Evaluation of Energetic Potential of Slaughterhouse Waste and Its Press Water Obtained by Pressure-Induced Separation via Anaerobic Digestion

Abstract

1. Introduction

2. Materials and Methods

| Sample | TS [%] | oTS [% TS] | C [% TS] | COD (mg/L) | H [% TS] | N [% TS] | Cl [%] | S [%] | O [% TS] | AC [% TS] | C:N Ratio | HHV [kJ/kg] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Inoculum | 4.06 ± 0.00 | 62.24 ± 0.00 | n.d | n.d | n.d | n.d | n.d | n.d | n.d | n.d | n.d | n.d |

| PW-CGS-M | 1.58 ± 0.05 | 63.23 ± 0.02 | n.d | n.d | n.d | n.d | n.d | n.d | n.d | n.d | n.d | n.d |

| RCCL | 10.85 ± 0.28 | 79 ± 0.01 | 41.88 ± 0.40 | n.d | 5.25 ± 0.16 | 2.55 ± 0.05 | 0.21 ± 003 | 0.13 ± 0.01 | 29.40 | 20.79 ± 0.01 | 19.16 | 17.48 |

| RC-GSL | 16.7 ± 0.09 | 82 ± 0.01 | 41.30 ± 0.59 | n.d | 5.46 ± 0.07 | 2.43 ± 0.05 | 0.22 ± 0.01 | 0.15 ± 0.02 | 32.94 | 17.72 ± 0.00 | 19.83 | 17.14 |

| RC-CGS-M | 11.34 ± 0.19 | 81 ± 0.00 | 40.65 ± 0.93 | n.d | 5.37 ± 0.18 | 2.45 ± 0.11 | 0.52 ± 0.02 | 0.18 ± 0.02 | 32.13 | 19.23 ± 0.00 | 19.40 | 17.46 |

| PC-CGS-M | 26.88 ± 0.34 | 82.25 ± 0.00 | 41.43 ± 0.20 | 26,380 | 5.49 ± 0.01 | 2.38 ± 0.02 | 0.19 ± 0.01 | 0.16 ± 0.02 | 32.79 | 17.75 ± 00 | 20.31 | 17.40 |

