Characteristics of Supercritical CO2 Non-Mixed Phase Replacement in Intraformational Inhomogeneous Low-Permeability Reservoirs

Abstract

:1. Introduction

2. Materials and Methods

2.1. Supercritical CO2 Displacement Experiment Materials

2.1.1. Cores Used in Experiments

2.1.2. Experimental Oil, Water and Gas

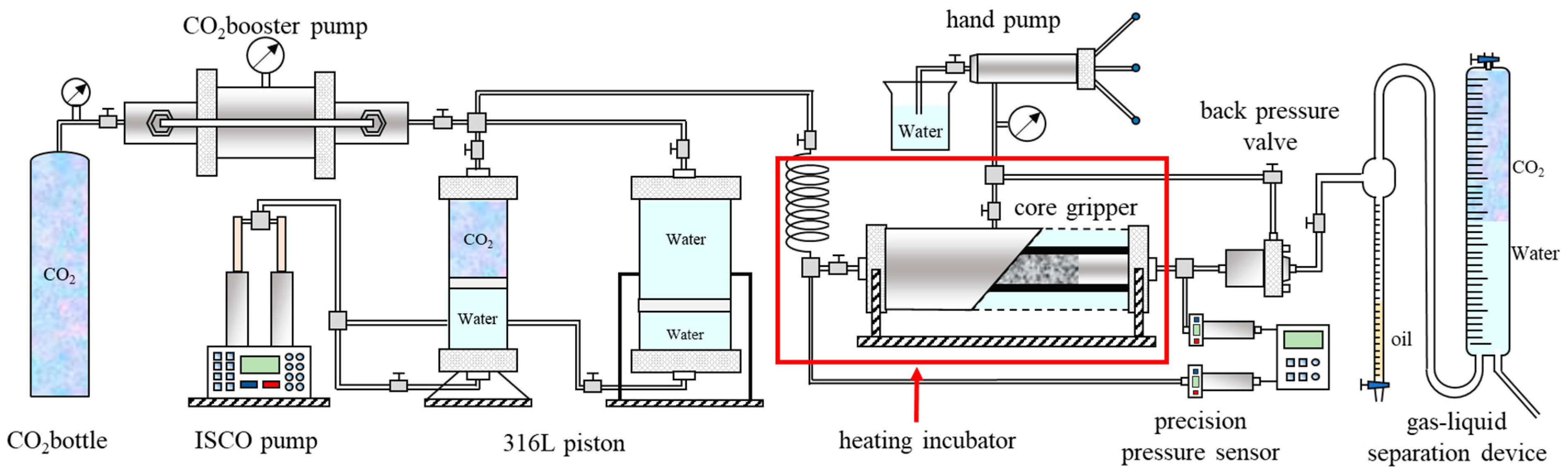

2.1.3. Experimental Equipment and Flowcharts

2.2. Experimental Program and Experimental Steps for Supercritical CO2 Displacement

2.2.1. Experimental Program

2.2.2. Experimental Steps

2.3. Numerical Simulation of Comsol for Supercritical CO2 Displacement

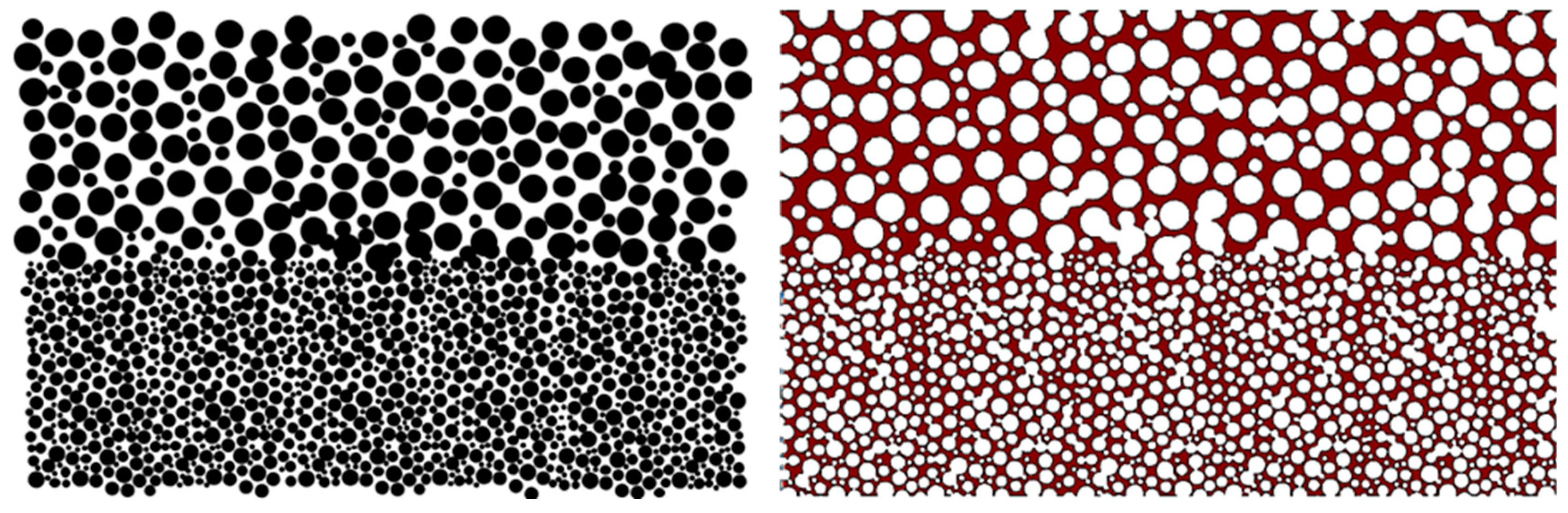

2.3.1. Introduction to the Bilayer Low-Permeability Inhomogeneous Model

2.3.2. Model Parameter Design

3. Results and Discussion

3.1. Water and Gas Alternation (WAG) Displacement and Pore Throat Utilization Characteristics in Low-Permeability Inhomogeneous Cores

