Numerical Study on Effect of Flue Gas Recirculation and Co-Firing with Biomass on Combustion Characteristics in Octagonal Tangentially Lignite-Fired Boiler

Abstract

1. Introduction

2. Model Description

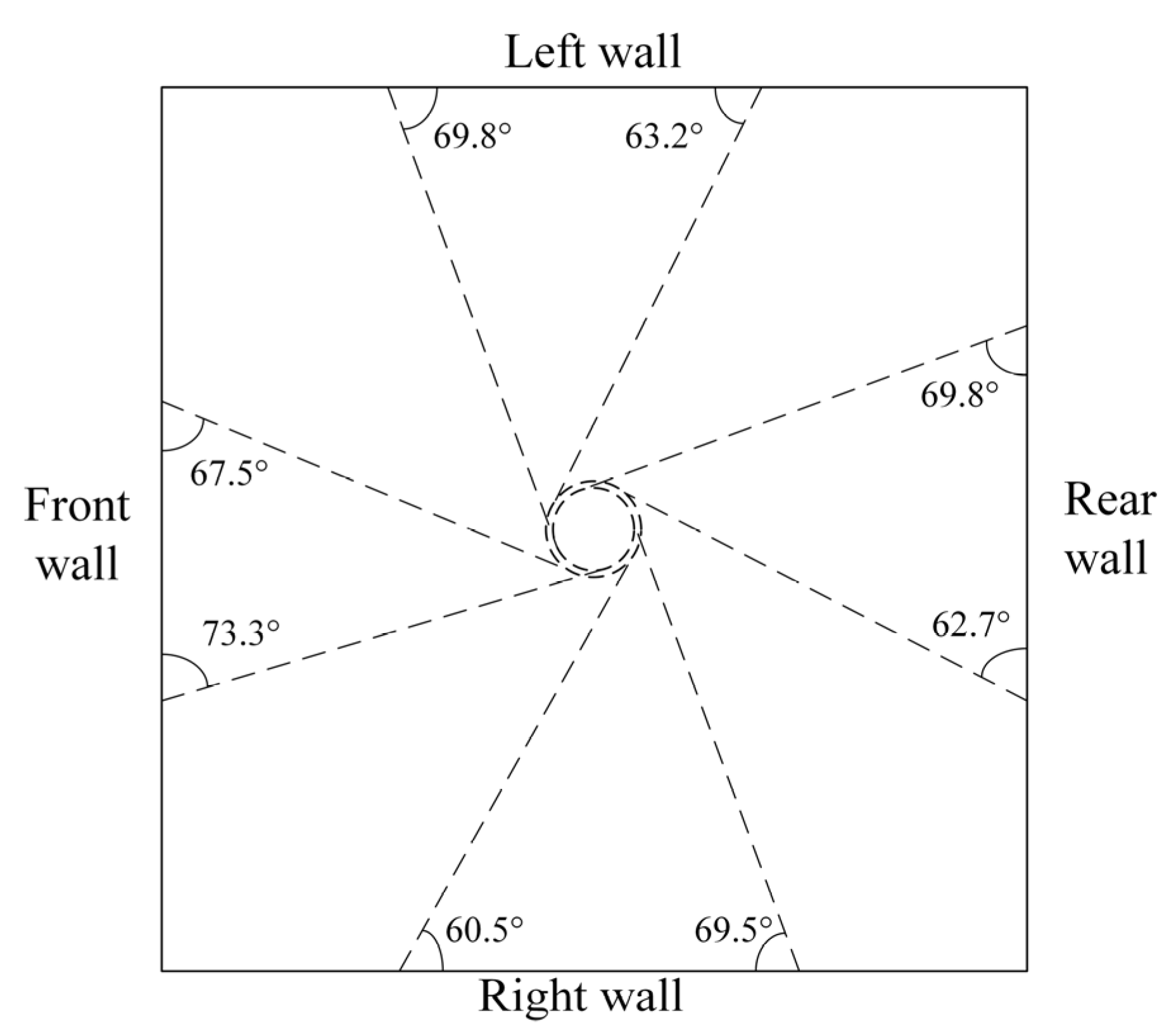

2.1. Physical Model

2.2. Numerical Model

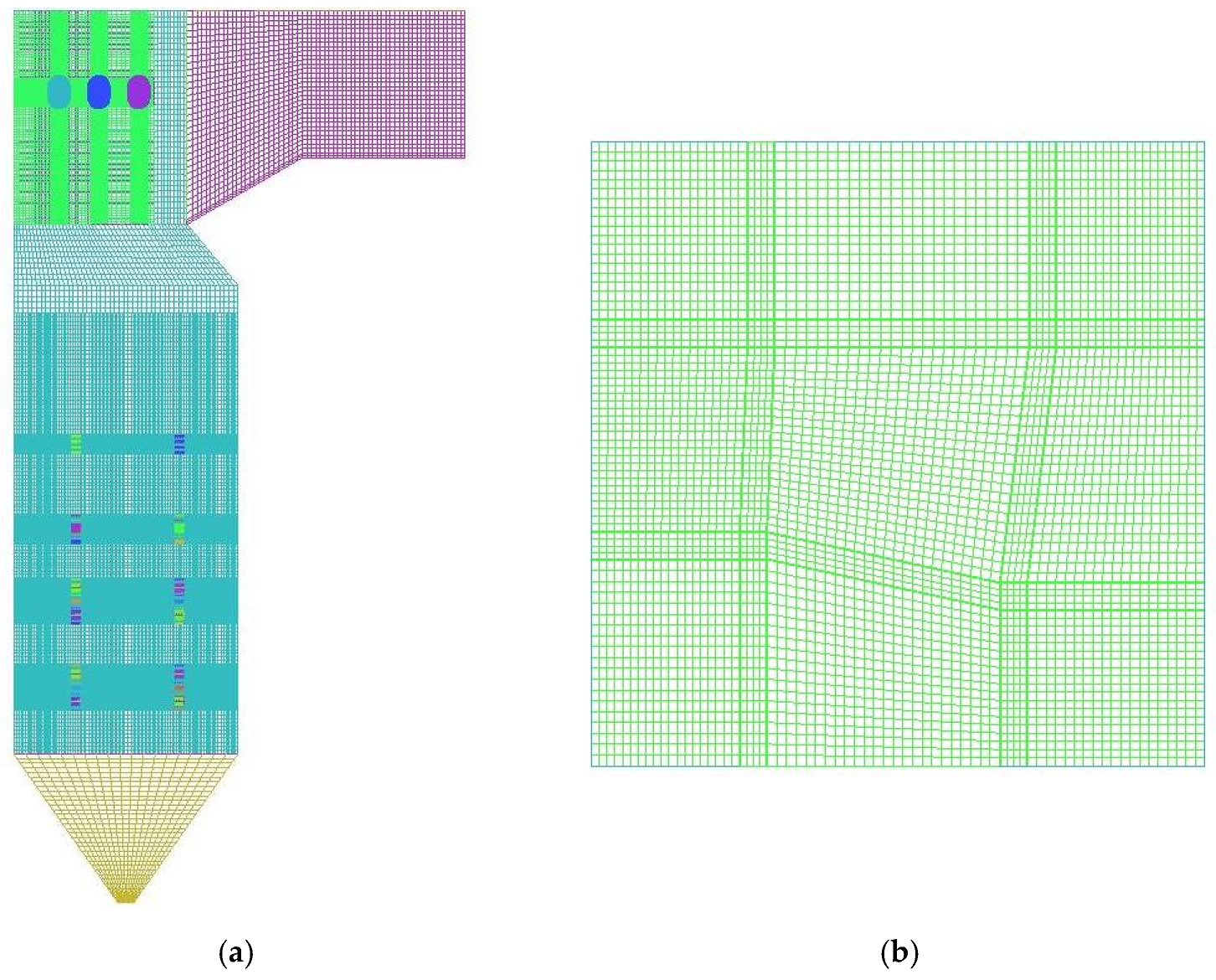

2.3. Mesh Generation

2.4. Boundary Conditions

2.5. Simulated Working Conditions

- When w changes, coal consumption and the amount of air remain constant [33].

- All the recirculating flue gas is extracted from the extraction openings and is then directed into the furnace through the primary air nozzles.

- The coal is heated into an air-drying-based state before entering the boiler. The primary air flow consists of flue gas, dry pulverized coal, and water vapor.

- When co-firing biomass, the blending ratio of each layer of burners is the same [34].

