Life Cycle Assessment of a Gas Turbine Installation

Abstract

1. Introduction

2. Materials and Methods

2.1. General Principles of LCA

2.2. Functional Unit

2.3. Limitations of LCA

- -

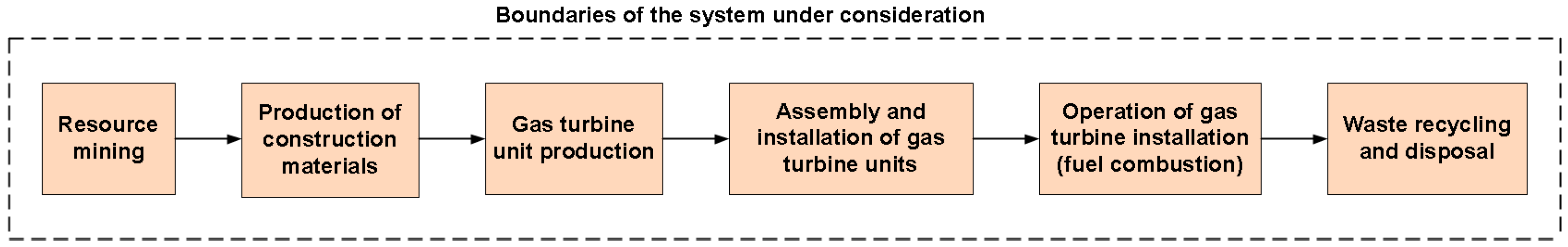

- The production stage, which includes the processes of obtaining structural materials, processing said materials, production of components, assembly and installation, and production of operating materials and spare parts;

- -

- The stage of producing fuel and electrical energy;

- -

- The operational stage, which includes the use of the device in the field, as well as maintenance and repair procedures (e.g., replacement of failed components);

- -

- The disposal stage, with processes including decomposition, processing (recycling), and disposal of materials at the end of their useful life.

2.4. Level of Detail in the Material Data

2.5. Environmental Impact Assessment Categories

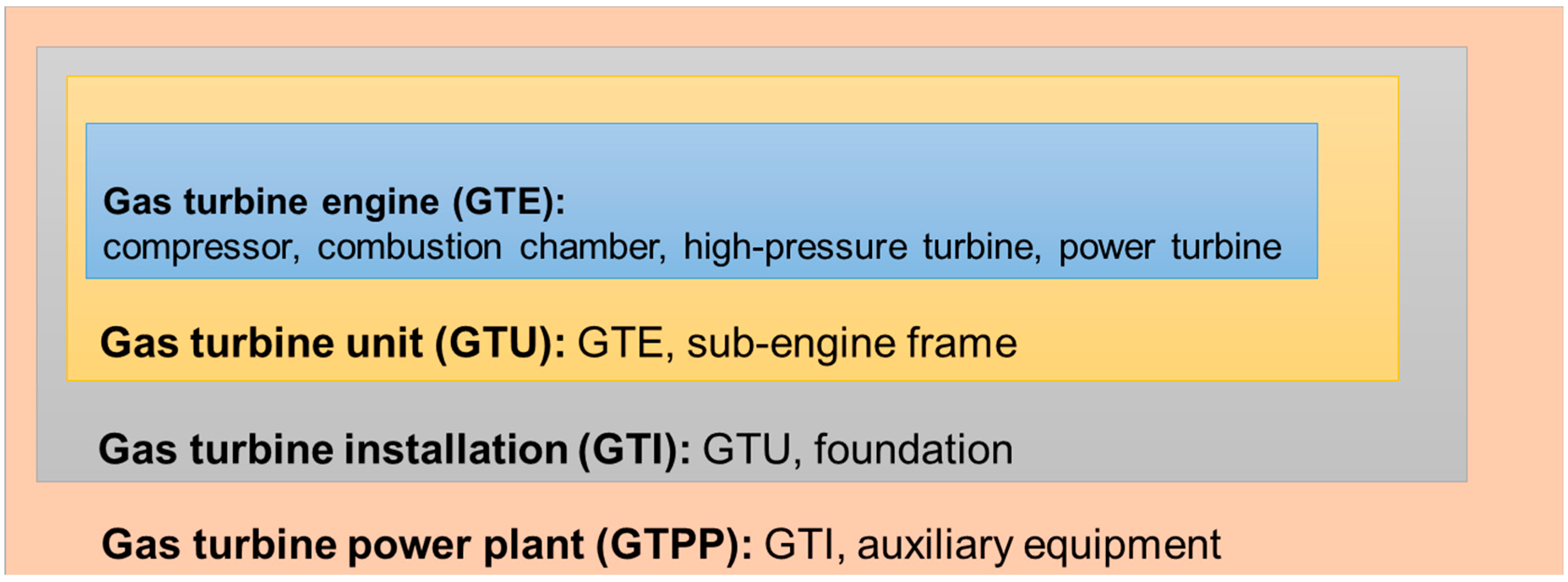

2.6. The GTI Considered

- -

- -

- a transmission with casings;

- -

- an input device;

- -

- noise-heat-insulating casing;

- -

- an output device;

- -

- a fuel unit cabinet;

- -

- pipeline and electrical communications.

