1. Introduction

There is an urgent need to address the environmental problems caused by the transport sector. In the European Union, road transport accounts for 21% of greenhouse gas emissions, with the heavy transport sector contributing 6% of the total [

1]. Thereby, driving losses need to be reduced. The two most significant driving losses for trucks are aerodynamic and rolling resistance. Rolling resistance is the force created by tyres opposing the motion of a vehicle. The majority of this resisting force (80–95%) is caused by the viscoelasticity of rubber [

2], while the remainder is attributed to stick–slip interactions between the rim and tyre, tyre-road contact, and aerodynamic windage losses from the wheel [

3].

The existing research primarily examines the impact of various parameters, e.g., tyre pressure and axle loads, on stabilised rolling resistance, while largely overlooking transient rolling resistance and the influence of tyre temperature on rolling resistance. A plausible explanation for why the effect of tyre temperature has been neglected is that the ISO 28580 standard describes a testing method where only stabilised rolling resistance is measured. Some articles have studied transient rolling resistance [

4,

5,

6,

7]; however, many of these still neglect the effects of ambient temperature. Hyttinen et al. [

8] investigated the effects of tyre temperature across a broad ambient temperature range (−30 to +25 °C) using a climate wind chamber, demonstrating that increasing tyre temperature can significantly reduce rolling resistance. Various articles [

7,

8,

9,

10,

11] indicate that ambient and tyre temperature are two of the most critical factors for rolling resistance. Another study by Hyttinen et al. [

7] introduced a transient rolling resistance model that takes ambient temperature into account.

To the authors’ knowledge, there are only few studies focusing on how to limit heat flow from the tyre to reduce rolling resistance. The air flow around tyres has been explored mainly in terms of reducing the vehicle’s aerodynamic drag and not the aerodynamic effects on tyre cooling. In the 1980s, a study [

9] showed that redirecting airflow away from the tyre could affect rolling resistance. More recently, Bode [

11] conducted on-road tests and showed a decrease in rolling resistance when a sheet metal box surrounds the tyre. Similarly, Hyttinen et al. [

12] conducted simulations showing that reducing the convective cooling of the tyre can significantly reduce rolling resistance. This study aims to determine with experimental methods whether keeping already generated strain-induced heat inside of tyres by encapsulating them and insulating the wheelhouses can be used to reduce rolling resistance. Additionally, the effects of increased temperature on tyre pressure are examined.

The outline of this study is as follows:

Section 2 provides a brief definition of rolling resistance.

Section 3 details the experimental setup, while

Section 4 presents the test results.

Section 5 presents the conclusions and discusses potential directions for future research.

2. Rolling Resistance

The coefficient of rolling resistance

, represents the relationship between the longitudinal resisting force

and the axle load

, and can be calculated as follows [

7,

13]:

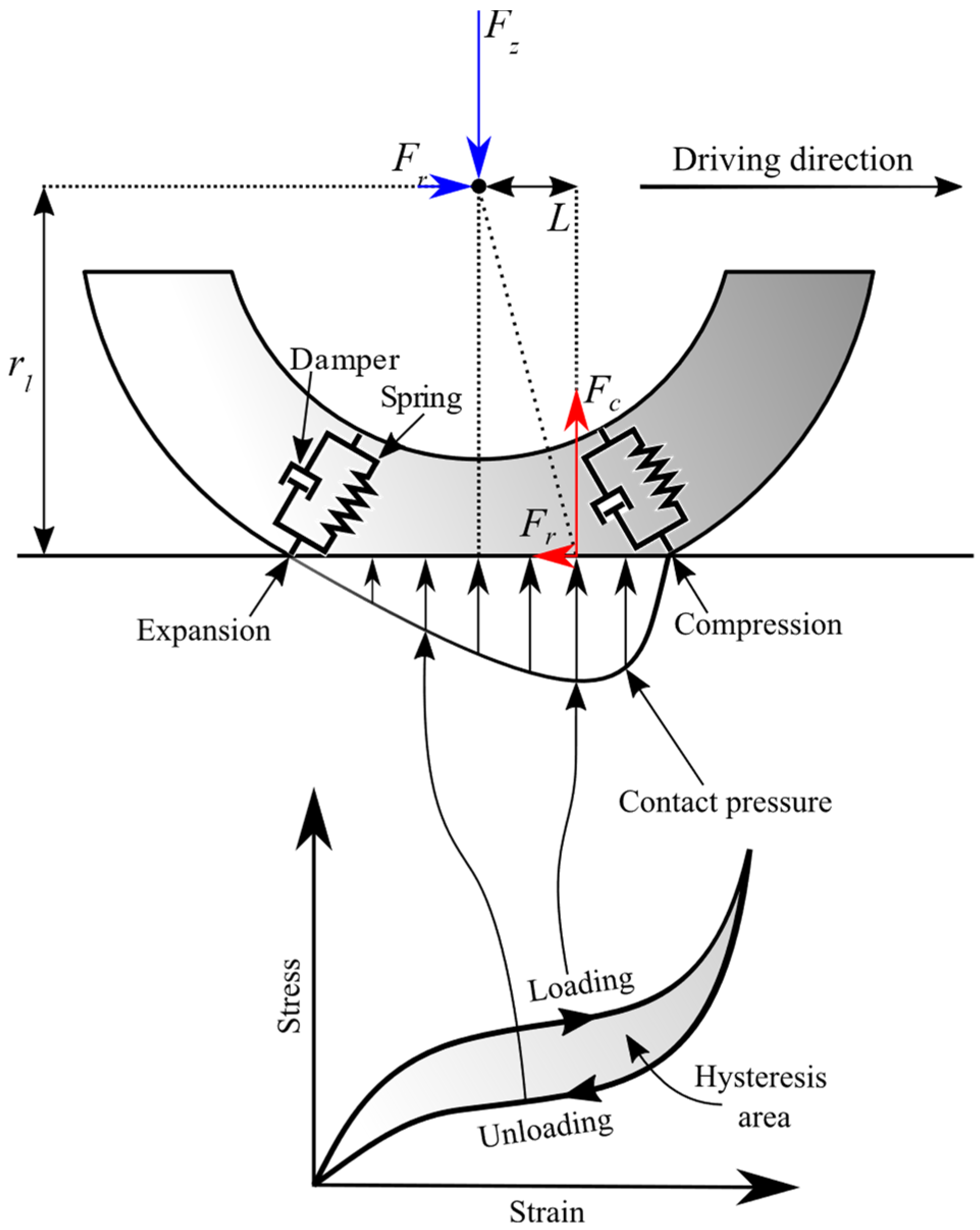

Rolling resistance is caused mainly by viscoelasticity in tyre rubber, as illustrated in

Figure 1. In this figure,

denotes the distance shift in the centre of pressure ahead of the tyre’s rotational axis,

is the sum of the contact forces in vertical direction at the contact patch, and

represents the loaded radius of the tyre. Using these parameters, the rolling resistance force can also be determined from the moment balance taken at the wheel centre:

Substituting this expression for

into Equation (1), the rolling resistance coefficient can be expressed as the ratio between the distance shift in the centre of pressure and the loaded radius of the tyre:

The viscoelasticity has considerable temperature dependency, and the energy dissipation reduces at increasing temperatures. Therefore, if tyres could be made to operate with a higher temperature without putting more energy into them, i.e., reduce cooling, the tyre rolling resistance could be reduced.

