AVR Fractional-Order Controller Based on Caputo–Fabrizio Fractional Derivatives and Integral Operators

Abstract

1. Introduction

- -

- A synchronous generator operates in a self-contained mode (the power system is replaced by an infinite bus);

- -

- The synchronous generator operates as part of a system (a multi-machine model of the system, which enables the analysis of the interactions between generators operating in this system).

- Proportional–integral–differential (PID) fractional-order controller

2. Mathematical Model of the Research System

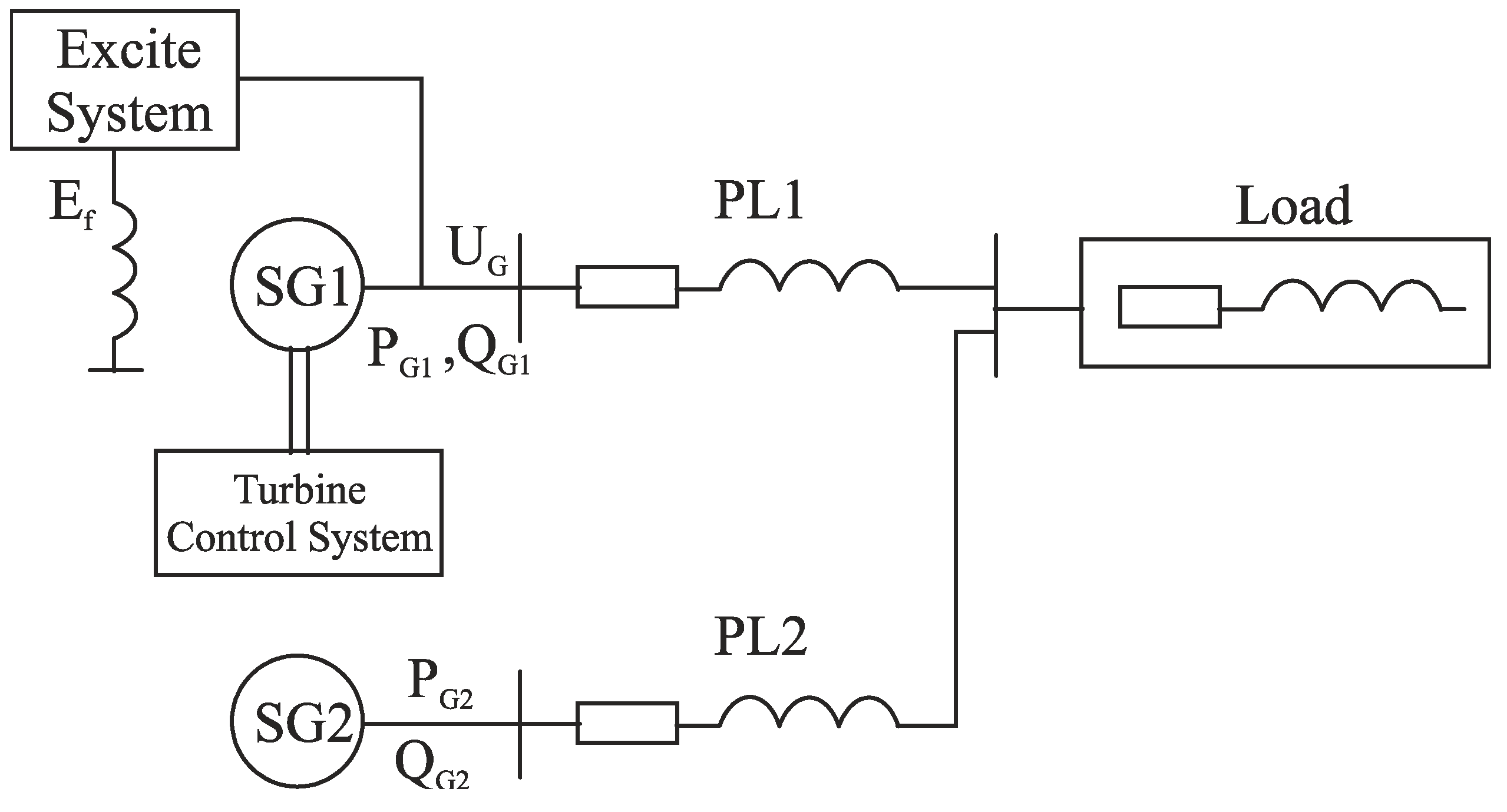