3. Results

3.1. Sample Characterisation

3.1.1. Waste Resource Assessment

3.1.2. AC, TS, oTS, and CHNO Fractions; S, Cl, and HHV of Raw and Experimental Samples

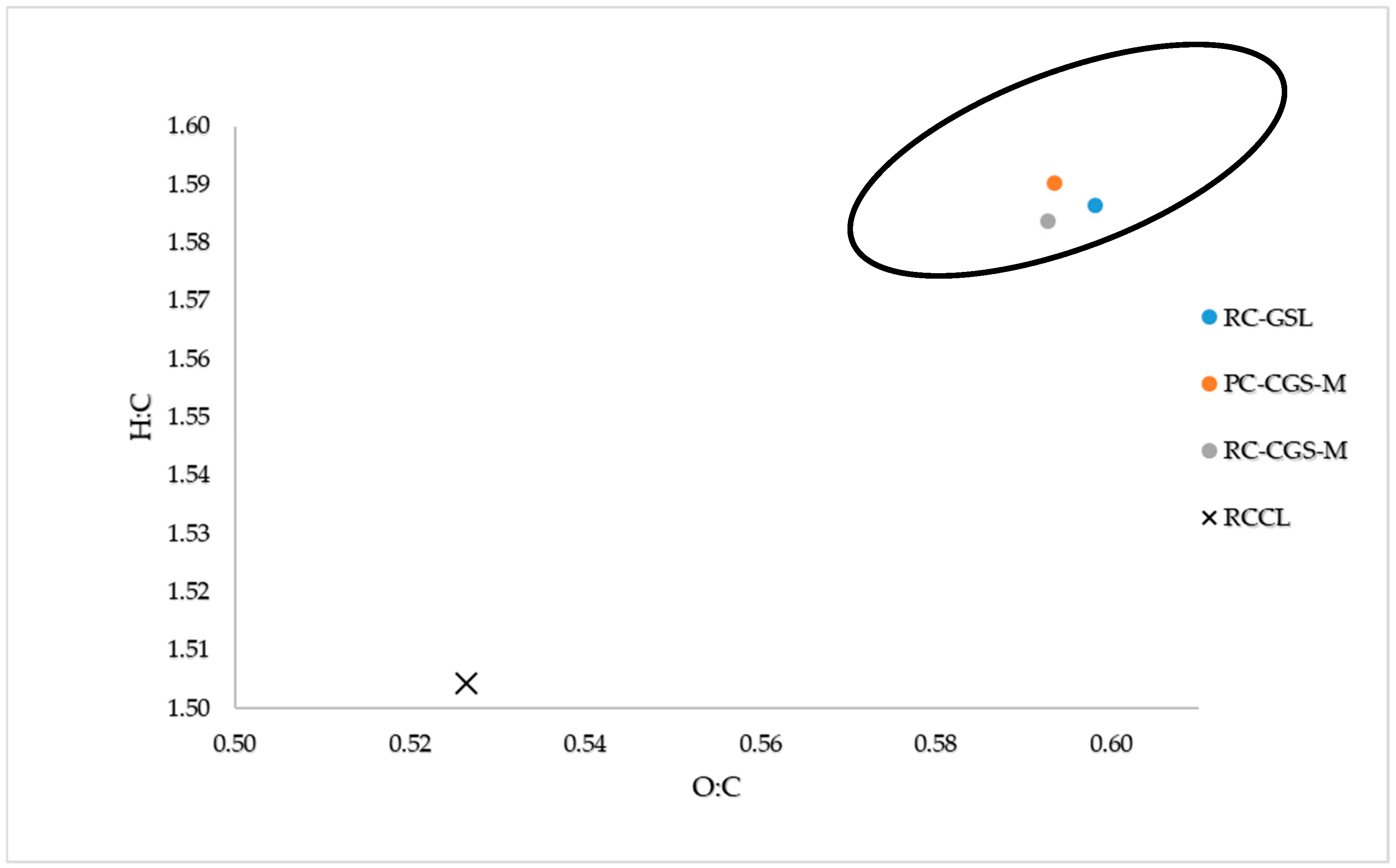

3.1.3. Elemental Analysis, IC, and AC

3.1.4. HHV

3.1.5. TE Concentrations

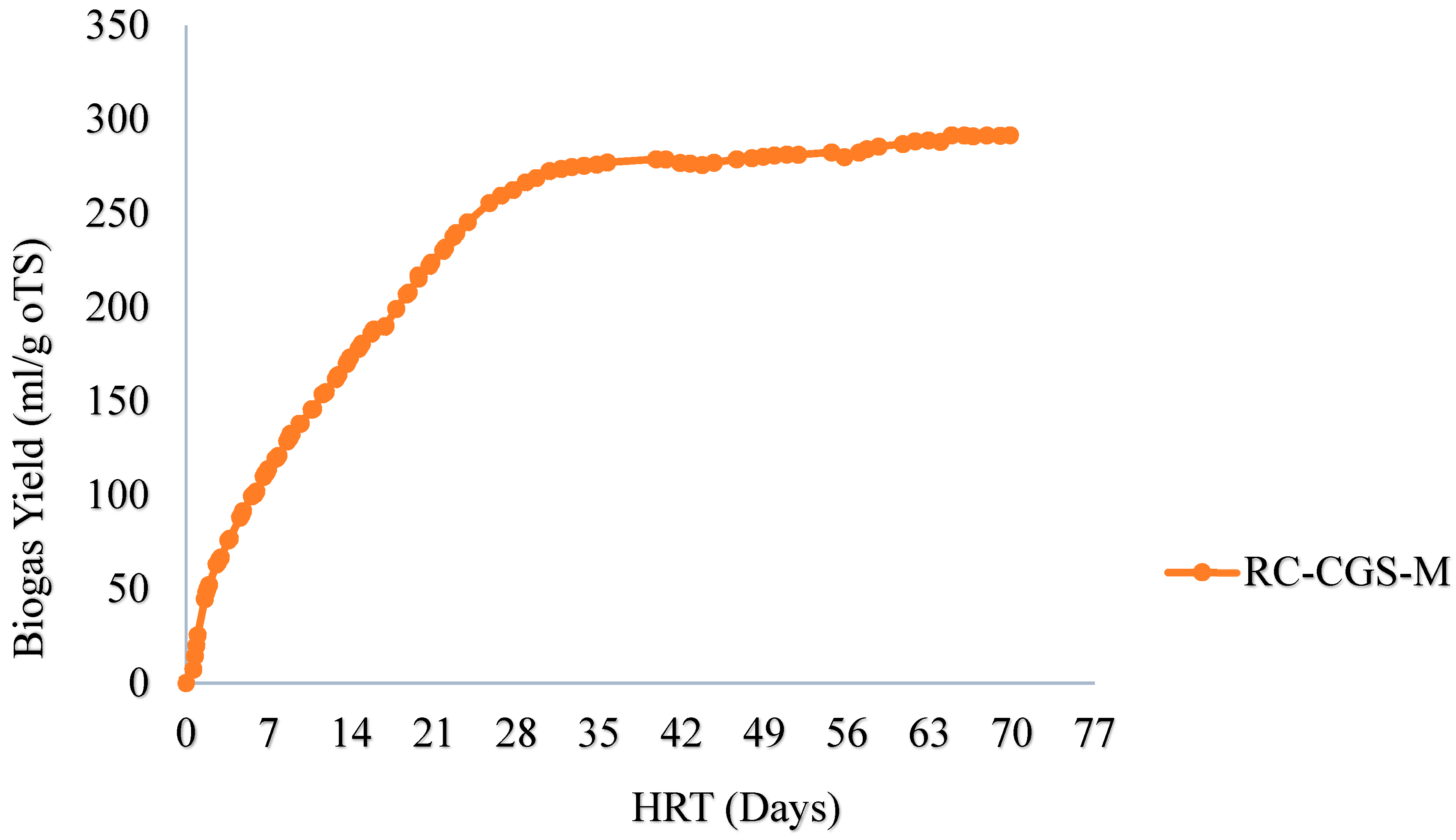

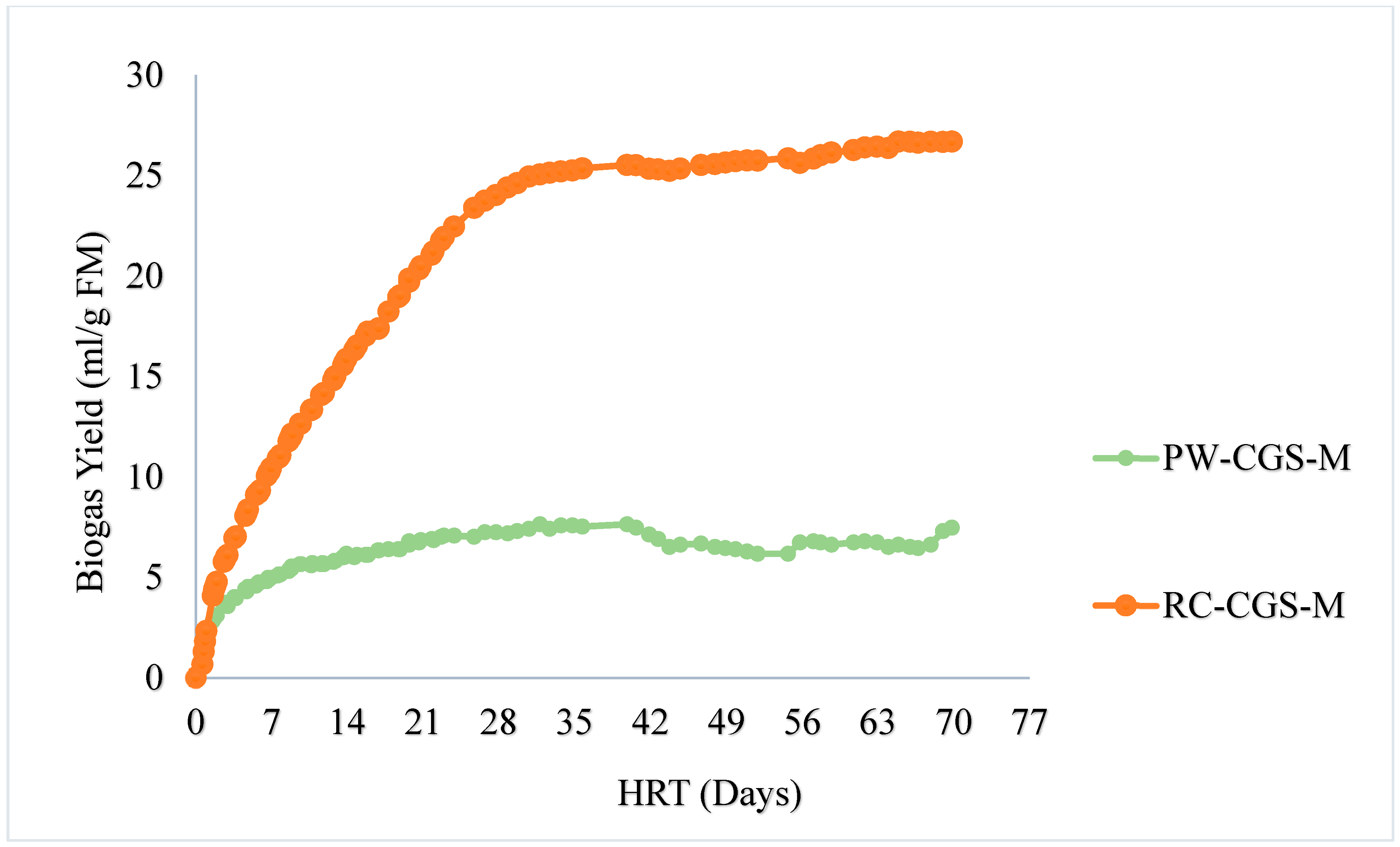

3.2. Biomethane Potential

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- IEA. Africa Energy Outlook 2022; IEA: Paris, France, 2023. [Google Scholar]

- Archana, K.; Visckram, A.S.; Senthil Kumar, P.; Manikandan, S.; Saravanan, A.; Natrayan, L. A review on recent technological breakthroughs in anaerobic digestion of organic biowaste for biogas generation: Challenges towards sustainable development goals. Fuel 2024, 358, 130298. [Google Scholar] [CrossRef]

- Afridi, Z.U.R.; Ullah, K.; Mustafa, M.F.; Saleem, H.; Shaker, B.; Ashraf, N.; Aslam, S. Biogas as sustainable approach for social uplift in South East Asian Region. Energy Rep. 2023, 10, 4808–4818. [Google Scholar] [CrossRef]

- Prasad, S.; Rathore, D.; Singh, A. Recent Advances in Biogas Production. Chem. Eng. Process. Tech. 2017, 3, 1038. [Google Scholar]

- Ibrahim, I.D.; Hamam, Y.; Alayli, Y.; Jamiru, T.; Sadiku, E.R.; Kupolati, W.K.; Ndambuki, J.M.; Eze, A.A. A review on Africa energy supply through renewable energy production: Nigeria, Cameroon, Ghana and South Africa as a case study. Energy Strategy Rev. 2021, 38, 100740. [Google Scholar] [CrossRef]

- Akintade, A.F. Biogas a Viable Source of Energy: Case Study; Centria University of Applied Sciences: Kokkola, Finland, 2021. [Google Scholar]

- Sárvári Horváth, I.; Tabatabaei, M.; Karimi, K.; Kumar, R. Recent updates on biogas production—A review. BRJ 2016, 3, 394–402. [Google Scholar] [CrossRef]

- Singh, T.S.; Sankarlal, P. A Review on Advancements in Biogas Technologies. Int. J. Eng. Res. Technol. 2015, 6, 750–755. [Google Scholar] [CrossRef]