3. Results and Discussion

3.1. Model Validation

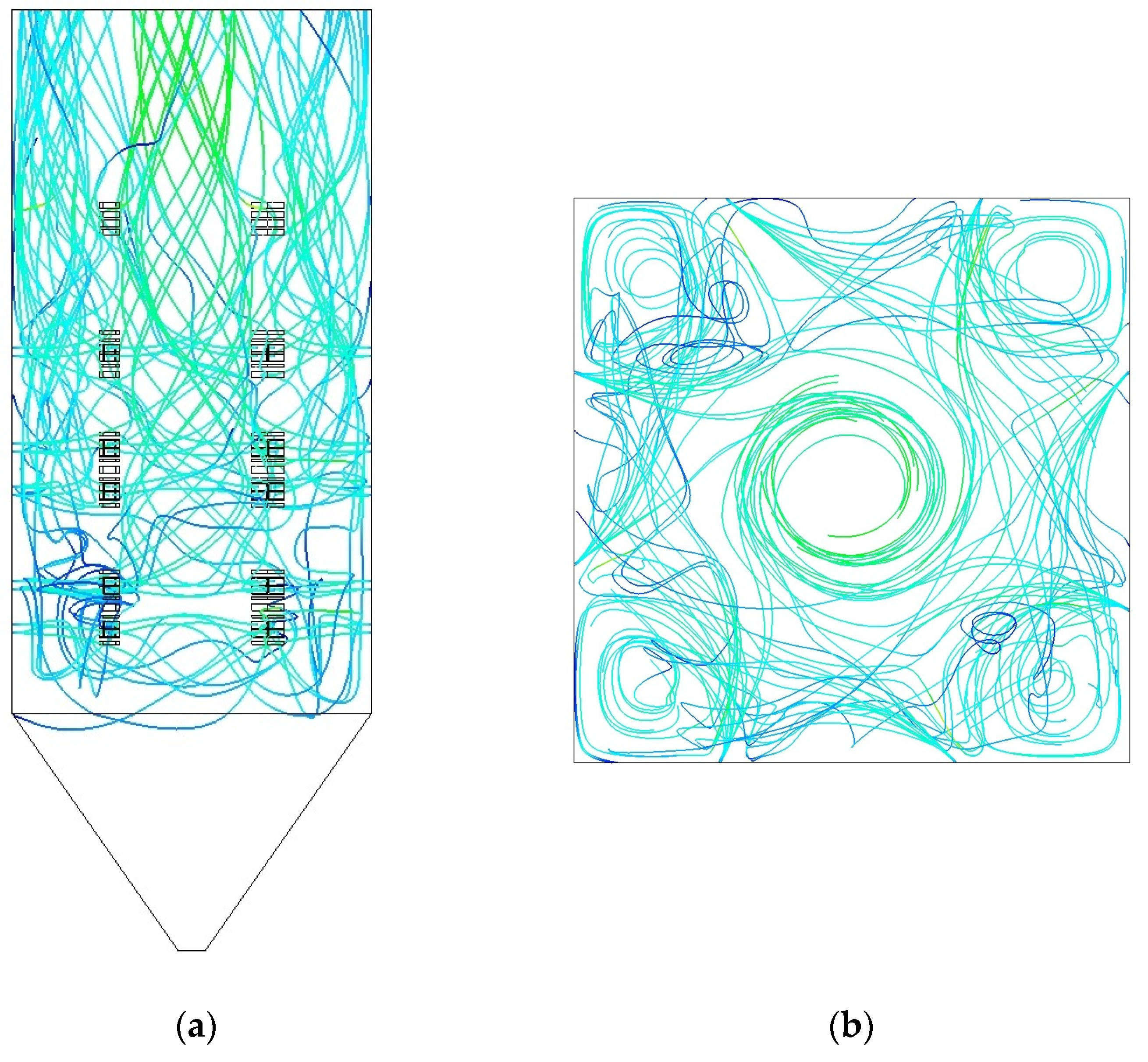

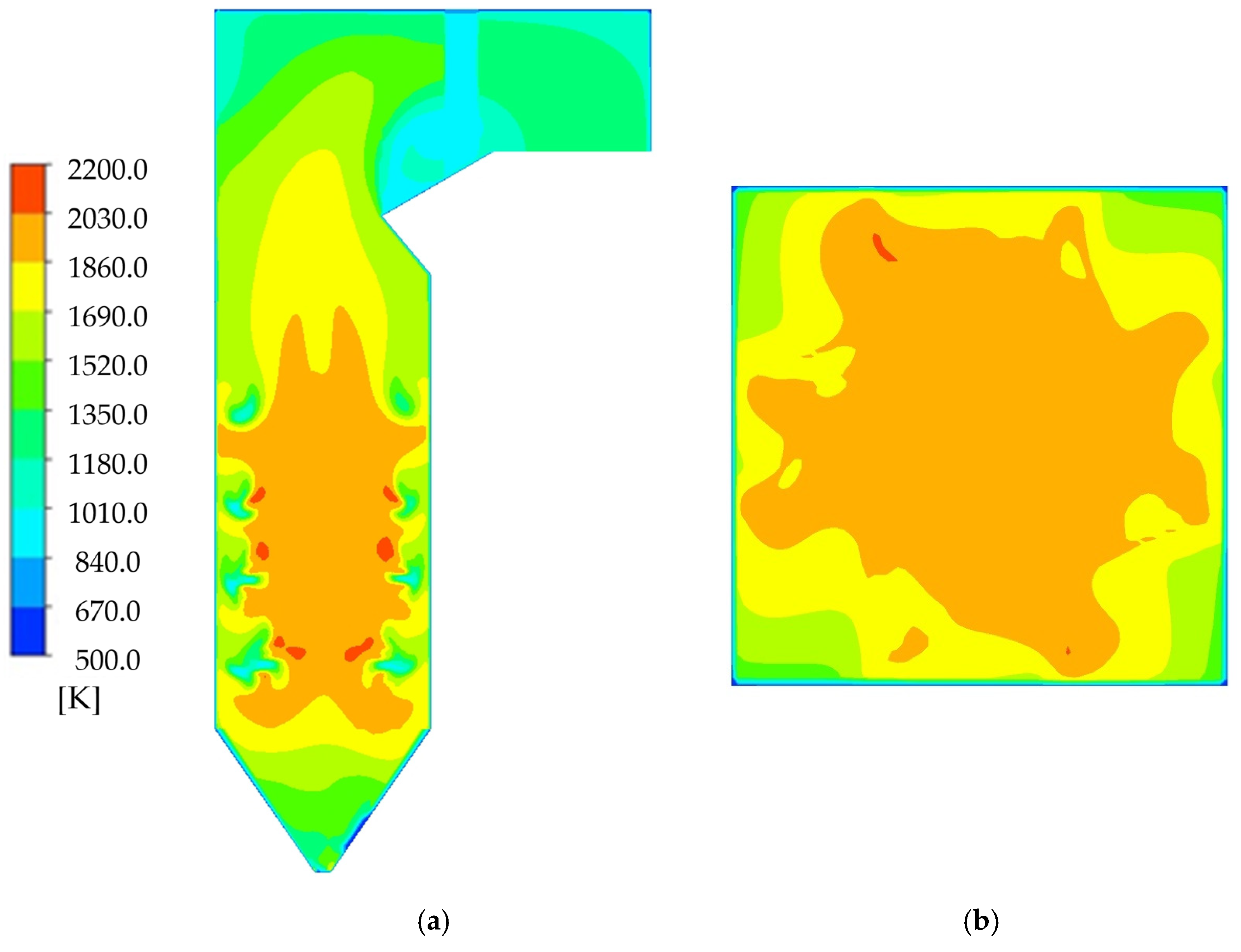

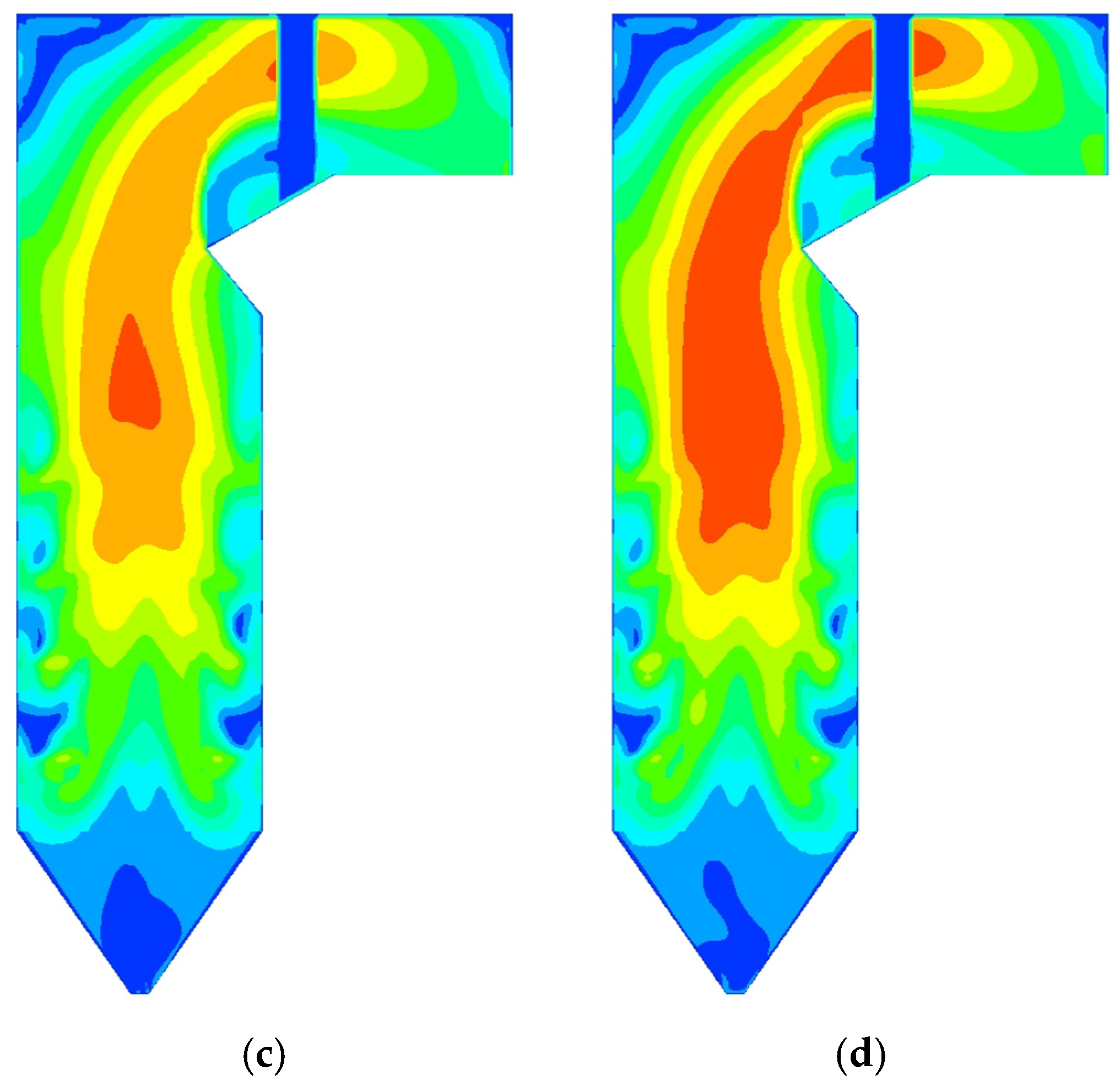

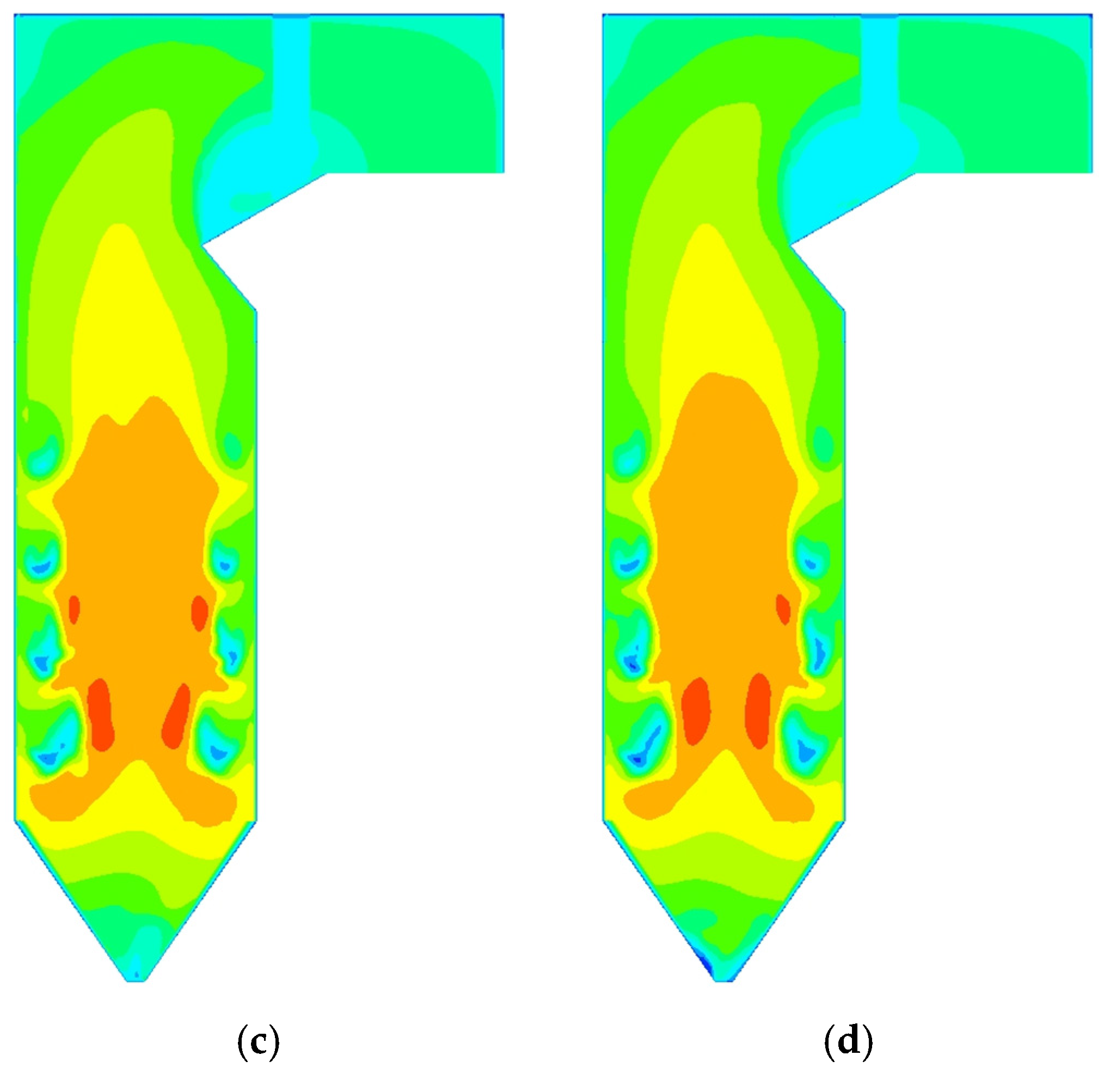

3.2. Heat and Mass Transfer without Flue Gas Recirculation and Co-Firing

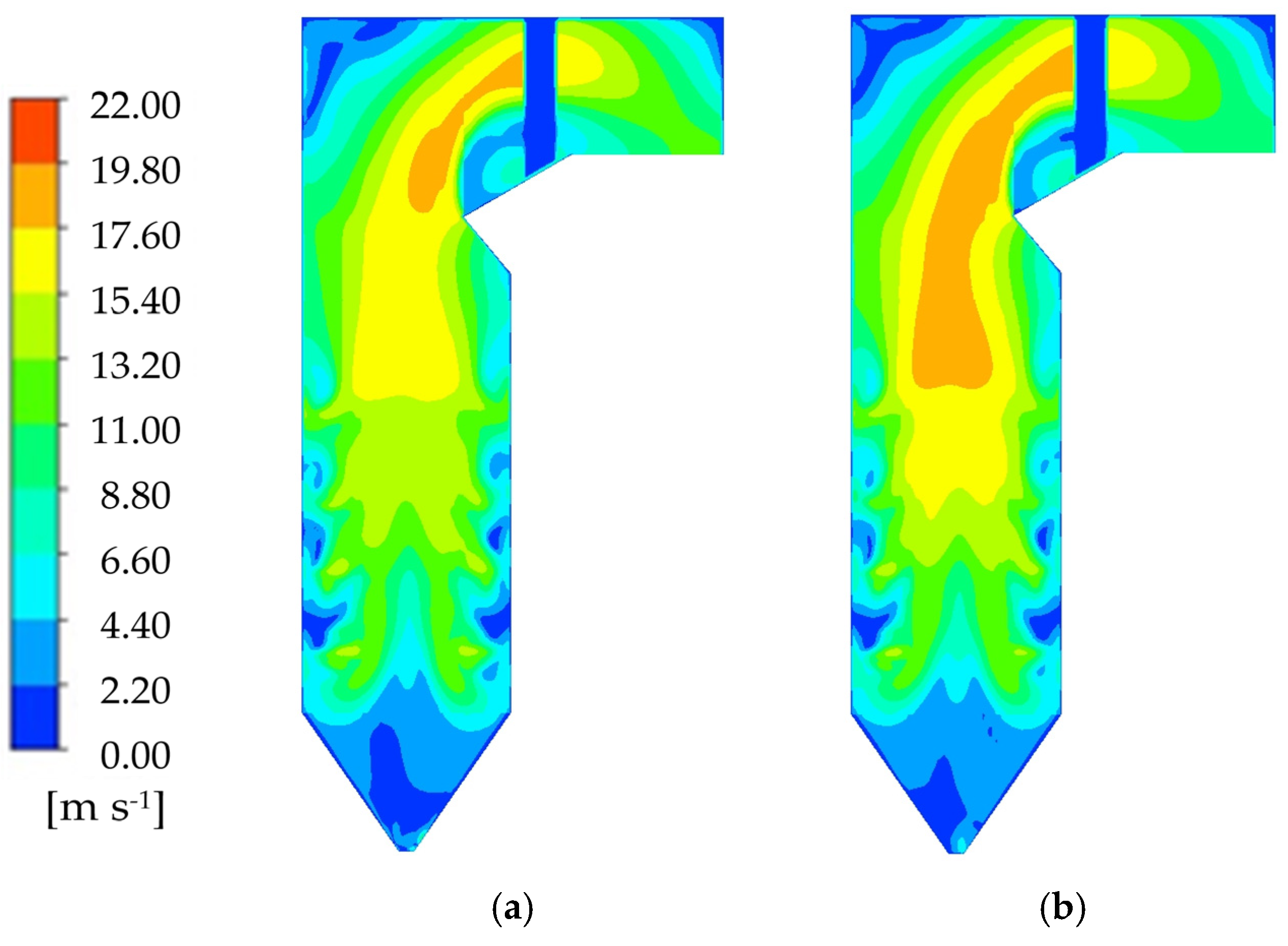

