execution of logistical asks. - Discrepancies in Cargo Dimensions: to prevent situations where the actual dimensions of the cargo differ from those specified in the transport order, the following measures are suggested:

- Detailed Verification of Transport Offers: Requiring the shipper to provide photos illustrating the cargo and its actual dimensions. Repeated discrepancies from the same contractor should lead to the termination of collaboration [51].

- Introduction of a Pre-Selection Measurement System: This system, based on advanced sensors placed at various points on the loading platform, would enable automatic scanning and comparison of the cargo dimensions with those specified in the transport order. In cases of discrepancies, the system would generate an alert, helping to avoid problems related to dimensional inconsistencies [52].

The proposed solutions aim to minimize critical risks identified in the process of transporting oversized cargo. Implementing these technologies and strategies will not only improve safety but also enhance operational efficiency by reducing potential delays and costs associated with logistical risks.

5. Conclusions

- –

- Two risks, located in the red area: potential accidents involving vehicles transporting oversized loads and discrepancies between the actual dimensions of the cargo and the transport documentation.

- –

- Five risks were classified as tolerable (yellow area), requiring preventive actions to mitigate their potential impacts.

- –

- The remaining eight risks were deemed acceptable (green area), characterized by low probability and minimal consequences; however, continued monitoring and preventive strategies are advisable.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tagiltseva, J.; Vasilenko, M.; Kuzina, E.; Drozdov, N.; Parkhomenko, R.; Prokopchuk, V.; Skichko, E.; Bagiryan, V. The economic efficiency justification of multimodal container transportation. Transp. Res. Procedia 2022, 63, 264–270. [Google Scholar] [CrossRef]

- Saidi, S.; Mani, V.; Mefteh, H.; Shahbaz, M.; Akhtar, P. Dynamic linkages between transport, logistics, foreign direct Investment, and economic growth: Empirical evidence from developing countries. Transp. Res. Part A Policy Pract. 2020, 141, 277–293. [Google Scholar] [CrossRef]

- Akbulaev, N.; Bayramli, G. Maritime transport and economic growth: Interconnection and influence (an example of the countriesin the Caspian sea coast; Russia, Azerbaijan, Turkmenistan, Kazakhstan and Iran). Mar. Policy 2020, 118, 104005. [Google Scholar] [CrossRef]

- Mooren, L.; Grzebieta, R.; Williamson, A.; Olivier, J.; Friswell, R. Safety management for heavy vehicle transport: A review of the literature. Saf. Sci. 2014, 62, 79–89. [Google Scholar] [CrossRef]

- Gnap, J.; Jagelčák, J.; Marienka, P.; Frančák, M.; Vojteková, M. Global Assessment of Bridge Passage in Relation to Oversized and Excessive Transport: Case Study Intended for Slovakia. Appl. Sci. 2022, 12, 1931. [Google Scholar] [CrossRef]

- Szczucka-Lasota, B. City logistics: Influence of oversized road transport on urban development. Sci. J. Silesian Univ. Technol. Ser. Transp. 2017, 97, 157–165. [Google Scholar] [CrossRef]

- Huang, D.; Han, M. An Optimization Route Selection Method of Urban Oversize Cargo Transportation. Appl. Sci. 2021, 11, 2213. [Google Scholar] [CrossRef]

- Petru, J.; Krivda, V. The Transport of Oversized Cargoes from the Perspective of Sustainable Transport Infrastructure in Cities. Sustainability 2021, 13, 5524. [Google Scholar] [CrossRef]

- Bensalah, A.; Barakat, G.; Amara, Y. Electrical Generators for Large Wind Turbine: Trends and Challenges. Energies 2022, 15, 6700. [Google Scholar] [CrossRef]

- Blanco, M.I. The economics of wind energy. Renew. Sustain. Energy Rev. 2009, 13, 1372–1382. [Google Scholar] [CrossRef]

