Drying Kinetics of Leucaena esculenta Seeds Using a Solar Dryer

Abstract

1. Introduction

2. Materials and Methods

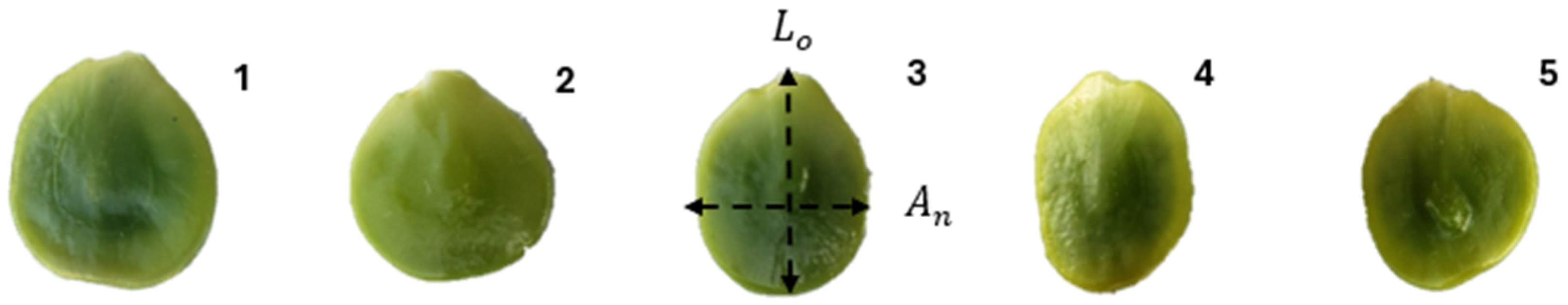

2.1. Leucaena esculenta

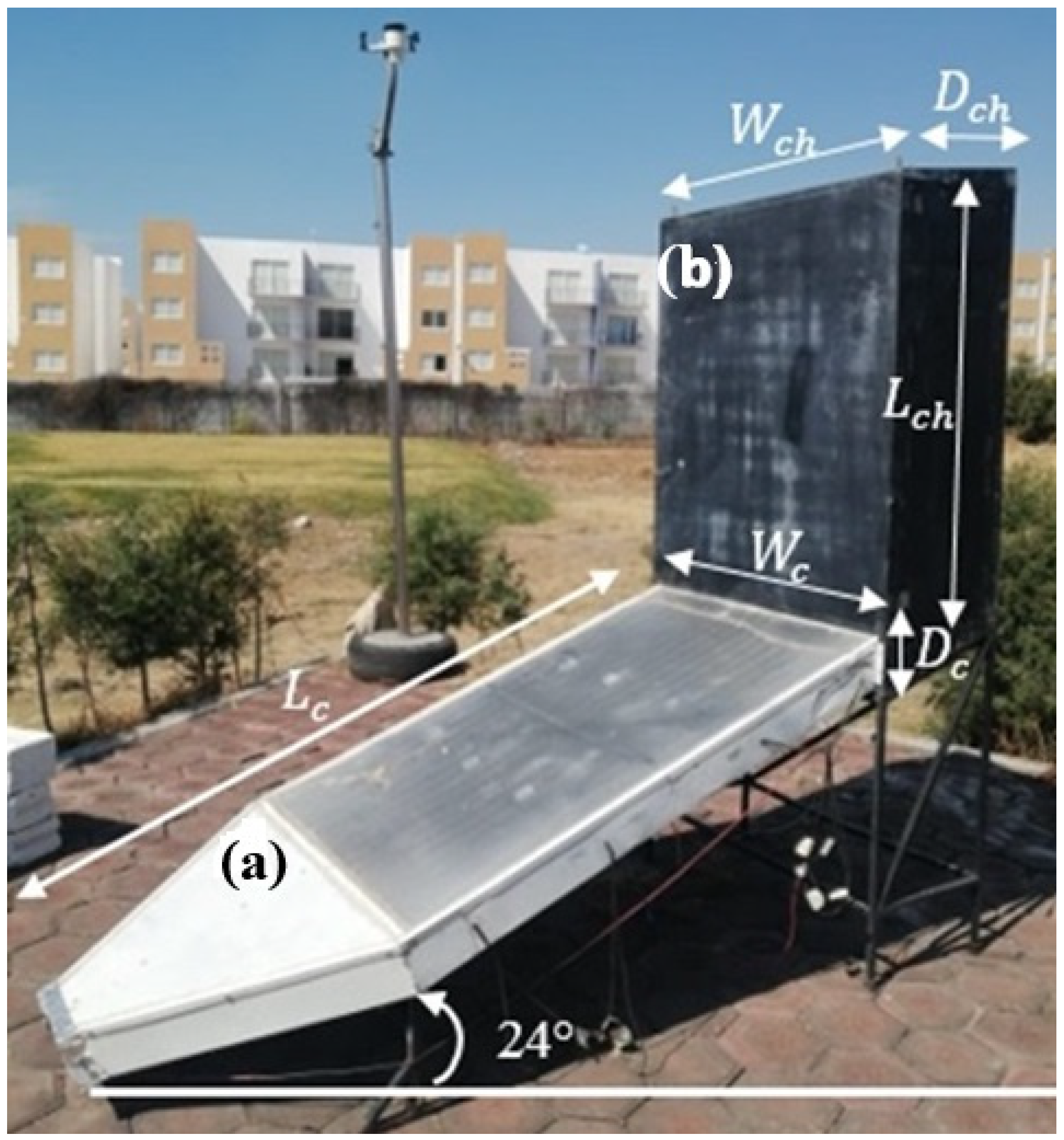

2.2. Experimental Model

2.3. Drying Kinetics

3. Results

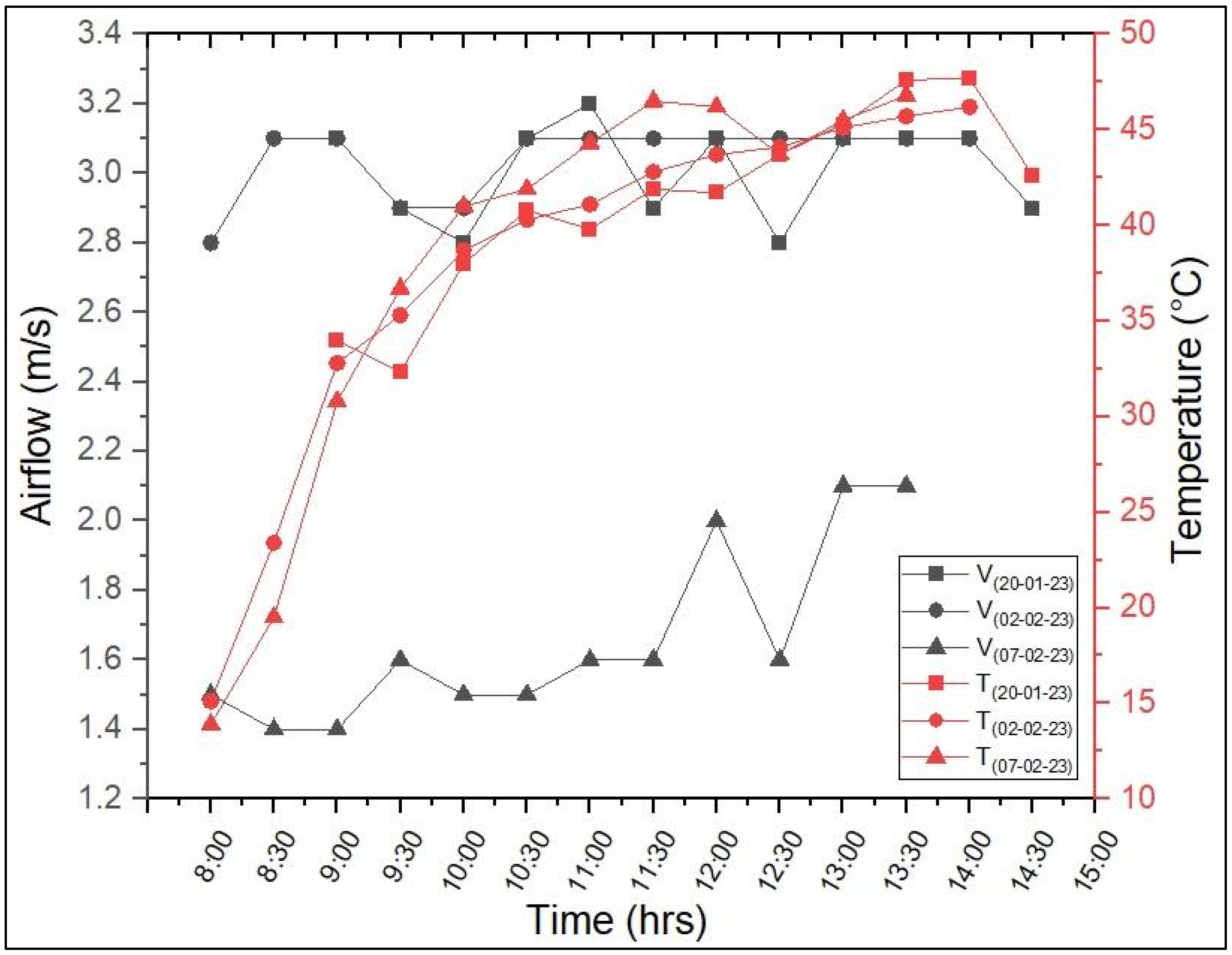

3.1. Weather Conditions

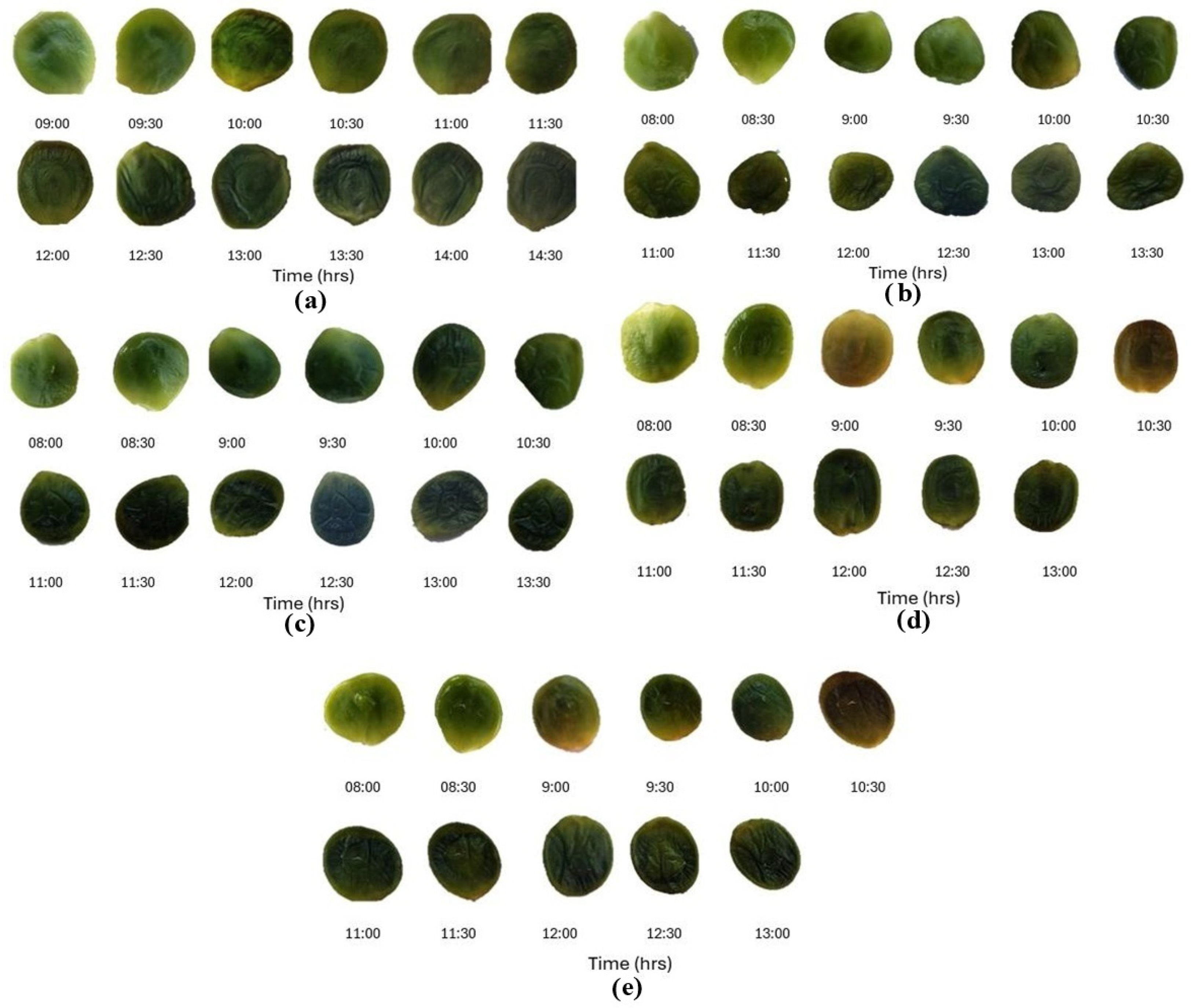

3.2. Characteristics of Leucaena esculenta

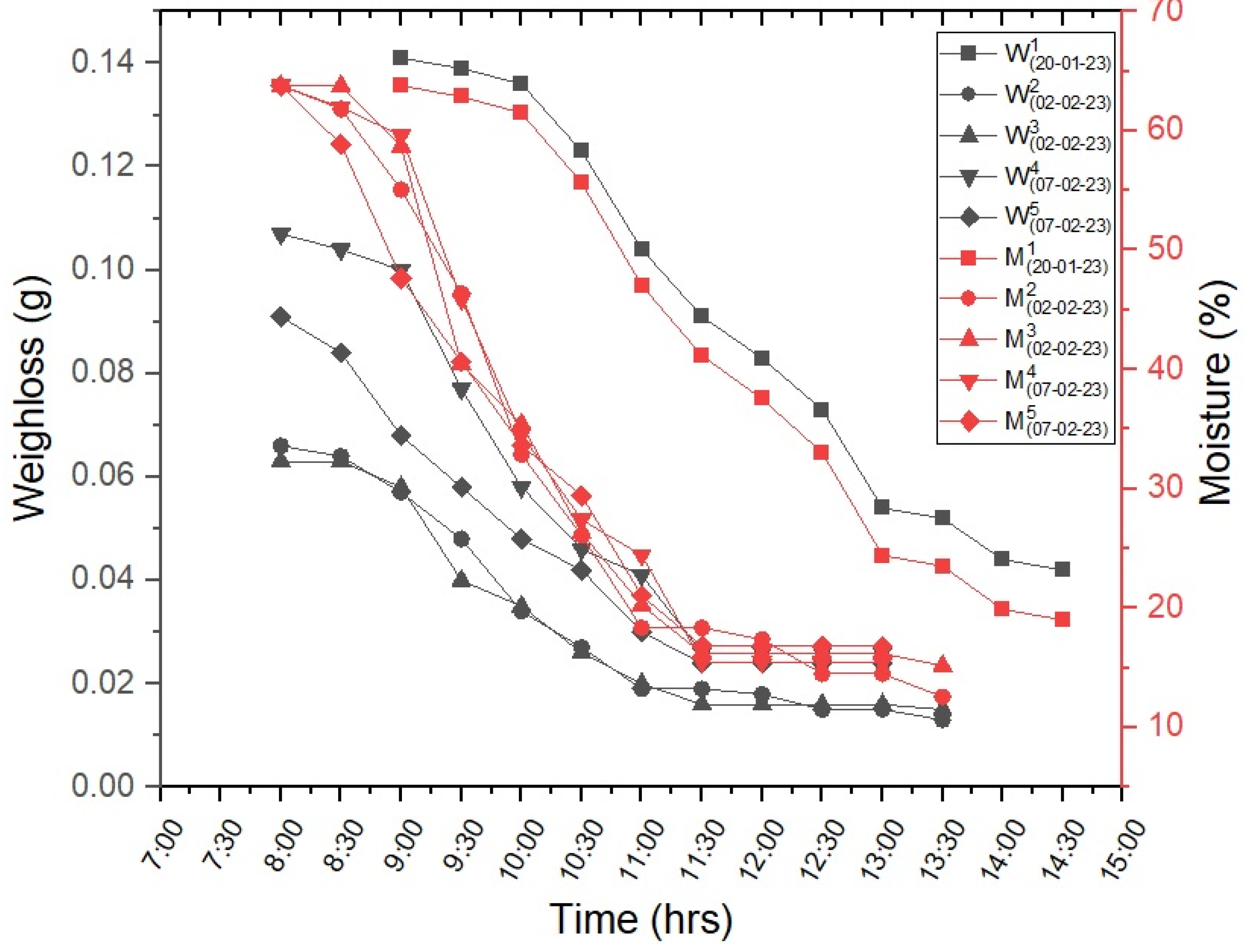

3.3. Calculation of Weight and Moisture Loss

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- García-Maceda, G.; Hernández-Montes, A.; Ybarra-Moncada, M.C.; Casañas-Pimentel, R.C. Perception and meanings of the red guaje Leucaena