3. Experimental Setup

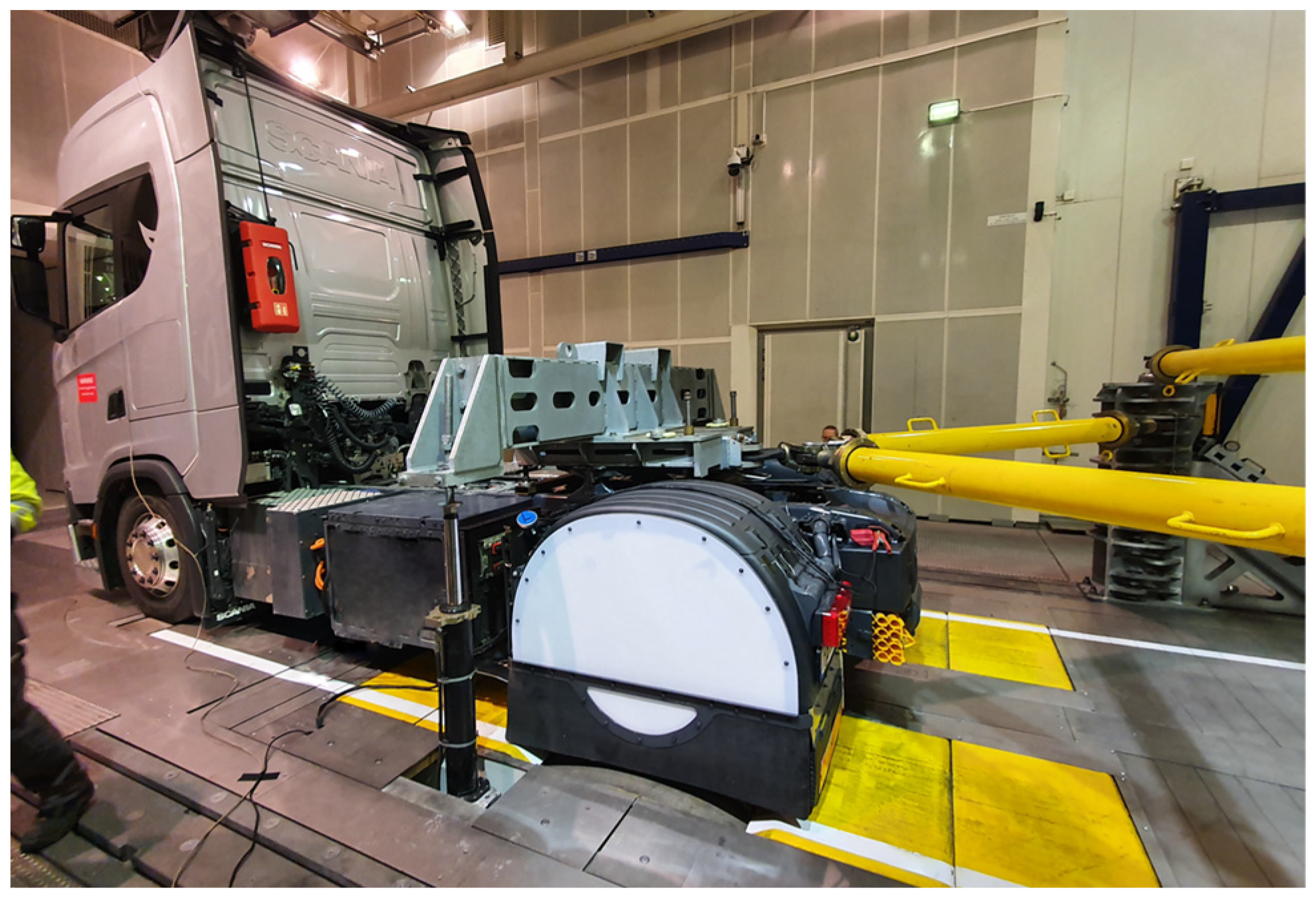

This section presents the measurement setup with and without tyre encapsulation. The experiments were performed in Södertälje Sweden at Scania’s climate wind chamber [

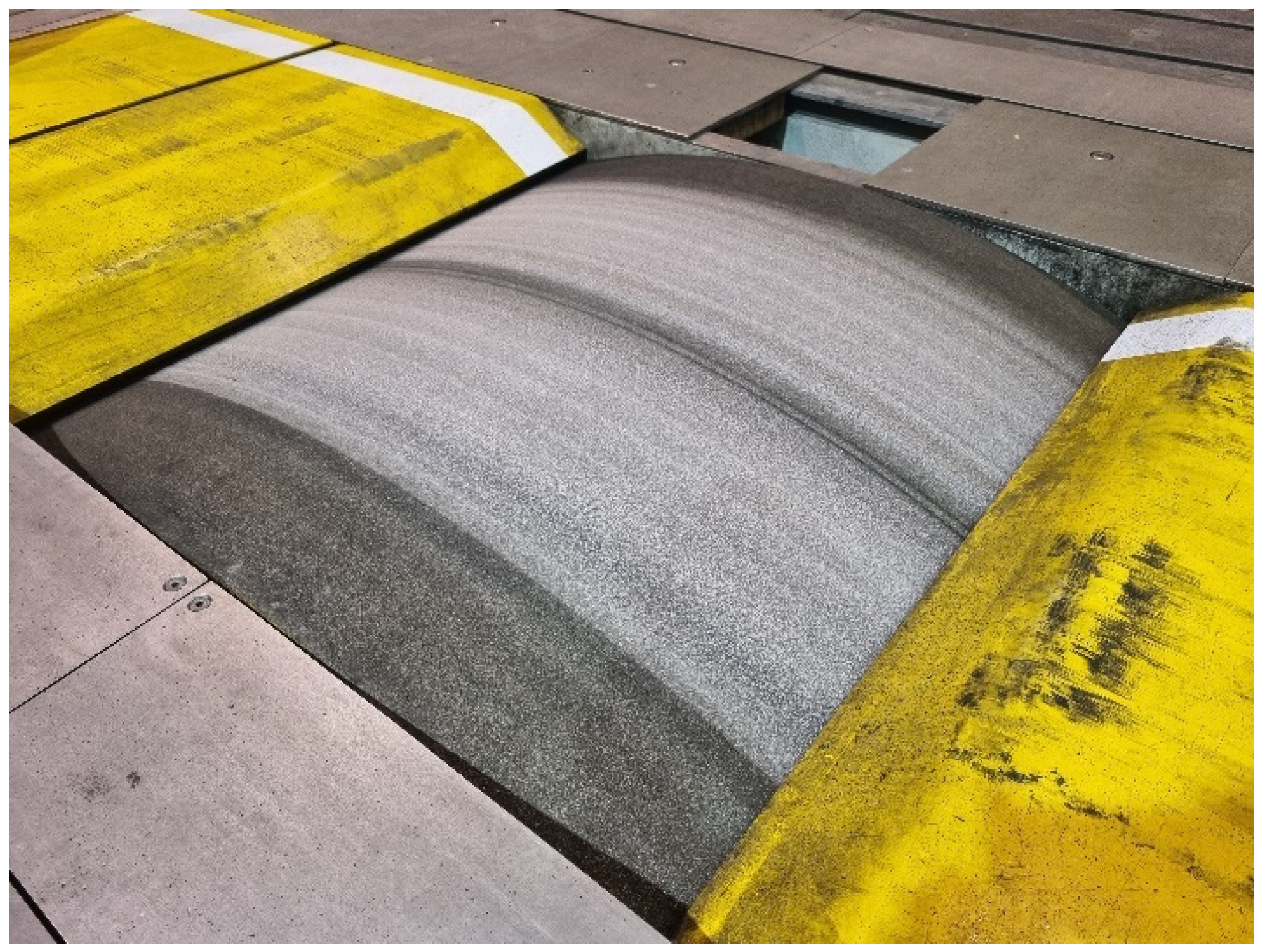

14]. The measurement drum, with a diameter of 2.5 m, is 0.5 m larger than the diameter recommended by the ISO 28580 standard for measuring rolling resistance [

15]. A larger diameter benefits the measurements by generating less heat, as it more accurately represents a flat road and reduces the drum’s penetration into the tyre. The steel drum has a rough texture that mimics the surface of an asphalt road, as shown in

Figure 2. However, drum measurements slightly differ from flat-road measurements, and correction equations are often used to make them comparable [

16].