- Strielkowski, W.; Civín, L.; Tarkhanova, E.; Tvaronavičienė, M.; Petrenko, Y. Renewable Energy in the Sustainable Development of Electrical Power Sector: A Review. Energies 2021, 14, 8240. [Google Scholar] [CrossRef]

- Jin, X.; Zhang, Z.; Shi, X.; Ju, W. A review on wind power industry and corresponding insurance market in China: Current status and challenges. Renew. Sustain. Energy Rev. 2014, 38, 1069–1082. [Google Scholar] [CrossRef]

- Sadiqa, A.; Gulagi, A.; Bogdanov, D.; Caldera, U.; Breyer, C. Renewable energy in Pakistan: Paving the way towards a fully renewables-based energy system across the power, heat, transport and desalination sectors by 2050. IET Renew. Power Gener. 2021, 16, 177–197. [Google Scholar] [CrossRef]

- Zaik, K.; Werle, S. Solar and wind energy in Poland as power sources for electrolysis process—A review of studies and experimental methodology. Int. J. Hydrogen Energy 2022, 48, 11628–11639. [Google Scholar] [CrossRef]

- Chomać-Pierzecka, E.; Gąsiński, H.; Rogozińska-Mitrut, J.; Soboń, D.; Zupok, S. Review of Selected Aspects of Wind Energy Market Development in Poland and Lithuania in the Face of Current Challenges. Energies 2023, 16, 473. [Google Scholar] [CrossRef]

- Brelik, A.; Nowaczyk, P.; Cheba, K. The Economic Importance of Offshore Wind Energy Development in Poland. Energies 2023, 16, 7766. [Google Scholar] [CrossRef]

- Olczak, P.; Surma, T. Energy Productivity Potential of Offshore Wind in Poland and Cooperation with Onshore Wind Farm. Appl. Sci. 2023, 13, 4258. [Google Scholar] [CrossRef]

- Robak, S.; Raczkowski, R.; Piekarz, M. Development of the Wind Generation Sector and Its Effect on the Grid Operation—The Case of Poland. Energies 2023, 16, 6805. [Google Scholar] [CrossRef]

- Ligęza, K.; Łaciak, M.; Ligęza, B. Centralized Offshore Hydrogen Production from Wind Farms in the Baltic Sea Area—A Study Case for Poland. Energies 2023, 16, 6301. [Google Scholar] [CrossRef]

- Wiśnicki, B.; Galor, A.; Kujawski, A.; Breitsprecher, M. Poprawa efektywności transportu nienormatywnego obsługującego farmy wiatrowe w Polsce. Logistyka 2010. [Google Scholar]

- Bollapragada, S. Practice Summary: General Electric Company Optimizes Wind Turbine Towers Sourcing and Logistics Operations. INFORMS J. Appl. Anal. 2024, 54, 264–266. [Google Scholar] [CrossRef]

- Barter, G.E.; Sethuraman, L.; Bortolotti, P.; Keller, J.; Torrey, D.A. Beyond 15 MW: A cost of energy perspective on the next generation of drivetrain technologies for offshore wind turbines. Appl. Energy 2023, 344, 121272. [Google Scholar] [CrossRef]

- Skala, A. Sustainable Transport and Mobility—Oriented Innovative Startups and Business Models. Sustainability 2022, 14, 5519. [Google Scholar] [CrossRef]

- Firoozi, A.A.; Firoozi, A.A.; Hejazi, F. Innovations in Wind Turbine Blade Engineering: Exploring Materials, Sustainability, and Market Dynamics. Sustainability 2024, 16, 8564. [Google Scholar] [CrossRef]

- Dominković, D.F.; Bačeković, I.; Pedersen, A.S.; Krajačić, G. The future of transportation in sustainable energy systems: Opportunities and barriers in a clean energy transition. Renew. Sustain. Energy Rev. 2018, 82, 1823–1838. [Google Scholar] [CrossRef]

