Analysis of the Sand Erosion Effect and Wear Mechanism of Wind Turbine Blade Coating

Abstract

1. Introduction

2. Numerical Simulation

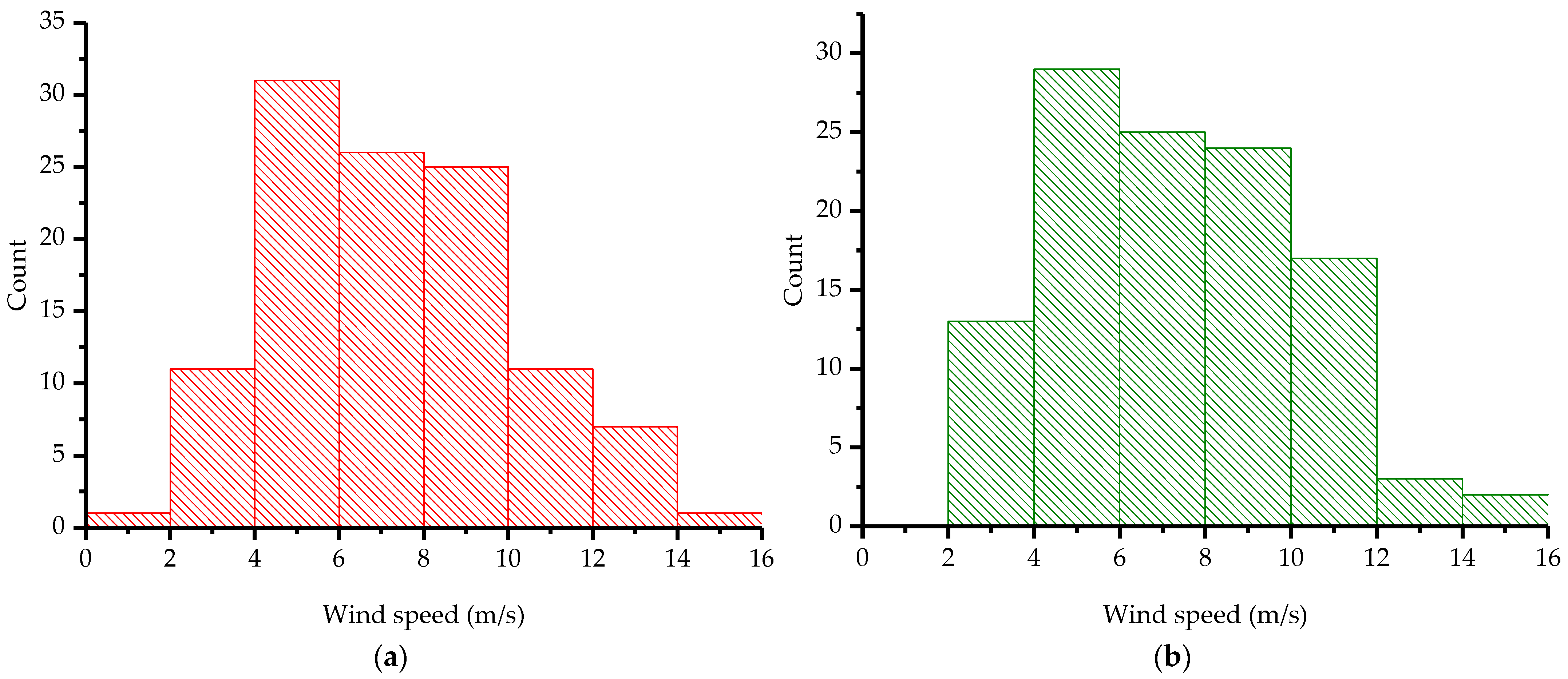

2.1. Parameters of the Wind–Sand Environment

2.1.1. Wind Speed