The tyres were maintained at the measurement temperature for a minimum of 10 h before the measurements began. Additionally, to isolate the rolling resistance from the losses in the gearbox and differential, the brake pads and drive shafts were disassembled from the rear axle. Furthermore, the air bellows were replaced with steel bars to eliminate variables influencing the axle load. During the tests, the drive axle was loaded with hydraulic cylinders that pull the vehicle to the drums. The total axle load for the drive axle was 10,400 kg.

Prior to every test, the truck was rolled away from the drum to warm up the measurement drum bearings by rotating the empty drum for 50 min at 80 km/h. This step was carried out to stabilise the force measurement. The empty drum measurement value at the end of the warm-up was used as the parasitic loss which was subtracted from the results. ISO 28580 [

15] describes parasitic loss as occurring when the axle load is reduced to nearly zero, allowing the tyre to barely touch the drum while continuing to rotate at the measurement speed level to isolate the aerodynamic and bearing losses from the measurements. This article defines parasitic loss differently from ISO 28580, as it is challenging to consistently reduce the truck’s axle load to nearly zero. Therefore, parasitic loss is determined solely using the empty drum value measurements taken at the initial measurement speed level.

Following the drum bearing warm-up and parasitic loss measurements, the truck was positioned back on the measurement drum, and the tyre pressure was adjusted to 8.5 bar. During the measurements, the wind speed was matched to the dynamometer drum’s speed.

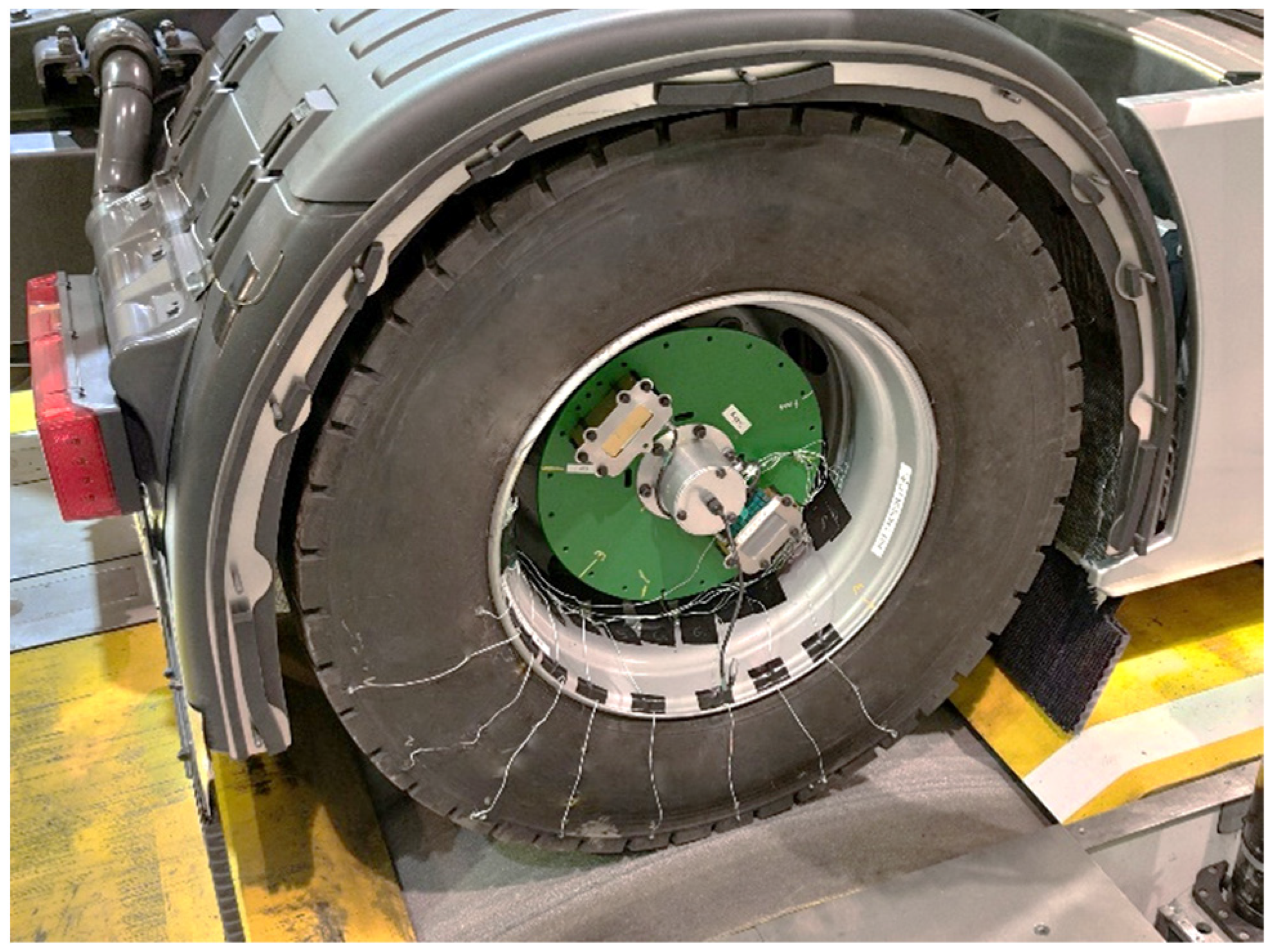

The temperature of a tyre has a significant impact on rolling resistance. However, standard methods for measuring rolling resistance, e.g., ISO 28580, omit the cooling effect of wind, potentially leading to underestimated rolling resistance values. To evaluate this effect, thermocouples were used to measure tyre temperature by embedding them in holes drilled into the tyre shoulder, as depicted in

Figure 3.