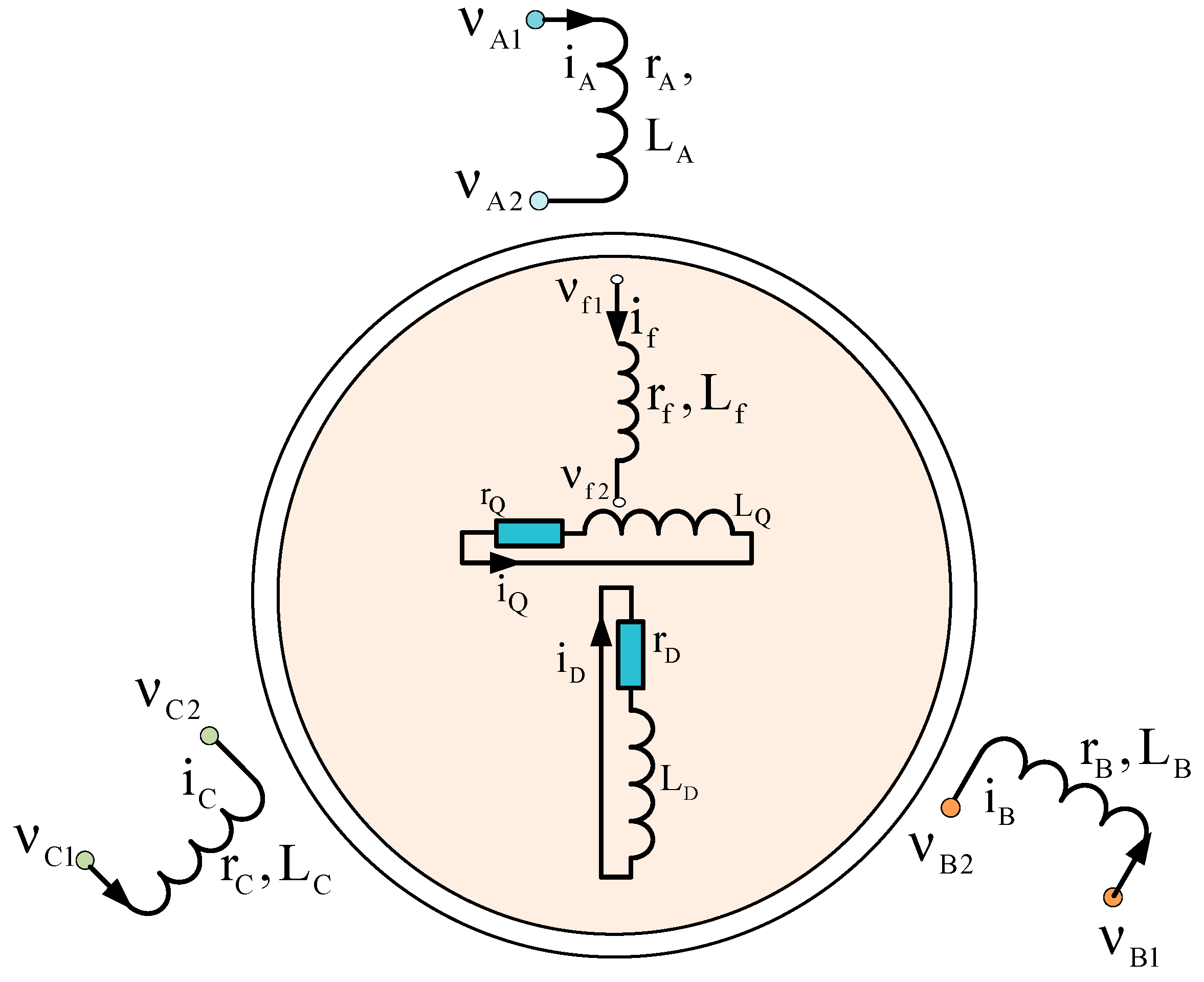

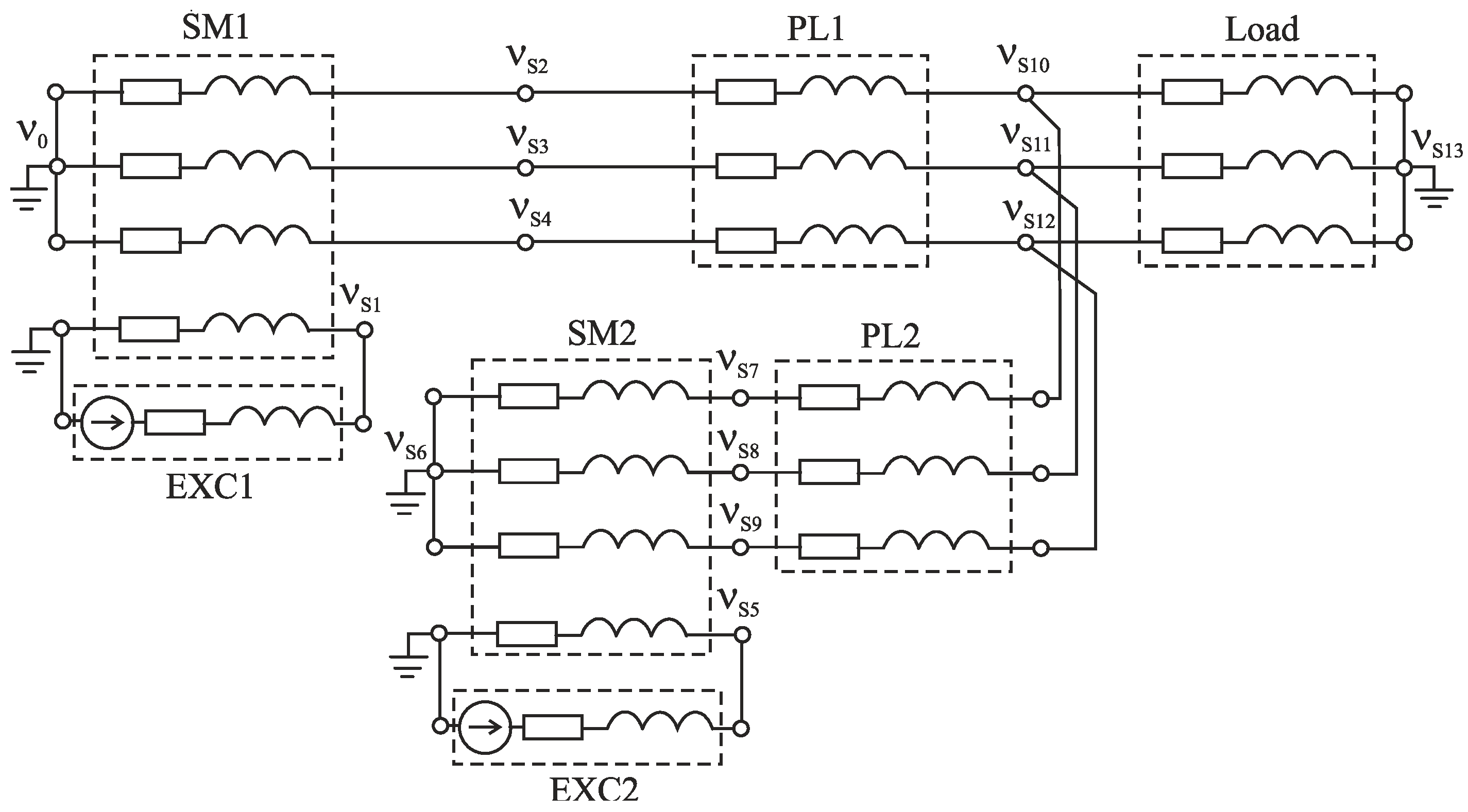

2.1. Mathematical Model of the Power Circuit

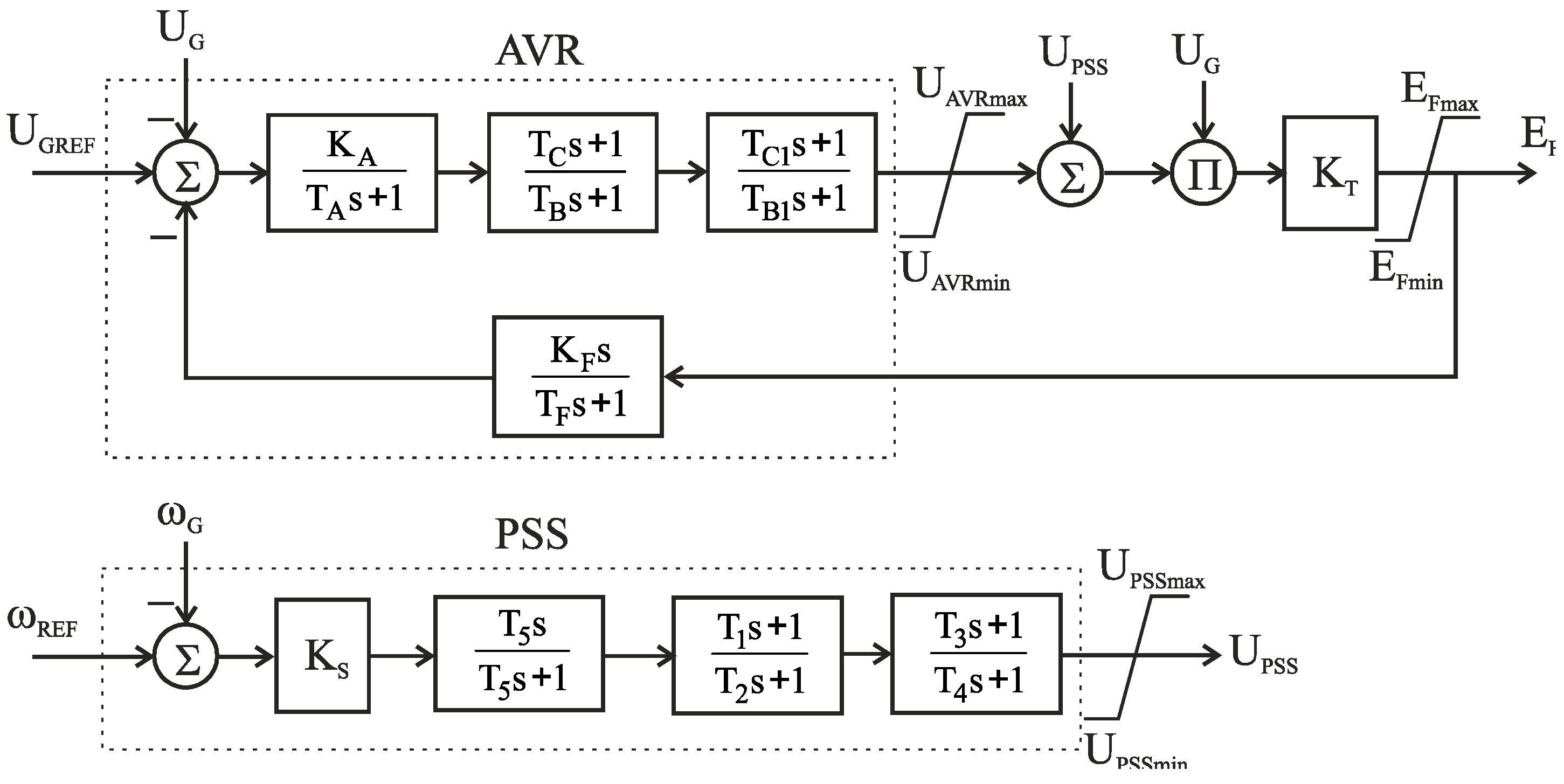

2.2. Mathematical Model of the Excitation Control System

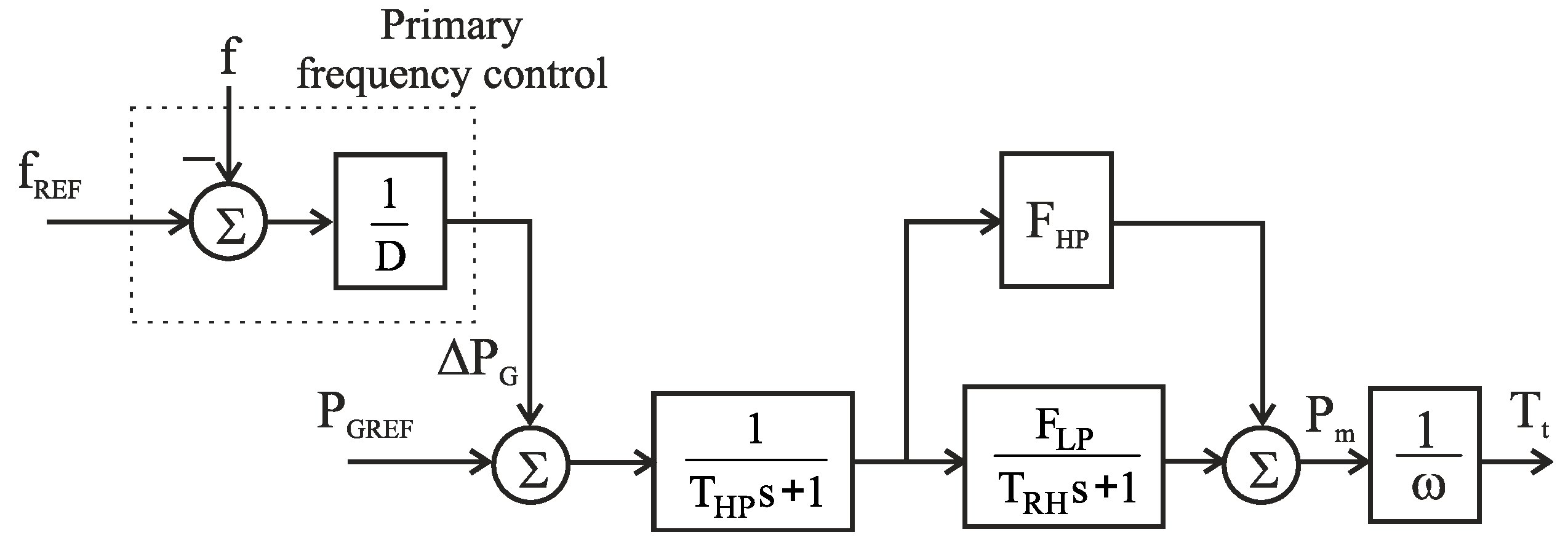

2.3. Steam Turbine Model