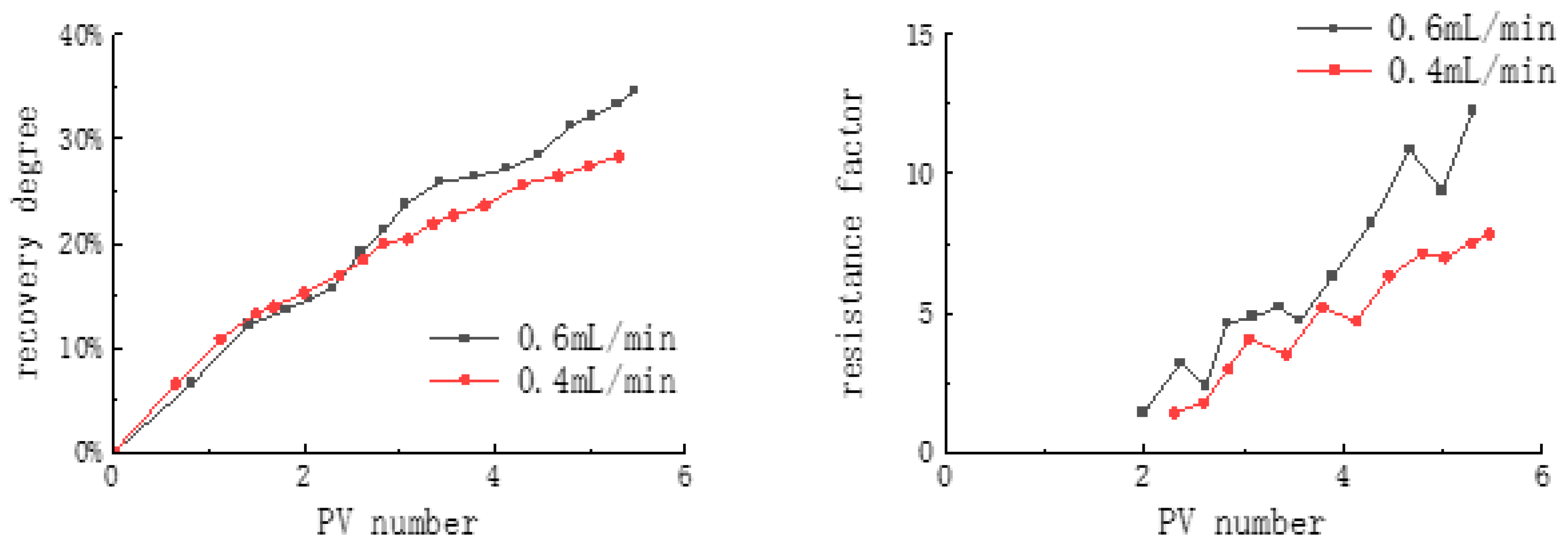

3.1.1. Influence of Different Velocities on WAG Displacement Characteristics in Inhomogeneous Cores

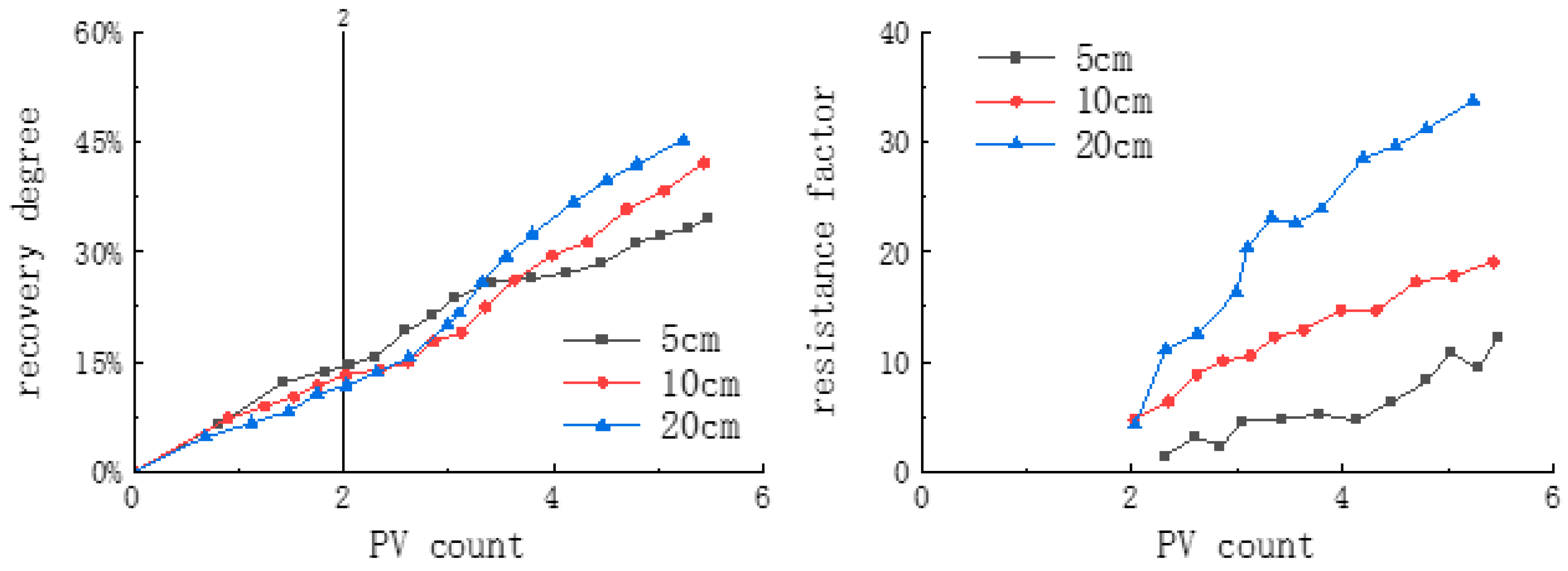

3.1.2. Influence of Core Length on the Effect of WAG

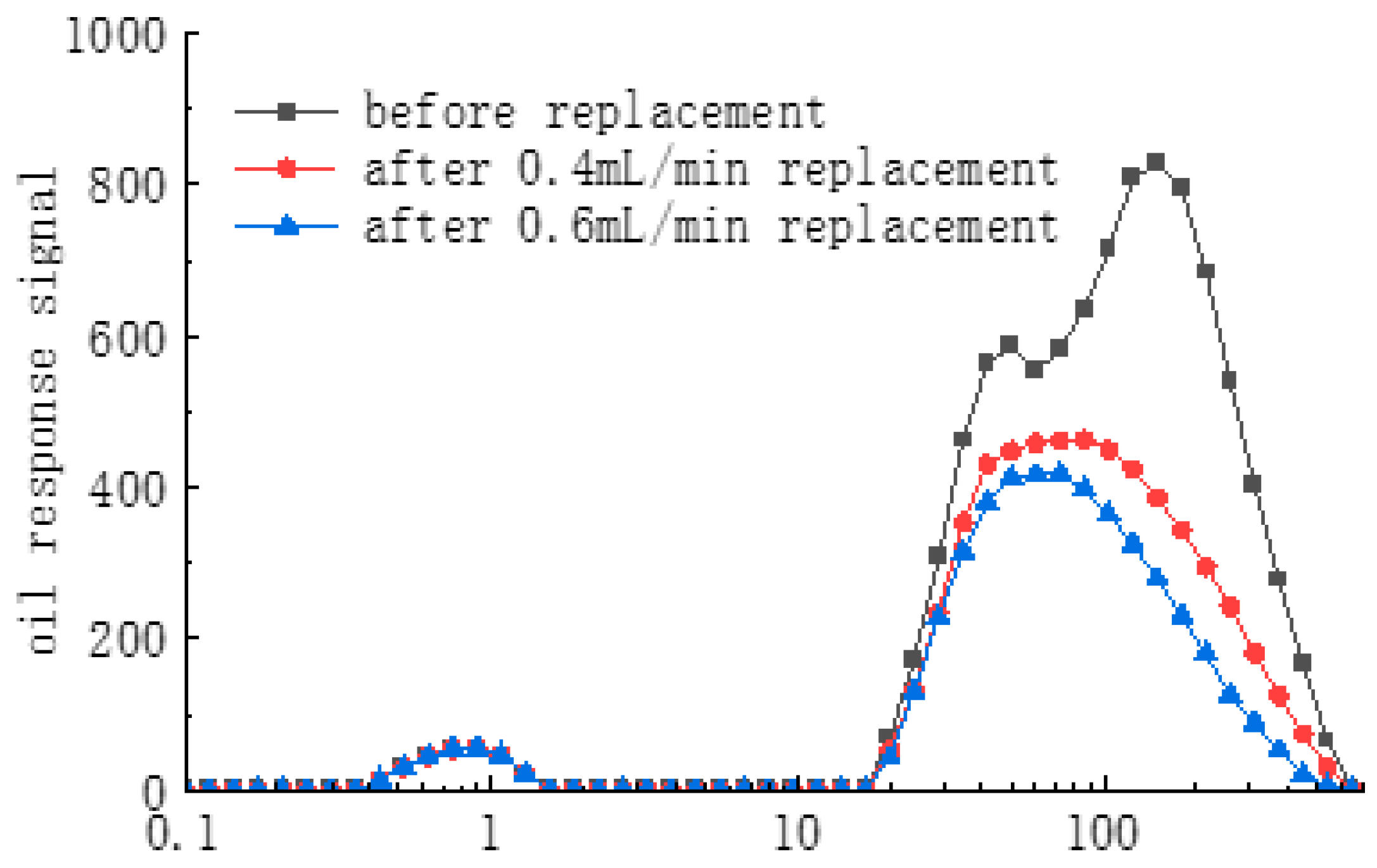

3.1.3. Characteristics of Pore Throat Utilization for WAG in Low-Permeability Inhomogeneous Cores

3.2. Non-Mixed-Phase Displacement Simulation Results from Low-Permeability Inhomogeneous Models

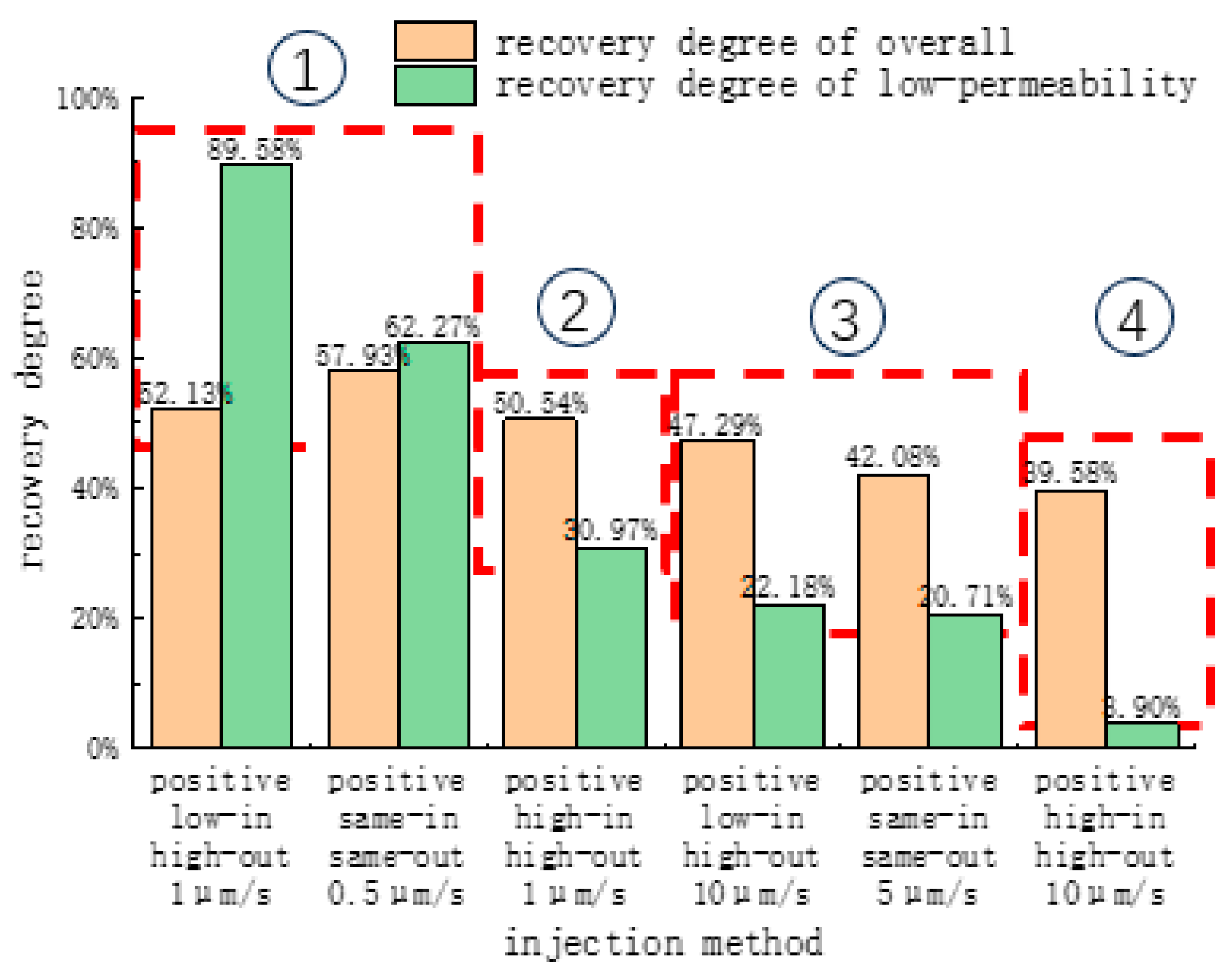

3.2.1. Simulation Results and Recovery Degree

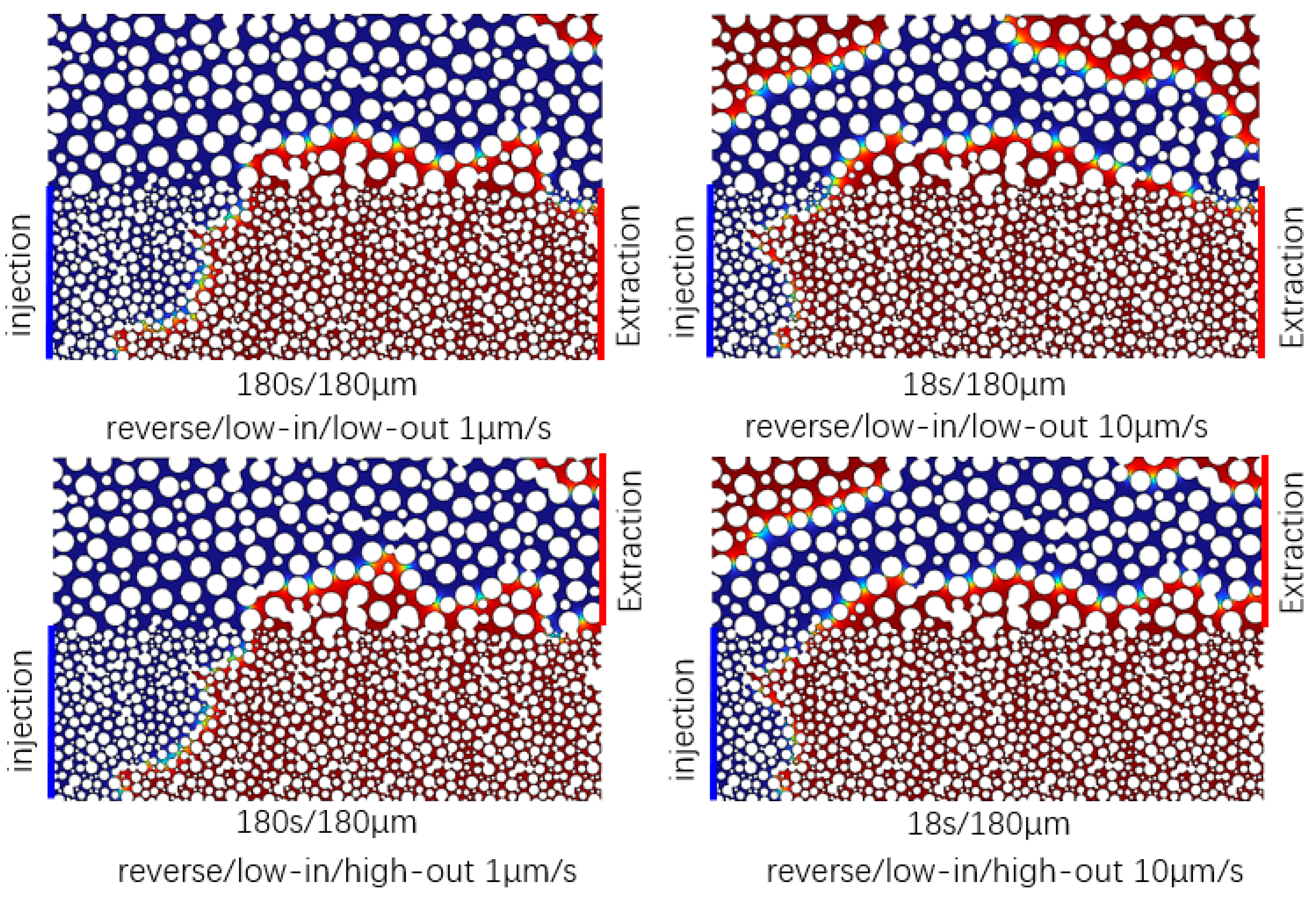

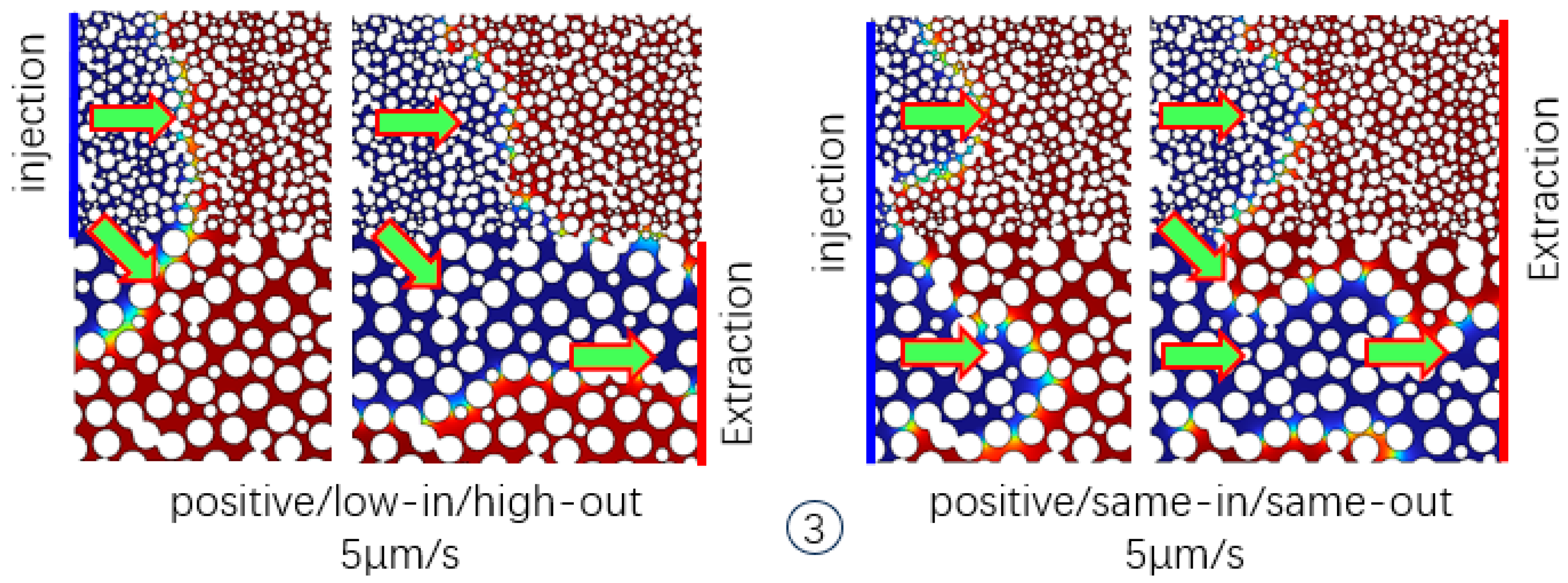

3.2.2. Influence of Gravity and Flow Rate Together on the Characteristics of the Displacement

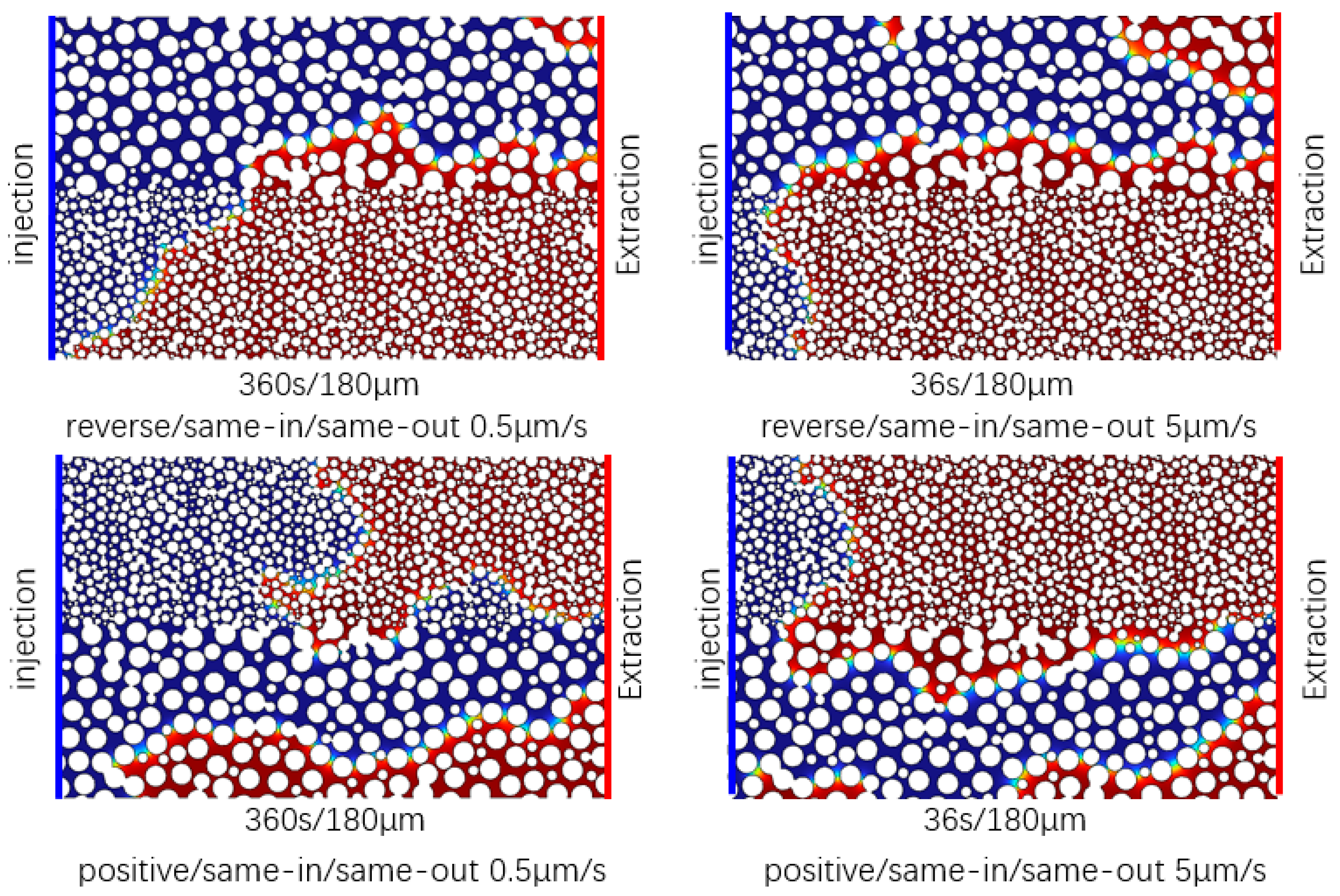

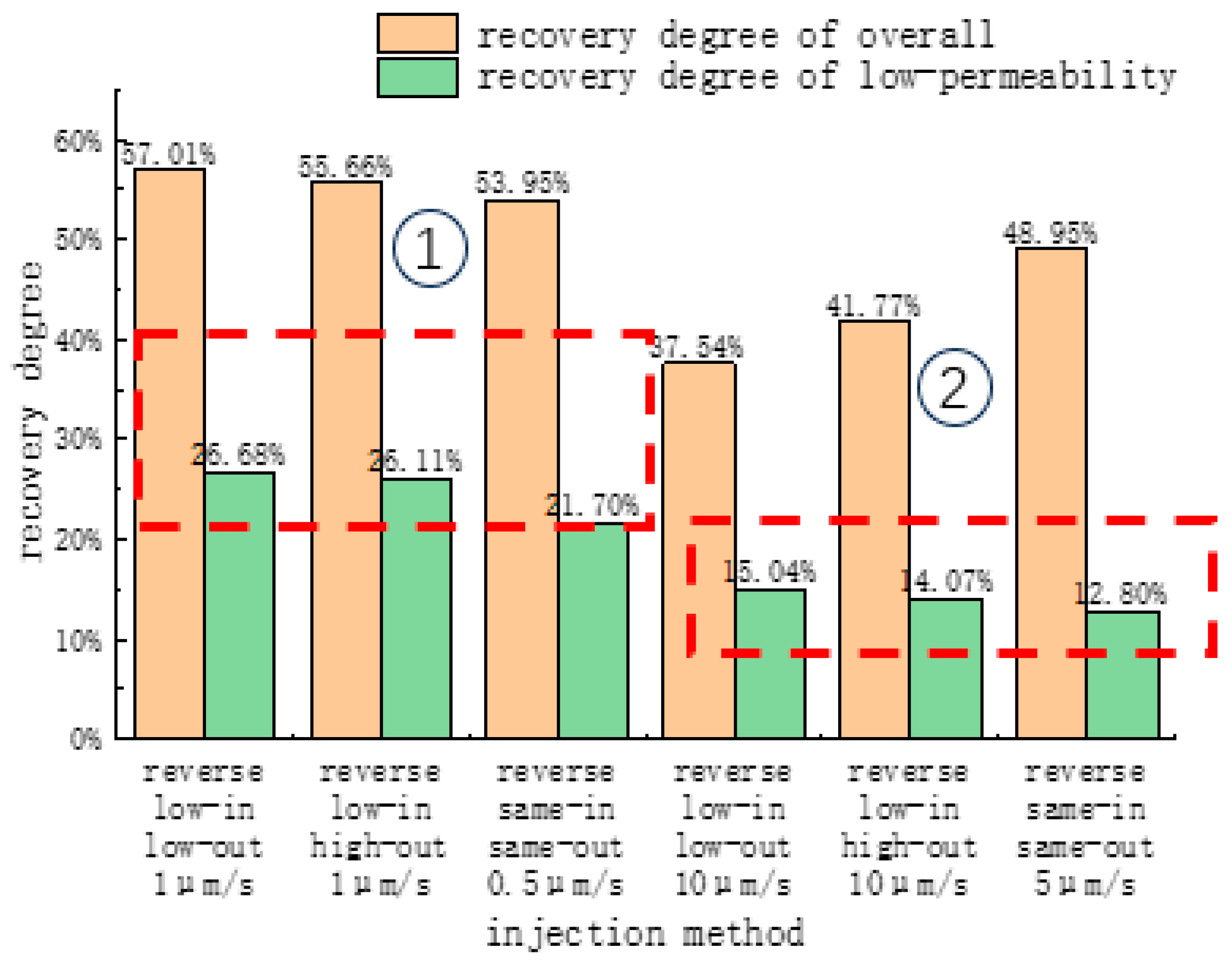

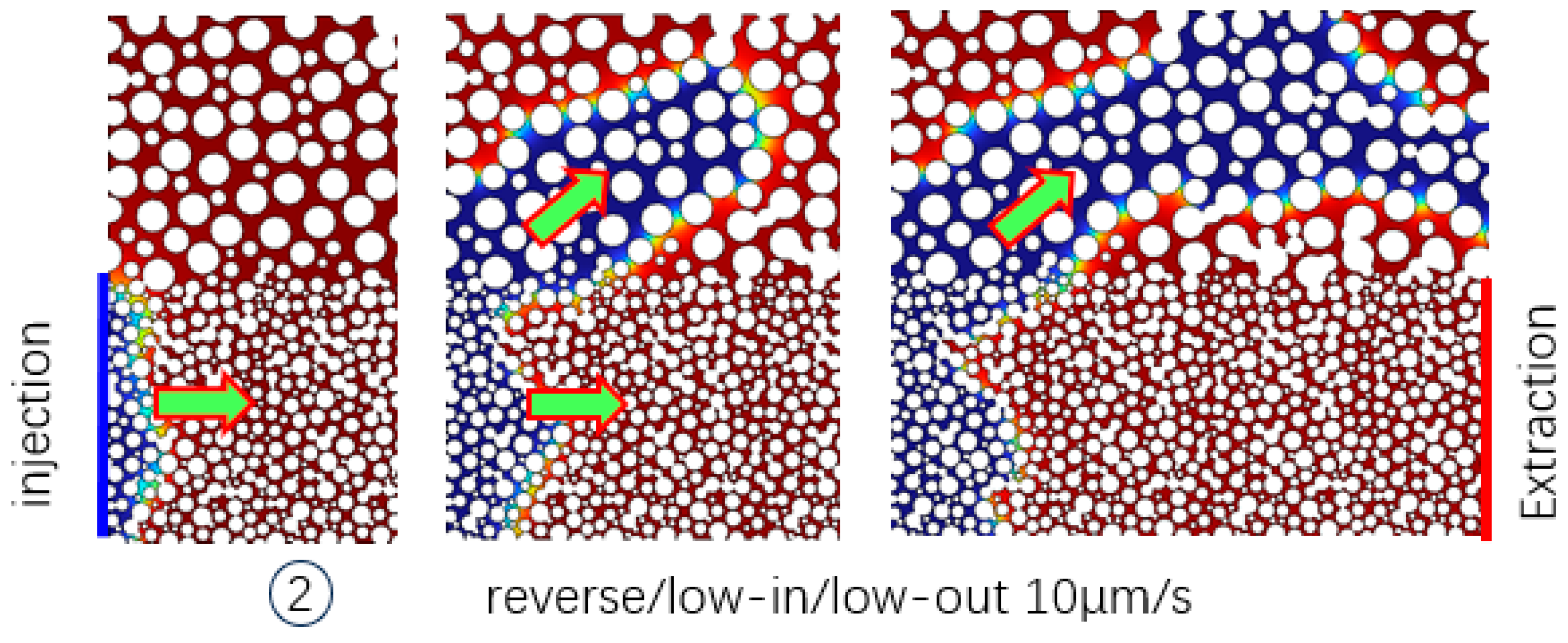

3.2.3. Preferred Development Methods for Reverse-Rhythm Reservoirs

3.2.4. Preferred Development Methods for Positive-Rhythm Reservoirs

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, Q.; Liu, J.-F.; Gao, Z.-H.; Chen, S.-Y.; Liu, B.-Y. Review on the Challenges and Strategies in Oil and Gas Industry’s Transition towards Carbon Neutrality in China. Pet. Sci. 2023, 20, 3931–3944. [Google Scholar] [CrossRef]