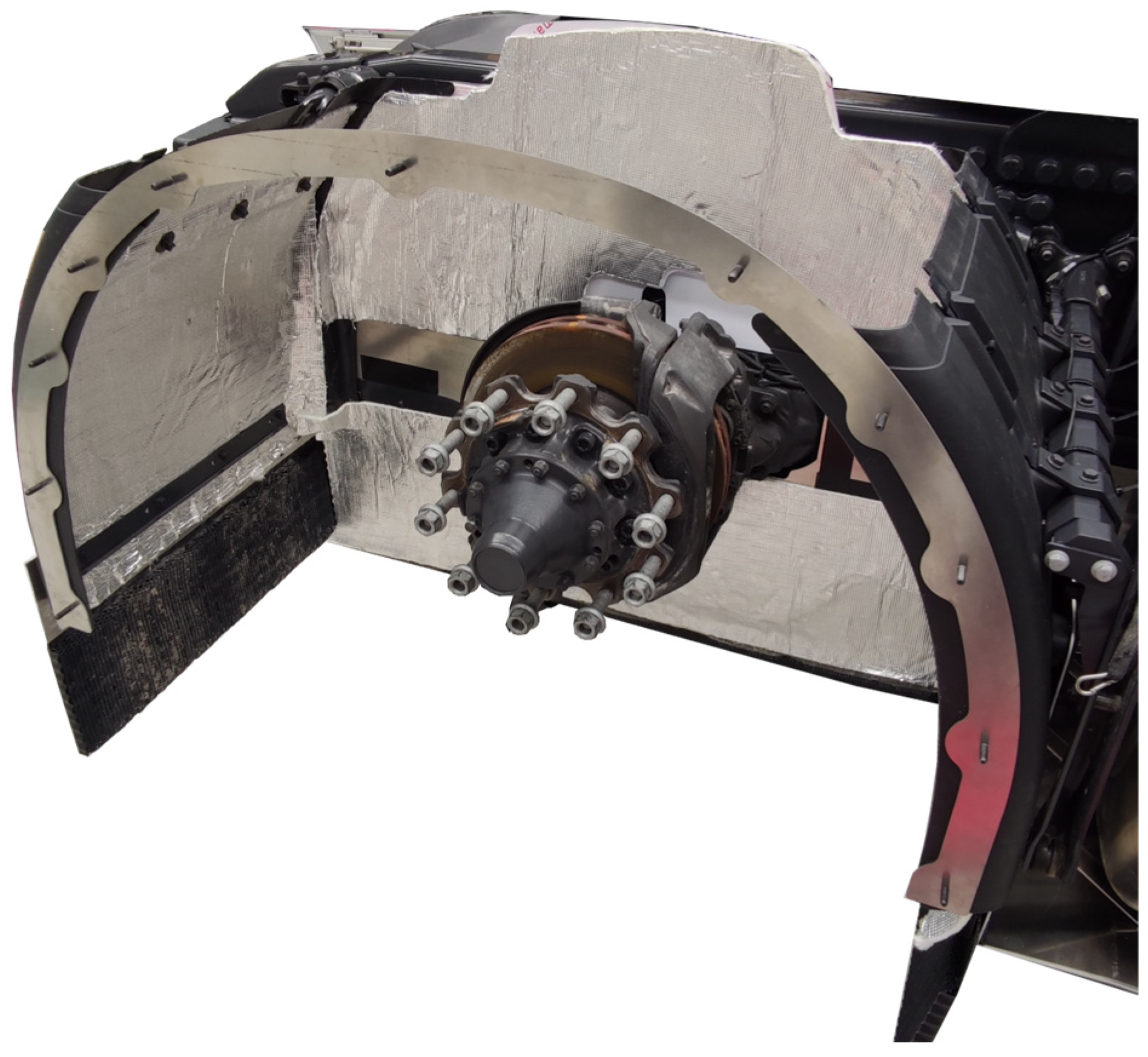

The encapsulation of the wheels reduces the relative velocity between the tyre and the surrounding airflow, which should cause a decrease in forced convection. The wheelhouse was modified so that the inner side of the wheelhouse was encapsulated nearly down to the ground. The lower part was attached to the axle, and the upper part to the frame. This way, the wheelhouse allows suspension movements during driving. The part closest to the ground is made of a flexible rubber mat that allows intermittent contact with obstacles during driving. Additionally, the wheelhouse is insulated using an aluminium glass fibre composite, as shown in

Figure 4. Using a reflective insulation material reduces radiative heat losses from the wheelhouse to the surroundings.

Figure 5 shows the wheelhouse with a closed wheelhouse setup. With the open wheelhouse (

Figure 6), the white cover shown in

Figure 5 was removed along with the wheelhouse top. Semi-trailer trucks often drive without the top covers, which is why this was chosen to be the open setup. Otherwise, the tests were identical.

4. Test Results

This section presents the experimental results.