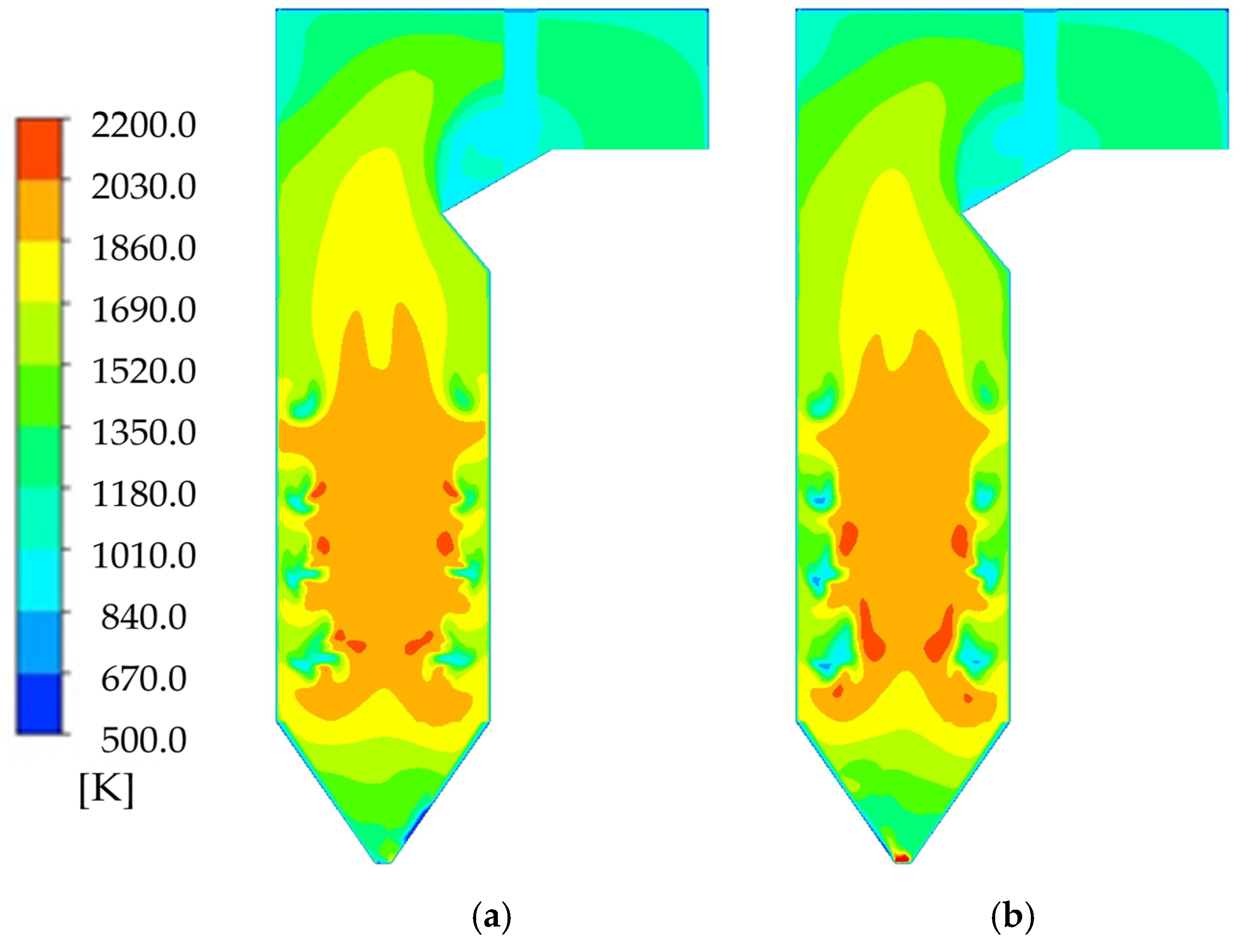

3.3. Effect of Flue Gas Recirculation Rate

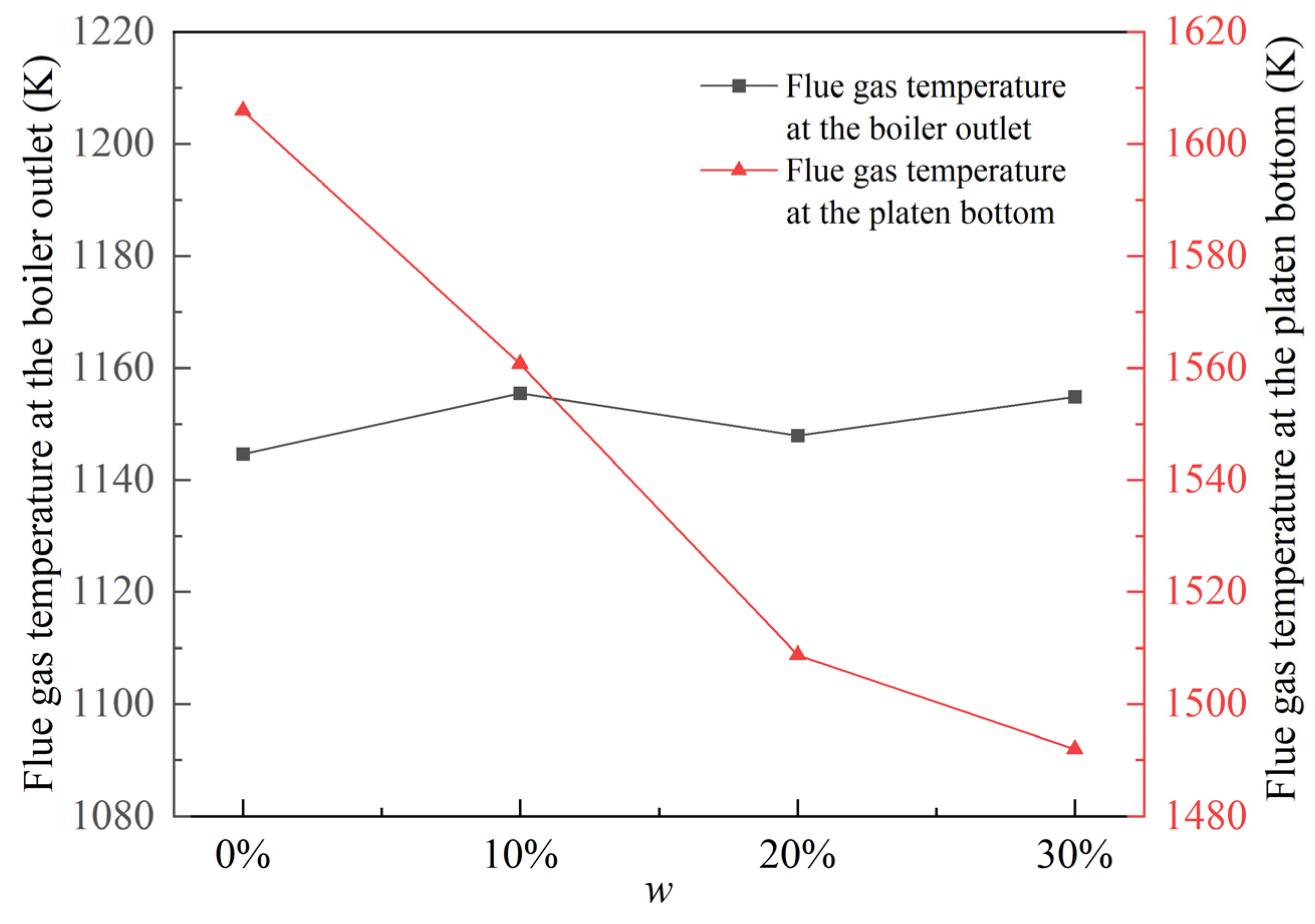

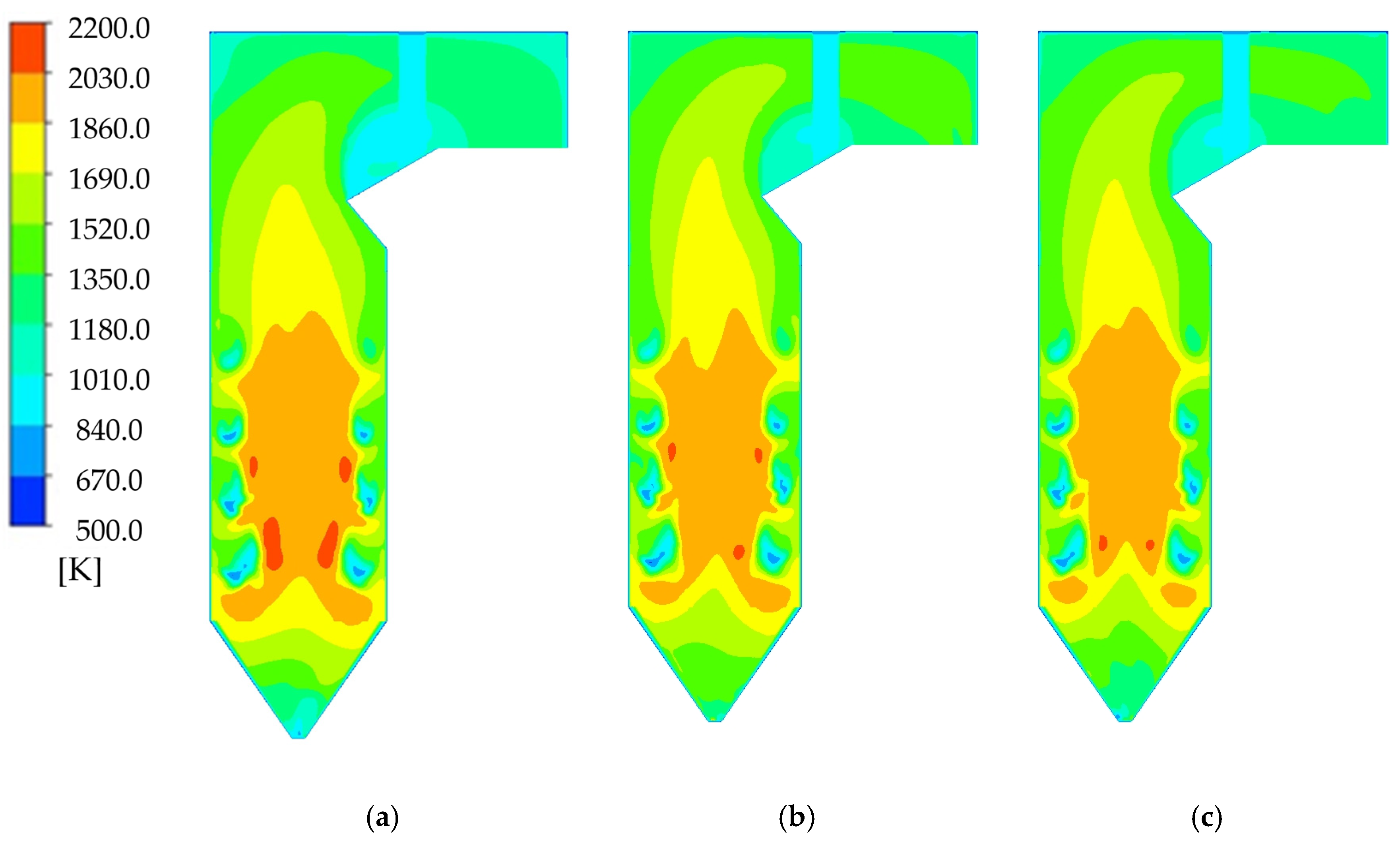

3.4. Effect of Biomass Blending Ratio

4. Conclusions

- The air flow from the eight rows of nozzles forms a wide range of tangential circles in the boiler. The flue gas temperature in the primary combustion zone increases with height. From the bottom burners to the top burners, the average temperature of the cross-section rises from 1595.5 to 1687.8 K. At the platen bottom, this temperature is 1605.9 K.

- Increasing the FGR rate does not significantly alter the flow field in the furnace, but it clearly results in a decrease in the temperature level. When the FGR rate increases from 0 to 30%, the maximum temperature in the furnace decreases by 56.3 K. Meanwhile, the average temperature of the center longitudinal section decreases by 57.1 K.

- When w increases from 0 to 30%, the maximum deviation of the outlet flue gas temperature in the four calculated working conditions is only 10.9 K. Therefore, the boiler efficiency remains basically unchanged. However, there is a significant decrease in the flue gas temperature at the platen bottom, dropping from 1605.9 to 1491.9 K. It is necessary to consider the heat absorption distribution of each heating surface.