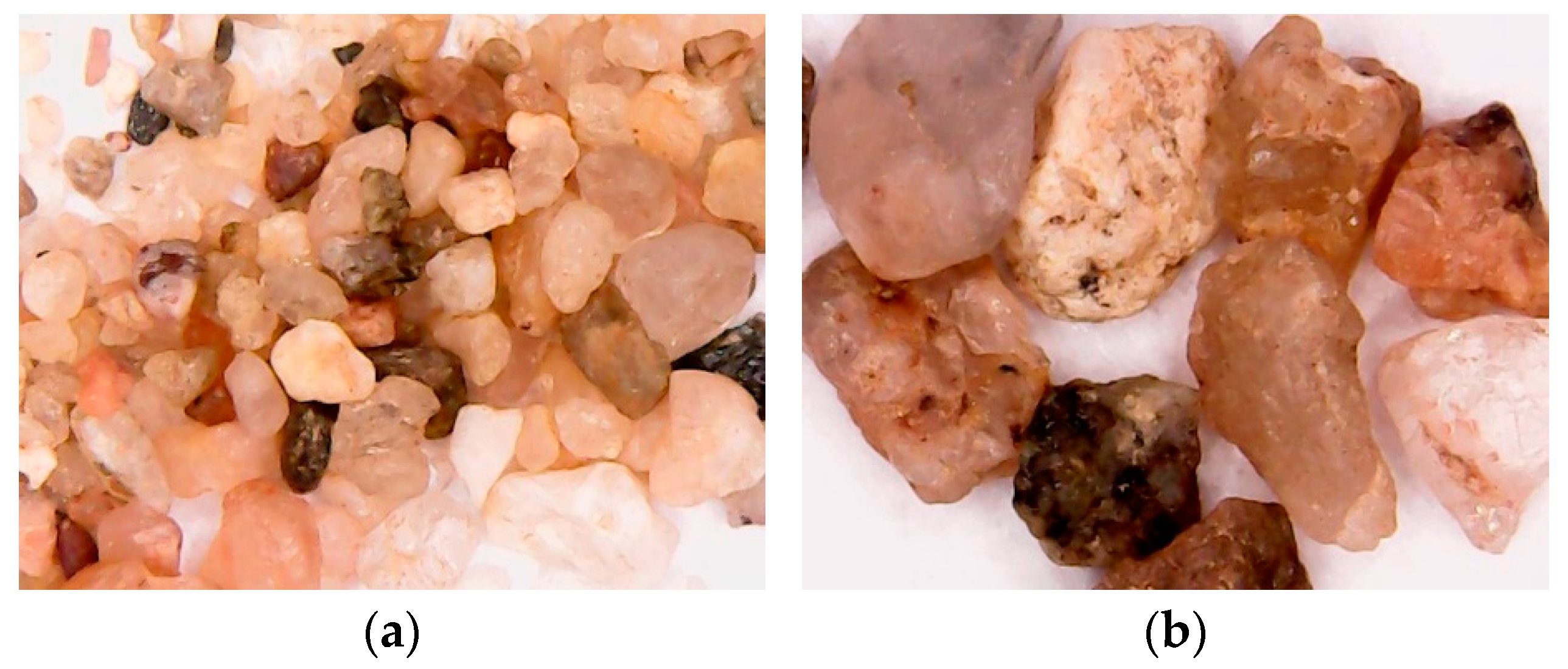

2.1.2. Sand Particle Size and Sand Mass Flow Rate

2.1.3. Erosion Angle and Erosion Time

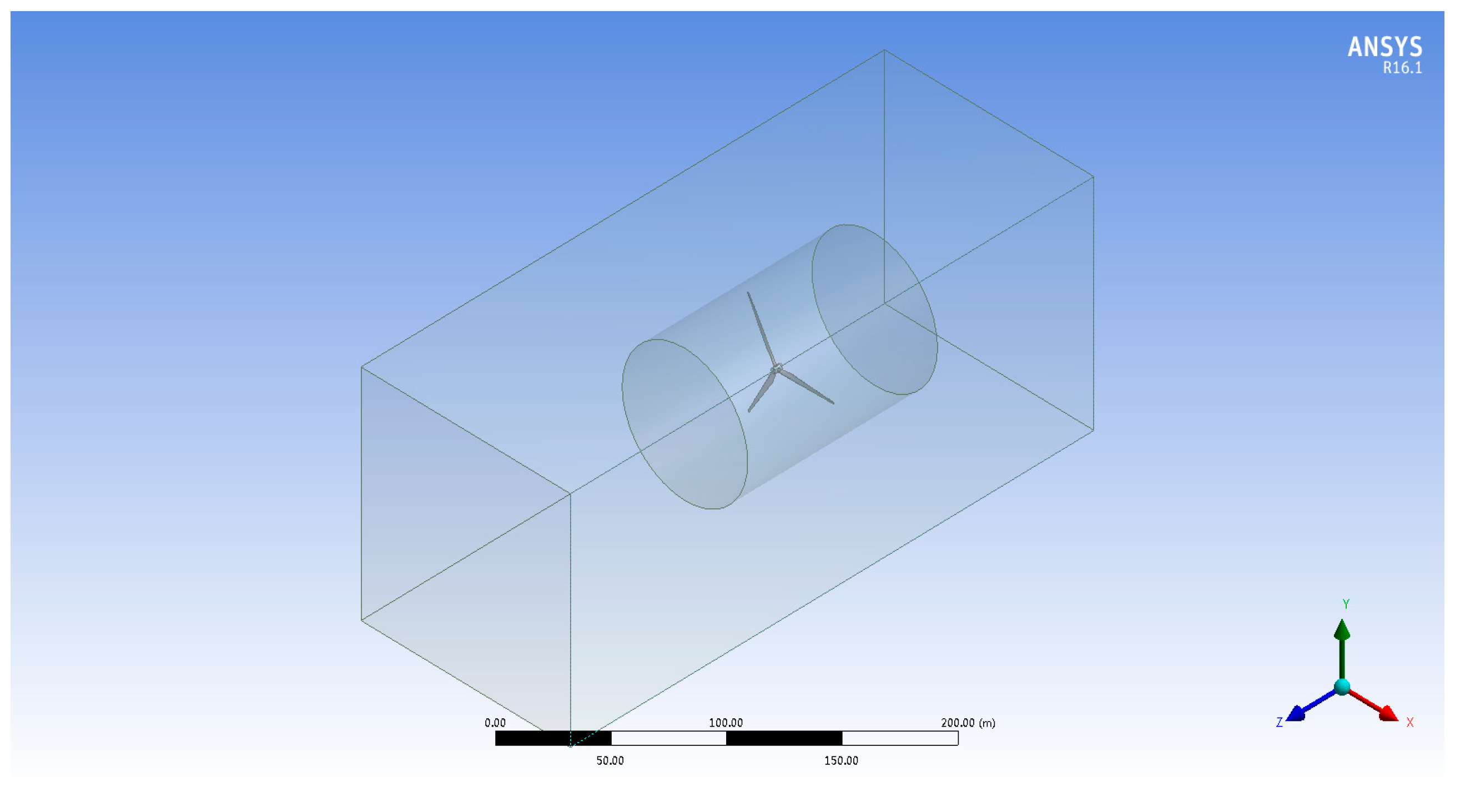

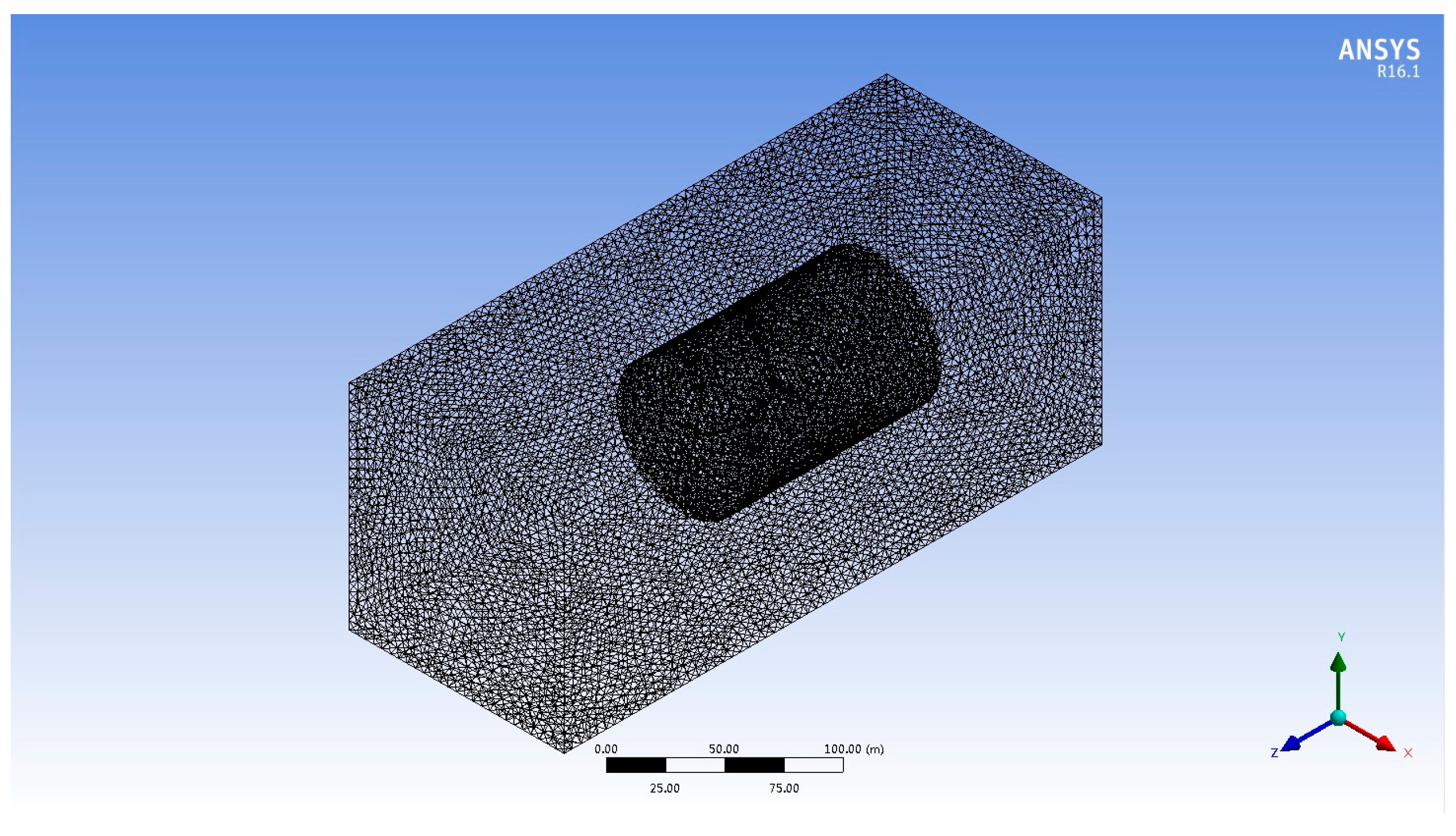

2.2. Model Establishment

2.3. Simulation Results and Analysis