- Yuan, S.; Han, H.; Wang, H.; Luo, J.; Wang, Q.; Lei, Z.; Xi, C.; Li, J. Research Progress and Potential of New Enhanced Oil Recovery Methods in Oilfield Development. Pet. Explor. Dev. 2024, 51, 963–980. [Google Scholar] [CrossRef]

- Zheng, X.; Shi, J.; Cao, G.; Yang, N.; Cui, M.; Jia, D.; Liu, H. Progress and Prospects of Oil and Gas Production Engineering Technology in China. Pet. Explor. Dev. 2022, 49, 644–659. [Google Scholar] [CrossRef]

- Qiu, L.; Wang, S.; Hu, B.; Yan, J.; Deng, S.; Shen, J.; Shi, C.; Ge, X.; Chen, B. A Review on High-Value Development and Utilization of Unconventional Methane-Containing Gaseous Fuel Resources. Energy Convers. Manag. 2024, 319, 118980. [Google Scholar] [CrossRef]

- Manfroni, M.; Bukkens, S.G.F.; Giampietro, M. Securing Fuel Demand with Unconventional Oils: A Metabolic Perspective. Energy 2022, 261, 125256. [Google Scholar] [CrossRef]

- Di, S.; Cheng, S.; Cao, N.; Gao, C.; Miao, L. AI-Based Geo-Engineering Integration in Unconventional Oil and Gas. J. King Saud Univ. -Sci. 2021, 33, 101542. [Google Scholar] [CrossRef]

