Efficiency and PF Improving Techniques with a Digital Control for Totem-Pole Bridgeless CRM Boost PFC Converters

Abstract

1. Introduction

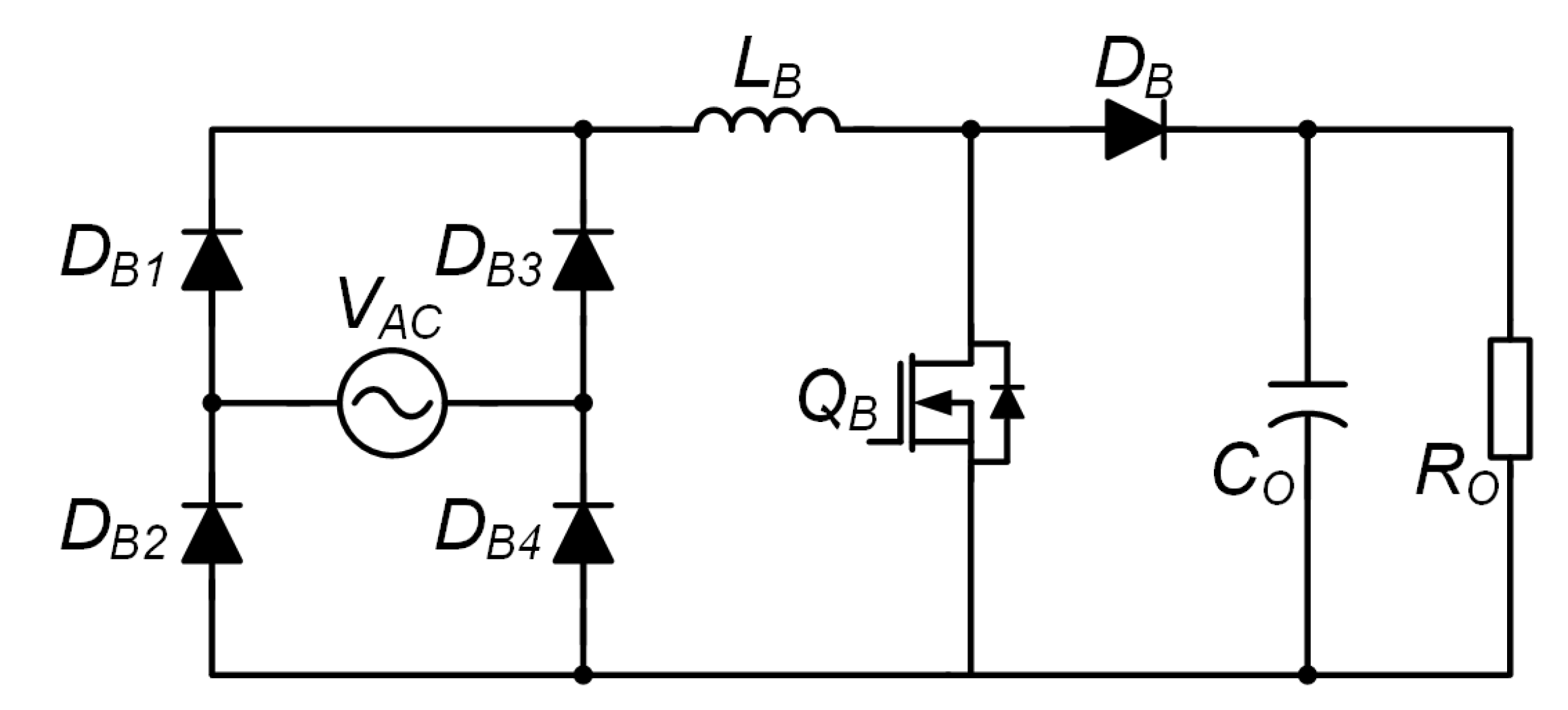

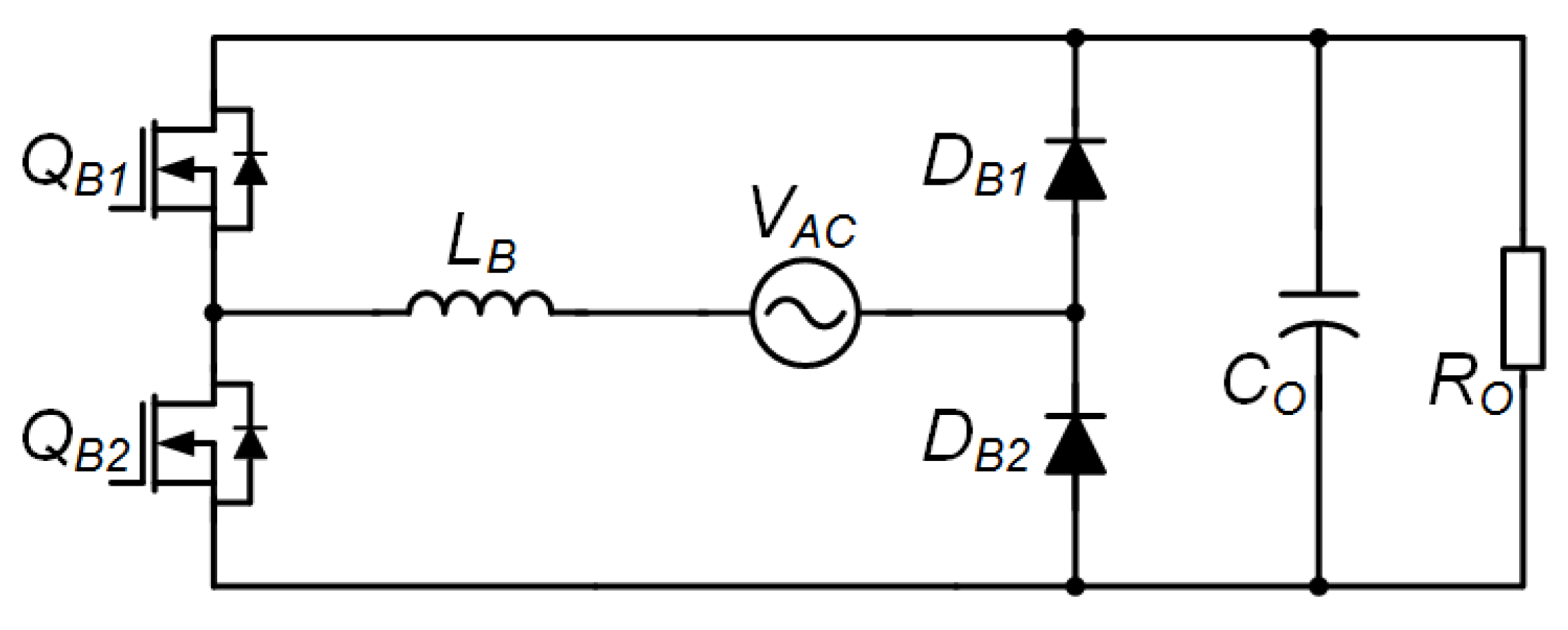