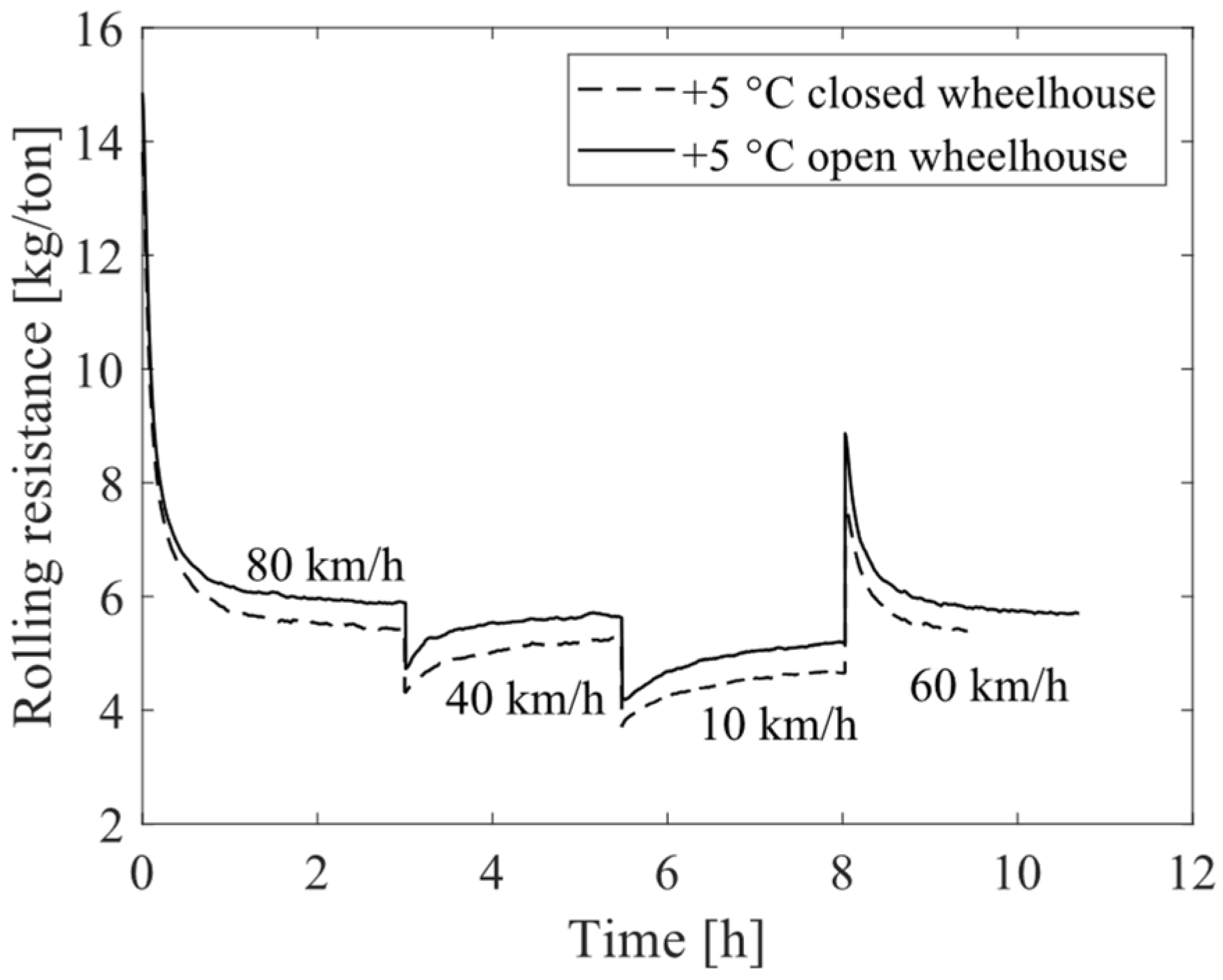

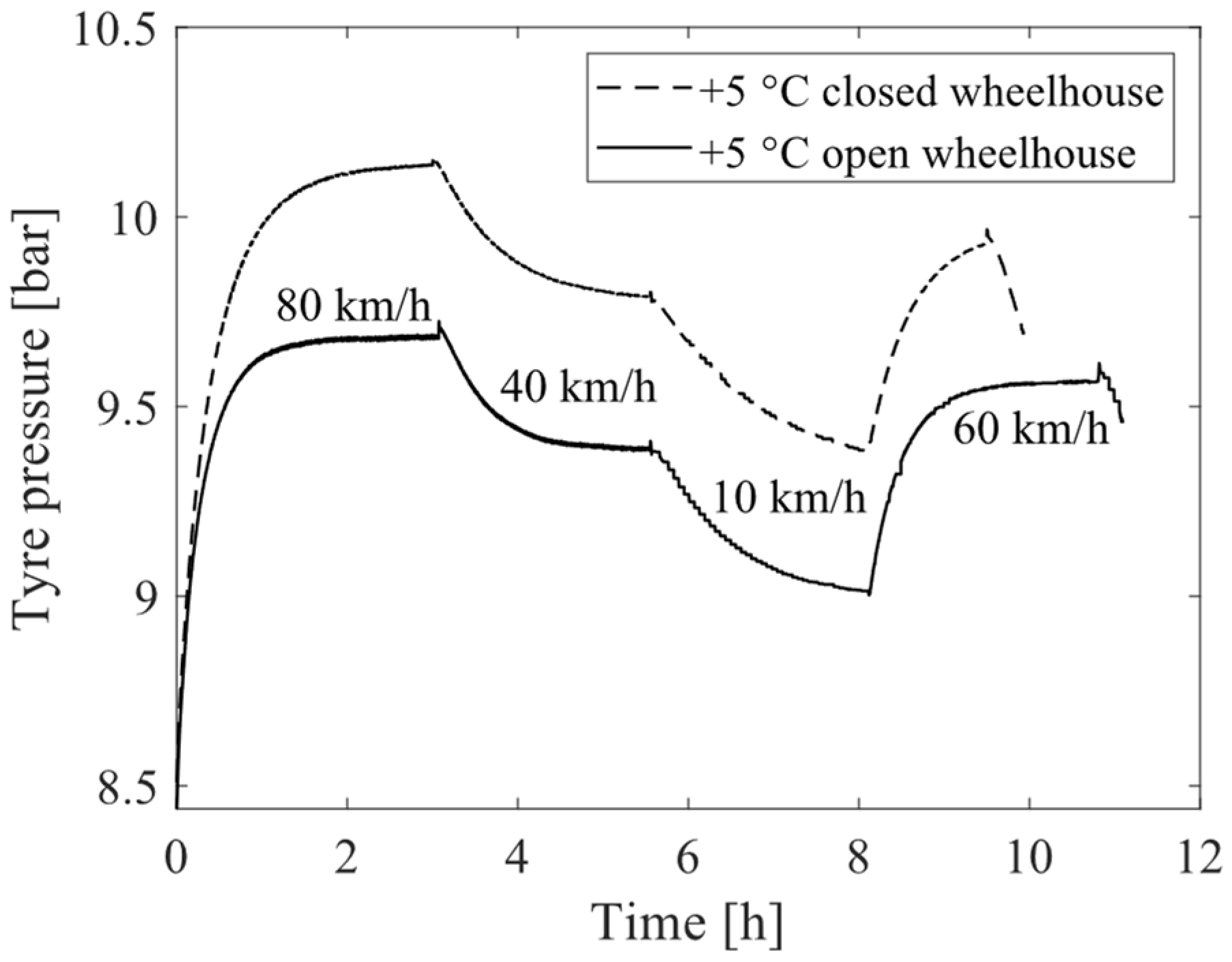

Figure 7 shows the measured rolling resistance with closed and open wheelhouses at different speeds. The tests included consecutive speed steps (80 km/h–40 km/h–10 km/h–60 km/h), similar to previous work by Hyttinen et al. [

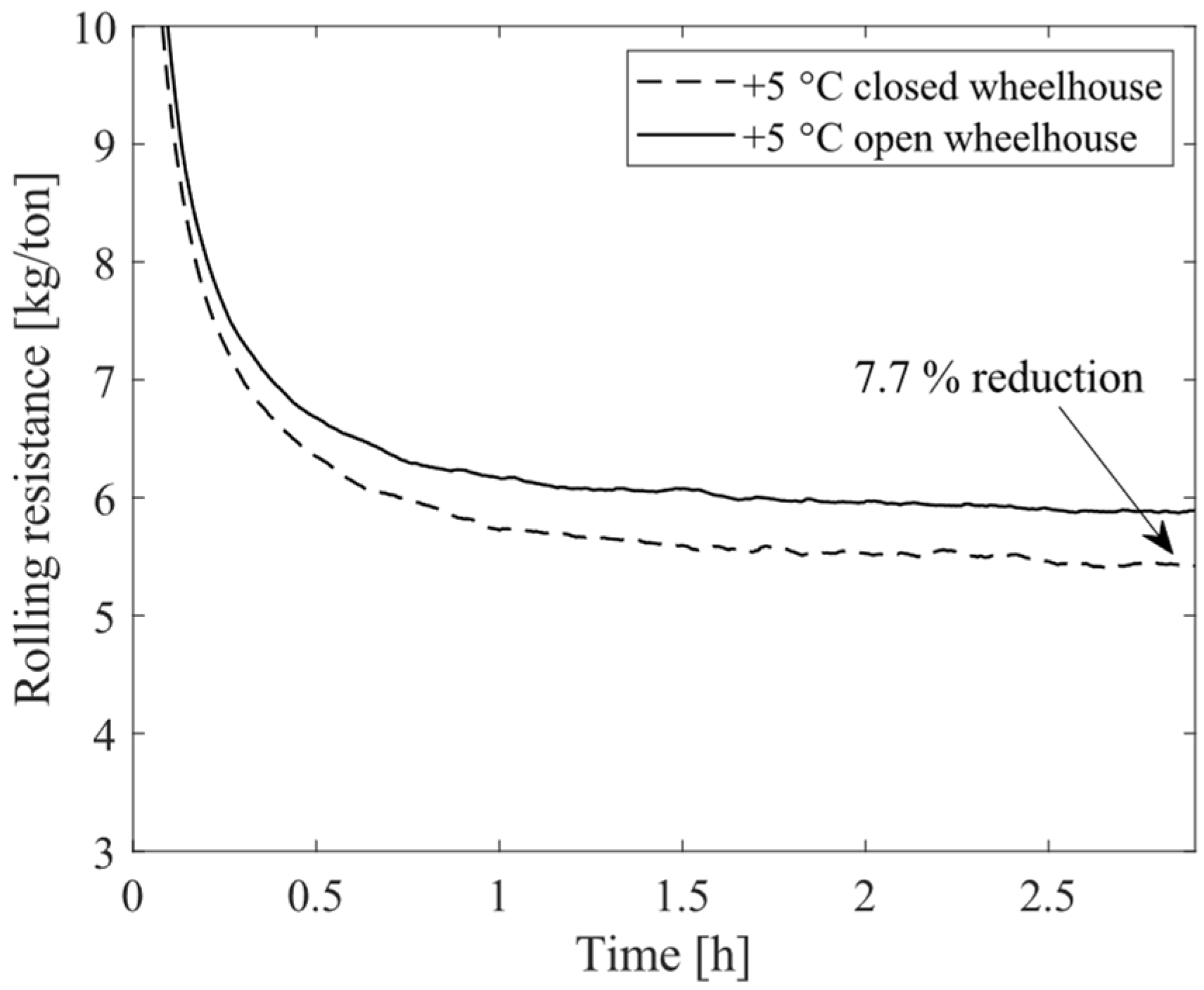

7]. Rolling resistance values start from similar values, and the shape of the time histories is similar for both measurements. However, the heat-insulated wheelhouse produces significantly lower rolling resistance at all evaluated speed levels. The reduction in rolling resistance at the end of the 80 km/h speed level is 7.7%, as highlighted in

