The Effect of Different Mixing Proportions and Different Operating Conditions of Biodiesel Blended Fuel on Emissions and Performance of Compression Ignition Engines

Abstract

1. Introduction

2. Materials and Methods

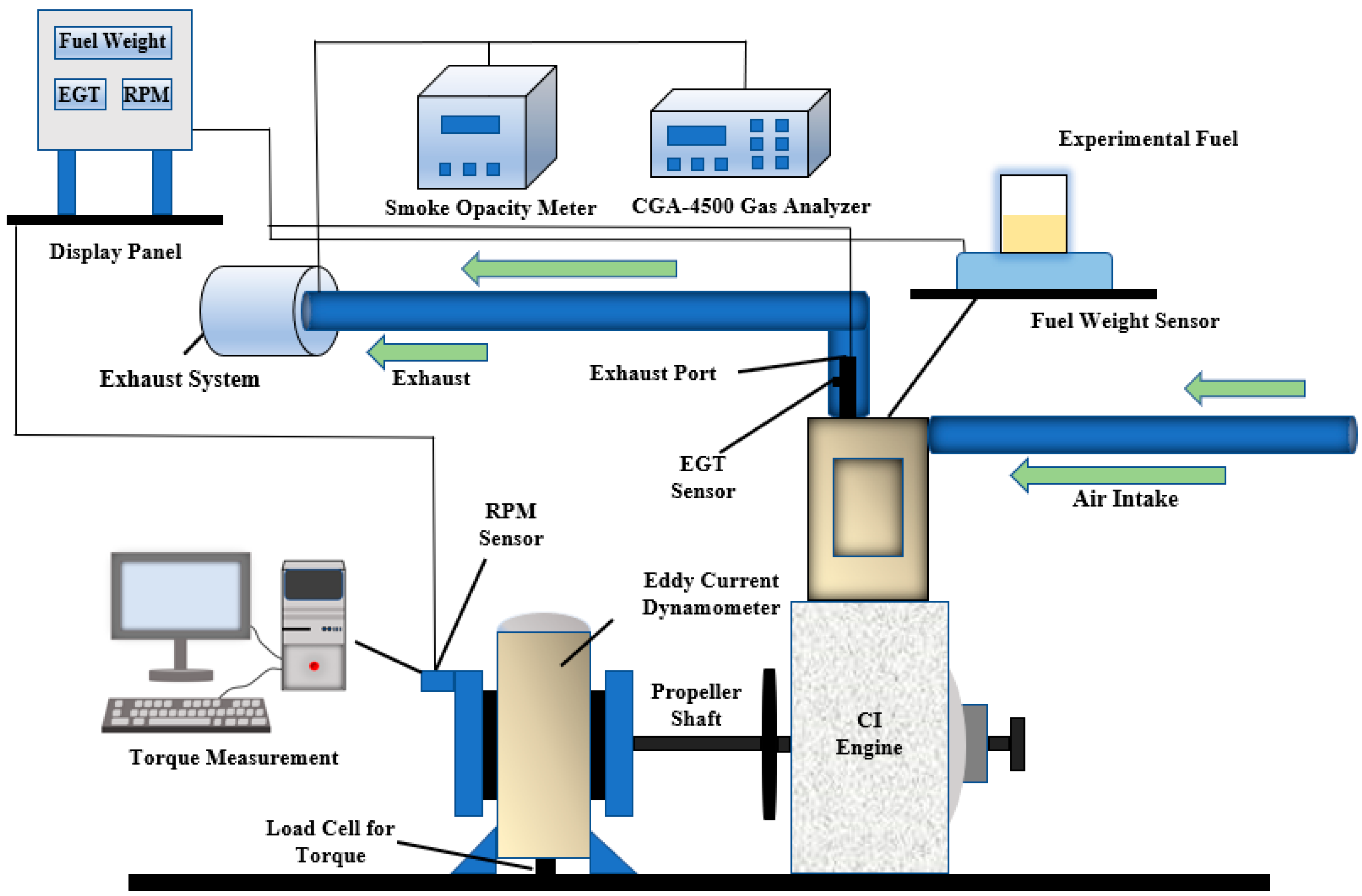

2.1. Experimental Equipment

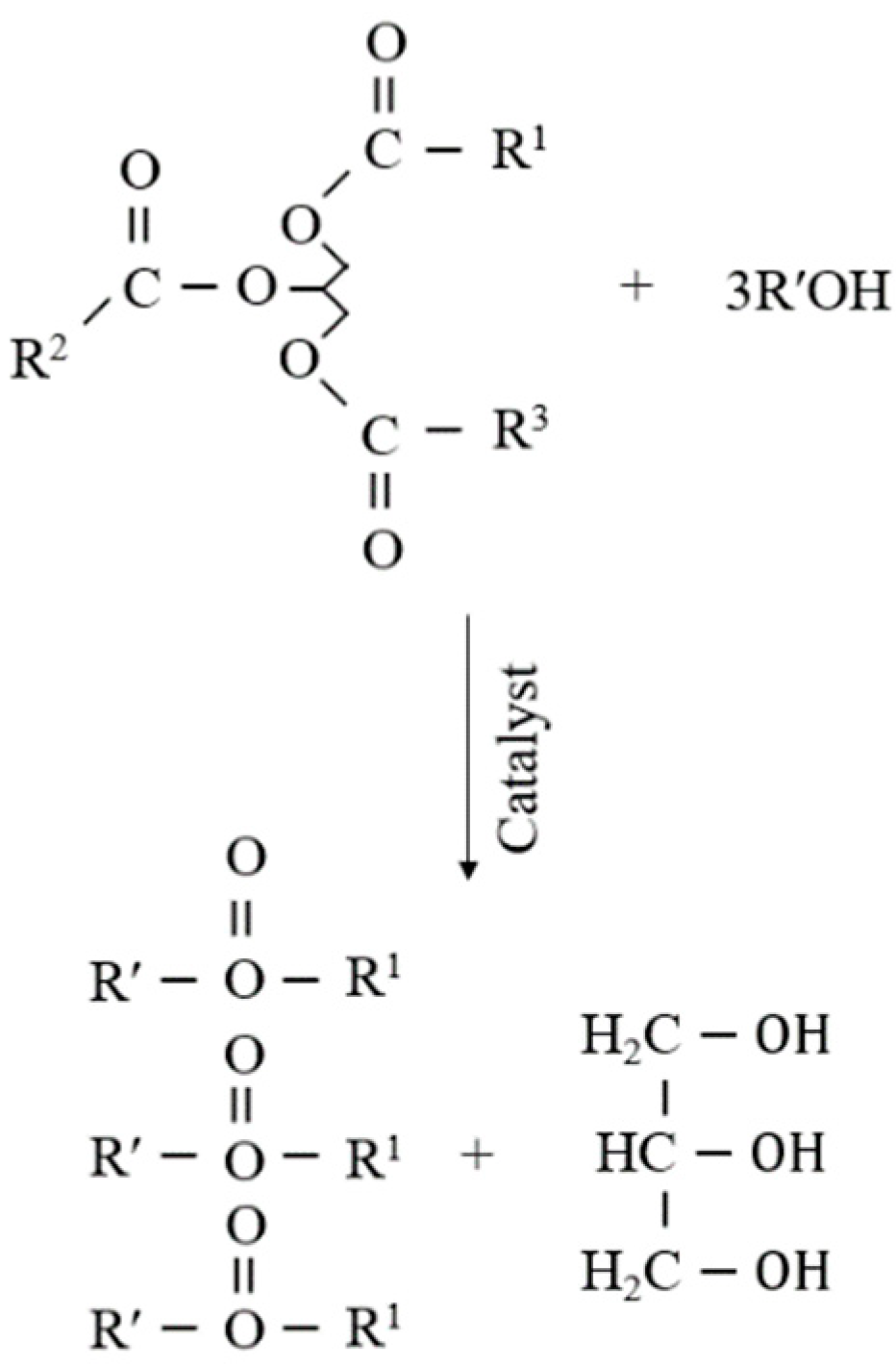