- Ghosh, P.; Shah, G.; Sahota, S.; Singh, L.; Vijay, V.K. Biogas production from waste: Technical overview, progress, and challenges. In Bioreactors; Elsevier: Amsterdam, The Netherlands, 2020; pp. 89–104. [Google Scholar] [CrossRef]

- Ebaye Bejor, S. Effect of Particle Size Distribution on Kinetics and Overall Degradation in Anaerobic Digestion of Waste Biomass. Ph.D. Thesis, University of Sheffield, Sheffield, UK, 2020. [Google Scholar]

- Kwietniewska, E.; Tys, J. Process characteristics, inhibition factors and methane yields of anaerobic digestion process, with particular focus on microalgal biomass fermentation. Renew. Sustain. Energy Rev. 2014, 34, 491–500. [Google Scholar] [CrossRef]

- Schnürer, A. Biogas Production: Microbiology and Technology. Adv. Biochem. Eng. Biotechnol. 2016, 156, 195–234. [Google Scholar] [CrossRef]

- Owhondah, R.O.; Walker, M.; Ma, L.; Nimmo, B.; Ingham, D.B.; Poggio, D.; Pourkashanian, M. Assessment and parameter identification of simplified models to describe the kinetics of semi-continuous biomethane production from anaerobic digestion of green and food waste. Bioprocess. Biosyst. Eng. 2016, 39, 977–992. [Google Scholar] [CrossRef][Green Version]

- Náthia-Neves, G.; Berni, M.; Dragone, G.; Mussatto, S.I.; Forster-Carneiro, T. Anaerobic digestion process: Technological aspects and recent developments. Int. J. Environ. Sci. Technol. 2018, 15, 2033–2046. [Google Scholar] [CrossRef]

- Kabeyi, M.J.B.; Oludolapo, A.O. Optimization of Biogas Production for Optimal Abattoir Waste Treatment with Bio-Methanation as Solution to Nairobi Slaughterhouses Waste Disposal. In Proceedings of the 2nd African International Conference on Industrial Engineering and Operations Management, Harare, Zimbabwe, 20–22 October 2020. [Google Scholar]

- Deepanraj, B.; Sivasubramanian, V.; Jayaraj, S. Biogas Generation through Anaerobic Digetsion Process: An Overview. Res. J. Chem. Environ. 2014, 18, 5. [Google Scholar]

- Reulein, J.; Stülpnagel, R.; Scheffer, K.; Wachendorf, M. Improving the Fuel Properties of Agricultural Biomass Through Mechanical Dewatering of Silage. Mitteilungen der Arbeitsgemeinschaft Grünland und Futterbau 2007, 8, 198–201. [Google Scholar]

- Yu, H.; Wang, Z.; Wu, Z.; Zhu, C. Enhanced waste activated sludge digestion using a submerged anaerobic dynamic membrane bioreactor: Performance, sludge characteristics and microbial community. Sci. Rep. 2016, 6, 20111. [Google Scholar] [CrossRef] [PubMed]

- Ferrer, I.; Ponsá, S.; Vázquez, F.; Font, X. Increasing biogas production by thermal (70 °C) sludge pre-treatment prior to thermophilic anaerobic digestion. Biochem. Eng. J. 2008, 42, 186–192. [Google Scholar] [CrossRef]

- Corton, J.; Toop, T.; Walker, J.; Donnison, I.S.; Fraser, M.D. Press fluid pre-treatment optimisation of the integrated generation of solid fuel and biogas from biomass (IFBB) process approach. Bioresour. Technol. 2014, 169, 537–542. [Google Scholar] [CrossRef]

- COP28; IRENA; GRA. Tripling Renewable Power and Doubling Energy Efficiency by 2030 Crucial Steps towards 1.5 °C; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2023. [Google Scholar]

- Asare, D.; Abubakari, M.; Mahama, M.; Mensah, D.A.O.; Amponsah, I.A.; Kwakye, A.D.; Duho, K.C.T. How Can Ghana Transition from a Linear to a Circular Economy of Waste Management? A Conceptual Analysis of Policy Approaches. In Circular Economy Strategies and the UN Sustainable Development Goals; Springer Nature: Singapore, 2023; pp. 125–154. [Google Scholar] [CrossRef]

- Tasantab, C. Solid Waste Management in Ghanaian Towns; A Case of Saboba; Kwamen Nkrumah University of Science and Technology: Northern Region, Ghana, May 2012. [Google Scholar]

- Bhave, P.P.; Palekar, A.L. Quantification and environmental impact of slaughter waste during its life cycle. Environ. Monit. Assess. 2024, 196, 225. [Google Scholar] [CrossRef]

- Hensgen, F.; Bühle, L.; Donnison, I.; Heinsoo, K.; Wachendorf, M. Energetic conversion of European semi-natural grassland silages through the integrated generation of solid fuel and biogas from biomass: Energy yields and the fate of organic compounds. Bioresour. Technol. 2014, 154, 192–200. [Google Scholar] [CrossRef]

- Richter, F.; Fricke, T.; Wachendorf, M. Influence of sward maturity and pre-conditioning temperature on the energy production from grass silage through the integrated generation of solid fuel and biogas from biomass (IFBB): 1. The fate of mineral compounds. Bioresour. Technol. 2011, 102, 4855–4865. [Google Scholar] [CrossRef]

- Nayono, S.E.; Gallert, C.; Winter, J. Co-digestion of press water and food waste in a biowaste digester for improvement of biogas production. Bioresour. Technol. 2010, 101, 6998–7004. [Google Scholar] [CrossRef]