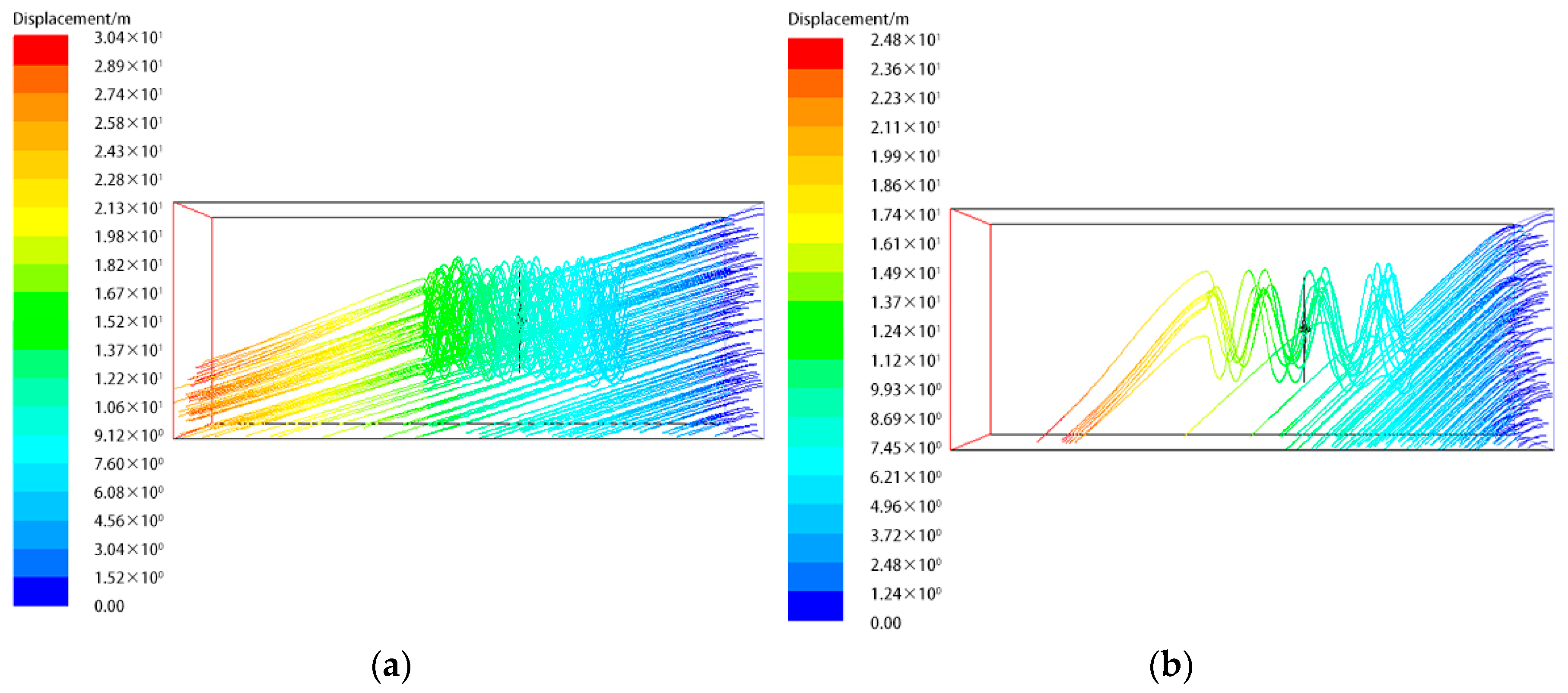

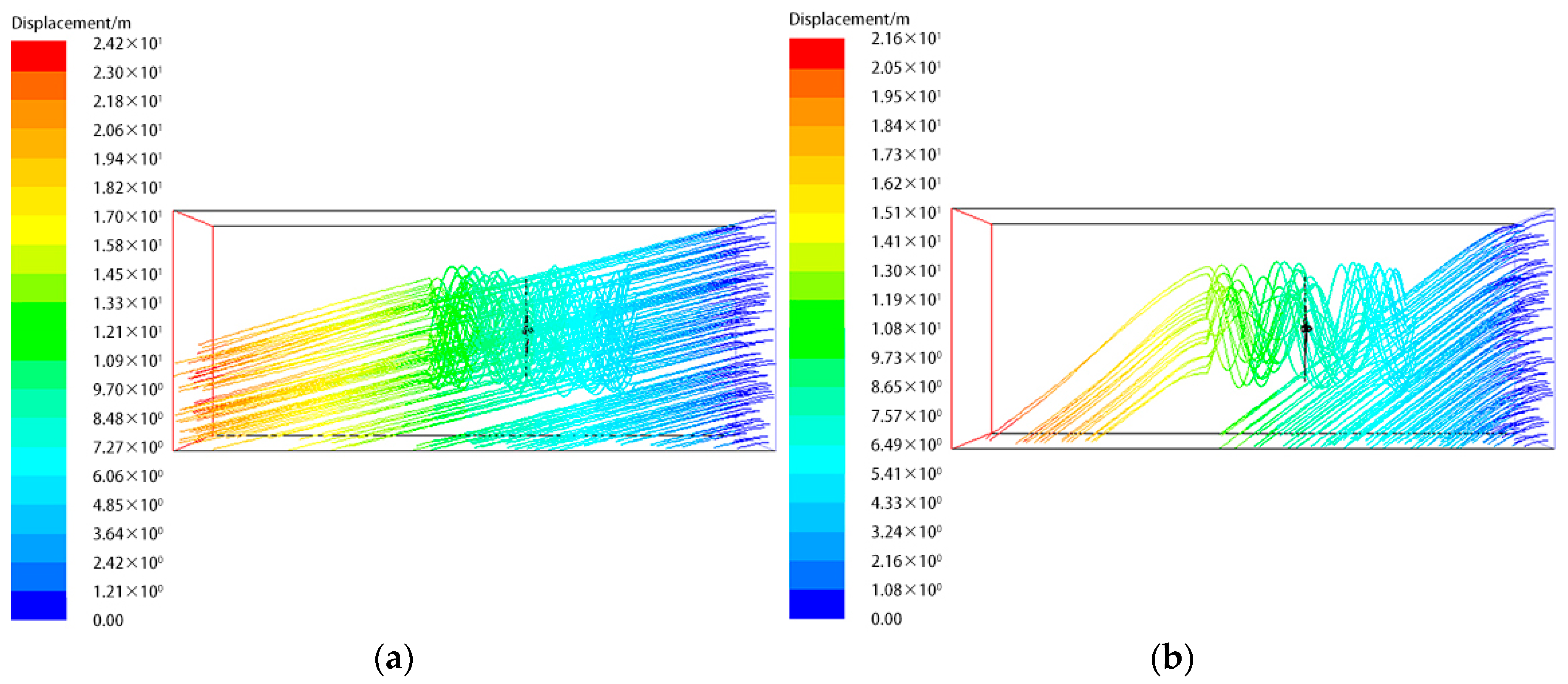

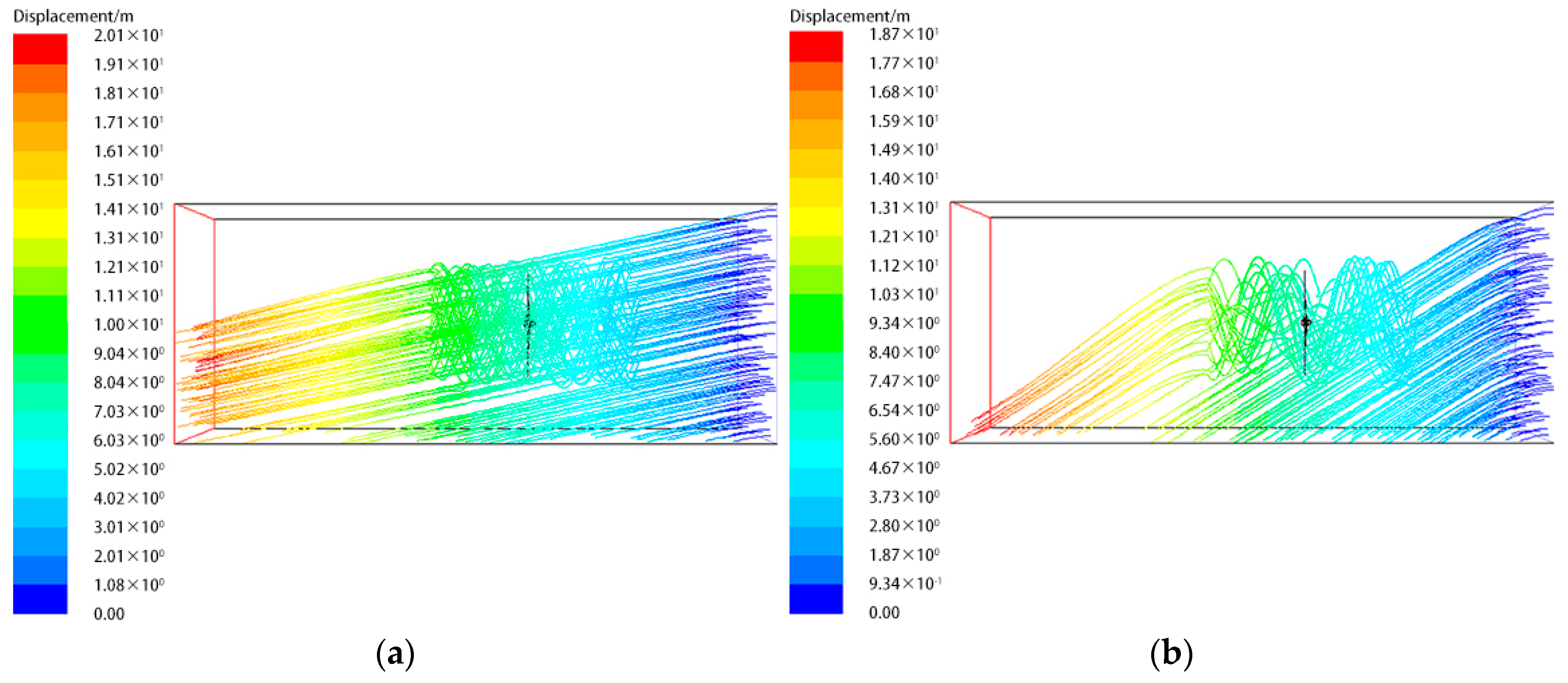

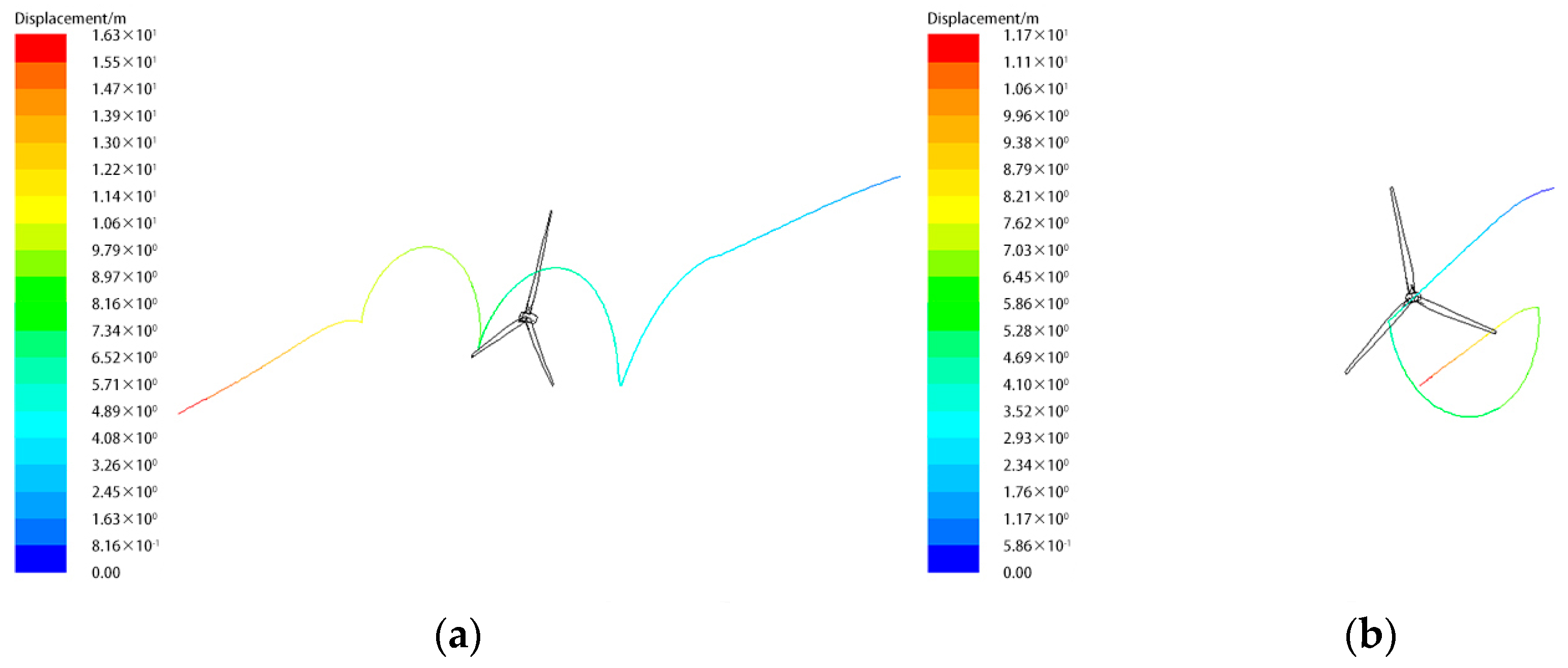

2.3.1. The Trajectory of Sand Particles

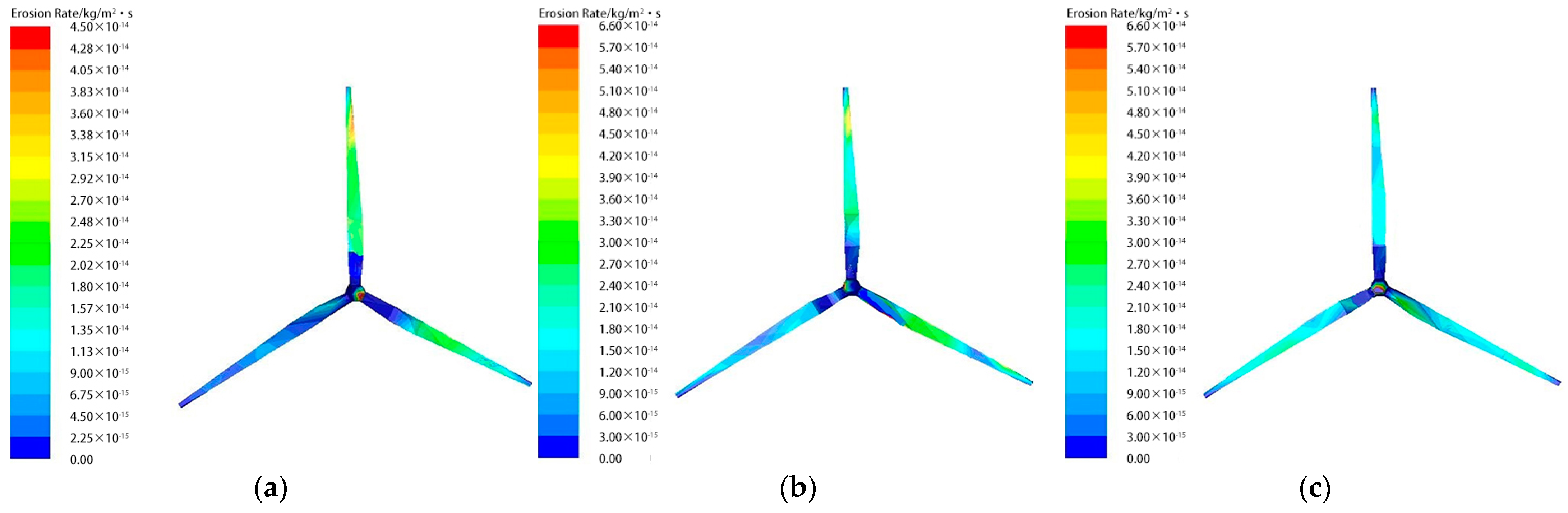

2.3.2. The Distribution of Wear Rate

