Logistic Decisions in the Installation of Offshore Wind Farms: A Conceptual Framework

Abstract

1. Introduction

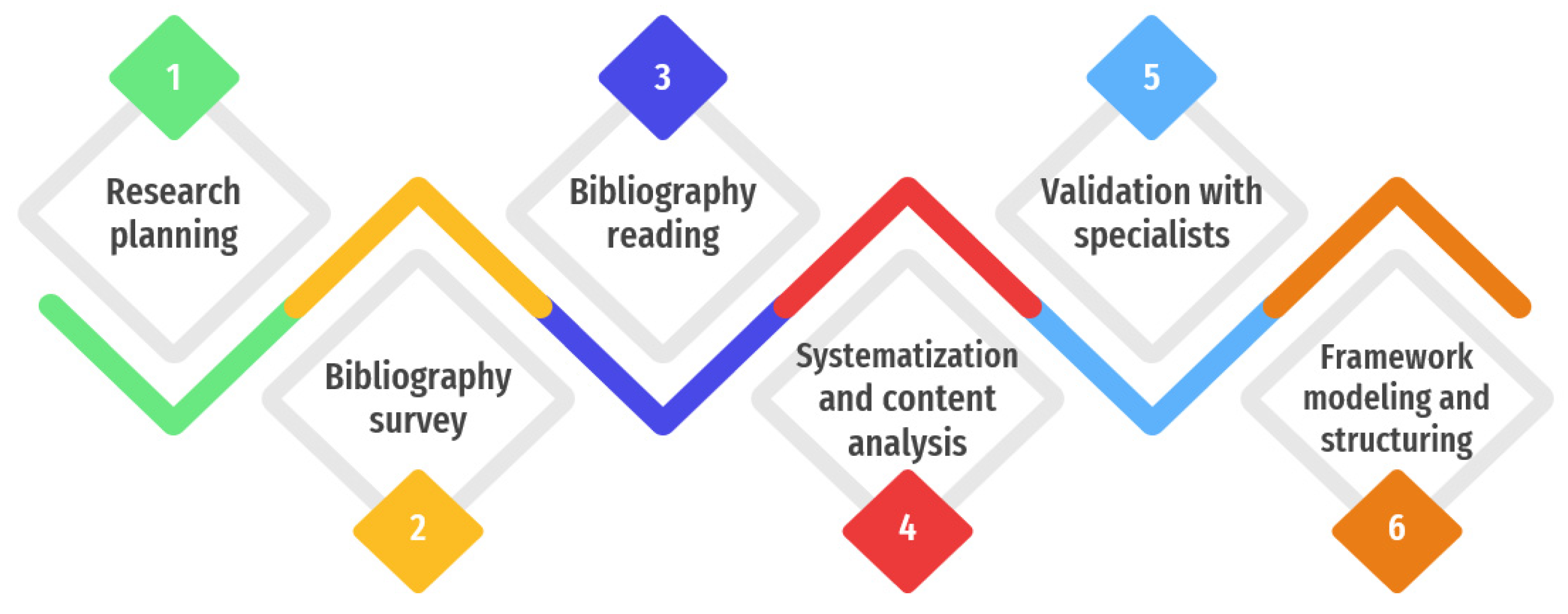

2. Materials and Methods

3. Literature Review

3.1. Offshore Wind Installation Logistics

3.1.1. Transport Strategies to OWF Installation

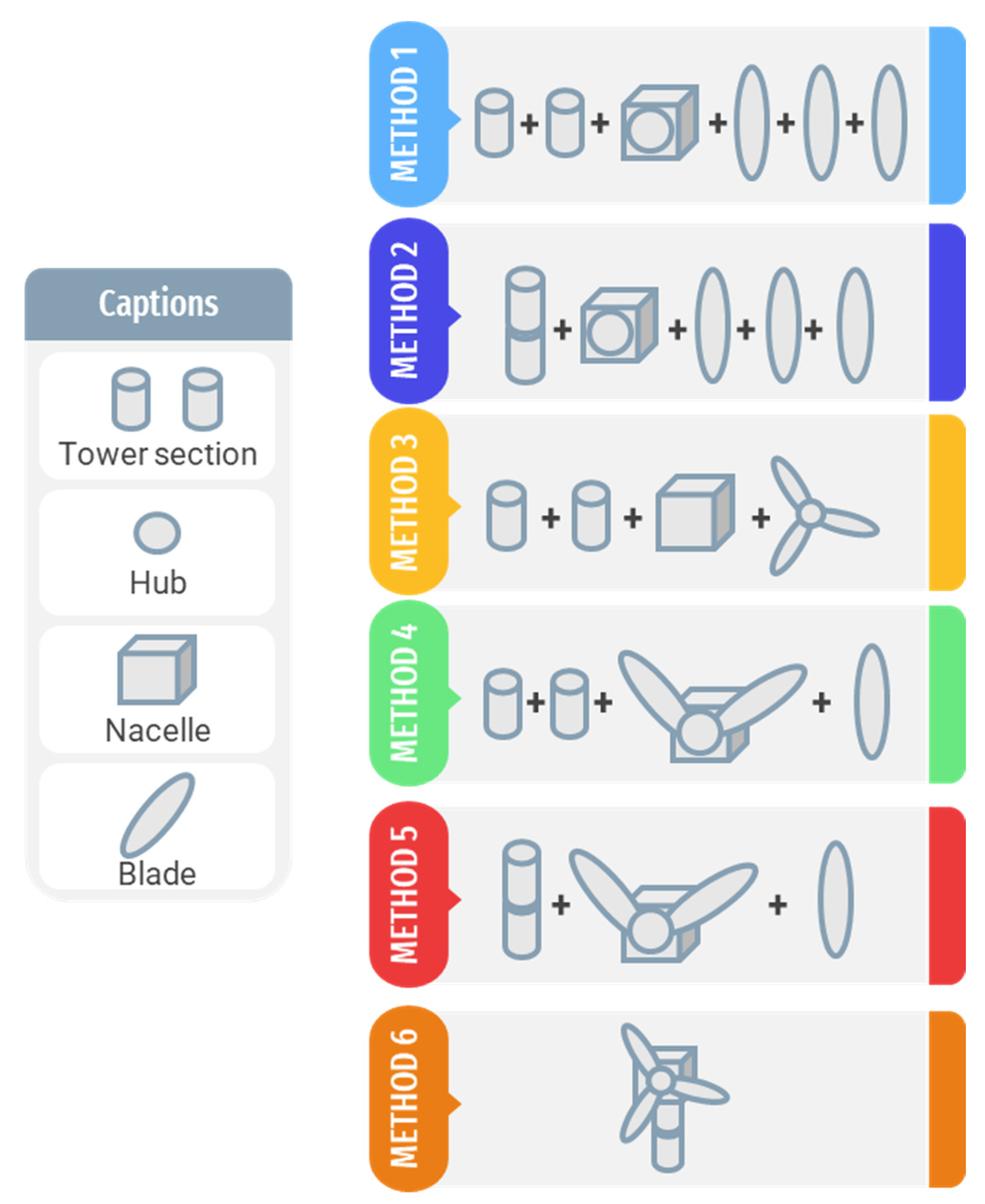

3.1.2. Installation of Offshore Wind Farm Components

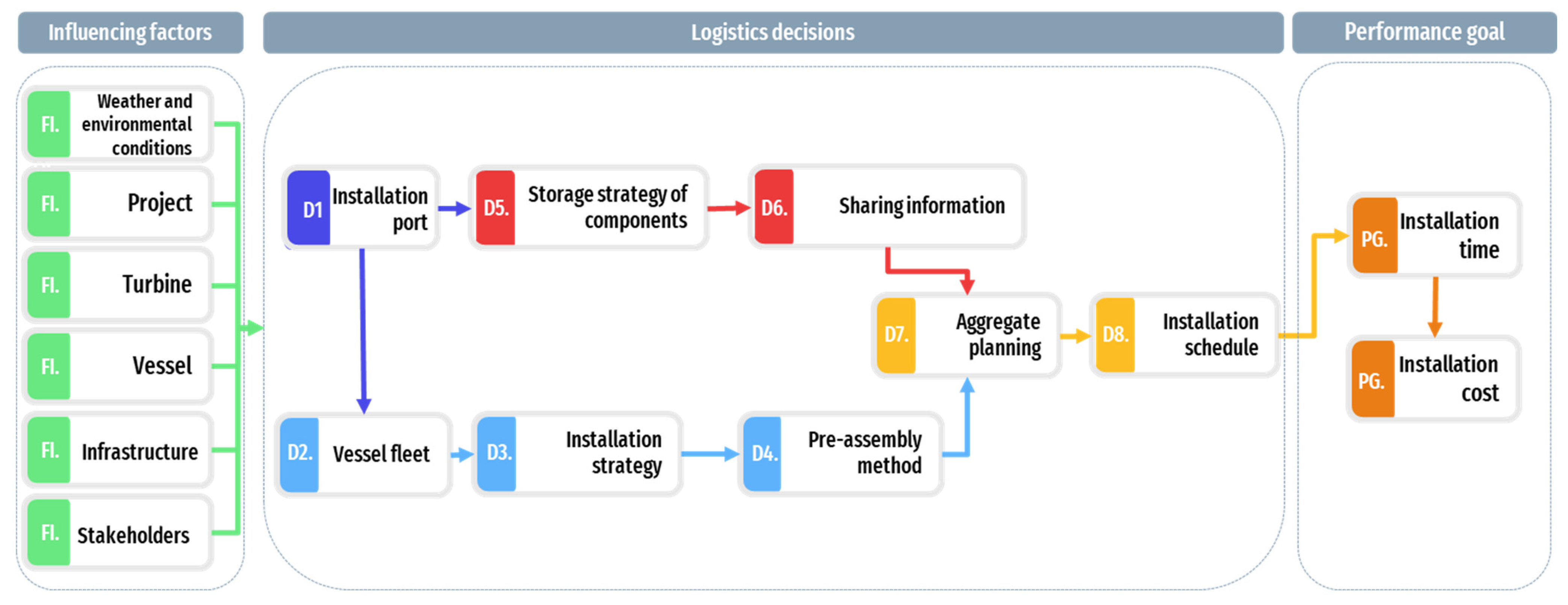

4. Logistical Decisions in the Process of Installing OWF: Conceptual Framework

4.1. Influencing Factors

4.2. Logistics Decision

4.3. Performance Goals

5. Discussion and Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chartron, S. Improving logistics scheduling and operations to support offshore wind construction phase. Logist. Res. 2019, 12, 8. [Google Scholar] [CrossRef]

- World Bank. Going Global-Expanding Offshore Wind to Emerging Markets; World Bank Group: Washington, DC, USA, 2019. [Google Scholar]

- GWEC. Global Offshore Wind Report 2024; Global Wind Energy Council: Brussels, Belgium, 2024; pp. 86–88. [Google Scholar]

- Chartron, S. Evaluating and Improving Logistics Costs During Offshore Wind Turbine Construction. Int. J. Transp. Eng. Technol. 2018, 4, 65–74. [Google Scholar] [CrossRef]

- González, M.O.A.; Santiso, A.M.; de Melo, D.C.; de Vasconcelos, R.M. Regulation for offshore wind power development in Brazil. Energy Policy 2020, 145, 111756. [Google Scholar] [CrossRef]

- Borràs Mora, E.; Spelling, J.; van der Weijde, A.H. Global sensitivity analysis for offshore wind cost modelling. Wind Energy 2021, 24, 974–990. [Google Scholar] [CrossRef]