- Nayono, S.E.; Winter, J.; Gallert, C. Anaerobic digestion of pressed off leachate from the organic fraction of municipal solid waste. Waste Manag. 2010, 30, 1828–1833. [Google Scholar] [CrossRef]

- Sailer, G.; Empl, F.; Kuptz, D.; Silberhorn, M.; Ludewig, D.; Lesche, S.; Pelz, S.; Müller, J. Characteristics and Anaerobic Co-Digestion of Press Water from Wood Fuel Preparation and Digested Sewage Sludge. Fermentation 2022, 8, 37. [Google Scholar] [CrossRef]

- Granada, C.E.; Hasan, C.; Marder, M.; Konrad, O.; Vargas, L.K.; Passaglia, L.M.; Giongo, A.; de Oliveira, R.R.; Pereira, L.D.M.; de Jesus Trindade, F.; et al. Biogas from slaughterhouse wastewater anaerobic digestion is driven by the archaeal family Methanobacteriaceae and bacterial families Porphyromonadaceae and Tissierellaceae. Renew. Energy 2018, 118, 840–846. [Google Scholar] [CrossRef]

- Kabeyi, M.J.B.; Olanrewaju, O.A. Sustainable Energy Transition for Renewable and Low Carbon Grid Electricity Generation and Supply. Front. Energy Res. 2022, 9, 743114. [Google Scholar] [CrossRef]

- Wang, S.; Jena, U.; Das, K.C. Biomethane production potential of slaughterhouse waste in the United States. Energy Convers. Manag. 2018, 173, 143–157. [Google Scholar] [CrossRef]

- Salehin, S.; Ahmed, S.S.U.; Hoque, M.E.; Mrigdad, M.S.; Hussain, S.M.A.; Intisar, S.M.T. Assessment of biogas generation potential from slaughterhouse wastes in Dhaka city, Bangladesh. Waste Dispos. Sustain. Energy 2021, 3, 41–48. [Google Scholar] [CrossRef]

- Samadi, M.T.; Leili, M.; Rahmani, A.; Moradi, S.; Godini, K. Anaerobic co-digestion using poultry slaughterhouse and vegetable wastes to enhance biogas yield: Effect of different C/N ratios. Biomass Conv. Bioref. 2022, 1–9. [Google Scholar] [CrossRef]

- Selormey, G.K.; Barnes, B.; Kemausuor, F.; Darkwah, L. A review of anaerobic digestion of slaughterhouse waste: Effect of selected operational and environmental parameters on anaerobic biodegradability. Rev. Environ. Sci. Biotechnol. 2021, 20, 1073–1086. [Google Scholar] [CrossRef]

- Shende, A.D.; Khan, M.S.; Dhenkula, S.; Rao, N.N.; Pophali, G.R. Waste to wealth in a slaughterhouse through effective biomass management. Biomass Conv. Bioref 2024, 14, 269–281. [Google Scholar] [CrossRef]

- Shende, A.D.; Pophali, G.R. Anaerobic treatment of slaughterhouse wastewater: A review. Environ. Sci. Pollut. Res. Int. 2021, 28, 35–55. [Google Scholar] [CrossRef]

- Sinsuw, A.A.E.; Wuisang, C.E.; Chu, C.-Y. Assessment of environmental and social impacts on rural community by two-stage biogas production pilot plant from slaughterhouse wastewater. J. Water Process Eng. 2021, 40, 101796. [Google Scholar] [CrossRef]

- Ware, A.; Power, N. Biogas from cattle slaughterhouse waste: Energy recovery towards an energy self-sufficient industry in Ireland. Renew. Energy 2016, 97, 541–549. [Google Scholar] [CrossRef]

- Widiasa, B.I.N.; Sunarso, S.J. Study on Slaughterhouse Wastes Potency and Characteristic for Biogas Production. Int. J. Waste Resour. 2015, 1, 4–7. [Google Scholar] [CrossRef]

- Oktavitri, N.I.; Pratiwi, W.B.; Purnamasari, I.; Hayati, M.; Fitrianingtyas, M.R.; Hadinnata, S. Anaerobic Digestion of Slaughterhouse Wastewater: CO2 Capture of Biogas Using Chlorella vulgaris. Indones. J. Chem. 2019, 19, 1. [Google Scholar] [CrossRef]

- Omondi, E.A.; Ndiba, P.K.; Chepkoech, G.K.; Kegode, A.A. Modeling anaerobic co-digestion of water hyacinth with ruminal slaughterhouse waste for first order, modified gompertz and logistic kinetic models. Int. J. Renew. Energy Dev. 2023, 12, 627–634. [Google Scholar] [CrossRef]

- Ware, A.; Power, N. What is the effect of mandatory pasteurisation on the biogas transformation of solid slaughterhouse wastes? Waste Manag. 2016, 48, 503–512. [Google Scholar] [CrossRef]

- Aklaku, E.D.; Jones, K.; Obiri-Danso, K. Integrated Biological Treatment and Biogas Production in a Small-Scale Slaughterhouse in Rural Ghana. Water Environ. Res. 2006, 78, 2335–2339. [Google Scholar] [CrossRef]

- Mapcarta. Asuakwa Map-Town-Sunyani Municipal District, Ghana. 4 April 2024. Available online: https://mapcarta.com/N5330125595 (accessed on 1 May 2024).