esculenta (DC.) Benth. in the Ngiwa culture from Puebla, México. Polibotánica 2023, 56, 287–309. [Google Scholar] [CrossRef]

- Román-Miranda, M.L.; Palma-García, J.M.; Zorrilla-Rios, J.M.; Mora-Santacruz, A. Producción de materia seca de Leucaena leucocephala y vegetación herbácea en un banco de proteína pastoreada por ovinos. Rev. Sist. Exp. 2016, 3, 42–50. [Google Scholar]

- Román-Cortés, N.; García-Mateos, M.R.; Castillo-González, A.M.; Sahagún-Castellanos, J.; Jiménez-Arellanes, A. Componentes nutricionales y antioxidantes de dos especies de guaje (Leucaena spp.): Un recurso ancestral subutilizado. Rev. Chapingo Ser. Hortic. 2014, 20, 157–170. [Google Scholar] [CrossRef]

- Zarate, S. Ethnobotany and domestication process of Leucaena in Mexico. J. Ethnobiol. 1999, 19, 1–23. [Google Scholar]

- Poonam, S.; Pushpa, R.K. Leucaena leucocephala a nutrition profile. Food Nutr. Bull. 1995, 16, 1–16. [Google Scholar] [CrossRef]

- Chandra Pandey, V.; Kumar, A. Leucaena leucocephala: An underutilized plant for pulp and paper production. Genet. Resour. Crop Evol. 2013, 60, 1165–1171. [Google Scholar] [CrossRef]

- Peralta-Juárez, I.; Gómez-Campos, A.; Romero-Castillo, P.A.; Reyes-Dorantes, A. Anthropocentric use of the guaje Leucaena esculenta (moc. & sessé ex. dc.) benth, in two communities in the mixteca baja region of Oaxaca, Mexico. Polibotánica 2017, 107, 199–204. [Google Scholar] [CrossRef]

