Advancements and Future Prospects in the Hydraulic Fracturing of Geothermal Reservoirs

Abstract

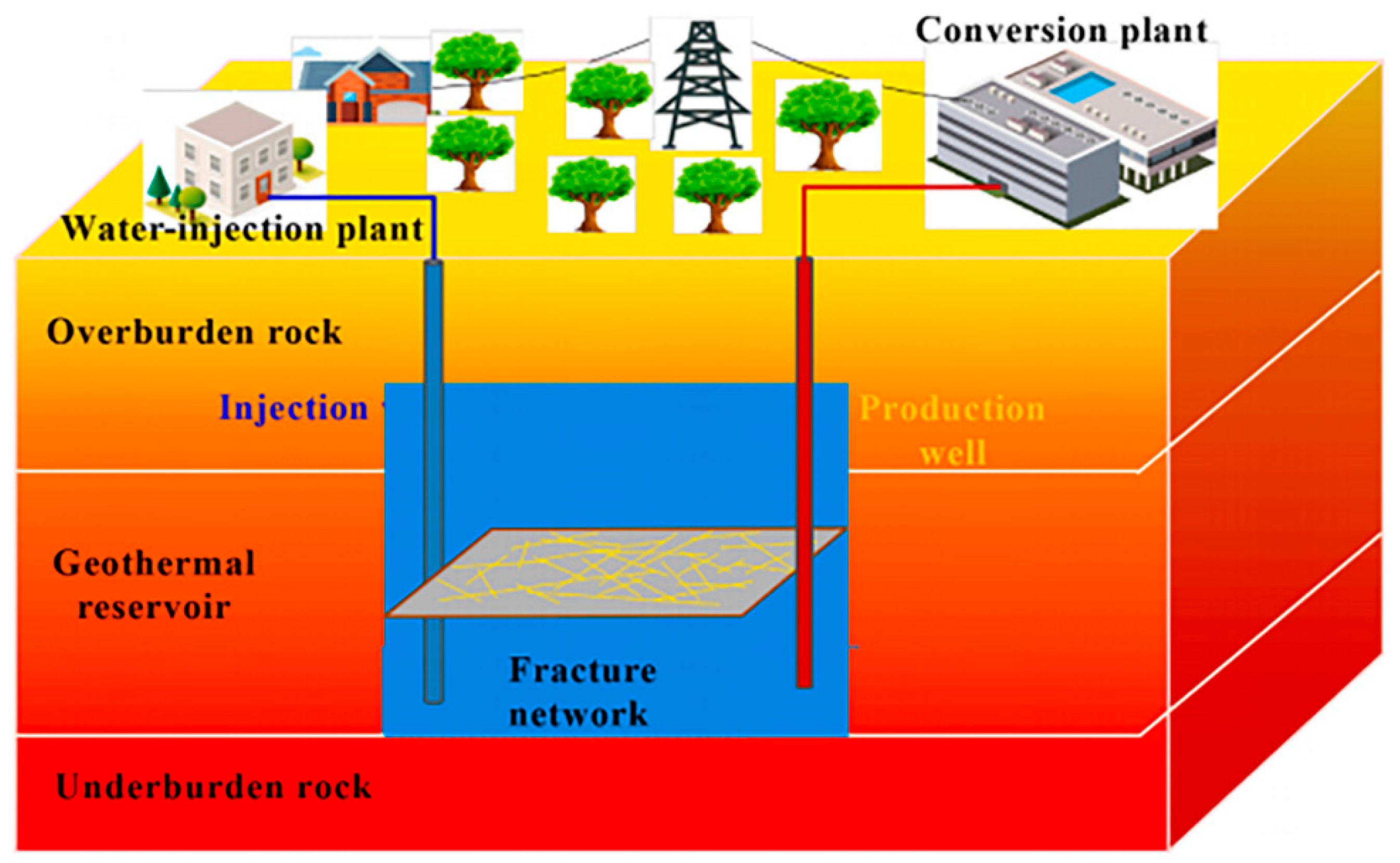

1. Introduction

2. A Comprehensive Study of Classic Cases in Geothermal Reservoir

2.1. Temperature

2.2. Porosity and Permeability

2.3. Fluid Properties

2.4. Geological Structure

3. Influencing Factors on Hydraulic Fracturing of Geothermal Reservoirs

3.1. Impact of Geologic and Physical Properties of Geothermal Reservoirs on Hydraulic Fracturing

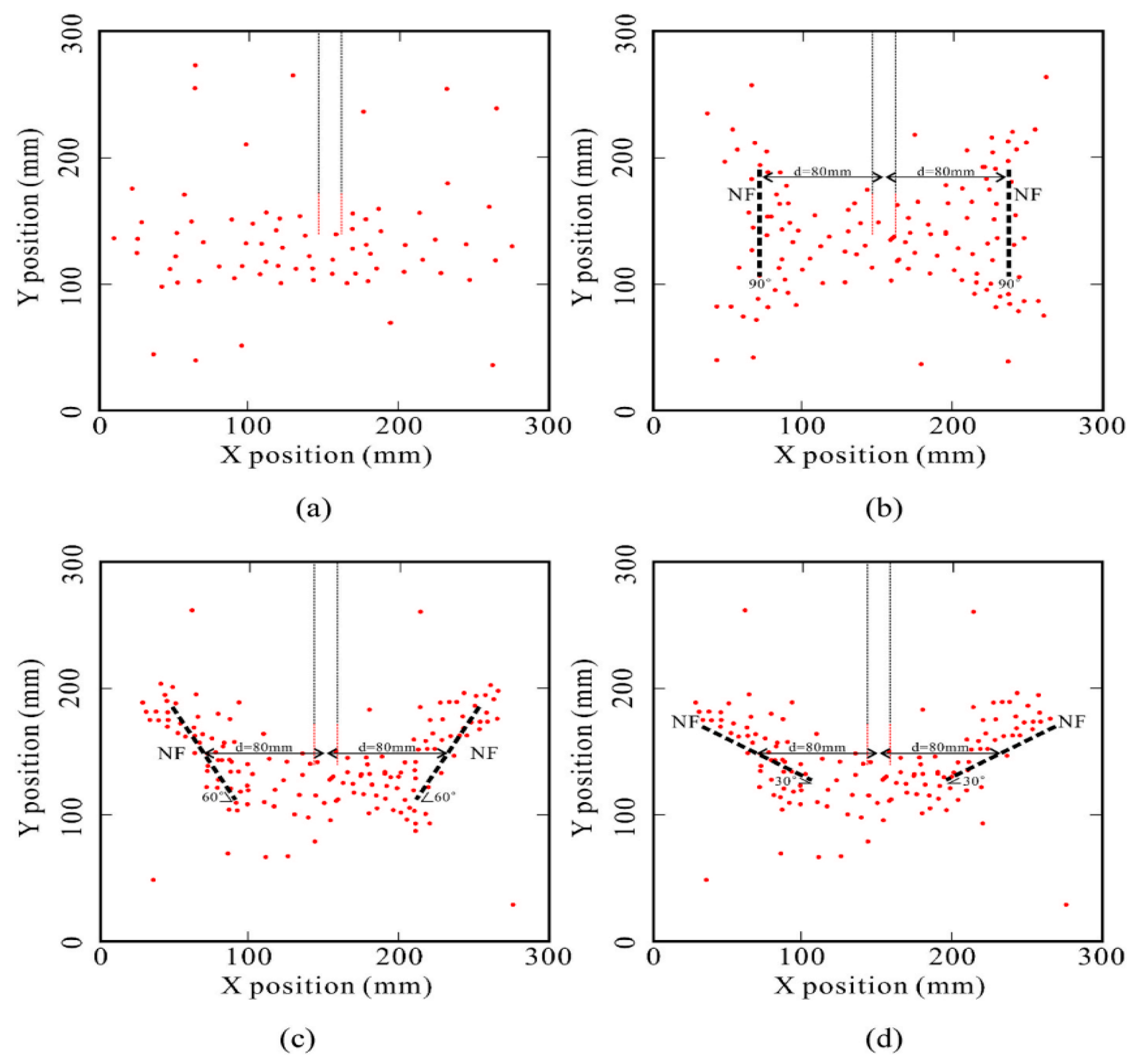

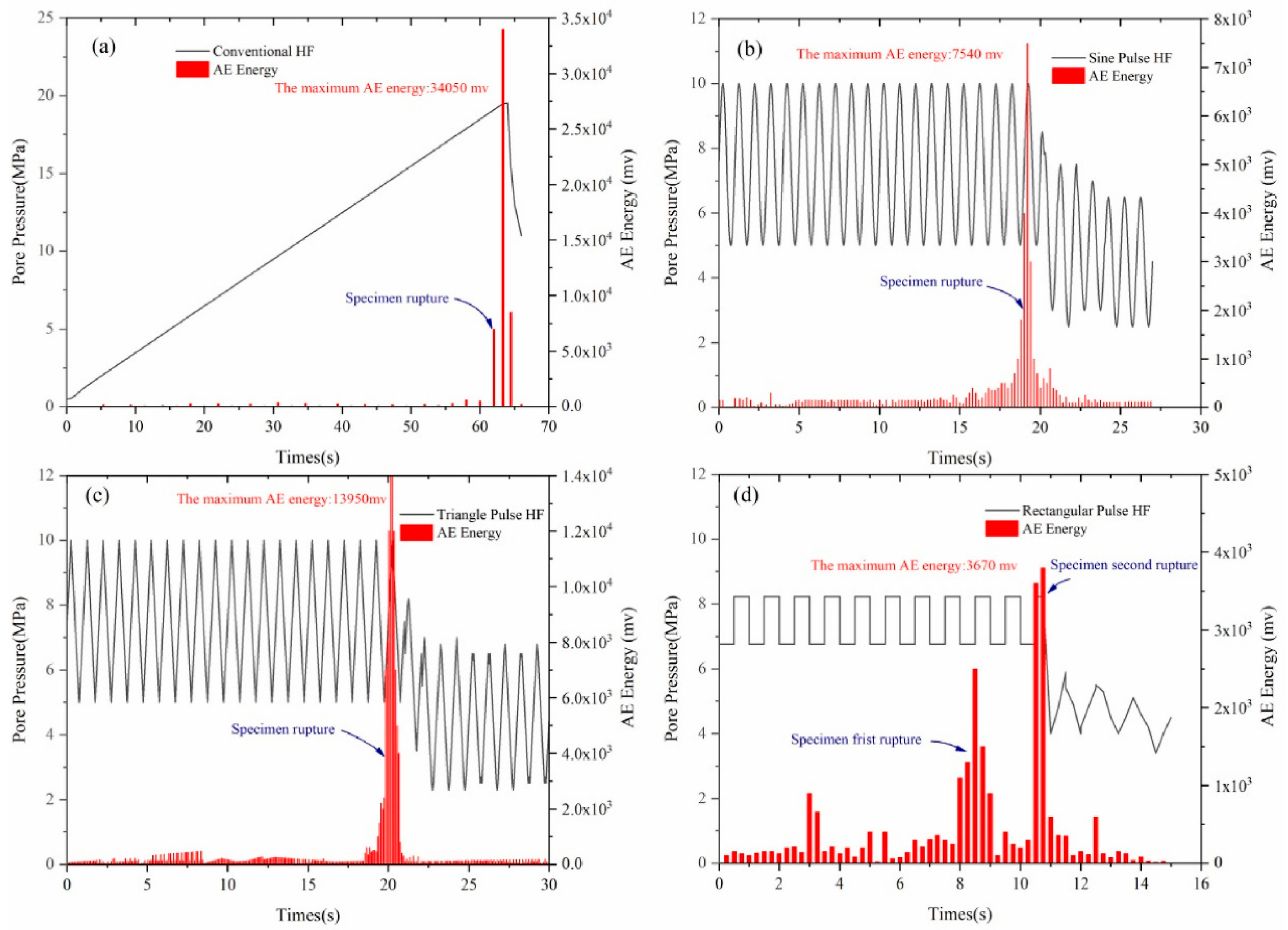

3.2. Impact of Injection Patterns on Hydraulic Fracturing

3.3. Effects of Thermal Stimulation on Hydraulic Fracturing

4. Evaluation and Optimization of the Effects of Stimulation

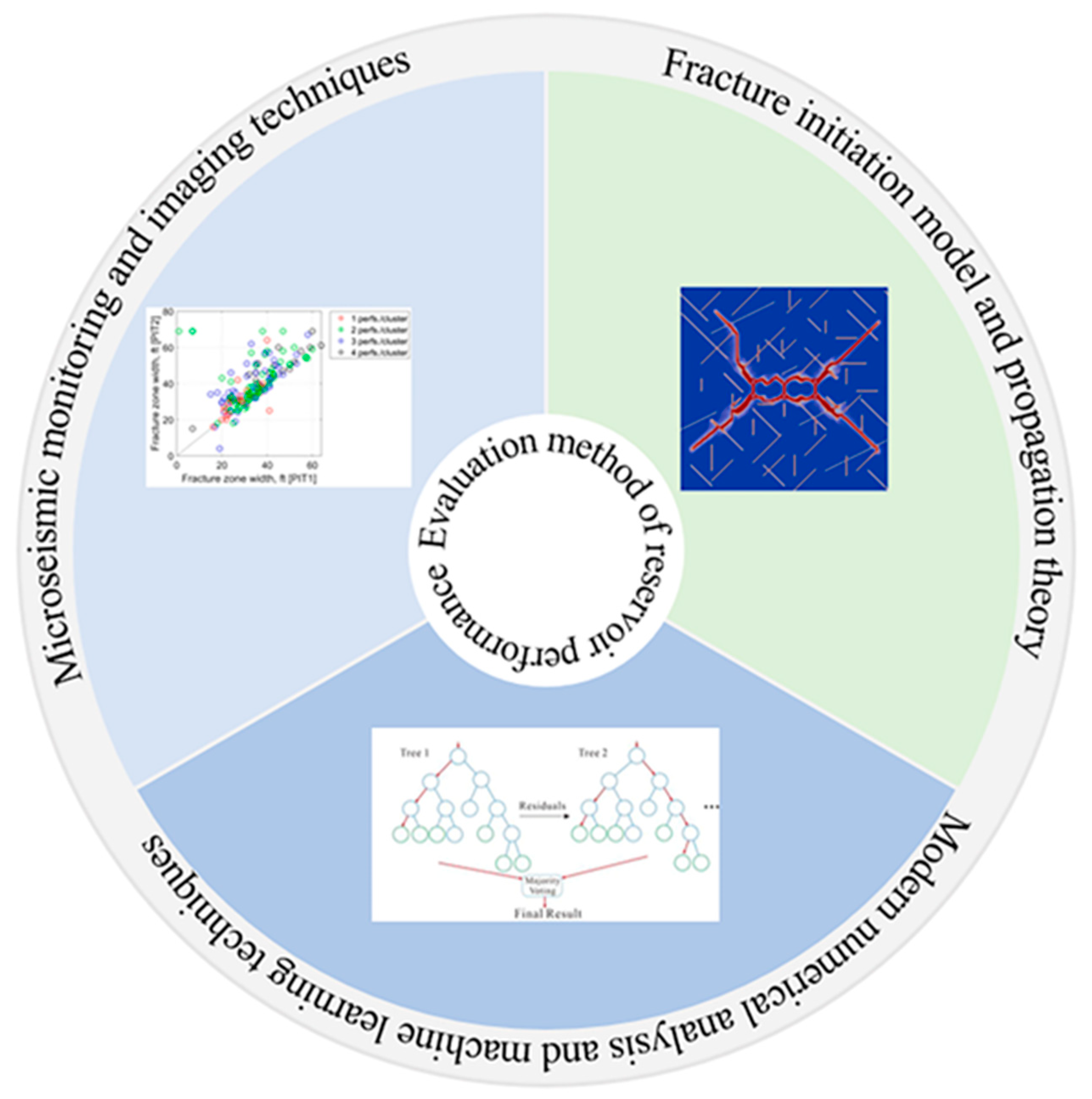

4.1. Methods for Assessing Reservoir Performance After Stimulation