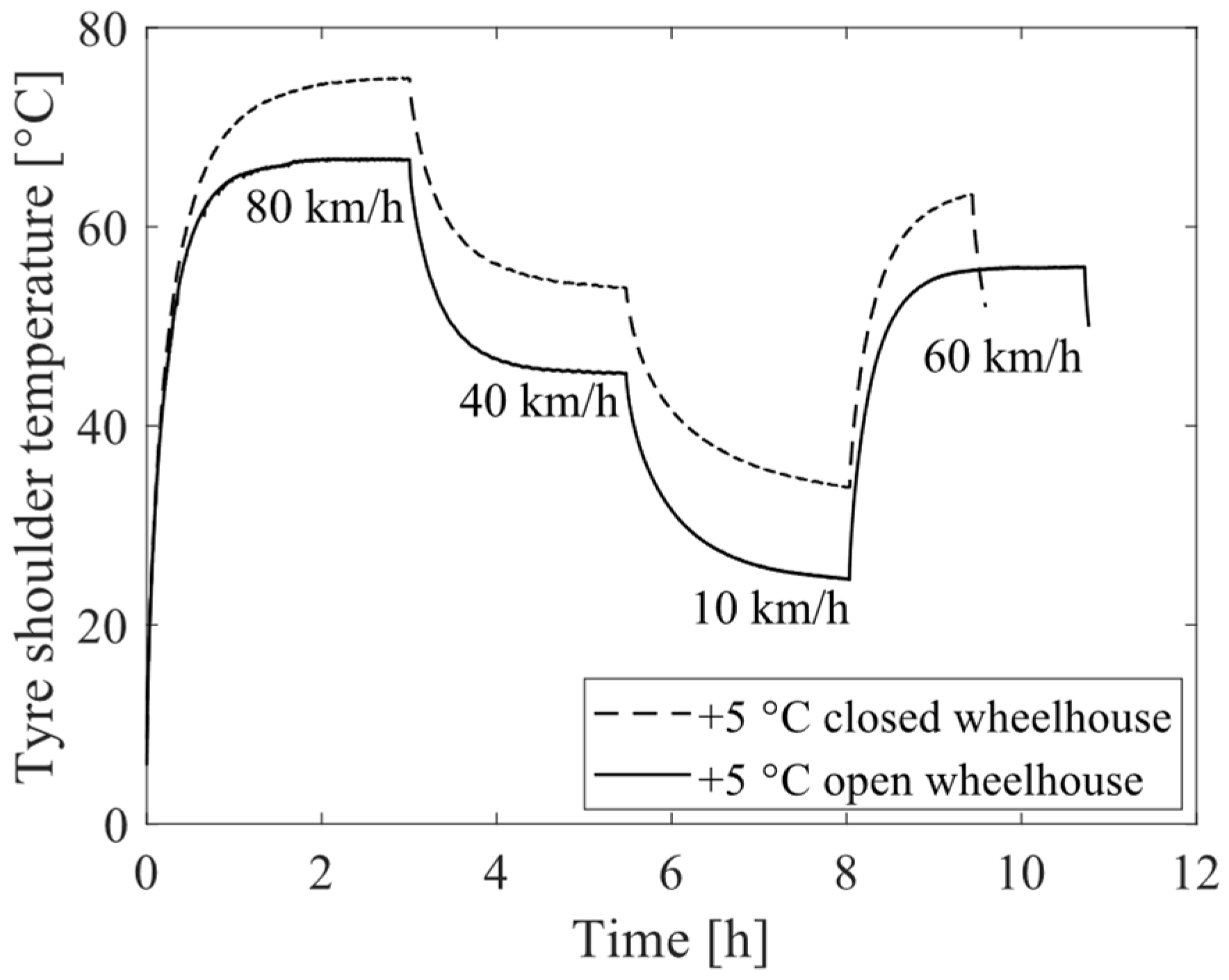

Figure 8. This is a considerable reduction from an energy consumption perspective, with an inexpensive solution and using the same tyres. The shape of the tyre temperature measurements is similar for both tests (