- Benítez-Bahena, Y.; Bernal-Hernández, A.; Cortés-Díaz, E.; Vera Castillo, G.; Carrillo Anzures, F. Orage production of guaje (Leucaena spp.) associated with grass (Brachiaria brizantha) TO SHEEP GRAZING. Rev. Mex. Cienc. Agrícolas 2010, 1, 397–411. [Google Scholar]

- Atawodi, S.E.; Mari, D.; Atawodi, J.C.; Yahaya, Y. Assessment of Leucaena leucocephala leaves as feed supplement in laying hens. Afr. J. Biotechnol. 2008, 7, 317–321. [Google Scholar]

- Shafiur Rahman, M. Handbook of Food Preservation, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2020; pp. 10–11. [Google Scholar]

- Yared, A.D.; Rewla, E.A.; Hailemariam, M.W.; Muluken, Z.G. Advancements in solar greenhouse dryers for crop drying. Energy Rep. 2024, 11, 5046–5058. [Google Scholar] [CrossRef]

- Al-Hamdani, A.; Jayasuriya, H.; Pathare, P.B.; Al-Attabi, Z. Drying Characteristics and Quality Analysis of Medicinal Herbs Dried by an Indirect Solar Dryer. Foods 2022, 11, 4103. [Google Scholar] [CrossRef] [PubMed]

- Muciaccia, P.F.; Nigro, A.; Aquilanti, A.; Tomassetti, S.; Muccioli, M.; Di Nicola, G. A Preliminary Experimental and Numerical Analysis of a Novel Solar Dryer. Energies 2024, 17, 6059. [Google Scholar] [CrossRef]

- Rana, M.S.; Rahman, A.N.M.A.; Ahmed, R.; Hossain, M.P.; Shadman, M.S.; Majumdar, P.K.; Islam, K.S.; Colton, J. Design, Fabrication, and Performance Evaluation of a Food Solar Dryer. AgriEngineering 2024, 6, 4506–4523. [Google Scholar] [CrossRef]