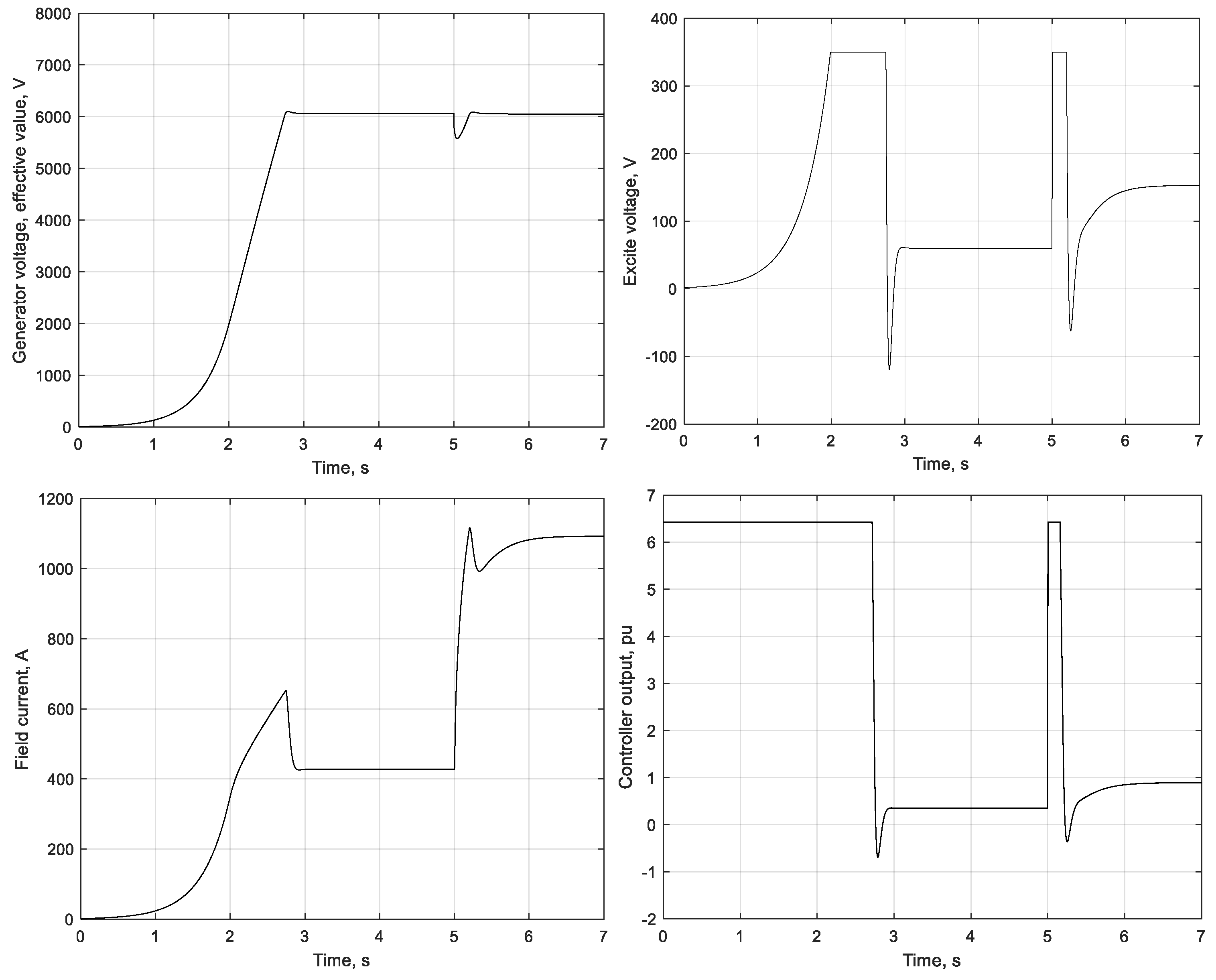

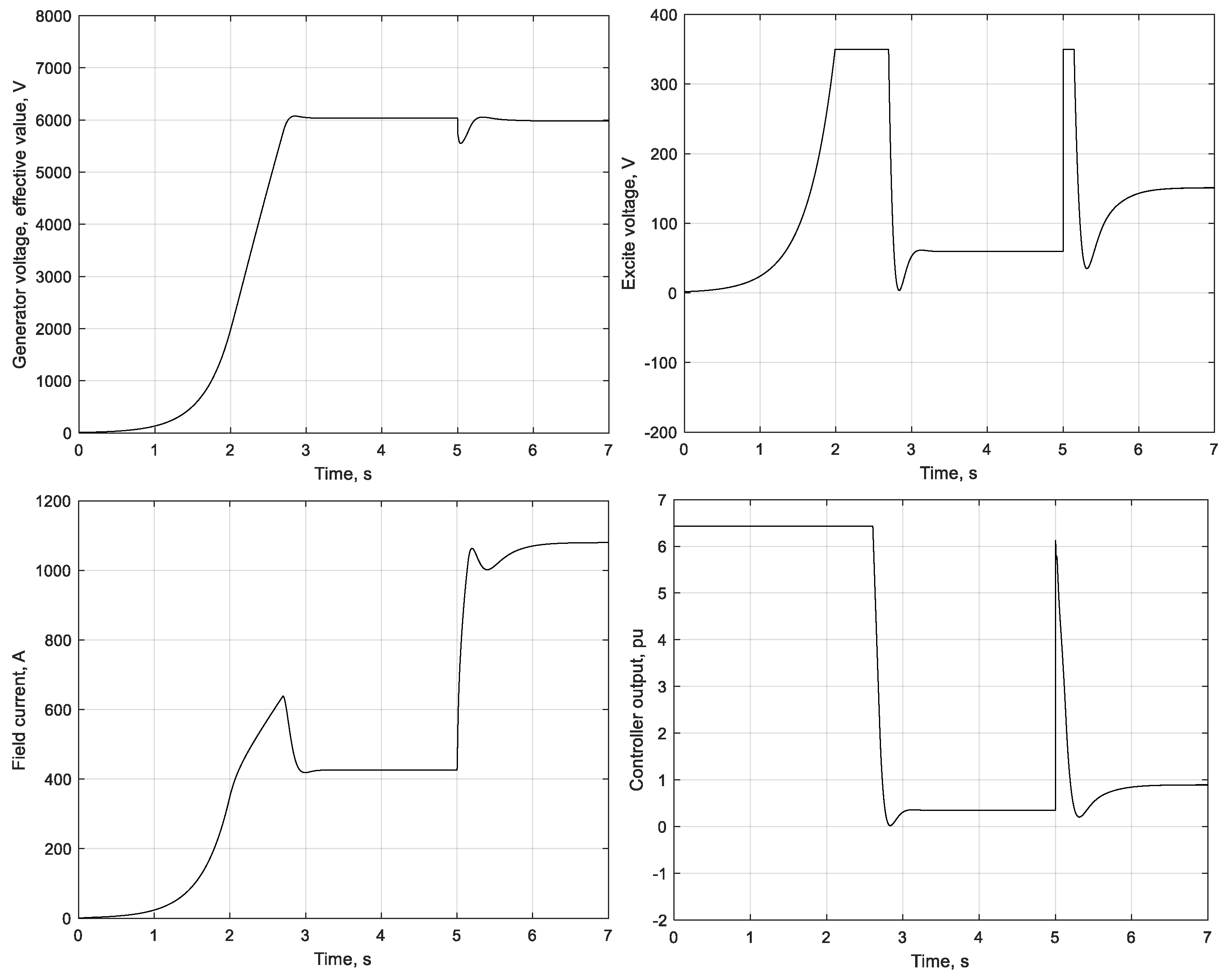

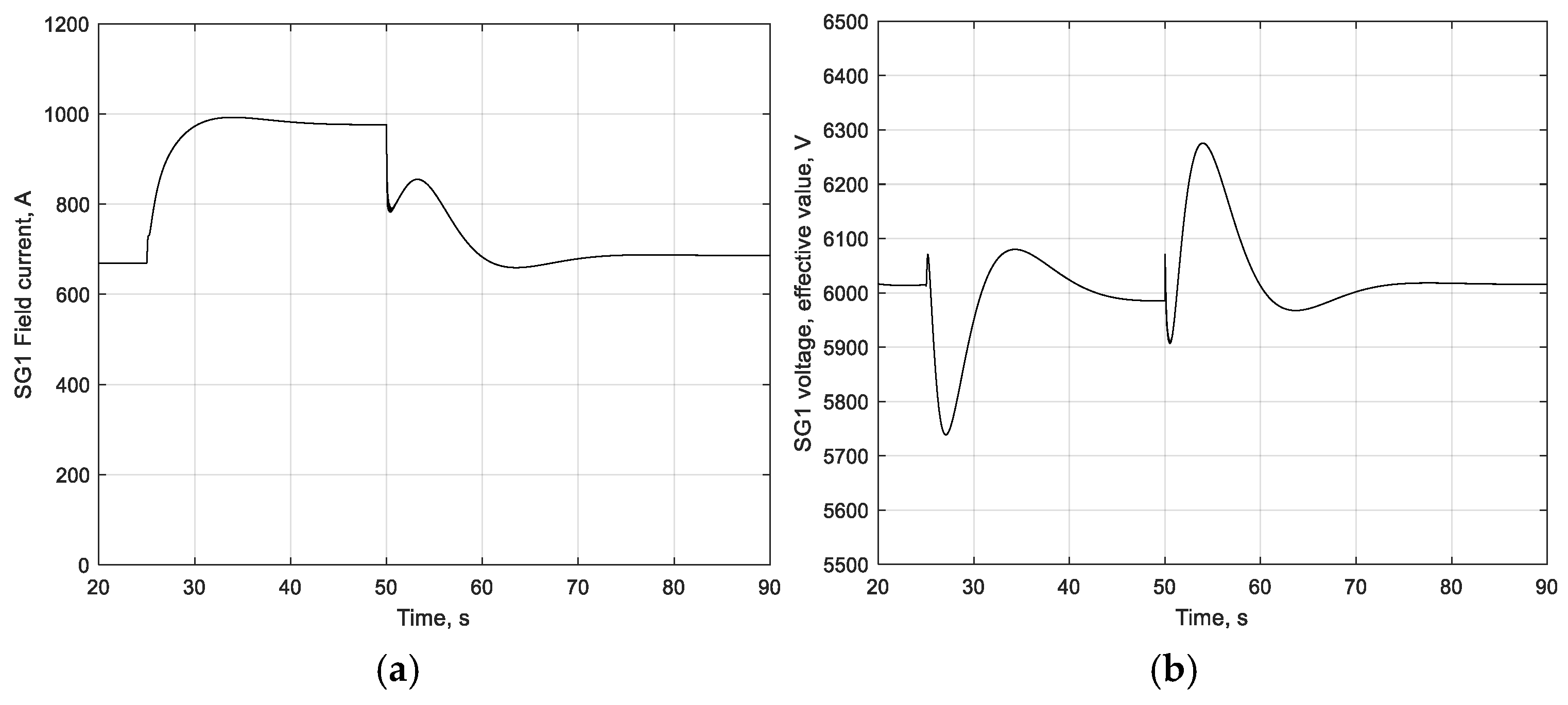

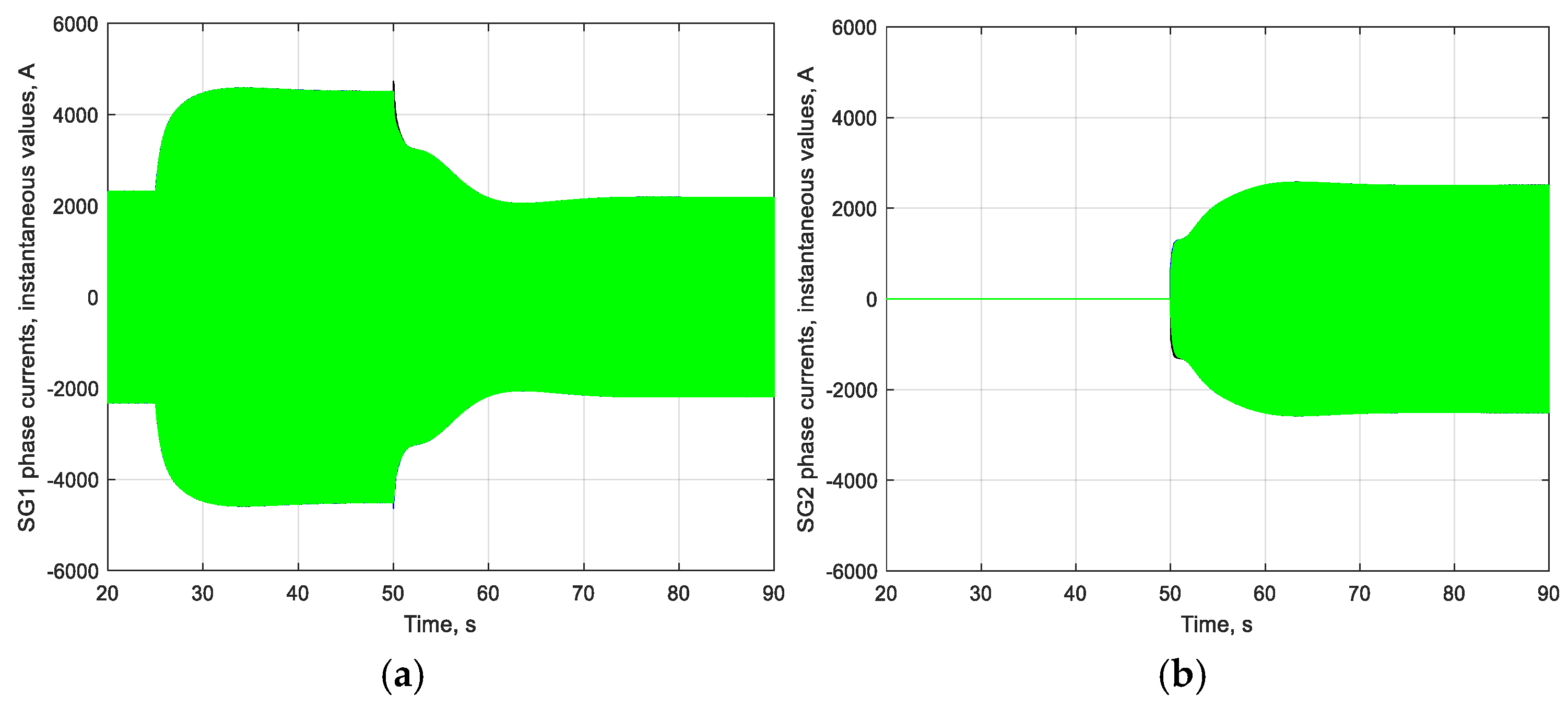

3. Verification of the Developed Mathematical Model

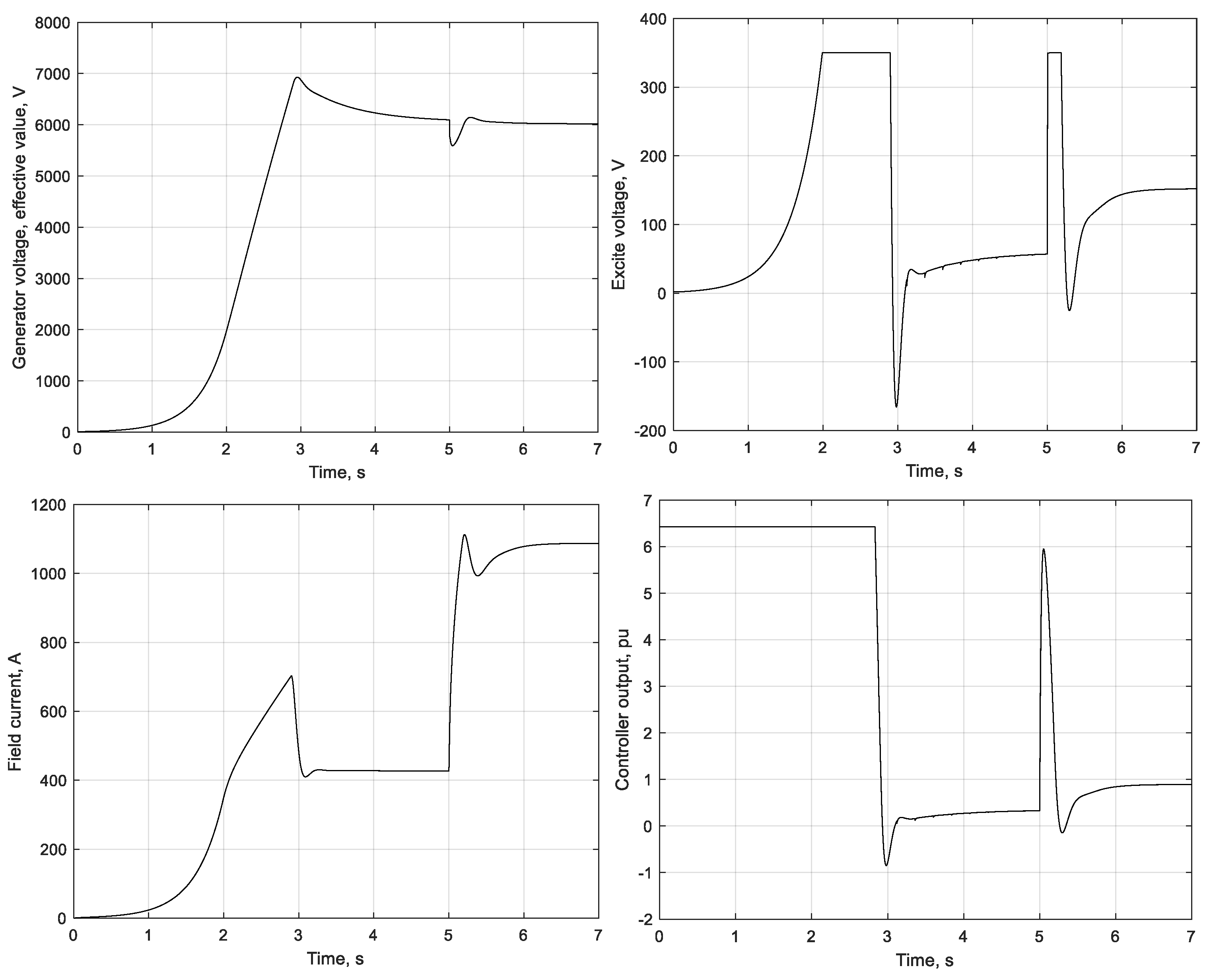

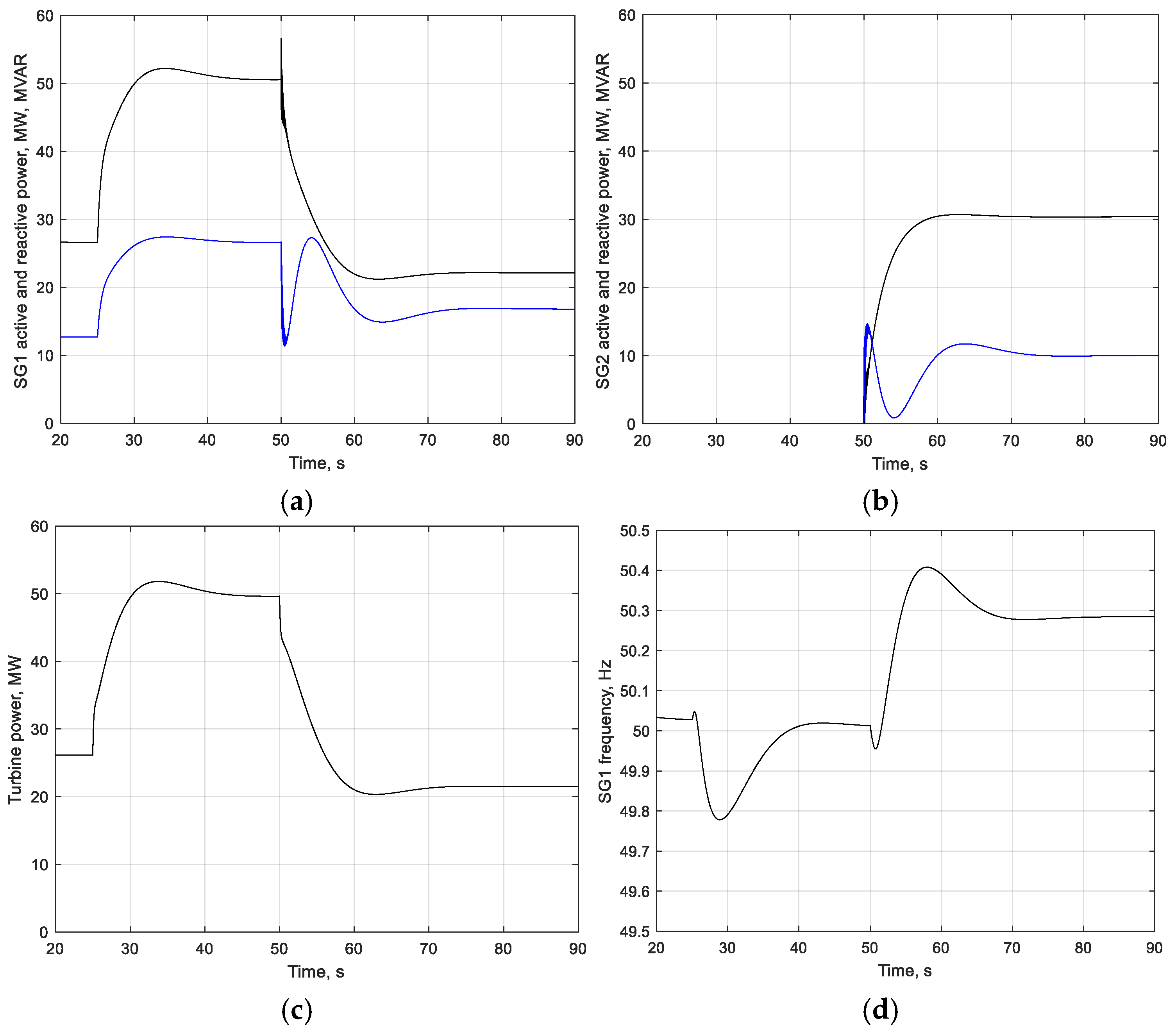