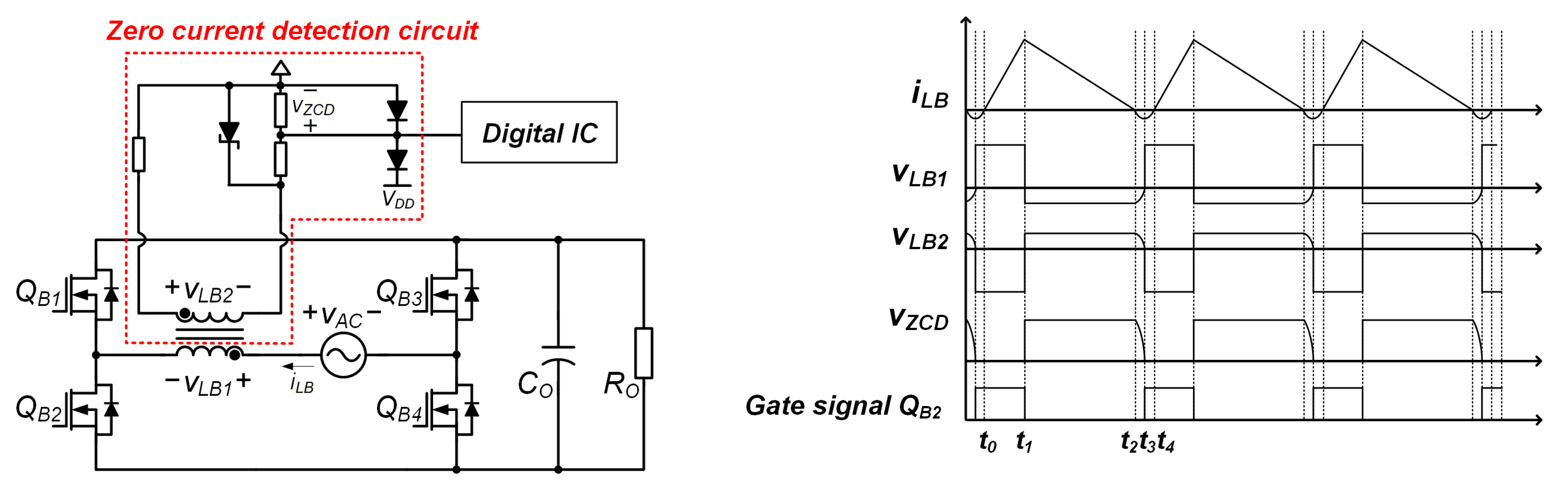

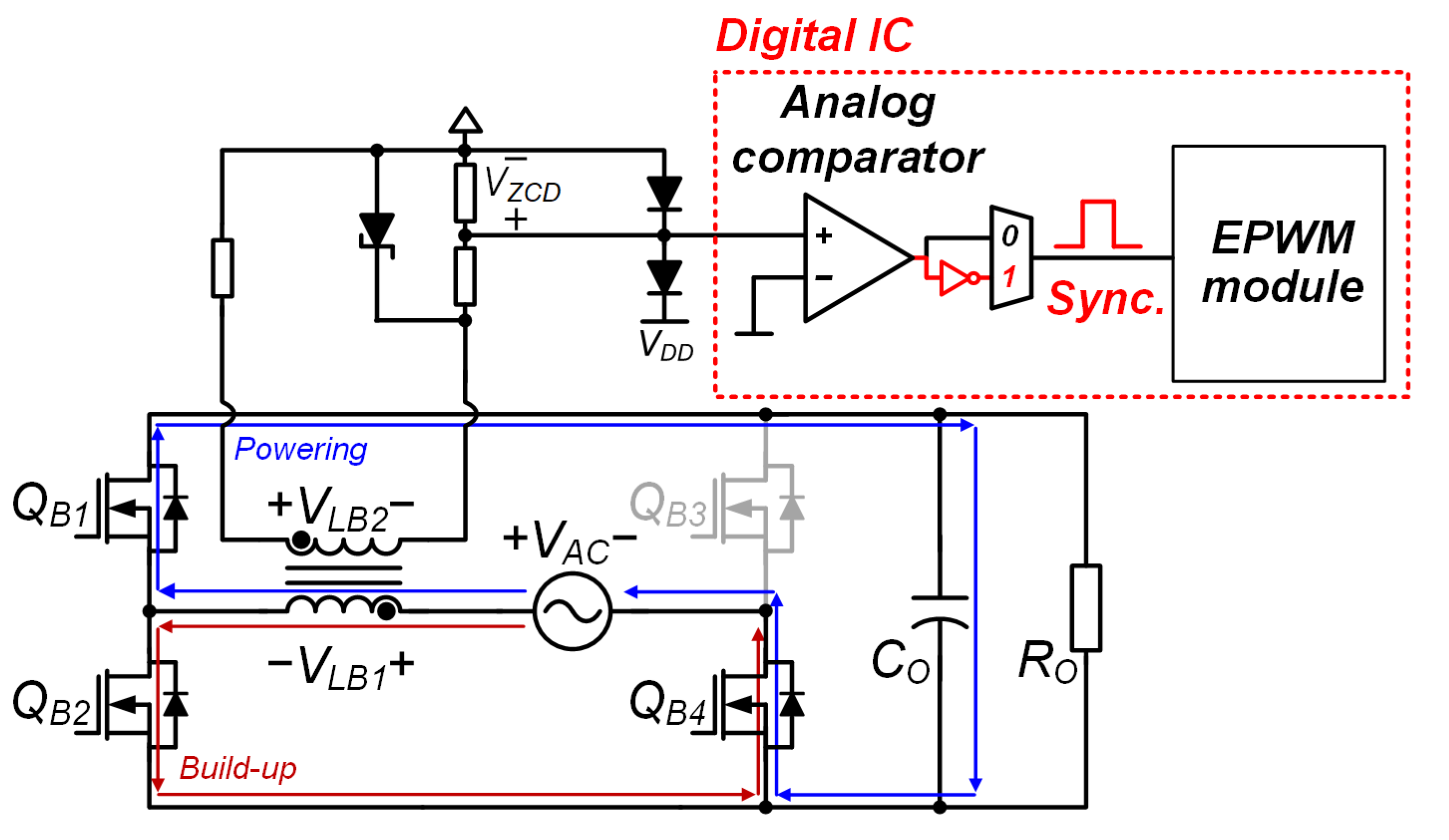

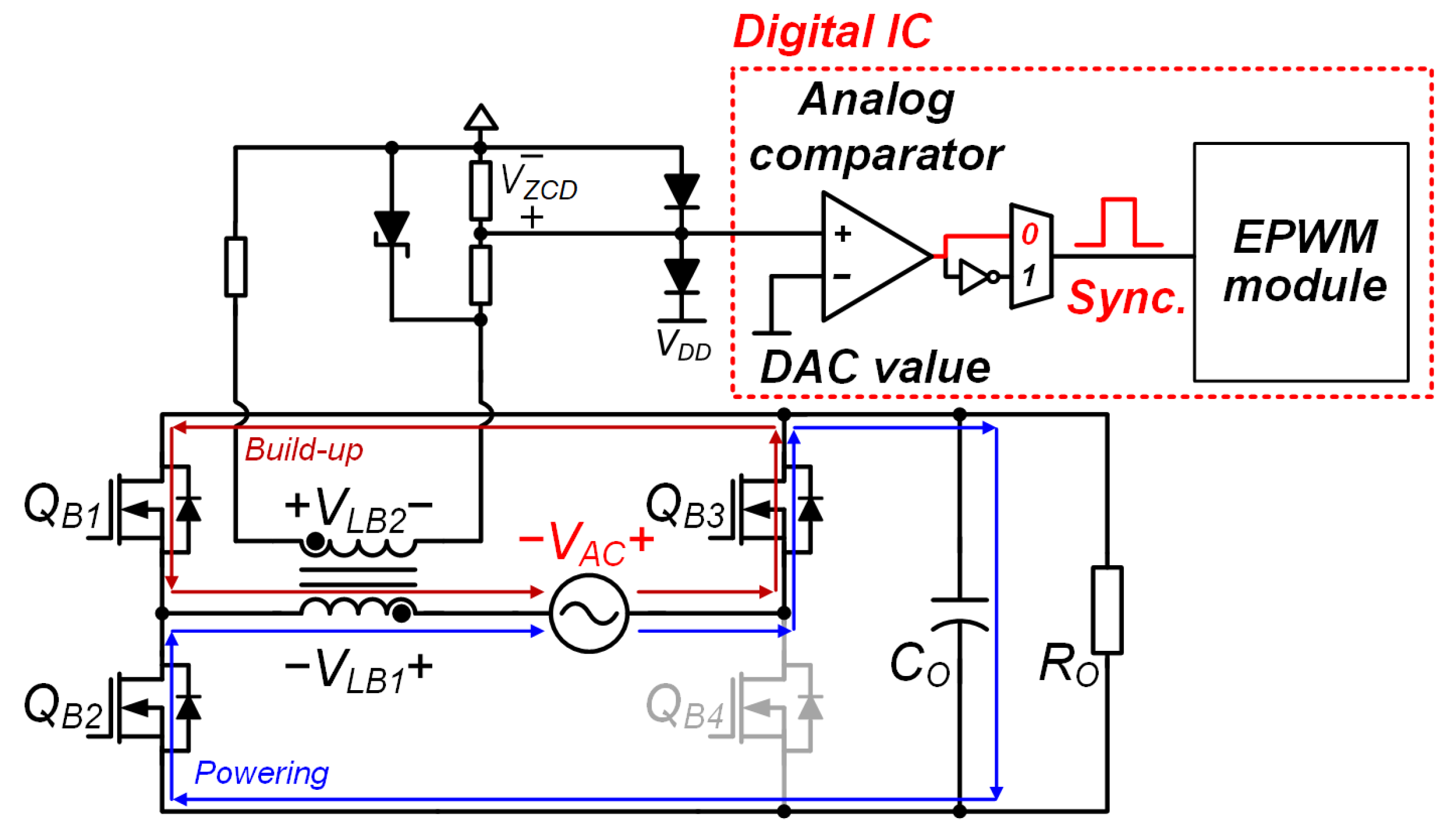

2. Basic Structure of the Digital Totem-Pole Bridgeless CRM Boost PFC Converter

3. Additional Control Techniques

