Abstract

Transitioning to a circular economy is crucial for sustainable energy development; yet, current energy supply chains lack comprehensive assessment tools. This study introduces the Holistic Multi-Indicator Decision Support System (HMI_DSS), an innovative tool grounded in life cycle thinking and advanced multi-criteria decision-making methodologies, including Entropy and PROMETHEE II. The HMI_DSS quantifies and assesses sustainability and circularity in energy systems by employing 49 indicators, with a focus on energy efficiency and greenhouse gas emissions. A case study on the rice straw energy supply chain for biogas production illustrates the tool’s effectiveness, comparing a baseline scenario to an alternative. The results show that the global warming potential (GWP) of the baseline is 122 gCO2eq/kWh, while the alternative is 116 gCO2eq/kWh. However, the baseline scenario has lower energy consumption (1.72 × 107 MJ annually) than the alternative (1.98 × 107 MJ). Overall, the alternative outperforms the baseline in terms of sustainability and circularity. The HMI_DSS offers a flexible and robust framework for evaluating trade-offs in energy systems, providing valuable insights for energy companies and researchers in adopting circular economy principles to achieve sustainable development.

1. Introduction

Transitioning to the circular economy (CE) is essential for achieving sustainable development [1,2]. A recent study [3,4] estimated that application of CE principles across the EU economy could boost the gross domestic product (GDP) by 0.5% in 2030 and create approximately 700,000 new jobs. There is also a clear business opportunity for companies. Since manufacturing companies in the EU spend around 40% of their budget on materials, adopting circular business models can increase their profits while also protecting them from fluctuations in resource price. It is estimated that eco-design and waste prevention could result in net savings of up to EUR 600 billion for EU companies while reducing greenhouse gas emissions by 2–4% [5,6]. Furthermore, additional measures to enhance the efficiency of resources by 30% by 2030 could create two million jobs and boost the average GDP of the EU by almost 1%.

Adopting circular business models (CBMs) is central to the transition to a CE [7]. The application of CBMs focuses on using resources efficiently, reducing waste, and restoring natural systems, thereby benefiting the economy, the environment, and society. By incorporating circular principles, companies can move from the traditional linear “take-make-dispose” paradigm to a more sustainable, robust, closed-loop system [3,7]. This change requires designing products and processes for long-term use, remanufacturing, refurbishing, recycling, and repurposing, decreasing material consumption and waste generation. Adopting a CBM can result in numerous advantages, including cost savings through waste reduction, increased competitiveness, greater resilience against resource price volatility, a stronger brand image, and new revenue streams. The adoption of CBMs also inspires innovation, promotes collaboration among stakeholders, and contributes to achieving global sustainability goals, such as the United Nations Sustainable Development Goals (SDGs) [1]. To successfully move to a CE, businesses must develop comprehensive strategies incorporating product design, supply chain management, business model innovation, and stakeholder engagement. In addition, ongoing adaptation, monitoring, and enhancement are required to maximize the prospective benefits of a circular approach and assure long-term success in this dynamic environment.

However, selecting the “best” alternative CBM for a company to improve its circularity and also its sustainability is challenging because circularity and sustainability are measured by using various indicators, including environmental, economic, social, recycling, reuse and many others. For example, Azevedo et al. (2017) suggested an index to evaluate manufacturing companies’ sustainability and circularity, which is composed of four environmental, three economic, seven social, and four circularity indicators [8]. This index is versatile and straight-forward, enabling the assessment of sustainability and circularity practices in manufacturing companies. However, this index is used for the individual company and cannot be used for the whole supply chain. Pollard et al. (2022) developed circularity indicators to evaluate the CE performance of electrical and electronic manufacturers’ products [9]. These circularity indicators were divided into 25 environmental, nine social, and six economic indicators. This study also considered the relationship between indicators and the life cycle product stage. De Pascale et al. (2021) provided a complete overview of CE indicators, considering 61 indicators in total: 14 indicators at the macro level, 15 indicators at the meso level, and 22 indicators at the micro level [10]. In addition, circularity indicators were also published by the European Commission (EC) [11] and the Ellen MacArthur Foundation [12].

Some indicators assessing aspects of sustainability and circularity of different alternatives are subject to conflict and trade-offs [13,14,15]. Options that are beneficial for the environment tend to sacrifice economic criteria, whereas options that are beneficial for the economy tend to be less advantageous for the environment and society [13]. Furthermore, circularity altenatives sometimes are not sustainable. The trade-off between cost-effective performance and environmental sustainability is also mentioned in Gružauskas et al. (2018) [16], which showed that a strategy which reduced transportation costs by 18.4% led to a 43% increase in CO2 emissions.

In this context, decision support systems (DSS) based on the life cycle thinking (LCT) approach are considered valuable tools for evaluating and selecting the optimal option for the supply chain. De Luca et al. (2017) demonstrated three ways for combining life cycle tools with multi-criteria decision analysis (MCDA) in agriculture for sustainability assessments [13]. In the first way, the MCDA techniques were integrated into a life cycle framework to enhance the results of sustainability evaluations. For example, MCDAs were used to choose the scenarios, the functional unit, the impact categories for defining the goal and the scope of the life cycle assessment (LCA). In addition, the typical elements of MCDA, such as normalization and weighting, were applied to finalize the result of the life cycle tool. In the second way, the life cycle results were used to provide information for MCDAs. The third way was to fully combine life cycle tools and MCDA methods, in which they were considered to be equally important. According to De Luca et al. (2018), life cycle tools, including LCA, life cycle costing (LCC), and social life cycle assessment (SLCA), were used to calculate sustainable indicator values [17]. Then, based on these indicator values, the Analytic Hierarchy Process (AHP) approach was employed to evaluate the overall sustainable level of the scenarios. Ekener et al. (2018) developed a decision-making tool that combine the Multi-Attribute Value Theory (MAVT) technique with the Life Cycle Sustainability Assessment (LCSA) approach to evaluate the sustainability performance of products [18]. This study used LCSA to calculate life cycle impact indicators, and the MAVT was used to weigh and rank these indicators. Ren & Toniolo (2018) and Ren et al. (2015) employed LCC, LCA, and SLCA to gather data on the alternative hydrogen production pathways concerning economic, environmental, and social criteria, respectively [19,20]. Based on the results of LCA and LCC, the data on the alternative hydrogen production pathways concerning environmental and economic criteria was determined. SLCA was used to define the data concerning the criteria in the social aspect. Subsequently, a decision-making matrix of various alternatives and criteria can be founded. These studies used the Decision Making Trial and Evaluation Laboratory technique for ranking alternatives. Abu et al. (2021) proposed a framework that combines these approaches to evaluate and prioritize sustainability options more effectively [21]. The paper examines how LCA can provide comprehensive environmental data, while MCDA helps in balancing this data with other criteria such as economic and social factor. Moro (2023) compared LCA methods with durability parameters and MCDM methods for evaluating concrete mixtures [22]. It finds that supplementary cementitious materials improve concrete performance and emphasizes the importance of reducing cement content, while MCDM methods provide consistent rankings of concrete mixtures compared to variable results from LCA methods with integrated durability. Torkayesh et al. (2022) presented a framework for integrating LCA- Multi-Criteria Decision-making (MCDM) approaches to assess sustainable waste management [23]. In this framework, the LCT approach was used to define criteria of sustainability, scope, data gathering and sustainable impact while MCDM methods are used to weigh criteria and rank sustainable waste management options. Lombardi & Todella (2023) Integrated LCA with MCDM methods to have comprehensive environmental impact analysis with systematic decision-support frameworks [24]. This integration allows for a holistic evaluation of sustainability by assessing various environmental, economic, and social criteria alongside traditional LCA metrics.

These decision-support tools in the literature have some limitations. These tools are subjective and challenging to use for companies. For example, the tool developed by Ren et al. (2015) used some qualitative indicators and compared pairs of indicators that are based on expert judgements, which makes decision results variable depending on the experts’ knowledge and experience [19]. De Luca et al. (2018) used AHP method for weighting criteria, but this study employed 15 experts to expressing their subjective opinion in pairwise comparisons of criteria [17]. Ekener et al. (2018) only focused on identifying environmental indicators, while social and economic indicators were sourced from the available literature, which might not exactly reflect the situation of the supply chain [18]. Furthermore, to the authors’ knowledge, no research considered both sustainability and circularity indicators. In addition, available studies only focused on describing methodology development, not to mention the creation of a computational tool.