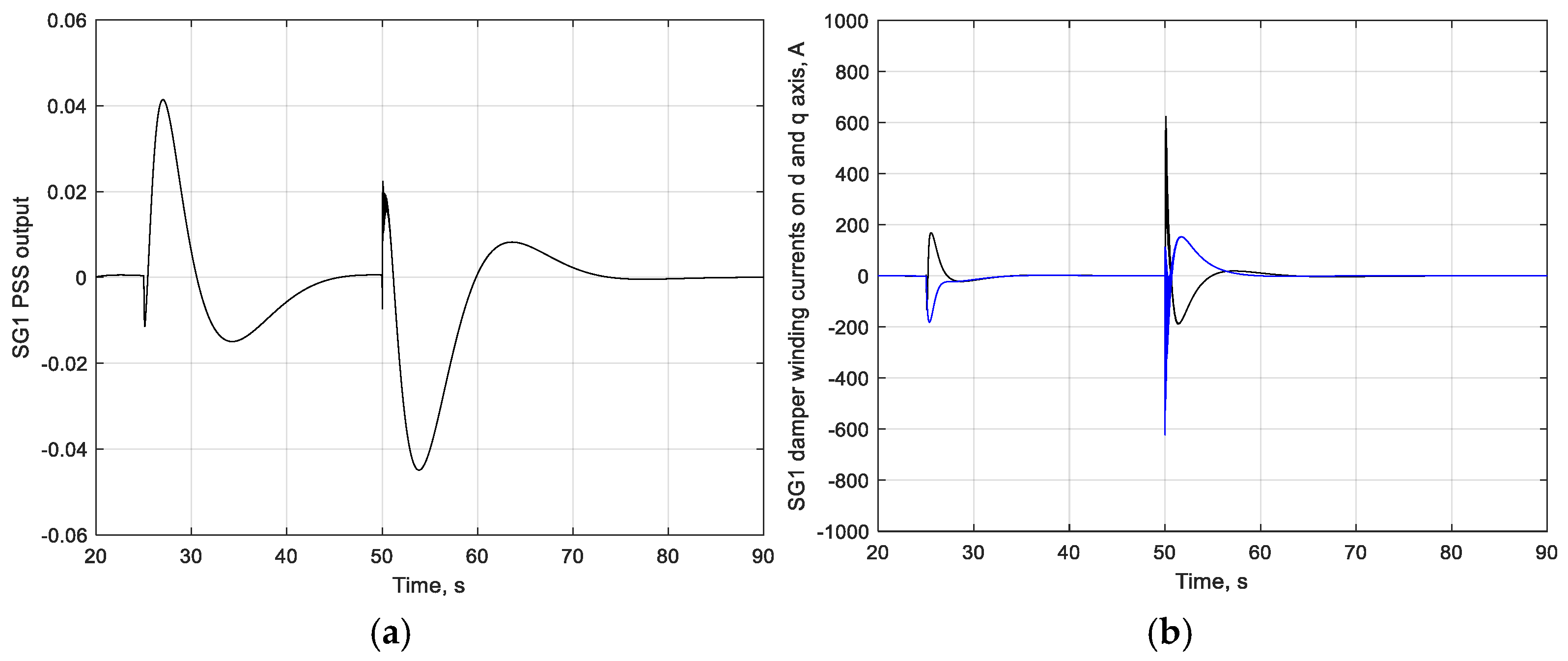

4. Simulation Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Buongiorno, J.; Corradini, M.; Parsons, J.; Petti, D. Nuclear Energy in a Carbon-Constrained World: Big Challenges and Big Opportunities. IEEE Power Energy Mag. 2019, 17, 69–77. [Google Scholar] [CrossRef]