3. Erosion Experiment

3.1. Experimental Blade

3.2. Experimental Equipment and Erosion Process

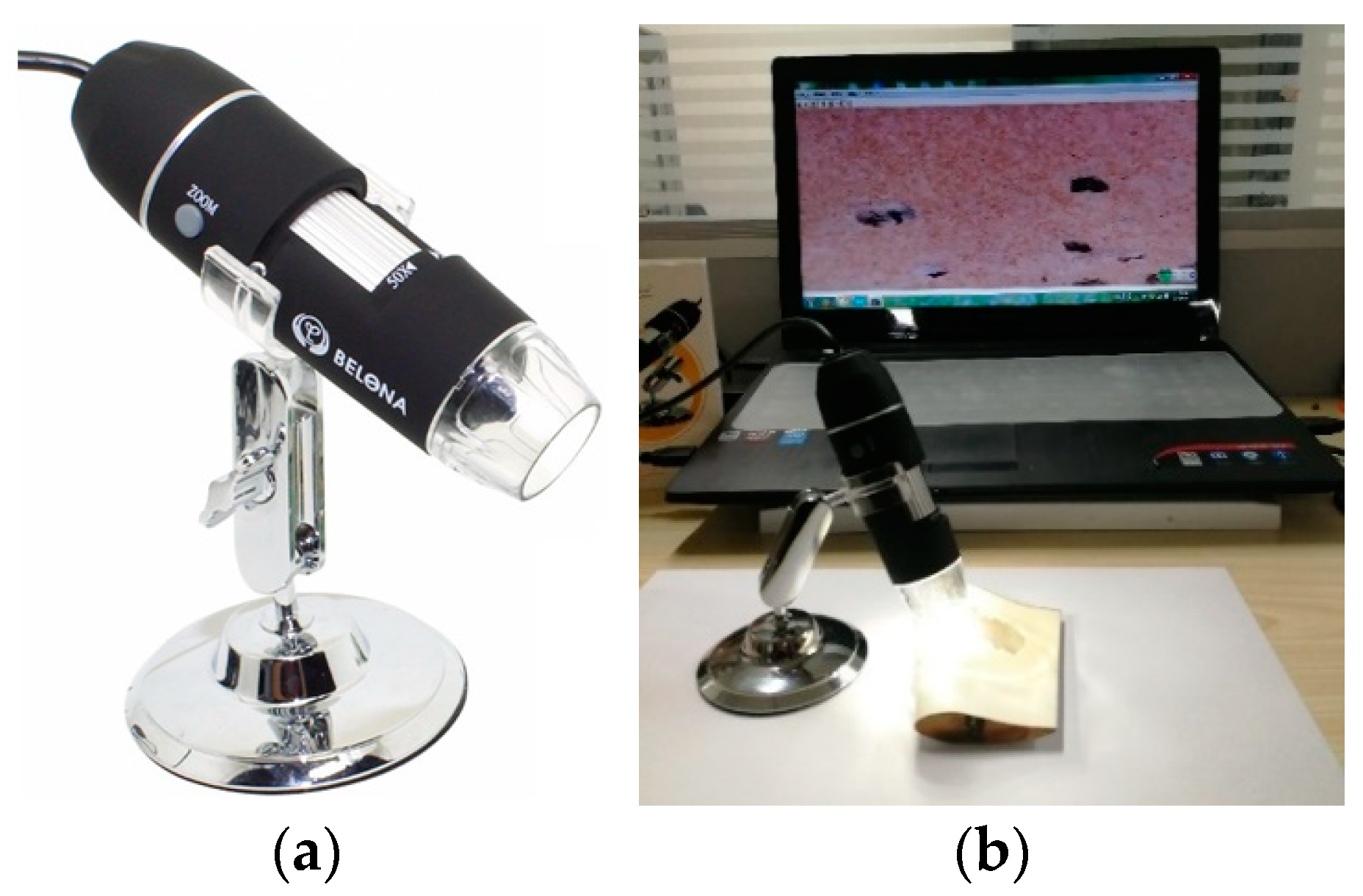

3.3. Results and Analysis

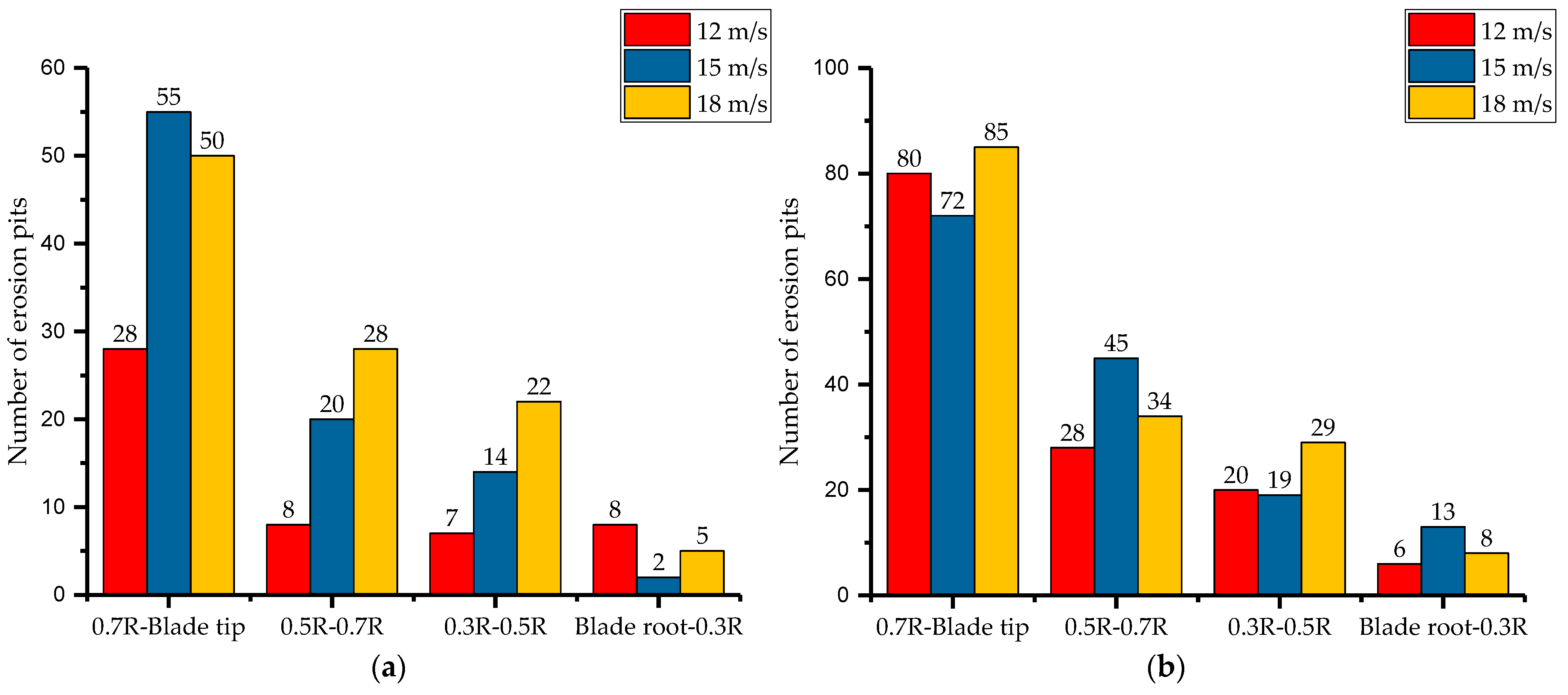

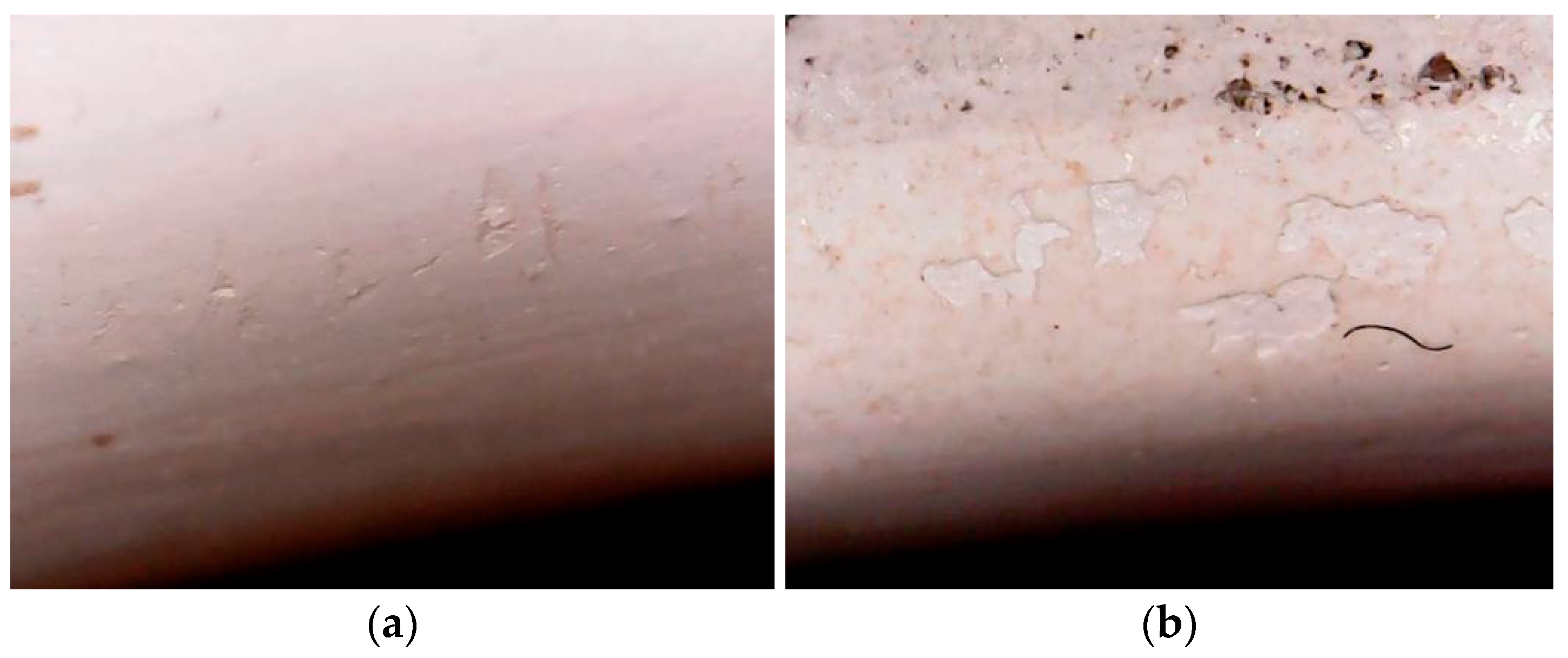