- The temperature level of the furnace continuously decreases as the biomass blending ratio increases. When the biomass blending ratio increases from 0 to 20%, the average temperature in the main combustion zone decreases from 1600.5 to 1571.2 K. Concurrently, the temperature in the central area of the boiler also decreases.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hassan, A.; Ilyas, S.Z.; Jalil, A.; Ullah, Z. Monetization of the environmental damage caused by fossil fuels. Environ. Sci. Pollut. Res. 2021, 28, 21204–21211. [Google Scholar]

- Mason, L.R.; Melton, C.C.; Gray, D.; Swallow, A.L. Climate change, social work, and the transition away from fossil fuels: A scoping review. Sustainability 2022, 14, 7086. [Google Scholar]

- Brown, M.; Kearley, V. Role of wood waste as source of biomass fuel in the UK. Energy Mater. 2012, 4, 162–165. [Google Scholar]

- Guan, R.; Yuan, H.; Yuan, S.; Yan, B.; Zuo, X.; Chen, X.; Li, X. Current development and perspectives of anaerobic bioconversion of crop stalks to Biogas: A review. Bioresour. Technol. 2021, 349, 126615. [Google Scholar] [CrossRef] [PubMed]

- Yorifuji, R.; Obara, S.Y. Economic design of artificial light plant factories based on the energy conversion efficiency of biomass. Appl. Energy 2022, 305, 117850. [Google Scholar] [CrossRef]

- Pulles, T.; Gillenwater, M.; Radunsky, K. CO2 emissions from biomass combustion accounting of CO2 emissions from biomass under the UNFCCC. Carbon Manag. 2022, 13, 181–189. [Google Scholar]

- Zhang, C.; Nie, J.; Yan, X. Estimation of biomass utilization potential in China and the impact on carbon peaking. Environ. Sci. Pollut. Res. 2023, 30, 94255–94275. [Google Scholar] [CrossRef]

- Dong, K.; Zhang, H.; Tan, H.; Zhang, J.; Hu, Z.; Cheng, Z.; Zhou, Y.; Wang, X. Numerical simulation of biomass high-ratio co-firing in a pre-pyrolysis pulverized coal industrial boiler. J. China Coal Soc. 2023, 48, 1395–1402. [Google Scholar]

- Karampinis, E.; Grammelis, P.; Agraniotis, M.; Violidakis, I.; Kakaras, E. Co-firing of biomass with coal in thermal power plants: Technology schemes, impacts, and future perspectives. Wiley Interdiscip. Rev. Energy Environ. 2014, 3, 384–399. [Google Scholar]

- Król, K.; Nowak-Woźny, D.; Moroń, W. Study of ash sintering temperature and ash deposition behavior during co-firing of polish bituminous coal with barley straw using non-standard tests. Energies 2023, 16, 4424. [Google Scholar]

- Choi, M.; Li, X.; Kim, K.; Sung, Y.; Choi, G. Detailed in-furnace measurements in a pulverized coal-fired furnace with combined woody biomass co-firing and air staging. J. Mech. Sci. Technol. 2018, 32, 4517–4527. [Google Scholar] [CrossRef]

- Taehyun, K.; Won, Y. Influence of biomass co-firing on a domestic pulverized coal power plant in terms of CO2 abatement and economical feasibility. J. Korean Soc. Combust. 2017, 22, 14–22. [Google Scholar]

- Cutz, L.; Berndes, G.; Johnsson, F. A techno-economic assessment of biomass co-firing in Czech Republic, France, Germany and Poland. Biofuel. Bioprod. Bior. 2019, 13, 1289–1305. [Google Scholar]

- Sun, J.; Zhao, X.; Xue, D. Computational fluid dynamics modeling of biomass co-firing in a 300 MW pulverized coal furnace. Therm. Sci. 2022, 26, 4179–4191. [Google Scholar] [CrossRef]

- Che, D. Boilers-Theory, Design and Operation; Xi’an Jiaotong University Press: Xi’an, China, 2008. [Google Scholar]

- Kolovos, N.; Sotiropoulos, D.; Georgakopoulos, A. Contribution on lignite recovery from multi-seam deposits. Energy Sources 2005, 27, 975–986. [Google Scholar]

- BP, p.l.c. BP Statistical Review of World Energy; BP Press: London, UK, 2022. [Google Scholar]

- Hu, L.; Wang, G.; Wang, Q. Efficient drying and oxygen-containing functional groups characteristics of lignite during microwave irradiation process. Dry. Technol. 2018, 36, 1086–1097. [Google Scholar]

- Li, Y.L.; Chen, X.; Zhang, C.Q.; Li, X.F.; Liu, P.; Chen, W.X.; Ren, S.X.; Lei, T.Z. Preparation and structural analysis of humic acid by co-thermal oxidation of wheat straw and Heilongjiang lignite. J. Fuel Chem. Technol. 2023, 51, 145–154. [Google Scholar]

- Zhou, F.; Cheng, J.; Wang, A.; Liu, J.; Zhou, J.; Cen, K. Enhancing slurryabilities of five lignites from Inner Mongolia of China by microwave irradiation. Dry. Technol. 2018, 36, 100–108. [Google Scholar]

- Gurel, B.; Kurtulus, K.; Yurdakul, S.; Dolgun, G.K.; Akman, R.; Onur, M.E.; Varol, M.; Kecebas, A.; Gurbuz, H. Combustion of chicken manure and Turkish lignite mixtures in a circulating fluidized bed. Renew. Sustain. Energy Rev. 2024, 189, 113960. [Google Scholar] [CrossRef]

- Guerel, B.; Kurtulus, K.; Yurdakul, S.; Varol, M.; Kecebas, A.; Gurbuz, H. Numerical and experimental investigation of co-combustion of chicken manure and lignite blends in a CFBB with novel compact combustion chamber. Energy 2023, 285, 129482. [Google Scholar]

- Markovic, J.Z.B.Z.; Marinkovic, A.D.; Savic, J.Z.; Mladenovic, M.R.; Eric, M.D.; Markovic, Z.J.; Ristic, M.D. Risk Evaluation of Pollutants Emission from Coal and Coal Waste Combustion Plants and Environmental Impact of Fly Ash Landfilling. Toxics 2023, 11, 396. [Google Scholar] [CrossRef] [PubMed]

- Chai, W.; Wang, W.; Huang, Y.; Han, G.; Cao, Y.; Liu, J. Further exploring on aqueous chemistry of micron-sized lignite particles in lignite–water slurry: Effects of humics adsorption. Fuel Process. Technol. 2018, 176, 190–196. [Google Scholar] [CrossRef]

- Gu, S.; Xu, Z.; Ren, Y.; Chai, Z.; Zhang, Y. Effect of lignite semi-coke on lignite microwave upgrade and its slurry ability. Energ. Source Part A 2023, 45, 6442–6455. [Google Scholar] [CrossRef]

- Hou, X.; Duan, H.; He, R.; Zhou, H.; Ban, Y.; Li, N.; Zhi, K.; Song, Y.; Liu, Q. Effect of ionic liquids on the microstructure and combustion performance of Shengli lignite. RSC Adv. 2023, 13, 23669–23681. [Google Scholar] [CrossRef] [PubMed]

- Zhang, T.; Lou, C.; Teng, D.; Li, G.; Li, P.; Yun, Q.; Zhou, G. Hot-air drying behavior of lignite and quantitative characterization for its surface damage. Dry. Technol. 2023, 41, 2171–2188. [Google Scholar]

- Nikolopoulos, N.; Agraniotis, M.; Violidakis, I.; Karampinis, E.; Nikolopoulos, A.; Grammelis, P.; Papapavlou, C.; Tzivenis, S.; Kakaras, E. Parametric investigation of a renewable alternative for utilities adopting the co-firing lignite/biomass concept. Fuel 2013, 113, 873–897. [Google Scholar]