- Lloyd, C.A.; Roulstone, T.; Lyons, R.E. Transport, constructability, and economic advantages of SMR modularization. Prog. Nucl. Energy 2021, 134, 103672. [Google Scholar] [CrossRef]

- Poudel, B.; Gokaraju, R. Small Modular Reactor (SMR) Based Hybrid Energy System for Electricity & District Heating. IEEE Trans. Energy Convers. 2021, 36, 2794–2802. [Google Scholar] [CrossRef]

- Poudel, B.; Joshi, K.; Gokaraju, R. A Dynamic Model of Small Modular Reactor Based Nuclear Plant for Power System Studies. IEEE Trans. Energy Convers. 2020, 35, 977–985. [Google Scholar] [CrossRef]

- Jenkins, J.D.; Zhou, Z.; Ponciroli, R.; Vilim, R.B.; Ganda, F.; de Sisternes, F.; Botterud, A. The benefits of nuclear flexibility in power system operations with renewable energy. Appl. Energy 2018, 222, 872–884. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, W.; Zhang, L.; Zhao, X.; Gao, Y.; Dinavahi, V. Small Modular Reactors: An Overview of Modeling, Control, Simulation, and Applications. IEEE Access 2024, 12, 39628–39650. [Google Scholar] [CrossRef]

- Anderson, P.M.; Fouad, A.A. Power System Control and Stability; IEEE Press: Piscataway, NJ, USA, 1994. [Google Scholar]

- Law, K.T.; Hill, D.J.; Godfrey, N.R. Robust controller structure for coordinated power system voltage regulator and stabilizer design. IEEE Trans. Control Syst. Technol. 1994, 2, 220–232. [Google Scholar] [CrossRef]

- Kundur, P. Power Systems Stability and Control; McGraw-Hill, Inc.: New York, NY, USA, 1994. [Google Scholar]

- Mira-Gebauer, N.; Rahmann, C.; Álvarez-Malebrán, R.; Vittal, V. Review of Wide-Area Controllers for Supporting Power System Stability. IEEE Access 2023, 11, 8073–8095. [Google Scholar] [CrossRef]

- Verrelli, C.M.; Marino, R.; Tomei, P.; Damm, G. Nonlinear Robust Coordinated PSS-AVR Control for a Synchronous Generator Connected to an Infinite Bus. IEEE Trans. Autom. Control 2022, 67, 1414–1422. [Google Scholar] [CrossRef]

- Machowski, J.; Robak, S.; Bialek, J.W.; Bumby, J.R.; Abi-Samra, N. Decentralized stability-enhancing control of synchronous generator. IEEE Trans. Power Syst. 2000, 15, 1336–1344. [Google Scholar] [CrossRef]

- Cao, Y.; Jiang, L.; Cheng, S.; Chen, D.; Malik, O.P.; Hope, G.S. A nonlinear variable structure stabilizer for power system stability. IEEE Trans. Energy Convers. 1994, 9, 489–495. [Google Scholar] [CrossRef]

- Loukianov, A.G.; Cañedo, J.M.; Fridman, L.M.; Soto-Cota, A. High-Order Block Sliding-Mode Controller for a Synchronous Generator With an Exciter System. IEEE Trans. Ind. Electron. 2011, 58, 337–347. [Google Scholar] [CrossRef]

- Doria-Cerezo, A.; Utkin, V.I.; Munoz-Aguilar, R.S.; Fossas, E. Control of a Stand-Alone Wound Rotor Synchronous Generator: Two Sliding Mode Approaches via Regulation of the d-Voltage Component. IEEE Trans. Control Syst. Technol. 2012, 20, 779–786. [Google Scholar] [CrossRef]

- Liu, X.; Han, Y. Decentralized multi-machine power system excitation control using continuous higher-order sliding mode technique. Int. J. Electr. Power Energy Syst. 2016, 82, 76–86. [Google Scholar] [CrossRef]

- Li, J.; Liu, Y.; Li, C.; Chu, B. Passivity-Based Nonlinear Excitation Control of Power Systems with Structure Matrix Reassignment. Information 2013, 4, 342–350. [Google Scholar] [CrossRef]

- Biletskyi, Y.O.; Shchur, I.Z.; Kuzyk, R.-I.V. Passivity-based control system for stand-alonehybrid electrogenerating complex. Appl. Asp. Inf. Technol. 2021, 4, 140–152. [Google Scholar] [CrossRef]

- Dong, Z.; Cheng, Z.; Lin, X.; Zhu, Y.; Chen, F.; Huang, X. Passivity-Based Control of Nuclear Reactors Considering Cold Side Temperature. In Proceedings of the IECON 2023—49th Annual Conference of the IEEE Industrial Electronics Society, Singapore, 16–19 October 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Roy, T.K.; Mahmud, M.A.; Shen, W.; Oo, A.M.T.; Haque, M.E. Robust nonlinear adaptive backstepping excitation controller design for rejecting external disturbances in multimachine power systems. Int. J. Electr. Power Energy Syst. 2017, 84, 76–86. [Google Scholar] [CrossRef]

- Roy, T.K.; Mahmud, M.A.; Shen, W.; Oo, A.M.T. Nonlinear Adaptive Excitation Controller Design for Multimachine Power Systems With Unknown Stability Sensitive Parameters. IEEE Trans. Control Syst. Technol. 2017, 25, 2060–2072. [Google Scholar] [CrossRef]

- Liying, S.; Zhihua, L. Nonlinear adaptive backstepping control for synchronous generator excitation system with output constraints. In Proceedings of the Fifth International Conference on Intelligent Control and Information Processing, Dalian, China, 18–20 August 2014; pp. 336–340. [Google Scholar] [CrossRef]

- Long, B.; Liao, Y.; Chong, K.T.; Rodríguez, J.; Guerrero, J.M. MPC-Controlled Virtual Synchronous Generator to Enhance Frequency and Voltage Dynamic Performance in Islanded Microgrids. IEEE Trans. Smart Grid 2021, 12, 953–964. [Google Scholar] [CrossRef]

- Kiaei, I.; Rostami, M.; Lotfifard, S. Robust Decentralized Control of Synchronous Generators for Improving Transient Stability of Multimachine Power Grids. IEEE Syst. J. 2021, 15, 3470–3479. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhou, J.; Zhu, W.; Zhang, C.; Li, C.; Fu, W. Design of a multi-mode intelligent model predictive control strategy for hydroelectric generating uni. Neurocomputing 2016, 207, 287–299. [Google Scholar] [CrossRef]

- Orchi, T.F.; Roy, T.K.; Mahmud, M.A.; Oo, A.M.T. Feedback Linearizing Model Predictive Excitation Controller Design for Multimachine Power Systems. IEEE Access 2018, 6, 2310–2319. [Google Scholar] [CrossRef]

- Kenné, G.; Goma, R.; Nkwawo, H.; Lamnabhi-Lagarrigue, F.; Arzandé, A.; Vannier, J.C. An improved direct feedback linearization technique for transient stability enhancement and voltage regulation of power generators. Int. J. Electr. Power Energy Syst. 2010, 32, 809–816. [Google Scholar] [CrossRef]

- Roy, T.K.; Mahmud, M.A.; Shen, W.X.; Oo, A.M.T. An Adaptive Partial Feedback Linearizing Control Scheme: An Application to a Single Machine Infinite Bus System. IEEE Trans. Circuits Syst. II Express Briefs 2020, 67, 2557–2561. [Google Scholar] [CrossRef]

- Leon, A.E.; Solsona, J.A.; Valla, M.I. Comparison among nonlinear excitation control strategies used for damping power system oscillations. Energy Convers. Manag. 2012, 53, 55–67. [Google Scholar] [CrossRef]

- Mahmud, M.A.; Pota, H.R.; Aldeen, M.; Hossain, M.J. Partial Feedback Linearizing Excitation Controller for Multimachine Power Systems to Improve Transient Stability. IEEE Trans. Power Syst. 2014, 29, 561–571. [Google Scholar] [CrossRef]

- Rigatos, G.; Siano, P.; Melkikh, A.; Zervos, N. A Nonlinear H-Infinity Control Approach to Stabilization of Distributed Synchronous Generators. IEEE Syst. J. 2018, 12, 2654–2663. [Google Scholar] [CrossRef]