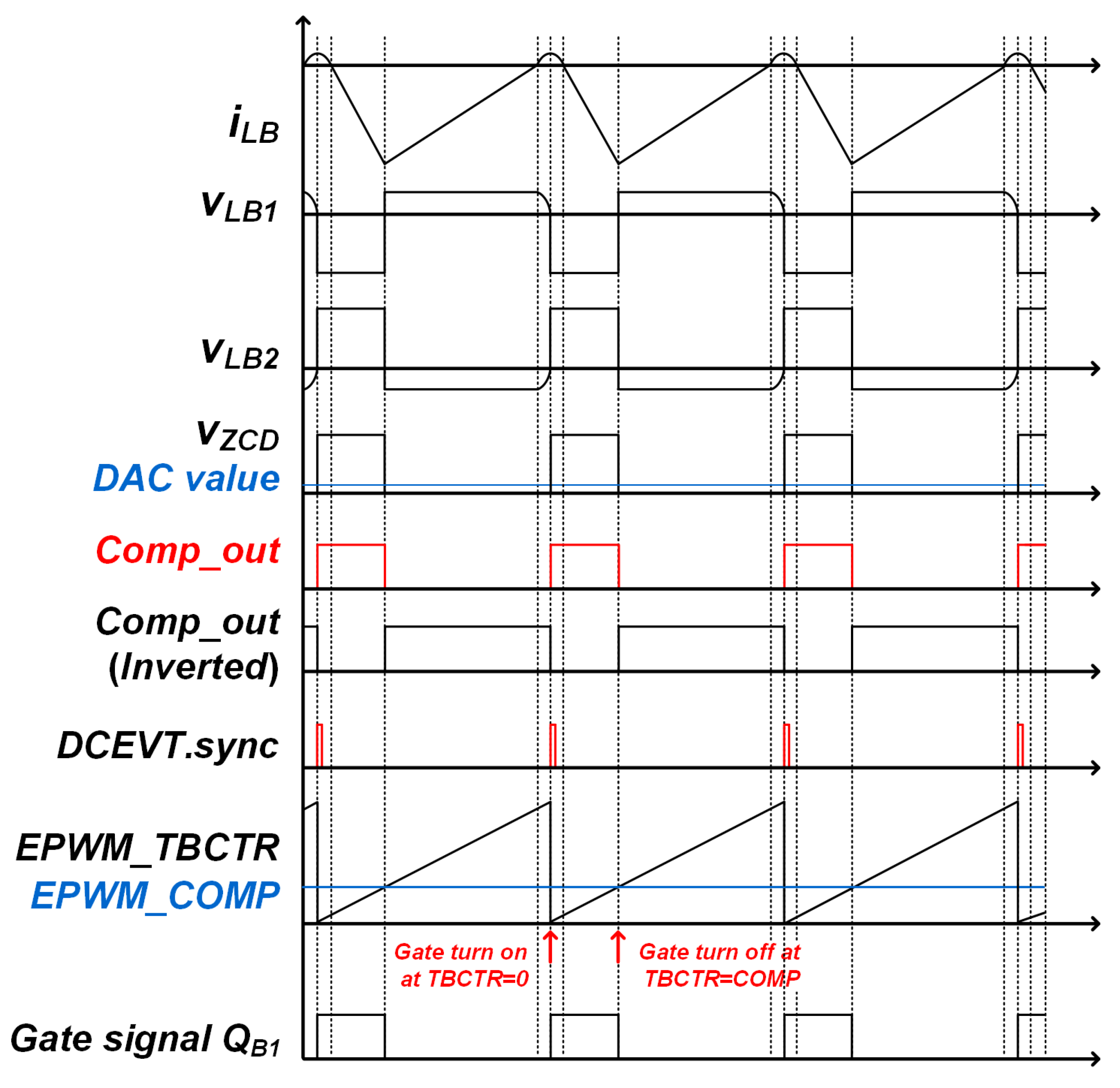

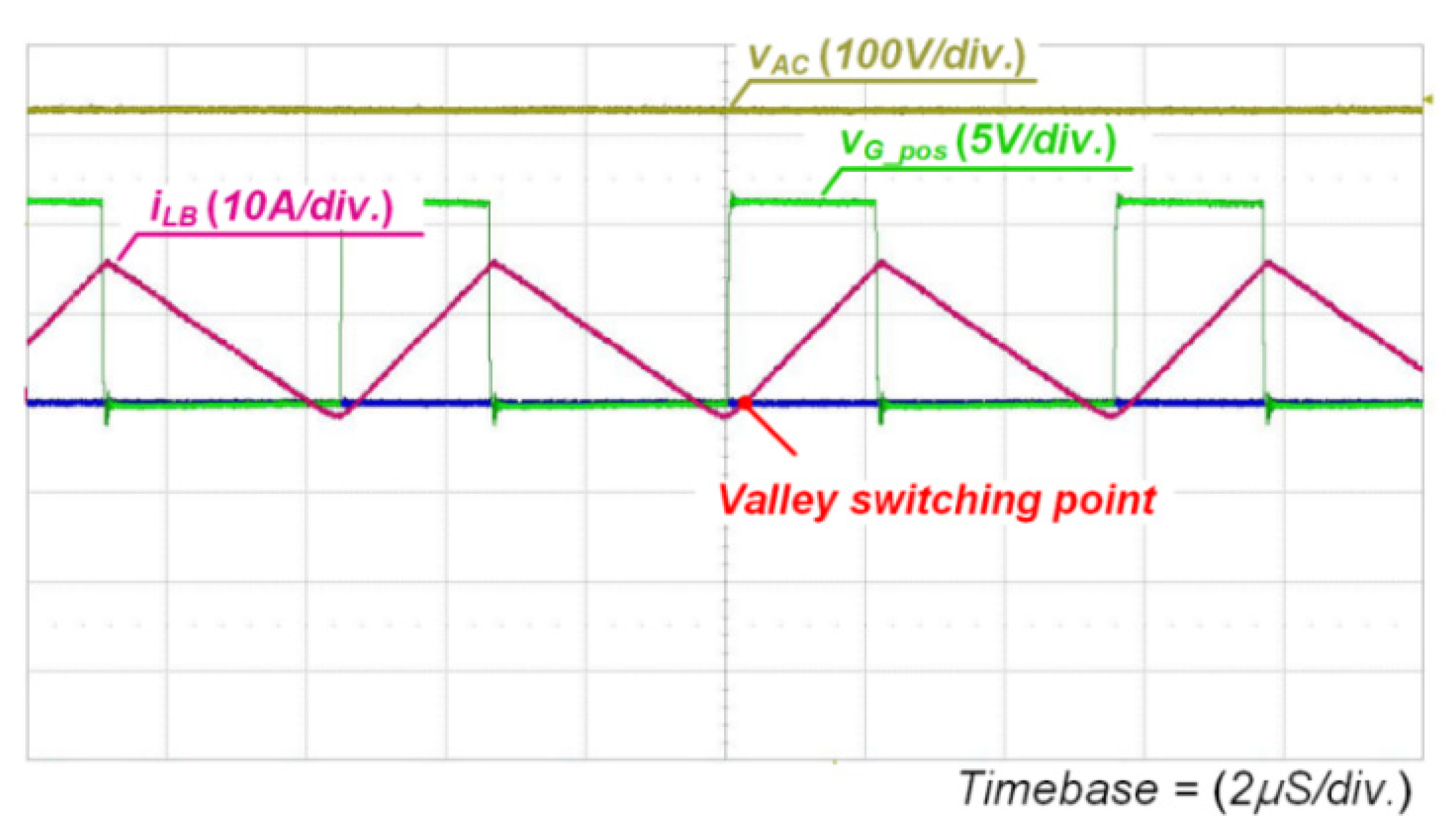

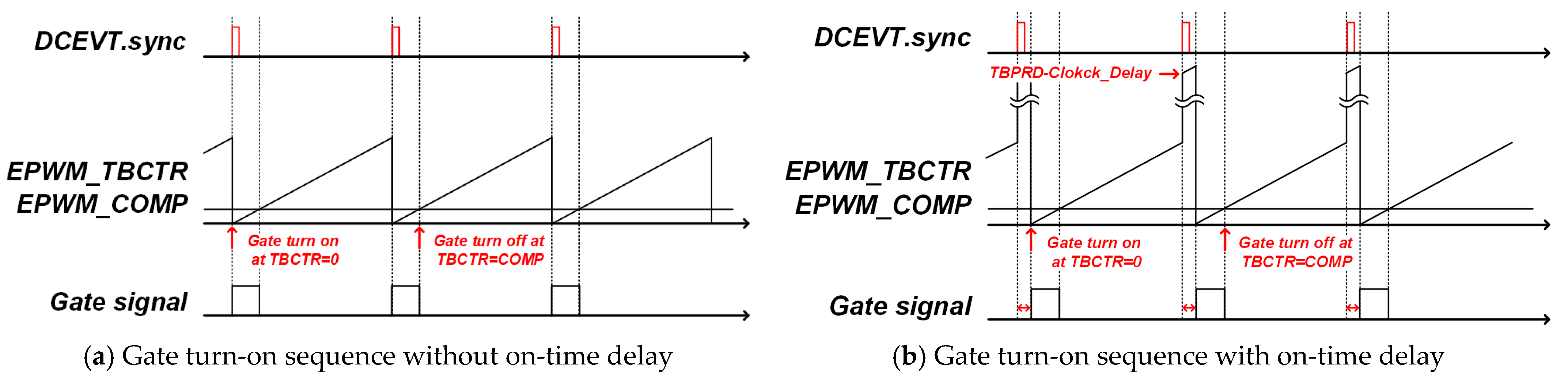

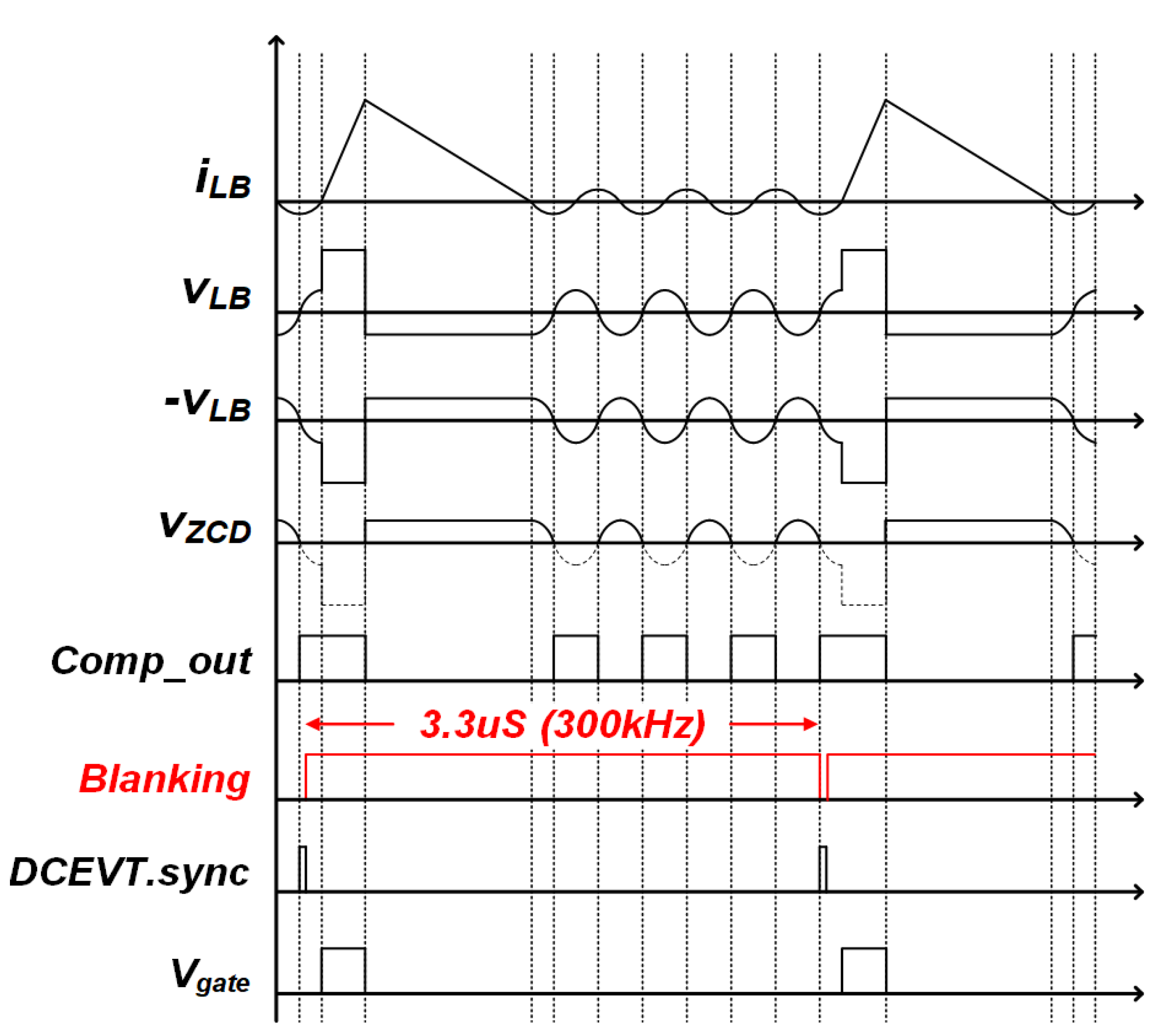

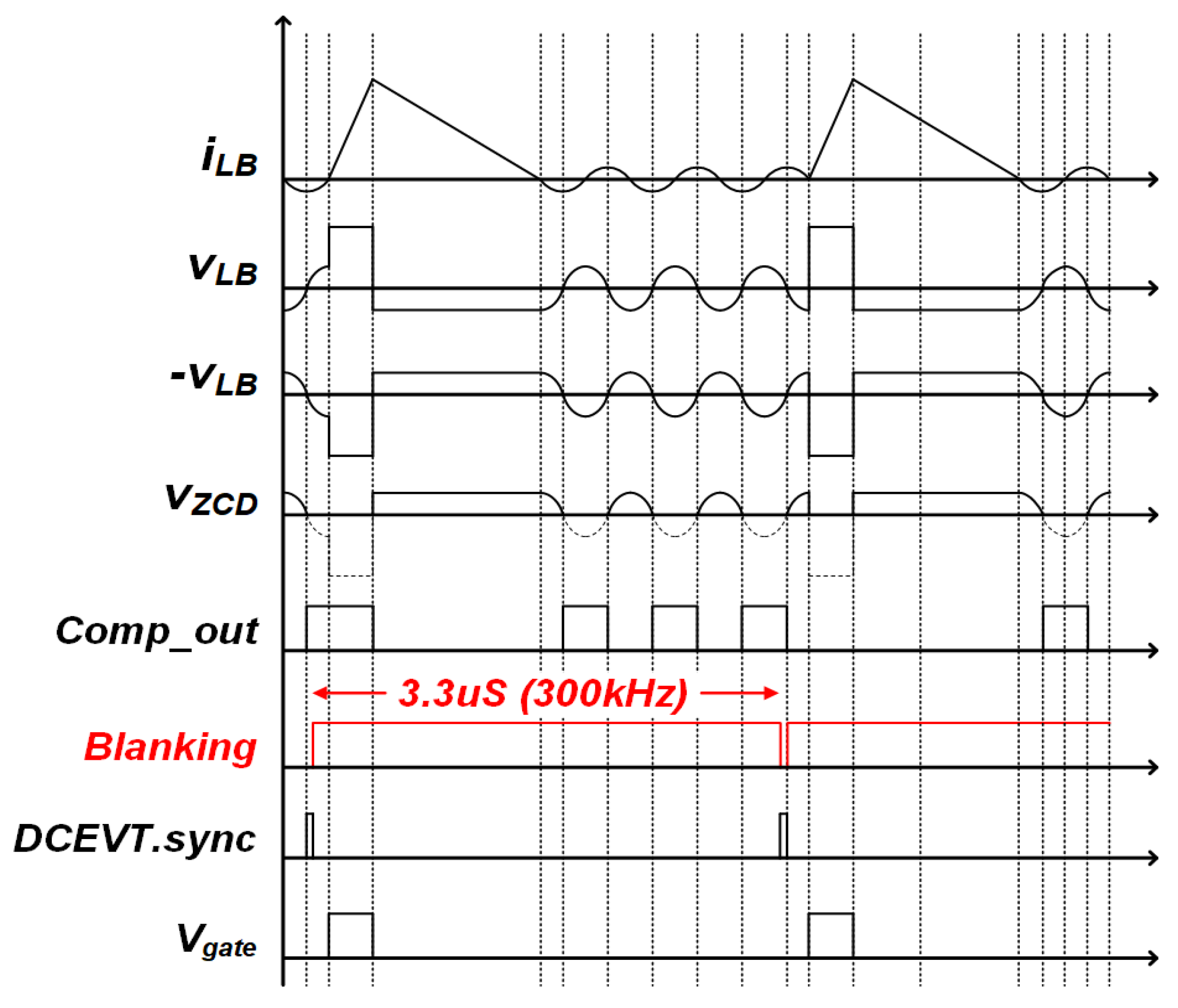