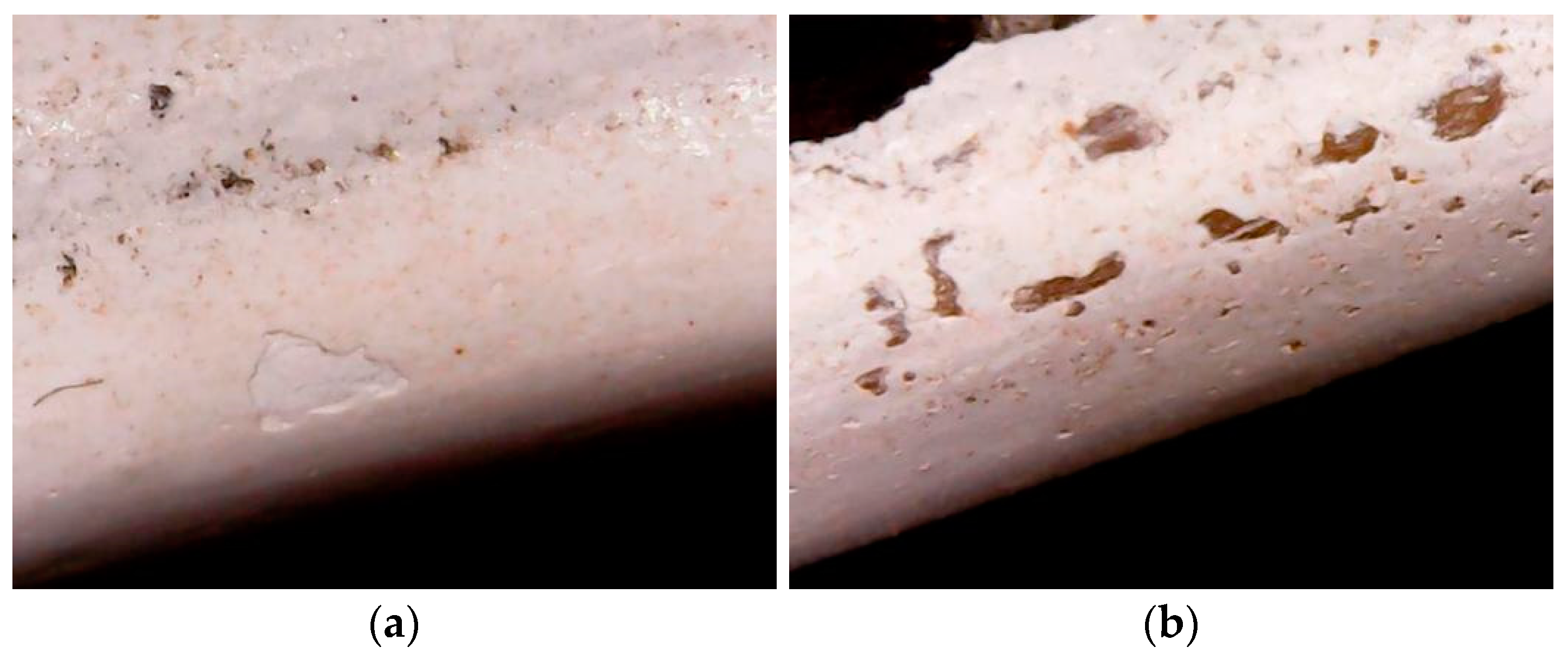

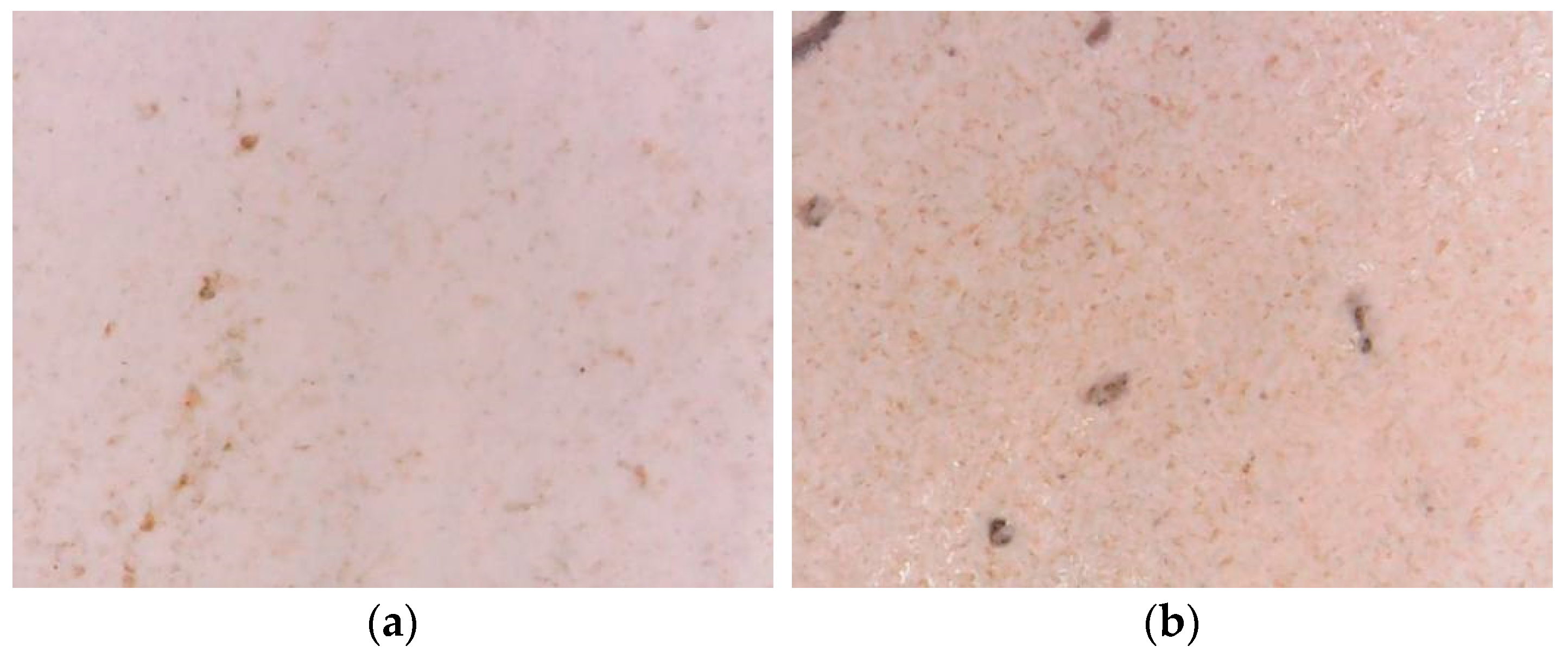

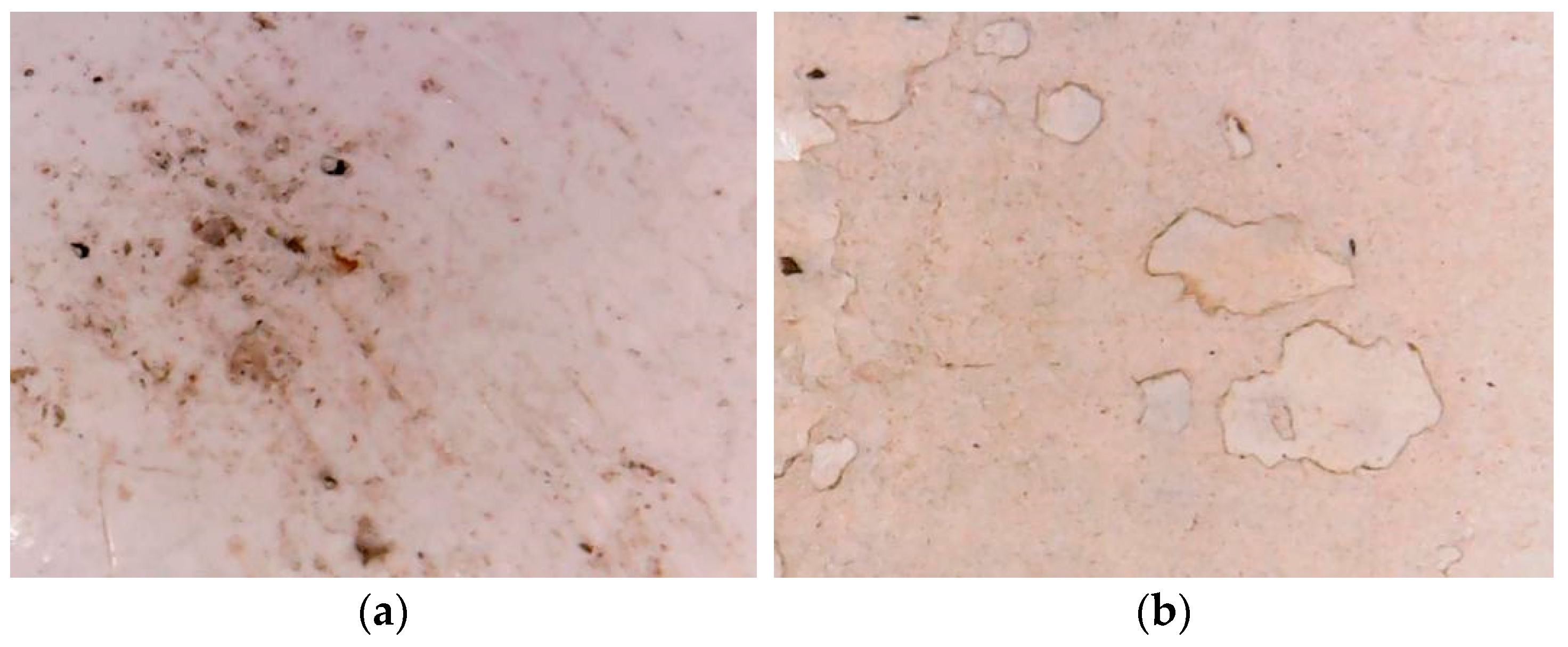

3.3.1. Distribution of Erosion Pits

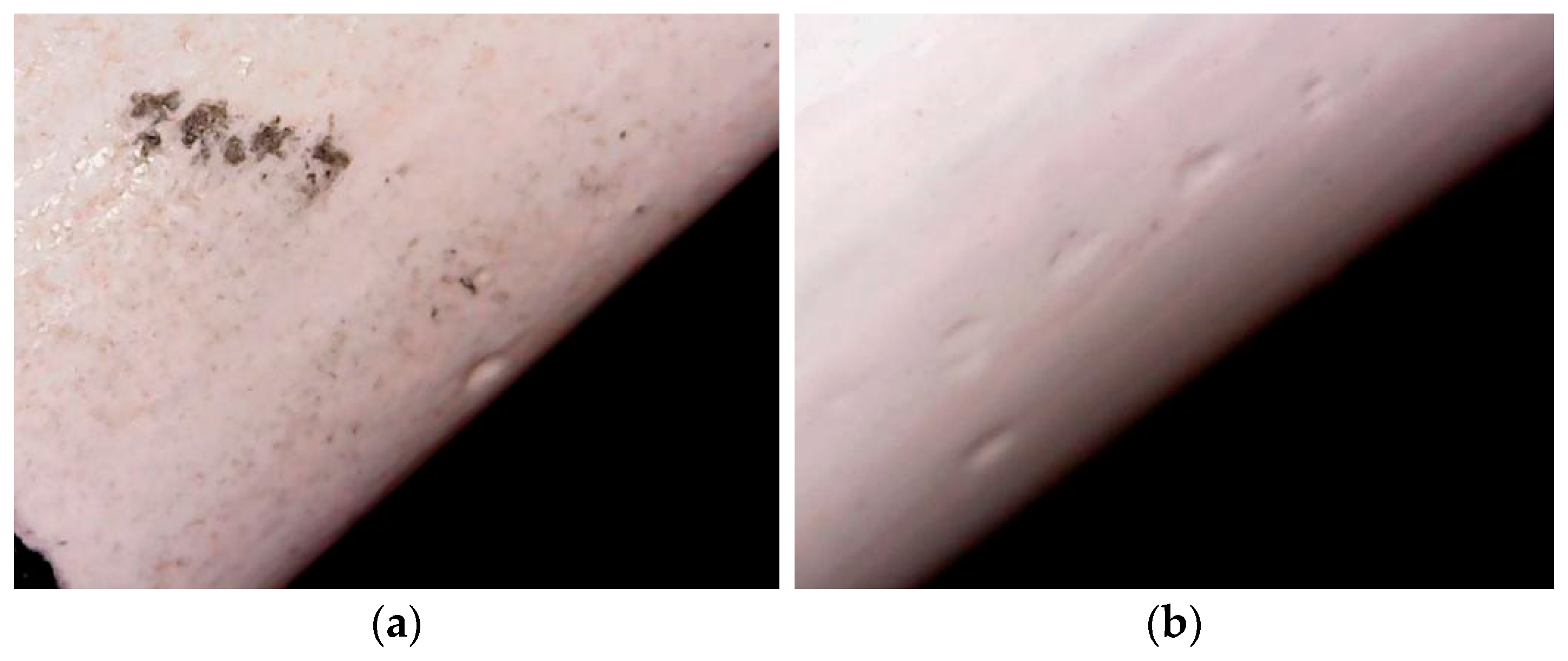

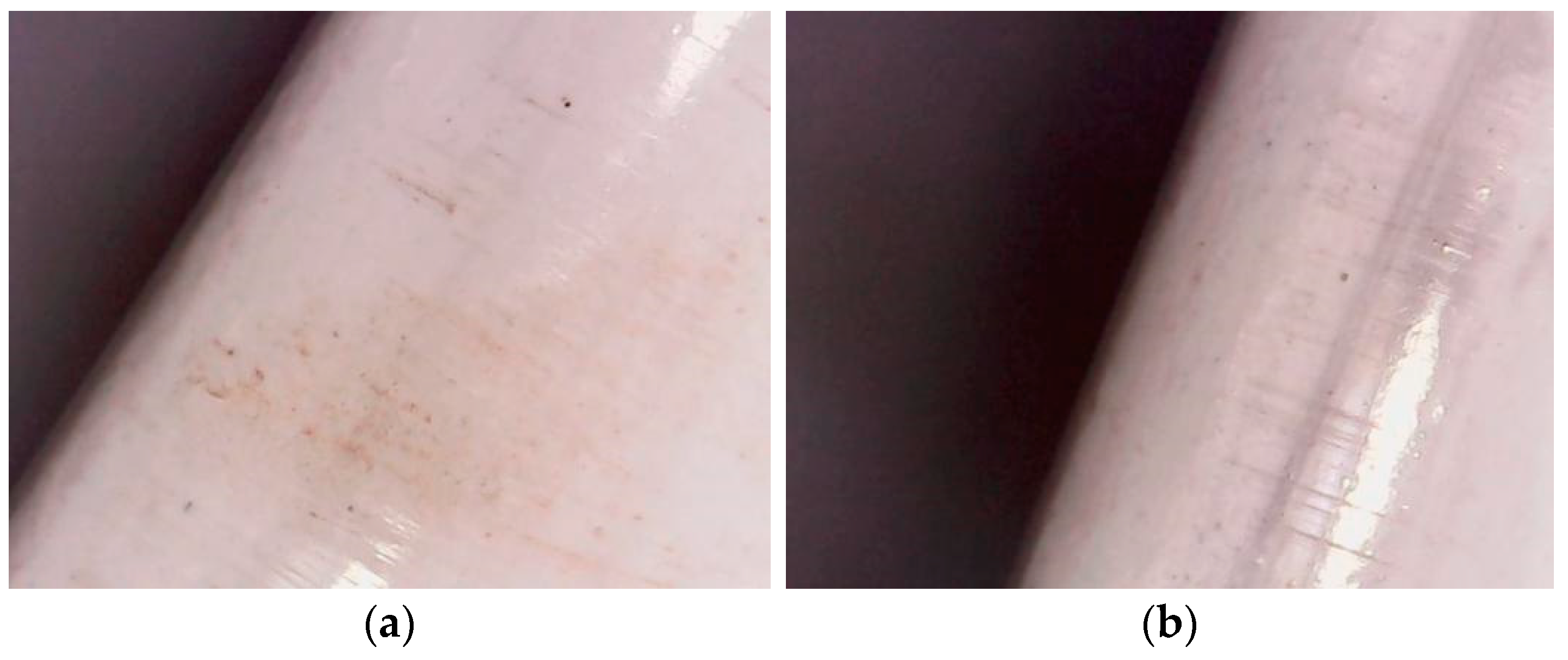