3. Results

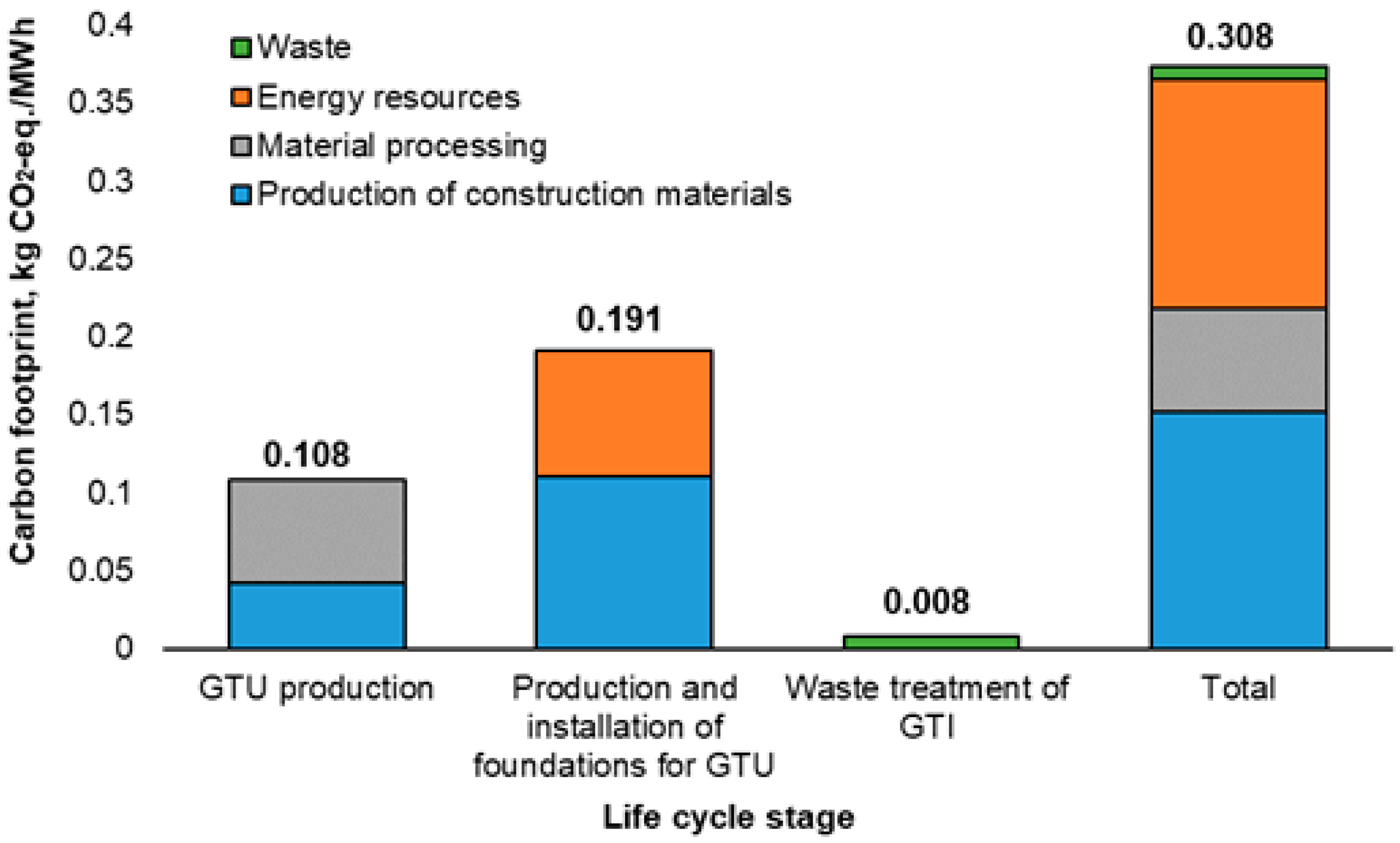

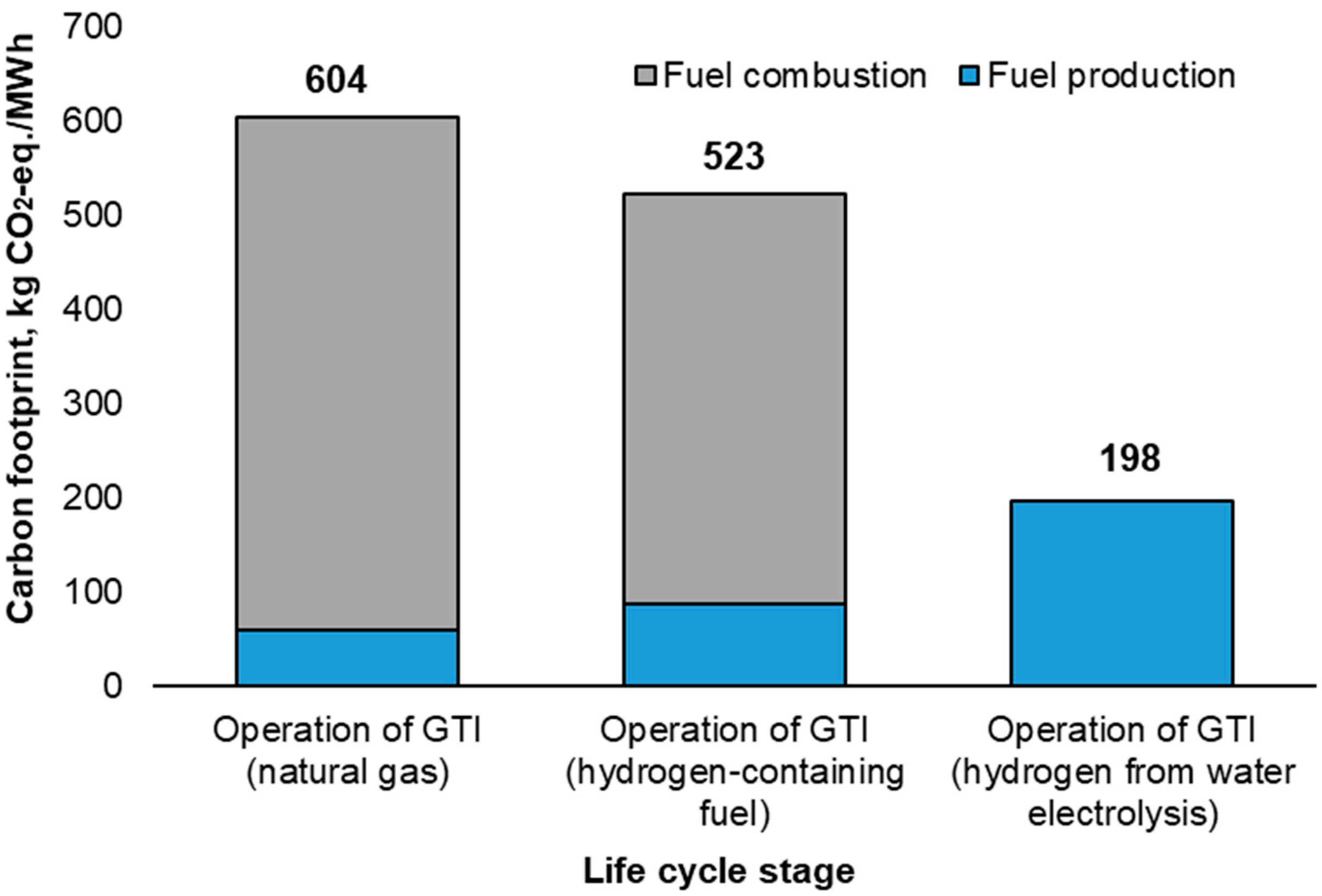

Carbon Footprint Assessment of the GTI

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sosna, M.K.; Maslennikova, M.V.; Kryuchkov, M.V.; Pustovalov, M.V. «Green» and/or «Blue» Hydrogen. Neftegazokhimiia. Oil Gas Chem. 2020, 3–4, 21–23. Available online: https://cyberleninka.ru/article/n/zelenyy-i-ili-goluboy-vodorod (accessed on 2 September 2023).

- Buslik, L.N. Gas Turbine Units for Energy and Gas Transportation. Device and Systems; IPP Contrast: Kharkov, Ukraine, 2013; 152p. [Google Scholar]

- Grigoriev, A.A. Theory, Calculation and Design of Gas Turbine Engines for Ground Use; PNRPU: Perm, Russia, 2012; 65p. [Google Scholar]

- Aksyutin, O.E.; Ishkov, A.G.; Khloptsov, V.G.; Kazaryan, V.A.; Stolyarevsky, A.Y. The Concept of Large-Scale Development of Innovative Systems for the Production and Distribution of Methane-Hydrogen Fuel as an Effective Alternative Energy Source. Available online: https://ccortes.ru/st_docs/klumpur2012.pdf (accessed on 4 September 2023).

- Balakin, A.M.; Badamshin, A.R.; Matveev, Y.V.; Laptev, M.A.; Barskov, V.V. Features of Operation of a Gas Turbine Unit Using a Mixture of Hydrogen and Natural Gas. Available online: https://eaf.etu.ru/assets/files/eaf21/papers/53-57.pdf (accessed on 2 September 2023).

- Griebel, P. Hydrogen in Gas Turbine Combustion Systems: Challenges and Opportunities. In Proceedings of the TOTeM 45 «Gas Turbines for Future Energy Systems», Cardiff, UK, 3–4 September 2018. [Google Scholar]