- Milicevic, A.; Belosevic, S.; Crnomarkovic, N.; Tomanovic, I.; Stojanovic, A.; Tucakovic, D.; Deng, L.; Che, D. Numerical study of co-firing lignite and agricultural biomass in utility boiler under variable operation conditions. Int. J. Heat Mass Transf. 2021, 181, 121728. [Google Scholar] [CrossRef]

- Adamczyk, W.P. Application of the numerical techniques for modelling fluidization process within industrial scale boilers. Arch. Comput. Methods Eng. 2017, 24, 669–702. [Google Scholar]

- Echi, S.; Bouabidi, A.; Driss, Z.; Abid, M.S. CFD simulation and optimization of industrial boiler. Energy 2019, 169, 105–114. [Google Scholar]

- Zhu, M.; Lu, H.; Zhao, W.; Huang, S.; Chang, X.; Dong, L.; Kong, D.; Jing, X. A numerical study of ash deposition characteristics in a 660mw supercritical tangential boiler. Adv. Theory Simul. 2023, 6, 2300133. [Google Scholar]

- Cheng, S.; Kuang, M.; Liu, S.; Qi, S. Lowering further NOx emissions and improving the hopper’s overheating environment in a low-NOx down-fired furnace by a staged arch-firing framework with a primary-burner flue gas recirculation. Case Stud. Therm. Eng. 2023, 51, 103546. [Google Scholar]

- Jiang, Y.; Park, K.-H.; Jeon, C.-H. Feasibility study of co-firing of torrefied empty fruit bunch and coal through boiler simulation. Energies 2020, 13, 3051. [Google Scholar]

- Zhou, Y.; Xu, T.; Hui, S.; Zhang, M. Experimental and numerical study on the flow fields in upper furnace for large scale tangentially fired boilers. Appl. Therm. Eng. 2009, 29, 732–739. [Google Scholar]

- Drosatos, P.; Nikolopoulos, N.; Agraniotis, M.; Kakaras, E. Numerical investigation of firing concepts for a flexible Greek lignite-fired power plant. Fuel Process. Technol. 2016, 142, 370–395. [Google Scholar] [CrossRef]

- Deng, L.; Dong, L.; Bai, Y.; Wu, Y.; Liu, H.; Belošević, S.; Tomanović, I.; Che, D. Effects of flue gas recirculation on combustion and heat flux distribution in 660 MW double-reheat tower-type boiler. Fuel 2022, 321, 123988. [Google Scholar]

- Ishihara, S.; Zhang, J.; Ito, T. Numerical calculation with detailed chemistry of effect of ammonia co-firing on NO emissions in a coal-fired boiler. Fuel 2020, 266, 116924. [Google Scholar]

- Gu, M.; Yuan, J.; Wang, M.; Wang, J.; Huang, X.; Chu, H. Effects of flue gas recirculation on nitrogen oxide formation in 1000 MW S-CO2 coal-fired boiler with partial expansion furnace. Int. J. Chem. React. Eng. 2022, 20, 929–945. [Google Scholar] [CrossRef]

- Zhu, Y.; Wang, C.; Chen, X. Combustion characteristic study with a flue gas internal and external double recirculation burner. Chem. Eng. Process. 2021, 162, 108345. [Google Scholar]

| Outlet Flow of Superheater (t h−1) | Superheated SteamTemperature (K) | Superheated Steam Pressure (MPa) | Feed Water Temperature (K) | Exhaust Gas Temperature (K) | Outlet Excess Air Ratio | Boiler Thermal Efficiency (%) |

|---|---|---|---|---|---|---|

| 1808.0 | 844.0 | 28.45 | 554.0 | 608.0 | 1.2 | 91.35 |

| Fuel | Proximate Analysis (%) | Elemental Analysis (%) | Qnet,ar (MJ kg−1) | |||||

|---|---|---|---|---|---|---|---|---|

| war (A) | war (M) | war (C) | war (H) | war (O) | war (N) | war (S) | ||

| Lignite | 19.46 | 50.00 | 28.85 | 2.19 | 7.87 | 0.3 | 0.24 | 10.26 |

| Corn straw | 10.60 | 7.00 | 44.63 | 7.57 | 28.76 | 0.75 | 0.16 | 17.51 |

| Region | Water-Cooled Wall | Division Platen Superheater | Rear Platen Superheater | Finishing Reheater | Finishing Superheater |

|---|---|---|---|---|---|

| Temperature (K) | 554 | 749 | 794 | 842 | 844 |

| Case Number | Flue Gas Recirculation Rate (%) | Flue Gas (t h−1) | Secondary Air (t h−1) | SOFA (t h−1) | Coal Consumption (t h−1) | Biomass Consumption (t h−1) |

|---|---|---|---|---|---|---|

| 1 | 0 | 0 | 1854.3 | 618.1 | 529.1 | 0 |

| 2 | 10 | 300.2 | 1854.3 | 618.1 | 529.1 | 0 |

| 3 | 20 | 600.3 | 1854.3 | 618.1 | 529.1 | 0 |

| 4 | 30 | 900.5 | 1854.3 | 618.1 | 529.1 | 0 |

| 5 | 20 | 587.1 | 1821.2 | 607.1 | 476.2 | 31.0 |

| 6 | 20 | 573.5 | 1786.7 | 595.6 | 423.3 | 62.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, J.; Yang, J.; Zhao, Y.; Guo, Q.; Da, Y.; Che, D. Numerical Study on Effect of Flue Gas Recirculation and Co-Firing with Biomass on Combustion Characteristics in Octagonal Tangentially Lignite-Fired Boiler. Energies 2024, 17, 475. https://doi.org/10.3390/en17020475

Du J, Yang J, Zhao Y, Guo Q, Da Y, Che D. Numerical Study on Effect of Flue Gas Recirculation and Co-Firing with Biomass on Combustion Characteristics in Octagonal Tangentially Lignite-Fired Boiler. Energies. 2024; 17(2):475. https://doi.org/10.3390/en17020475

Chicago/Turabian StyleDu, Jiajun, Jiahui Yang, Yonggang Zhao, Qianxin Guo, Yaodong Da, and Defu Che. 2024. "Numerical Study on Effect of Flue Gas Recirculation and Co-Firing with Biomass on Combustion Characteristics in Octagonal Tangentially Lignite-Fired Boiler" Energies 17, no. 2: 475. https://doi.org/10.3390/en17020475

APA StyleDu, J., Yang, J., Zhao, Y., Guo, Q., Da, Y., & Che, D. (2024). Numerical Study on Effect of Flue Gas Recirculation and Co-Firing with Biomass on Combustion Characteristics in Octagonal Tangentially Lignite-Fired Boiler. Energies, 17(2), 475. https://doi.org/10.3390/en17020475