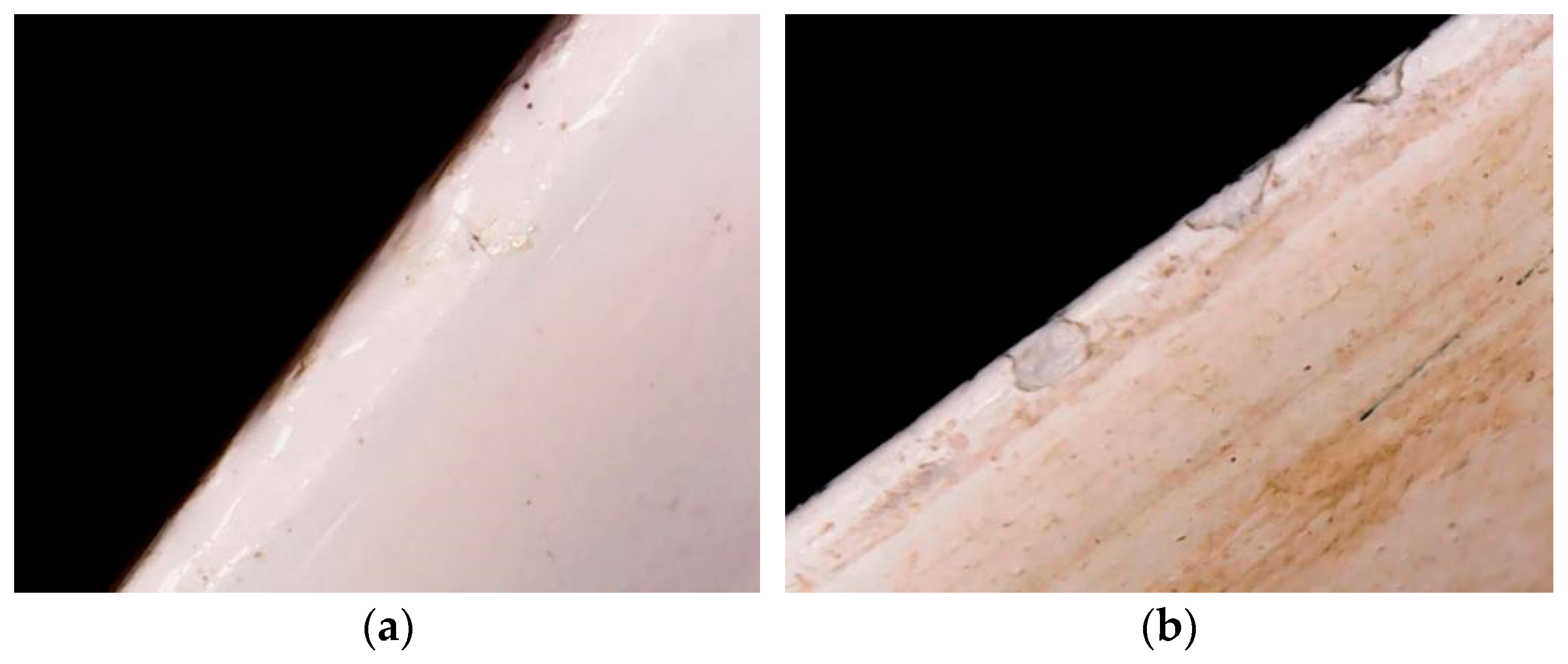

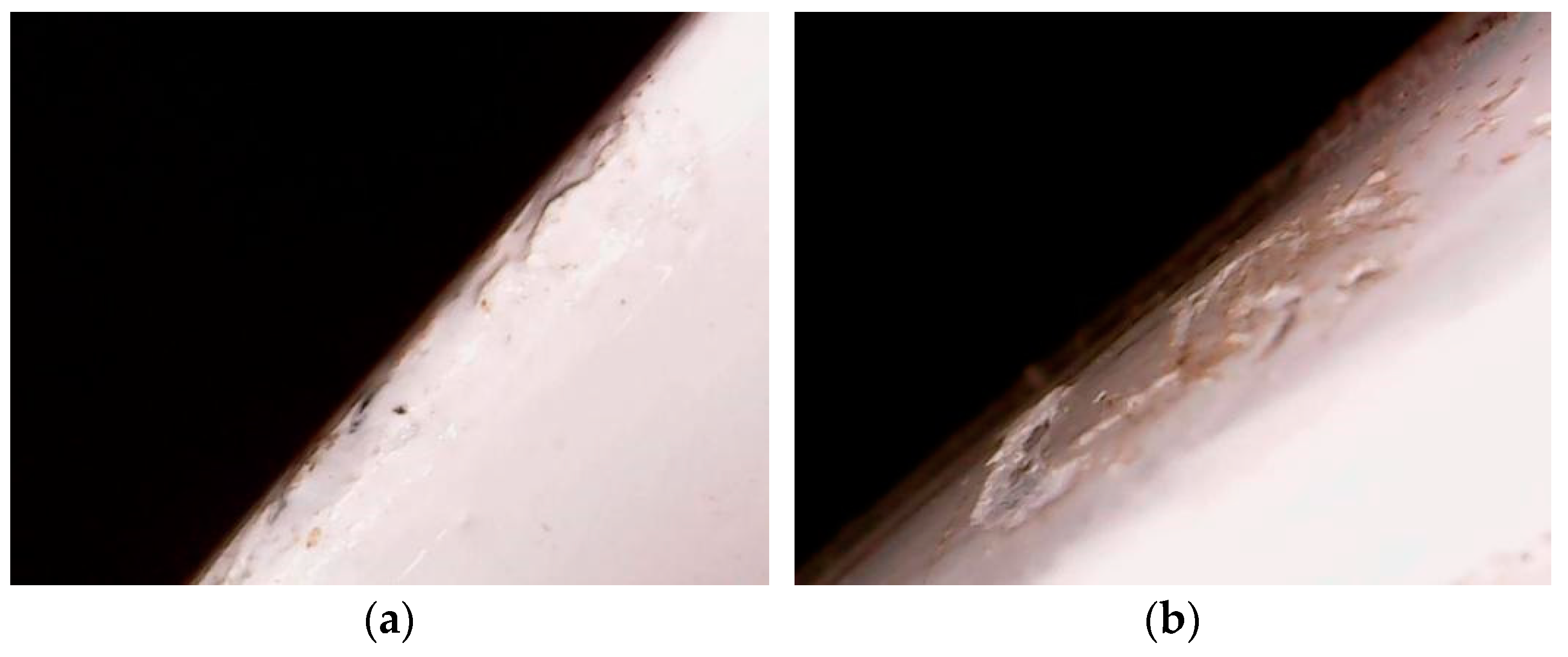

3.3.2. Erosion Morphology and Wear Mechanism

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cai, H.; Peng, Z.Y.; Wu, C.; Qi, W.C.; Xie, Z.J.; Xu, Z. Study on reactive control of flexible DC method reactive power in offshore wind farms. Power Capacit. React. Power Compens. 2019, 40, 153–157. [Google Scholar]

- Solar Photovoltaic Network of Beijixing. Available online: https://guangfu.bjx.com.cn/news/20230222/1290425.shtml (accessed on 20 June 2023).