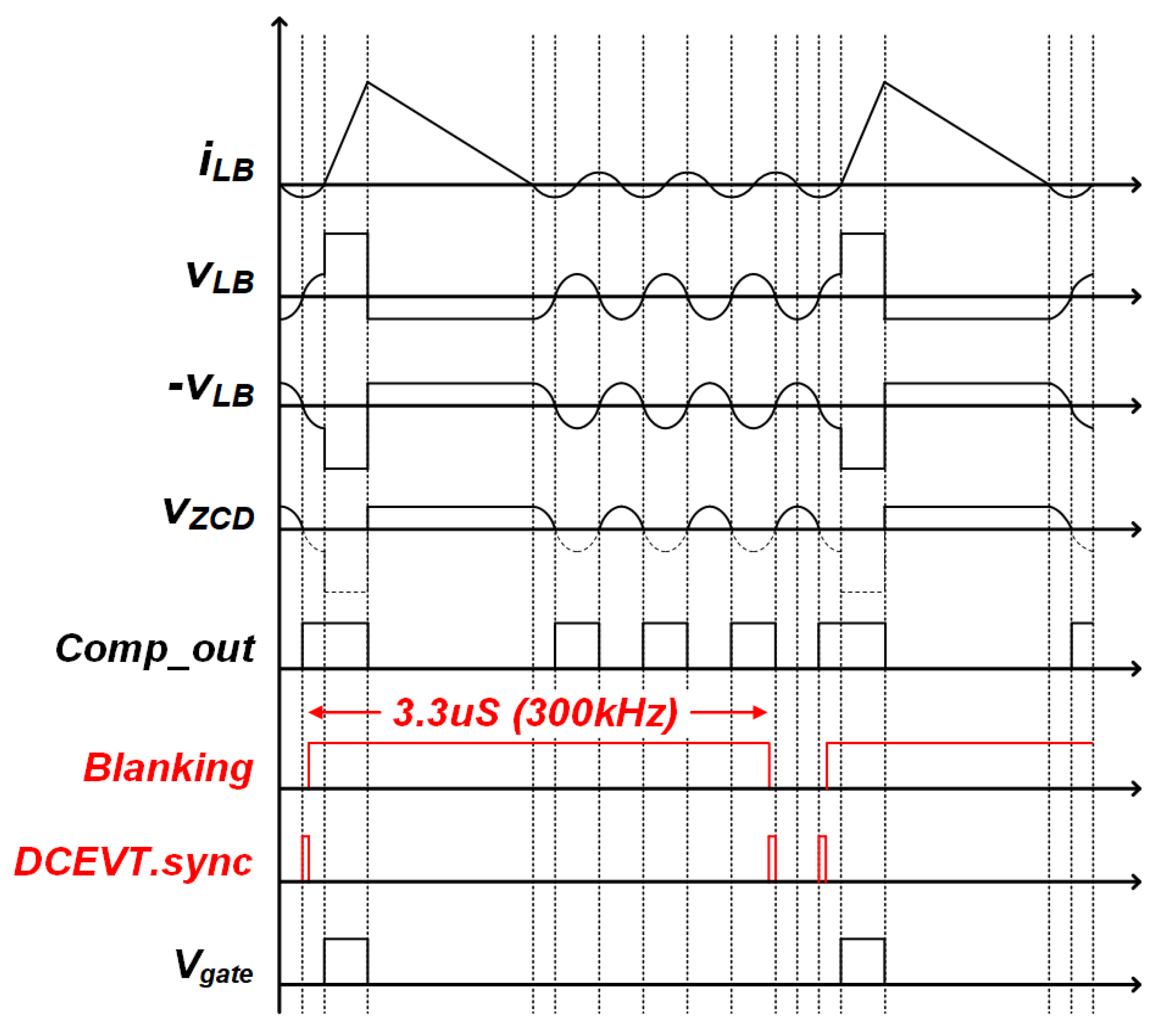

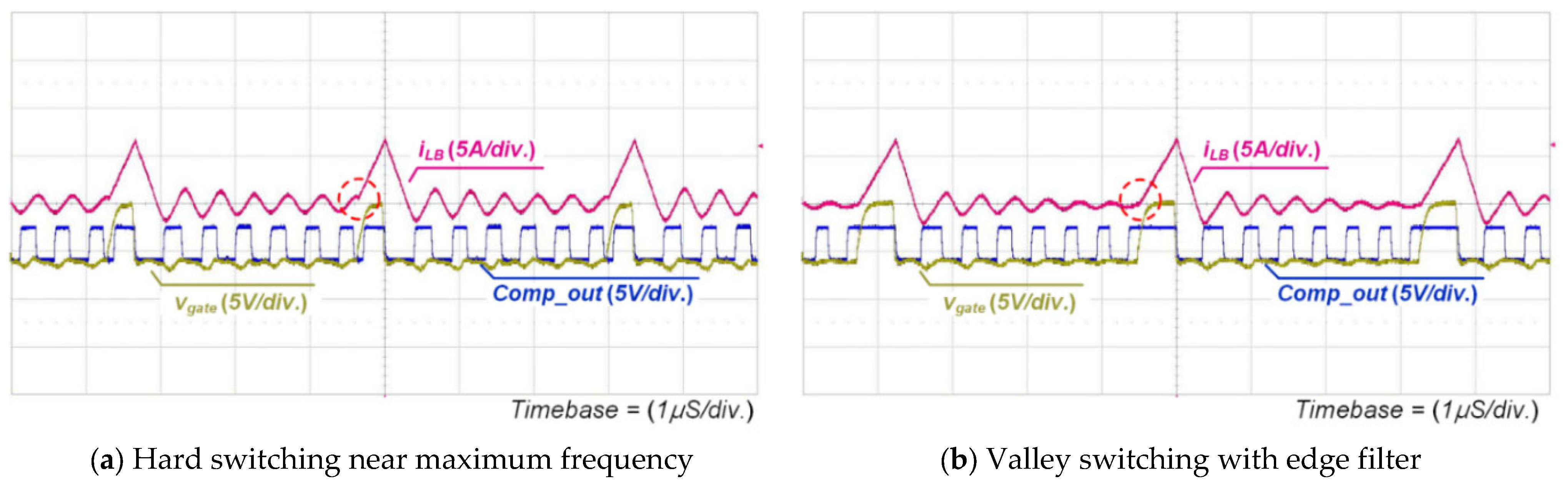

3.1. On-Time Delay Scheme for Valley Switching

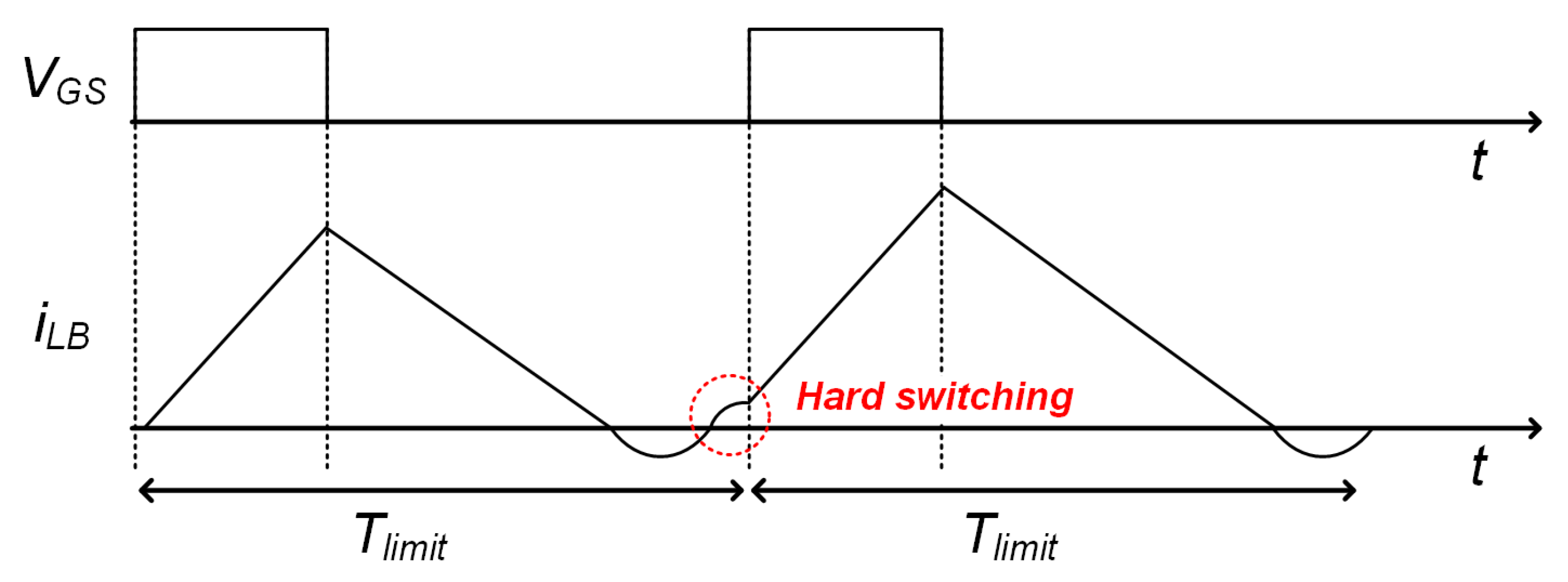

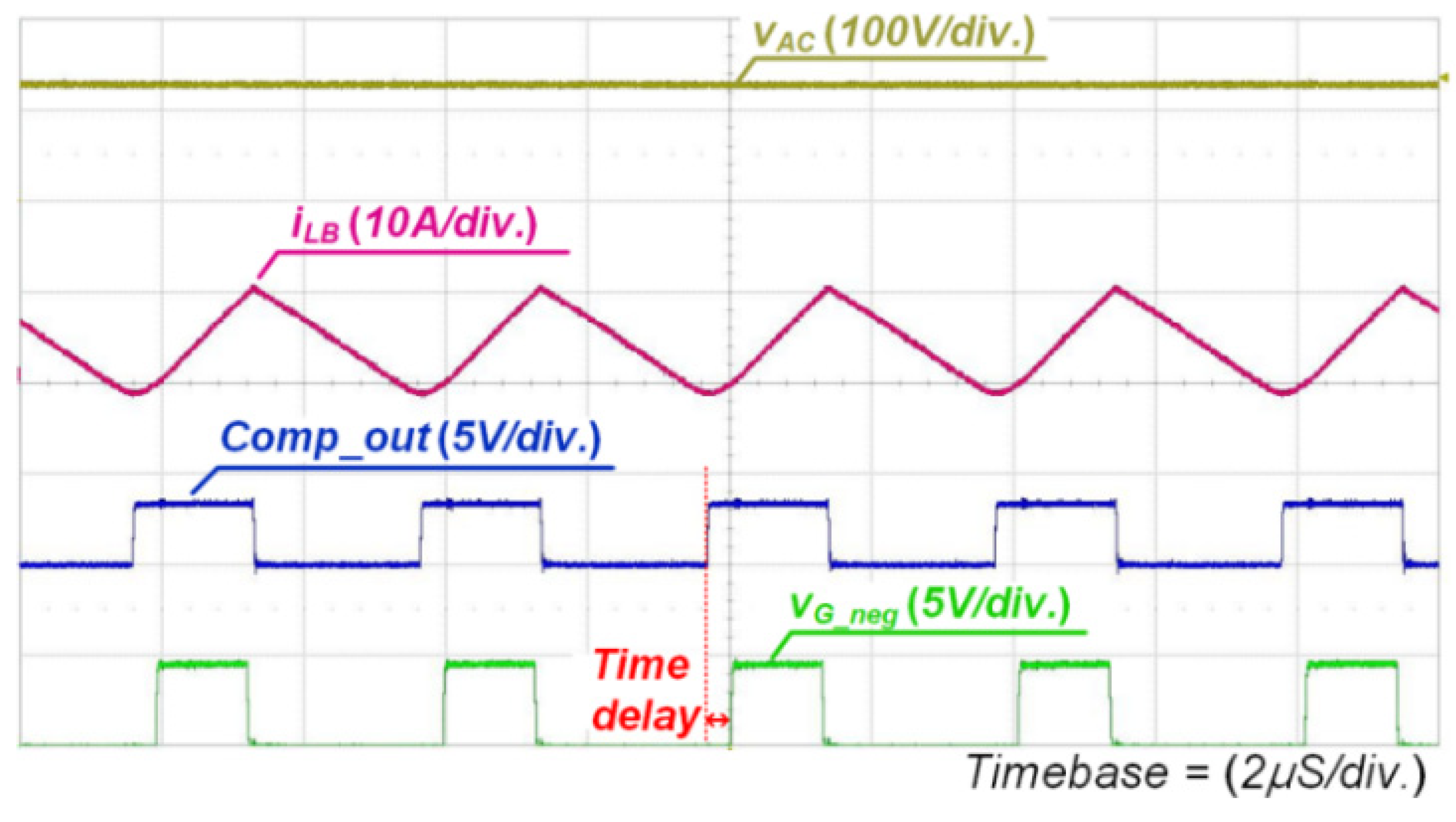