This work aims to address the lack of DSS tools that holistically evaluate and prioritize circular supply chain alternatives within the energy context. By resolving conflicts and trade-offs between sustainability and circularity aspects, and minimizing subjective bias, the proposed DSS leverages a multi-indicator approach to provide a comprehensive framework for decision-making. In this paper, authors present the development of this tool and demonstrate its applicability in supporting sustainable and circular supply chain decisions. The tool is called “HMI_DSS: Holistic Multi-Indicator Decision Support System”. In this tool, the LCT approach is combined with multi-criteria methodologies, including the Preference Ranking Organization Method for Enrichment Evaluations (PROMETHEE) II and entropy methods. The HMI_DSS is a flexible tool for selecting the best alternative or scenario for a supply chain based on different sustainability and circularity aspects, for example, choosing according to one of four aspects of environment, economy, society and circularity, or total aspects. A set of 49 sustainability and circularity indicators has been selected to use as criteria in this tool that aligns with the United Nations SDGs and the European Commission’s guidelines for transitioning to a CE [3]. Furthermore, in this paper, a new decision support framework has been also proposed for a company in the supply chain. The objective of this methodology framework is to evaluate sustainability and circularity of a company, including assessment of sustainability and circularity for the present situation, and identifying the best sustainability and circularity alternative. In this framework, the weighting indicators are taken in multiple ways, which can help users analyze the sensitivity of sustainable alternatives according to indicator weight. By using PROMETHEE II and entropy methods, the ranking process directly uses results from the LCT approach. This is necessary to have a comprehensive assessment and reduce subjective and expert-dependent decision-making. The HMI_DSS tool can be used for guiding enterprises in the supply chain in the application of CE and sustainability models based on a LCT approach and, the achievement of SDGs.

In summary, the results of this work is a new tool developed, that integrates the PROMETHEE II method with multi-weighting techniques to provide objective and subjective ranking results and adaptability to company-specific conditions. The key tasks include constructing an indicator system aligned with SDGs and European Commission guidelines, applying the tool in a case study of the rice straw supply chain, and addressing data accessibility challenges. The results demonstrate the tool’s effectiveness in evaluating sustainability and circularity, with suggestions for future improvements.

In the following sections, some issues relevant to the HMI_DSS tool are presented. The methodology for developing the HMI_DSS tool is presented in Section 2. The main features of the HMI_DSS tool are described in Section 3, including selecting sustainability and circularity indicators, proposing HMI_DSS methodology framework, and designing and creating software for the HMI_DSS tool. In Section 4, the paper presents a simple application of the HMI_DSS tool to the rice straw supply chain for assessing and selecting scenarios of circularity and sustainability. Section 5 presents a discussion on the strengths and limitations of the HMI_DSS tool. Finally, Section 6 presents conclusions of paper.

2. Methodology for Developing HMI_DSS Tool

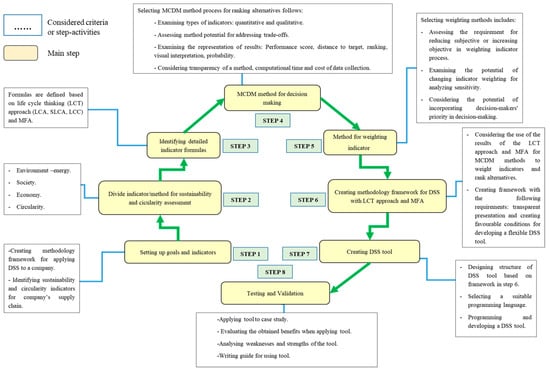

The HMI_DSS tool was developed in eight steps (Figure 1).

Figure 1.

Steps of developing the HMI_DSS tool.

- Step 1 defines the main issue that needs to be addressed. The issue is to create a tool for companies in supply chain to assess and select circularity and sustainability alternatives that include the identification of sustainability and circularity indicators and a methodology framework for DSS applied to a company.

- Steps 2 to 3 aim to divide sustainability and circularity indicators into groups according to the LCT approach and then identify a specific formula for calculating the value of each indicator.

- In step 4, the selection of the MCDM method for decision-making is carried out. This selection considers the kind of indicators to be examined (qualitative and quantitative indicators), the potential for addressing trade-offs, the representation of results (performance score, ranking, visual interpretation, distance to target, probability), method transparency, computational time, and data collection cost.

- Step 5 is related to the selection of the method for indicator weighting. The selection of the method for indicator weighting is crucial and is guided by various criteria, including the type of indicators (qualitative or quantitative), solving trade-off, reducing subjectivity, analyzing sensitivity, and incorporating decision-makers’ preferences.

Several methods are considered, each with its advantages and disadvantages depending on the scenario:

- -

- Entropy Method: This method is highly objective and data-driven, making it suitable for situations where quantitative data is abundant [25]. It minimizes subjectivity and is efficient for analyzing data variability. However, it lacks the ability to incorporate qualitative insights or expert judgment, which might limit its application in scenarios requiring stakeholder engagement.

- -

- AHP: AHP allows for the integration of expert input, which can be particularly useful in complex scenarios that require qualitative assessments or when stakeholder preferences need to be incorporated. While it handles trade-offs well [26], it can be time-consuming and subjective, especially when used in larger, multi-criteria decision-making environments. It’s ideal for situations where expert judgment is key, but enterprises need to be prepared to invest time in the process.

- -

- Fuzzy AHP: This method extends AHP by incorporating uncertainty, which is beneficial in contexts where data or expert opinions are uncertain or imprecise [27]. However, its complexity makes it harder to implement, requiring more advanced computational tools and expertise, which might not be practical for all enterprises.

- -

- Weighted Sum Model (WSM): This method is simple and easy to apply, making it suitable for small-scale or less complex decision-making processes [26]. However, it does not handle trade-offs between conflicting criteria well, which limits its effectiveness in more complex decision scenarios.

Enterprises with limited resources or data might prefer simpler methods like WSM or AHP, while those with access to rich datasets and computational resources might find Entropy or Fuzzy AHP more effective. By allowing for flexibility in method selection, the tool can adapt to different enterprise needs and capacities.

- Step 6 involves creating a methodology framework for a DSS with LCT approach and MFA. This step entails considering utilizations of indicator calculation results obtained by the LCT approach and MFA for MCDM methods to address two key issues: weighting indicators and ranking alternatives. Based on these combinations, the methodology framework is developed, adhering to the following requirements: transparent presentation and the establishment of favorable conditions for developing a flexible DSS tool.

- In step 7, the DSS tool is developed. First, this step involves designing the structure of the DSS tool based on the methodology framework developed in step 6. Then, the programming language is selected to be compatible with the mathematical formulas and algorithms used in the calculation of these indicators and MCDM methods. This selection is critical to ensure that the chosen language can accurately and efficiently handle tasks such as matrix operations, statistical analysis, and optimization. Programming languages like Python 3.12.7, MATLAB 2021b, R-4.4.1, or Julia 1.11 are typically considered due to their strengths in scientific computing and data analysis. These languages are widely used in scientific research and have extensive libraries for numerical and statistical analysis, making them well suited for implementing indicator formulas. In addition, these languages have large user communities, providing access to a wealth of resources, tutorials, and libraries that facilitate development and problem solving. After that, the programming process created DSS tool is taken. This process considers some criteria of the DSS tool, such as facilitating easy collection and importation of data, enabling monitoring and storage of results, and providing visibility into each calculation step. The result of this step is a new DSS tool created.

- The final step is the testing and validation of the tool. In here, the DSS tool is applied to a specific case study. The obtained results are used to test how the tool works. The weaknesses and strengths of the tool are also assessed.

The methodology for developing the HMI_DSS tool builds on the foundational structure of existing DSS and MCDM tools [13,22,24,28], specifically addressing key limitations and gaps in sustainability and circularity assessments. Current tools often exhibit inflexibility in adapting to varying operational contexts and fail to integrate both qualitative and quantitative indicators effectively. For example, many tools are rigid in their indicator selection, which can hinder firms from making context-specific decisions. The primary objectives of the HMI_DSS tool are to enhance adaptability, ensure comprehensive indicator coverage, and improve user-friendly applications for firms across different sectors. Key principles guiding its development include (1) integrating sustainability and circularity indicators that align with global frameworks such as the UN SDGs and EC guidelines, (2) enabling user-defined customization of indicator weightings to reflect specific organizational priorities, and (3) providing a balanced inclusion of qualitative and quantitative measures to ensure actionable and context-relevant insights. These improvements aim to address the limitations of existing tools by offering greater flexibility, transparency, and practical relevance for decision-makers.

3. Developing Holistic Multi-Indicator Decision Support System Tool—HMI_DSS

The HMI_DSS tool is programmed by GUI and Script of Matlab. Matlab GUI has been used to design User interfaces [29], while the Script has been employed to program the main program and subprograms [30]. After programming, the HMI_DSS tool is created. Some main points of developing this tool are presented in sub-sections below, including the following:

Defining sustainability and circularity indicators of the company within the supply chain (Step 1–3 of Figure 1);

Proposing the decision support methodology framework of the HMI_DSS tool (Step 4–6 of Figure 1);

Creating and testing the HMI _DSS tool (Step 7,8 of Figure 1).