- Woranuch, J. Meat products drying with a compacts solar cabinet dryer. Energy Procedia 2017, 138, 1048–1054. [Google Scholar] [CrossRef]

- Rizal, T.A.; Muhammad, Z. Fabrication and testing of hybrid solar-biomass dryer for drying fish. Case Stud. Therm. Eng. 2018, 12, 489–496. [Google Scholar] [CrossRef]

- Deef, M.; Helal, H.S.; El-Sebaee, I.; Nadimi, M.; Paliwal, J.; Ibrahim, A. Harnessing Solar Energy: A Novel Hybrid Solar Dryer for Efficient Fish Waste Processing. AgriEngineering 2023, 5, 2439–2457. [Google Scholar] [CrossRef]

- Mawire, M.; Ramokali, M.; Mothupi, M.; Vanierschot, M. An experimental evaluation of drying banana slices using a novel indirect solar dryer under variable conditions. Heliyon 2024, 10, e28268. [Google Scholar] [CrossRef]

- John Mongi, R. Physicochemical properties, microbial loads and shelf life prediction of solar dried mango (Mangifera indica) and pineapple (Ananas comosus) in Tanzania. J. Agric. Food Res. 2023, 11, 100522. [Google Scholar] [CrossRef]

- Ssemwanga, M.; Makule, E.; Kayondo, S. The effect of traditional and improved solar drying methods on the sensory quality and nutritional composition of fruits: A case of mangoes and pineapples. Heliyon 2020, 6, e04163. [Google Scholar] [CrossRef]

- Daliran, A.; Taki, M.; Marzban, A.; Rahnama, M.; Farhadi, R. Experimental evaluation and modeling the mass and temperature of dried mint in greenhouse solar dryer; Application of machine learning method. Case Stud. Therm. Eng. 2023, 47, 103048. [Google Scholar] [CrossRef]

- Sukkanta, S.; Eiamkij, K.; Junset, N.; Mongkoldhumrongkul, K. Oyster mushroom drying efficiency using a solar dryer. Energy Rep. 2023, 9, 479–486. [Google Scholar] [CrossRef]

- Ram, P.M.; Narayan, L.P. Drying kinetics, quality assessment and socio environmental evaluation of solar dried underutilized arid vegetable Cucumis callosus. Energy Nexus 2022, 7, 100128. [Google Scholar] [CrossRef]

- Akter, J.; Hassan, J.; Rahman, M.M.; Biswas, M.S.; Khan, H.I.; Rajib, M.M.R.; Ahmed, M.R.; Khan, M.N.E.A.; Hasan, M.F.A. Colour, nutritional composition and antioxidant properties of dehydrated carrot (Daucus carota var. sativus) using solar drying techniques and pretreatments. Heliyon 2024, 10, e24165. [Google Scholar] [CrossRef] [PubMed]

- Azumah, L.C.; Abu, M.; Ama Kaburi, S.; Padi Lamptey, F. Effect of pre-drying treatments on the quality of solar-dehydrated tomato (Lycopersicon esculentum L.) fruits. Appl. Food Res. 2024, 4, 100422. [Google Scholar] [CrossRef]

- Kaveh, M.; Zomorodi, S.; Mariusz, S.; Dziwulska-Hunek, A. Determination of Drying Characteristics and Physicochemical Properties of Mint (Mentha spicata L.) Leaves Dried in Refractance Window. Foods 2024, 13, 2867. [Google Scholar] [CrossRef]

- Jayasuriya, H.; Pathare, P.B.; Al-Attabi, Z.; Al-Hamdani, A. Drying Kinetics and Quality Analysis of Coriander Leaves Dried in an Indirect, Stand-Alone Solar Dryer. Processes 2023, 11, 1596. [Google Scholar] [CrossRef]

- Doymaz, I. Drying behaviour of green beans. J. Food Eng. 2005, 69, 161–165. [Google Scholar] [CrossRef]

- Tlatelpa-Becerro, A.; Rico-Martínez, R.; Cárdenas-Manríquez, M.; Urquiza, G.; Castro-Gómez, L.L.; Alarcón-Hernández, F.B.; Torres, C.; Montiel, E. Drying kinetics of Cecina from Yecapixtla using a forced flow indirect solar dryer. Rev. Mex. Ing. Química 2022, 21, 2. [Google Scholar] [CrossRef]