- Semenov, S.V.; Nikhamkin, M.S.; Plotnikov, A.I. Review of research and development on gas turbine power plants using hydrogen fuel. Aviat. Engines 2022, 3, 73–85. [Google Scholar] [CrossRef]

- Hydrogen Fueled Gas Turbine. GE Gas Power. Available online: https://www.ge.com/gas-power/future-of-energy/hydrogen-fueled-gas-turbines (accessed on 6 January 2023).

- Bohan, K.; Klapdor, E.V.; Prade, B.; Haeggmark, A.; Bulat, G.; Prasad, N.; Welch, M.; Adamsson, P.; Johnke, T. Hydrogen Power with Siemens Gas Turbines: Reliable Carbon-Free Power with Flexibility; Siemens. Siemens Gas and Power: Munich, Germany, 2020; 22p, Available online: https://www.infrastructureasia.org/-/media/Articles-for-ASIA-Panel/Siemens-Energy---Hydrogen-Power-with-Siemens-Gas-Turbines.pdf?la=en&hash=1B91FADA342293EFB56CDBE312083FE1B64DA111 (accessed on 14 September 2023).

- Solid Oxide Fuel Cell. Available online: https://fuelcellsworks.com/knowledge/technologies/sofc/ (accessed on 6 December 2023).

- Advantages and Disadvantages to Fuel Cells. Techetch. Available online: https://techetch.com/blog/advantages-and-disadvantages-to-fuel-cells/ (accessed on 6 October 2023).

- Battelle Memorial Institute. Manufacturing Cost Analysis of PEM Fuel Cell Systems for 5- and 10-kW Backup Power Applications; U.S. Department of Energy: Washington, DC, USA, 2016; 124p. Available online: https://www.energy.gov/eere/fuelcells/articles/manufacturing-cost-analysis-pem-fuel-cell-systems-5-and-10-kw-backup-power#:~:text=At%20the%20largest%20annual%20production,potential%20for%20further%20cost%20reductions (accessed on 6 October 2023).

- Ecoinvent Database, version 3.8; Ecoinvent: Zurich, Switzerland, 2021.