3.1. Defining Company Sustainability and Circular Economy Indicators for Use in the HMI_DSS Tool

This tool uses 49 indicators for evaluating sustainability and circularity concerning the achievement of the SDGs with the EC’s guidelines transitioning to a CE [31]. To choose this set of indicators, sustainability indicators were collected from sources such as SDG, ReCiPe midpoint [32], UNEP/SETAC (2009) [33], and relevant literature on sustainable assessment and decision-making [20,31,34,35,36,37,38,39,40]. Circularity indicators were drawn from additional literature and the EC’s indicator set [9,11,41,42,43,44].

A systematic process for constructing the indicator system consists of four main steps. First, sustainability and circular economy indicators are collected from sources such as the SDGs, ReCiPe, and UNEP/SETAC. This ensures a solid foundation based on recognized frameworks and standards. Next, these indicators are evaluated for their applicability to companies, with a focus on prioritizing quantitative indicators and ensuring data accessibility. In the third step, the indicators are carefully reviewed for their relevance to the characteristics of companies in the energy sector, with irrelevant indicators being excluded. During this phase, any indicators, that were deemed irrelevant based on specific criteria, such as lack of direct applicability or insufficient data availability, were excluded. Finally, the indicators are standardized and consolidated, leaving 49 indicators to be used for evaluating the DSS of these companies.

The selection was influenced by the indicators’ applicability at different levels—micro, meso, and macro—and their potential to provide actionable insights. A balance between qualitative and quantitative indicators ensures both measurable data and a contextual understanding of sustainability challenges. Data availability and quality were critical to ensure that selected indicators deliver reliable, practical assessments, addressing both operational and strategic needs [45]. The explanations for each indicator are provided in the Supplementary Materials, Table S1.

Furthermore, the chosen indicators address sustainability and circularity challenges specific to supply chains by reflecting key environmental, social, and economic risks. For example, supply chain disruption and economic viability are captured through indicators that assess resource dependency and operational resilience. Additionally, flexibility in weighting allows companies to prioritize certain risks, such as economic risks in highly competitive markets or environmental risks in resource-intensive industries.

The indicators defined within the HMI_DSS tool are crucial for guiding decision-making by providing insights into sustainability and circularity dimensions. Their selection aligns with the United Nations SDGs and European Commission guidelines, ensuring practical relevance across various sectors. Organizations can prioritize indicators based on their operational contexts; for instance, firms with high-energy consumption may focus on energy-related indicators, while those emphasizing social responsibility might highlight measures assessing social impact. This adaptability allows the tool to yield actionable insights tailored to specific circumstances.

Moreover, the flexibility in adjusting indicator weightings enhances decision-making capabilities, enabling companies to align their sustainability goals with practical, data-driven choices. By modifying the importance of specific indicators, firms can effectively navigate the complexities of sustainability assessments, ensuring that decisions are informed by a balanced consideration of environmental, social, and economic factors. This approach provides a balanced consideration of environmental, social, and economic factors, ultimately delivering a robust framework for organizations to improve their sustainability performance while managing risks and adapting to evolving market conditions.

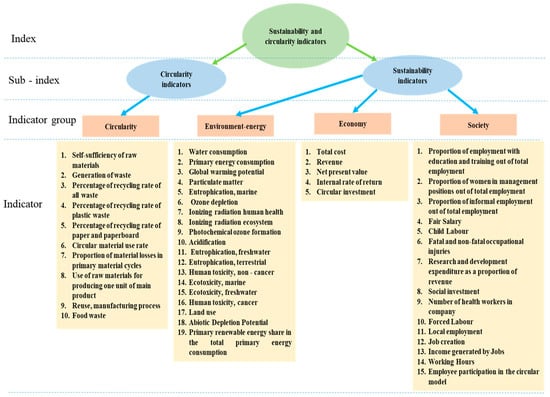

To assess sustainability indicators (environment, society, and economy), LCT tools are popularly employed, including LCA, LCC, and SLCA. Meanwhile, Material Flow Analysis (MFA), LCA, and Input–Output (IO) analysis are important methods used to calculate circular economy indicators [46,47]. In this paper, LCA, SLCA, LCC, and MFA are chosen for developing the HMI_DSS tool. According to the potential of applying these methods for defining indicator values, 49 selected indicators are re-divided into four groups: circularity, environment-energy, economy, and society (Figure 2), corresponding to the MFA, LCA, LCC, and SLCA methods.

Figure 2.

Company circularity and sustainability indicators using in HMI_DSS tool.

3.2. Proposing Decision Support Methodology Framework of the HMI_DSS Tool

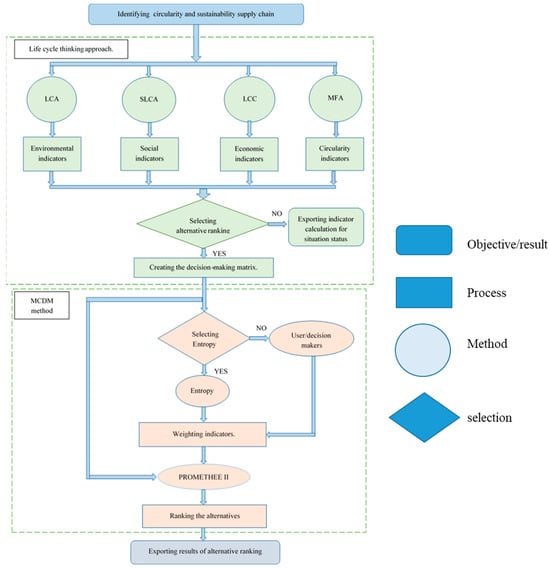

In the proposed methodology framework (Figure 3), the LCT approach has been employed to collect data for determining the indicator values of alternatives. Specially, the LCA approach has been employed to determine environmental impacts for the alternatives of the supply chain, i.e., climate change, particulate matter formulation, human toxicity, land use, and fossil depletion [37,39,48,49,50,51]. The LCC approach has been used to compute economic criteria aspects of alternatives, such as net present value (NPV), total cost, and internal rate of return (IRR) [36,38,39,40,52,53]. The SLCA approach has been used to determine social criteria data for alternatives, i.e., fair salary, job creation, working hours and social investment [28,54,55,56,57,58,59]. Besides that, the Material Flow Analysis (MFA) approach has been employed to calculate the circularity criteria data for alternatives based on the material flows [60,61,62,63]. The results of these approaches can be used for evaluating the circularity and sustainability of a company in the present situation or to create the decision-making matrix that is used in MCDM methods for weighting indicators and ranking alternatives.

Figure 3.

Methodology framework of DSS based on life cycle approach.

Because of the requirement of evaluating various sustainability and circularity indicators and the potential for solving their trade-offs, MCDM methods are considered suitable choices. Techniques such as AHP, Technique for Order of Preference by Similarity to Ideal Solution (TOPSIS), analytic network process (ANP), PROMETHEE, and VIseKriterijumska Optimizacija I Kompromisno Resenje (VIKOR) are feasible for ranking alternatives, while AHP, expert judgment, and Entropy methods can be used for weighting indicators.

Although there are various MCDM methods for ranking alternatives, this study selected the PROMETHEE II method for developing the methodology framework for the following reasons:

- PROMETHEE II directly uses the values of indicators for ranking alternatives. This is a strong point of these techniques compared to AHP and ANP, which transfer indicator values into the Saaty scale. The Saaty scale typically consists of values from 1 to 9, with each value representing a different level of importance or preference [64], and the process of transferring indicator values into the Saaty scale is subjective. Therefore, using PROMETHEE II is easier and more advantageous for programming and reducing subjectivity in decision-making.

- The PROMEETHEE II method is relatively simple, both in concept and practice, compared to the other MCDM methods [65].

- PROMETHEE’s lack of weighting ability can be solved when combined with other methods. It facilitates the use of a variety of weighting methods for sensitivity analysis.

- PROMETHEE is considered an effective approach for prioritizing and choosing among a limited set of option actions, while considering multiple conflicting criteria [65].

Weight selection is a pivotal aspect of the MCDM technique that allows for the incorporation of stakeholders’ preferences into the process of decision-making. It had a profound impact on the resulting decisions. In this study, the Entropy method and user/decision-maker definition were selected for weighting indicators based on some points:

- The Entropy method is also a relatively simple ranking method, both in concept and practice, compared to the other MCDM methods.

- Using the Entropy method promotes objectivity and reduces the risk of bias by distributing weights based on the information entropy of indicators (directly using values of indicators like PROMETHEE II).

- Choosing the Entropy method to weight the indicators can be appropriate because it does not require expert judgment, which is subjective and sometimes difficult for companies to obtain. By directly using values of indicators, the Entropy method also gives objective weighting factor results.

- By using the Entropy method, decision-makers can ensure that no single indicator overly influences the decision outcome. Instead, the method promotes a balanced consideration of all indicators, leading to more robust and fair decision-making.

- Unlike the Entropy method, user definition allows decision-makers to explicitly express their subjective judgments and priorities regarding the importance of different indicators.