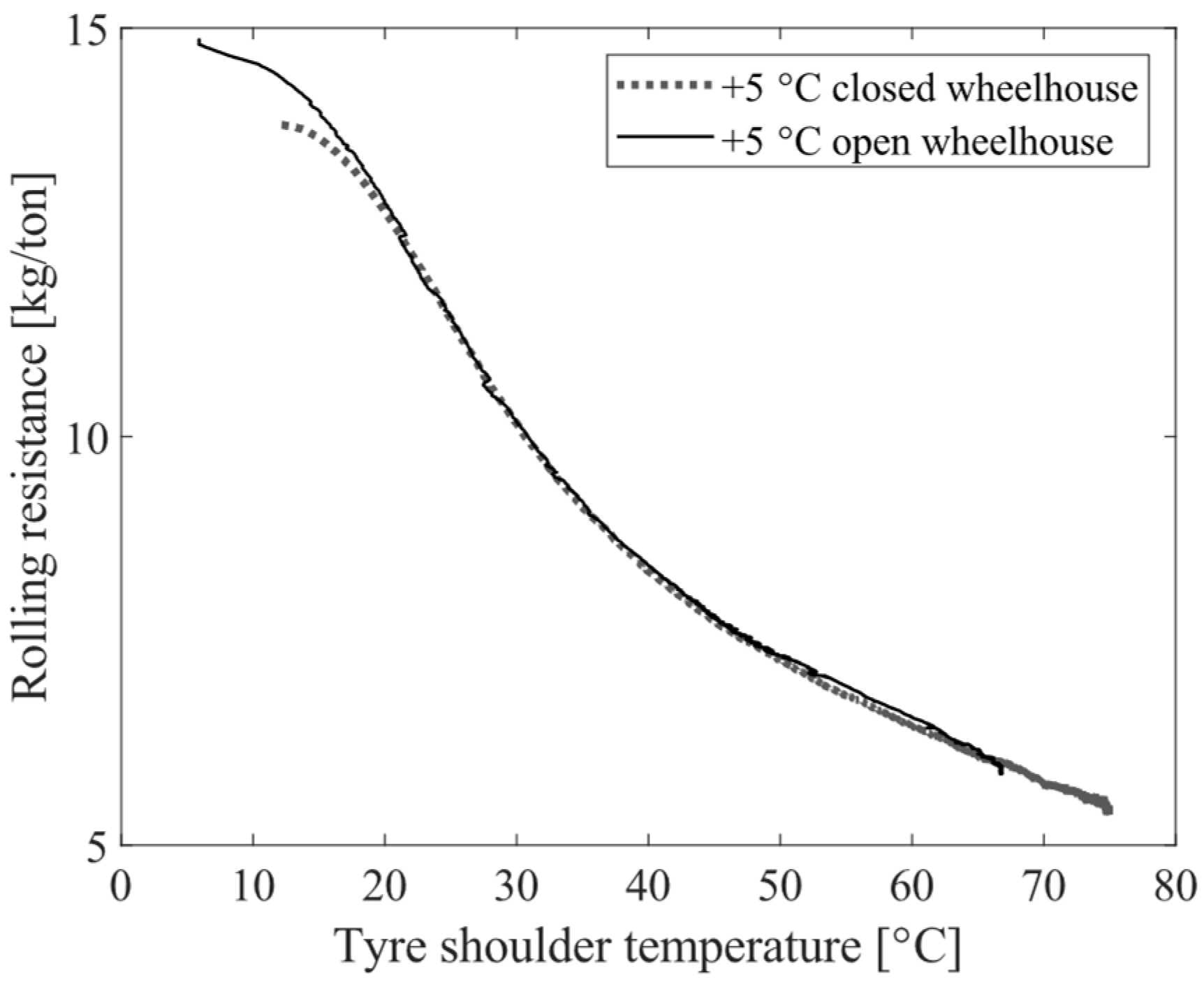

Figure 9), except that the tyre with encapsulated wheelhouse reaches higher temperatures than the tyre with open wheelhouse. In addition, the cooling is slightly slower with the closed wheelhouse when driving stops. Plotting the rolling resistance as a function of tyre shoulder temperature (

Figure 10) shows how both measurements follow similar trends. However, the closed wheelhouse reaches higher temperatures, leading to lower rolling resistance. This type of decrease in rolling resistance with increasing tyre temperature has previously been shown by Hyttinen et al. [

7,

8,

13]. Consequently, the rise in tyre temperature also leads to significantly elevated tyre pressure, as illustrated in

Figure 11. The decrease in rolling resistance is due to a combination of the increased pressure (reduced deformations) and reduced energy dissipation of the tyre rubber.

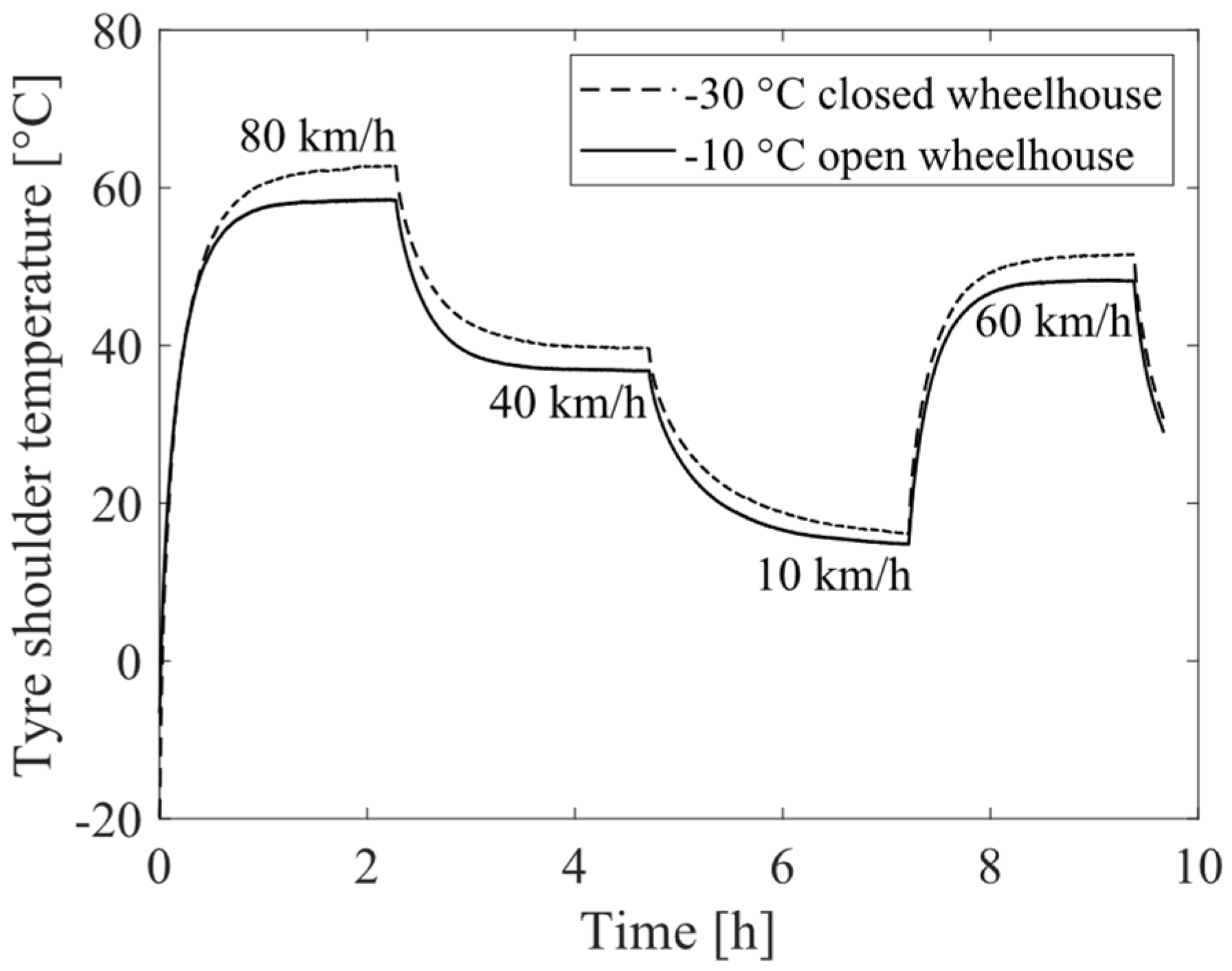

Two additional tests were conducted measuring only tyre temperature: one at −30 °C ambient temperature using the insulated wheelhouse and another at −10 °C with an open wheelhouse (

Figure 12). An interesting fact is that the temperature inside the tyre at −30 °C using an insulated wheelhouse was even higher than with the open wheelhouse at a temperature of −10 °C. Hyttinen et al. [

7,

8] have previously shown that similar changes in tyre temperature at colder temperatures cause larger changes in rolling resistance. Therefore, it can be expected that the reduction in rolling resistance with a closed wheelhouse is even larger at colder temperatures than at +5 °C ambient temperature as used in this article. In addition, the open setup still has more insulation than a regular wheelhouse and more coverage from the inner wheel side than normal wheelhouses (

Figure 4 and

Figure 5). Therefore, the positive effects of encapsulated wheelhouses on rolling resistance could be even more significant than shown in this article.

Covered wheelhouses are also expected to decrease aerodynamic losses by eliminating multiple rotating turbulence sources and blocking airflow under the truck. In addition, encapsulated tyres could decrease tyre-induced noise. The encapsulation of non-steered tyres is easy to implement in various vehicles, and is a cost-efficient way to reduce rolling resistance significantly without any other modifications. However, too high tyre pressures, caused by the increased tyre temperature, might cause more frequent tyre explosions, the overheating of brakes, accelerated tyre ageing, and increased tyre and brake pad wear. When the wheelhouse is covered or insulated, monitoring tyre temperature and inflation pressure becomes crucial to avoid tyre explosions. A positive aspect is that the most significant gains in the reduction in energy consumption are most likely at low ambient temperatures, where the risk of increased tyre and brake wear, overheating brakes, and tyre explosions is not as significant as at higher ambient temperatures.