- Yuan, G.B. Characteristics and cause of sandstorm in Inner Mongolia in 2001–2015. J. Desert Res. 2017, 37, 1204–1209. [Google Scholar]

- Zhang, Y.; Huang, C.; Liu, Z.; Liu, C.X.; Yang, L.J.; Gao, X. Research on properties of wind turbine blade coating under the wind-carrying action. Mater. Rev. 2016, 30, 95–99. [Google Scholar]

- Yang, X.Y.; Zhang, Y.F.; Lv, W.; Wang, D. Image recognition of wind turbine blade damage based on a deep learning model with transfer learning and an ensemble learning classifier. Renew. Energy 2021, 163, 386–397. [Google Scholar] [CrossRef]

- Matthias, S.; Hamid, R.; Bernhard, S.; Kim, T. The influence of eroded blades on wind turbine performance using numerical simulations. Energies 2017, 10, 1420. [Google Scholar]

- Malecha, Z.; Sierpowski, K. Numerical studies of the impact of erosion and dirt of turbine blades on the operation of wind turbine. Instal 2023, 7–8, 7–13. [Google Scholar]

- Kang, S.Y.; Li, X.M. Numerical simulation study on erosion wear of wind turbine blade materials. Renew. Energy Resour. 2015, 33, 656–661. [Google Scholar]

- Cen, H.T.; Tian, W.L.; Li, P.W.; Wei, R.T.; Na, R.S. Simulation analysis on polyurethane coating of wind turbine. J. Shanghai Jiaotong Univ. (Sci.) 2019, 24, 496–499. [Google Scholar] [CrossRef]

- Zhen, Q.; Chen, S.L.; Wan, D.Q.; Yan, C.X.; Sun, K.; Li, D.L. Numerical research on erosion and wear of wind turbine blades in sand-carrying wind. Acta Energiae Solaris Sin. 2022, 43, 257–263. [Google Scholar]

- Gao, J.; Zhang, Y.; Wang, J.; Su, L.D.; Wu, G.J.; Qi, G.Q. Study on coatings erosion of blades under sand-carrying wind. Acta Energiae Solaris Sin. 2020, 41, 367–371. [Google Scholar]

- Li, D.S.; Wang, C.Z.; Li, Y.R.; Li, R.N.; Ma, R.J. Numerical simulation of wind turbine blade erosion in sandy environment. Acta Energiae Solaris Sin. 2018, 39, 627–632. [Google Scholar]

- Zhou, R.Y.; Duan, H.B.; Ye, H.; Wang, T.; Zhou, H.X.; Yao, Y.; Liang, X.Y. Experimental and Numerical Study of Erosion Wear of Fan Blades in Microgrid. J. Phys. 2021, 2005, 012039. [Google Scholar] [CrossRef]

- Dai, L.P.; Yao, S.G.; Wang, X.D.; Kang, S. Numerical investigation of wind turbine blades erosion characteristics impacted by air flow containing sand particles. Acta Energiae Solaris Sin. 2018, 39, 247–252. [Google Scholar]

- Li, D.S.; Liang, E.P.; Li, Y.R.; Zhao, Y.; Xu, M.F.; Yu, M.Y. Wind tunnel experimental study on erosion and wear characteristics fo wind turbine blade coating. Acta Energiae Solaris Sin. 2022, 43, 196–203. [Google Scholar]

- Wang, J.; Du, G.Z.; Zhang, Y.; Wu, Z.; Gao, J.; Su, L.D. Research on sand erosion wear of wind turbine blade coating in operation state. Mater. Rep. 2021, 35, 04177–04180. [Google Scholar]

- Alajmi, A.; Ramulu, M. Investigation of the leading-edge erosion of wind turbine blades using multivariant analysis method. In Proceedings of the ASME 2022 International Mechanical Engineering Congress and Exposition, Columbus, OH, USA, 30 October–3 November 2022. [Google Scholar] [CrossRef]

- Hassanian, R.; Riede, M. Leading-edge erosion and floating particles: Stagnation point simulation in particle-laden turbulent flow via Lagrangian particle tracking. Machines 2023, 11, 556. [Google Scholar] [CrossRef]

- Li, Y.H.; Zhang, Y.; Yuan, B. Current situation and construction measures of ecological environment in Alashan League. Mod. Agric. Sci. Technol. 2021, 4, 185–187. [Google Scholar]

- Wan, W.; Yan, C.Z. Research progress of eco-environmental degradation in Alashan Plateau. J. Earth Environ. 2018, 9, 109–122. [Google Scholar]

- GB-T-20480:2017; Classification of sand and dust weather. Standards press of China: Beijing, China, 2017.

- Jiang, M.Y.; Zhao, L.N.; Lu, J.J.; Wang, C. Research and application of quantitative classification method of sand and dust weather. Clim. Environ. Res. 2007, 12, 350–357. [Google Scholar]

- Duan, G.L. Experimental Research on Erosion Wear of Steel-Structure Coating in Sandstorm; Inner Mongolia Agricultural University Press: Hohhot, China, 2014. [Google Scholar]

- Li, M.; Tian, D.; Wang, H.K.; Han, Q.L.; Ma, G.X. Load test experiment of variable pitch wind turbine rotor blade model. Acta Energiae Solaris Sin. 2013, 34, 1574–1578. [Google Scholar]

- Li, D.S.; Wang, C.Z.; Li, Y.R.; Li, R.N.; Ma, R.J. Aerodynamic characteristics analysis of wind turbine based on similarity theory. Acta Energiae Solaris Sin. 2015, 36, 2917–2921. [Google Scholar]

- Song, T.; Chen, Z.; Ma, Q.; Si, Z.M.; Liu, H.Y.; Xuan, C.Z. Design and performance experiment of shunt-hedging sand sampler. Trans. Chin. Soc. Agric. Mach. 2015, 46, 173–177. [Google Scholar]

- Sareen, A.; Sapre, C.A.; Selig, M.S. Effects of leading edge erosion on wind turbine blade performance. Wind Energy 2014, 17, 1531–1542. [Google Scholar] [CrossRef]

- Pathak, S.; Kumar, V.; Bonu, V.; Mishnaevsky, L.; Lakshmi, R.; Bera, P.; Barshilia, H. Development of cellulose-reinforced polyurethane coatings: A novel eco-friendly approach for wind turbine blade protection. Energies 2023, 16, 1730. [Google Scholar] [CrossRef]

- Zheng, J.; Zhang, Q.H.; Luo, Z.H.; Zeng, W.R.; Zhan, X.L.; Chen, F.Q. Progress on the protective coating layer materials of wind turbine blades. Polym. Mater. Sci. Eng. 2012, 28, 182–186. [Google Scholar]

| Wind Speed | Width × Height × Length (Experimental Section) | Cross-Sectional Turbulence | Airflow Velocity Uniformity | Airflow Stability |

|---|---|---|---|---|

| 0–18 m/s | 1 m × 1.2 m × 7.2 m | ≤1% | <1% | ≤3% |

| Erosion Characteristics | Diameter/Depth (mm) |

|---|---|

| Sand Hole | 0.51 |

| Small Pit | 2.54 |

| Coating Peeling | 3.81 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Gao, J.; Zhang, Y.; Cui, H. Analysis of the Sand Erosion Effect and Wear Mechanism of Wind Turbine Blade Coating. Energies 2024, 17, 413. https://doi.org/10.3390/en17020413

Wang J, Gao J, Zhang Y, Cui H. Analysis of the Sand Erosion Effect and Wear Mechanism of Wind Turbine Blade Coating. Energies. 2024; 17(2):413. https://doi.org/10.3390/en17020413

Chicago/Turabian StyleWang, Jian, Jin Gao, Yong Zhang, and Hongmei Cui. 2024. "Analysis of the Sand Erosion Effect and Wear Mechanism of Wind Turbine Blade Coating" Energies 17, no. 2: 413. https://doi.org/10.3390/en17020413

APA StyleWang, J., Gao, J., Zhang, Y., & Cui, H. (2024). Analysis of the Sand Erosion Effect and Wear Mechanism of Wind Turbine Blade Coating. Energies, 17(2), 413. https://doi.org/10.3390/en17020413