- If only using the Entropy method for weighting method, it is also difficult to perform sensitivity analysis by changing indicator weights. Meanwhile, user definition offers flexibility and customization, as decision-makers can tailor the weights to fit with their specific decision context and objectives.

To sum up, in this framework, for identifying criteria (indicator) weights, the Entropy method or user/decision-maker definition has been used, while the PROMETHEE II method has been utilised for ranking alternatives [66,67,68,69,70]. The Entropy method is a multi-criteria technique that is useful for evaluating and making decisions involving multiple factors. This method was developed based on Shannon’s (1948) information entropy principle in the field of information theory [71]. Entropy can be employed to measure the uncertainty (or variability) of information. The Entropy method allows to identify weights of criteria without decision-makers intervention [25,72,73,74,75]. PROMETHEE II is an extension of the original PROMETHEE method, designed to provide a comprehensive alternative ranking in MCDM issues [66,67,68,69,70]. PROMETHEE II maintains its focus on assessing and prioritizing alternatives according to multiple criteria while accounting for decision-maker preferences [70]. In this framework, Entropy only uses a decision-making matrix to weight indicators while the PROMETHEE II uses both decision-making matrix and indicator weights to rank alternatives.

The methodology framework also shows that, before ranking alternatives by PROMETHEE II, the selection of weight values must be carried out. The value of the index weight significantly influences the decision-making outcome. When choosing objective weight values, the decision outcome will be more accurate and objective. In this methodological framework, selecting index weights involves two options. One option is to choose index weights using the Entropy method for calculation; the second is to select index weights according to the decision-maker.

When selecting the Entropy method to identify index weights, the value of the weights is considered objective due to the method’s inherent impartiality and reliance on mathematical principles (details in Section 3.3.3). This method objectively assigns weights to indicators based on the variability and uncertainty present in the data, rather than relying on subjective judgements or preferences of individuals. By considering the inherent characteristics of the data without bias towards any specific criteria, the Entropy method ensures fairness and objectivity in the determination of indicator weights. When PROMETHEE II uses these weights for ranking alternatives, the ranking results ensure fairness in contributions from the indicators and are considered objective.

Conversely, when the second option is selected, the weights are completely defined due to the decision-maker’s knowledge and preferences. Therefore, the indicator weights are highly subjective. In this case, the decision-maker’s inclinations toward specific evaluation indicators will heavily influence and potentially skew the final decision. However, in this study, this option is mainly used for sensitivity analysis based on changes in the weights of the indicators.

Compared with Torkayesh et al. (2022) [23] and other studies (Section 1), this methodology framework is well-suited for evaluating both sustainability and circularity, providing a higher level of comprehensiveness. The selected MDCM method directly takes advantage of the calculation results of the LCT approach for ranking. Thus, the results of the ranking are objective and reduced dependence on expert judgements. In addition, this framework allows for the selection of different weighting methods (Entropy or decision-maker definition). This helps users to have a more comprehensive assessment when choosing the best alternative because sensitivity analysis is easily performed by changing indicator weighting. This also allows using expert opinions or decision-maker expectations for ranking if it is necessary. Furthermore, this framework also allows not only ranking alternatives but also calculating the indicators of situational status for sustainability and circularity assessment.

3.3. Creating HMI _DSS Tool

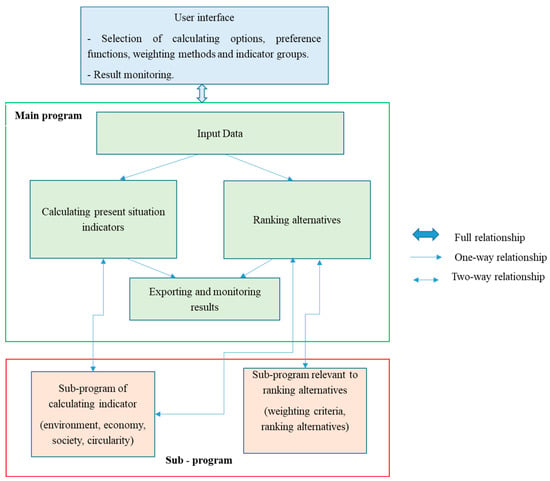

To program the HMI_DSS tool, a structure of software for the DSS tool was built. The structure of a software system refers to the organization of the system into distinct components and the relationships that exist among these components [76]. In this study, the structure has to cover all methods and functions used in the proposed framework. It is also organized to effectively program and easily monitor the results of the calculated steps. This structure includes three components, including a User interface, a Main-program, and sub-programs. The DSS tool structure is reported as shown Figure 4.

Figure 4.

Structure of DSS tool-HMI_DSS.

Figure 4 reveals the relationship between components: The User interface directly connects with the Main-program to perform selections and monitor calculation results; the sub-programs link to the Main-program to perform calculations of indicators and ranking alternatives. Sub-programs are categorized into two groups, including sub-programs used to calculate indicators and sub-programs relevant to ranking alternatives. There are two calculation options in the Main-program, including the calculation of indicators for the present situation and ranking alternatives. To calculate sustainability and circularity indicators of the current situation for the supply chain, Main-program uses indicator calculation sub-programs. Meanwhile, indicator calculation and ranking sub-programs are employed by the Main-program to perform the ranking of circularity and sustainability alternatives. In addition, Figure 4 also shows that importing input data and exporting results are performed in the Main-program.

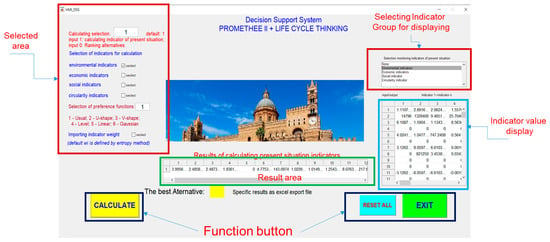

3.3.1. Designing User Interface

The User interface is designed for selecting calculation options, indicator types, preference function of PROMETHEE II, weighting criteria, and result display. The DSS tool User interface is presented in Figure 5. The left corner of the User interface is used for selection. Specifically, there is a text box to choose the calculation options by typing 0 or 1. If users want to calculate present situation indicators, 1 is typed in this text box. Meanwhile, 0 is typed for ranking alternatives. There are four click boxes to select the sustainability and circularity indicators. The click box is also used to choose the method of weighting indicators. In addition, the text box for selecting the preference function of the PROMETHEE II method is mounted in this corner. This method has six preference function, which are proposed by Brans and Vincke (1985) [77] (usual, V-shape, U-shape, linear, level, and Gaussian function) [66]. These functions are used to aggregate the user preferences on each criterion. The right side of the User interface is used to monitor the indicator calculation results of the supply chain’s current situation or ranking alternatives. The results are displayed in the middle-bottom of the User interface. The best alternative is also shown at the bottom of the User interface. The calculating, reset and exit buttons at the bottom of User interface are used to compute, reset, and exit the program. Additionally, the ranking result is presented in graphical form.

Figure 5.

User interface of HMI_DSS tool.

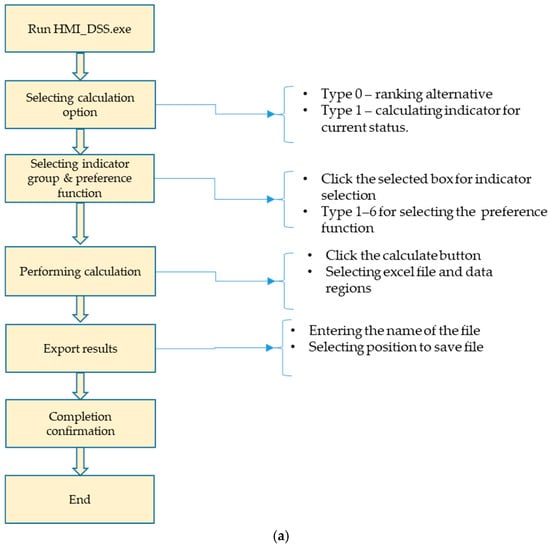

The User interface will appear when the user runs the HMI_DSS tool. The application process of the HMI_DSS tool involves the following processes, as shown in Figure 6a. The selection of data from the Excel-2016 file for calculation is shown in Figure 6b.

Figure 6.

(a) Guide to using the HMI_DSS tool, (b) Selecting data for importing.