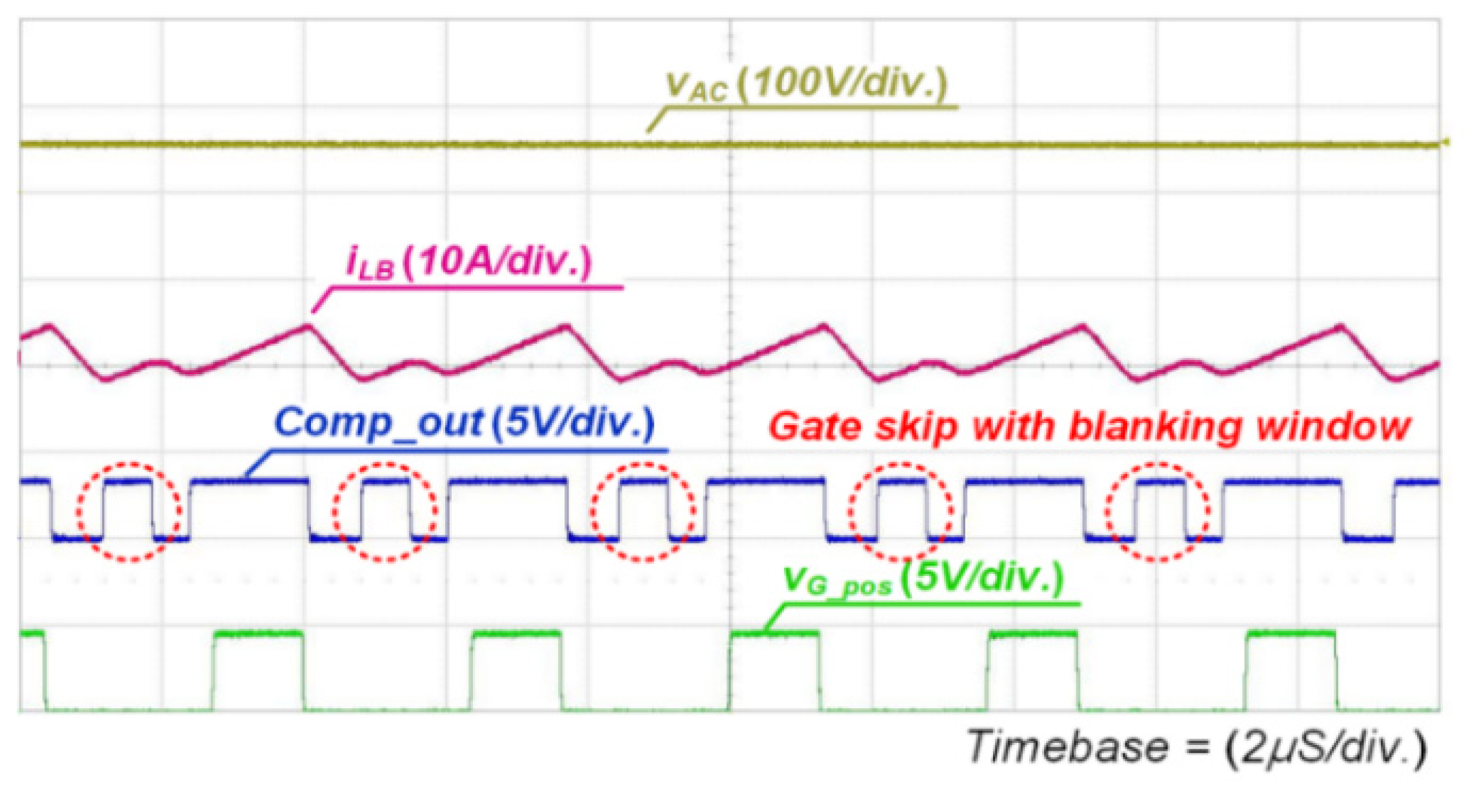

3.2. Maximum Frequency Limitation Scheme

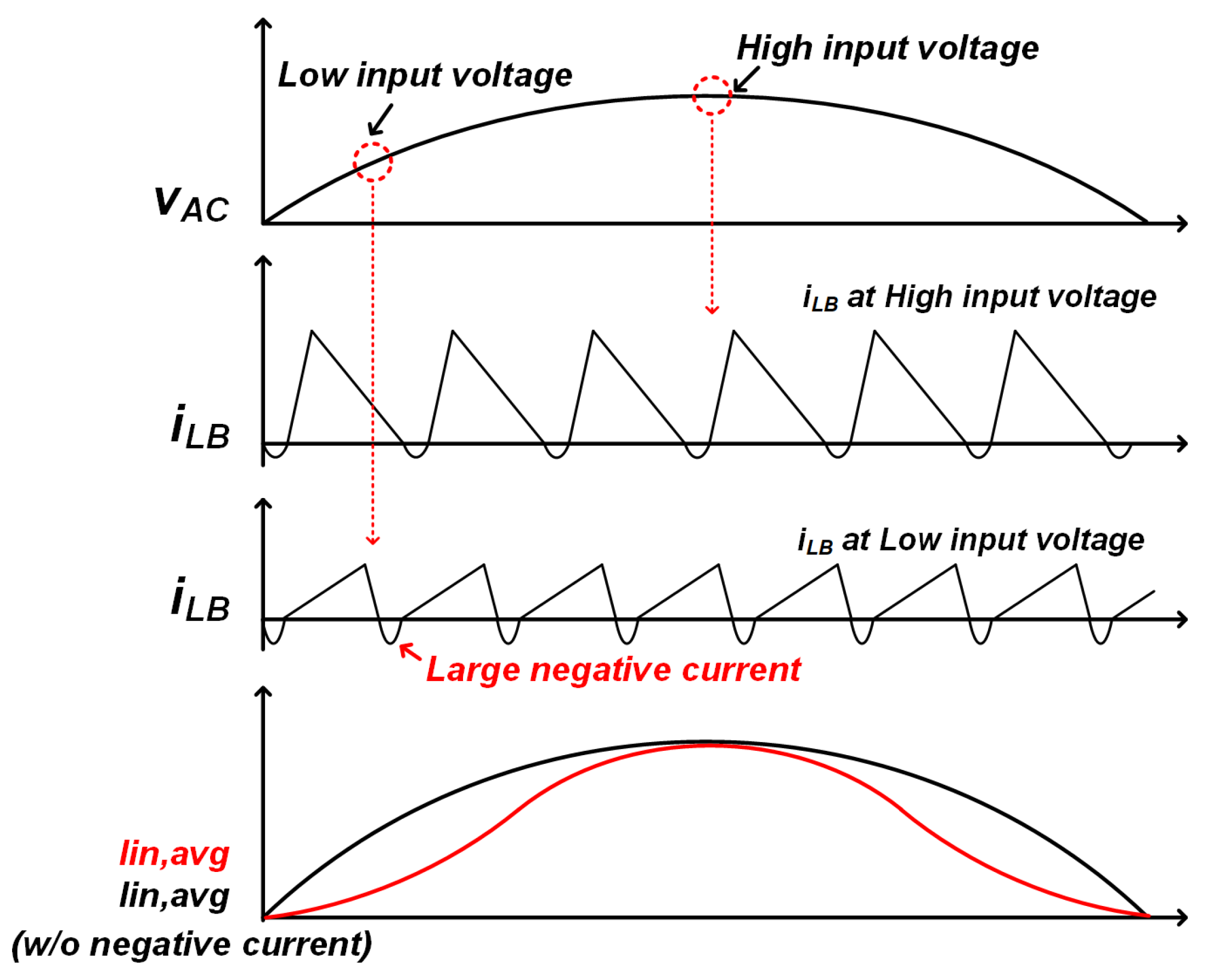

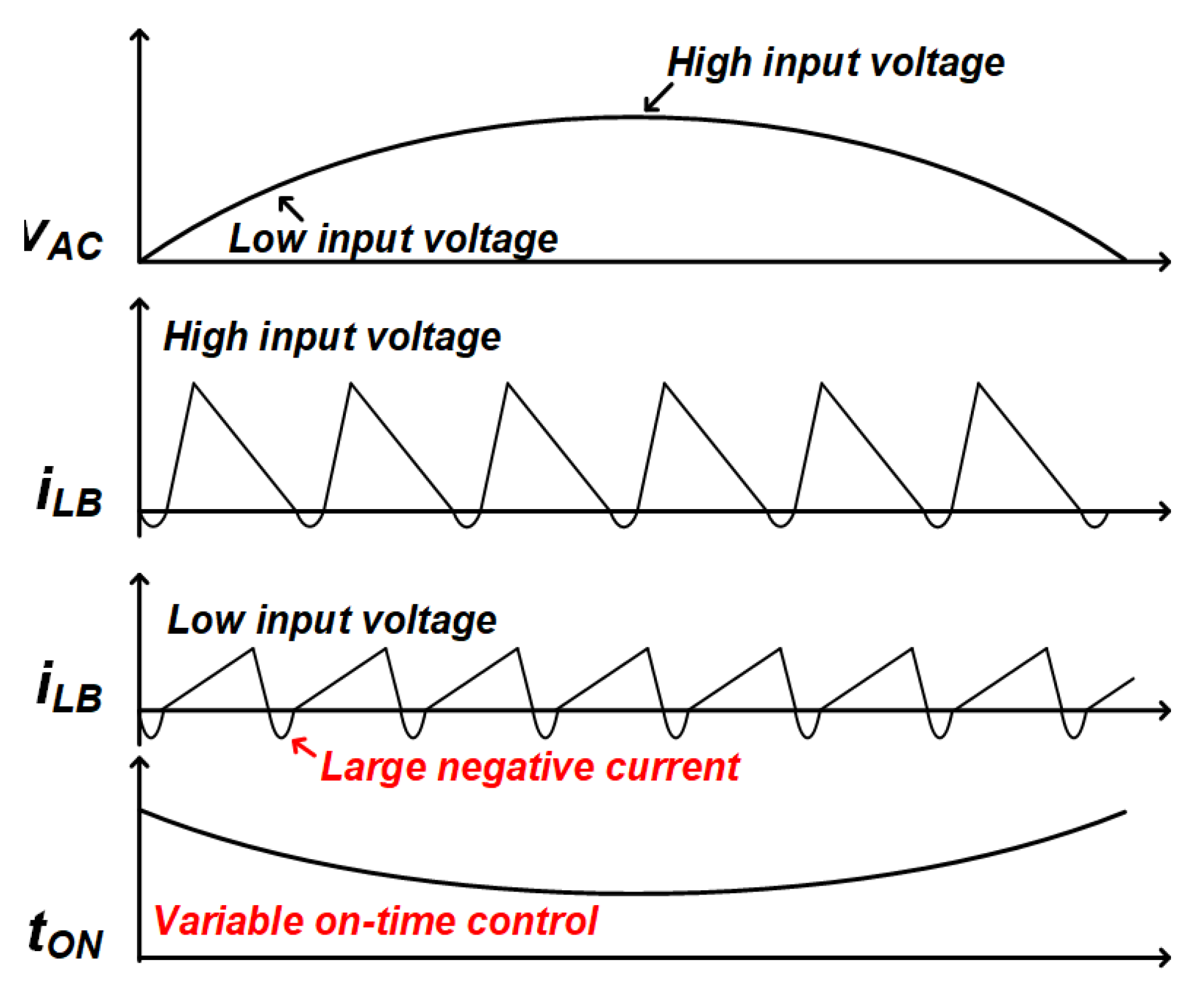

3.3. Additional On-Time Control

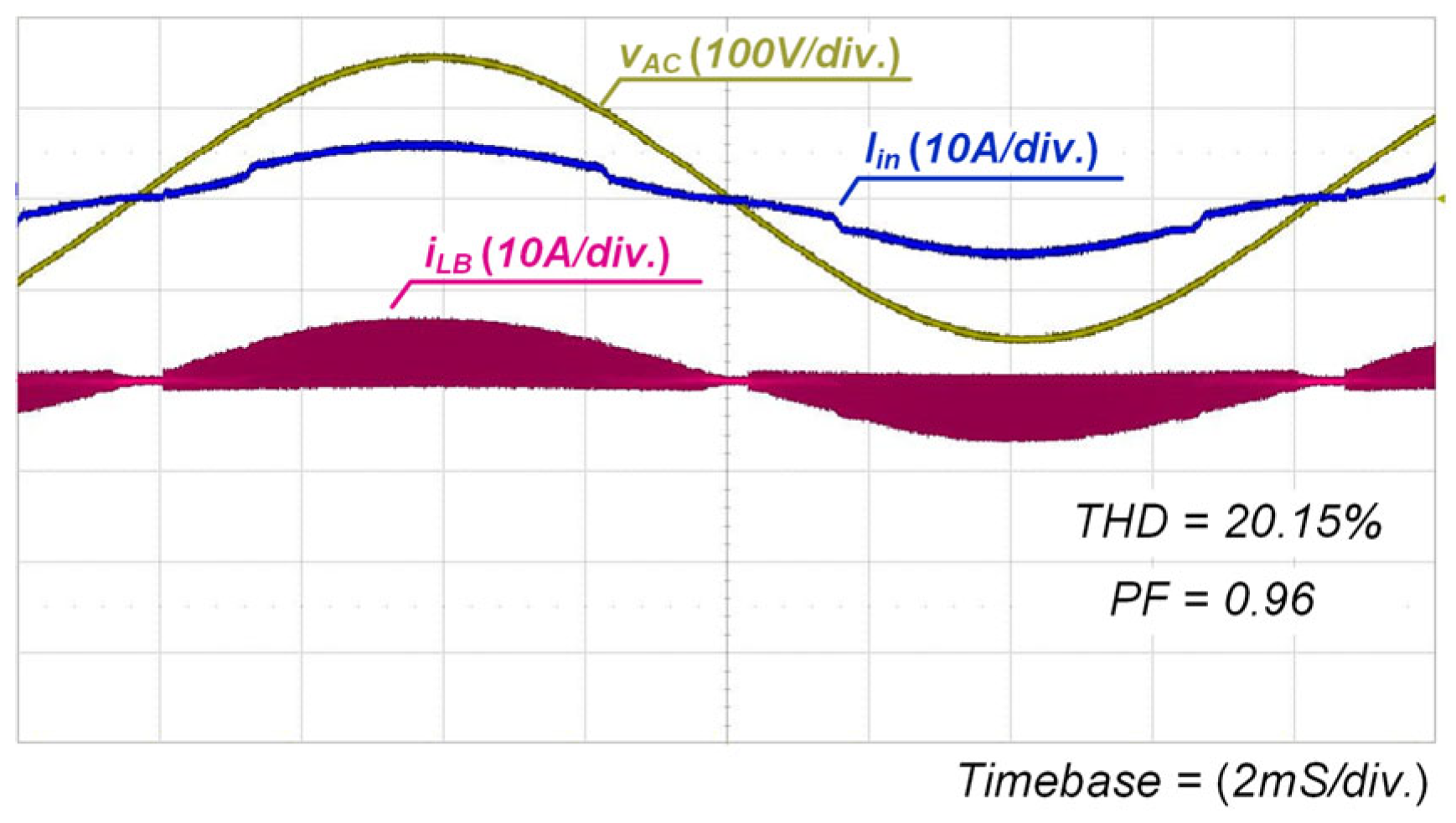