- Gan, K.E.; Taikan, O.; Gan, T.Y.; Weis, T.; Yamazaki, D.; Schüttrumpf, H. Enhancing Renewable Energy Systems, Contributing to Sustainable Development Goals of United Nation and Building Resilience Against Climate Change Impacts. Energy Technol. 2023, 11, 2300275. [Google Scholar] [CrossRef]

- Sadorsky, P. Wind energy for sustainable development: Driving factors and future outlook. J. Clean. Prod. 2021, 289, 125779. [Google Scholar] [CrossRef]

- Crainic, T.G. Long-Haul Freight Transportation. In Handbook of Transportation Science; Hall, R.W., Ed.; International Series in Operations Research & Management Science; Springer: Boston, MA, USA, 1999; Volume 23. [Google Scholar] [CrossRef]

- Acocella, A.; Caplice, C. Research on truckload transportation procurement: A review, framework, and future research agenda. J. Bus. Logist. 2023, 44, 228–256. [Google Scholar] [CrossRef]

- Semenov, I.; Kaup, M. Risk management of oversize cargo transport. WUT J. Transp. Eng. 2020, 129, 63–71. [Google Scholar] [CrossRef]

- Kwasiborska, A.; Kądzioła, K. Application of causal analysis of disruptions and the functional resonance analysis method (fram) in analyzing the risk of the baggage process. Sci. J. Silesian Univ. Technol. Ser. Transp. 2023, 119, 63–81. [Google Scholar] [CrossRef]

- Bošnjaković, M.; Katinić, M.; Santa, R.; Marić, D. Wind Turbine Technology Trends. Appl. Sci. 2022, 12, 8653. [Google Scholar] [CrossRef]

- Rezamand, M.; Kordestani, M.; Carriveau, R.; Ting, D.S.-K.; Orchard, M.E.; Saif, M. Critical wind turbine components prognostics: A comprehensive review. IEEE Trans. Instrum. Meas. 2020, 69, 9306–9328. [Google Scholar] [CrossRef]

- Veers, P.; Bottasso, C.L.; Manuel, L.; Naughton, J.; Pao, L.; Paquette, J.; Robertson, A.; Robinson, M.; Ananthan, S.; Barlas, T.; et al. Grand challenges in the design, manufacture, and operation of future wind turbine systems. Wind. Energy Sci. 2023, 8, 1071–1131. [Google Scholar] [CrossRef]

- Skibko, Z.; Hołdyński, G.; Borusiewicz, A. Impact of Wind Power Plant Operation on Voltage Quality Parameters—Example from Poland. Energies 2022, 15, 5573. [Google Scholar] [CrossRef]

- Sitarz, M.; Chruzik, K.; Wachnik, R. Application of RAMS and FMEA methods in safety management system of railway transport. J. KONBiN 2012, 24, 149–160. [Google Scholar] [CrossRef][Green Version]

- Popkowski, T. Transport Ładunków Niebezpiecznych i Ponadwymiarowych; Biblioteka Międzynarodowej Wyższej Szkoły Logistyki i Transportu we Wrocławiu, Oficyna Wydawnicza Atut: Wrocław, Poland, 2021. [Google Scholar]

- Galor, W. Carriage and Securing of Oversize Cargo in Transport, Maritime Experts Association; Maritime University of Szczecin: Szczecin, Poland, 2011. [Google Scholar]

- Juściński, S. Logistyka Transportu Ładunków Nienormatywnych (Ang. Logistics of an Abnormal Load Transport); Towarzystwo Wydawnictw Naukowych LIBROPOLIS: Lublin, Poland, 2016. [Google Scholar]

- Betkier, I. Analysis of the Routing Stage for an Oversize Vehicle in Poland from the Traffic Safety Viewpoint. In Proceedings of the Education Excellence and Innovation Management: A 2025 Vision to Sustain Economic Development During Global Challenges, Seville, Spain, 1–2 April 2020; pp. 545–558. [Google Scholar]

