5.1. Production Case Study

Currently, a substantial portion of both domestic and international natural gas reservoirs consists of condensate gas reservoirs, which are crucial for the development of gas fields. Incomplete statistics indicate that the depth of these condensate gas reservoirs typically lies below 4500 m, with formation temperatures ranging from 40 to 187 °C and original formation pressures between 20 and 40 MPa. Most reservoirs are categorized as porous or porous–fractured types, exhibiting medium-to-low porosity and permeability. The ΔP

fd of fluids in condensate gas fields is relatively small, varying from 0.7 to 10.4 MPa, with an average of 2.9 MPa. Additionally, these fields generally exhibit a low relative density of natural gas, characterized by a high total hydrocarbon content and a low non-hydrocarbon content. Condensate oil is typically characterized by low density, a high content of light components, and a low content of heavy components, with condensate oil concentrations ranging from 22 g/m

3 to 1297 g/m

3.

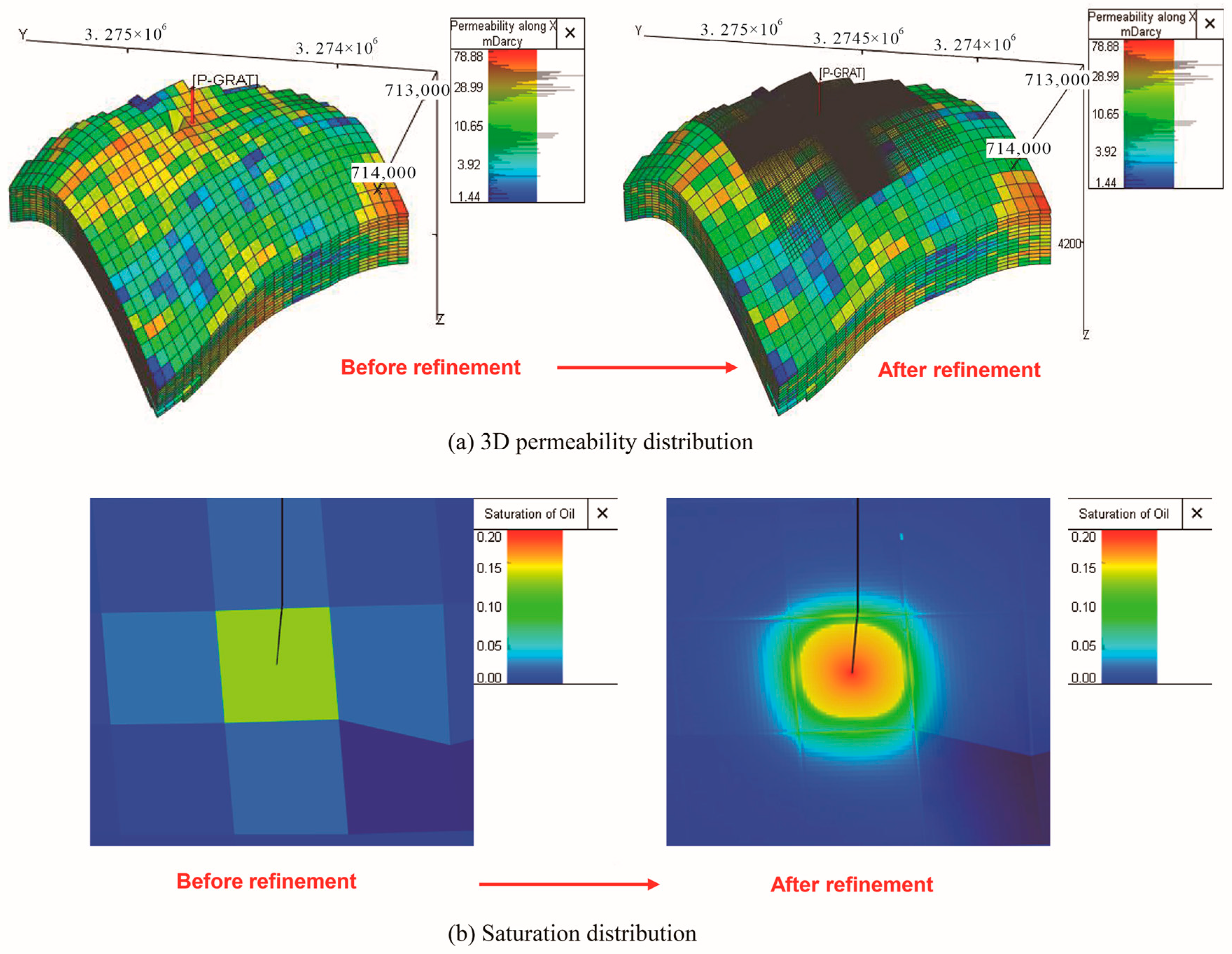

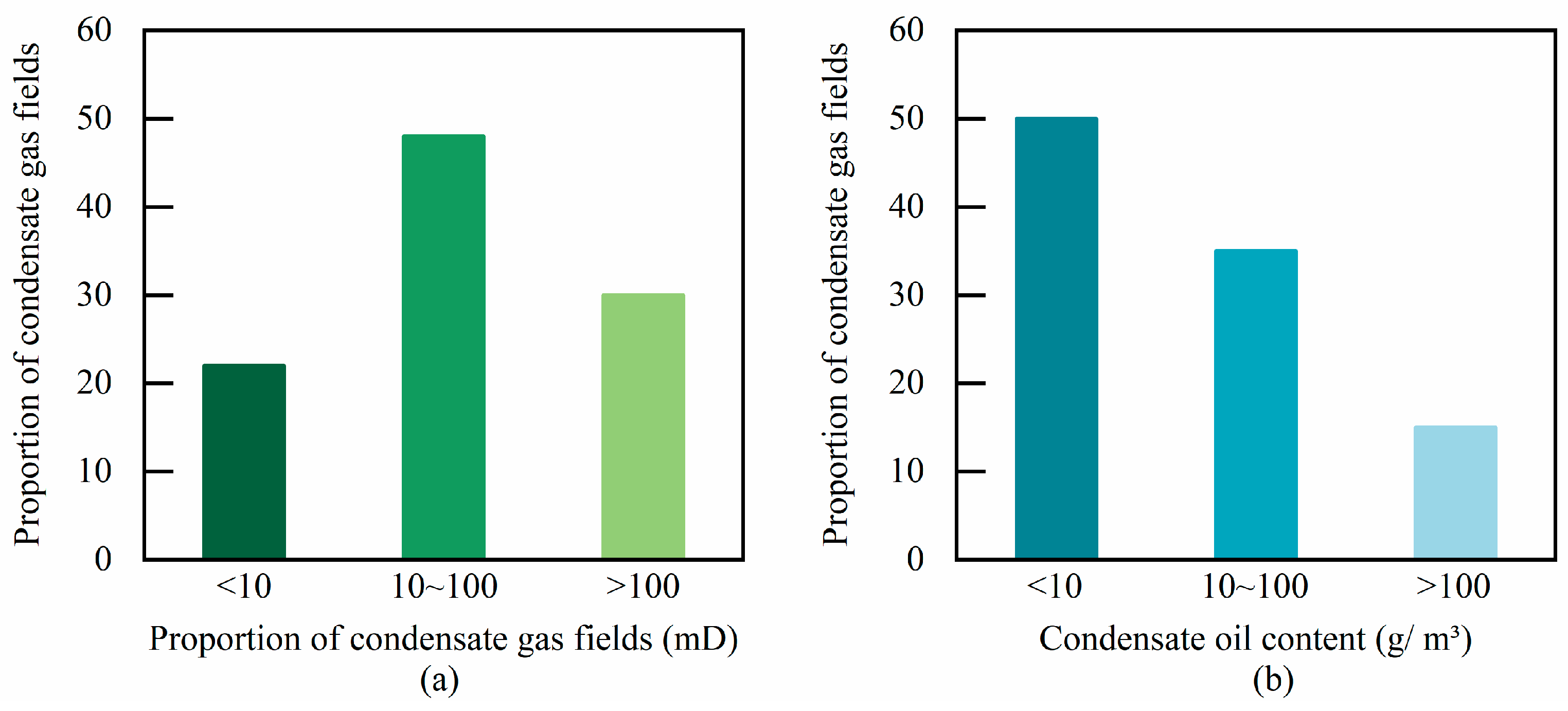

Figure 12 shows the permeability of the condensate reservoir and the distribution of condensate oil content.