- Doymaz, I.; Kipcak, A.S.; Piskin, S. Microwave Drying of Green Bean Slices: Drying Kinetics and Physical Quality. Czech J. Food Sci. 2015, 33, 367–376. [Google Scholar] [CrossRef]

- Koşan, M.; Karaca Dolgun, G.; Aktekeli, B.; Sacilik, K. Design and analysis of new solar-powered sustainable dryers: Alfalfa crop. Food Process Eng. 2022, 46, e14253. [Google Scholar] [CrossRef]

- Resende, O.; Correa, P.C.; Jarén, C.; Moure, A.J. Bean moisture diffusivity and drying kinetics: A comparison of the liquid diffusion model when taking into account and neglecting grain shrinkage. Span. J. Agric. Res. 2007, 5, 51–58. [Google Scholar] [CrossRef]

- Valdes-Barrón, M.; Riveros-Rosas, D.; Arancibia-Bulnes, C.A.; Bonifaz, R. The solar resource assessment in Mexico: State of the art. Energy Procedia 2014, 57, 1299–1308. [Google Scholar] [CrossRef]

- Montoya-Flores, M.D.; Molina-Botero, I.C.; Arango, J.; Romano-Muñoz, J.L.; Solorio-Sánchez, J.S.; Aguilar-Pérez, C.F.; Ku-Vera, J.C. Efect of Dried Leaves of Leucaena leucocephala on Rumen Fermentation, Rumen Microbial Population, and Enteric Methane Production in Crossbred Heifers. Animals 2020, 10, 300. [Google Scholar] [CrossRef] [PubMed]

- Pendyala, V.; Baburao, C.; Chandrasekhar, K.B. Studies on some physicochemical properties of Leucaena leucocephala bark gum. J. Adv. Pharm. Technol. Res. 2010, 1, 253–259. [Google Scholar] [CrossRef]

- Salim, R.; Asik, J.; Sani Sarjadi, M.; Kang Chiang, L. Chemical composition and potential uses of Leucaena leucocephala stem bark. Wood Res. 2023, 68, 241–256. [Google Scholar] [CrossRef]

- Moreira Cavalcati-Mata, M.E.R.; Martins Duarte, M.E.; Vasconcelos Lira, V.; Farias de Oliveira, R.; Lima costa, N.; Lisboa Oliverira, H.M. A new approach to the traditional drying models for the thin-layer drying kinetics of chickpeas. J. Food Process Eng. 2020, 43, e13569. [Google Scholar] [CrossRef]

- Cocco Mariani, V.; Augusto Perussello, C.; Canceller, A.; Jefferson Lopes, T.; Da Silva, A. HotAir Drying Characteristics of Soybeans and Influence of Temperature and Velocity on Kinetic Parameters. J. Food Process Eng. 2014, 37, 619–627. [Google Scholar] [CrossRef]

- Alemán-Ramirez, J.L.; Okoye, P.U.; Torres-Arellano, S.; Mejía-López, M.; Sebastian, P.J. A review on bioenergetic applications of Leucaena leucocephala. Ind. Crops Prod. 2022, 182, 114847. [Google Scholar] [CrossRef]

- Halliday, M.J.; Padmanabha, J.; McSweeney, C.S.; Kerven, G.; Shelton, H.M. Leucaena toxicity: A new perspective on the most widely used forage tree legume. Trop. Grassl.-Forrajes Trop. 2013, 1, 1. [Google Scholar] [CrossRef]

- Aquino-González, L.V.; Noyola-Altamirano, B.; Méndez-Lagunas, L.L.; Rodríguez-Ramírez, J.; Sandoval-Torres, S.; Bernal, L.G.B. Potential of Leucaena leucocephala and Leucaena esculenta Seeds in Human Nutrition: Composition, Techno-functional Properties, Toxicology and Pretreatment Technologies. Legume Res. 2023, 46, 1261–1270. [Google Scholar] [CrossRef]

