Model Predictive Hybrid PID Control and Energy-Saving Performance Analysis of Supercritical Unit

Abstract

1. Introduction

2. Supercritical Unit Coordination System

2.1. System Description

2.2. Coordinated Control System

3. Methods

3.1. Subspace Identification Modeling

3.2. PID–MPC Hybrid Control Strategy

3.2.1. PID Controller for Output Power

3.2.2. Design of MPC

3.3. Perfermance Index

3.3.1. Control Performance

3.3.2. Energy-Saving Performance

4. Results and Discussion

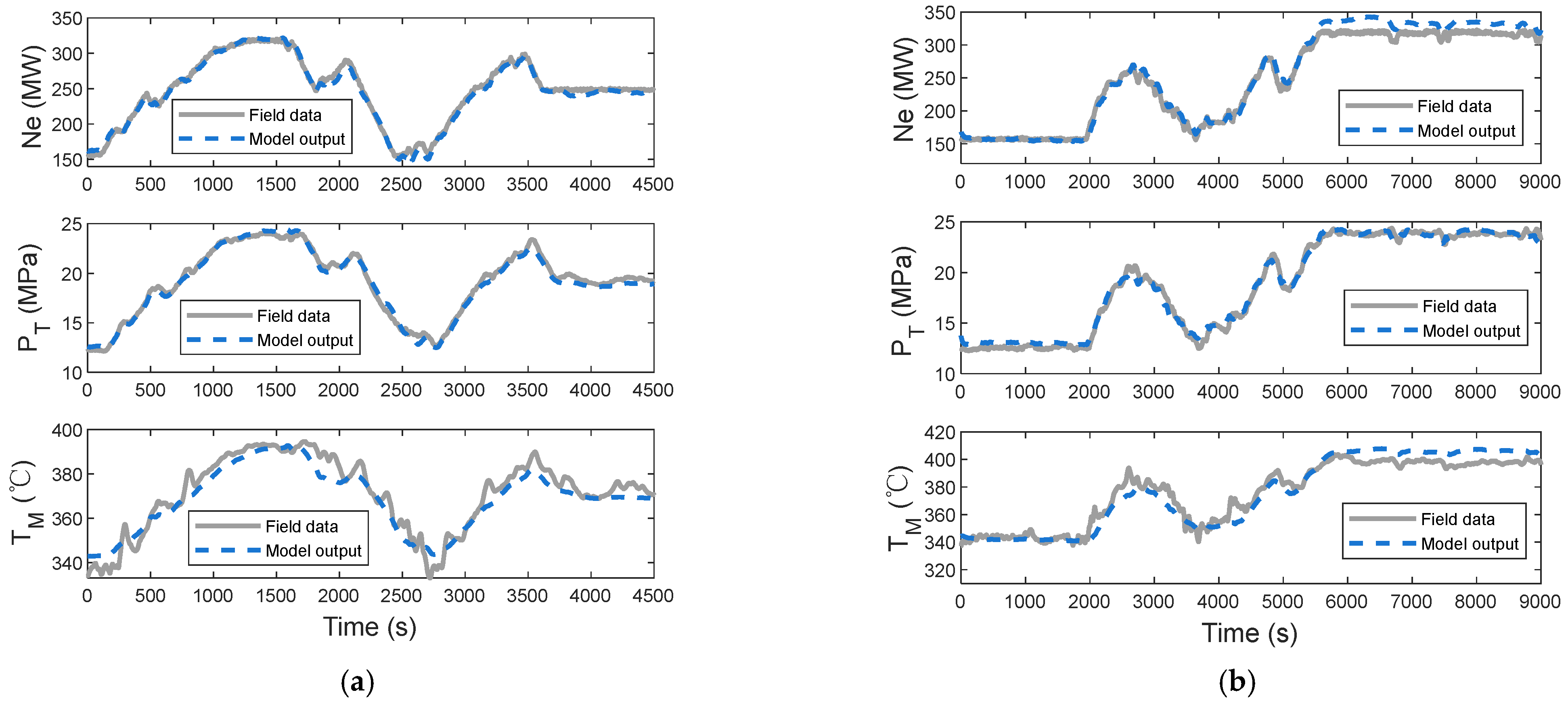

4.1. Model Validation

4.2. Wide-Range Load Change

4.3. Uncertainty Disturbances

5. Conclusions

- A dynamic model of a supercritical unit is constructed using the subspace identification method. The model’s high precision is confirmed by its alignment with field data, providing a solid foundation for the design of subsequent control strategies.

- In variable load simulation tests, the PID–MPC hybrid control strategy shows faster response times and more precise tracking capabilities compared to the traditional feedforward-PID strategy. It achieves substantial improvements in the IAE index for three loops, with increases of 29.2%, 54.1%, and 57.3% over the feedforward-PID controller, closely matching the performance of a classic MPC controller and effectively enhancing the system’s dynamic response performance.