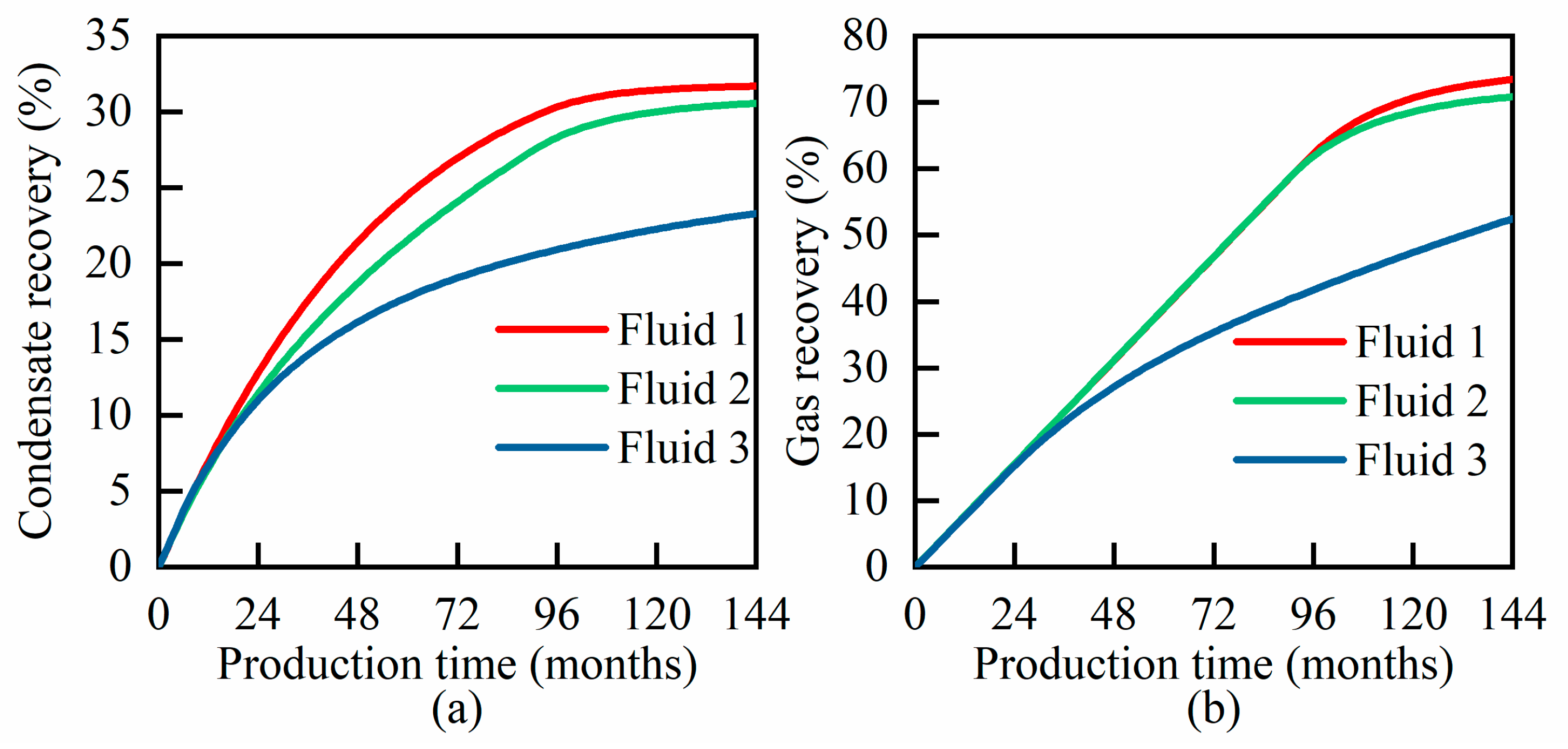

Currently, condensate gas fields predominantly use depletion and gas cycling recovery methods. The range of condensate recovery rates is quite extensive, as shown in

Figure 13, with recovery rates as low as 2% in the absence of production measures and as high as 88.5% when such measures are implemented. As indicated in

Table 9, gas reservoirs with high condensate oil content primarily utilize gas injection recovery, achieving condensate recovery rates exceeding 40%. In contrast, medium- and low-condensate-oil-content gas reservoirs mainly rely on depletion recovery, with recovery rates approximately between 20% and 30%. The predominant drive types are gas drive and water drive, with gas production rates varying from a minimum of 0.19% to a maximum of 8% [

32,

33,

34,

35,

36,

37,

38].

- (1)

QD Gas Field:

The QD Gas Field is a complete anticline structure comprising four gas–water systems with analogous fluid properties and reservoir characteristics, arranged from bottom to top. The predominant reservoir rocks include lithic sandstones and feldspathic lithic sandstones, characterized primarily by intergranular dissolution pores.