- Yan, D.; Zhao, L.; Song, X.; Tang, J.; Zhang, F. Fracability Evaluation Model for Unconventional Reservoirs: From the Perspective of Hydraulic Fracturing Performance. Int. J. Rock Mech. Min. Sci. 2024, 183, 105912. [Google Scholar] [CrossRef]

- Verma, A.; Pal, N.; Kumar, N.; Al-Yaseri, A.; Ali, M.; Ojha, K. Nanoparticles Stabilized Foam Fluid for Hydraulic Fracturing Application of Unconventional Gas Reservoirs: A Review of the Properties, Progress and Future Prospects. Pet. Res. 2024, in press. [CrossRef]

- Zhang, S.; Zhang, B.; Wang, X.; Feng, Z.; He, K.; Wang, H.; Fu, X.; Liu, Y.; Yang, C. Gulong Shale Oil Enrichment Mechanism and Orderly Distribution of Conventional—Unconventional Oils in the Cretaceous Qingshankou Formation, Songliao Basin, NE China. Pet. Explor. Dev. 2023, 50, 1045–1059. [Google Scholar] [CrossRef]

- Bai, Y.; Pu, W.; Jin, X.; Shen, C.; Ren, H. Review of the Micro and Macro Mechanisms of Gel-Based Plugging Agents for Enhancing Oil Recovery of Unconventional Water Flooding Oil Reservoirs. J. Mol. Liq. 2024, 399, 124318. [Google Scholar] [CrossRef]