- Melo, D.C. Framework De Um Sistema Especialista De Análise Econômica Para Empreendimentos De Usinas Eólicas Offshore. Universidade Federal Do Rio Grande Do Norte Centro: Natal, Brazil, 2020; 152p. [Google Scholar]

- Santhakumar, S.; Heuberger-Austin, C.; Meerman, H.; Faaij, A. Technological learning potential of offshore wind technology and underlying cost drivers. Sustain. Energy Technol. Assess. 2023, 60, 103545. [Google Scholar] [CrossRef]

- Torres, E.S.; Thies, P.R.; Lawless, M. Offshore Logistics: Scenario Planning and Installation Modeling of Floating Offshore Wind Projects. ASME Open J. Eng. 2023, 2, 021013. [Google Scholar] [CrossRef]

- Lerche, J.; Lindhard, S.; Enevoldsen, P.; Neve, H.H.; Møller, D.E.; Jacobsen, E.L.; Teizer, J.; Wandahl, S. Causes of delay in offshore wind turbine construction projects. Prod. Plan. Control 2023, 34, 1513–1526. [Google Scholar] [CrossRef]

- Poulsen, T.; Hasager, C.B. How expensive is expensive enough? Opportunities for cost reductions in offshoreWind energy logistics. Energies 2016, 9, 437. [Google Scholar] [CrossRef]

- Lacal-Arántegui, R.; Yusta, J.M.; Domínguez-Navarro, J.A. Offshore wind installation: Analysing the evidence behind improvements in installation time. Renew. Sustain. Energy Rev. 2018, 92, 133–145. [Google Scholar] [CrossRef]

- Scholz-Reiter, B.; Heger, J.; Lütjen, M.; Schweizer, A. A MILP for installation scheduling of offshore wind farms. Int. J. Math. Model. Methods Appl. Sci. 2011, 5, 371–378. [Google Scholar]

- Guo, Y.; Wang, H.; Lian, J. Review of integrated installation technologies for offshore wind turbines: Current progress and future development trends. Energy Convers. Manag. 2022, 255, 115319. [Google Scholar] [CrossRef]