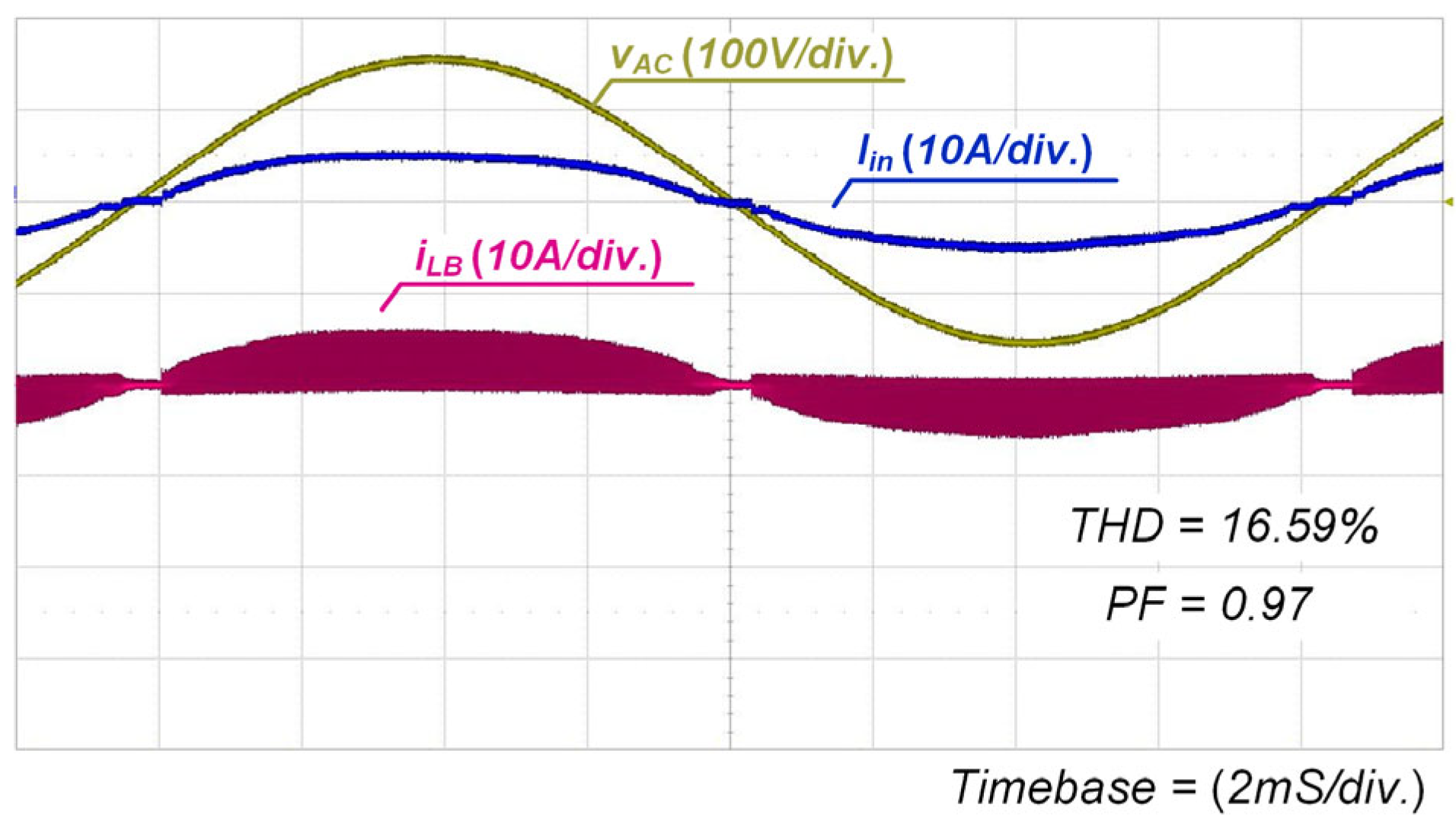

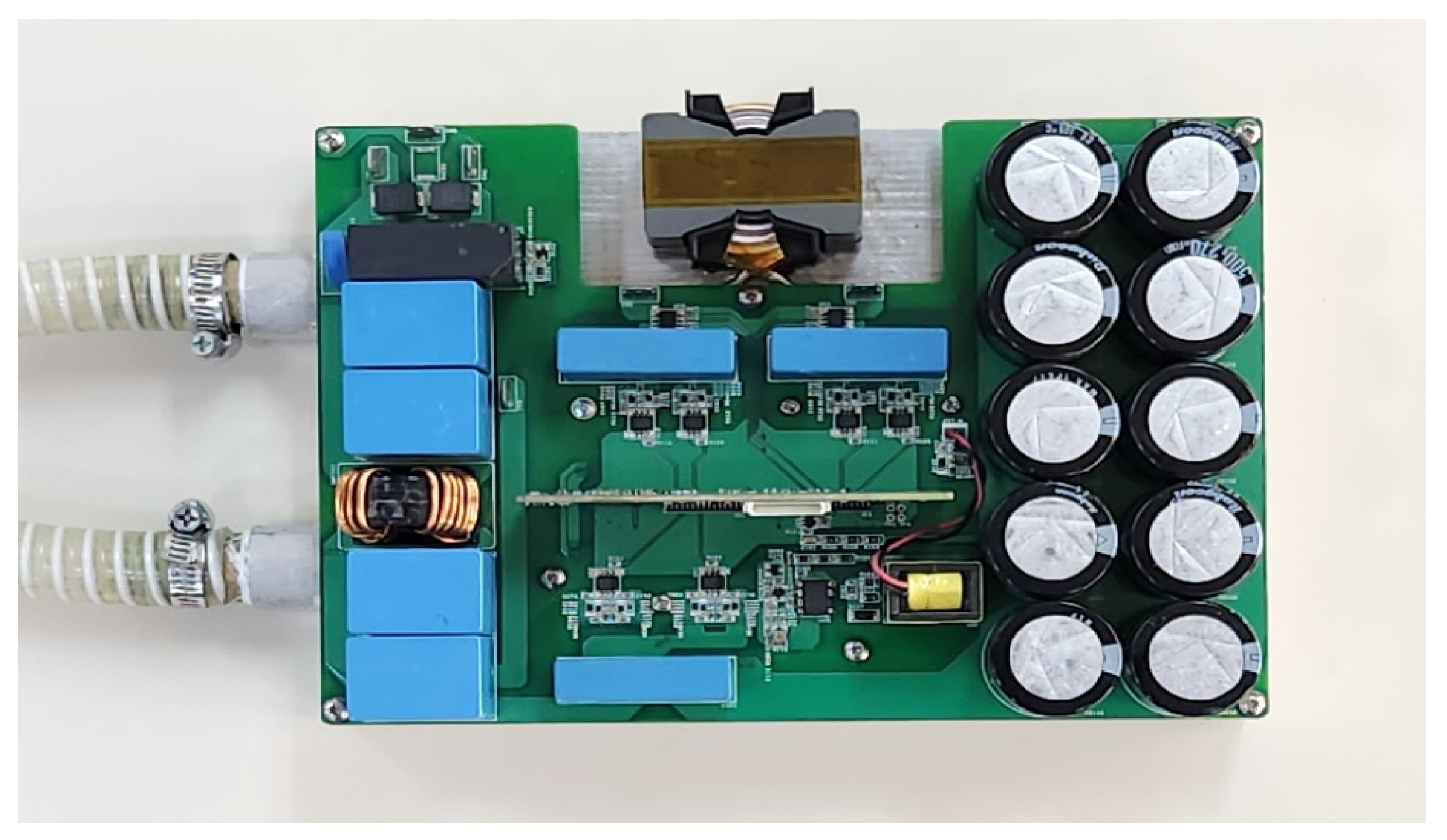

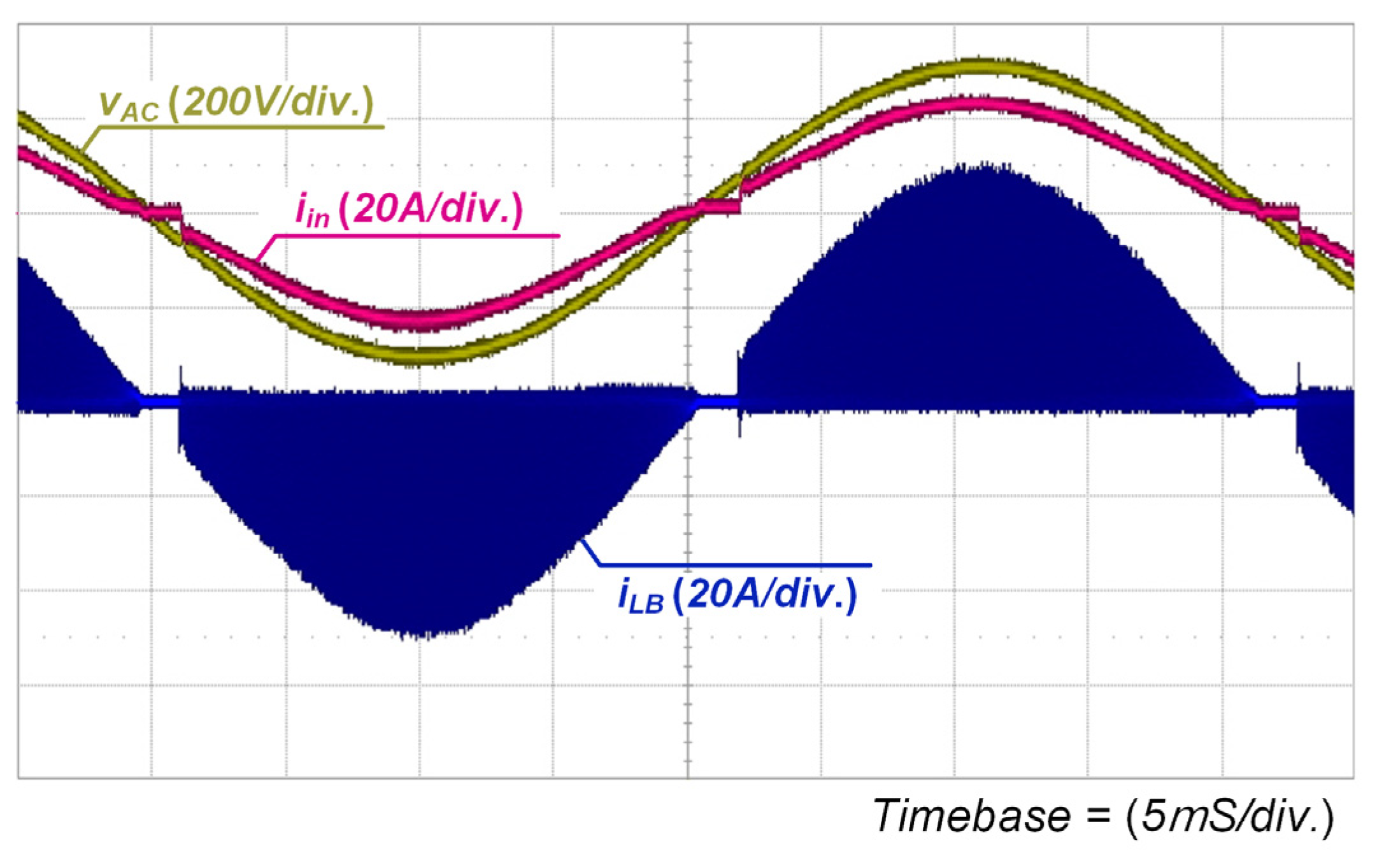

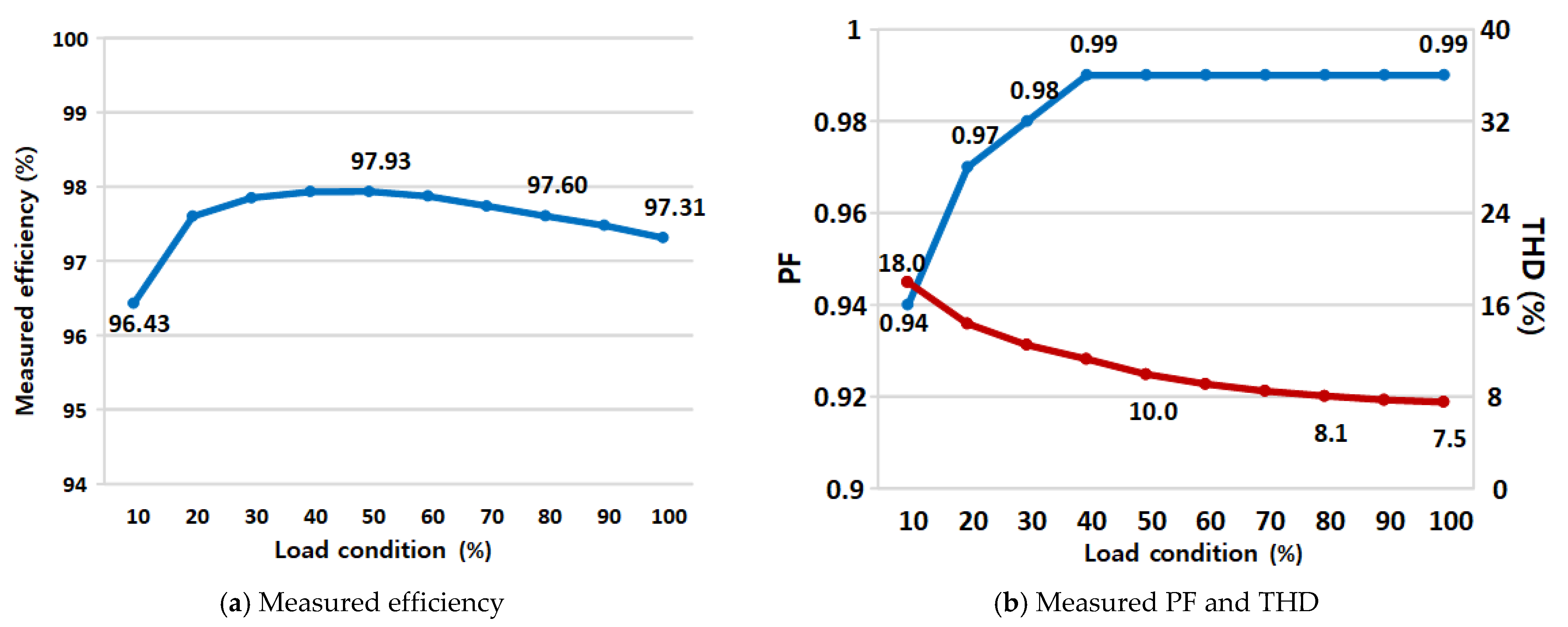

4. Experimental Results

5. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, L.; Wang, Y.; Wang, Z. Robust Lateral Motion Control for In-Wheel-Motor-Drive Electric Vehicles with Network Induced Delays. IEEE Trans. Veh. Technol. 2019, 68, 10585–10593. [Google Scholar] [CrossRef]