The interlayers separating the gas reservoirs are well developed and stable, ensuring effective sealing properties. The primary producing formation is the Middle Jurassic Xishanyao Formation (J2x), situated at a depth of 3246.5 m in the central region of the field. This formation is classified as a low-permeability sandstone reservoir, consisting of sheet sand deposits located at the front of a fan delta, with an orientation approximately north–south. The lithology is predominantly silt-bearing fine sandstone and medium–fine sandstone, exhibiting relatively dense rock characteristics. Porosity within the reservoir ranges from 3.7% to 13.0%, with an average of 10.5%. Reservoir permeability varies from 1.1 mD to 12.0 mD, averaging 4.1 mD. The gas reservoir temperature fluctuates between 93.4 °C and 100.6 °C, while the formation pressure ranges from 31.3 MPa to 34.6 MPa, with an average of 32.24 MPa and a temperature gradient of 2.56 °C/100 m. The condensate oil content within the gas reservoir ranges from 190.5 g/m3 to 260.4 g/m3, indicating a medium condensate gas reservoir with an average condensate oil content of 226.3 g/m3. The differential pressure between the formation and the surface is relatively small, ranging from 0.12 MPa to 2.53 MPa, with an average of 1.47 MPa. Notably, the gas reservoir is characterized by an absence of sulfur, a low non-hydrocarbon content (less than 1.56%), and inactive edge and bottom water energy, with no significant water production observed in the gas wells.