- Hülsemann, B.; Zhou, L.; Merkle, W.; Hassa, J.; Müller, J.; Oechsner, H. Biomethane Potential Test: Influence of Inoculum and the Digestion System. Appl. Sci. 2020, 10, 2589. [Google Scholar] [CrossRef]

- VDI 4630; Fermentation of Organic Materials—Characterisation of the Substrate, Sampling, Collection of Material Data, Fermentation Tests. 2016. Available online: https://www.scirp.org/(S(351jmbntv-nsjt1aadkposzje))/reference/referencespapers.aspx?referenceid=2950958 (accessed on 28 March 2023).

- DIN EN ISO 21656:2021-06; Feste Sekundärbrennstoffe_-Bestimmung des Aschegehaltes (ISO_21656:2021). DIN Media GmbH: Berlin, Germany, 2021.

- DIN ISO 3310-1:2017-11; Analysensiebe_-Technische Anforderungen und Prüfung_-Teil_1: Analysensiebe mit Metalldrahtgewebe (ISO_3310-1:2016). DIN Media GmbH: Berlin, Germany, 2017.

- Paczkowski, S.; Sarquah, K.; Yankyera, J.; Sarfo Agyemang Derkyi, N.; Empl, F.; Jaeger, D.; Pelz, S. Hydrothermal treatment (HTT) improves the combustion properties of regional biomass waste to face the increasing sustainable energy demand in Africa. Fuel 2023, 351, 128928. [Google Scholar] [CrossRef]

- DIN EN ISO 18122:2023-02; Biogene Festbrennstoffe_-Bestimmung des Aschegehaltes (ISO_18122:2022). DIN Media GmbH: Berlin, Germany, 2023.

- DIN EN ISO 11885:2009-09; Wasserbeschaffenheit_-Bestimmung von Ausgewählten Elementen Durch Induktiv Gekoppelte Plasma-Atom-Emissionsspektrometrie (ICP-OES) (ISO_11885:2007). DIN Media GmbH: Berlin, Germany, 2009.

- DIN 22022-2:2001-02; Feste Brennstoffe_-Bestimmung der Gehalte an Spurenelementen_-Teil_2: ICP-OES. DIN Media GmbH: Berlin, Germany, 2001.

- Shehab, M.; Stratulat, C.; Ozcan, K.; Boztepe, A.; Isleyen, A.; Zondervan, E.; Moshammer, K. A Comprehensive Analysis of the Risks Associated with the Determination of Biofuels’ Calorific Value by Bomb Calorimetry. Energies 2022, 15, 2771. [Google Scholar] [CrossRef]

- DIN EN ISO 14780:2020-02; Biogene Festbrennstoffe_-Probenherstellung (ISO_14780:2017_+ Amd_1:2019). DIN Media GmbH: Berlin, Germany, 2020.

- DIN EN ISO 18125:2017-08; Biogene Festbrennstoffe_-Bestimmung des Heizwertes (ISO_18125:2017). DIN Media GmbH: Berlin, Germnay, 2017.

- Herfeld, C.; Ivanova, M. Introduction: First principles in science—Their status and justification. Synthese 2021, 198, 3297–3308. [Google Scholar] [CrossRef]

- Rodrigues, R.P.; Rodrigues, D.P.; Klepacz-Smolka, A.; Martins, R.C.; Quina, M.J. Comparative analysis of methods and models for predicting biochemical methane potential of various organic substrates. Sci. Total Environ. 2019, 649, 1599–1608. [Google Scholar] [CrossRef] [PubMed]

- DIN ISO 15705:2003-01; Wasserbeschaffenheit_-Bestimmung des chemischen Sauerstoffbedarfs (ST-CSB)_-Küvettentest (ISO_15705:2002). DIN Media GmbH: Berlin, Germany, 2003.

- International Renewable Energy Agency. Measuring Small-Scale Biogas Capacity and Production; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2016. [Google Scholar]

- Carbon Trust. Energy and Carbon Conversions: Greenhouse Gas Conversions; Carbon Trust: London, UK, 2023. [Google Scholar]

- Wijaya, A.S.; Jariyaboon, R.; Reungsang, A.; Kongjan, P. Biochemical Methane Potential (BMP) of Cattle Manure, Chicken Manure, Rice Straw, and Hornwort in Mesophilic Mono-digestion. Int. J. Integr. Eng. 2020, 12, 1–8. [Google Scholar]

- Achi, C.G.; Hassanein, A.; Lansing, S. Enhanced Biogas Production of Cassava Wastewater Using Zeolite and Biochar Additives and Manure Co-Digestion. Energies 2020, 13, 491. [Google Scholar] [CrossRef]

- Marañón, E.; Salter, A.M.; Castrillón, L.; Heaven, S.; Fernández-Nava, Y. Reducing the environmental impact of methane emissions from dairy farms by anaerobic digestion of cattle waste. Waste Manag. 2011, 31, 1745–1751. [Google Scholar] [CrossRef] [PubMed]

- Sailer, G.; Eichermüller, J.; Poetsch, J.; Paczkowski, S.; Pelz, S.; Oechsner, H.; Müller, J. Datasets on chemical composition and anaerobic digestion of organic fraction of municipal solid waste (OFMSW), digested sewage sludge (inoculum) and ashes from incineration or gasification. Data Brief. 2020, 31, 105797. [Google Scholar] [CrossRef]

- Lin, R.; Cheng, J.; Murphy, J.D. Unexpectedly low biohydrogen yields in co-fermentation of acid pretreated cassava residue and swine manure. Energy Convers. Manag. 2017, 151, 553–561. [Google Scholar] [CrossRef]