- Lasota, M.; Jacyna, M.; Wasiak, M.; Zabielska, A. The Use of Multi-Criteria Methods in the Problem of Selecting Vehicles for Oversize Cargo Transport. In Challenges and Solutions for Present Transport Systems. TSTP 2022; Sierpiński, G., Masoumi, H., Macioszek, E., Eds.; Lecture Notes in Networks and Systems; Springer: Cham, Switzerland, 2023; Volume 609. [Google Scholar] [CrossRef]

- Chkalova, O.; Kirushin, S.; Bolshakova, I.; Kopasovskaya, N.; Korenkova, M. Improving the oversized cargo movement management in trade. World Rev. Intermodal Transp. Res. 2022, 11, 108–132. [Google Scholar] [CrossRef]

- Liu, P.; Wu, Y.; Li, Y.; Wu, X. An improved FMEA method based on the expert trust network for maritime transportation risk management. Expert Syst. Appl. 2023, 238, 121705. [Google Scholar] [CrossRef]

- Huang, W.; Li, Y.; Kou, X.; Wang, W.; Xu, Y. Using a FMEA–TIFIAD Approach to Identify the Risk of Railway Dangerous Goods Transportation System. Group Decis. Negot. 2020, 30, 63–95. [Google Scholar] [CrossRef]

- Kudláč, Š.; Štefancová, V.; Majerčák, J. Using the Saaty Method and the FMEA Method for Evaluation of Constraints in Logistics Chain. Procedia Eng. 2017, 187, 749–755. [Google Scholar] [CrossRef]

- Boufaied, A.; Thabet, R.; Korbaa, O. Dynamic delay risk assessing using cost-based FMEA for transportation systems. In Proceedings of the 2016 IEEE International Conference on Systems, Man, and Cybernetics (SMC), Budapest, Hungary, 9–12 October 2016; pp. 001057–001062. [Google Scholar] [CrossRef]

- Arabian-Hoseynabadia, H.; Oraeea, H.; Tavner, P.J. Failure Modes and Effects Analysis (FMEA) for wind turbines. Int. J. Electr. Power Energy Syst. 2010, 32, 817–824. [Google Scholar] [CrossRef]

- Szkoda, M.; Satora, M. The application of failure mode and effects analysis (FMEA) for the risk assessment of changes in the maintenance system of railway vehicles. Tech. Trans. 2019, 8, 159–172. [Google Scholar] [CrossRef]

- Akram, M.; Zahid, K.; Kahraman, C. Integrated outranking techniques based on spherical fuzzy information for the digitalization of transportation system. Appl. Soft Comput. 2023, 134, 109992. [Google Scholar] [CrossRef]

- Martínez-Maldonado, V.; Barragán-Escandón, A.; Serrano-Guerrero, X.; Zalamea-Leon, E.F. Optimal routing for mass transit systems using multicriteria methodologies. Energy Strat. Rev. 2023, 47, 101077. [Google Scholar] [CrossRef]

- Adewopo, V.A.; Elsayed, N.; ElSayed, Z.; Ozer, M.; Abdelgawad, A.; Bayoumi, M. A review on action recognition for accident detection in smart city transportation systems. J. Electr. Syst. Inf. Technol. 2023, 10, 57. [Google Scholar] [CrossRef]