- Ugalde-Loo, C.E.; Acha, E.; Licéaga-Castro, E. Multi-machine power system state-space modelling for small-signal stability assessments. Appl. Math. Model. 2013, 37, 10141–10161. [Google Scholar] [CrossRef]

- Fathollahi, A.; Andresen, B. Multi-Machine Power System Transient Stability Enhancement Utilizing a Fractional Order-Based Nonlinear Stabilizer. Fractal Fract. 2023, 7, 808. [Google Scholar] [CrossRef]

- Ugalde Loo, C.E.; Vanfretti, L.; Liceaga-Castro, E.; Acha, E. Synchronous Generators Modeling and Control Using the Framework of Individual Channel Analysis and Design: Part 1. Int. J. Emerg. Electr. Power Syst. 2007, 5, 1–25. [Google Scholar] [CrossRef]

- Wang, X.; Chen, Y.; Han, G.; Song, C. Nonlinear dynamic analysis of a single-machine infinite-bus power system. Appl. Math. Model. 2015, 39, 2951–2961. [Google Scholar] [CrossRef]

- Panday, R.; Harun, N.F.; Zhang, B.; Maloney, D.; Tucker, D.; Bayham, S. Analyzing Gas Turbine-Generator Performance of the Hybrid Power System. IEEE Trans. Power Syst. 2022, 37, 543–550. [Google Scholar] [CrossRef]

- Badakhshan, S.; Senemmar, S.; Zhang, J. Dynamic Modeling and Reliable Operation of All-Electric Ships with Small Modular Reactors and Battery Energy Systems. In Proceedings of the 2023 IEEE Electric Ship Technologies Symposium (ESTS), Alexandria, VA, USA, 1–4 August 2023; pp. 327–332. [Google Scholar] [CrossRef]

- Wang, L.; Zeng, S.-Y.; Feng, W.-K.; Prokhorov, A.V.; Mokhlis, H.; Huat, C.K. Damping of Subsynchronous Resonance in a Hybrid System With a Steam-Turbine Generator and an Offshore Wind Farm Using a Unified Power-Flow Controller. IEEE Trans. Ind. Appl. 2021, 57, 110–120. [Google Scholar] [CrossRef]

- Ouassaida, M.; Maaroufia, M.; Cherkaoui, M. A real-time nonlinear decentralized control of multimachine power systems. Syst. Sci. Control. Eng. Open Access J. 2014, 2, 135–142. [Google Scholar] [CrossRef]

- Kutsyk, A.; Semeniuk, M.; Korkosz, M.; Podskarbi, G. Diagnosis of the Static Excitation Systems of Synchronous Generators with the Use of Hardware-In-the-Loop Technologies. Energies 2021, 14, 6937. [Google Scholar] [CrossRef]

- Sabir, A.; Michaelson, D.; Jiang, J. Load-Frequency Control With Multimodule Small Modular Reactor Configuration: Modeling and Dynamic Analysis. IEEE Trans. Nucl. Sci. 2021, 68, 1367–1380. [Google Scholar] [CrossRef]

- Zhang, Q.-H.; Lu, J.-G.; Xu, J.; Chen, Y.-Q. Solution Analysis and Novel Admissibility Conditions of SFOSs: The 1 < α < 2 Case. IEEE Trans. Syst. Man Cybern. Syst. 2022, 52, 5056–5067. [Google Scholar] [CrossRef]

- Yu, Y.; Guan, Y.; Kang, W.; Chaudhary, S.K.; Vasquez, J.C.; Guerrero, J.M. Fractional-Order Virtual Synchronous Generator. IEEE Trans. Power Electron. 2023, 38, 6874–6879. [Google Scholar] [CrossRef]

- Gulzar, M.M.; Gardezi, S.; Sibtain, D.; Khalid, M. Discrete-Time Modeling and Control for LFC Based on Fuzzy Tuned Fractional-Order PDμ Controller in a Sustainable Hybrid Power System. IEEE Access 2023, 11, 63271–63287. [Google Scholar] [CrossRef]

- AbdelAty, A.M.; Al-Durra, A.; Zeineldin, H.H.; Kanukollu, S.; El-Saadany, E.F. Enhancing Dynamic Performance of Islanded Microgrids by Fractional-Order Derivative Droop. IEEE Trans. Ind. Inform. 2024, 20, 9427–9444. [Google Scholar] [CrossRef]

- Kazemi, M.V.; Sadati, S.J.; Gholamian, S.A. Adaptive Frequency Control of Microgrid Based on Fractional Order Control and a Data-Driven Control With Stability Analysis. IEEE Trans. Smart Grid 2022, 13, 381–392. [Google Scholar] [CrossRef]

- Podlubny, I. Fractional-order systems and PIλDμ-controllers. IEEE Trans. Autom. Control 1999, 44, 208–214. [Google Scholar] [CrossRef]

- Pan, I.; Das, S. Chaotic multi-objective optimization based design of fractional order PIλDμ controller in AVR system. Int. J. Electr. Power Energy Syst. 2012, 43, 393–407. [Google Scholar] [CrossRef]

- Xue, D.; Zhao, C.; Chen, Y. A Modified Approximation Method of Fractional Order System. In Proceedings of the 2006 International Conference on Mechatronics and Automation, Luoyang, China, 25–28 June 2006; pp. 1043–1048. [Google Scholar] [CrossRef]

- Birs, I.; Muresan, C.; Nascu, I.; Ionescu, C. A Survey of Recent Advances in Fractional Order Control for Time Delay Systems. IEEE Access 2019, 7, 30951–30965. [Google Scholar] [CrossRef]

- Caputo, M.; Fabrizio, M. A New Definition of Fractional Derivative without Singular Kernel. Prog. Fract. Differ. Appl. 2015, 2, 73–85. [Google Scholar]

- Losada, J.; Nieto, J.J. Properties of a new fractional derivative without singular kernel. Prog. Fract. Differ. Appl. 2016, 1, 87–92. [Google Scholar]

- Nchama, G.A.M.; Mecıas, A.L.; Richard, M.R. The Caputo-Fabrizio Fractional Integral to Generate Some New Inequalities. Inf. Sci. Lett. 2019, 8, 73–80. [Google Scholar]

- IEEE Std 421.5-2016; IEEE Recommended Practice for Excitation System Models for Power System Stability Studies—Redline. IEEE: New York, NY, USA, 2016; pp. 1–453.

- Plakhtyna, O.; Kutsyk, A.; Lozynskyy, A. Method of average voltages in integration step: Theory and application. Electr. Eng. 2020, 102, 2413–2422. [Google Scholar] [CrossRef]

- Boudot, C.; Droin, J.-B.; Sciora, P.; Besanger, Y.; Robisson, B.; Mazauric, A.-L. Small Modular Reactor-based solutions to enhance grid reliability: Impact of modularization of large power plants on frequency stability. EPJ N—Nucl. Sci. Technol. 2022, 8, 16. [Google Scholar] [CrossRef]

- Göran, A. Dynamics and Control of Electric Power Systems; EEH—Power Systems Laboratory; ETH Zurich: Zurich, Switzerland, 2012. [Google Scholar]

- Avon, G.; Bucolo, M.; Buscarino, A.; Fortuna, L. Sensing Frequency Drifts: A Lookup Table Approach. IEEE Access 2022, 10, 96249–96259. [Google Scholar] [CrossRef]