- Fajobi, M.O.; Lasode, O.A.; Adeleke, A.A.; Ikubanni, P.P.; Balogun, A.O. Investigation of physicochemical characteristics of selected lignocellulose biomass. Sci. Rep. 2022, 12, 2918. [Google Scholar] [CrossRef]

- Becker, C.M.; Marder, M.; Junges, E.; Konrad, O. Technologies for biogas desulfurization—An overview of recent studies. Renew. Sustain. Energy Rev. 2022, 159, 112205. [Google Scholar] [CrossRef]

- Singh, Y.D.; Mahanta, P.; Bora, U. Comprehensive characterization of lignocellulosic biomass through proximate, ultimate and compositional analysis for bioenergy production. Renew. Energy 2017, 103, 490–500. [Google Scholar] [CrossRef]

- Demirel, B.; Scherer, P. Trace element requirements of agricultural biogas digesters during biological conversion of renewable biomass to methane. Biomass Bioenergy 2011, 35, 992–998. [Google Scholar] [CrossRef]

- Sailer, G.; Eichermüller, J.; Poetsch, J.; Paczkowski, S.; Pelz, S.; Oechsner, H.; Müller, J. Optimizing anaerobic digestion of organic fraction of municipal solid waste (OFMSW) by using biomass ashes as additives. Waste Manag. 2020, 109, 136–148. [Google Scholar] [CrossRef] [PubMed]

- Lima, A.; Victor, V.M. Physical properties of cattle dung. Pharma Innov. 2022, 11, 399–402. [Google Scholar]

- Thomas, H.L.; Seira, J.; Escudié, R.; Carrère, H. Lime Pretreatment of Miscanthus: Impact on BMP and Batch Dry Co-Digestion with Cattle Manure. Molecules 2018, 23, 1608. [Google Scholar] [CrossRef] [PubMed]

- Khatun, M.L.; Nime, J.; Nandi, R.; Alam, M.M.; Saha, C.K. Co-digestion of poultry droppings and banana waste for maximizing biogas production in Bangladesh. Fuel 2023, 346, 128346. [Google Scholar] [CrossRef]

- Bułkowska, K.; Mikucka, W.; Pokój, T. Enhancement of biogas production from cattle manure using glycerine phase as a co-substrate in anaerobic digestion. Fuel 2022, 317, 123456. [Google Scholar] [CrossRef]

- Elif Gulsen Akbay, H. Anaerobic mono and co-digestion of agro-industrial waste and municipal sewage sludge: Biogas production potential, kinetic modelling, and digestate characteristics. Fuel 2024, 355, 129468. [Google Scholar] [CrossRef]

- Bessah, E.; Amponsah, W.; Ansah, S.O.; Afrifa, A.; Yahaya, B.; Wemegah, C.S.; Tanu, M.; Amekudzi, L.K.; Agyare, W.A. Climatic zoning of Ghana using selected meteorological variables for the period 1976–2018. Meteorol. Appl. 2022, 29, e2049. [Google Scholar] [CrossRef]

- Chae, K.J.; am Jang Yim, S.K.; Kim, I.S. The effects of digestion temperature and temperature shock on the biogas yields from the mesophilic anaerobic digestion of swine manure. Bioresour. Technol. 2008, 99, 1–6. [Google Scholar] [CrossRef]

- Nuchdang, S.; Phalakornkule, C. Anaerobic digestion of glycerol and co-digestion of glycerol and pig manure. J. Environ. Manag. 2012, 101, 164–172. [Google Scholar] [CrossRef] [PubMed]

- Morsink-Georgali, P.-Z.; Kylili, A.; Fokaides, P.A.; Papadopoulos, A.M. Compost versus biogas treatment of sewage sludge dilemma assessment using life cycle analysis. J. Clean. Prod. 2022, 350, 131490. [Google Scholar] [CrossRef]

- Smith, J.; Abegaz, A.; Matthews, R.B.; Subedi, M.; Orskov, E.R.; Tumwesige, V.; Smith, P. What is the potential for biogas digesters to improve soil fertility and crop production in Sub-Saharan Africa? Biomass Bioenergy 2014, 70, 58–72. [Google Scholar] [CrossRef]

- Abubakar, B.S.U.I.; Ismail, N. Anaerobic digestion of cow dung for biogas production. ARPN J. Eng. Appl. Sci. 2012, 7, 169–172. [Google Scholar]

- Kasinath, A.; Fudala-Ksiazek, S.; Szopinska, M.; Bylinski, H.; Artichowicz, W.; Remiszewska-Skwarek, A.; Luczkiewicz, A. Biomass in biogas production: Pretreatment and codigestion. Renew. Sustain. Energy Rev. 2021, 150, 111509. [Google Scholar] [CrossRef]

- Schaum, C.; Lensch, D.; Bolle, P.-Y.; Cornel, P. Sewage sludge treatment: Evaluation of the energy potential and methane emissions with COD balancing. J. Water Reuse Desalination 2015, 5, 437–445. [Google Scholar] [CrossRef][Green Version]