- Oladimeji, D.; Gupta, K.; Kose, N.A.; Gundogan, K.; Ge, L.; Liang, F. Smart Transportation: An Overview of Technologies and Applications. Sensors 2023, 23, 3880. [Google Scholar] [CrossRef]

| Risk R | Risk Acceptability | Risk Class |

|---|---|---|

| R ≤ 80 | Acceptable | 1 (green color/area) |

| 80 < R ≤ 110 | Tolerable (permissible) | 3 (yellow color/area) |

| R > 110 | Unacceptable | 4 (red color)/area |

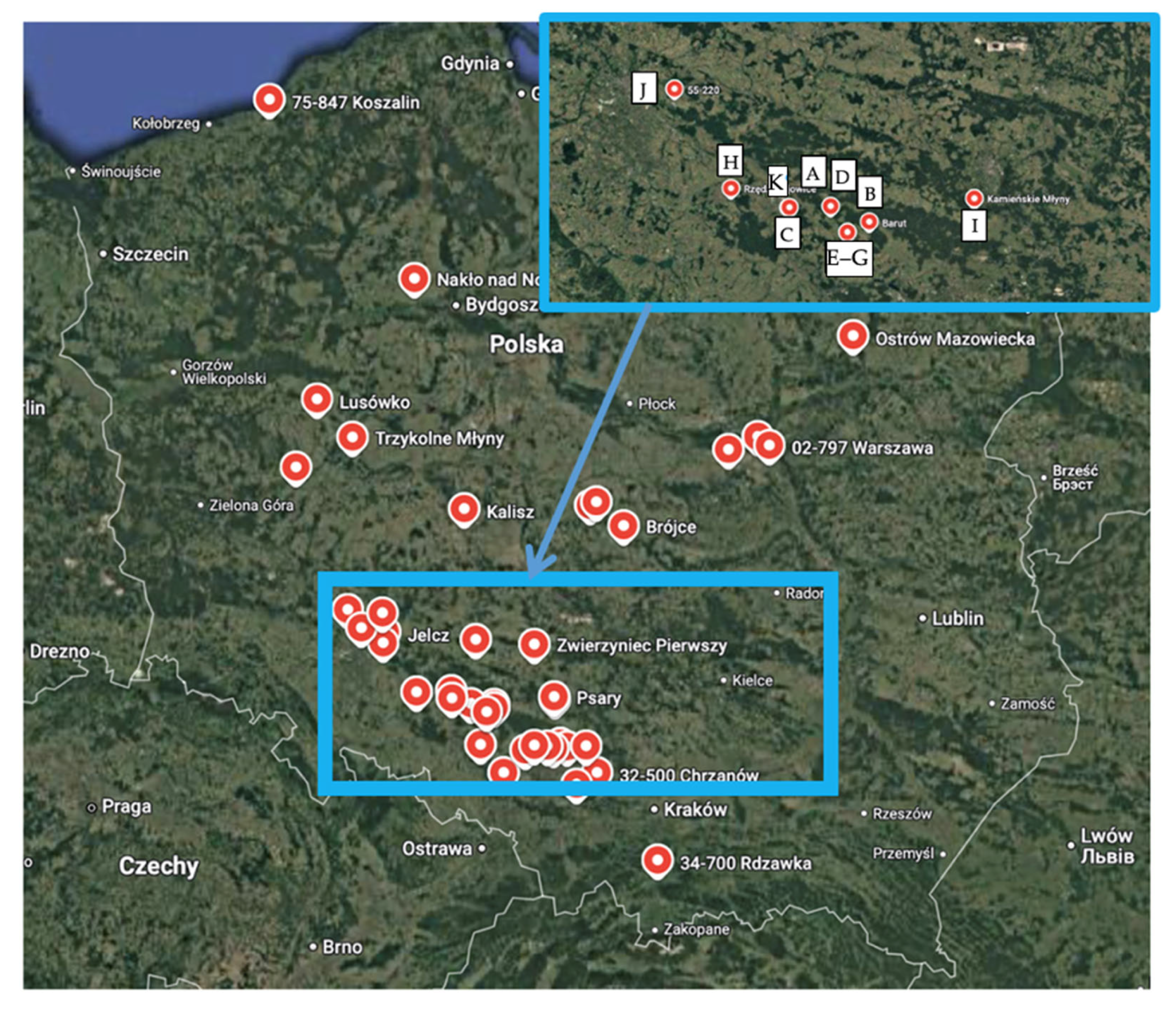

| Company | Location | Fleet Size | Specialization | Number of Drivers |

|---|---|---|---|---|

| A | Opole | 44 | Transport of industrial machinery and equipment, steel constructions, agricultural machinery, construction elements, wind power plant components | 49 |