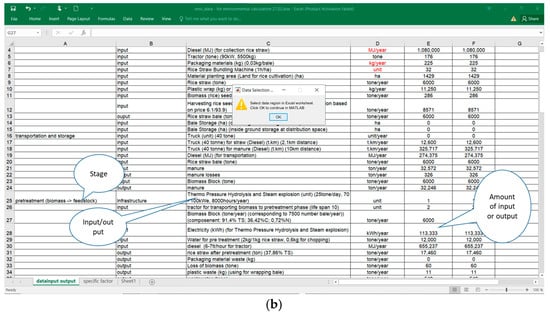

3.3.2. Designing Main_program

The Main_program is designed to import input data, perform calculations of indicators and ranking alternatives, and export results. For carrying out the calculation options, the input data, including numbers and text formats, is imported from Excel files. The data for indicator calculation includes the supply chain inputs/outputs and the specific impact factors of each indicator corresponding to each input and output (Figure 6b). Additionally, for calculating economic indicators, some general information must be included in the Excel file, such as life span, discount rate, etc. The input data for indicator calculations is organized in four Excel files corresponding to four indicator groups, such as environmental, economic, social, and circular indicators. Each file in Excel contains two main sheets of data: the amount of input or output and specific impact factors of indicators. The imported data are also used to rank alternatives if users use weighting indicators from external sources to present their expectations. The importing of data is carried out in the Main-program according to selection at the User interface. After importing input data, the calculations are carried out by using sub-programs.

The Main-program also exports calculation and ranking results to an Excel file and displays them in the User interface. For example, the resulting file of situation calculation includes five sheets, each sheet containing the results of the total, the environmental, the social, the economic, and the circularity indicators. In the environmental indicator sheet, the indicator results of each input or output are stored in a row, so users can monitor and calculate impacts for stages of the life cycle (if they want). This is also similar to social and circularity sheets. In the economic sheet, the costs are shown in columns corresponding to each input or output and the sum of them, including initial, operation, maintenance and fuel costs. Additionally, the cash flow of a project’s lifetime is also present when economic indicators are calculated. Furthermore, the ranking result file consists of the indicator value of the alternatives, the decision matrix, the normalization matrix, the criterion weights, and the outranking results. Each result is presented on an individual sheet. Therefore, users have more advantages in assessing and checking results.

3.3.3. Designing Sub-Program for Calculating Indicators and Ranking Alternatives

The sub-programs in this tool are divided into two groups (Figure 4). One includes sub-programs for the indicator calculation: environmental, economic, social and circularity indicators. In this paper, these indicators are calculated for case study based on data collected from the rice straw supply chain in Northern Italy, applying the LCT approach and MFA. These data are sourced from Main-program. The calculation of these indicators not only provides an overview of environmental impacts but also assesses economic and social efficiency, and the contribution to CE models. Another one comprises sub-programs for ranking alternatives and weighting indicators. This ranking is performed using MCDM methods, such as the Entropy and PROMETHEE II methods, allowing for optimal decision-making by balancing environmental, economic, social, and circular factors. In this paper, the results from the indicator calculations for the rice straw supply chain are used as inputs for these sub-programs. The output of the sub-programs provides the scores of the alternatives. All of them were programmed in Matlab Script. The mathematical basics for programming sub-programs are described as follows:

- Calculated indicator sub-programs

The sub-programs for calculating indicators are programmed based on formulas to identify indicators’ values. For example, environmental indicators can be defined using the input or output and specific impact factors, as shown in Equation (1).

Here, the variables are defined as follows:

Ik—Environmental indicator k (unit of indicator k).

IFkij—Specific impact factor for environmental indicator k of output or input data j of stage i of the supply chain (unit of indicator k per unit of output or input).

mij—Amount of inputs/outputs j of stage i.

N—Number of stages in the supply chain.

Mi—Number of inputs/outputs/emissions of stage i.

Other equations for calculating the remaining indicators are presented in the Supplementary Materials.

Four indicator calculation sub-programs were created for the HMI_DSS tool that correspond to environmental, economic, social, and circularity indicators. This makes the HMI_DSS tool more flexible in terms of indicator selection priorities in assessment. It also gives users an advantage in collecting and preparing data for calculation when each indicator category is based on an individual methodology.

The LCT and MFA results are used to establish the matrix of alternatives and indicators, which is called the decision-making matrix.

In this matrix, X11 to Xnm are the values of indicators of alternatives.

- 2.

- Weighting and ranking sub-programs

The weighting and ranking sub-program are programing based on Entropy and PROMETHEE II methods.

- Entropy method

The Entropy method is based on information theory, quantifying uncertainty by analyzing the distribution of values across indicators. It identifies indicators with significant variation, thereby providing valuable information while minimizing subjective bias by relying solely on data instead of personal preferences. Weights are assigned based on the data’s inherent characteristics, ensuring that indicators that are more variable receive higher weights. This results in a balanced, data-driven approach that enhances decision-making, accurately reflecting the true impact of each indicator without preconceived biases.

This method requires the declaration of m alternatives and n indicators. The evaluation of the indicator j in the alternative i is represented by Xij. In this paper, Xij is provided by the decision-making matrix.

First, the evaluated value Xij is normalized. The normalized value of the indicator j in the alternative i, denoted as pij, is calculated as follows [78]:

In the entropy weighting method (EWM), the entropy value Ej of the indicator i is defined as follows [78]:

In fact, assessment utilizing the EWM, Ej is typically set when pij = 0 for the advantage of calculation.

The entropy value Ej ranges from 0 to 1. The difference in the indicator j of assessed alternatives is largest, when Ej approaches 1 and vice versa. In the EWM, the weight calculation is expressed by the following equation [78]:

- b.

- Method of PROMETHEE II

The ranking process of the PROMETHEE II technique includes the following steps:

Step 1 aims at normalize the matrix of decision-making to range 0–1 by using the following equations [65]:

Step 2 involves calculating the preferred degree value for each criterion in every possible decision pair. gj(a) is the value of indicator j in alternative a and gj(a) = Raj. dj (a, b) is the difference between indicator j of the two alternatives a and b.

Pj (a, b) represents the priority degree of indicator j for two alternatives a and b. The preference functions that are employed to calculate these priority degrees are identified as follows [66]:

Step 3 refers to identifying all criteria priority degrees for each pair of possible decisions. For each possible choice pair, a priority index is computed. C represents the set of indicator and wj is the weight of indicator j. In this case, the priority index for two alternatives a and b is identified using the following calculation [65]:

Step 4 focuses on calculating the outranking flows. The positive and negative outranking flow (φ−(a) and φ+(a)) are computed for each alternative a when it is compared with remaining alternatives. A represents the set of the alternatives and n is the number of alternatives. The positive (and negative) outranking flows of the alternative a are defined using the following equations [65]:

In the last step (Step 5), the ranking of all alternatives is established using the net outranking flows. The positive (and negative) outranking flows are used to determine the net outranking flows for each alternative. φ(a) represents the net outranking flow for alternative a, which is calculated as following equation [65]:

A higher net outranking flow value for alternative a indicates that the alternative a is more favorable.

3.3.4. Creating and Run Software of DSS Tool

After programming with Matlab GUI and Script, the DSS software HMI_DSS-V1 is generated as an executable (exe) file. The DSS tool comprises several files located in the same folder, including.exe files for running the tool, Excel files used for data input following a template structure, and some text files for the guide.

4. Testing HMI_DSS Tool

4.1. Selecting a Case Study

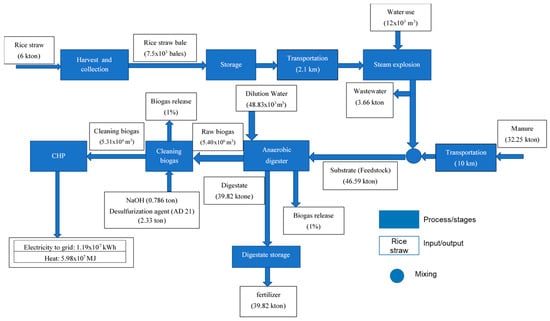

The case study described in this work concerns an anaerobic digestion (AD) plant using rice straw as a feedstock to produce biogas in Northern Italy. The biogas is, in turn, transformed into electricity and heat. The supply chain based on this AD plant was selected to apply the HMI_DSS tool for sustainability and circularity assessment for the baseline configuration and the proposed alternatives. Figure 7 shows the baseline configuration (A0) for energy production from the rice straw assessed in the case study. The rice straw is initially collected and transported to the AD plant. Before feeding to the AD plant, the rice straw, with 91.4% total solids, is pretreated in a steam explosion (SE) unit to partially deconstruct the biomass, thus increasing the potential of biogas production up to 450 m3/ton of straw with a methane content of 53% by volume. After the SE treatment, the straw, with 37.86% total solids, is mixed with animal manure to reach the optimal ratio of C/N required for the AD plant feeding. Water is also introduced to the digester to reduce the total solid content of the slurry to 15%.

Figure 7.

The baseline configuration of the rice straw supply chain.

The raw biogas is then cleaned by sodium hydroxide scrubbing for sulfur removal and utilized to produce energy (heat and electricity) in a Combined Heat and Power (CHP) plant. The electricity generated is partly used for self-consumption in the AD and CHP sections, with the surplus being supplied to the local electrical grid.

