1. Introduction

With the rapid advancement of artificial intelligence technology, traditional extensive economic models are facing unsustainable challenges, compelling China to pivot towards a path of high-quality development. This transformation involves not only technological innovation and industrial upgrading but also the creation of a sustainable future economic system. In the pursuit of Chinese modernization, the stability of economic growth should be balanced with rational energy use and reduced pollution emissions to foster improvements in the ecological environment. Hence, setting scientifically sound environmental emission standards is crucial for enhancing the country’s sustainable development capabilities and urban energy efficiency. According to research by Gokmenoglu et al. [

1], the recent continuous growth in energy consumption in China mainly stems from the expansion of industrial production activities. Therefore, accelerating industrial upgrading and optimizing energy structures are central to deepening and implementing the concept of green development.

In this context, the advancement of smart manufacturing and Industry 4.0 strategies has made industrial robots a key component of automated and intelligent production. Data from the International Federation of Robotics (IFR) shows that the global stock of industrial robots has grown from 756,500 units in 2001 to 3.907 million units in 2022, with an average annual growth rate of 7.48%, highlighting their increasingly prominent role in modern manufacturing and the overall economy. China has actively integrated into this technological revolution, promoting the widespread use of industrial robots nationwide to help enterprises reduce production costs and enhance efficiency. In fact, China has become the largest robot market in Asia, with an installation of nearly 300,000 units in 2022, up 5% year-on-year, and for two consecutive years, the annual installation of industrial robots in China has surpassed the total of all other countries.

At the technological forefront, industrial robots, used as mechanical devices designed to automate tasks, are increasingly integral to modern industrial systems. Their widespread adoption has notably bolstered China’s capabilities in environmental protection and resource conservation, profoundly influencing both the nation’s industrial advancement and the daily lives of its citizens. This has injected fresh vigor into China’s initiatives for green development. However, this capital-intensive technological progress has escalated the demand for highly skilled labor, and, concurrently, the extensive deployment of industrial robots may introduce environmental challenges such as pollution and climate change, posing new hurdles for enhancing energy efficiency. A thorough review of the pertinent literature reveals significant research gaps: primarily, there is a notable dearth of in-depth analysis on the specific impacts of industrial robots on green development. Research into whether industrial robots confer an environmental benefit remains sparse, characterized by underdeveloped theoretical frameworks and embryonic stages of empirical research. Additionally, the interaction between industrial robots and China’s green development is poorly explored, with research perspectives remaining quite narrow. Moreover, empirical studies on green total factor energy efficiency in China are largely confined to the provincial level, whereas city-level research mainly concentrates on assessing the impact of various environmental and energy conservation policies, with detailed investigations into urban green total factor energy efficiency being particularly rare. Consequently, determining whether the application of industrial robots can rejuvenate China’s green development and potentially elevate China’s green strategies to a new phase warrants further profound investigation.