| B | Strzelce Opolskie | 40 | Transport of machinery and steel structures, wind power plant components | 44 |

| C | Dolna | 44 | Transport of steel structures, wind power plant structures | 47 |

| D | Opole | 69 | Transport of wind power plants, relocation of machinery, production lines | 74 |

| E | Strzelce Opolskie | 10 | Transport of steel structures and wind power plants | 13 |

| F | Strzelce Opolskie | 25 | Transport of wind turbines, with concentrated mass of long loads | 31 |

| G | Strzelce Opolskie | 71 | Transport of wind power plants, long loads | 75 |

| H | Psary | 26 | Transport of long loads, transport of silos and wind turbines | 25 |

| I | Piotrówka | 35 | Transport of heavy machinery, steel structures and wind power plant components | 37 |

| J | Jelcz Laskowice | 7 | Agricultural machinery, steel structures, heavy construction equipment and wind turbine components | 11 |

| K | Niemodlin | 44 | Transport of reactors, transformers, transport of heavy loads | 43 |

| No. | Entity Responsible for the Defect | Potential Type of Defect | Potential Effect of the Defect | Potential Causes | P | I | D | R | Corrective Action |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Other road users | Potential accident in front of a vehicle transporting an oversize load. | Forced stoppages along the transit route. End-to-end rerouting. Need to manoeuvre cargo in certain directions to create a corridor of life. | Bravado driving by a driver who is immediately in front of a driver carrying an abnormal load. Excessive speed with the possibility of losing control of the vehicle. Failure to comply with the rules of the road regarding, for example, giving way. Negative weather conditions. | 3.5 | 6.6 | 6 | 138.6 | Provision of a sufficient number of alternative routes, whereby it is possible to bypass a route that is temporarily impassable route. |

| 2 | Independent factors | Unexpected tire shot while driving. | Loss of control of the vehicle. Risk of the lorry and semi-trailer tipping over. Loss of load stability. Need to call the road safety services to secure the scene. Material damage to the transport company. | Mechanical damage to the tire. Carrying a load on a vehicle with under-inflated tires. Lack of systematic observation of tire wear. Overheating of the tire through prolonged driving at high speed. | 3.3 | 3.4 | 4.8 | 53.9 | Introduction of a permanent tire check each time before the vehicle leaves the loading bay. |

| 3 | Road administrator responsible for the road/State administrator/ Customs authority /GDDKiA | The lengthy process of obtaining a permit for oversize goods. | Increasing total costs of providing a transport service. Reducing the efficiency of the company’s transport services. Staff dissatisfaction. Insufficient time to plan the route accurately | Complex regulations governing the transport of oversized goods. Lack of complete and correctly completed documents. Overloading of authorities. Clerks’ slowness as regards the time taken to process an application. | 6 | 5.7 | 2.7 | 92.3 | The introduction of uniform rules for the issuing of transit permits in all EU countries and shortening the maximum time for issuing permits to a few days. |

| 4 | Hired pilot | Late arrival at the loading bay of a pilot hired for a specific order. | Departure from the loading site late. Forced reduction in driver’s working hours during night time. The need to change cargo stopping plans. Longer closure of road and motorway sections. | Possibility of incorrectly locating the loading place. Incorrectly described loading place. Communication problems between forwarder/carrier and external company. | 4.5 | 5.1 | 3.1 | 71.1 | Introducing contractual penalties for companies responsible for pilotage for causing transport delay. |