- Beinke, T.; Quandt, M.; Ait-Alla, A.; Freitag, M. The impact of information sharing on installation processes of offshore wind farms—Process modelling and simulation-based analysis. Int. J. Shipp. Transp. Logist. 2020, 12, 92–116. [Google Scholar] [CrossRef]

- Sarker, B.R.; Faiz, T.I. Minimizing transportation and installation costs for turbines in offshore wind farms. Renew. Energy 2017, 101, 667–679. [Google Scholar] [CrossRef]

- Shafiee, M. Maintenance logistics organization for offshore wind energy: Current progress and future perspectives. Renew. Energy 2015, 77, 182–193. [Google Scholar] [CrossRef]

- Ahn, D.; Shin, S.C.; Kim, S.Y.; Kharoufi, H.; Kim, H.C. Comparative evaluation of different offshore wind turbine installation vessels for Korean west–south wind farm. Int. J. Nav. Archit. Ocean Eng. 2016, 9, 45–54. [Google Scholar] [CrossRef]

- Poulsen, T. Logistics in Offshore Wind; Aalborg University: Aalborg, Denmark, 2018. [Google Scholar]

- Tekle Muhabie, Y.; Rigo, P.; Cepeda, M.; de Almeida D’Agosto, M.; Caprace, J.-D. A discrete-event simulation approach to evaluate the effect of stochastic parameters on offshore wind farms assembly strategies. Ocean Eng. 2018, 149, 279–290. [Google Scholar] [CrossRef]

- de Falani, S.Y.A.; González, M.O.A.; Barreto, F.M.; de Toledo, J.C.; Torkomian, A.L.V. Trends in the technological development of wind energy generation. Int. J. Technol. Manag. Sustain. Dev. 2020, 19, 43–68. [Google Scholar] [CrossRef]

- Poulsen, T.; Lema, R. Is the supply chain ready for the green transformation? The case of offshore wind logistics. Renew. Sustain. Energy Rev. 2017, 73, 758–771. [Google Scholar] [CrossRef]

- Habakurama, I.I.; Baluku, J. The Challenges in Installation of Offshore Wind Farms a Case of Lillgrund and Anholt Wind Farms; Chalmers University of Technology: Gothenburg, Sweden, 2016; 70p. [Google Scholar]

- The Wind Power. Haliade-X 12 MW; The Wind Power—Wind Energy Market Intelligence: Tournefeuille, France, 2020. [Google Scholar]

- Judge, F.; McAuliffe, F.D.; Sperstad, I.B.; Chester, R.; Flannery, B.; Lynch, K.; Murphy, J. A lifecycle financial analysis model for offshore wind farms. Renew. Sustain. Energy Rev. 2019, 103, 370–383. [Google Scholar] [CrossRef]

- Paterson, J.; D’Amico, F.; Thies, P.R.; Harrison, G. Offshore wind installation vessels—A comparative assessment for UK offshore rounds 1 and 2. Ocean Eng. 2017, 15, 637–649. [Google Scholar] [CrossRef]

- Kaiser, M.J.; Snyder, B.F. Modeling offshore wind installation vessel day-rates in the United States. Marit. Econ. Logist. 2012, 14, 220–248. [Google Scholar] [CrossRef]

- Vis, I.F.A.; Ursavas, E. Assessment approaches to logistics for offshore wind energy installation. Sustain. Energy Technol. Assess. 2016, 14, 80–91. [Google Scholar] [CrossRef]

- Irawan, C.A.; Jones, D.; Ouelhadj, D. Bi-objective optimisation model for installation scheduling in offshore wind farms. Comput. Oper. Res. 2017, 78, 393–407. [Google Scholar] [CrossRef]

- Barlow, E.; Tezcaner Öztürk, D.; Revie, M.; Boulougouris, E.; Day, A.H.; Akartunali, K. Exploring the impact of innovative developments to the installation process for an offshore wind farm. Ocean Eng. 2015, 109, 623–634. [Google Scholar] [CrossRef]

- Jiang, Z. Installation of offshore wind turbines: A technical review. Renew. Sustain. Energy Rev. 2021, 139, 110576. [Google Scholar] [CrossRef]

- Jesson, J.; Matheson, L.; Lacey, F.M. Doing Your Systematic Review—Traditional and Systematic Techniques, 1st ed.; Sage Publications: London, UK, 2011; 192p, ISBN 978-1-84860-154-3. [Google Scholar]

- Kitchenham, B.A.; Dybå, T.; Jørgensen, M. Evidence-based Software Engineering. In Proceedings of the 26th International Conference on Software Engineering, Edinburgh, UK, 28 May 2004; p. 9. [Google Scholar]

- Kitchenham, B.; Pearl Brereton, O.; Budgen, D.; Turner, M.; Bailey, J.; Linkman, S. Systematic literature reviews in software engineering—A systematic literature review. Inf. Softw. Technol. 2009, 51, 7–15. [Google Scholar] [CrossRef]

- González, M.O.A.; de Toledo, J.C. Customer integration in the product development process: A systematic bibliographic review and themes for research. Producao 2012, 22, 14–26. [Google Scholar] [CrossRef]

- Gollub, P.; Jensen, J.F.; Giese, D.; Güres, S. Flanged foundation connection of the offshore wind farm Amrumbank West—Concept, approval, design, tests and installation. Stahlbau 2014, 83, 522–528. [Google Scholar] [CrossRef]

- Ku, N.; Roh, M. Il Dynamic response simulation of an offshore wind turbine suspended by a floating crane. Ships Offshore Struct. 2015, 10, 621–634. [Google Scholar] [CrossRef]

- Hongyan, D.; Jijian, L.; Aidong, L.; Puyang, Z. One-Step-Installation of Offshore Wind Turbine on Large-Scale Bucket-Top-Bearing Bucket Foundation. Trans. Tianjin Univ. 2009, 15, 70–74. [Google Scholar] [CrossRef]

- Cheng, M.Y.; Wu, Y.F.; Wu, Y.W.; Ndure, S. Fuzzy Bayesian schedule risk network for offshore wind turbine installation. Ocean Eng. 2019, 188, 106238. [Google Scholar] [CrossRef]

- Kerkhove, L.P.; Vanhoucke, M. Optimised scheduling for weather sensitive offshore construction projects. Omega 2017, 66, 58–78. [Google Scholar] [CrossRef]

- Ait-Alla, A.; Quandt, M.; Lütjen, M. Simulation-based aggregate Installation Planning of Offshore Wind Farms. Int. J. Energy 2013, 72, 23–30. [Google Scholar]

- Sovacool, B.K.; Enevoldsen, P.; Koch, C.; Barthelmie, R.J. Cost performance and risk in the construction of offshore and onshore wind farms. Wind Energy 2017, 20, 891–908. [Google Scholar] [CrossRef]