There are different possibilities for implementing this design idea, depending on the climate. The wheelhouse could be used throughout the whole year in colder countries. If tyre temperature becomes too high in warmer countries, encapsulation could be used only during the winter season. Alternatively, trucks could be equipped with active cooling vents to let more air into the wheelhouse if the tyres or brakes start overheating. In this case, the tyres could be operated with a more optimal tyre temperature nearly at all times while remaining within an acceptable limit of avoiding thermal ageing.

The high degree of insulation in the wheelhouse tested in this article might not be easily attainable in an on-road application. However, even if only half of the reduction in rolling resistance shown here were achieved, it would still significantly reduce CO2 emissions caused by trucks.

5. Discussion and Conclusions

This article investigated the effect of covering and insulating the wheelhouse of a truck to decrease the cooling effects of the tyre, thereby reducing rolling resistance. The experimental study was conducted in a climate wind chamber. The key findings of the study are as follows:

By encapsulating the tyre and insulating the wheelhouse, both tyre temperature and inflation pressure considerably increased.

Rolling resistance significantly decreased at all investigated speed levels when the tyre was encapsulated.

At the beginning of the measurements, the reduction in rolling resistance was nearly the same with or without tyre encapsulation. However, after a short time, the tyres that were encapsulated reached higher temperatures than those in the open wheelhouse setup, resulting in a considerably lower rolling resistance.

The experimental results indicate that minimising the tyre’s cooling effect has a substantial impact on rolling resistance. For example, when driving at 80 km/h, the rolling resistance value with a closed wheelhouse was 7.7% lower than with an open wheelhouse after driving approximately three hours at +5 °C.

The tyre temperature with a closed wheelhouse at an ambient temperature of −30 °C was higher than the tyre temperature with an open wheelhouse at −10 °C. This indicates that rolling resistance at −30 °C could be lower with a closed wheelhouse compared to an open wheelhouse at a significantly higher ambient temperature.

This study showed the effect of a heat-insulated wheelhouse on rolling resistance, and found a significant potential for reducing rolling resistance. However, it is unknown how the increased temperature in the wheelhouse will affect, e.g., (I) tyre wear at the contact patch, (II) tyre ageing at the warmest point of the tyre (near crown belts), (III) brake overheating, or (IV) brake pad wear. Excessive thermal ageing might reduce the ability to retread truck tyres multiple times. These possible drawbacks of the encapsulated wheelhouse design should be studied further.

Encapsulated tyres seem promising from a rolling resistance perspective, and active cooling vents could possibly provide a good compromise between the benefits and drawbacks of the design. In the future, more experimental and computational studies should be conducted to examine how much insulation is needed to reach substantial effects on rolling resistance. Furthermore, the tests should be validated with on-road measurements to confirm the results. Moreover, research should explore the performance of different tyre types in similar tests and if the encapsulated wheelhouse influences the possible accumulation of snow or mud within it.

Author Contributions

Conceptualization, J.H.; Investigation, J.H. and M.U.; Data curation, J.H.; Writing—original draft, J.H.; Writing—review & editing, M.U.; Supervision, R.Ö., J.J. and L.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Swedish Innovation Agency Vinnova (grant number 2016-05195), the Strategic Research Area TRENoP, and Scania.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Acknowledgments

The authors would like to thank the Centre for ECO2 Vehicle Design funded by the Swedish Innovation Agency Vinnova (grant number 2016-05195), the strategic research area TRENoP, and Scania for financial support.

Conflicts of Interest

Authors Jukka Hyttinen, Matthias Ussner, Rickard Österlöf were employed by the company Scania CV AB. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Reducing CO2 Emissions from Heavy-Duty Vehicles. 2019. Available online: https://ec.europa.eu/clima/eu-action/transport-emissions/road-transport-reducing-co2-emissions-vehicles/reducing-co2-emissions-heavy-duty-vehicles_en (accessed on 9 February 2022).

- Aldhufairi, H.S.; Olatunbosun, O.A. Developments in tyre design for lower rolling resistance: A state of the art review. Proc. Inst. Mech. Eng. Part. D J. Automob. Eng. 2018, 232, 1865–1882. [Google Scholar] [CrossRef]

- Nakajima, Y. Advanced Tire Mechanics; Springer: Singapore, 2019. [Google Scholar]

- Greiner, M.; Unrau, H.J.; Gauterin, F. A model for prediction of the transient rolling resistance of tyres based on inner-liner temperatures. Veh. Syst. Dyn. 2018, 56, 78–94. [Google Scholar] [CrossRef]

- Luchini, J.R.; Popio, J.A. Modeling transient rolling resistance of tires. Tire Sci. Technol. 2007, 35, 118–140. [Google Scholar] [CrossRef]

- Nielsen, L.; Sandberg, T. A New Model For Rolling Resistance of Pneumatic Tires. J. Passeng. Car Mech. Syst. J. 2002, 111, 1572–1579. [Google Scholar] [CrossRef]

- Hyttinen, J.; Ussner, M.; Österlöf, R.; Jerrelind, J.; Drugge, L. Truck tyre transient rolling resistance and temperature at varying vehicle velocities-Measurements and simulations. Polym. Test. 2023, 122, 108004. [Google Scholar] [CrossRef]

- Hyttinen, J.; Ussner, M.; Österlöf, R.; Jerrelind, J.; Drugge, L. Effect of ambient and tyre temperature on truck tyre rolling resistance. Int. J. Automot. Technol. 2022, 23, 1651–1661. [Google Scholar] [CrossRef]

- Ejsmont, J.; Taryma, S.; Ronowski, G.; Swieczko-Zurek, B. Influence of temperature on the tyre rolling resistance. Int. J. Automot. Technol. 2018, 19, 45–54. [Google Scholar] [CrossRef]

- Ejsmont, J.; Ronowski, G.; Owczarzak, W.; Sommer, S. Temperature influence on tire rolling resistance measurements quality. Int. J. Automot. Technol. 2022, 23, 109–123. [Google Scholar] [CrossRef]

- Bode, O. Der Einfluss von Wärmeverlusten auf den Rollwiderstand von Reifen. FAT-Schriftenreihe 2020, 325, 51–54. [Google Scholar]

- Hyttinen, J.; Österlöf, R.; Jerrelind, J.; Drugge, L. A semi-physical thermodynamic transient rolling resistance model with nonlinear viscoelasticity. Mech. Time-Depend. Mater. 2023, 28, 895–916. [Google Scholar] [CrossRef]

- Hyttinen, J. Modelling and Experimental Testing of Truck Tyre Rolling Resistance; KTH Royal Institute of Technology: Stockholm, Sweden, 2023. [Google Scholar]

- Duell, E.; Kharazi, A.; Nagle, P.; Elofsson, P.; Söderblom, D.; Ramden, C.M. Scania’s New CD7 Climatic Wind Tunnel Facility for Heavy Trucks and Buses. SAE Int. J. Passeng. Cars-Mech. Syst. 2016, 9, 785–799. [Google Scholar] [CrossRef]

- SS-ISO 28580:2018; Passenger Car, Truck and Bus Tyre Rolling Resistance Measurement Method. Swedish Standards Institute: Stockholm, Sweden, 2018.

- Freudenmann, T.; Unrau, H.J.; El-Haji, M. Experimental determination of the effect of the surface curvature on rolling resistance measurements. Tire Sci. Technol. 2009, 37, 254–278. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).