| 5 | Local road administration/ operator of the road in question | Unforeseen road closures that occur after the journey has already started and which prevent the load from being transported along the previously planned route. | Need to change initial route to an alternative route. Unplanned vehicle downtime. Cargo entrapment if an alternative route cannot be found. | Necessary repairs to be carried out. Collision or road accident. Damage to the road surface. | 3.3 | 5.6 | 4.5 | 83.2 | Provision of a sufficient number of alternative routes, whereby it is possible to bypass a route that is temporarily impassable route. |

| 6 | Independent factors | Need to change or modify route due to inconvenient roundabout. | The need to negotiate a section of the route including a roundabout against traffic or in a straight line. Delays in the delivery of freight on time. | Incorrectly estimated dimensions of the load and the turning radius of the entire fleet. Insufficient experience of the driver in efficient manipulation of the load during turns. Inappropriately matched type of semi-trailer to the dimensions and load capacity of the goods. | 3.7 | 4.6 | 3.5 | 59.6 | Incomplete demolition of the roundabout to such an extent that it would be possible to drive through it without the need for complete demolition. |

| 7 | Highway manager | Narrow entry/exit to/from the motorway/s making it difficult to maneuver the vehicle freely. | High probability of damage to cargo or property. Blocking the entrance/exit to/from the motorway/s in relation to other road users. Slowing down traffic. Need to perform a reversing maneuver. | Incorrectly estimated dimensions of the load and the turning radius of the entire fleet. Insufficient experience of the driver in efficient manipulation of the load during turns. Inappropriately matched type of semi-trailer to the dimensions and load capacity of the goods. | 3.7 | 4.4 | 3.7 | 60.2 | Introduction of appropriate legal regulations regarding the design of road infrastructure, taking into account the possibility of oversized transport. |

| 8 | Independent factors | Infrastructure elements not shown on maps. | The need to change or modify the route. Potential violations of regulations by drivers. Reconstruction of some elements of road infrastructure. | Lack of accuracy and precision in the presentation of individual objects on maps. Lack of road map updates. Overlooking details on the map by the planner/freight forwarder. Introduction of changes to a given route after the travel planning phase. | 4.1 | 4.9 | 4.5 | 90.4 | Designing and implementing maps of specific countries and cities containing sensitive locations from the point of view of oversized transport. |

| 9 | Cargo shipper | The transported load actually turns out to be longer/wider/higher than specified in the order. | Incorrectly selected trailer in relation to the actual dimensions of the transported goods. Greater difficulties in maneuvering the load. The need to re-analyze critical points throughout the entire route. | Error in measurement or assessment of load. | 6.1 | 6.5 | 3.4 | 134.8 | More detailed verification of a potential order and a request to include a photo illustrating the actual dimensions of the load. |

| 10 | Local road administration/road operator | The turning radii on roads under reconstruction in the event of repairs are improperly profiled, making it difficult for cargo to pass through. | Incorrectly estimated transport date in relation to the time of roadworks. Error in route planning by the forwarder. Inadequate execution of procedures accompanying the acceptance of a transport order for execution. | Damage to road infrastructure (including road surface, road signs, curbs—if any). Damage to an oversized vehicle (tractor and/or semi-trailer). Damage to the load on the semi-trailer. Damage to the tires of the semi-trailer combination. | 4.2 | 4.6 | 3.8 | 73.4 | It is not possible to propose modifications due to the specific nature of the difficulty. |

| 11 | Driver | Driver accidentally catching the load on an element of road infrastructure during transport (e.g., a roadside tree). | Potential damage to the tractor and/or semi-trailer along with the goods on it. Financial losses for the transport company due to the damaged goods. Potential image losses for the transport company. Legal consequences for the driver in the form of a ticket, penalty points or civil liability. | Driver error while maneuvering the vehicle. Lack of proper communication with the pilot warning about critical points of road infrastructure. Failure to take into account the height or width of the vehicle in the context of the exact dimensions of the vehicle. | 4.4 | 4.7 | 5 | 103.4 | More detailed analysis of the route of the transported load and in-depth analysis of the potential driver’s experience. |