The digestate co-produced in the AD section is extracted from the bottom of the digester using a centrifugal shredder pump and sent to a separator. The output includes a solid fraction (15% w/w) and a liquid one (85% w/w). Both digestate fractions are kept in open concrete tanks and used as biofertilizers.

In the alternative option (A1), the raw biogas is sent to a separation section to produce biomethane and purified liquid CO2, intended for the domestic market. In the considered scenario, the biomethane is only fed to the CHP section. A further option involves the injection of biomethane into the local natural gas grid, but it was not included in this study due to the strong dependence on incentives that can vary a lot in different countries, making the results not widely usable.

4.2. Examination of Sustainability and Circularity of Rice Straw Supply Chain by DSS_HMI Tool

To calculate the indicators, input data for the HMI_DSS tool was collected from the plant site, Ecoinvent database [79] and literature [35,80,81]. The data collection process started with collecting documents describing the technological processes of the plants. Technical specifications were taken from the plant introduction and Ecoinvent, while data on production process parameters was taken directly from the plant.

Data was categorized as input or output to calculate the respective indicator groups. Impact factors for each input and output were sourced from Ecoinvent and literature. For instance, greenhouse gas emissions (GWP) at the harvesting and collection stages were taken from Ecoinvent [79] and literature [35,80,81,82]. Before being processed in the AD, the biomass undergoes pre-treatment via steam explosion (SE). Data on SE processes were provided by Leona’s plants and the Teofipol plant in Ukraine [83]. With environmental data, the data on the input/output amount of the stage-treatment stage were collected from the plant site database (Table 1). Material data for AD plant construction were collected from Ecoinvent (Table 2) and then scaled to real AD plant size [35]. This transparent approach ensures that all values used in calculating indicators are backed by credible, traceable sources, enhancing the reproducibility and reliability of the analysis.

Table 1.

Amount of input/output of pretreatment stage.

Table 2.

Data of AD plant construction with a capacity of 170 kWel AD-CHP, adapted from [79].

The calculation of the present situation is shown in Table 3. The results of the baseline situation indicate 49 indicators of environmental, economic, and social aspects and the circularity rate. For example, the GWP of the supply chain is 1.46 × 106 kgCO2eq/year or 122 gCO2eq per kWh of electricity, while the acidification potential (AP) of rice straw in this study is 9.47 × 103 kg SO2 eq per year (0.797 gSO2 eq per kWh). The economic indicator results reveal that the internal rate of return (IRR) for the rice straw supply chain case study in Northern Italy is 6.62%. In addition, the net present value (NPV) for this case study is EUR 1.10 million, calculated for the entire lifespan of the project. The relatively low NPV is due to the high investment cost of the steam explosion unit and the significant labor costs associated with its operation. Furthermore, the results of the social indicators also show that the rate of informal labor is high (82.10%) because most of them are farmers who plant and harvest biomass. The results also show that child labor is zero, because there is no data recorded (child labor is prohibited by law Legge 17 Ottobre 67). The circularity indicators results show that the recycling rate out of all waste is 70.77% because the digestate of AD plant is used as biofertilizer. On the other hand, the circular material use is at 80.61%, and the proportion of material losses in primary material is 14.61%.

Table 3.

The value of the indicators for the current status of rice straw supply chain.

Furthermore, the result calculation is exported to an Excel file, which allows users to monitor indicator values for all life cycle stages. For example, the GWP can be calculated for each stage, as shown in Table 4. The results show that the hotspot point of the GWP indicator is pretreatment (45.92%) because this stage uses a lot of water and energy for processing. Comparing the existing reference with a similar process system (AD-CHP) [35,84], the value of the indicators calculated by the HMI_DSS tool is reliable to assess the supply chain and provide helpful evidence for decision-making. For example, the GWP of the AD-CHP system calculated by Fusi et al. (2016) [35] ranges from −39 to 408 gCO2eq per kWh, while in this paper, it is 122 gCO2eq per kWh. The IRR of this rice straw supply chain is 7.57%, while the AD-CHP system carried out by Pasciucco et al. (2023) is 5.94% [84].

Table 4.

The value of the GWP indicator in life cycle stages.

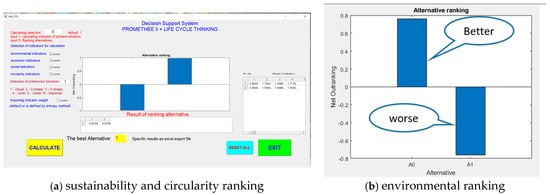

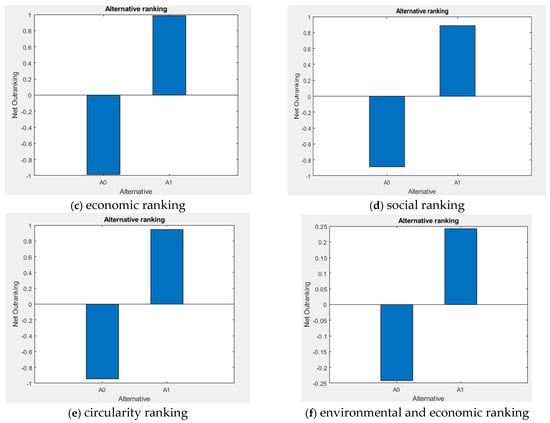

4.3. Ranking Alternative

4.3.1. Ranking with Indicator Weighting by Entropy

In this analysis, the Entropy method is utilized to rank alternatives when multiple options are considered. The scenarios include (a) all indicators, (b) only environmental, (c) only economic, (d) only social, (e) only circularity, and (f) both environmental and economic indicators. The results of the ranking for all six scenarios are presented in Figure 8. Specifically, Figure 8a monitors ranking results for scenario (a). In this scenario, the outranking value of A0 is −0.9728 while A1 is 0.9728, indicating that A1 is better than A0. Figure 8a also shows a diagram of the outranking results. In addition, the value of indicators is also shown in the right part of the User interface. The result of indicator calculation and indicator weighting factors by Entropy for scenario (a) are also shown in Table 5. Meanwhile, Figure 8b–f present diagrams of outranking for different scenarios.

Figure 8.

Outranking result diagram of six scenarios (a) all, (b) only environmental, (c) only economic, (d) only social, (e) only circularity and (f) both environmental and economic indicators.

Table 5.

Result of calculating alternative indicators and weighted factors by Entropy method.

As shown in Figure 8b, A0 is better than A1 if only the environmental aspects are taken into account. In contrast, in all remaining scenarios, A1 is better than A0. This is because in alternative A1, capturing CO2 and converting it into liquefied CO2 increases revenue and NPV, making it higher than that of A0; it also makes the IRR of A1 higher than that of A0 (as presented in Figure 8c, with consideration of only economic impacts). In addition, A1 can improve social impacts like increasing jobs and income generated by jobs and working hours (as presented in Figure 8d, with consideration of only social impacts). Furthermore, some circularity indicators are also improving, such as the rate of recycled waste, reducing waste generation, and increasing labor participation in the circular model (as presented in Figure 8e).

The trade-off is shown in the ranking results in Figure 8a,f. A1 is better than A0 when all aspects of sustainability and circularity are considered (Figure 8a). Moreover, in case the environmental effects are compensated by the economic benefits, the A1 is better than A0 (Figure 8f). Additionally, the trade-off is shown in each indicator of the group. For example, in the environmental-energy group, A1 consumes more energy than A0 (1.98 × 107 MJ per year and 1.7 × 107 MJ per year, respectively), but it has lower GWP impact than A0 (1.21 Mton CO2 per year with 1.46 Mton CO2 per year, respectively). This is because in A1, a biogas upgrade device is added to the system to capture CO2. The addition of this equipment needs more material and energy input, which causes an increase in energy consumption in A1. Meanwhile, this equipment captures CO2, which brings a lower GWP in A1. To sum up, A1 is a better choice for sustainability and circularity than A0, so applying the CE principle is a promising alternative to improve sustainability for the rice straw supply chain.

To deepen the analysis, a sensitivity analysis will be conducted to assess the impact of different weighting methods on the final rankings. While the Entropy method offers a balanced approach by normalizing indicator values, the sensitivity analysis will explore how alternative weighting methods influence decision outcomes. The details of this analysis are provided in Section 4.3.2.

4.3.2. Sensitivity Analysis with Different Weighting Indicators by Using Other Weighting Method

To evaluate the reliability and robustness of the final ranking, it is essential to assess sensitivity of each the criterion’s weights. The weights assigned to each criterion are crucial in determining the priority of alternatives. In the DSS tool, the sensitivity evaluation is taken when users select the weighting method by user definition. The indicator weight is imported from an Excel file, so users can give a high value to some indicators that are considered important. Otherwise, some indicators, which users do not want to concern themselves with, can obtain a value of 0. For example, the user can give the indicator weight factors the same weight of 1/49 or they can give the index groups the same weight of 0.25, and indicators of each group also have the same value (equal to 0.25/number of indicators in the group) (Table 6).