- Nehdi, I.A.; Sbihi, H.; Tan, C.P.; Al-Resayes, S.I. Leucaena leucocephala (Lam.) de Wit seed oil: Characterization and uses. Ind. Crops Prod. 2014, 52, 582–587. [Google Scholar] [CrossRef]

| Sample | pH | |

|---|---|---|

| Before | After | |

| 1 | 5.56 | 6.34 |

| 2 | 5.56 | 5.98 |

| 3 | 5.27 | 5.97 |

| 4 | 5.31 | 5.82 |

| 5 | 5.26 | 6.07 |

| Thickness | Thickness | Thickness | Thickness | Thickness | |||||

|---|---|---|---|---|---|---|---|---|---|

| 2.8 | 9.906 × 10−8 | 2.8 | 1.230 × 10−7 | 2.4 | 8.252 × 10−8 | 2.4 | 9.268 × 10−8 | 2.1 | 6.256 × 10−8 |

| 8.541 × 10−8 | 8.297 × 10−8 | 7.579 × 10−8 | 7.787 × 10−8 | 5.674 × 10−8 | |||||

| 6.115 × 10−8 | 6.917 × 10−8 | 5.172 × 10−8 | 6.436 × 10−8 | 5.121 × 10−8 | |||||

| 5.572 × 10−8 | 4.015 × 10−8 | 4.140 × 10−8 | 4.650 × 10−8 | 3.631 × 10−8 | |||||

| 5.054 × 10−8 | 2.651 × 10−8 | 3.224 × 10−8 | 4.119 × 10−8 | 3.631 × 10−8 | |||||

| 3.651 × 10−8 | 7.685 × 10−9 | 1.734 × 10−8 | 3.620 × 10−8 | 1.716 × 10−8 | |||||

| 2.843 × 10−8 | 7.685 × 10−9 | 1.734 × 10−8 | 1.303 × 10−8 | 9.078 × 10−9 | |||||

| 1.529 × 10−8 | 7.685 × 10−9 | 7.020 × 10−9 | 5.792 × 10−9 | 3.546 × 10−9 | |||||

| 1.263 × 10−8 | 7.685 × 10−9 | 3.582 × 10−9 | 2.574 × 10−9 | 3.546 × 10−9 | |||||

| 8.086 × 10−9 | 7.685 × 10−9 | 3.582 × 10−9 | 2.574 × 10−9 | 2.270 × 10−9 | |||||

| 8.086 × 10−9 | 2.510 × 10−9 | 3.582 × 10−9 | 2.574 × 10−9 | 2.270 × 10−9 | |||||

| 8.086 × 10−9 | 2.510 × 10−9 | 1.289 × 10−9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tlatelpa Becerro, A.; Rico Martínez, R.; Carbajal Pérez, G.R.; Navarrete Procopio, M.; Zezatti Flores, V.M.; Castañeda Magadan, E.O.; Portillo Contreras, S.; Avilés López, S.I.; López-Vidaña, E.C. Drying Kinetics of Leucaena esculenta Seeds Using a Solar Dryer. Energies 2024, 17, 6364. https://doi.org/10.3390/en17246364

Tlatelpa Becerro A, Rico Martínez R, Carbajal Pérez GR, Navarrete Procopio M, Zezatti Flores VM, Castañeda Magadan EO, Portillo Contreras S, Avilés López SI, López-Vidaña EC. Drying Kinetics of Leucaena esculenta Seeds Using a Solar Dryer. Energies. 2024; 17(24):6364. https://doi.org/10.3390/en17246364

Chicago/Turabian StyleTlatelpa Becerro, Angel, Ramiro Rico Martínez, Guillermo Raúl Carbajal Pérez, Miriam Navarrete Procopio, Víctor Manuel Zezatti Flores, Erick Omar Castañeda Magadan, Samuel Portillo Contreras, Salvador Israel Avilés López, and Erick César López-Vidaña. 2024. "Drying Kinetics of Leucaena esculenta Seeds Using a Solar Dryer" Energies 17, no. 24: 6364. https://doi.org/10.3390/en17246364

APA StyleTlatelpa Becerro, A., Rico Martínez, R., Carbajal Pérez, G. R., Navarrete Procopio, M., Zezatti Flores, V. M., Castañeda Magadan, E. O., Portillo Contreras, S., Avilés López, S. I., & López-Vidaña, E. C. (2024). Drying Kinetics of Leucaena esculenta Seeds Using a Solar Dryer. Energies, 17(24), 6364. https://doi.org/10.3390/en17246364