4.2. Optimization Strategies for Reservoir Stimulation

5. Environmental Impact and Risk Management

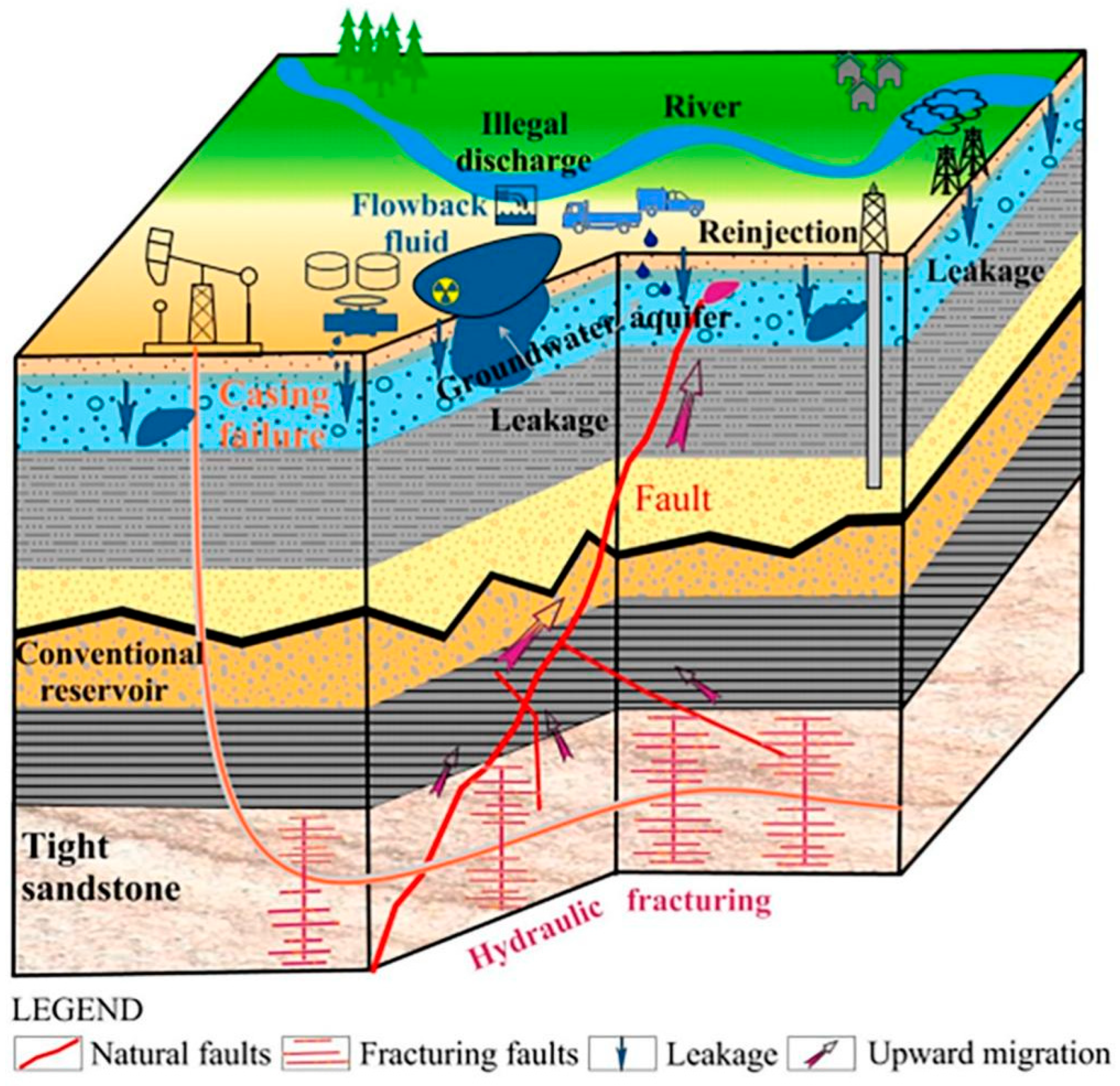

5.1. Environmental Impacts of Hydraulic Fracturing

5.2. Risk Assessment and Security Measures

6. Conclusions and Recommendations

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, Q.; Li, Q.; Han, Y. A Numerical Investigation on Kick Control with the Displacement Kill Method during a Well Test in a Deep-Water Gas Reservoir: A Case Study. Processes 2024, 12, 2090. [Google Scholar] [CrossRef]

- Qiao, M.; Jing, Z.; Feng, C.; Li, M.; Chen, C.; Zou, X.; Zhou, Y. Review on heat extraction systems of hot dry rock: Classifications, benefits, limitations, research status and future prospects. Renew. Sustain. Energy Rev. 2024, 196, 114364. [Google Scholar] [CrossRef]