- Prasad, S.K.; Sangwai, J.S.; Byun, H.-S. A Review of the Supercritical CO2 Fluid Applications for Improved Oil and Gas Production and Associated Carbon Storage. J. CO2 Util. 2023, 72, 102479. [Google Scholar] [CrossRef]

- Gou, B.; Li, X.; Guo, J.; Liu, C.; Chen, C.; Guan, C. Experimental Investigation of the Impacts of Supercritical Carbon Dioxide on Acid-Etching Fracture Morphology and Conductivity in Tight Carbonate Reservoir. Fuel 2024, 360, 130526. [Google Scholar] [CrossRef]

- Jiang, J.; Rui, Z.; Hazlett, R.; Lu, J. An Integrated Technical-Economic Model for Evaluating CO2 Enhanced Oil Recovery Development. Appl. Energy 2019, 247, 190–211. [Google Scholar] [CrossRef]

- Davoodi, S.; Al-Shargabi, M.; Wood, D.A.; Mehrad, M.; Rukavishnikov, V.S. Carbon Dioxide Sequestration through Enhanced Oil Recovery: A Review of Storage Mechanisms and Technological Applications. Fuel 2024, 366, 131313. [Google Scholar] [CrossRef]

- Liu, B.; Shi, J.; Wang, M.; Zhang, J.; Sun, B.; Shen, Y.; Sun, X. Reduction in Interfacial Tension of Water—Oil Interface by Supercritical CO2 in Enhanced Oil Recovery Processes Studied with Molecular Dynamics Simulation. J. Supercrit. Fluids 2016, 111, 171–178. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, Y.; Zou, R.; Zou, R.; Huang, L.; Liu, Y.; Meng, Z.; Wang, Z.; Lei, H. A Systematic Review of CO2 Injection for Enhanced Oil Recovery and Carbon Storage in Shale Reservoirs. Int. J. Hydrog. Energy 2023, 48, 37134–37165. [Google Scholar] [CrossRef]

- Mukherjee, M.; Misra, S.; Gupta, A. Control of Pore-Size Distribution on CO2 Adsorption Volume and Kinetics in Gondwana Coals: Implications for Shallow-Depth CO2 Sequestration Potential. J. Nat. Gas Sci. Eng. 2021, 89, 103901. [Google Scholar] [CrossRef]

- Lang, D.; Lun, Z.; Lyu, C.; Wang, H.; Zhao, Q.; Sheng, H. Nuclear Magnetic Resonance Experimental Study of CO2 Injection to Enhance Shale Oil Recovery. Pet. Explor. Dev. 2021, 48, 702–712. [Google Scholar] [CrossRef]

- Wang, Z.; Li, S.; Jin, Z.; Li, Z.; Liu, Q.; Zhang, K. Oil and Gas Pathway to Net-Zero: Review and Outlook. Energy Strategy Rev. 2023, 45, 101048. [Google Scholar] [CrossRef]

- Wang, Z.L.; Chen, H.L. The Distribution and Evolution of Fluid Pressure and Its Influence on Natural Gas Accumulation in the Upper Paleozoic of Shenmu-Yulin Area, Ordos Basin. Sci. China Ser. D Earth Sci. 2007, 50, 59–74. [Google Scholar] [CrossRef]