| Operation Mode | Characteristic Indicators | Mismatch Value, % |

|---|---|---|

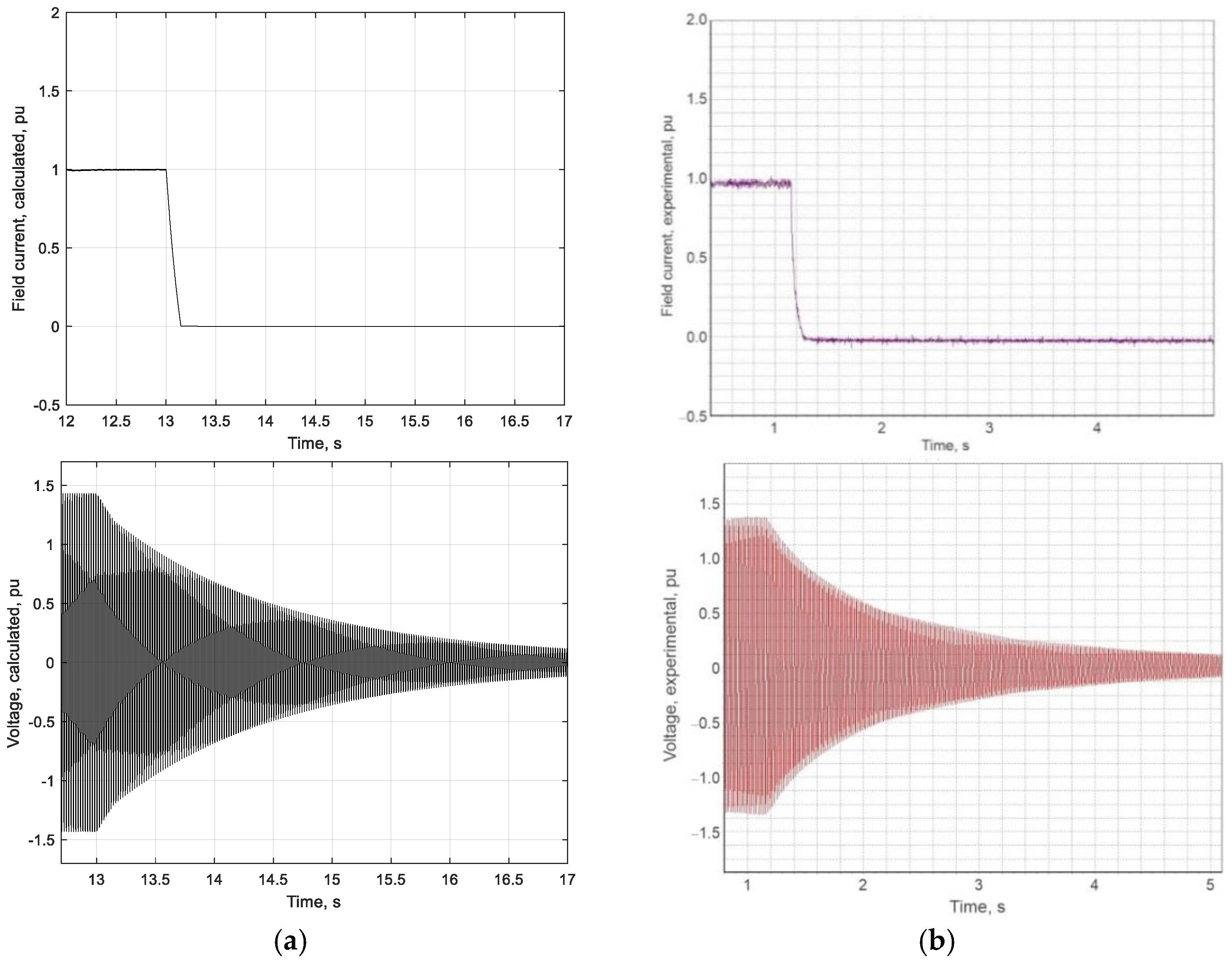

| Initial generator excitation at no-load | Amplitude of excitation current oscillations at the beginning of the transient process | 4 |

| Duration of initial excitation | 2.5 | |

| Overshoot of excitation current | 2 | |

| Generator voltage steady-state value | 1.2 | |

| De-excitation of the generator | Time for the excitation current to drop off | 4.8 |

| Time for the generator voltage to drop to 10% of the nominal value, Tde | 5 | |

| Generator voltage decrease in time 0.5Tde | 2 | |

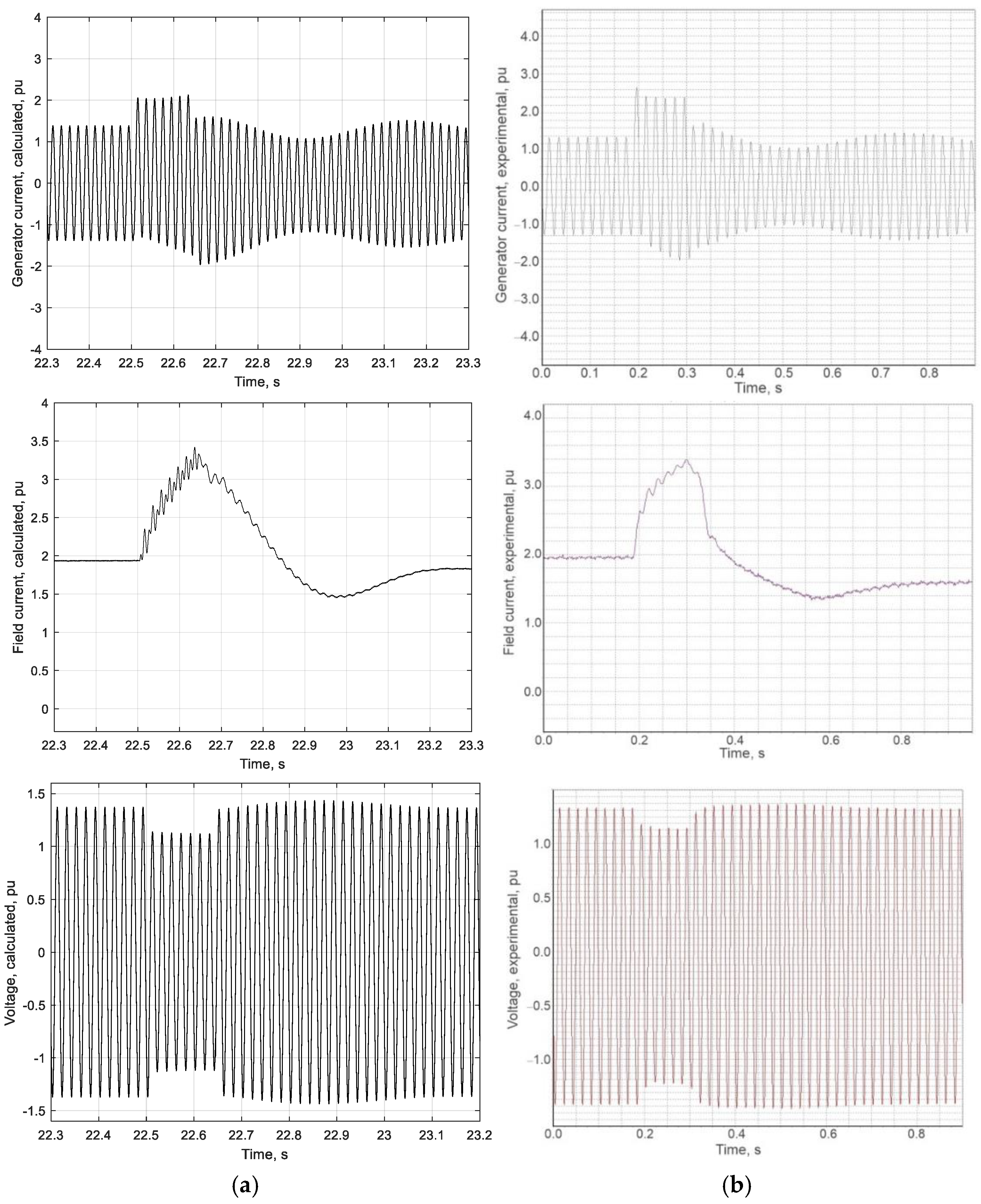

| Short-circuit in power line | The effective stator current value during short-circuit | 14 |

| Maximum stator current instantaneous value after short-circuit disconnection | 11 | |

| Minimum amplitude value of the stator current after short-circuit disconnection | 2 | |

| Period of self-oscillation after short-circuit disconnection | 5.5 | |

| The maximum value of the excitation current | 6 | |

| The minimum value of the excitation current (after short-circuit disconnection) | 8 | |

| Generator voltage during short-circuit | 3 | |

| Maximum generator voltage instantaneous value after short-circuit disconnection | 7 | |

| Average value | 4.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lozynskyy, A.; Kozyra, J.; Kutsyk, A.; Łukasik, Z.; Kuśmińska-Fijałkowska, A.; Kasha, L.; Lishchuk, A. AVR Fractional-Order Controller Based on Caputo–Fabrizio Fractional Derivatives and Integral Operators. Energies 2024, 17, 5913. https://doi.org/10.3390/en17235913

Lozynskyy A, Kozyra J, Kutsyk A, Łukasik Z, Kuśmińska-Fijałkowska A, Kasha L, Lishchuk A. AVR Fractional-Order Controller Based on Caputo–Fabrizio Fractional Derivatives and Integral Operators. Energies. 2024; 17(23):5913. https://doi.org/10.3390/en17235913

Chicago/Turabian StyleLozynskyy, Andriy, Jacek Kozyra, Andriy Kutsyk, Zbigniew Łukasik, Aldona Kuśmińska-Fijałkowska, Lidiia Kasha, and Andriy Lishchuk. 2024. "AVR Fractional-Order Controller Based on Caputo–Fabrizio Fractional Derivatives and Integral Operators" Energies 17, no. 23: 5913. https://doi.org/10.3390/en17235913

APA StyleLozynskyy, A., Kozyra, J., Kutsyk, A., Łukasik, Z., Kuśmińska-Fijałkowska, A., Kasha, L., & Lishchuk, A. (2024). AVR Fractional-Order Controller Based on Caputo–Fabrizio Fractional Derivatives and Integral Operators. Energies, 17(23), 5913. https://doi.org/10.3390/en17235913