- Wachowicz-Pyzik, A.; Sowiżdżał, A.; Maćkowski, T.; Stefaniuk, M. A New Approach to the Development of Geothermal Water Utilization in the Context of Identifying and Meeting the Social Needs of Local Communities: A Case Study from the Mogilno–Łódź Trough, Central Poland. Sustainability 2023, 16, 37. [Google Scholar] [CrossRef]

- Wang, G.-l.; Wang, W.-l.; Zhang, W.; Ma, F.; Liu, F. The status quo and prospect of geothermal resources exploration and development in Beijing-Tianjin-Hebei region in China. China Geol. 2020, 3, 173–181. [Google Scholar] [CrossRef]

- Gong, L.; Han, D.; Chen, Z.; Wang, D.; Jiao, K.; Zhang, X.; Yu, B. Research status and development trend of key technologies for enhanced geothermal systems. Nat. Gas Ind. B 2023, 10, 140–164. [Google Scholar] [CrossRef]

- Zhu, J.; Cui, Z.; Feng, B.; Ren, H.; Liu, X. Numerical Simulation of Geothermal Reservoir Reconstruction and Heat Extraction System Productivity Evaluation. Energies 2022, 16, 127. [Google Scholar] [CrossRef]

- Xue, Y.; Liu, S.; Chai, J.; Liu, J.; Ranjith, P.G.; Cai, C.; Gao, F.; Bai, X. Effect of water-cooling shock on fracture initiation and morphology of high-temperature granite: Application of hydraulic fracturing to enhanced geothermal systems. Appl. Energy 2023, 337, 120858. [Google Scholar] [CrossRef]

- Zhao, J.; Liu, P.; Li, J.; Chen, Z.; Li, Y.; Li, F. Fracture propagation induced by hydraulic fracturing using microseismic monitoring technology: Field test in CBM wells in Zhengzhuang region, Southern Qinshui Basin, China. Front. Earth Sci. 2023, 11, 1130280. [Google Scholar] [CrossRef]

- Sun, R.; Wang, J. Effects of In Situ Stress and Multiborehole Cluster on Hydraulic Fracturing of Shale Gas Reservoir from Multiscale Perspective. J. Energy Eng. 2024, 150, 04024002. [Google Scholar] [CrossRef]