- Caldeira-Pires, A.; Da Silva Ribeiro, R. Life cycle assessment (LCA) of a gas turbine power plant. In Proceedings of the 7th International Congress of Mechanical Engineering, São Paulo, Brazil, 10–14 November 2003. [Google Scholar]

- Annisa, R.; Jiwandono, K.; Marteda, G.; Sinisuka, N.I. Life cycle Assessment of natural gas combined cycle steam power generation systems in Indonesia: Case Study on Gresik power plant. IOP Conf. Ser. Earth Environ. Sci. 2021, 753, 012039. [Google Scholar] [CrossRef]

- The International EPD® System; EPD Southeast Asia. Electricity from Grati Power Generation and O&M Service Unit Combined-Cycle Power Plant; Environmental Product Declaration; The International EPD® System: Stockholm, Sweden; EPD Southeast Asia: Jakarta Barat, Indonesia, 2022; 15p, Available online: https://api.environdec.com/api/v1/EPDLibrary/Files/9b6a4ab2-6404-48ea-cf46-08daa1eb7336/Data (accessed on 10 October 2023).

- Song, G.; Zhao, Q.; Shao, B.; Zhao, H.; Wang, H.; Tan, W. Life Cycle Assessment of Greenhouse Gas (GHG) and NOx Emissions of Power-to-H2-to-Power Technology Integrated with Hydrogen-Fueled Gas Turbine. Energies 2023, 16, 977. [Google Scholar] [CrossRef]

- The International EPD® System. Rizziconi Combined-Cycle Gas Turbine Plant; Environmental Product Declaration; The International EPD® System: Stockholm, Sweden, 2019; 16p, Available online: https://www.axpo.com/content/dam/axpo19/ch/files-ch/private/engagement/nature---environment/1912_Axpo_Umweltdeklaration_Rizziconi_2019_EN.pdf (accessed on 2 October 2023).

- Sosnina, E.N.; Masleeva, O.V.; Kryukov, E.V.; Erdili, N.I. Environmental life cycle assessment of mini-CHP with different types of engines. Izv. TulGU. Tech. Sci. 2021, 4, 206–214. [Google Scholar]

- Ferraz de Paula, L.; Carmo, B.S. Environmental Impact Assessment and Life Cycle Assessment for a Deep Water Floating Offshore Wind Turbine on the Brazilian Continental Shelf. Wind 2022, 2, 495–512. [Google Scholar] [CrossRef]

- Martin, E. The Wind Turbine: Energy. Available online: http://www.designlife-cycle.com/wind-turbines (accessed on 11 October 2023).

- Haapala, K.R.; Prempreeda, P. Comparative life cycle assessment of 2.0 MW wind turbines. Int. J. Sustain. Manuf. 2014, 3, 170–185. [Google Scholar] [CrossRef]

- Alsaleh, A.; Sattler, M. Comprehensive life cycle assessment of large wind turbines in the US. Clean Technol. Environ. Policy 2019, 21, 887–903. [Google Scholar] [CrossRef]

- Farina, A.; Anctil, A. Material consumption and environmental impact of wind turbines in the USA and globally. Resour. Conserv. Recycl. 2022, 176, 105938. [Google Scholar] [CrossRef]

- Gomaa, M.R.; Rezk, H.; Mustafa, R.J.; Al-Dhaifallah, M. Evaluating the Environmental Impacts and Energy Performance of a Wind Farm System Utilizing the Life-Cycle Assessment Method: A Practical Case Study. Energies 2019, 12, 3263. [Google Scholar] [CrossRef]

- Younes, N.; Bina, S.M.; Rahmani, K. Life Cycle Energy and Greenhouse Gas Emission Assessment of a Wind Turbine Installed in Northeast of Iran. Int. J. Energy Policy Manag. 2018, 3, 8–15. [Google Scholar]

- Sikand, S. Life Cycle Assessment of Wind Turbines: Waste and Emissions. Available online: http://www.designlife-cycle.com/wind-turbines (accessed on 11 October 2022).

- Carrara, S.; Alves Dias, P.; Plazzotta, B.; Pavel, C. Raw Materials Demand for Wind and Solar PV Technologies in the Transition towards a Decarbonised Energy System; Publication Office of the European Union: Luxembourg, 2020; 70p. [Google Scholar]

- Kukreja, B. Life Cycle Analysis of Electric Vehicles. Quantifying the Impact; UBC Sustainability Scholar: Vancouver, BC, Canada, 2018; 17p, Available online: https://www.readkong.com/page/life-cycle-analysis-of-electric-vehicles-7883081 (accessed on 1 October 2023).

- Koroma, M.S.; Philippot, M.; Cardellini, G.; Hosen, M.S.; Coosemans, T.; Messagie, M. Life cycle assessment of battery electric vehicles: Implications of future electricity mix and different battery end-of-life management. Sci. Total Environ. 2022, 831, 154859. [Google Scholar] [CrossRef] [PubMed]

- Kozlov, A.V.; Porsin, A.V.; Dobrovolsky, Y.A.; Kashin, A.M.; Terenchenko, A.S.; Gorin, M.A.; Tikhonov, A.N.; Milov, K.V. Life cycle assessment of power plants based on a battery, hydrogen fuel cells, and internal combustion engine for city buses in the Moscow region. Russ. J. Appl. Chem. 2021, 94, 784–805. [Google Scholar] [CrossRef]

- Jemioło, W. Life Cycle Assessment of Current and Future Passenger Air Transport in Switzerland. Master’s Thesis, Technology Assessment Group, Laboratory for Energy System Analysis Paul Scherrer Institute (PSI), Villigen, Switzerland, 2015. [Google Scholar]

- Kolios, A.; Howe, S.; Asproulis, N.; Salonitis, K. Environmental impact assessment of the manufacturing of a commercial aircraft. In Proceedings of the 11th International Conference on Manufacturing Research (ICMR2013), Advances in Manufacturing Technology XXVII, Cranfield, Bedfordshire, UK, 19–20 September 2013. [Google Scholar]

- Okura, T. Materials for Aircraft Engines; ASEN 5063 Aircraft Propulsion Final Report; 2015; 14p. Available online: https://www.colorado.edu/faculty/kantha/sites/default/files/attached-files/73549-116619_-_takehiro_okura_-_dec_17_2015_1027_am_-_asen_5063_2015_final_report_okura.pdf (accessed on 9 October 2023).