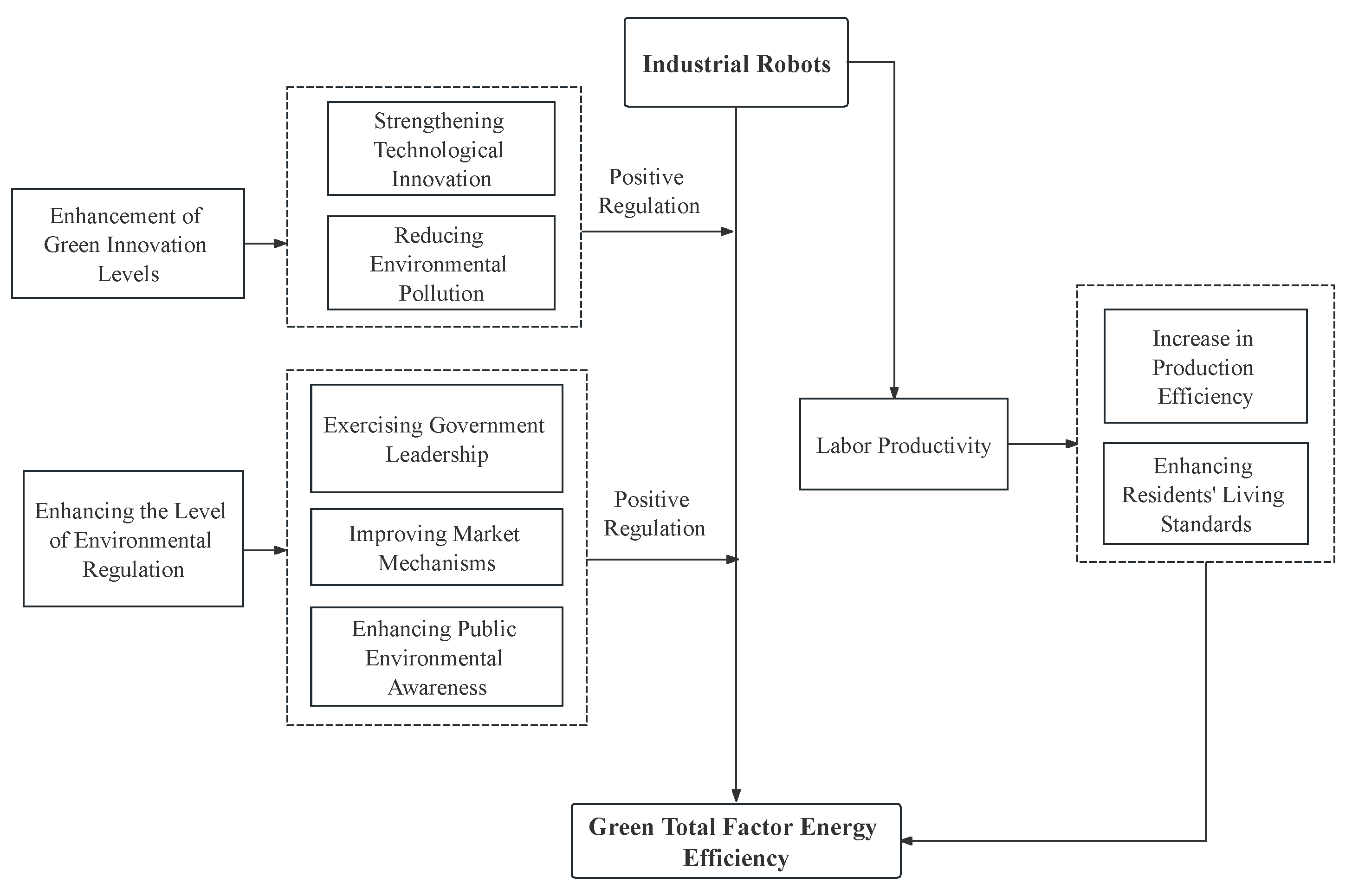

Thus, in the context of rapid advancements in Industry 4.0 and artificial intelligence technologies, examining the role of industrial robots in enhancing energy efficiency and scientifically formulating policies to reduce energy intensity is not only an essential requirement for achieving global economic and environmental sustainability goals but also a critical necessity to address the conflict between substantial industrial energy consumption and green sustainable development. This study focuses on the impact of industrial robots on green total factor energy efficiency, thereby pioneering a new field in robotics research that demonstrates how such technology can advance sustainable development goals. By analyzing the penetration of industrial robots and their specific effects on green energy efficiency from the perspective of prefecture-level cities, this paper not only reveals the intrinsic links between robotics technology and environmental efficiency but also examines how this technology elicits differentiated policy responses across various regions and types of cities. Furthermore, this research provides new evidence on how factors such as labor productivity, green innovation, and environmental regulation act as mediating and moderating variables in this relationship, thus offering theoretical and practical guidance for the formulation of more precise and effective environmental policies. The findings not only enhance our understanding of the role of robotics technology in boosting green productivity but also lay the groundwork for further exploration of its applications in other sustainable domains.