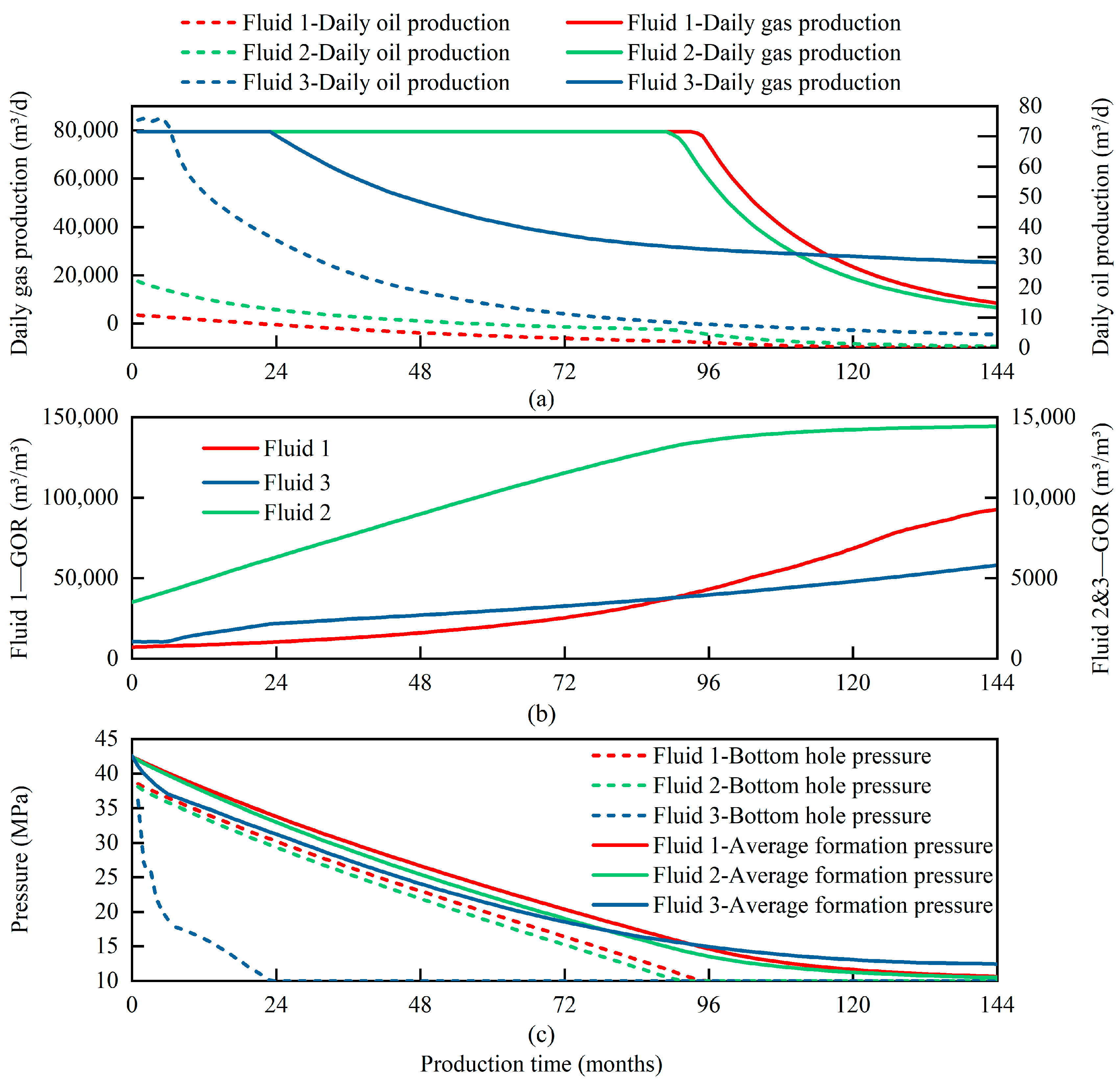

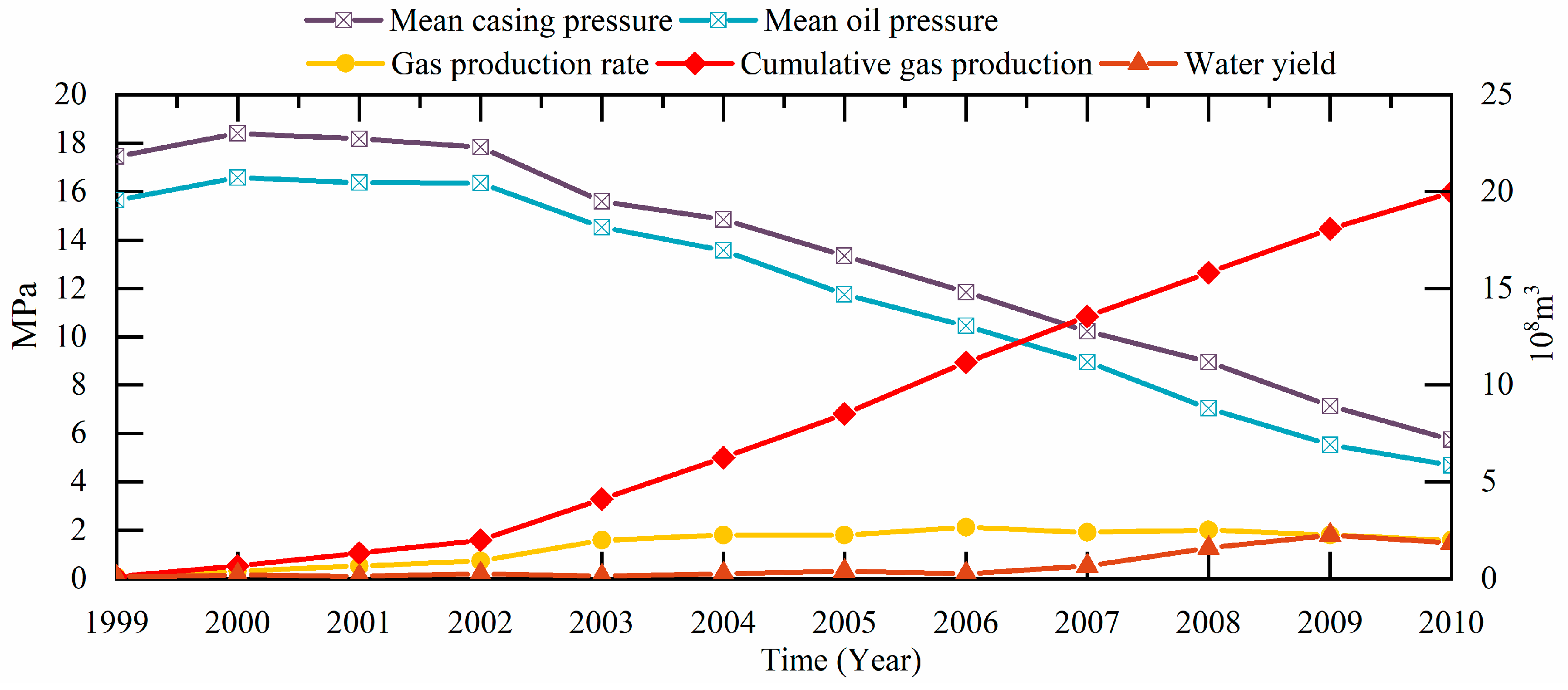

The natural gas production curve of the QD Gas Field is shown in

Figure 14. The field adopted a depletion development strategy in October 1998. By the end of 2009, the field had 15 gas production wells, with a current gas production rate of 2.93%, a natural gas recovery rate of 26%, and a condensate recovery rate of 19.26%. The maximum retrograde condensation pressure within the field ranges from approximately 10 to 15 MPa. Following a decade of depletion development, the formation pressure has decreased to 13.68 MPa, marking the onset of the maximum retrograde condensation pollution stage [

39]. An analysis of well test data reveals that all 14 wells currently in production are experiencing varying degrees of retrograde condensation pollution. Notably, three of these wells have exhibited a reduction in gas-phase permeability near the wellbore, ranging from 37.5% to 44%, alongside a decrease in the gas supply radius of 66.17% to 88.61%. Consequently, the entire gas field is significantly affected by retrograde condensation pollution.