- ISO 14040-2022; Environmental Management–Life Cycle Assessment–Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2022.

- Gross, R.; Hanna, R.; Gambhir, A.; Heptonstall, P.; Speirs, J. How long does innovation and commercialisation in the energy sectors take? Historical case studies of the timescale from invention to widespread commercialisation in energy supply and end use technology. Energy Policy 2018, 123, 682–699. [Google Scholar] [CrossRef]

- Razdan, P.; Garrett, P. Life Cycle Assessment of Electricity Production from an Onshore V110-2.0 MW Wind Plant; Vestas Wind Systems A/S: Aarhus, Denmark, 2015; Available online: https://www.vestas.de/content/dam/vestas-com/global/en/sustainability/reports-and-ratings/lcas/LCAV11020MW181215.pdf.coredownload.inline.pdf (accessed on 9 September 2023).

- Inozemtsev, A.A.; Konyaev, E.A.; Medvedev, V.V.; Neradko, A.V.; Ryassov, A.E. Aviation Engine PS-90A; Fizmatlit: Moscow, Russia, 2007; 320p. [Google Scholar]

- Rabe, W.; Kostka, G.; Stegen, S.K. China’s supply of critical raw materials: Risks for Europe’s solar and wind industries? Energy Policy 2017, 101, 692–699. [Google Scholar] [CrossRef]

- Razdan, P.; Garrett, P. Life Cycle Assessment of Electricity Production from an Onshore V136-3.45 MW Wind Plant; Vestas Wind Systems A/S: Aarhus, Denmark, 2017; Available online: https://www.vestas.com/content/dam/vestas-com/global/en/sustainability/reports-and-ratings/lcas/V1363%2045MW_Mk3a_ISO_LCA_Final_31072017.pdf.coredownload.inline.pdf (accessed on 9 September 2023).

- Younesi, R.; Veith, G.M.; Johansson, P.; Edström, K.; Vegge, T. Lithium salts for advanced lithium batteries: Li–metal, Li–O2, and Li–S. Energy Environ. Sci. 2015, 8, 1905–1922. [Google Scholar] [CrossRef]

- Cox, B.; Jemiolo, W.; Mutel, C. Life cycle assessment of air transportation and the Swiss commercial air transport fleet. Transp. Res. Part D Transp. Environ. 2018, 58, 1–13. [Google Scholar] [CrossRef]

- Inozemtsev, A.A.; Nikhamkin, M.A.; Sandratsky, V.L. Fundamentals of the Design of Aircraft Engines and Power Plants; Mashinostroenie: Moscow, Russia, 2008. [Google Scholar]

- Snitko, M.A.; Morozov, P.M. GTU-16PM with MEKS Entered into Operation. Turbines Diesels 2021, July–August, 34–36. Available online: http://www.turbine-diesel.ru/sites/default/files/n4-2021/Aviadvigatel.pdf (accessed on 15 September 2023).

- United Engine Company. Gas Turbine Installation GTU-16P. Available online: https://www.uecrus.com/products-and-services/products/gazoperekachivayushchie-ustanovki/gazoturbinnaya-ustanovka-gtu-16p4323/ (accessed on 12 September 2023).

- Burov, V.D.; Rybakov, B.A.; Savitenko, M.A. Combustion of hydrogen-containing gases in gas turbine plants. Turbines Diesels 2021, March–April, 18–24. [Google Scholar]

- Simon, N. Retrofitting Gas Turbine Facilities for Hydrogen Blending; ICF International Inc.: Reston, VA, USA, 2022; Available online: https://www.icf.com/insights/energy/retrofitting-gas-turbines-hydrogen-blending (accessed on 20 September 2023).

- Cecere, D.; Giacomazzi, E.; Di Nardo, A.; Calchetti, G. Gas Turbine Combustion Technologies for Hydrogen Blends. Energies 2023, 16, 6829. [Google Scholar] [CrossRef]

- Korzh, V.V. Gas Turbine Units; USTU: Ukhta, Russia, 2010; 180p. [Google Scholar]

- Schafrik, R.E.; Ward, D.D.; Groh, J.R. Application of Alloy 718 in GE Aircraft Engines: Past, Present and Next Five Years. In Proceedings of the International Symposium on Superalloys and Various Derivatives, Pittsburgh, PA, USA, 17–20 June 2001; pp. 1–11. [Google Scholar]

- Faramawy, S.; Zaki, T.; Sakr, A.A.-E. Natural gas origin, composition, and processing: A review. J. Nat. Gas Sci. Eng. 2016, 34, 34–54. [Google Scholar] [CrossRef]

- LM2500 Aeroderivative Gas Turbine. Available online: https://www.ge.com/gas-power/products/gas-turbines/lm2500 (accessed on 12 December 2023).

- Lim, D.; Kim, A.; Cheon, S.; Byun, M.; Lim, H. Life cycle techno-economic and carbon footprint analysis of H2 production via NH3 decomposition: A Case study for the Republic of Korea. Energy Convers. Manag. 2021, 250, 114881. [Google Scholar] [CrossRef]

- International Energy Agency. Available online: https://www.iea.org/energy-system/industry/steel (accessed on 25 September 2023).

- World Steel Association. Climate Change and the Production of Iron and Steel. Available online: https://worldsteel.org/publications/policy-papers/climate-change-and-the-production-of-iron-and-steel/ (accessed on 25 September 2023).

- World Steel Association. Sustainability Indicators 2023 Report. Available online: https://worldsteel.org/steel-topics/sustainability/sustainability-indicators/ (accessed on 25 September 2023).