The remaining structure of this paper is outlined as follows:

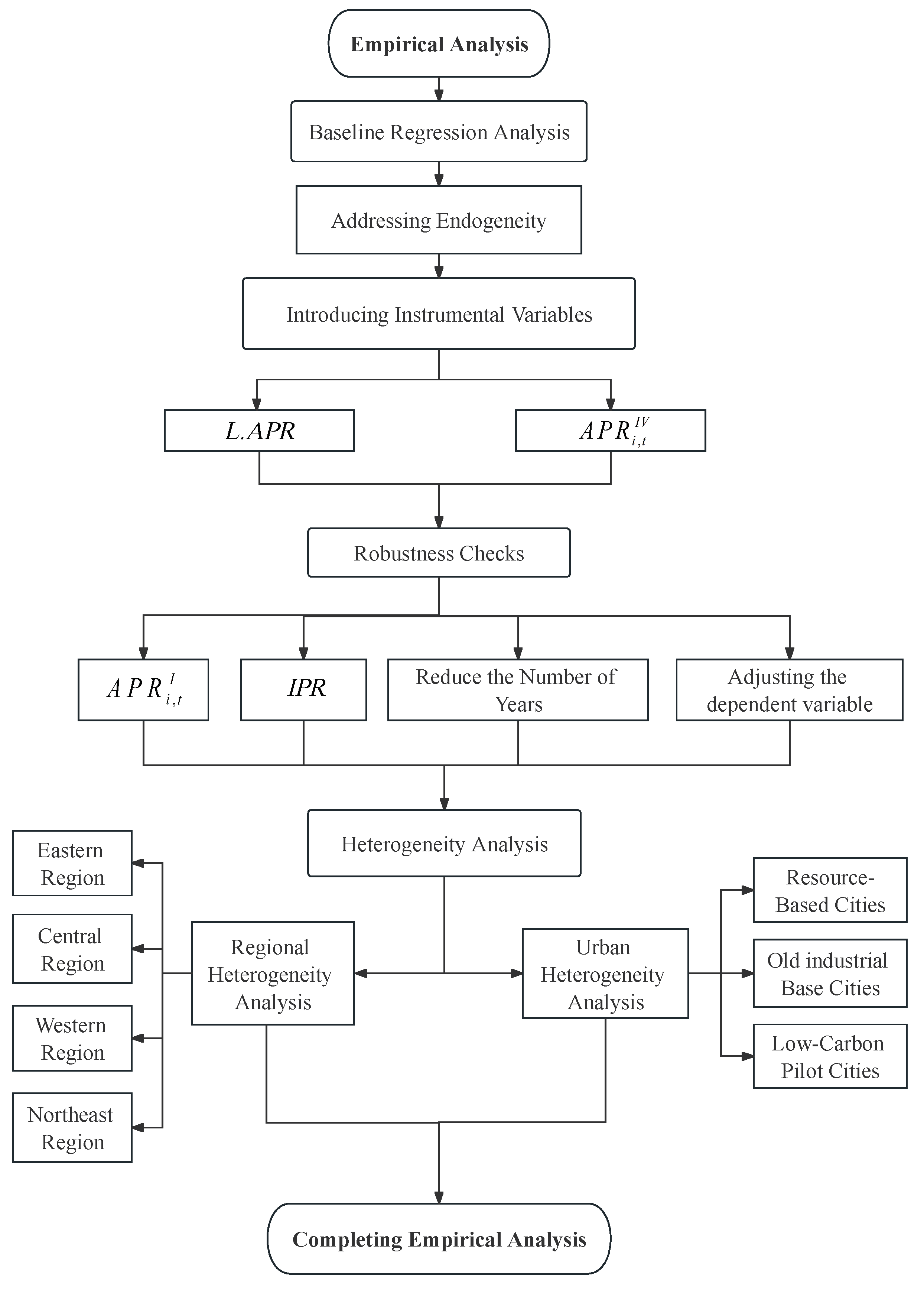

Section 2 reviews relevant literature concerning the national policy background of industrial robots and green total factor energy efficiency, clearly defines the research route and innovative aspects of the study.