- Wang, W.; Bai, Y. Investigation on installation of offshore wind turbines. J. Mar. Sci. Appl. 2010, 9, 175–180. [Google Scholar] [CrossRef]

- Rippel, D.; Jathe, N.; Lütjen, M.; Freitag, M. Evaluation of loading bay restrictions for the installation of offshore wind farms using a combination of mixed-integer linear programming and model predictive control. Appl. Sci. 2019, 9, 5030. [Google Scholar] [CrossRef]

- Irawan, C.A.; Akbari, N.; Jones, D.F.; Menachof, D. A combined supply chain optimisation model for the installation phase of offshore wind projects. Int. J. Prod. Res. 2018, 56, 1189–1207. [Google Scholar] [CrossRef]

- Li, L.; Acero, W.G.; Gao, Z.; Moan, T. Assessment of allowable sea states during installation of offshore wind turbine monopiles with shallow penetration in the seabed. J. Offshore Mech. Arct. Eng. 2016, 138, 041902. [Google Scholar] [CrossRef]

- Leontaris, G.; Morales-Nápoles, O.; Wolfert, A.R.M. Probabilistic scheduling of offshore operations using copula based environmental time series—An application for cable installation management for offshore wind farms. Ocean Eng. 2016, 125, 328–341. [Google Scholar] [CrossRef]

- Gintautas, T.; Sørensen, J.D.; Vatne, S.R. Towards a Risk-based Decision Support for Offshore Wind Turbine Installation and Operation & Maintenance. Energy Procedia 2016, 94, 207–217. [Google Scholar] [CrossRef]

- Bingol, F. Feasibility of large scale wind turbines for offshore gas platform installation. AIMS Energy 2018, 6, 967–978. [Google Scholar] [CrossRef]

- Verma, A.S.; Vedvik, N.P.; Gao, Z. A comprehensive numerical investigation of the impact behaviour of an offshore wind turbine blade due to impact loads during installation. Ocean Eng. 2019, 172, 127–145. [Google Scholar] [CrossRef]

- Ren, Z.; Jiang, Z.; Skjetne, R.; Gao, Z. Development and application of a simulator for offshore wind turbine blades installation. Ocean Eng. 2018, 166, 380–395. [Google Scholar] [CrossRef]

- Leontaris, G.; Morales-Nápoles, O.; Wolfert, A.R.M. Planning cable installation activities for offshore wind farms including risk of supply delays. In Risk, Reliability and Safety: Innovating Theory and Practice, Proceedings of the 26th European Safety and Reliability Conference, ESREL 2016 Glasgow, Scotland, 25–29 September 2016; CRC Press, Taylor & Francis Group: Boca Raton, FL, USA, 2017; p. 104. [Google Scholar]

- Lian, J.; Wang, P.; Le, C.; Dong, X.; Yang, X.; Jiang, Q.; Yang, Y.; Jiang, J. Reliability analysis on one-step overall transportation of composite bucket foundation for offshore wind turbine. Energies 2019, 13, 23. [Google Scholar] [CrossRef]

- Ding, H.; Feng, Z.; Zhang, P.; Le, C.; Guo, Y. Floating performance of a composite bucket foundation with an offshore wind tower during transportation. Energies 2020, 13, 882. [Google Scholar] [CrossRef]

- Zhang, P.; Han, Y.; Ding, H.; Zhang, S. Field experiments on wet tows of an integrated transportation and installation vessel with two bucket foundations for offshore wind turbines. Ocean Eng. 2015, 108, 769–777. [Google Scholar] [CrossRef]

- Zhao, Y.; Cheng, Z.; Sandvik, P.C.; Gao, Z.; Moan, T.; Van Buren, E. Numerical modeling and analysis of the dynamic motion response of an offshore wind turbine blade during installation by a jack-up crane vessel. Ocean Eng. 2018, 165, 353–364. [Google Scholar] [CrossRef]

- Guachamin Acero, W.; Gao, Z.; Moan, T. Numerical study of a novel procedure for installing the tower and Rotor Nacelle Assembly of offshore wind turbines based on the inverted pendulum principle. J. Mar. Sci. Appl. 2016, 16, 243–260. [Google Scholar] [CrossRef]

- Ait-Alla, A.; Quandt, M.; Lütjen, M. Aggregate Installation Planning of Offshore Wind Farms. In Proceedings of the International Conference on Communications and Information Technology, Beirut, Lebanon, 19–21 June 2013; Volume 7, pp. 23–30. [Google Scholar]

- Ursavas, E. A benders decomposition approach for solving the offshore wind farm installation planning at the North Sea. Eur. J. Oper. Res. 2017, 258, 703–714. [Google Scholar] [CrossRef]

- Castro-Santos, L.; Filgueira-Vizoso, A.; Lamas-Galdo, I.; Carral-Couce, L. Methodology to calculate the installation costs of offshore wind farms located in deep waters. J. Clean. Prod. 2018, 170, 1124–1135. [Google Scholar] [CrossRef]

- Beinke, T.; Ait-Alla, A.; Freitag, M. Resource Sharing in the Logistics of the Offshore Wind Farm Installation Process based on a Simulation Study. Int. J. e-Navig. Marit. Econ. 2017, 7, 42–54. [Google Scholar] [CrossRef]

- Zhang, P.; Ding, H.; Le, C.; Huang, X. Motion analysis on integrated transportation technique for offshore wind turbines. J. Renew. Sustain. Energy 2013, 5, 16. [Google Scholar] [CrossRef]

- Lian, J.; Jiang, J.; Dong, X.; Wang, H.; Zhou, H.; Wang, P. Coupled motion characteristics of offshore wind turbines during the integrated transportation process. Energies 2019, 12, 2023. [Google Scholar] [CrossRef]

- Antoniou, M.; Gelagoti, F.M.; Anastasopoulos, I. A compliant guyed system for deep-sea installations of offshore wind turbines: Concept, design insights and dynamic performance. Soil Dyn. Earthq. Eng. 2019, 119, 235–252. [Google Scholar] [CrossRef]

- Zhang, P.; Guo, Y.; Liu, Y.; Ding, H. Experimental study on installation of hybrid bucket foundations for offshore wind turbines in silty clay. Ocean Eng. 2016, 114, 87–100. [Google Scholar] [CrossRef]

- Esteban, M.D.; Couñago, B.; López-Gutiérrez, J.S.; Negro, V.; Vellisco, F. Gravity based support structures for offshore wind turbine generators: Review of the installation process. Ocean Eng. 2015, 110, 281–291. [Google Scholar] [CrossRef]

- Acero, W.G.; Gao, Z.; Moan, T. Methodology for assessment of the allowable sea states during installation of an offshore Wind turbine transition piece structure onto a monopile foundation. J. Offshore Mech. Arct. Eng. 2017, 139, 061901. [Google Scholar] [CrossRef]