- The energy-saving performance analysis indicates that the proactive control actions of both the PID–MPC and MPC strategies lead to dynamic exergy efficiency and CCRs with a broader range of dynamic process changes.

- Faced with a variety of control disturbance scenarios, the PID–MPC hybrid controller proves its robust anti-interference capabilities. This strategy consistently shows less overshoot, achieves faster settling times, and minimizes control deviation when compared to the conventional feedforward-PID controller.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Forrester, N. Catching the Rays: My Part in Morocco’s Renewable-Energy Revolution. Nature 2024, 626, 1156. [Google Scholar] [CrossRef] [PubMed]

- Guo, M.; Liu, Y.; Chen, Y.; Gao, W.; Wang, D.; Tang, H.; Liu, H. Study on the Effect of Different Types and Distribution Ratio of Heat Users on Operation Performance of the Distributed Solar Centralized Heating System. Energy Build. 2022, 270, 112265. [Google Scholar] [CrossRef]

- Tong, Y.; Duan, L.; Pang, L. Off-Design Performance Analysis of a New 300 MW Supercritical CO2 Coal-Fired Boiler. Energy 2021, 216, 119306. [Google Scholar] [CrossRef]

- Yang, M.; Zhou, Y.; Yang, J.; Bao, J.; Wang, D.; Yu, Q. Performance Analysis of an Efficient Waste Heat Utilization System in an Ultra-Supercritical Coal-Fired Power Plant. Energy Rep. 2022, 8, 5871–5882. [Google Scholar] [CrossRef]

- Fan, H.; Su, Z.; Wang, P.; Lee, K.Y. A Dynamic Nonlinear Model for a Wide-Load Range Operation of Ultra-Supercritical Once-through Boiler-Turbine Units. Energy 2021, 226, 120425. [Google Scholar] [CrossRef]

- Borase, R.P.; Maghade, D.K.; Sondkar, S.Y.; Pawar, S.N. A Review of PID Control, Tuning Methods and Applications. Int. J. Dynam. Control 2021, 9, 818–827. [Google Scholar] [CrossRef]

- Çetin, G.; Özkaraca, O.; Keçebaş, A. Development of PID Based Control Strategy in Maximum Exergy Efficiency of a Geothermal Power Plant. Renew. Sustain. Energy Rev. 2021, 137, 110623. [Google Scholar] [CrossRef]

- Sánchez, A.J.; Gallego, A.J.; Escaño, J.M.; Camacho, E.F. Event-Based MPC for Defocusing and Power Production of a Parabolic Trough Plant under Power Limitation. Sol. Energy 2018, 174, 570–581. [Google Scholar] [CrossRef]

- Elsisi, M.; Bazmohammadi, N.; Guerrero, J.M.; Ebrahim, M.A. Energy Management of Controllable Loads in Multi-Area Power Systems with Wind Power Penetration Based on New Supervisor Fuzzy Nonlinear Sliding Mode Control. Energy 2021, 221, 119867. [Google Scholar] [CrossRef]

- Tafti, H.D.; Sangwongwanich, A.; Yang, Y.; Pou, J.; Konstantinou, G.; Blaabjerg, F. An Adaptive Control Scheme for Flexible Power Point Tracking in Photovoltaic Systems. IEEE Trans. Power Electron. 2019, 34, 5451–5463. [Google Scholar] [CrossRef]

- Stanger, L.; Bartik, A.; Hammerschmid, M.; Jankovic, S.; Benedikt, F.; Müller, S.; Schirrer, A.; Jakubek, S.; Kozek, M. Model Predictive Control of a Dual Fluidized Bed Gasification Plant. Appl. Energy 2024, 361, 122917. [Google Scholar] [CrossRef]

- Dai, B.; Wang, F.; Chang, Y.; Chu, F.; Song, S. Process Model-Assisted Optimization Control Method Based on Model Predictive Control and Deep Reinforcement Learning for Coordinated Control System in Coal-Fired Power Unit. IEEE Trans. Autom. Sci. Eng. 2024. [Google Scholar] [CrossRef]

- Kim, D.; Wang, Z.; Brugger, J.; Blum, D.; Wetter, M.; Hong, T.; Piette, M.A. Site Demonstration and Performance Evaluation of MPC for a Large Chiller Plant with TES for Renewable Energy Integration and Grid Decarbonization. Appl. Energy 2022, 321, 119343. [Google Scholar] [CrossRef]

- Wu, X.; Wang, M.; Shen, J.; Li, Y.; Lawal, A.; Lee, K.Y. Reinforced Coordinated Control of Coal-Fired Power Plant Retrofitted with Solvent Based CO2 Capture Using Model Predictive Controls. Appl. Energy 2019, 238, 495–515. [Google Scholar] [CrossRef]