| 12 | Driver | The driver who has been assigned a specific transport order is under the influence of alcohol before leaving the loading site. | Exposure of the transport company to additional costs related to the delay in departure from the loading site. Legal consequences in the form of a fine, penalty points, withdrawal of the driver’s license or suspension of the given driver from the duties entrusted to him. Image losses for the company. The need to find a replacement driver. | Uncontrolled alcohol consumption by the driver on the day before departure. Lack of sense of responsibility and awareness of the risks associated with driving while intoxicated. | 2.9 | 6.5 | 4.1 | 77.3 | More frequent sobriety checks by relevant services (e.g., Road Transport Inspection) under the influence of alcohol before leaving the loading site taking place just before the driver leaves the loading site. |

| 13 | Carrier/Shipper/Shipper/Freight forwarder | Transport with improperly secured cargo contributing to a potential accident. | Potential risk of a road accident. Possible damage/destruction of goods due to improper transportation. Image losses for the company. Load slipping off the trailer. Vehicle tilting due to incorrect distribution of the weight of the goods. | Lack of proper supervision of the person responsible for loading the goods. Lack of awareness of the proper rules for securing the load on the vehicle. Incorrect distribution of the load on the vehicle. Inappropriate materials or techniques for securing the load. | 3.6 | 5.9 | 4 | 85.0 | Preparation, introduction and exertion of pressure in the context of enforcing the rules of safe cargo securing. |

| 14 | Local road administration/road operator | A detour from the regular route resulting in failure to deliver the load on time. | Delay in delivery of goods to the destination. Additional travel time and costs related to organizing a detour. In some cases, it is not possible to transport the cargo via an alternative route/detour. | Road accident. Road works, road repairs or modernization. Traffic jams between 6:00 and 9:00 and 15:00 and 17:00. Unfavorable road conditions. | 3.6 | 5.2 | 4 | 74.9 | It is not possible to propose modifications due to the specific nature of the difficulty. |

| 15 | Independent factors | A roundabout arc that does not allow for a traditional bypass and requires driving against the flow of traffic (or having to rebuild it). | Extending the time, it takes to overcome the obstacle in the form of a roundabout. The necessity to block the fluidity and capacity of the roundabout for the time of travel. Causing traffic congestion in the area of access roads to the roundabout. | Lack of appropriate detour routes. Incorrectly calculated dimensions of the vehicle with the trailer and turning radii. Incorrect assessment of the size of the roundabout. Obstacles impossible to remove during transport. | 4 | 4.7 | 3.7 | 69.6 | It is not possible to propose modifications due to the specific nature of the difficulty. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Masłowski, D.; Dendera-Gruszka, M.; Giera, J.; Kulińska, E.; Olejnik, K.; Szumidłowska, J. Risks and Challenges of Oversized Transport in the Energy Industry. Energies 2024, 17, 6444. https://doi.org/10.3390/en17246444

Masłowski D, Dendera-Gruszka M, Giera J, Kulińska E, Olejnik K, Szumidłowska J. Risks and Challenges of Oversized Transport in the Energy Industry. Energies. 2024; 17(24):6444. https://doi.org/10.3390/en17246444

Chicago/Turabian StyleMasłowski, Dariusz, Małgorzata Dendera-Gruszka, Julia Giera, Ewa Kulińska, Krzysztof Olejnik, and Justyna Szumidłowska. 2024. "Risks and Challenges of Oversized Transport in the Energy Industry" Energies 17, no. 24: 6444. https://doi.org/10.3390/en17246444

APA StyleMasłowski, D., Dendera-Gruszka, M., Giera, J., Kulińska, E., Olejnik, K., & Szumidłowska, J. (2024). Risks and Challenges of Oversized Transport in the Energy Industry. Energies, 17(24), 6444. https://doi.org/10.3390/en17246444