- Scharff, R.; Siems, M. Monopile foundations for offshore wind turbines—Solutions for greater water depths. Steel Constr. 2013, 6, 47–53. [Google Scholar] [CrossRef]

- Scharff, R.; Siems, M. Pushing the limits—Mega monopile foundations for offshore wind turbines. Steel Constr. 2013, 6, 178–185. [Google Scholar] [CrossRef]

- Nielsen, M.B.; Jensen, J.F.; Harper, C.; Knudsen, L.S.; Pedersen, R.R. State-of-the-art framework for design of offshore wind jacket foundations. Steel Constr. 2019, 12, 209–214. [Google Scholar] [CrossRef]

- Collu, M.; Maggi, A.; Gualeni, P.; Rizzo, C.M.; Brennan, F. Stability requirements for floating offshore wind turbine (FOWT) during assembly and temporary phases: Overview and application. Ocean Eng. 2014, 84, 164–175. [Google Scholar] [CrossRef]

- Zhang, P.; Liang, D.; Ding, H.; Le, C.; Zhao, X. Floating state of a one-step integrated transportation vessel with two composite bucket foundations and offshore wind turbines. J. Mar. Sci. Eng. 2019, 7, 263. [Google Scholar] [CrossRef]

- Acero, W.G.; Gao, Z.; Moan, T. Assessment of the Dynamic Responses and Allowable Sea States for a Novel Offshore Wind Turbine Installation Concept Based on the Inverted Pendulum Principle. Energy Procedia 2016, 94, 61–71. [Google Scholar] [CrossRef][Green Version]

- Barlow, E.; Tezcaner Öztürk, D.; Revie, M.; Akartunalı, K.; Day, A.H.; Boulougouris, E. A mixed-method optimisation and simulation framework for supporting logistical decisions during offshore wind farm installations. Eur. J. Oper. Res. 2018, 264, 894–906. [Google Scholar] [CrossRef]

- Quandt, M.; Beinke, T.; Ait-Alla, A.; Freitag, M. Simulation Based Investigation of the Impact of Information Sharing on the Offshore Wind Farm Installation Process. J. Renew. Energy 2017, 2017, 8301316. [Google Scholar] [CrossRef]

- Akbari, N.; Irawan, C.A.; Jones, D.F.; Menachof, D. A multi-criteria port suitability assessment for developments in the offshore wind industry. Renew. Energy 2017, 102, 118–133. [Google Scholar] [CrossRef]

- Hong, S.; McMorland, J.; Zhang, H.; Collu, M.; Halse, K.H. Floating offshore wind farm installation, challenges and opportunities: A comprehensive survey. Ocean Eng. 2024, 304, 117793. [Google Scholar] [CrossRef]

- Amorosi, L.; Fischetti, M.; Paradiso, R.; Roberti, R. Optimization models for the installation planning of offshore wind farms. Eur. J. Oper. Res. 2024, 315, 1182–1196. [Google Scholar] [CrossRef]

- Kikuchi, Y.; Ishihara, T. Assessment of weather downtime for the construction of offshore wind farm by using wind and wave simulations. J. Phys. Conf. Ser. 2016, 753, 092016. [Google Scholar] [CrossRef]

- Lütjen, M.; Karimi, H.R. Approach of a port inventory control system for the offshore installation of wind turbines. In Proceedings of the International Offshore and Polar Engineering Conference, Rhodes, Greece, 17–23 June 2012; pp. 502–508. [Google Scholar]

- Fan, H.; Lin, J.; Shi, Q. Installation vessel and method for offshore wind turbine in ultra-shallow water. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering—OMAE, Shanghai, China, 6–11 June 2010; Volume 3, pp. 357–363. [Google Scholar]

- Li, L.; Ren, J. Offshore wind turbines and their installation. In Proceedings of the CICC-ITOE 2010—2010 International Conference on Innovative Computing and Communication, 2010 Asia-Pacific Conference on Information Technology and Ocean Engineering, Macao, China, 30–31 January 2010; pp. 248–251. [Google Scholar]

- Barlow, E.; Tezcaner Öztürk, D.; Day, A.H.; Boulougouris, E.; Revie, M.; Akartunalı, K. A support tool for assessing the risks of heavy lift vessel logistics in the installation of offshore wind farms. In Proceedings of the Marine Heavy Transport & Lift IV, London, UK, 29–30 October 2014; pp. 11–20. [Google Scholar]

- Barlow, E.; Tezcaner Öztürk, D.; Day, S.; Boulougouris, E.; Revie, M.; Akartunali, K. An Assessment of Vessel Characteristics for the Installation of Offshore Wind Farms. In Proceedings of the ICMT, Strathclyde, UK, 7–9 July 2014; pp. 1–7. [Google Scholar]

- Wu, G.; Tohbai, Y.; Takahashi, T. Construction and operational properties of offshore wind farm power generation system with self-commuted HVDC transmission. In Proceedings of the 2010 International Conference on Power System Technology, Zhejiang, Hangzhou, China, 24–28 October 2010; pp. 1–6. [Google Scholar]

- Lerche, J.; Neve, H.; Pedersen, K.B.; Wandahl, S.; Gross, A. Why would location-based scheduling be applicable for offshore oil and gas construction? In Proceedings of the 27th Annual Conference of the International Group for Lean Construction, Dublin, Ireland, 1–7 June 2019; pp. 1295–1306. [Google Scholar]

- Beinke, T.; Ait-Alla, A.; Freitag, M. Resource and information sharing for the installation process of the offshore wind energy. In Proceedings of the IFIP International Conference on Advances in Production Management Systems (APMS), Hamburg, Germany, 3–7 September 2017; Volume 514, pp. 268–275. [Google Scholar]

- Cairney, J. Offshore wind farm case study—How to achieve cost reduction at offshore wind farm construction projects. In Proceedings of the Annual Offshore Technology Conference, Houston, TX, USA, 4–7 May 2015; Volume 6, pp. 4398–4405. [Google Scholar]

- Leontaris, G.; Morales-Nápoles, O.; Wolfert, A.R.M.R. Probabilistic decision support for offshore wind operations: A Bayesian Network approach to include the dependence of the installation activities. In Proceedings of the Probabilistic Safety Assessment and Management PSAM 14, Los Angeles, CA, USA, 16–21 September 2018. [Google Scholar]

- Ait-Alla, A.; Oelker, S.; Lewandowski, M.; Freitag, M.; Thoben, K.D. A study of new installation concepts of offshore wind farms by means of simulation model. In Proceedings of the International Offshore and Polar Engineering Conference, San Francisco, CA, USA, 25−30 June 2017; pp. 607–612. [Google Scholar]

- Gao, Z.; Verma, A.; Zhao, Y.; Jiang, Z.; Ren, Z. A summary of the recent work at ntnu on marine operations related to installation of offshore wind turbines. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering—OMAE, Madrid, Spain, 17–22 June 2018; Volume 11A, pp. 1–9. [Google Scholar]