- Ding, X.; Wang, Z.; Zhang, L.; Wang, C. Longitudinal Vehicle Speed Estimation for Four-Wheel-Independently-Actuated Electric Vehicles Based on Multi-Sensor Fusion. IEEE Trans. Veh. Technol. 2020, 69, 12797–12806. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, Z.; Drugge, L.; Nybacka, M. Evaluating Model Predictive Path Following and Yaw Stability Controllers for Over-Actuated Autonomous Electric Vehicles. IEEE Trans. Veh. Technol. 2020, 69, 12807–12821. [Google Scholar] [CrossRef]

- Zinchenko, D.; Blinov, A.; Chub, A.; Vinnikov, D.; Verbytskyi, I.; Bayhan, S. High-Efficiency Single-Stage On-Board Charger for Electrical Vehicles. IEEE Trans. Veh. Technol. 2021, 70, 12581–12592. [Google Scholar] [CrossRef]

- Meher, S.R.; Banerjee, S.; Vankayalapati, B.T.; Singh, R.K. A Reconfigurable On-Board Power Converter for Electric Vehicle with Reduced Switch Count. IEEE Trans. Veh. Technol. 2020, 69, 3760–3772. [Google Scholar] [CrossRef]

- Tong, M.; Cheng, M.; Hua, W.; Ding, S. A Single-Phase On-Board Two-Stage Integrated Battery Charger for EVs Based on a Five-Phase Hybrid-Excitation Flux-Switching Machine. IEEE Trans. Veh. Technol. 2020, 69, 3793–3804. [Google Scholar] [CrossRef]

- Kim, D.-H.; Lee, B.-K. Asymmetric Control Algorithm for Increasing Efficiency of Nonisolated On-Board Battery Chargers with a Single Controller. IEEE Trans. Veh. Technol. 2017, 66, 6693–6706. [Google Scholar] [CrossRef]

- Lee, B.-K.; Kim, J.-P.; Kim, S.-G.; Lee, J.-Y. An Isolated/Bidirectional PWM Resonant Converter for V2G(H) EV On-Board Charger. IEEE Trans. Veh. Technol. 2017, 66, 7741–7750. [Google Scholar] [CrossRef]

- Khaligh, A.; D’Antonio, M. Global Trends in High-Power On-Board Chargers for Electric Vehicles. IEEE Trans. Veh. Technol. 2019, 68, 3306–3324. [Google Scholar] [CrossRef]

- Mallik, A.; Khaligh, A. Intermediate DC-Link Capacitor Reduction in a Two-Stage Cascaded AC/DC Converter for More Electric Aircrafts. IEEE Trans. Veh. Technol. 2018, 67, 935–947. [Google Scholar] [CrossRef]

- Li, G.; Yang, D.; Zhou, B.; Zhang, H. A Topology-Reconfigurable LLC Resonant Converter for Wide Output Range Applications. IEEE Trans. Veh. Technol. 2022, 71, 10389–10399. [Google Scholar] [CrossRef]

- Mallik, A.; Lu, J.; Khaligh, A. Sliding Mode Control of Single-Phase Interleaved Totem-Pole PFC for Electric Vehicle Onboard Chargers. IEEE Trans. Veh. Technol. 2018, 67, 8100–8109. [Google Scholar] [CrossRef]

- Park, M.-H.; Baek, J.; Jeong, Y.; Moon, G.-W. An Interleaved Totem-Pole Bridgeless Boost PFC Converter with Soft-Switching Capability Adopting Phase-Shifting Control. IEEE Trans. Power Electron. 2019, 34, 10610–10618. [Google Scholar] [CrossRef]

- Amiri, P.; Eberle, W.; Gautam, D.; Botting, C. An Adaptive Method for DC Current Reduction in Totem Pole Power Factor Correction Converters. IEEE Trans. Power Electron. 2021, 36, 11900–11909. [Google Scholar] [CrossRef]

- LE, T.-T.; Hakim, R.M.; Choi, S. A High-Efficiency Bidirectional Single-Stage AC-DC Converter Under Wide Voltage Range for Fast Chargers. IEEE Trans. Power Electron. 2023, 38, 4945–4956. [Google Scholar] [CrossRef]

- Fischer, G.d.S.; Rech, C.; de Novaes, Y.R. Extensions of Leading-Edge Modulated One-Cycle Control for Totem-Pole Bridgeless Rectifiers. IEEE Trans. Power Electron. 2020, 35, 5447–5460. [Google Scholar] [CrossRef]

- Valipour, H.; Mahdavi, M.; Ordonez, M.; Ksiazek, P.F.; Khandekar, R.M. Extended Range Bridgeless PFC Converter with High-Voltage DC Bus and Small Inductor. IEEE Trans. Power Electron. 2021, 36, 157–173. [Google Scholar] [CrossRef]

- Tausif, A.; Dusmez, S. A Unified Differential Mode Noise Estimation Method and Filter Size Comparison in Single-Phase Multileg and Multilevel Totem-Pole PFC Converters. IEEE Trans. Power Electron. 2023, 38, 7197–7206. [Google Scholar] [CrossRef]

- Belkamel, H.; Kim, H.; Choi, S. Interleaved Totem-Pole ZVS Converter Operating in CCM for Single-Stage Bidirectional AC–DC Conversion with High-Frequency Isolation. IEEE Trans. Power Electron. 2021, 36, 3486–3495. [Google Scholar] [CrossRef]

- Zhang, J.; He, Y.; Hang, L. A Novel Interleaved Parallel Cascaded Three-Level PFC with Low Inductance Volt-Second and Low Common-Mode Noise. IEEE Trans. Power Electron. 2023, 38, 17–21. [Google Scholar] [CrossRef]

- Cheng, W.-C.; Chen, C.-L. A Zero-Current Detection Circuit with Optimal ZVS/VS for Boundary Mode Boost PFC Converter. In Proceedings of the 2012 IEEE International Symposium on Industrial Electronics, Hangzhou, China, 28–31 May 2012; pp. 137–142. [Google Scholar]

- Shin, J.-W.; Seo, G.-S.; Cho, B.-H.; Lee, K.-C. Modeling and implementation of digital control for critical conduction mode power factor correction rectifier. In Proceedings of the 2012 IEEE 13th Workshop on Control and Modeling for Power Electronics (COMPEL), Kyoto, Japan, 10–13 June 2012; pp. 1–8. [Google Scholar]

- Cho, K.-S.; Lee, B.-K.; Kim, J.-S. CRM PFC Converter with New Valley Detection Method for Improving Power System Quality. Electronics 2019, 9, 38. [Google Scholar] [CrossRef]

- Huber, L.; Irving, B.T.; Jovanovic, M.M. Effect of Valley Switching and Switching-Frequency Limitation on Line-Current Distortions of DCM/CCM Boundary Boost PFC Converters. IEEE Trans. Power Electron. 2009, 24, 339–347. [Google Scholar] [CrossRef]

- Han, J.-K.; Baek, J.-I.; Jeong, Y.; Yeon, C.-O.; Moon, G.-W. A Simple THD Improving Method for CCM Boost PFC Converter Under Mixed Conduction Mode Operation. In Proceedings of the 2017 IEEE 3rd International Future Energy Electronics Conference and ECCE Asia, Kaohsiung, Taiwan, 3–7 June 2017. [Google Scholar]

- Yang, Y.; Li, Z.; Song, D.; Wang, S.; Zhang, Z.; Ren, X.; Chen, Q. SR Control with Zero Current Detection Delay Compensation for GaN CRM Totem-Pole PFC Rectifier. IEEE Trans. Power Electron. 2023, 38, 7059–7068. [Google Scholar] [CrossRef]

- Shahzad, D.; Farooq, M.; Pervaiz, S.; Afridi, K.K. A High-Power-Density High-Efficiency Soft-Switched Single-Phase Universal Input to 28-V Isolated AC–DC Converter Module Designed for Paralleled Operation. IEEE Trans. Power Electron. 2022, 37, 8262–8280. [Google Scholar] [CrossRef]

- Soares, J.W.M.; Badin, A.A. High-Efficiency Interleaved Totem-Pole PFC Converter with Voltage Follower Characteristics. IEEE J. Emerg. Sel. Top. Power Electron. 2023, 11, 1879–1887. [Google Scholar] [CrossRef]

- Jia, Y.; Wu, H.; Yang, L.; Xu, X.; Liu, Y.; Yang, F.; Xing, Y. Characterization and Optimal Control of Totem-Pole PFC Converter with High Frequency GaN HEMTs and Low Frequency Si Diodes. IEEE Trans. Ind. Electron. 2021, 68, 10740–10749. [Google Scholar] [CrossRef]

- Chen, J.; Tai, W.; Xun, B.; Gong, C.; Chen, J. Improved Control Strategies for Totem-Pole PFC with True Full Range ZVS Operation. IEEE Trans. Ind. Electron. 2023, 70, 2419–2430. [Google Scholar] [CrossRef]

| Totem-Pole Bridge-Less CRM Boost PFC Converter | |

|---|---|

| Input/output specifications | VAC = 220 VRMS, fline = 60 Hz Vout = 450 V, Pout = 3.3 kW |

| DSP | TMS320F28377 |

| Maximum switching frequency | fsw = 300 kHz |

| QB1, QB2 | GS66516T (600 V, 25 mΩ) |

| Output capacitance COSS(TR) | 335 pF |

| DB1, DB2 | LL25XB60 (600 V, 0.87 VF) |

| Output inductor | PQ5030(18 μH, 0.1 Φ × 300) |

| Power analyzer | Yokogawa WT1800 |

| Ref. [23] | Ref. [24] | Ref. [25] | This Paper | |

|---|---|---|---|---|

| Features | Optimal valley switching | Valley switching with frequency limitation | Increasing light load PF & THD | Optimal valley switchng, increasing light load PF & THD |

| Efficiency | Increase | Increase | – | Increase |

| PF | – | Increase | Increase | Increase |

| THD | – | Increase | Increase | Increase |

| Auxiliary components | 2 capacitors | 2 monoflops | 3 resistors | – |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, J.-K. Efficiency and PF Improving Techniques with a Digital Control for Totem-Pole Bridgeless CRM Boost PFC Converters. Energies 2024, 17, 369. https://doi.org/10.3390/en17020369

Han J-K. Efficiency and PF Improving Techniques with a Digital Control for Totem-Pole Bridgeless CRM Boost PFC Converters. Energies. 2024; 17(2):369. https://doi.org/10.3390/en17020369

Chicago/Turabian StyleHan, Jung-Kyu. 2024. "Efficiency and PF Improving Techniques with a Digital Control for Totem-Pole Bridgeless CRM Boost PFC Converters" Energies 17, no. 2: 369. https://doi.org/10.3390/en17020369

APA StyleHan, J.-K. (2024). Efficiency and PF Improving Techniques with a Digital Control for Totem-Pole Bridgeless CRM Boost PFC Converters. Energies, 17(2), 369. https://doi.org/10.3390/en17020369