- Shang, Y.; Li, Z.; Zhu, Q.; Guo, W.; Liu, Z.; Zheng, Z.; Feng, Y.; Yin, H. A salt-induced smart and tough clean hydrofracturing fluid with superior high-temperature and high-salinity resistance. Energy 2024, 286, 129685. [Google Scholar] [CrossRef]

- Shan, K.; Zheng, Y.; Zhang, Y.; Shan, Z.; Li, Z. Effects of different fracture parameters on microseisms induced by hydraulic fracturing. Bull. Eng. Geol. Environ. 2023, 82, 231. [Google Scholar] [CrossRef]

- Zheng, Y.; Shan, K.; Xu, Y.; Chen, X. Numerical simulation of mechanical characteristics of concrete face rockfill dam under complicated geological conditions. Arab. J. Geosci. 2019, 12, 674. [Google Scholar] [CrossRef]

- Zheng, Y.; Coop, M.R.; Tang, H.; Fan, Z. Effects of overconsolidation on the reactivated residual strength of remoulded deep-seated sliding zone soil in the Three Gorges Reservoir Region, China. Eng. Geol. 2022, 310, 106882. [Google Scholar] [CrossRef]

- Ramlan, A.S.; Zin, R.M.; Abu Bakar, N.F.; Othman, N.H. Recent progress on proppant laboratory testing method: Characterisation, conductivity, transportation, and erosivity. J. Pet. Sci. Eng. 2021, 205, 108871. [Google Scholar] [CrossRef]

- Cheng, Y.; Zhang, Y. Hydraulic Fracturing Experiment Investigation for the Application of Geothermal Energy Extraction. ACS Omega 2020, 5, 8667–8686. [Google Scholar] [CrossRef]

- Goto, R.; Watanabe, N.; Sakaguchi, K.; Miura, T.; Chen, Y.; Ishibashi, T.; Pramudyo, E.; Parisio, F.; Yoshioka, K.; Nakamura, K.; et al. Creating Cloud-Fracture Network by Flow-induced Microfracturing in Superhot Geothermal Environments. Rock Mech. Rock Eng. 2021, 54, 2959–2974. [Google Scholar] [CrossRef]

- Li, N.; Xie, H.; Gao, Z.; Li, C. Study on the Hydraulic Fracturing Failure Behaviour of Granite and Its Comparison with Gas Fracturing. Sustainability 2022, 14, 14593. [Google Scholar] [CrossRef]

- Liu, J.; Shao, C.; Yang, B.; Ramadhani Ngata, M.; Mwangomba, M.; Josephat, S.; Dahiru Aminu, M. Advances in enhanced geothermal systems: Integrating laboratory, numerical and field insights. Appl. Therm. Eng. 2024, 249, 123350. [Google Scholar] [CrossRef]

- Zhuang, L.; Zang, A. Laboratory hydraulic fracturing experiments on crystalline rock for geothermal purposes. Earth-Sci. Rev. 2021, 216, 103580. [Google Scholar] [CrossRef]

- Cao, M.; Hirose, S.; Sharma, M. Factors controlling the formation of complex fracture networks in naturally fractured geothermal reservoirs. J. Pet. Sci. Eng. 2022, 208, 109642. [Google Scholar] [CrossRef]

- Li, L.; Guo, X.; Zhou, M.; Chen, Z.; Zhao, L.; Wang, S. Numerical modeling of fluid flow in tight oil reservoirs considering complex fracturing networks and Pre-Darcy flow. J. Pet. Sci. Eng. 2021, 207, 109050. [Google Scholar] [CrossRef]

- Liu, Y.; Hu, Y.; Kang, Y. The Propagation of Hydraulic Fractures in a Natural Fracture Network: A Numerical Study and Its Implications. Appl. Sci. 2022, 12, 4738. [Google Scholar] [CrossRef]

- Qin, Q.; Xue, Q.; Ma, Z.; Zheng, Y.; Zhai, H. Hydraulic Fracturing Simulations with Real-Time Evolution of Physical Parameters. Energies 2021, 14, 1678. [Google Scholar] [CrossRef]

- Zhang, Y.; Ma, Y.; Hu, Z.; Lei, H.; Bai, L.; Lei, Z.; Zhang, Q. An experimental investigation into the characteristics of hydraulic fracturing and fracture permeability after hydraulic fracturing in granite. Renew. Energy 2019, 140, 615–624. [Google Scholar] [CrossRef]

- Chatterjee, S.; Mishra, P.; Keesari, T.; Pant, H.J. Why is it imperative to use multicomponent geothermometry in medium/low enthalpy thermal waters? Insights from the Gujarat geothermal region, India. Environ. Earth Sci. 2023, 82, 557. [Google Scholar] [CrossRef]

- Torresan, F.; Piccinini, L.; Cacace, M.; Pola, M.; Zampieri, D.; Fabbri, P. Numerical modeling as a tool for evaluating the renewability of geothermal resources: The case study of the Euganean Geothermal System (NE Italy). Environ. Geochem. Health 2021, 44, 2135–2162. [Google Scholar] [CrossRef]

- Sun, Y.; Zuo, Y.; Zhang, L.; Zhang, C.; Wang, Y.; Zhang, T.; Li, X.; Yang, M.; Yan, K.; Cui, L. Geothermal resource evaluation of the Middle Permian Qixia-Maokou Formation in the southern Sichuan Basin, China. Geothermics 2024, 122, 103073. [Google Scholar] [CrossRef]

- Ye, X.; Yu, Z.; Xu, T.; Zhang, Y.; Guo, L. Numerical study on the geomechanical responses in the Jilin Oilfield CO2-EOR and CGS projects in China. Energy 2024, 310, 133306. [Google Scholar] [CrossRef]