- Stempinski, F.; Wenzel, S.; Lüking, J.; Martens, L.; Hortamani, M. Modelling installation and construction of offshore wind farms. In Proceedings of the ASME 2014 33rd International Conference on Ocean, Offshore and Arctic Engineering, San Francisco, CA, USA, 8–13 June 2014; Volume 9B, pp. 1–12. [Google Scholar]

- Gintautas, T.; Sørensen, J.D. Evaluating a novel approach to reliability decision support for offshore wind turbine installation. In Progress in Renewable Energies Offshore, Proceedings of the 2nd International Conference on Renewable Energies Offshore, RENEW 2016, Lisbon, Portugal, 24–26 October 2016; CRC Press: Boca Raton, FL, USA, 2016; pp. 733–740. [Google Scholar]

- O’Sullivan, J.; Arjona, J.F.; Aghili, M. Comparison of installation scenarios for offshore wind farms using operations simulator with Markov wind & wave weather model. Proc. Offshore Technol. Conf. 2011, 4, 3265–3269. [Google Scholar] [CrossRef]

- Cholley, J.M.; Cahay, M. Offshore wind turbine and substructure modelling for float over installation design. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering—OMAE, Honolulu, HI, USA, 31 May–5 June 2009; Volume 4, pp. 791–798. [Google Scholar] [CrossRef]

- Hatledal, L.I.; Zhang, H.; Halse, K.H.; Hildre, H.P. Numerical study for a catamaran gripper-monopile mechanism of a novel offshore wind turbine assembly installation procedure. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering—OMAE, Trondheim, Norway, 25–30 June 2017; Volume 9. [Google Scholar]

- Devoy McAuliffe, F.; Lynch, K.; Sperstad, I.B.; Nonas, L.M.; Halvorsen-Weare, E.E.; Jones, D.; Akbari, N.; Wall, G.; Irawan, C.; Norstad, I.; et al. The LEANWIND suite of logistics optimisation and full lifecycle simulation models for offshore wind farms. J. Phys. Conf. Ser. 2018, 1104, 012002. [Google Scholar] [CrossRef]

- Thumann, V.M.; Yetginer-Tjelta, T.; Van Foeken, R.J. Design & installation monitoring experience of large diameter monopiles for offshore wind farm in highly variable North Sea soil conditions. In Proceedings of the Annual Offshore Technology Conference, Houston, TX, USA, 1–4 May 2017; Volume 6, pp. 4623–4641. [Google Scholar]

- Li, L.; Gao, Z.; Moan, T. Numerical simulations for installation of offshore wind turbine monopiles using floating vessels. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering—OMAE, Nantes, France, 8–13 June 2013; Volume 8, pp. 1–11. [Google Scholar]

- Puyang, Z.; Ding, H.; Le, C.; Zhang, S.; Huang, X. Preliminary analysis on integrated transportation technique for offshore wind turbines. In Proceedings of the ASME 2013 32nd International Conference on Ocean, Offshore and Arctic Engineering, Nantes, France, 8–13 June 2013; pp. 1–6. [Google Scholar]

- Haugvaldstad, J.; Gudmestad, O.T. Testing of a new transport and installation method for offshore wind turbines. IOP Conf. Ser. Mater. Sci. Eng. 2019, 700, 012004. [Google Scholar] [CrossRef]

- Beinke, T.; Quandt, M.; Schweizer, A. Developing standardized logistics processes for the offshore wind energy industry. In Proceedings of the DEWEK 2012, Bremen, Germany, 7–8 November 2012; p. 4. [Google Scholar]

- Sarkar, A.; Gudmestad, O.T. Installation of monopiles for offshore wind turbines—By using end-caps and a subsea holding structure. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering—OMAE, Rotterdam, The Netherlands, 18–23 June 2011; Volume 5, pp. 309–315. [Google Scholar]

- Muhabie, Y.T.; Caprace, J.-D.; Petcu, C.; Rigo, P. Improving the installation of offshore wind farms by the use of discrete event simulation. In Proceedings of the World Maritime Technology Conference (WMTC), Providence, RI, USA, 3–7 November 2015; pp. 1–10. [Google Scholar]

- Ait-Alla, A.; Quandt, M.; Beinke, T.; Freitag, M. Improving the decision-making process during the installation process of offshore wind farms by means of information sharing. In Proceedings of the International Offshore and Polar Engineering Conference, Rhodes, Greece, 26 June–1 July 2016; pp. 144–150. [Google Scholar]

- Scholz-Reiter, B.; Lütjen, M.; Heger, J.; Schweizer, A. Planning and control of logistics for offshore wind farms. In Proceedings of the 12th WSEAS International Conference on Mathematical and Computational Methods in Science and Engineering, Faro, Portugal, 3–5 November 2010; pp. 242–247. [Google Scholar]

- Arshad, M.; O’kelly, B.C. Offshore wind-turbine structures: A review. Proc. Inst. Civ. Eng. Energy 2013, 166, 139–152. [Google Scholar] [CrossRef]

- Tranberg, B.; Kratmann, K.K.; Stege, J. Determining offshore wind installation times using machine learning and open data. In Proceedings of the Offshore WindEurope conference, Bilbao, Spain, 2–4 April 2019; pp. 1–12. [Google Scholar]

- Ding, H.; Zhang, P.; Le, C.; Liu, X. Construction and installation technique of large-scale top-bearing bucket foundation for offshore wind turbine. In Proceedings of the 2011 2nd International Conference on Mechanic Automation and Control Engineering, MACE 2011, Inner Mongolia, China, 15–17 July 2011; pp. 7234–7237. [Google Scholar]

- Rippel, D.; Jathe, N.; Becker, M.; Lütjen, M.; Szczerbicka, H.; Freitag, M. A review on the planning problem for the installation of offshore wind farms. IFAC-PapersOnLine 2019, 52, 1337–1342. [Google Scholar] [CrossRef]

- Ekici, D.; White, M.; Drunsic, M. Offshore Wind Farm OWF Installation Best Practices Based on Field Experience. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 2–5 May 2016. [Google Scholar]

- Lange, K.; Rinne, A.; Haasis, H.D. Planning maritime logistics concepts for offshore wind farms: A newly developed decision support system. In Proceedings of the Third International Conference, ICCL 2012, Shanghai, China, 24–26 September 2012; Lecture Notes in Computer Science; Volume 7555, pp. 142–158. [Google Scholar] [CrossRef]

- Backe, S. Strategic optimization of offshore wind farm installation. In Computational Logistics, Proceedings of the 8th International Conference, ICCL 2017, Southampton, UK, 18–20 October 2017, Proceedings 8; Springer: Cham, Switzerland, 2017; Lecture Notes in Computer Science; Volume 10572, pp. 285–299. [Google Scholar] [CrossRef]

- Ozturk, T. On Using Simulation to Model the Installation Process Logistics for an Offshore Wind Farm. 2017; pp. 1–30. Available online: https://strathprints.strath.ac.uk/60880/ (accessed on 23 July 2021).