Condensate oil pollution leads to a reduction in gas-phase permeability. To address this issue, the QD Gas Field employs hydraulic fracturing production technology, which aims to enhance reservoir permeability, improve fluid flow capacity, and increase the permeability of the near-wellbore area. This technique is instrumental in mitigating retrograde condensation pollution within the QD Gas Field, ultimately contributing to increased production levels. Hydraulic fracturing was conducted on wells QD22, QD25, and QD26, and the results are summarized in

Table 10. Notably, after the fracturing process, the gas–oil ratio of well QD25 decreased from 6731 m

3/m

3 to 3939 m

3/m

3, while natural gas productivity surged by a factor of three, and condensate oil production rose by 2.54 times. These findings indicate that hydraulic fracturing has effectively alleviated retrograde condensation pollution.

- (2)

KK Gas Field:

The KK Gas Field is characterized by a short-axis anticline structure that extends nearly east–west, with lithology predominantly consisting of fine sandstone. The reservoir depth ranges from 2960 to 4000 m, with temperatures varying between 82 °C and 142 °C and an initial formation pressure of 39.4 MPa. The gas-bearing area of the reservoir measures 27.5 km

2, and the cumulative proven natural gas geological reserve is estimated at 38.99 billion m

3 alongside a condensate oil geological reserve of 1.4425 million tons. The porosity ranges from 9% to 18%, with an average of 12%. Permeability ranges from 5.5 to 126 mD, yielding an average permeability of 40 mD. Additionally, the fluid in this gas reservoir has a condensate oil content between 300 and 700 g/m

3, categorizing it as a gas reservoir with medium-to-high condensate oil content [

42].

The gas field was put into development in 1988 using depletion development. The formation pressure declined rapidly, and many wells experienced reduced production or shutdown due to retrograde condensation pollution in the formation around the wellbore or liquid accumulation at the well bottom. Among them, gas wells K416, K354, and K233 lost production due to retrograde condensation pollution. The surface condensate oil production of the entire gas field decreased, and the gas–oil ratio increased rapidly.

A comprehensive dynamic monitoring system was established for this condensate gas reservoir. Different development methods were adjusted for different layers and blocks to optimize gas field recovery rates and increase economic benefits.