2.2. Production Methods and Processes of Castor Biodiesel

2.3. Experimental Fuel Characteristics

2.4. Error Analysis and Uncertainty

3. Results and Analysis

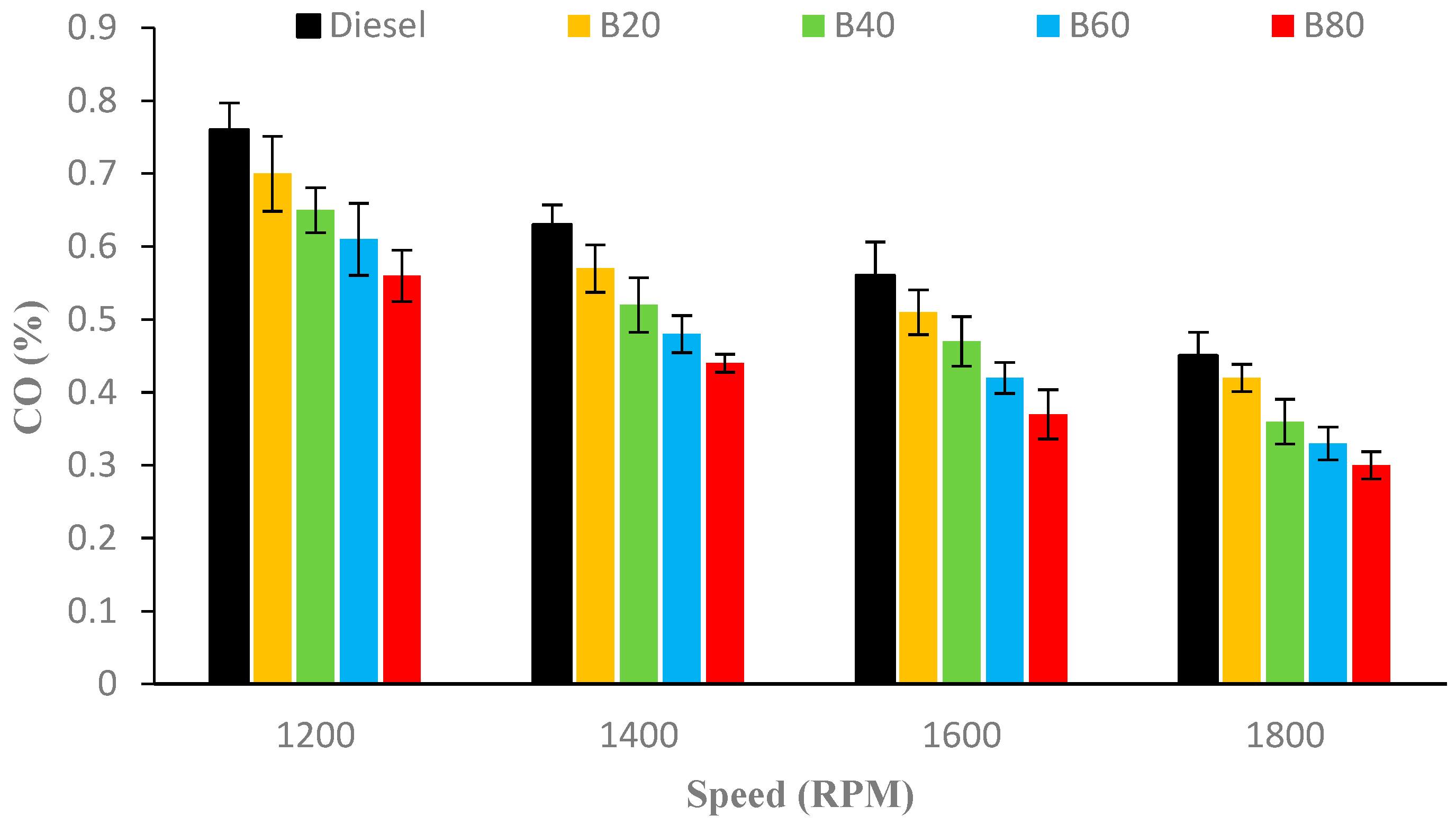