- Parvizi, H.; Rezaei-Gomari, S.; Nabhani, F.; Turner, A. Evaluation of heterogeneity impact on hydraulic fracturing performance. J. Pet. Sci. Eng. 2017, 154, 344–353. [Google Scholar] [CrossRef]

- Ye, X.; Yu, Z.; Xu, T.; Zhang, Y.; Guo, L. Mechanism of Subsurface Deformation Transmission and Geomechanical Response Inversion in Carbon Capture and Storage Project: Integrating Small Baseline Subset-Interferometric Synthetic Aperture Radar, Mechanical Experiments, and Numerical Simulation. SPE J. 2024, 1–16. [Google Scholar] [CrossRef]

- Domagała, K.; Maćkowski, T.; Stefaniuk, M.; Reicher, B. Prediction of Reservoir Parameters of Cambrian Sandstones Using Petrophysical Modelling—Geothermal Potential Study of Polish Mainland Part of the Baltic Basin. Energies 2021, 14, 3942. [Google Scholar] [CrossRef]

- Yu, Z.; Ye, X.; Zhang, Y.; Gao, P.; Huang, Y. Experimental research on the thermal conductivity of unsaturated rocks in geothermal engineering. Energy 2023, 282, 129019. [Google Scholar] [CrossRef]

- Liu, Y.; Zheng, X.; Peng, X.; Zhang, Y.; Chen, H.; He, J. Influence of natural fractures on propagation of hydraulic fractures in tight reservoirs during hydraulic fracturing. Mar. Pet. Geol. 2022, 138, 105505. [Google Scholar] [CrossRef]

- Zimmermann, G.; Zang, A.; Stephansson, O.; Klee, G.; Semiková, H. Permeability Enhancement and Fracture Development of Hydraulic In Situ Experiments in the Äspö Hard Rock Laboratory, Sweden. Rock Mech. Rock Eng. 2018, 52, 495–515. [Google Scholar] [CrossRef]

- He, P.; Lu, Z.; Lu, Y.; Huang, Y.; Pan, L.; Ouyang, L.; Zhou, J. Experimental study on fracture propagation and induced earthquake reduction by pulse hydraulic fracturing in shale reservoirs. Gas Science and Engineering 2023, 110. [Google Scholar] [CrossRef]

- Kang, H.; Zhang, J.; Fan, X.; Huang, Z.; Li, X. Cyclic Injection to Enhance Hydraulic Fracturing Efficiency: Insights from Laboratory Experiments. Geofluids 2020, 2020, 8844293. [Google Scholar] [CrossRef]

- Ren, Z.; Wang, S.; Dong, K.; Yu, W.; Lu, L. Exploring the Mechanism of Pulse Hydraulic Fracturing in Tight Reservoirs. Processes 2023, 11, 3398. [Google Scholar] [CrossRef]

- Yu, Z.; Lu, S.; Bai, L.; Zheng, T. Research Progress on Rock Mechanics of CO2 Geological Sequestration. J. Jilin Univ. 2023, 53, 1–15. [Google Scholar]

- Su, X.; Li, D.; Zhu, Q.; Ma, J. Experimental study of fatigue load effect on the hydraulic fracturing behavior of granite. Fatigue Fract. Eng. Mater. Struct. 2022, 46, 540–554. [Google Scholar] [CrossRef]

- Xi, X.; Yang, S.; McDermott, C.I.; Shipton, Z.K.; Fraser-Harris, A.; Edlmann, K. Modelling Rock Fracture Induced By Hydraulic Pulses. Rock Mech. Rock Eng. 2021, 54, 3977–3994. [Google Scholar] [CrossRef]

- Wei, C.; Li, S.; Yu, L.; Zhang, B.; Liu, R.; Pan, D.; Zhang, F. Study on Mechanism of Strength Deterioration of Rock-Like Specimen and Fracture Damage Deterioration Model Under Pulse Hydraulic Fracturing. Rock Mech. Rock Eng. 2023, 56, 4959–4973. [Google Scholar] [CrossRef]

- Lin, R.; Peng, S.; Zhao, J.; Jiang, H.; Ren, L.; Zhou, B.; Wu, J.; Song, Y.; Shen, C. Multiple hydraulic fracture propagation simulation in deep shale gas reservoir considering thermal effects. Eng. Fract. Mech. 2024, 303, 110147. [Google Scholar] [CrossRef]

- Li, Q.; Li, Q.; Wang, F.; Wu, J.; Wang, Y. The Carrying Behavior of Water-Based Fracturing Fluid in Shale Reservoir Fractures and Molecular Dynamics of Sand-Carrying Mechanism. Processes 2024, 12, 2051. [Google Scholar] [CrossRef]

- Maity, D.; Ciezobka, J. Diagnostic assessment of reservoir response to fracturing: A case study from Hydraulic Fracturing Test Site (HFTS) in Midland Basin. J. Pet. Explor. Prod. Technol. 2021, 11, 3177–3192. [Google Scholar] [CrossRef]

- Maity, D.; Ciezobka, J. Understanding near-field fiberoptic observations in the context of completion designs, fracturing effectiveness, and drainage characteristics. A case study from the hydraulic fracturing test site (HFTS-2) in Delaware basin. Gas Sci. Eng. 2023, 112, 204929. [Google Scholar] [CrossRef]

- Ismail, A.; Azadbakht, S. A comprehensive review of numerical simulation methods for hydraulic fracturing. Int. J. Numer. Anal. Methods Geomech. 2024, 48, 1433–1459. [Google Scholar] [CrossRef]

- Kar, S.; Chaudhuri, A.; Singh, A.; Pal, S. Phase field method to model hydraulic fracturing in saturated porous reservoir with natural fractures. Eng. Fract. Mech. 2023, 286, 109289. [Google Scholar] [CrossRef]

- Huang, L.; Li, B.; Wang, B.; Zhang, J. Effects of coal bedding dip angle on hydraulic fracturing crack propagation. Geomech. Geophys. Geo-Energy Geo-Resour. 2023, 9, 30. [Google Scholar] [CrossRef]