Section 3 explores the potential impact mechanisms of industrial robots on green total factor energy efficiency, proposing foundational research hypotheses.

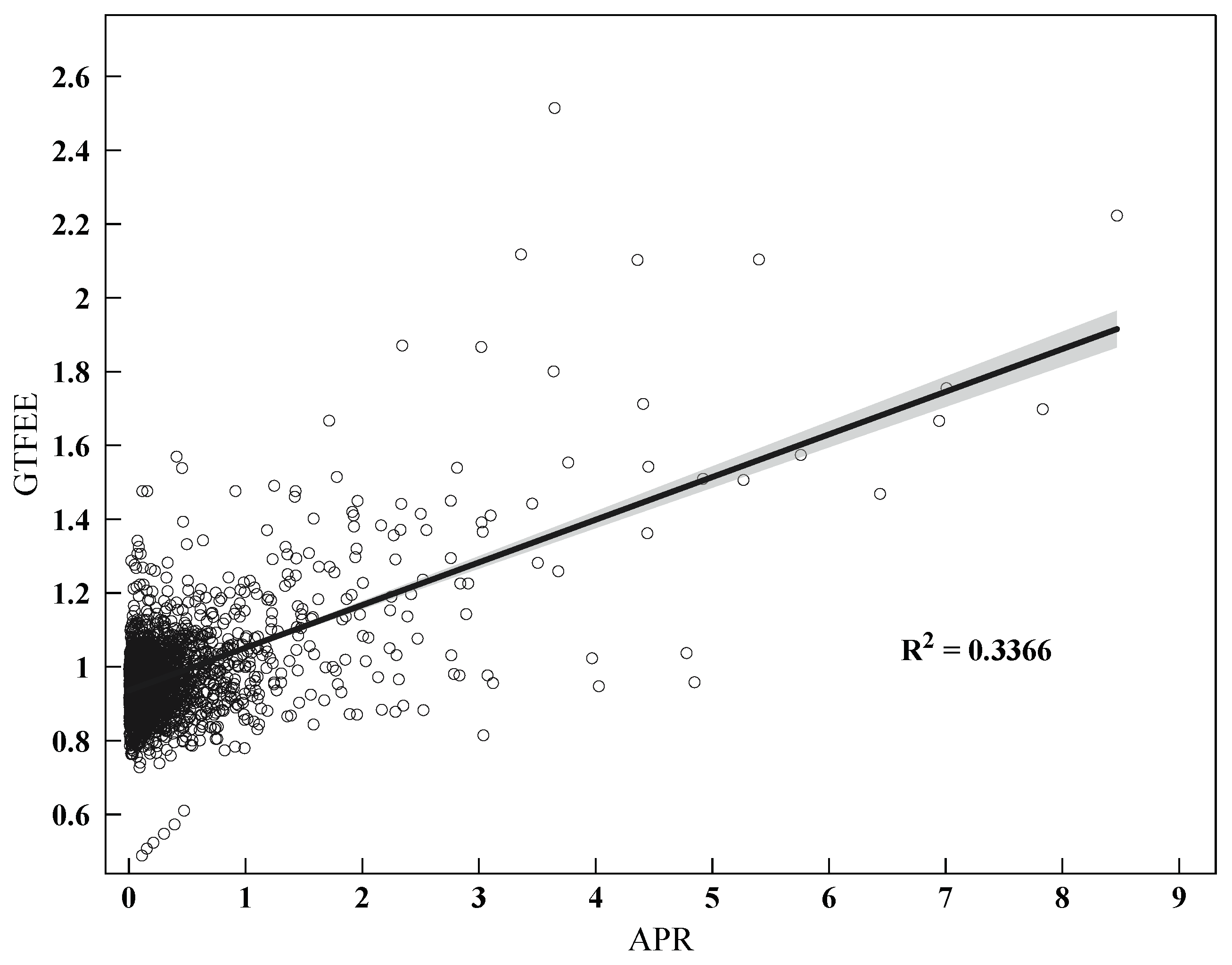

Section 4 constructs a baseline regression model, clarifying variable selection and measurement methods, and introduces data sources and processing. This Section previews the relationships between variables through descriptive statistics and scatter plots, laying the groundwork for subsequent empirical analysis.

Section 5 examines the effects of industrial robots on green total factor energy efficiency through baseline regression analysis, endogeneity analysis, robustness tests, and heterogeneity analysis, validating the theoretical discussions and research hypotheses presented in

Section 3.

Section 6 analyzes how industrial robots influence green total factor energy efficiency through mediation effects and moderation effects involving labor productivity, green innovation, and environmental regulatory standards.

Section 7 presents the main conclusions and policy recommendations of this paper, while also highlighting potential issues and shortcomings.

2. Literature Review

The measurement of energy efficiency can be categorized into single-factor energy efficiency, total factor energy efficiency (TFEE), and green total factor energy efficiency (GTFEE). Single-factor energy efficiency considers only one input factor, typically measured by energy productivity or energy intensity, as noted in sources [

2,

3]. However, as this approach neglects the input of other production factors such as labor and capital, it fails to comprehensively assess their impact on output, potentially leading to less accurate efficiency evaluations. Hu and Wang [

4] incorporated multiple input factors including capital, labor, and energy into their model, defining the resulting measure as TFEE, which assesses the ratio of actual energy input to optimal energy input. A ratio close to one indicates that the actual energy input is nearly optimal.

Building on the foundation of TFEE, Yang [