- Chi, G.; Giles, P.S.; Williamson, M.A.; Lavoie, D.; Bertrand, R. Diagenetic History and Porosity Evolution of Upper Carboniferous Sandstones from the Spring Valley #1 Well, Maritimes Basin, Canada—Implications for Reservoir Development. J. Geochem. Explor. 2003, 80, 171–191. [Google Scholar] [CrossRef]

- Spina, V.; Olagundoye, O.; Chizea, C.; Pellettier, J.; Onyeanuna, C.; Parsa, A.; Joubert, T.; Fashanu, M.; Enuma, C.; Ifihan, J.J.; et al. Unravelling the Impact of Geological Heterogeneities in the Reservoir Management. An Integrated Study of the Deep-Water Akpo Field (Niger Delta). Mar. Pet. Geol. 2023, 150, 106132. [Google Scholar] [CrossRef]

- Handhal, A.M.; Ettensohn, F.R.; Al-Abadi, A.M.; Ismail, M.J. Spatial Assessment of Gross Vertical Reservoir Heterogeneity Using Geostatistics and GIS-Based Machine-Learning Classifiers: A Case Study from the Zubair Formation, Rumaila Oil Field, Southern Iraq. J. Pet. Sci. Eng. 2022, 208, 109482. [Google Scholar] [CrossRef]

- Mclaughlin, J.F.; Garcia-Gonzalez, M. Detailed Geologic Characterization of Core and Well Data from the Weber and Madison Formations and Associated Seals at a Potential CO2 Sequestration Site in Southwest Wyoming: Definining the Lithologic, Geochemical, Diagenetic, and Burial Histories Relative to Successful CO2 Storage. In Geological CO2 Storage Characterization; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar] [CrossRef]

- Kassem, A.A.; Nabawy, B.S.; Mogren, S.; Abdel-Fattah, M.I.; Radwan, A.A.; Ibrahim, E. Implications of the Depositional and Diagenetic Attributes on the Reservoir Properties of the Siliciclastic Mangahewa Formation, Taranaki Basin, New Zealand: Integrated Petrographical and Petrophysical Studies. Mar. Pet. Geol. 2024, 164, 106823. [Google Scholar] [CrossRef]

- Wei, J.; Zhou, J.; Li, J.; Zhou, X.; Dong, W.; Cheng, Z. Experimental Study on Oil Recovery Mechanism of CO2 Associated Enhancing Oil Recovery Methods in Low Permeability Reservoirs. J. Pet. Sci. Eng. 2021, 197, 108047. [Google Scholar] [CrossRef]

- Jia, P.; Cui, C.; Wu, Z.; Yan, D. Influence of Reservoir Heterogeneity on Immiscible Water-Alternating-CO2 Flooding: A Case Study. Energy Geosci. 2024, 5, 100272. [Google Scholar] [CrossRef]

- Gao, Y.; Zhao, M.; Wang, J.; Zong, C. Performance and Gas Breakthrough during CO2 Immiscible Flooding in Ultra-Low Permeability Reservoirs. Pet. Explor. Dev. 2014, 41, 88–95. [Google Scholar] [CrossRef]

- Jadhawar, P.S. Co2-Assisted Gravity Drainage EOR: Numerical Simulation and Scaling Models Study. Ph.D. Thesis, The University of Adelaide, Adelaide, Australia, 2010. [Google Scholar]

- Enab, K.; Ertekin, T. Screening and Optimization of CO2-WAG Injection and Fish-Bone Well Structures in Low Permeability Reservoirs Using Artificial Neural Network-ScienceDirect. J. Pet. Sci. Eng. 2020, 200, 108268. [Google Scholar] [CrossRef]

- Lv, G.; Li, Q.; Wang, S.; Li, X. Key Techniques of Reservoir Engineering and Injection—Production Process for CO2 Flooding in China’s SINOPEC Shengli Oilfield. J. CO2 Util. 2015, 11, 31–40. [Google Scholar] [CrossRef]

- Wang, Y.; Shang, Q.; Zhou, L. Utilizing Macroscopic Areal Permeability Heterogeneity to Enhance the Effect of CO2 Flooding in Tight Sandstone Reservoirs in the Ordos Basin. J. Pet. Sci. Eng. 2021, 196, 107633. [Google Scholar] [CrossRef]

- Zhao, Y.; Song, Y.; Wang, T.; Liu, Y.; Jiang, L.; Zhu, N.; Yang, W. Visualisation of Water Flooding and Subsequent Supercritical CO2 Flooding in Fractured Porous Media with Permeability Heterogeneity Using MRI. Energy Procedia 2013, 37, 6942–6949. [Google Scholar] [CrossRef]

- Yu, B.; Zhang, X.; Du, M.; Ju, Y. Evaluation and Selection of CO2-Water Alternating Flooding Favorable Area Based on Flow-Units Analysis. Energy Procedia 2017, 114, 4557–4563. [Google Scholar] [CrossRef]

- Rabemanana, V.; Violette, S.; de Marsily, G.; Robain, H.; Deffontaines, B.; Andrieux, P.; Bensimon, M.; Parriaux, A. Origin of the High Variability of Water Mineral Content in the Bedrock Aquifers of Southern Madagascar. J. Hydrol. 2005, 310, 143–156. [Google Scholar] [CrossRef]

- Zhang, L.; Zhao, F.L.; Hou, J.R. Experimental Study of Improving the CO2 Flooding Development Effect in Ultra-Low Permeability Reservoir. Adv. Mater. Res. 2012, 594–597, 2470–2474. [Google Scholar] [CrossRef]

- Wei, J.; Anlun, W. Experimental and Simulation Investigations of Carbon Storage Associated with CO2 EOR in Low-Permeability Reservoir. Int. J. Greenh. Gas Control 2021, 104, 103203. [Google Scholar] [CrossRef]

- Jadhawar, P.S.; Sarma, H.K. Effect of Well Pattern and Injection Well Type on the CO2-Assisted Gravity Drainage Enhanced Oil Recovery. J. Pet. Sci. Eng. 2012, 98–99, 83–94. [Google Scholar] [CrossRef]

- Wang, C.; Liu, P.; Wang, F.; Atadurdyyev, B.; Ovluyagulyyev, M. Experimental Study on Effects of CO2 and Improving Oil Recovery for CO2 Assisted SAGD in Super-Heavy-Oil Reservoirs. J. Pet. Sci. Eng. 2018, 165, 1073–1080. [Google Scholar] [CrossRef]

- Shi, L.; Liu, P.; Shen, D.; Liu, P.; Xi, C.; Zhang, Y. Improving Heavy Oil Recovery Using a Top-Driving, CO2-Assisted Hot-Water Flooding Method in Deep and Pressure-Depleted Reservoirs. J. Pet. Sci. Eng. 2019, 173, 922–931. [Google Scholar] [CrossRef]

- Al-Obaidi, D.A.; Al-Mudhafar, W.J.; Al-Jawad, M.S. Experimental Evaluation of Carbon Dioxide-Assisted Gravity Drainage Process (CO2-AGD) to Improve Oil Recovery in Reservoirs with Strong Water Drive. Fuel 2022, 324, 124409. [Google Scholar] [CrossRef]

- Zheng, W.; Li, Z.; Huang, H.; Cao, X.; Wu, G.; Wang, J.; Kang, H. Evaluation and Improvement of CO2 Assisted Gravity Drainage for Enhanced Oil Production in China. Energy Rep. 2023, 10, 4465–4473. [Google Scholar] [CrossRef]