- Guo, Q. Evaluation of oil Wells performance ranking in high water cut stage. Comput. Geosci. 2021, 25, 1821–1835. [Google Scholar] [CrossRef]

- Wang, Z.; Tang, H.; Hou, Y.; Shi, H.; Li, J.; Yang, T.; Feng, Y.; Meng, W. Quantitative evaluation of unconsolidated sandstone heavy oil reservoirs based on machine learning. Geol. J. 2022, 58, 2321–2341. [Google Scholar] [CrossRef]

- Zhou, L. Optimization and field application of reservoir stimulation of the Sinian Deng 4 member in the Sichuan Basin. Nat. Gas Ind. B 2022, 9, 277–288. [Google Scholar] [CrossRef]

- Qi, J.; Liu, Y.; Ju, Y.; Zhang, K.; Liu, L.; Liu, Y.; Xue, X.; Zhang, L.; Zhang, H.; Wang, H.; et al. A transfer learning framework for well placement optimization based on denoising autoencoder. Geoenergy Sci. Eng. 2023, 222, 211446. [Google Scholar] [CrossRef]

- Wang, L.; Yang, J.; Peng, J.; Han, H.; Wang, Y.; Lv, Z. Temporary Plugging Agent Evaluation Technology and Its Applications in Shale Reservoirs in the Sichuan Basin. Processes 2023, 11, 2799. [Google Scholar] [CrossRef]

- Zhang, H.; Wu, W.; Chen, Z.; Jing, J. Well logs reconstruction of petroleum energy exploration based on bidirectional Long Short-term memory networks with a PSO optimization algorithm. Geoenergy Sci. Eng. 2024, 239, 212975. [Google Scholar] [CrossRef]

- Dong, K.; Liu, N.; Chen, Z.; Huang, R.; Ding, J.; Niu, G. Geomechanical analysis on casing deformation in Longmaxi shale formation. J. Pet. Sci. Eng. 2019, 177, 724–733. [Google Scholar] [CrossRef]

- Amini, A.; Eberhardt, E. Influence of tectonic stress regime on the magnitude distribution of induced seismicity events related to hydraulic fracturing. J. Pet. Sci. Eng. 2019, 182, 106284. [Google Scholar] [CrossRef]

- Steliga, T.; Kluk, D.; Jakubowicz, P. Analysis of Chemical and Toxicological Properties of Fluids for Shale Hydraulic Fracturing and Flowback Water. Pol. J. Environ. Stud. 2015, 24, 2185–2196. [Google Scholar] [CrossRef]

- He, X.; Li, P.; Shi, H.; Xiao, Y.; Guo, Y.; Zhao, H. Identifying strontium sources of flowback fluid and groundwater pollution using 87Sr/86Sr and geochemical model in Sulige gasfield, China. Chemosphere 2022, 306, 135594. [Google Scholar] [CrossRef]

- He, P.; Xiong, J.; Lu, Z.; Pan, L.; Qin, D. Study of Pulse Wave Propagation and Attenuation Mechanism in Shale Reservoirs During Pulse Hydraulic Fracturing. Arab. J. Sci. Eng. 2018, 43, 6509–6522. [Google Scholar] [CrossRef]

- He, P.; Lu, Z.; Deng, Z.; Huang, Y.; Qin, D.; Ouyang, L.; Li, M. An advanced hydraulic fracturing technique: Pressure propagation and attenuation mechanism of step rectangular pulse hydraulic fracturing. Energy Sci. Eng. 2022, 11, 299–316. [Google Scholar] [CrossRef]

- Xie, X.; Sun, K.; Sheng, Y. Experimental Study on Energy Evolution and Acoustic Emission Characteristics of Fractured Sandstone under Cyclic Loading and Unloading. Appl. Sci. 2024, 14, 2686. [Google Scholar] [CrossRef]

- Liang, C.; Yu, Y.; Wu, F.; Kang, L.; Tang, J. Local stress field inverted for a shale gas play based on focal mechanisms determined from the joint source scanning algorithm. Earthq. Sci. 2021, 34, 222–233. [Google Scholar] [CrossRef]

- Chen, Z.; Zhao, F.; Sun, F.; LÜ, H.; Wang, C.; Wu, H.; Zhou, X. Hydraulic Fracturing-induced Seismicity at the Hot Dry Rock Site of the Gonghe Basin in China. Acta Geol. Sin.-Engl. Ed. 2021, 95, 1835–1843. [Google Scholar] [CrossRef]

- Duan, L.; Huang, M.; Gross, M.; Fehler, D. Monitoring Subsurface Fracture Flow Using Unsupervised Deep Learning of Borehole Microseismic Waveform Data. Geosci. Remote Sens. 2024, 62, 5907712. [Google Scholar] [CrossRef]

- Rampton, D.; Mitchell, J. Assessment of hydraulic fracture height and distribution using timelapse crosswell shear-wave data. J. Appl. Geophys. 2024, 226, 105399. [Google Scholar] [CrossRef]

- Li, D.; Zhang, M.; Zheng, J.; Yang, R.; Peng, S. How induced earthquakes respond to pre-existing fractures and hydraulic fracturing operations? A case study in South China. J. Geophys. Res. Solid Earth 2024, 129, e2024JB028691. [Google Scholar] [CrossRef]

- Schultz, R.; Beroza, G.; Ellsworth, W.; Baker, J. Risk-Informed Recommendations for Managing Hydraulic Fracturing–Induced Seismicity via Traffic Light Protocols. Bull. Seismol. Soc. America. 2020, 110, 2411–2422. [Google Scholar] [CrossRef]

- Schultz, R.; Beroza, G.C.; Ellsworth, W.L. A risk-based approach for managing hydraulic fracturing-induced seismicity. Science 2021, 372, 504–507. [Google Scholar] [CrossRef]