5] has further integrated resource and environmental constraints into the assessment framework for economic development quality, thus deriving the metric of GTFEE. In calculating GTFEE, most scholars predominantly employ the Data Envelopment Analysis (DEA) method, coupled with the Malmquist–Luenberger (ML) index, which decomposes the efficiency into components of technological progress and efficiency improvements. Park and Kim [

6] used energy data from South Korea from 1993 to 2000 to measure energy efficiency through a hybrid model combining DEA and Artificial Neural Networks (ANNs). Huang and Wang [

7] utilized a three-stage SBM model to measure TFEE across various regions in China, revealing generally low energy efficiency with a ”U-shaped” developmental trend and significant regional imbalances. Tao et al. [

8], using historical data from China’s industrial sectors between 2004 and 2015, employed the SBM model and ML productivity index to measure green TFEE from an industry perspective.

Related closely to this paper is another area of research focusing on the penetration of industrial robots and their impact on the labor market. The International Federation of Robotics defines robots as multipurpose manipulative devices capable of automatic control, reprogramming, and performing multiple tasks. Current research on industrial robots primarily concentrates on how they influence the labor supply, enhance total factor productivity, drive economic growth, improve employment structure, and narrow gender wage gaps [

9,

10,

11,

12,

13]. Acemoglu and Restrepo [

9] found that the application of industrial robots reduces the labor force, specifically indicating that for every additional robot per thousand workers, unemployment could rise by 0.2% and wages might decrease by 0.42%. The application of industrial robots not only relieves traditional labor constraints on corporate production factors but also improves the neoclassical economic growth model through the application of intelligent technology, promoting balanced economic development. However, Ballestar et al. [

14] found that the introduction of industrial robots did not negatively impact employment; between 2008 and 2015, small and medium-sized manufacturing enterprises in Spain actually created more job opportunities after adopting industrial robots.