- Xiaolong, C.; Yiqiang, L.; Xiang, T.; Huan, Q.; Xuebing, S.; Jianghao, L. Effect of Gravity Segregation on CO2 Flooding under Various Pressure Conditions: Application to CO2 Sequestration and Oil Production. Energy 2021, 226, 120294. [Google Scholar] [CrossRef]

- Khan, M.Y.; Mandal, A. Improvement of Buckley-Leverett Equation and Its Solution for Gas Displacement with Viscous Fingering and Gravity Effects at Constant Pressure for Inclined Stratified Heterogeneous Reservoir. Fuel 2021, 285, 119172. [Google Scholar] [CrossRef]

- Al-Mudhafar, W.J.; Rao, D.N.; Srinivasan, S. Reservoir Sensitivity Analysis for Heterogeneity and Anisotropy Effects Quantification through the Cyclic CO2-Assisted Gravity Drainage EOR Process—A Case Study from South Rumaila Oil Field. Fuel 2018, 221, 455–468. [Google Scholar] [CrossRef]

- Khan, M.Y.; Mandal, A. Analytical Model for Gravity Segregation in WAG Displacement Recovery of Inclined Stratified Reservoirs. J. Pet. Sci. Eng. 2020, 186, 106722. [Google Scholar] [CrossRef]

- Li, Q.; Li, Q.; Wang, F.; Wu, J.; Wang, Y. The Carrying Behavior of Water-Based Fracturing Fluid in Shale Reservoir Fractures and Molecular Dynamics of Sand-Carrying Mechanism. Processes 2024, 12, 2051. [Google Scholar] [CrossRef]

- Li, Q.; Li, Q.; Han, Y. A Numerical Investigation on Kick Control with the Displacement Kill Method during a Well Test in a Deep-Water Gas Reservoir: A Case Study. Processes 2024, 12, 2090. [Google Scholar] [CrossRef]

| Ionic Species | K+ & Na+ | Mg2+ | Ca2+ | Cl− | SO42− | HCO3− | CO32− |

| Ionic Concentration mg/L | 2704.30 | 11.87 | 68.49 | 880.50 | 20.45 | 4690.94 | 68.49 |

| Total Mineralization | 8912.08 mg/L | ||||||

| Inject Method/Inject Volume/Recovery Degree | 30 μm | 60 μm | 90 μm | 120 μm | 150 μm | 180 μm |

|---|---|---|---|---|---|---|

| reverse/low-in/low-out 1 μm/s | 9.27% | 24.00% | 34.97% | 47.28% | 56.58% | 57.01% |

| reverse/low-in/low-out 10 μm/s | 12.32% | 24.95% | 36.26% | 36.77% | 36.93% | 37.54% |

| reverse/low-in/high-out 1 μm/s | 13.40% | 26.01% | 39.15% | 51.76% | 54.38% | 55.66% |

| reverse/low-in/high-out 10 μm/s | 14.38% | 26.44% | 40.66% | 40.82% | 41.70% | 41.77% |

| reverse/same-in/same-out 0.5 μm/s | 21.86% | 33.51% | 46.75% | 53.13% | 53.27% | 53.95% |

| reverse/same-in/same-out 5 μm/s | 21.47% | 35.74% | 47.08% | 48.37% | 48.80% | 48.95% |

| positive/low-in/high-out 1 μm/s | 13.23% | 24.29% | 36.66% | 49.96% | 51.81% | 52.13% |

| positive/low-in/high-out 10 μm/s | 14.84% | 28.98% | 43.52% | 46.46% | 47.07% | 47.29% |

| positive/high-in/high-out 1 μm/s | 22.78% | 43.68% | 49.70% | 49.75% | 50.41% | 50.54% |

| positive/high-in/high-out 10 μm/s | 20.51% | 38.10% | 38.44% | 38.74% | 38.89% | 39.58% |

| positive/same-in/same-out 0.5 μm/s | 17.85% | 35.21% | 53.27% | 54.94% | 57.06% | 57.93% |

| positive/same-in/same-out 5 μm/s | 19.72% | 37.89% | 42.00% | 42.13% | 42.21% | 42.08% |

| Inject Method/Inject Volume/Recovery Degree | 30 μm | 60 μm | 90 μm | 120 μm | 150 μm | 180 μm |

|---|---|---|---|---|---|---|

| reverse/low-in/low-out 1 μm/s | 14.43% | 15.20% | 22.24% | 24.44% | 25.78% | 26.68% |

| reverse/low-in/low-out 10 μm/s | 7.62% | 12.00% | 13.04% | 13.19% | 13.22% | 15.04% |

| reverse/low-in/high-out 1 μm/s | 13.41% | 17.35% | 19.52% | 22.68% | 22.92% | 26.11% |

| reverse/low-in/high-out 10 μm/s | 8.73% | 11.02% | 12.24% | 13.95% | 13.96% | 14.07% |

| reverse/same-in/same-out 0.5 μm/s | 7.22% | 8.95% | 10.15% | 14.06% | 17.94% | 21.70% |

| reverse/same-in/same-out 5 μm/s | 5.34% | 5.68% | 6.39% | 7.31% | 11.01% | 12.80% |

| positive/low-in/high-out 1 μm/s | 19.49% | 42.21% | 69.94% | 81.87% | 88.81% | 89.58% |

| positive/low-in/high-out 10 μm/s | 14.49% | 18.09% | 20.42% | 20.51% | 20.75% | 22.18% |

| positive/high-in/high-out 1 μm/s | 11.92% | 24.98% | 29.24% | 29.54% | 30.52% | 30.97% |

| positive/high-in/high-out 10 μm/s | 1.34% | 2.03% | 3.01% | 3.28% | 3.82% | 3.90% |

| positive/same-in/same-out 0.5 μm/s | 21.63% | 33.20% | 48.00% | 51.52% | 61.08% | 62.27% |

| positive/same-in/same-out 5 μm/s | 13.50% | 14.87% | 16.26% | 18.32% | 20.38% | 20.71% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, M.; Song, K.; Wang, L.; Fu, H.; Wang, T. Characteristics of Supercritical CO2 Non-Mixed Phase Replacement in Intraformational Inhomogeneous Low-Permeability Reservoirs. Energies 2024, 17, 5608. https://doi.org/10.3390/en17225608

Liu M, Song K, Wang L, Fu H, Wang T. Characteristics of Supercritical CO2 Non-Mixed Phase Replacement in Intraformational Inhomogeneous Low-Permeability Reservoirs. Energies. 2024; 17(22):5608. https://doi.org/10.3390/en17225608

Chicago/Turabian StyleLiu, Mingxi, Kaoping Song, Longxin Wang, Hong Fu, and Tianhao Wang. 2024. "Characteristics of Supercritical CO2 Non-Mixed Phase Replacement in Intraformational Inhomogeneous Low-Permeability Reservoirs" Energies 17, no. 22: 5608. https://doi.org/10.3390/en17225608

APA StyleLiu, M., Song, K., Wang, L., Fu, H., & Wang, T. (2024). Characteristics of Supercritical CO2 Non-Mixed Phase Replacement in Intraformational Inhomogeneous Low-Permeability Reservoirs. Energies, 17(22), 5608. https://doi.org/10.3390/en17225608