- Aragón-Briceño, C.; Ross, A.B.; Camargo-Valero, M.A. Evaluation and comparison of product yields and bio-methane potential in sewage digestate following hydrothermal treatment. Appl. Energy 2017, 208, 1357–1369. [Google Scholar] [CrossRef]

| Animal Type | Cow | Sheep | Goat |

|---|---|---|---|

| Average quantity of each type of ruminant slaughtered | |||

| Per day | 16 | 6 | 10 |

| Per week | 96 | 36 | 60 |

| Average mass of rumen content per animal slaughtered (kg) | |||

| Per day | 25 | 2.5 | 2.1 |

| Total mass of rumen content disposed per animal | |||

| Per day | 400 | 15 | 21 |

| Per week | 2400 | 90 | 125 |

| Total | 2615 | ||

| Ratio of weekly waste | 92% | 3% | 5% |

| Variant | Sample ID | Description |

|---|---|---|

| 1 | RCCL | Rumen content of cow—liquid form |

| 2 | RC-GSL | Rumen content of goat–sheep mixture—liquid form |

| 3 | RCGL | Rumen content of goat—liquid form |

| 4 | RCSL | Rumen content of sheep—liquid form |

| Variant I | RC-CGS-M | A dried mixture of cow rumen content and goat–sheep rumen content |

| Variant II | PW-CGS-M | The liquid extract obtained from Variant I after mechanical pressing |

| Variant III | PC-CGS-M | The solid residue obtained from Variant I after mechanical pressing |

| Variant | Fraction of Waste Extractible for Biogas Generation (%) |

|---|---|

| RC-CGS-M | 100 |

| PW-CGS-M | 53 |

| TE | RCCL (mg/kg TS) | PW-CGS-M (mg/kg TS) | PC-CGS-M (mg/kg TS) | RC-CGS-M (mg/kg TS) | Inhibitory Levels (mg/L) | Optimum Ranges (mg/kg TS) |

|---|---|---|---|---|---|---|

| Fe | 1879.82 ± 245.20 | 38.07 ± 5.74 | 884.48 ± 88.57 | 3188.03 ± 943.11 | - | 1500–3000 |

| Mn | 543.37 ± 13.78 | 5.50 ± 0.90 | 226.45 ± 20.51 | 449.94 ± 8.55 | - | 100–1500 |

| Zn | 66.204 ± 1.52 | 3.474 ± 2.44 | 42.775 ± 2.05 | 64.995 ± 1.62 | 150 | 30–150 |

| Na | 6223.86 ± 14.10 | 1235.02 ± 41.56 | 3077.15 ± 379.84 | 6218.10 ± 31.41 | 5000–15,000 | - |

| K | 6620.51 ± 491.65 | 916.06 ± 109.43 | 2347.70 ± 246.53 | 8259.85 ± 598.75 | 4800 (I (50)) | - |

| Ca | 8978.04 ± 291.32 | 125.18 ± 14.19 | 4054.04 ± 350.41 | 8952.164 ± 405.40 | 4800 (I (50)) | - |

| Mg | 1233.53 ± 5.82 | 52.46 ± 7.67 | 779.83 ± 82.64 | 1237.37 ± 5.28 | 1900 (I (50)) | - |

| S | 2020.49 ± 101.23 | 84.59 ± 9.98 | 851.01 ± 94.85 | 1993.68 ± 42.08 | 30 (H2S) | - |

| Trial Sample | oTS Ratio |

|---|---|

| RC-CGS-M | 0.02 |

| PW-CGS-M | 0.07 |

| Substrate | BMP (mL/goTS) | BMP (mL/gTS) | BMP (mL/gFM) | SD | TMBMP (mL/goTS) |

|---|---|---|---|---|---|

| RC-CGS-M | 160.4 | 129.9 | 14.7 | 28.78 | 495.93 |

| PW-CGS-M | - | - | 4.11 | 23 | 20.39 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yankyera Kusi, J.; Empl, F.; Müller, R.; Pelz, S.; Poetsch, J.; Sailer, G.; Kirchhof, R.; Agyemang Derkyi, N.S.; Attiogbe, F.; Siabi, S.E. Evaluation of Energetic Potential of Slaughterhouse Waste and Its Press Water Obtained by Pressure-Induced Separation via Anaerobic Digestion. Energies 2024, 17, 5522. https://doi.org/10.3390/en17225522

Yankyera Kusi J, Empl F, Müller R, Pelz S, Poetsch J, Sailer G, Kirchhof R, Agyemang Derkyi NS, Attiogbe F, Siabi SE. Evaluation of Energetic Potential of Slaughterhouse Waste and Its Press Water Obtained by Pressure-Induced Separation via Anaerobic Digestion. Energies. 2024; 17(22):5522. https://doi.org/10.3390/en17225522

Chicago/Turabian StyleYankyera Kusi, Joseph, Florian Empl, Ralf Müller, Stefan Pelz, Jens Poetsch, Gregor Sailer, Rainer Kirchhof, Nana Sarfo Agyemang Derkyi, Francis Attiogbe, and Sarah Elikplim Siabi. 2024. "Evaluation of Energetic Potential of Slaughterhouse Waste and Its Press Water Obtained by Pressure-Induced Separation via Anaerobic Digestion" Energies 17, no. 22: 5522. https://doi.org/10.3390/en17225522

APA StyleYankyera Kusi, J., Empl, F., Müller, R., Pelz, S., Poetsch, J., Sailer, G., Kirchhof, R., Agyemang Derkyi, N. S., Attiogbe, F., & Siabi, S. E. (2024). Evaluation of Energetic Potential of Slaughterhouse Waste and Its Press Water Obtained by Pressure-Induced Separation via Anaerobic Digestion. Energies, 17(22), 5522. https://doi.org/10.3390/en17225522