As a result of technological innovation, robots not only demonstrate technological progress but also embody the characteristics of capital, showing clear technological bias with varying degrees of substitutability for different types of workers. The impact of industrial robot technology on the labor income ratio essentially reflects the elasticity of substitution between capital and total labor [

15,

16]. Specifically, for workers with vocational or undergraduate degrees, the substitutive effect of industrial robots is stronger; for those with graduate degrees or higher, the impact is nearly negligible; and for those with high school or lower educational levels, the application of robots significantly propels them forward. Wang and Dong [

17] analyzed data from Chinese industrial enterprises to study the impact of industrial robots on China’s labor market, revealing significant effects on labor demand across different skill levels, characterized by “employment polarization”. This phenomenon is marked by increased demand for high-skilled and low-skilled workers, while the demand for medium-skilled workers decreases.

Moreover, the impact of industrial robots on employment largely depends on the quality of human capital. Song and Zuo [

18] explored the relationship between changes in labor supply and the introduction of industrial robots, concluding that when the labor supply is insufficient, societal progress and the pursuit of higher living standards will drive industrial enterprises to continually foster technological innovation. Yang and Hou [

13] incorporated robot pricing behavior and scale effects into the task-based model, theoretically dissecting how industrial robots can not only directly influence economic growth but also affect it through total factor productivity, further substantiating their positive impact on economic growth through empirical analysis. Xu et al. [

19] examined the effects of industrial robot application on the gender wage gap, finding that the deployment of industrial robots significantly raised wage levels in China and notably narrowed the gender wage gap.

In this context, some scholars have also investigated the energy consumption of industrial robots. Brossog et al. [

20] discovered that industrial robots can enhance the productivity of manufacturing enterprises, save production and operational costs, and ultimately reduce energy consumption, fostering green sustainable development. Li et al. [

21] proposed that industrial robots help reduce greenhouse gas emissions by lowering energy consumption. Huang and Jiang [

22] constructed a theoretical model including industrial robots and energy inputs, finding that industrial robots could facilitate urban industrial carbon emission reductions. Zhang and Yan [

23] indicated that while the large-scale adoption of industrial robots can increase enterprise productivity, it might also elevate energy consumption, thereby exacerbating the environmental burden. Wang et al. [

24] further explained from the perspectives of population mobility and energy rebound effects that the application of industrial robots has a certain inhibitory effect on regional carbon emissions. Therefore, the impact of industrial robots on energy efficiency remains inconclusive and warrants further analysis and verification.

The marginal contributions of this paper are as follows: First, from the perspective of the research angle, the existing literature primarily focuses on the impact of industrial robots on the labor market, with insufficient exploration of their role in environmental and energy aspects. This paper aims to investigate the influence of industrial robots on green total factor energy efficiency, providing a new perspective and direction for this emerging research field. Second, regarding the research subjects, this paper employs a more granular analytical approach by assessing green total factor energy efficiency and the penetration of industrial robots at the prefecture-city level. It further explores the causal relationships between these variables to discern variations in policy responses across diverse regions and urban classifications. Third, for the empirical analysis, this paper emphasizes the intrinsic relationship between robot application and green total factor energy efficiency and verifies these relationships through robustness tests and analysis of endogeneity issues. Furthermore, addressing the gaps in channel analysis and mechanism exploration found in existing research, this paper selects labor productivity as a mediating variable and uses the level of green innovation and environmental regulatory standards as moderating variables, thus more precisely analyzing the effects of mediating and moderating mechanisms.