- He, X.; Lima, F.V. A Modified SQP-Based Model Predictive Control Algorithm: Application to Supercritical Coal-Fired Power Plant Cycling. Ind. Eng. Chem. Res. 2020, 59, 15671–15681. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhang, K.; Zhu, Y.; Jiang, P.; Zhou, J. Development of a Three-Term MPC and Its Application to an Ultra-Supercritical Coal Fired Power Plant. Control Eng. Pract. 2024, 143, 105787. [Google Scholar] [CrossRef]

- Sanama, C.; Xia, X.; Nguepnang, M. PID-MPC Implementation on a Chiller-Fan Coil Unit. J. Math. 2022, 2022, 8405361. [Google Scholar] [CrossRef]

- Sen, M.; Singh, R.; Ramachandran, R. A Hybrid MPC-PID Control System Design for the Continuous Purification and Processing of Active Pharmaceutical Ingredients. Processes 2014, 2, 392–418. [Google Scholar] [CrossRef]

- Van Overschee, P.; De Moor, B. Subspace Identification for Linear Systems: Theory—Implementation—Applications; Springer Science & Business Media: Berlin, Germany, 2012. [Google Scholar]

- Guo, M.; Hao, Y.; Nižetić, S.; Lee, K.Y.; Sun, L. Modelica-Based Heating Surface Modelling and Dynamic Exergy Analysis of 300 MW Power Plant Boiler. Energy Convers. Manag. 2024, 312, 118557. [Google Scholar] [CrossRef]

- Chen, Y.; Guo, M.; Liu, Y.; Wang, D.; Zhuang, Z.; Quan, M. Energy, Exergy, and Economic Analysis of a Centralized Solar and Biogas Hybrid Heating System for Rural Areas. Energy Convers. Manag. 2023, 276, 116591. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Sampling time | 4 |

| Predictive horizon | 25 |

| Control horizon | 10 |

| Error weight of main steam pressure | 1 |

| Error weight of water wall outlet temperature | 0.9 |

| Controller | IAE1 | IAE2 | IAE3 |

|---|---|---|---|

| PID–MPC | 2320.4 | 452.7 | 1669.8 |

| MPC | 1998.2 | 430.1 | 2067.4 |

| Feedforward-PID | 3278.3 | 985.6 | 3909.9 |

| Case | Controller | IAE1 | IAE2 | IAE3 | ME1 (MW) | ME2 (MPa) | ME3 (℃) | (%) | CCRave (kg/MW·h) |

|---|---|---|---|---|---|---|---|---|---|

| Case 1: Throttle valve opening disturbance (7500 s) | PID–MPC | 34.2 | 20.5 | 114.7 | 0.10 | 0.02 | −0.14 | 30.47 | 613.7 |

| MPC | 13.1 | 12.7 | 99.5 | −0.03 | 0.01 | −0.12 | 30.47 | 613.7 | |

| Feedforward-PID | 327.4 | 103.7 | 201.9 | −0.32 | −0.09 | −0.33 | 30.45 | 614.1 | |

| Case 2: Coal feed rate disturbance (500 s) | PID–MPC | 21.2 | 4.7 | 69.7 | 0.08 | 0.02 | 0.23 | 30.48 | 613.6 |

| MPC | 1.2 | 4.1 | 46.7 | 0.01 | 0.01 | 0.16 | 30.48 | 613.6 | |

| Feedforward-PID | 73.5 | 20.8 | 550.9 | 0.09 | −0.03 | 1.32 | 30.49 | 613.3 | |

| Case 3: Water feed rate disturbance (4000 s) | PID–MPC | 56.2 | 3.8 | 25.4 | −0.10 | −0.01 | −0.09 | 30.48 | 613.4 |

| MPC | 5.1 | 2.4 | 20.5 | −0.16 | −0.01 | −0.06 | 30.49 | 613.5 | |

| Feedforward-PID | 116.4 | 3.2 | 48.6 | −0.20 | 0.01 | −0.09 | 30.49 | 613.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Q.; Chen, G.; Guo, M.; Chen, T.; Luo, L.; Sun, L. Model Predictive Hybrid PID Control and Energy-Saving Performance Analysis of Supercritical Unit. Energies 2024, 17, 6356. https://doi.org/10.3390/en17246356

Yang Q, Chen G, Guo M, Chen T, Luo L, Sun L. Model Predictive Hybrid PID Control and Energy-Saving Performance Analysis of Supercritical Unit. Energies. 2024; 17(24):6356. https://doi.org/10.3390/en17246356

Chicago/Turabian StyleYang, Qingfeng, Gang Chen, Mengmeng Guo, Tingting Chen, Lei Luo, and Li Sun. 2024. "Model Predictive Hybrid PID Control and Energy-Saving Performance Analysis of Supercritical Unit" Energies 17, no. 24: 6356. https://doi.org/10.3390/en17246356

APA StyleYang, Q., Chen, G., Guo, M., Chen, T., Luo, L., & Sun, L. (2024). Model Predictive Hybrid PID Control and Energy-Saving Performance Analysis of Supercritical Unit. Energies, 17(24), 6356. https://doi.org/10.3390/en17246356