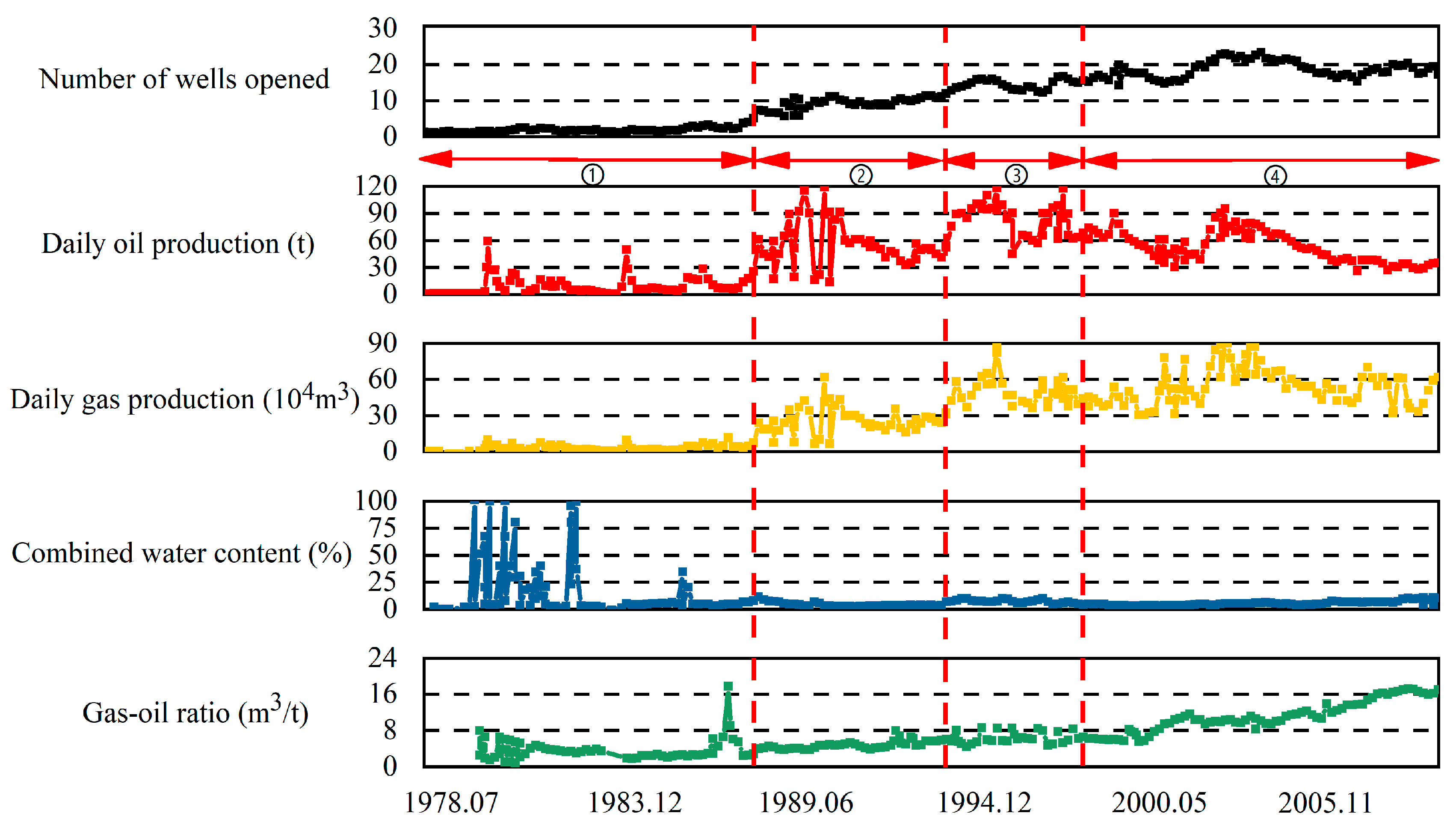

The comprehensive production curves for the X

42 to X

51 gas production layers are shown in

Figure 15. This gas layer began trial production from 1984 to 1988 (phase ① in the figure). From 1989 to 1994 (phase ② in the figure), both the gas cap and oil ring were produced simultaneously. However, the newly drilled oil ring wells did not perform well, making it impossible to implement the strategy of producing the oil ring first. Later, new wells were drilled at the edge of the oil ring. After years of development, retrograde condensation pollution became severe, with condensate oil saturation near the well bottom reaching about 17%. Therefore, from 1994 to 1997 (phase ③ in the figure), a gas cycling test was conducted. During the gas injection period, the X

51 block significantly suppressed the retrograde condensation of heavy components underground. The condensate recovery rate increased by 18.2% compared to depletion development, rising from 21% to 39.2%. Since 1998 (phase ④ in the figure), the development has entered a comprehensive adjustment phase. On the one hand, new wells were drilled to extract the remaining oil and gas in enriched areas; on the other hand, layer adjustment was implemented to improve recovery rates further.