- Xu, B.; Hu, J.; Hu, T.; Wang, F.; Luo, K.; Wang, Q.; He, X. Quantitative assessment of seismic risk in hydraulic fracturing areas based on rough set and Bayesian network: A case analysis of Changning shale gas development block in Yibin City, Sichuan Province, China. J. Pet. Sci. Eng. 2021, 200, 108226. [Google Scholar] [CrossRef]

- Milton-Thompson, O.; Javadi, A.A.; Kapelan, Z.; Cahill, A.G.; Welch, L. Developing a fuzzy logic-based risk assessment for groundwater contamination from well integrity failure during hydraulic fracturing. Sci. Total Environ. 2021, 769, 145051. [Google Scholar] [CrossRef]

- Badjadi, M.A.; Zhu, H.; Zhang, C.; Safdar, M. A Bayesian Network Model for Risk Management during Hydraulic Fracturing Process. Water 2023, 15, 4159. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, D.; Bian, H. Quantifying aquifer contamination risk from casing rupture using support vector machine: A comprehensive assessment. Stoch. Environ. Res. Risk Assess. 2023, 38, 923–936. [Google Scholar] [CrossRef]

| Project Name | Country | Running Time | Development Methodology | Development Period | Primary Purpose | Earnings |

|---|---|---|---|---|---|---|

| Fenton Hill | America | 1973–2000 | By drilling deep wells and performing hydraulic fracturing tests to create or activate large-scale fracture networks. | Phase I (1973–1980): Thermal storage depth of about 3 km, temperature 200 °C. Phase II (1979–2000): thermal storage depth of about 4 km, temperature of 300 °C. | Development of methods for the economic extraction of thermal energy from high-temperature crystalline or metamorphic rock bodies, as well as validation of the technical feasibility of the dry-heat rock concept. | Failed to give a complete description of the performance required at a commercial scale from a commercial development perspective, but the project provided valuable experience and data. |

| Rosemanowes | England | 1978–1991 | Microseismic monitoring and tracing techniques to evaluate reservoir fracturing effectiveness and fluid flow paths during development. | Phase I (1977–1980): drilling of wells to a depth of 300 m and establishment of water circulation. Phase II (1980–1988): reservoir development at 2 km depth. Phase III (1988–1991): development of a prototype commercial system | Development of relevant equipment and technology for use in deep geothermal mining projects. | The technical feasibility of establishing water circulation and reservoir development in granite was verified, and high-temperature instrumentation was developed to provide the necessary technical support for the construction of a commercial HDR system. |

| Hijiori | Japan | 1985–2002 | Drilling deep wells and testing hydraulic fracturing to create artificial thermal storage systems in high-temperature rocks. | Phase I (1985–1991): Shallow reservoirs were created and multiple HDR technology developments were made. Phase II (1992–2002): Larger, higher temperature reservoirs were created and a two-layer reservoir HDR system was established in 1994. | Verification of the technical feasibility of establishing an artificial thermal storage system in a high-temperature rock body for long-term heat extraction tests. | A data integration methodology was developed that enables the integration of geologic structures, core data, and logging data into the model. |

| Soultz | France | 1987–Present | Artificially constructed deep heat exchangers to extract thermal energy from deep thermal reservoirs and used it to generate electricity. | Phase I (1987–2007): Work such as hydraulic and chemical excitation between wells was completed. Phase II (2007–2009): A demonstration power plant of 1.5 MW enhanced geothermal system was built. Phase III (2009–present): Grid-connected power generation was carried out. | Thermal energy in deep thermal reserves is mined and used to generate electricity by artificially constructing deep heat exchangers. | Successfully created a commercial-scale artificially stimulated reservoir. |

| Cooper Basin | Australia | 2003–Present | Adoption of the “one injection, one mining” model for development and testing. | Started in 2003; connected cycle realized in 2009; trial power generation realized in 2013: trial power generation realized after installation of 1 MW pilot duplex genset. | Validation of the feasibility of an enhanced geothermal system (EGS) in a high-temperature granite substrate for commercial power generation. | The project estimates that the well group has the potential to generate up to 2.5 MW of electricity. |

| Gonghe | China | 2013–Present | Based on the characteristics of dry-heat rocks in the Republican Basin, the EGS model was established to analyze the influence of key parameters. | / | Promote new breakthroughs in the development of dry-heat rock geothermal heat, and form a number of dry-heat rock development demonstration areas. | Supporting the restructuring of the national energy structure and helping to realize the country’s “dual-carbon” goal. |

| Huangshadong | China | 2017–Present | Modeling four types of geothermal power plants suitable for the Huangshadong geothermal field. | / | Provide reference for the subsequent dry hot rock resource exploration and target area selection in the same type of area along the southeast coast. | Provide a demonstration for the commercial development of geothermal energy. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shan, K.; Zou, Q.; Li, C.; Yu, Z. Advancements and Future Prospects in the Hydraulic Fracturing of Geothermal Reservoirs. Energies 2024, 17, 6082. https://doi.org/10.3390/en17236082

Shan K, Zou Q, Li C, Yu Z. Advancements and Future Prospects in the Hydraulic Fracturing of Geothermal Reservoirs. Energies. 2024; 17(23):6082. https://doi.org/10.3390/en17236082

Chicago/Turabian StyleShan, Kun, Qinqin Zou, Chongshuai Li, and Ziwang Yu. 2024. "Advancements and Future Prospects in the Hydraulic Fracturing of Geothermal Reservoirs" Energies 17, no. 23: 6082. https://doi.org/10.3390/en17236082

APA StyleShan, K., Zou, Q., Li, C., & Yu, Z. (2024). Advancements and Future Prospects in the Hydraulic Fracturing of Geothermal Reservoirs. Energies, 17(23), 6082. https://doi.org/10.3390/en17236082