7. Conclusions, Policy Implications, and Limitations

7.1. Conclusions

This paper employs empirical analysis methods, utilizing data from prefecture-level and above cities from 2010 to 2019, to thoroughly examine the impact of industrial robot applications on urban green total factor energy efficiency. The research findings underscore the crucial role that industrial robots play in enhancing green total factor energy efficiency. Robots directly promote the efficient use of energy and environmental protection by optimizing production processes and reducing energy consumption. Additionally, industrial robots also indirectly affect urban green total factor energy efficiency by enhancing regional labor productivity. With the gradual increase in the application of industrial robots, both urban labor productivity and green total factor energy efficiency have seen significant improvements. Moreover, the continuous enhancement of urban green innovation levels and environmental regulation also further strengthens the positive impact of industrial robots on green total factor energy efficiency, promoting the sustainable use of energy.

Furthermore, through regional heterogeneity analysis, this paper also finds that the impact of industrial robots on enhancing green total factor energy efficiency is most significant in the Northeast region. This is primarily due to the Northeast region’s lead in the application and technical support of industrial robots compared to other regions. Specifically, in resource-based cities, industrial base cities, and low-carbon pilot cities, the impact of industrial robots on green total factor energy efficiency is more pronounced. This finding highlights the differentiated needs and potential of different types of cities in advancing the application of industrial robots and enhancing energy efficiency.

7.2. Policy Implications

Based on the findings, the application of industrial robots can drive improvements in green total factor energy efficiency, indicating that promoting the deployment of industrial robots nationwide to achieve green development is feasible. To further tap into the potential of industrial robots in fostering green development, this study offers three following recommendations.

7.2.1. Enhance Investment in Technology R&D and Talent Development

First, investments should be bolstered in domestic robotics research and development, and through homegrown innovation, decrease reliance on foreign operating systems and chips, which will significantly reduce the production and operational costs of domestic industrial robots. Second, businesses should continually refine their employment structures, hire a substantial number of professional technical talents in the field of robotics, and boost investment in internal talent training to expand employees’ expertise and skills in robot operation, maintenance, and energy management, thereby ensuring effective utilization of robot technology. Finally, sustainable urban development can be realized through a dual strategy of equipment upgrading and talent development, expediting the application and widespread adoption of artificial intelligence and emerging industry technologies.

7.2.2. Adopt Differentiated Environmental Policies

It is recommended that different environmental policies be adopted according to regional characteristics. For central and western regions, it is advised to accelerate the phasing out of high-energy-consuming and technologically outdated industries and continue to promote the development of the urban industrial internet. Additionally, the government should provide comprehensive support for enterprises in funding, technology, and talent training to adopt robotic manufacturing, enabling non-resource-based cities, non-industrial base cities, and non-low-carbon pilot cities to promote intelligent transformation in industry and other sectors through knowledge and technology, thus enhancing the potential of industrial robots in energy conservation and emission reduction.

7.2.3. Boost Urban Green Innovation and Environmental Regulation

Cities are encouraged to adopt green technologies to replace traditional technologies and attract more talented individuals to the green innovation sector. This is crucial for enhancing a city’s green innovation capabilities. Furthermore, perfecting the environmental regulatory policy framework is a key component in enhancing urban green total factor energy efficiency. Government agencies need to continuously leverage advanced technological means to strengthen the enforcement of environmental regulations; they should also guide the public and the media to monitor and evaluate the implementation and effects of environmental policies, thereby forming an effective external supervision and constraint mechanism. For major environmental protection projects, the government should disclose information and regularly hold public hearings to fully listen to and integrate public opinions and suggestions, thereby improving regulatory transparency and public participation, and continuously promoting sustainable urban development.

7.3. Limitations

We have explored the enhancement of GTFEE through the use of industrial robots, but there are still areas that need further investigation. First, we examined the impact of industrial robots on the GTFEE of cities from a macro perspective but did not delve into how these robots could reduce resource wastage and improve energy efficiency within regional trade activities. Second, we have not yet analyzed how micro-enterprises can improve their production processes and energy management by adopting industrial robots, thereby enhancing their green productivity. Consequently, future research could broaden the current study framework to more comprehensively investigate how industrial robots can enhance resource efficiency in trade activities and how technological innovations in micro-enterprises can promote environmental sustainability.