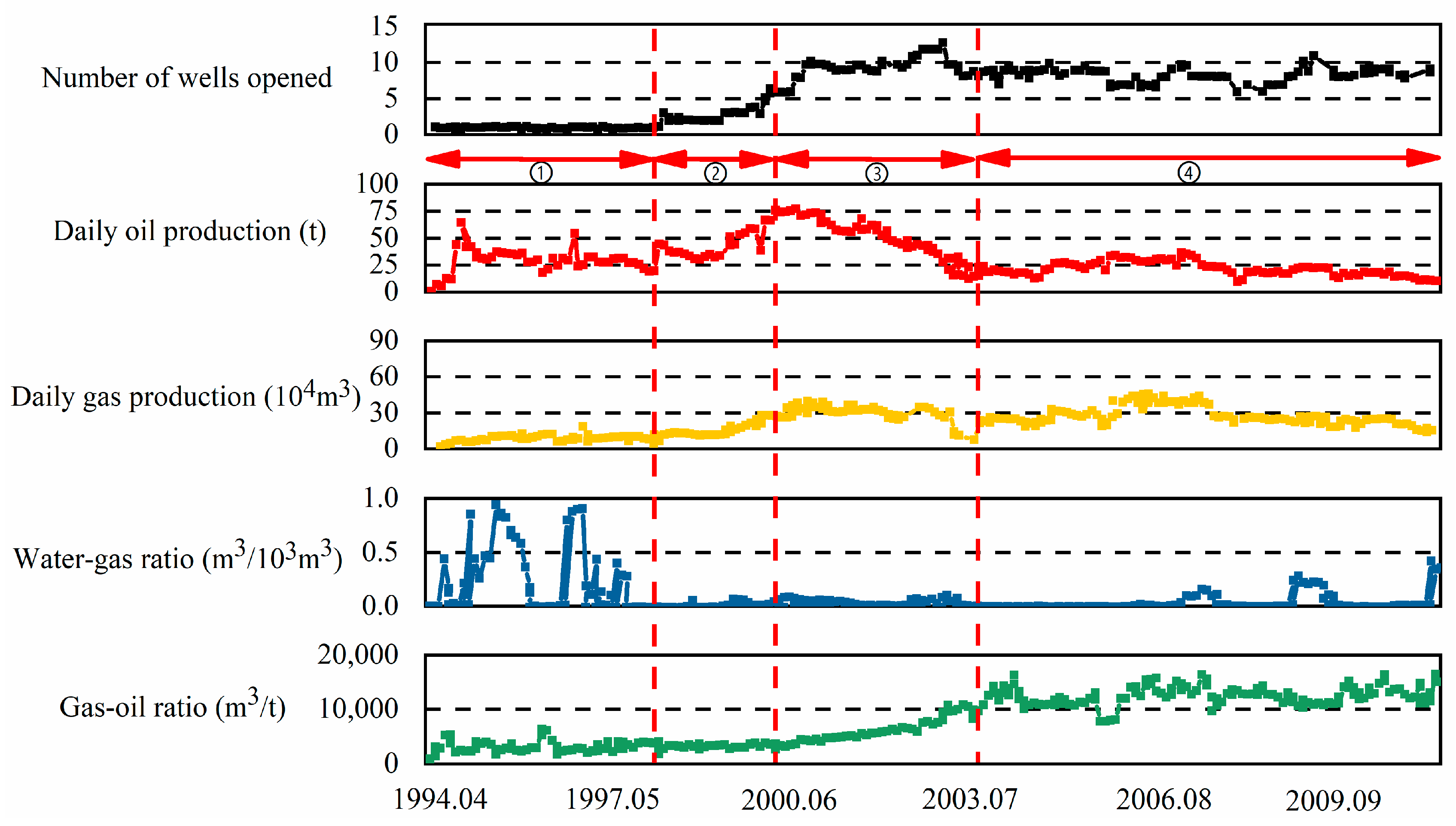

Figure 16 shows the comprehensive production curve for the X

41 gas production layers. This gas layer began trial production in 1994 (phase ①), with an average daily gas production of 100,000 m

3 and a daily oil production of 30 tons. The reservoir static pressure was 30 MPa, and the fluid dew point pressure was 37.2 MPa, indicating the onset of retrograde condensation pollution in the formation. In 1997 (phase ②), gas cycling development was implemented, with the reservoir static pressure at 27 MPa at that time. When the number of producing wells reached around 10 (phase ③), both the daily gas production and daily oil production began to decline, and the gas–oil ratio increased year by year. Despite the gas cycling, the reservoir pressure continued to decline. Due to severe reservoir heterogeneity and poor connectivity between injection and production wells, the gas cycling development method was not effective. Consequently, in 2003 (phase ④), gas injection was stopped, and depletion development was adopted, at which point the increase in the gas–oil ratio slowed down.

The remaining gas layers are similar to the ones described above, with development strategies being continuously adjusted through real-time monitoring. For the X52 layer, depletion development was adopted in 1983. The condensate oil production was relatively low, and the gas–oil ratio continued to increase. The X72 gas production layers began using depletion development in 1995. Gas cycling was implemented in 2003, but the results were not satisfactory, so depletion development continued after 2010.

The original formation pressure of the condensate gas reservoir in the KK Gas Field was 39.4 MPa. During production, as the pressure in each production layer dropped below the dew point pressure, the formation pressure decreased by 50% to 60% by 2012. Retrograde condensation pollution appeared at the well bottom, causing a significant increase in the gas–oil ratio in each layer and a decline in condensate oil production. The natural gas recovery rate for the field is 37%, and the expected condensate recovery rate ranges from 35% to 50%. Therefore, during the development process, it is necessary to gradually regulate the pressure and development methods for the entire gas field to achieve the maximum economic benefits.