- Semenyuk, M. Offshore Wind Farm Installation Planning. Decision-Support Tool for the Analysis of New Installation Concepts; TU Delft: Delft, The Netherlands, 2019; 150p. [Google Scholar]

- Versendaal, J. Exploring the Potential of the Pre-Assembled Installation Method for the Installation of Offshore Wind Turbines; TU Delft: Delft, The Netherlands, 2017; 66p. [Google Scholar]

- Scheltes, M. An Offshore Port Concept to Reduce the Construction Costs in Offshore Wind; TU Delft: Delft, The Netherlands, 2018; 218p. [Google Scholar]

- Faiz, T.I. Minimization of Transportation, Installation and Maintenance Operations Costs for Offshore Wind Turbines; Louisiana State University and Agricultural and Mechanical College Follow: Baton Rouge, LA, USA, 2014; 104p. [Google Scholar]

- Kumar, V. Optimization of Offshore Wind Farm Installation Procedure With a Targeted Finish Date; TU Delft: Delft, The Netherlands, 2017; 91p. [Google Scholar]

- Desemberg, J. Optimization of the Installation Process of Offshore Wind Turbines; University of Liège: Liège, Belgium, 2014; 111p. [Google Scholar]

- Uraz, E. Offshore Wind Turbine Transportation & Installation Analyses. Planning Optimal Marine Operations for Offshore Wind Projects; Gotland University: Visby, Sweden, 2011; 65p. [Google Scholar]

- BVG. Associates UK Ports for the Offshore Wind Industry: Time to Act; BVG: Swindon, UK, 2009. [Google Scholar]

- The Crown Estate; ORE Catapult; BVG Associates. A Guide to an Offshore Wind Farm; BVG: Swindon, UK, 2019. [Google Scholar]

- Roberts, A.; Blanch, M.; Weston, J.; Valpy, B. UK Offshore Wind Supply Chain: Capabilities and Opportunities. 2014. Available online: https://www.gov.uk/government/publications/uk-offshore-wind-supply-chain-capabilities-and-opportunities (accessed on 12 August 2022).

- Maples, B.; Saur, G.; Hand, M.; van Pietermen, R.; Obdam, T. Installation, Operation, and Maintenance Strategies to Reduce the Cost of Offshore Wind Energy. 2013. Available online: https://research-hub.nrel.gov/en/publications/installation-operation-and-maintenance-strategies-to-reduce-the-c (accessed on 12 August 2023).

- Teillant, B.; Raventos, A.; Chainho, P.; Goormachtigh, J.; Nava, V.; Ruiz, P.; Jepsen, R. Methodology Report and Logistic Model Flow Charts. 2014. Available online: https://www.google.com/url?sa=t&source=web&rct=j&opi=89978449&url=https://www.france-energies-marines.org/wp-content/uploads/2023/07/DTO_WP5_ECD_D5.1.pdf&ved=2ahUKEwjBmd2rnO2JAxVN5MkDHcTzKi8QFnoECCAQAQ&usg=AOvVaw14c4Okoz9HYbdCiOP7KiAV (accessed on 18 August 2023).

- Akbari, N. Ports suitability assessment for offshore wind development-Case studies report. In Proceedings of the LEANWIND Consortium (2015), Cork, Ireland, 31 July 2015. [Google Scholar]

- Kaiser, M.J.; Snyder, B.F. Offshore Wind Energy Installation and Decommissioning Cost Estimation in the U.S. Outer Continental Shelf; TA&R study 648; U.S. Dept. of the Interior, Bureau of Ocean Energy Management, Regulation and Enforcement: Herndon, VA, USA, 2010; 340p. [Google Scholar]

- Walther, L.; Schwientek, A. Logistic Process Analysis to Develop the Supply Chain for Offshore Wind Farm Installations. In Pioneering Solutions in Supply Chain Performance Management: Concepts, Technology and Applications; Fraunhofer IML: Dortmund, Germany, 2013; pp. 89–103. [Google Scholar]

- Díaz, H.; Rodrigues, J.M.; Soares, C.G. Preliminary cost assessment of an offshore floating wind farm installation on the Galician coast. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering—OMAE, Busan, South Korea, 19–24 June 2016; Volume 10. [Google Scholar] [CrossRef]

- Lange, K.; Haasis, H.D. Offshore Wind Supply Chain Design: Analysis of logistics concepts for a cost-efficient installation of offshore wind farms—With a focus on the rotor blades. In Development in Maritime Transportatio and Exploitation of Sea Resources; Routledge: Offshore, UK, 2013; p. 8. [Google Scholar]

- CSCMP. CSCMP Supply Chain Management Definitions and Glossary; CSCMP: Nashville, TN, USA, 2013. [Google Scholar]

- EWEA; Arapogianni, A.; Moccia, J.; Williams, D.; Phillips, J. Wind in Our Sails: The Coming of Europe’s Offshore Wind Energy Industry; EWEA: Brussels, Belgium, 2011; Volume 96. [Google Scholar]

- IRENA. Innovation Outlook: Offshore Wind; IRENA: Masdar City, United Arab Emirates, 2016; ISBN 9789295111356. [Google Scholar]

- Tjaberings, J.; Fazi, S.; Ursavas, E. Evaluating operational strategies for the installation of offshore wind turbine substructures. Renew. Sustain. Energy Rev. 2022, 170, 112951. [Google Scholar] [CrossRef]

- Crowle, A.P.; Thies, P.R. Floating offshore wind turbines port requirements for construction. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2022, 236, 1047–1056. [Google Scholar] [CrossRef]

- Halvorsen-Weare, E.E.; Nonas, L.M. Maritime logistics optimisation for predictive maintenance at offshore wind farms. J. Phys. Conf. Ser. 2023, 2626, 012040. [Google Scholar] [CrossRef]

- Kaiser, M.J.; Snyder, B.F. Modeling offshore wind installation costs on the U.S. Outer Continental Shelf. Renew. Energy 2013, 50, 676–691. [Google Scholar] [CrossRef]

- Ward, P.A.; Corgnale, C.; Teprovich, J.A.; Motyka, T.; Hardy, B.; Peters, B.; Zidan, R. High performance metal hydride based thermal energy storage systems for concentrating solar power applications. J. Alloys Compd. 2015, 645, S374–S378. [Google Scholar] [CrossRef]

- de Vasconcelos, R.M.; Silva, L.L.C.; González, M.O.A.; Santiso, A.M.; de Melo, D.C. Environmental licensing for offshore wind farms: Guidelines and policy implications for new markets. Energy Policy 2022, 171, 113248. [Google Scholar] [CrossRef]