- Carbon Neutral? Markatur. Available online: https://www.markatur.no/artikler/carbon-neutral (accessed on 25 September 2023).

- Wei, W.; Samuelsson, P.; Pär, J.; Rutger, G.; Björn, G. Energy Consumption and Greenhouse Gas Emissions of High-Carbon Ferrochrome Production. Miner. Met. Mater. Soc. 2023, 75, 1206–1220. [Google Scholar] [CrossRef]

- Suer, J.; Ahrenhold, F.; Traverso, M. Carbon Footprint and Energy Transformation Analysis of Steel Produced via a Direct Reduction Plant with an Integrated Electric Melting Unit. J. Sustain. Metall 2022, 8, 1532–1545. [Google Scholar] [CrossRef] [PubMed]

- Erneuerbare Energien in Deutschland. Geschäftsstelle der Arbeitsgruppe Erneuerbare Energien-Statistik (AGEE-Stat) am Umweltbundesamt, 2018. Available online: https://www.umweltbundesamt.de/publikationen/erneuerbare-energien-in-deutschland-2018 (accessed on 28 September 2023).

- Shadrikov, D. On the Way to Carbon Neutrality with Aluminum ALLOW. 2022. Available online: https://www.ncpack.ru/images/analitika/shadrikov.pdf (accessed on 28 September 2023).

- Greenhouse Gas Emissions—Aluminium Sector. International Aluminum Institute. Available online: https://international-aluminium.org/statistics/greenhouse-gas-emissions-aluminium-sector/ (accessed on 30 September 2023).

- ALLOW. Available online: https://allow.rusal.ru/allow/construction/ (accessed on 30 September 2023).

- Lapteva, A.V.; Lisenko, V.G.; Chesnokov, Y.N. Carbon footprint of aluminum production when obtaining alumina using the Bayer process. In Proceedings of the XIV International Scientific and Practical Conference, Sistema Upravleniya Ekologicheskoi Bezopasnostyu, UrFU, Ekaterinburg, Russia, 20–21 May 2020; pp. 264–268. [Google Scholar]

- Klausner, J.F. Innovating the Future of Titanium Production at the U.S. Department of Energy Advanced Research Project Agency-Energy. Washington, 2015. Available online: https://cdn.ymaws.com/titanium.org/resource/resmgr/titaniumUSA2015/tues_and_wednesday_papers/KlausnerJamesTiUSA2015.pdf (accessed on 30 September 2023).

- ELG HANIEL GROUP. Sustainability Report. 2015. Available online: https://www.elgmetals.com/site/assets/files/2025/elg_cr_report_2015_online.pdf (accessed on 2 October 2023).

- Lyons, R.; Newell, A.; Ghadimi, P.; Papakostas, N. Environmental impacts of conventional and additive manufacturing for the production of Ti-6Al-4V knee implant: A life cycle approach. Int. J. Adv. Manuf. Technol. 2021, 112, 787–801. [Google Scholar] [CrossRef]

- Rajemi, M.; Mativenga, P.; Syed, J. Energy and carbon footprint analysis for machining titanium Ti-6Al-4V Alloy. J. Mach. Eng. 2009, 9, 103–112. [Google Scholar]

- IperionX’s Recycled Titanium Is a Low Carbon Champion. Stockhead. Available online: https://www.linkedin.com/posts/janemorganmanagement_iperionxs-recycled-titanium-is-a-low-carbon-activity-7057122618222555136-YMIL (accessed on 4 October 2023).

- Nickel Institute. Life Cycle Data. Executive Summary. 2023. Available online: https://nickelinstitute.org/media/fbmdel4y/lifecycledata-summary-updatejan2023.pdf (accessed on 1 October 2023).

- Conte, N. The Carbon Emissions of Producing Energy Transition Metals: Charted. 2022. Available online: https://elements.visualcapitalist.com/the-carbon-emissions-of-producing-energy-transition-metals-charted/#:~:text=Along%20with%20this%2C%20producing%20high,per%20kilogram%20of%20nickel%20content (accessed on 1 October 2023).

- Norilsk Nickel Climate Change Strategy. Nornickel. Available online: https://nornickel.com/sustainability/climate-change/strategy/ (accessed on 1 October 2023).

- Mistry, M.; Gediga, J.; Boonzaier, S. Life cycle assessment of nickel product. Int. J. Life Cycle Assess. 2016, 21, 1559–1572. [Google Scholar] [CrossRef]

- Norgate, T.; Jahanshahi, S. Assessing the energy and greenhouse gas footprints of nickel laterite processing. Miner. Eng. 2011, 24, 698–707. [Google Scholar] [CrossRef]

- Nickel Institute. Ferronickel Life Cycle Data. 2020. Available online: https://nickelinstitute.org/media/8d9bf11555fd1ac/202112-lca-ferronickel.pdf (accessed on 3 October 2023).

- Wei, W.; Samuelsson, P.B.; Tilliander, A.; Gyllenram, R.; Jönsson, P.G. Energy Consumption and Greenhouse Gas Emissions of Nickel Products. Energies 2020, 13, 5664. [Google Scholar] [CrossRef]

- Ovchinnikov, K.N. The carbon footprint of the metallurgical industry and a review of promising solutions for its decarbonization in China, the USA and Germany. Nedropolzovanie XXI Vek 2022, November, 97–107. [Google Scholar]

- World Steel Association. Raw Materials. Available online: https://worldsteel.org/steel-topics/raw-materials/ (accessed on 4 October 2023).

- What Is the Carbon Footprint of Steel? Sustainable Ships. Available online: https://www.sustainable-ships.org/stories/2022/carbon-footprint-steel (accessed on 11 October 2023).