Table 6.

Value of indicator weights defined by Entropy and users/decision-makers.

By using the HMI_DSS tool, the alternative ranking results of different indicator weights are taken, as shown in Table 7.

Table 7.

Outranking results with weighting indicators by Entropy and users concerning all indicators.

The application of different weighting methods is crucial for robust decision-making. When all indicators are assigned equal weights, A0 has an outranking value of −0.2041, while A1 has a value of 0.2041. This indicates that A1 is preferred over A0 when weights are uniformly distributed. When equal weights are applied to indicator groups, A0’s outranking value is −0.2889, and A1’s is 0.2889. This demonstrates how the group-based weighting alters the ranking compared to the indicator-level weighting.

Furthermore, choosing one or some groups of indicators to rank in sub-Section 4.3.1 is also considered a case of sensitivity analysis. In the scenarios above, unselected indicators are equivalent to giving them zero weight. The selected indicators are weighted by Entropy.

Figure 8b–f demonstrate that while A1 consistently ranks better than A0 in most scenarios, the choice of weighting method influences the outcomes. Sensitivity analysis reveals that variations in weight assignments can lead to substantial changes in rankings. For example, if environmental indicators are given higher weights, A0 might rank higher due to its lower environmental impact compared to A1. Conversely, if economic indicators are weighted more heavily, A1’s higher revenue and NPV would improve its ranking.

Selecting indicator groups combined with Entropy for weighting indicators is considered a helpful approach in sensitivity analysis, which provides result rankings in various scenarios of priority indicator groups. This combination also represents the effect of subjective and objective factors in decision-making. Here, the weighting of indicators is objective, while selecting groups is subjective due to user expectations. These sensitivity analyses show how changes in indicator weights can significantly influence decision outcomes. For instance, prioritizing environmental indicators can result in alternatives with lower environmental impacts ranking higher, while emphasizing economic indicators may favor options with greater revenues and net present values.

Additional sensitivity analysis results demonstrate how variations in weight assignments can lead to differing rankings. The findings indicate that uniformly distributing weights across all indicators simplifies the ranking process but may not accurately reflect the significance of specific criteria. In contrast, employing the Entropy method provides an objective approach based on data distribution; however, it may overlook the subjective preferences of decision-makers.

Alternatively, applying Entropy-based weights provides an objective measure based on data distribution, but it may not fully capture the decision-makers preferences or the relative importance of different indicators. This approach is useful for scenarios with a large number of indicators where subjective judgments might be less reliable.

To sum up, the HMI_DSS tool allows decision-makers to have a more comprehensive view based on the multiple weighting methods. The results of total cases seem to show A1 better than A0, as shown in Table 6 and Figure 8. The results of ranking allow decision-makers to have a more comprehensive view. However, with the weight of the indicator defined by users, the selecting result is subjective and varies with the user’s knowledge.

5. Discussion

The HMI_DSS tool stands as an effective means for assessing sustainability and circularity indicators for companies within the supply chain, offering several noteworthy advantages. It provides a comprehensive array of indicators, enabling the evaluation of businesses based on circular economy models and sustainable development principles. One of its key strengths lies in its simultaneous assessment of sustainability and circularity indicators, aided by the integration of the PROMETHEE II method, which facilitates the appraisal of alternatives across various supply chain stages. Unlike decision support systems that use other MDCM techniques (AHP and ANP), HMI_DSS can yield objective ranking results because it directly uses indicator results obtained from the LCT approach and MFA, reducing reliance on subject matter experts [13,15,17,18,20]; for example, De Luca employed 15 experts [17]. Furthermore, its adaptability to company-specific conditions allows for its implementation using data from individual companies. By utilizing MFA and life cycle tool results as the input for the MCDM method, the tool equips decision-makers with valuable and comprehensive information for making informed choices in complex scenarios involving multiple criteria and trade-offs. Presenting results according to each life cycle stage and each step of the calculation process in Excel format also helps users effectively observe hotspots in the life cycle and data errors during the calculation process.

Despite the advantages of PROMETHEE II and Entropy methods, they have inherent limitations. When all alternatives have the same values for some indicators, these methods cannot perform normalization of the decision-making matrix. Thus, the ranking alternative process cannot be taken. However, the HMI_DSS tool has addressed these issues by giving zero value for these indicators, so the final result ranking is still performed. This tool also provides two distinct quantification techniques for indicator weighting, Entropy-based quantification and decision-maker-determined weights, so it can help users make better decisions according to their priorities. These approaches not only help mitigate potential drawbacks but also enhance the tool’s usability and reliability in the assessment of circularity and sustainability indicators in the supply chain.

However, the HMI_DSS tool requires users to collect impact factor values for inputs and outputs because they are not available in the tool. Therefore, it is an issue for companies to collect these data due to the level of their available databases. When the number of inputs and outputs is large, it can take a lot of effort to collect data on impact factors. To improve the HMI_DSS tool, a centralized impact factor database should be integrated or linked to open-access databases, reducing the need for manual data collection. Additionally, automating data collection through interfaces that capture impact factor values from external sources would further streamline the process. These enhancements would minimize user effort and make the tool more efficient. As a result, future versions of the HMI_DSS tool would be more practical and user-friendly, accommodating companies with different data capabilities.

In addition, circularity indicators of the HMI_DSS tool are used for the general supply chain. However, some specific fields, such as electronics or construction, need to add more CE indicators that are important for these fields, for example, the electronic waste recycling rate, the recycling construction and demolition waste rate, or the ecologically certified material proportion in material use [41,45]. To enhance the tool’s relevance and accuracy for these industries, it is essential to expand and refine the circularity indicators to reflect their specific characteristics and requirements. Future research should focus on integrating these industry-specific indicators to improve the tool’s applicability and effectiveness.

Furthermore, in this study, the application of the new tool is conducted for a single case study. Although the results provide a comprehensive reflection of the circularity and sustainability of the rice straw supply chain, they do not fully capture the tool’s potential for all biomass energy production chains. To enhance its applicability, it is essential to conduct additional experimental calculations and gather feedback on its implementation across various companies and supply chains in different industries and countries, such as forestry, agricultural waste management, and bioenergy production. The results of the case study application highlight that large biomass chains, which may span multiple regions and countries, present significant data collection challenges due to the volume and diversity of information required. Additionally, varying national policies can significantly affect evaluation results and the selection of the final optimal solution. Addressing these issues will be critical in future research to establish the universality and robustness of the HMI_DSS tool.

Despite these limits highlighted, the advantages considered above render the HMI_DSS a promising tool for effectively evaluating sustainability and circularity indicators within the supply chain.

6. Conclusions

This study shows that the HMI_DSS tool has been developed as an effective and innovative solution for the comprehensive evaluation of both sustainability and circularity levels of the supply chain, which is lacking in the existing DSS framework. Its integration of the PROMETHEE II method with multi-weighting methods makes this tool robust in solving trade-offs, and its adaptability to individual company conditions makes it a valuable decision-support tool for transitioning to a CE. This tool employs a set of 49 indicators that align with the United Nations SDGs and the European Commission’s guidelines for transitioning to a CE. In addition, the definition of these indicators completely unifies the approach under the LCT approach. This makes this tool a comprehensive evaluation and suitable for the company’s objectives in the transition to a circular economy and sustainable development. To sum up, the tool’s strengths lie in its objectivity, detailed presentation, and flexibility in weighting indicators, providing decision-makers with a holistic view of alternatives at various supply chain stages.

The application for the case study in the energy sector reveals that the HMI_DSS tool can also give companies helpful information on sustainability and circularity levels for their present supply chain. For example, in the case study, some important indicators are calculated, such as the GWP (122 gCO2eq/kWh of electricity), IRR (6.62%), and NPV (EUR 1.1 million). This information is scientifically fundamental for defining alternative actions to improve sustainability and circularity.

Nevertheless, the HMI_DSS tool has limitations. It requires users to collect impact factor values, which may pose challenges due to data availability issues. Additionally, indicators used in this tool are general, so there is a need for the inclusion of industry-specific circularity indicators. Further research is recommended to address these limitations, ensuring a more seamless and industry-tailored application of the tool.

Overall, the HMI_DSS tool is a promising asset for guiding enterprises towards embracing circular economy models and sustainable practices. Its comprehensive approach fits the United Nations SDGs and the European Commission’s guidelines, making it a valuable contribution to the field of decision support systems for sustainable and circular supply chain management. As the circular economy landscape evolves, ongoing refinement and expansion of the tool’s capabilities will contribute to its continued relevance and effectiveness in fostering sustainable and circular practices within diverse industries.

Supplementary Materials

The following supporting information can be downloaded at https://www.mdpi.com/article/10.3390/en17205179/s1, Table S1: Indicators of circularity and sustainability for company in supply chain.