- Peng, S.; Rippel, D.; Lütjen, M.; Becker, M.; Szczerbicka, H. Simulation-based scheduling for offshore wind farm installation using timed petri nets approach. Simul. Ser. 2020, 52, 56–67. [Google Scholar]

- González, M.; Santiso, A.; Jones, D.; Akbari, N.; Vasconcelos, R.; Melo, D. Offshore Wind Power Growth and Industrial Development in Emerging Markets. Energies 2024, 17, 4712. [Google Scholar] [CrossRef]

| ID | Contains in the Title | ||

|---|---|---|---|

| 1 | Offshore wind | and | Installation |

| 2 | Offshore wind | and | Transportation |

| 3 | Offshore wind | and | Construction |

| 4 | Offshore wind | and | Logistics |

| 5 | Offshore wind | and | Assembly |

| Publication | Number of Publications | References |

|---|---|---|

| Articles in journals | 64 | [1,4,11,12,13,14,15,16,18,20,22,26,27,28,29,30,36,37,38,39,40,41,42,43,44,45,46,47,48,49,50,51,52,53,54,55,56,57,58,59,60,61,62,63,64,65,66,67,68,69,70,71,72,73,74,75,76,77,78] |

| Conference proceedings | 36 | [79,80,81,82,83,84,85,86,87,88,89,90,91,92,93,94,95,96,97,98,99,100,101,102,103,104,105,106,107,108,109,110,111,112] |

| Dissertations | 11 | [19,23,113,114,115,116,117,118,119,120,121] |

| Technical reports | 7 | [122,123,124,125,126,127,128] |

| Books | 4 | [113,129,130,131] |

| Total | 122 |

| Criteria | Number of Articles | Percentage |

|---|---|---|

| Climate (weather and environmental conditions) | 54 | 87% |

| Turbine installation | 31 | 50% |

| Turbine and foundation installation | 19 | 31% |

| OWF installation (all components) | 8 | 13% |

| Region of study | 36 | 58% |

| Port Characteristics | Relevant Articles |

|---|---|

| Physical characteristics | |

| [10,23,76,127] |

| [23,76,127] |

| Port connectivity | |

| [76,121,125,136] |

| [76,119,121] |

| [9,10,12,76,121] |

| Layout | |

| [10,23,28,76,112,136] |

| Vessel Characteristics | Relevant Articles |

|---|---|

| Deck space | [28,119,131] |

| Vessel speed | [28,60,84,119,121] |

| Vessel availability | [113,120,121,125] |

| Operating limits | [1,4,9,28,84,120] |

| Workability | [104,119] |

| Crane performance | [41,58,119,120] |

| Experience | [74] |

| Loading capacity | [9,84,116,121] |

| Factors | Relevant Articles |

|---|---|

| Vessel characteristics | |

| [37,121] |

| [20,94,113,119] |

| [128] |

| [128] |

| [128] |

| [128] |

| Project characteristics | |

| [23,119] |

| [23,28,119,128] |

| [23] |

| [20,23,119,120,128] |

| Weather conditions | [106,137] |

| Factors | Relevant Articles |

|---|---|

| Vessel characteristics | |

| [110,128] |

| [91,127,128,138] |

| [18,20,121,128] |

| [18,20,28,91,110,121,127,128,138,139] |

| Turbine characteristics | |

| [18,121,128] |

| [30,125] |

| [27,128,138] |

| Port characteristics | |

| [121] |

| [18,125] |

| Variables | Relevant Articles |

|---|---|

| Port capacity | [15,75,87,105] |

| Weather forecast | [15,75,87,105] |

| Availability of vessels | [15,87] |

| Main Variables | Relevant Articles |

|---|---|

| Fleet vessel | [41,58,60] |

| Weather conditions | [59,104] |

| Start date | [41,58,104] |

| Operations time | [60,89] |

| Operations costs | [60] |

| Logistical strategies | [60,112] |

| Main Parameters | Relevant Articles |

|---|---|

| Number of turbines | [41,58,60,89,104] |

| Operations time | [41,58,59,104] |

| Turbine capacity | [60] |

| Operational limits | [41] |

| Number of vessels | [89] |

| Number of components on the vessel | [104] |

| Project characteristics | [112] |

| Main Variables | Relevant Articles |

|---|---|

| Start date | [20,40,44,74,86,114,119] |

| Pre-assembly method | [20,86] |

| Number of turbines | [20,40] |

| Risks | [39] |

| Weather conditions | [40,141] |

| Vessels | [44,114,119] |

| Dock capacity | [44] |

| Uncertainty in times | [74] |

| Turbine power | [119] |

| Foundation size | [119] |

| Port | [119] |

| Main Parameters | Relevant Articles |

|---|---|

| Number of turbines | [13,29,39,40,74,81,114] |

| Process time | [13,20,29,40,44,86,106,114,141] |

| Distance from coast/port | [39,74,114] |

| Operational limits | [20,40,44,74,114] |

| Turbine/project capacity | [20,39,40,74,86,114,119] |

| Vessel capacity | [20,29,39,44] |

| Vessel speed | [20,74] |

| Depth | [74,114] |

| Pre-assembly method | [39,86,119] |

| Weather conditions | [13,39,106,119] |

| Number of vessels | [20,29,74] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

González, M.O.A.; Nascimento, G.; Jones, D.; Akbari, N.; Santiso, A.; Melo, D.; Vasconcelos, R.; Godeiro, M.; Nogueira, L.; Almeida, M.; et al. Logistic Decisions in the Installation of Offshore Wind Farms: A Conceptual Framework. Energies 2024, 17, 6004. https://doi.org/10.3390/en17236004

González MOA, Nascimento G, Jones D, Akbari N, Santiso A, Melo D, Vasconcelos R, Godeiro M, Nogueira L, Almeida M, et al. Logistic Decisions in the Installation of Offshore Wind Farms: A Conceptual Framework. Energies. 2024; 17(23):6004. https://doi.org/10.3390/en17236004

Chicago/Turabian StyleGonzález, Mario O. A., Gabriela Nascimento, Dylan Jones, Negar Akbari, Andressa Santiso, David Melo, Rafael Vasconcelos, Monalisa Godeiro, Luana Nogueira, Mariana Almeida, and et al. 2024. "Logistic Decisions in the Installation of Offshore Wind Farms: A Conceptual Framework" Energies 17, no. 23: 6004. https://doi.org/10.3390/en17236004

APA StyleGonzález, M. O. A., Nascimento, G., Jones, D., Akbari, N., Santiso, A., Melo, D., Vasconcelos, R., Godeiro, M., Nogueira, L., Almeida, M., & Oprime, P. (2024). Logistic Decisions in the Installation of Offshore Wind Farms: A Conceptual Framework. Energies, 17(23), 6004. https://doi.org/10.3390/en17236004