- Valckx, N.; Stuermer, M.; Seneviratne, D.; Ananthakrishnan, P. Metal Demand from Energy Transition May Top Current Global Supply. International Monetary Fund. Available online: https://www.imf.org/en/Blogs/Articles/2021/12/08/metals-demand-from-energy-transition-may-top-current-global-supply (accessed on 11 October 2023).

- International Aluminum Institute. Aluminum. Available online: https://www.iea.org/energy-system/industry/aluminium (accessed on 11 October 2023).

- Yurkov, A.L.; Kuroshev, I.S.; Dobrokhotova, M.V. Aluminum Production. Available online: https://anoire.center/wp-content/uploads/2022/08/aluminum.pdf (accessed on 15 October 2023).

- RUSAL Confirms an Unprecedentedly Low Carbon Footprint for ALLOW INERTA Aluminium. Available online: https://rusal.ru/en/press-center/press-releases/rusal-confirms-an-unprecedentedly-low-carbon-footprint-for-allow-inerta-aluminium/#:~:text=A%20branch%20of%20T%C3%9CV%20Austria,metal%20(Scope%201%20and%202) (accessed on 15 October 2023).

- Gazprombank Investments. How Does EN+ Group Work and How Effective Is It? Available online: https://gazprombank.investments/blog/reviews/en-group (accessed on 14 October 2023).

- World Nuclear Association. Carbon Dioxide Emissions from Electricity. Available online: https://www.world-nuclear.org/information-library/energy-and-the-environment/carbon-dioxide-emissions-from-electricity.aspx (accessed on 14 October 2023).

- Raadal, H.L.; Vold, B.I.; Myhr, A.; Nygaard, T.A. GHG emissions and energy performance of offshore wind power. Renew. Energy 2014, 66, 314–324. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, T. Life cycle assessment of CO2 emissions from wind power plants: Methodology and case studies. Renew. Energy 2012, 43, 30–36. [Google Scholar] [CrossRef]

- Kadiyala, A.; Raghava, K.; Huque, Z. Characterization of the life cycle greenhouse gas emissions from wind electricity generation systems. Int. J. Energy Environ. Eng. 2017, 8, 55–64. [Google Scholar] [CrossRef]

- Dolan, S.L.; Heath, G.A. Life cycle greenhouse gas emissions of utility-scale wind power. J. Ind. Ecol. 2012, 16, 136–154. [Google Scholar] [CrossRef]

- Weinzettel, J.; Reenaas, M.; Solli, C.; Hertwich, E.G. Life cycle assessment of a floating offshore wind turbine. Renew. Energy 2009, 34, 742–747. [Google Scholar] [CrossRef]

- Wagner, H.-J.; Baack, C.; Eickelkamp, T.; Epe, A.; Lohmann, J.; Troy, S. Life cycle assessment of the offshore wind farm alpha ventus. Energy 2011, 36, 2459–2464. [Google Scholar] [CrossRef]

- Al-Khori, K.; Al-Ghamdi, S.G.; Boulfrad, S.; Koç, M. Life Cycle Assessment for Integration of Solid Oxide Fuel Cells into Gas Processing Operations. Energies 2021, 14, 4668. [Google Scholar] [CrossRef]

- Kim, R.H.; Baek, C.; Kim, E.; Jeong, Y.; Cho, S. Potential global warming impact of 1 kW polymer electrolyte membrane fuel cell system for residential buildings on operation phase. Energy Sustain. Dev. 2023, 73, 376–386. [Google Scholar] [CrossRef]

- Staffell, I.; Ingram, A.; Kendall, K. Energy and carbon payback times for solid oxide fuel cell based domestic CHP. Int. J. Hydrog. Energy 2012, 37, 2509–2523. [Google Scholar] [CrossRef]

- European Investment Bank. Methodologies for the Assessment of Project Greenhouse Gas Emissions and Emission Variations; EIB Project Carbon Footprint; European Investment Bank: Luxembourg, 2022; 62p, Available online: https://www.dirittobancario.it/wp-content/uploads/2022/03/EIB-Project-Carbon-footprint-methodologies-2022.pdf (accessed on 16 October 2023).

- Cánovas, A.; Zah, R.; Gassó, S. Comparative Life-Cycle Assessment of Residential Heating Systems, Focused on Solid Oxide Fuel Cells. In Sustainability in Energy and Buildings, Proceedings of the 4th International Conference in Sustainability in Energy and Buildings (SEBߣ12), Stockholm, Sweden, 3–5 September 2012; Springer: Berlin/Heidelberg, Germany, 2013; pp. 659–668. [Google Scholar]

| Options | Designation | Value |

|---|---|---|

| Power turbine shaft power (performance) | MW | 16.0 |

| Efficiency of the power turbine shaft | % | 35.2 |

| Total efficiency | % | 84.7 |

| Gas temperature in front of the gas generator turbine | °C | 1196 |

| Exhaust gas consumption | kg/s | 54.7 |

| Gas temperature behind the gas generator turbine | °C | 805 |

| Temperature of gases behind the power turbine | °C | 540 |

| Fuel consumption | kg/h | 3350 |

| Overall dimensions (L × W × H) | mm | 8250 × 3200 × 3200 |

| Weight (dry) | kg | 5150 |

| Full installation resources | thous. h | 100 |

| Gas generator life before major overhaul | thous. h | 25 |

| Power turbine service life before major overhaul | thous. h | 50 |

| Name | Value per 1 GTU | Calculation or Reference |

|---|---|---|

| Production of construction materials | ||

| Structural alloy steel, kg | 2150 | Calculations based on [13,50] |

| Stainless steel (chromium), kg | 480 | |

| Titanium alloys, kg | 750 | |

| Nickel alloys, kg | 1530 | |

| Aluminum alloys, kg | 240 | |

| Material processing | ||

| Structural steel casting, kg * | 2150 | Calculations based on [43] |

| Metalworking, average for the production of structural steel products | 2150 | |