Author Contributions

Conceptualization, S.L. and T.Q.N.; methodology, T.Q.N. and S.L.; resources, M.C.; data curation, T.Q.N., A.B. and L.B.; writing—original draft preparation, T.Q.N. and L.Q.L.; writing—review and editing, all authors; supervision, M.C., S.L., A.B. and L.B. All authors equally contributed to the paper’s development and writing. All authors have read and agreed to the published version of the manuscript.

Funding

This research was financed by the Italian Ministry of Education, University and Research through the National Operational Program (PON) of the Ministry of Education, University and Research, entitled “For the School-skills and environments for learning”, and by the European Structural Funds, which contains the strategic priorities of the education sector and has a seven-year duration from 2014 to 2020.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Acknowledgments

The authors would like to thank ENI for their support in collecting data about rice straw supply chains, biomass process technologies, and chemical processes in biomass treatment and conversion.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

| AD | Anaerobic digestion |

| AHP | Analytic Hierarchy Process |

| AP | Acidification potential |

| BSC | Biomass supply chain |

| CBM | Circular business models |

| CE | Circular economy |

| CHP | Combined Heat and Power |

| DSS | Decision support system |

| EC | European Commission |

| GDP | Gross domestic product |

| GWP | Global warming potential |

| HMI_DSS | Holistic Multi-Indicator Decision Support System |

| IO | Input–Output |

| LCA | Life cycle assessment |

| LCC | Life cycle costing |

| LCSA | Life Cycle Sustainability Assessment |

| LCT | Life cycle thinking |

| MAVT | Multi-Attribute Value Theory |

| MCDA | Multi-Criteria Decision Analysis |

| MCDM | Multi-Criteria Decision-Making |

| MFA | Material Flow Analysis |

| NPV | Net present value |

| PROMETHEE | Preference Ranking Organization Method for Enrichment Evaluations |

| SDG | Sustainable Development Goal |

| SE | Steam explosion |

| SLCA | Social life cycle assessment |

References

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A New Sustainability Paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Garcia-Saravia Ortiz-de-Montellano, C.; Samani, P.; Van Der Meer, Y. How Can the Circular Economy Support the Advancement of the Sustainable Development Goals (SDGs)? A Comprehensive Analysis. Sustain. Prod. Consum. 2023, 40, 352–362. [Google Scholar] [CrossRef]

- European Commission. A New Circular Economy Action Plan, Communication from the Commission to the European Parliament, The COUNCIL, The European Economic and Social Committee and the Committee of the Regions; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- De Pascale, A.; Di Vita, G.; Giannetto, C.; Ioppolo, G.; Lanfranchi, M.; Limosani, M.; Szopik-Depczyńska, K. The Circular Economy Implementation at the European Union Level. Past, Present and Future. J. Clean. Prod. 2023, 423, 138658. [Google Scholar] [CrossRef]

- EC Questions and Answers on the Commission Communication “Towards a Circular Economy” and the Waste Targets Review 2014. Available online: https://ec.europa.eu/commission/presscorner/detail/en/MEMO_15_6204 (accessed on 11 December 2023).

- Kalmykova, Y.; Sadagopan, M.; Rosado, L. Circular Economy—From Review of Theories and Practices to Development of Implementation Tools. Resour. Conserv. Recycl. 2018, 135, 190–201. [Google Scholar] [CrossRef]

- The Ellen MacArthur Foundation (TEMF). Towards the Circular Economy Vol 1_ an Economic and Business Rationale for an Accelerated Transition 2013. Available online: https://emf.thirdlight.com/file/24/xTyQj3oxiYNMO1xTFs9xT5LF3C/Towards%20the%20circular%20economy%20Vol%201%3A%20an%20economic%20and%20business%20rationale%20for%20an%20accelerated%20transition.pdf (accessed on 11 December 2023).

- Azevedo, S.; Godina, R.; Matias, J. Proposal of a Sustainable Circular Index for Manufacturing Companies. Resources 2017, 6, 63. [Google Scholar] [CrossRef]

- Pollard, J.; Osmani, M.; Cole, C.; Grubnic, S.; Colwill, J.; Díaz, A.I. Developing and Applying Circularity Indicators for the Electrical and Electronic Sector: A Product Lifecycle Approach. Sustainability 2022, 14, 1154. [Google Scholar] [CrossRef]

- De Pascale, A.; Arbolino, R.; Szopik-Depczyńska, K.; Limosani, M.; Ioppolo, G. A Systematic Review for Measuring Circular Economy: The 61 Indicators. J. Clean. Prod. 2021, 281, 124942. [Google Scholar] [CrossRef]

- Moraga, G.; Huysveld, S.; Mathieux, F.; Blengini, G.A.; Alaerts, L.; Van Acker, K.; De Meester, S.; Dewulf, J. Circular Economy Indicators: What Do They Measure? Resour. Conserv. Recycl. 2019, 146, 452–461. [Google Scholar] [CrossRef]

- Goddin, J.; Marshall, K.; Pereira, A.; Tuppen, C.; Herrmann, S.; Jones, S.; Krieger, T.; Lenges, C.; Coleman, B.; Pierce, C.J.; et al. Circularity Indicators: An Approach to Measuring Circularity, Methodology. 2019. Available online: https://www.researchgate.net/publication/353687971_Circularity_Indicators_An_Approach_to_Measuring_Circularity_Methodology (accessed on 11 December 2023). [CrossRef]

- De Luca, A.I.; Iofrida, N.; Leskinen, P.; Stillitano, T.; Falcone, G.; Strano, A.; Gulisano, G. Life Cycle Tools Combined with Multi-Criteria and Participatory Methods for Agricultural Sustainability: Insights from a Systematic and Critical Review. Sci. Total Environ. 2017, 595, 352–370. [Google Scholar] [CrossRef]

- Kravchenko, M.; Pigosso, D.C.; McAloone, T.C. Towards the Ex-Ante Sustainability Screening of Circular Economy Initiatives in Manufacturing Companies: Consolidation of Leading Sustainability-Related Performance Indicators. J. Clean. Prod. 2019, 241, 118318. [Google Scholar] [CrossRef]

- Kravchenko, M.; Pigosso, D.C.A.; McAloone, T.C. Developing a tool to Support Decisions in Sustainability-Related Trade-Off Situations: Understanding Needs and Criteria. Proc. Des. Soc. Des. Conf. 2020, 1, 265–274. [Google Scholar] [CrossRef]

- Gružauskas, V.; Baskutis, S.; Navickas, V. Minimizing the Trade-off between Sustainability and Cost Effective Performance by Using Autonomous Vehicles. J. Clean. Prod. 2018, 184, 709–717. [Google Scholar] [CrossRef]

- De Luca, A.I.; Falcone, G.; Stillitano, T.; Iofrida, N.; Strano, A.; Gulisano, G. Evaluation of Sustainable Innovations in Olive Growing Systems: A Life Cycle Sustainability Assessment Case Study in Southern Italy. J. Clean. Prod. 2018, 171, 1187–1202. [Google Scholar] [CrossRef]

- Ekener, E.; Hansson, J.; Larsson, A.; Peck, P. Developing Life Cycle Sustainability Assessment Methodology by Applying Values-Based Sustainability Weighting—Tested on Biomass Based and Fossil Transportation Fuels. J. Clean. Prod. 2018, 181, 337–351. [Google Scholar] [CrossRef]

- Ren, J.; Manzardo, A.; Mazzi, A.; Zuliani, F.; Scipioni, A. Prioritization of Bioethanol Production Pathways in China Based on Life Cycle Sustainability Assessment and Multicriteria Decision-Making. Int. J. Life Cycle Assess. 2015, 20, 842–853. [Google Scholar] [CrossRef]

- Ren, J.; Toniolo, S. Life Cycle Sustainability Decision-Support Framework for Ranking of Hydrogen Production Pathways under Uncertainties: An Interval Multi-Criteria Decision Making Approach. J. Clean. Prod. 2018, 175, 222–236. [Google Scholar] [CrossRef]

- Abu, R.; Aziz, M.A.A.; Noor, Z.Z. Integrated Life Cycle Assessment, Life Cycle Costing and Multi Criteria Decision Making for Food Waste Composting Management. J. Adv. Res. Bus. Manag. Stud. 2021, 21, 1–9. [Google Scholar] [CrossRef]

- Moro, C. Comparative Analysis of Multi-Criteria Decision Making and Life Cycle Assessment Methods for Sustainable Evaluation of Concrete Mixtures. Sustainability 2023, 15, 12746. [Google Scholar] [CrossRef]

- Torkayesh, A.E.; Rajaeifar, M.A.; Rostom, M.; Malmir, B.; Yazdani, M.; Suh, S.; Heidrich, O. Integrating Life Cycle Assessment and Multi Criteria Decision Making for Sustainable Waste Management: Key Issues and Recommendations for Future Studies. Renew. Sustain. Energy Rev. 2022, 168, 112819. [Google Scholar] [CrossRef]