| Rolled stainless steel, kg | 480 | |

| Metalworking, medium for the production of steel products ** | 480 | |

| Metalworking, average for the production of titanium alloy products ** | 750 | |

| Metalworking, average for the production of products from nickel alloys ** | 1530 | |

| Aluminum casting, kg * | 240 | |

| Name | Value per 1 GTU [13] |

|---|---|

| Concrete, m3 | 50.0 |

| Copper (cathode), kg | 5000 |

| Low-pressure polyethylene, kg | 15,000 |

| Reinforcing steel, kg | 47,500 |

| Diesel fuel (for operation of construction equipment), MJ | 759,000 |

| Electricity, kW | 46,900 |

| Heat supply, MJ | 721,050 |

| Land allocation (industrial zone), m2/year | 15,000 |

| Conversion of land of undetermined purpose, m2 | 1000 |

| Transfer of land to an industrial zone, m2 | 1000 |

| Name | Value per 1 GTI per MWh | Calculation or References |

|---|---|---|

| In the case of natural gas combustion | ||

| Natural gas consumption, kg CO2-eq. | 60.6 | [13,49] |

| CO2-eq. from natural gas combustion, kg | 543.4 | Calculation based on natural gas composition [49,51] |

| In the case of hydrogen combustion | ||

| Hydrogen consumption, kg CO2-eq. | 197.7 | [52,53] |

| CO2-eq. from hydrogen combustion, kg | 0 | - |

| Name | Value per 1 GTI | Calculation or References |

|---|---|---|

| End-of-life gas turbine unit | ||

| Steel waste (steel scrap), kg | 2630 | Calculation based on [13,50] |

| Titanium waste (titanium scrap), kg * | 750 | |

| Nickel waste (nickel scrap), kg * | 1530 | |

| Aluminum waste (aluminum scrap), kg | 240 | |

| End-of-life foundation | ||

| Reinforced concrete waste, kg | 167,500 | [13] |

| Copper waste (copper scrap), kg | 5000 | |

| Low-pressure polyethylene waste, kg | 15,000 | |

| Metal (Alloy) | Carbon Footprint, t CO2-eq./t Metal | |||||

|---|---|---|---|---|---|---|

| Accepted Values | Average Value | Based on Production Method/Type | Based on Energy Source | Using Recycled Materials | ||

| Global | Russia | |||||

| Steel | 1.89 (structural steel) 5.07 (stainless steel) | 1.4–1.85 [54,55] | 1.4 [55] | 2.32 (BF-BOF) 0.67 (EAF) 1.65 (DRI-EAF) [56]/6.15 (stainless steel) [57] 1.8–5.5 (stainless steel) [58] | 1.9 (coal) [59] 1.4 (renewable energy sources and natural gas) [59,60] 0.76 (renewable energy sources and hydrogen) [59,60] | 0.4 [59] |

| Aluminum | 5.51 | 12.5 [61,62] | 4.0 [63] | 4.28 (alumina electrolysis) [64] 0.01 (inert anode technology) [61] | 16.5 (coal) 7.5 (natural gas) 2.4 (hydroelectric power station) [61] | 0.6 [62] |

| Titanium | 46.06 | 18.5 [57,65] | no data | 16.9 (titanium 6–4 alloy) [66] 35.6 (Kroll process) [67] 55.0 (6Al-4V alloy) [68] | no data | 3.2 (titanium 6–4 alloy) [66] 7.8 [69] |

| Nickel | 16.67 | 13.0 [70,71] | 8.1 [72] | 7.2 (class 1 sulphide ore) [73] 27.5 (class 1 laterite ore) [74] 45.0 (class 2 laterite ore) [75] 8.5 (Inconel 718 alloy) [66] | 16.0 (coal) 14.0 (grid mix) 7.0 (hydroelectric power station) 6.0 (natural gas) [76] | 1.6 (Inconel 718 alloy) [66] |

| Object | Carbon Footprint (without Fuel Combustion) (kg CO2-eq./MWh) | Carbon Footprint (Fuel Combustion Included) (kg CO2-eq./MWh) |

|---|---|---|

| Wind turbine | 3.0–45.0 [23,25,86,87,88,89,90,91] | - |

| Fuel cell | 30 [92] | 176–372 * [93] 410–530 [94] |

| Gas turbine installation | 0.374 [13] 0.98–4.72 [17] | 47.0–54.3 ** [17] 353–575 (natural gas) [95] 402–500 (natural gas) [18] 481–757 (light fuel oil) 629 (heavy fuel oil) [95] |

| Gas turbine installation (authors’ own research) | 0.308 | 198 (hydrogen) 523 (hydrogen-containing fuel) 604 (natural gas) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mozzhegorova, Y.; Ilinykh, G.; Korotaev, V. Life Cycle Assessment of a Gas Turbine Installation. Energies 2024, 17, 345. https://doi.org/10.3390/en17020345

Mozzhegorova Y, Ilinykh G, Korotaev V. Life Cycle Assessment of a Gas Turbine Installation. Energies. 2024; 17(2):345. https://doi.org/10.3390/en17020345

Chicago/Turabian StyleMozzhegorova, Yulia, Galina Ilinykh, and Vladimir Korotaev. 2024. "Life Cycle Assessment of a Gas Turbine Installation" Energies 17, no. 2: 345. https://doi.org/10.3390/en17020345

APA StyleMozzhegorova, Y., Ilinykh, G., & Korotaev, V. (2024). Life Cycle Assessment of a Gas Turbine Installation. Energies, 17(2), 345. https://doi.org/10.3390/en17020345