3.1. Carbon Monoxide (CO)

3.2. Hydrocarbon (HC)

3.3. Carbon Dioxide (CO2)

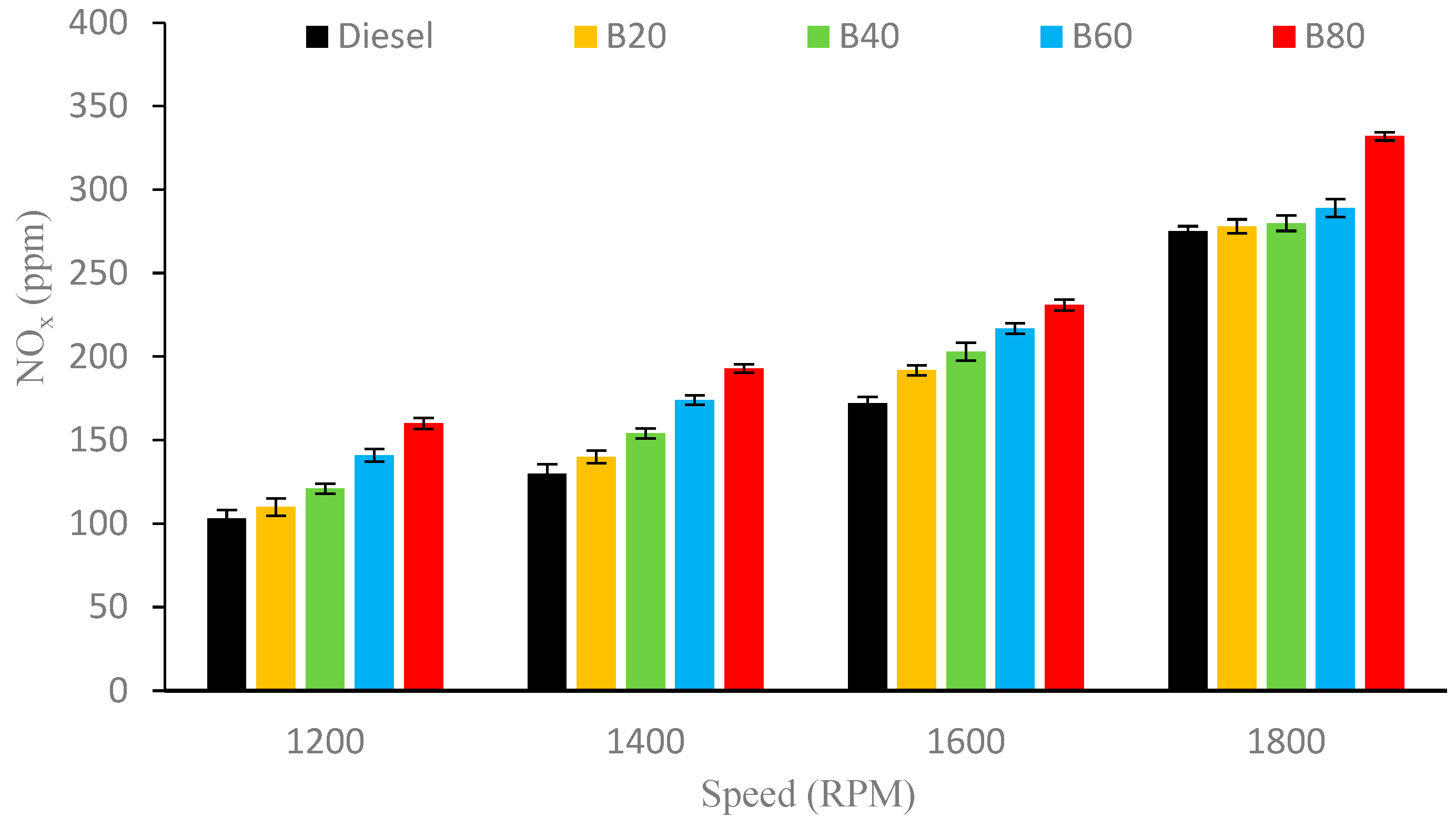

3.4. Nitrogen Oxide Compound (NOx)

3.5. Smoke

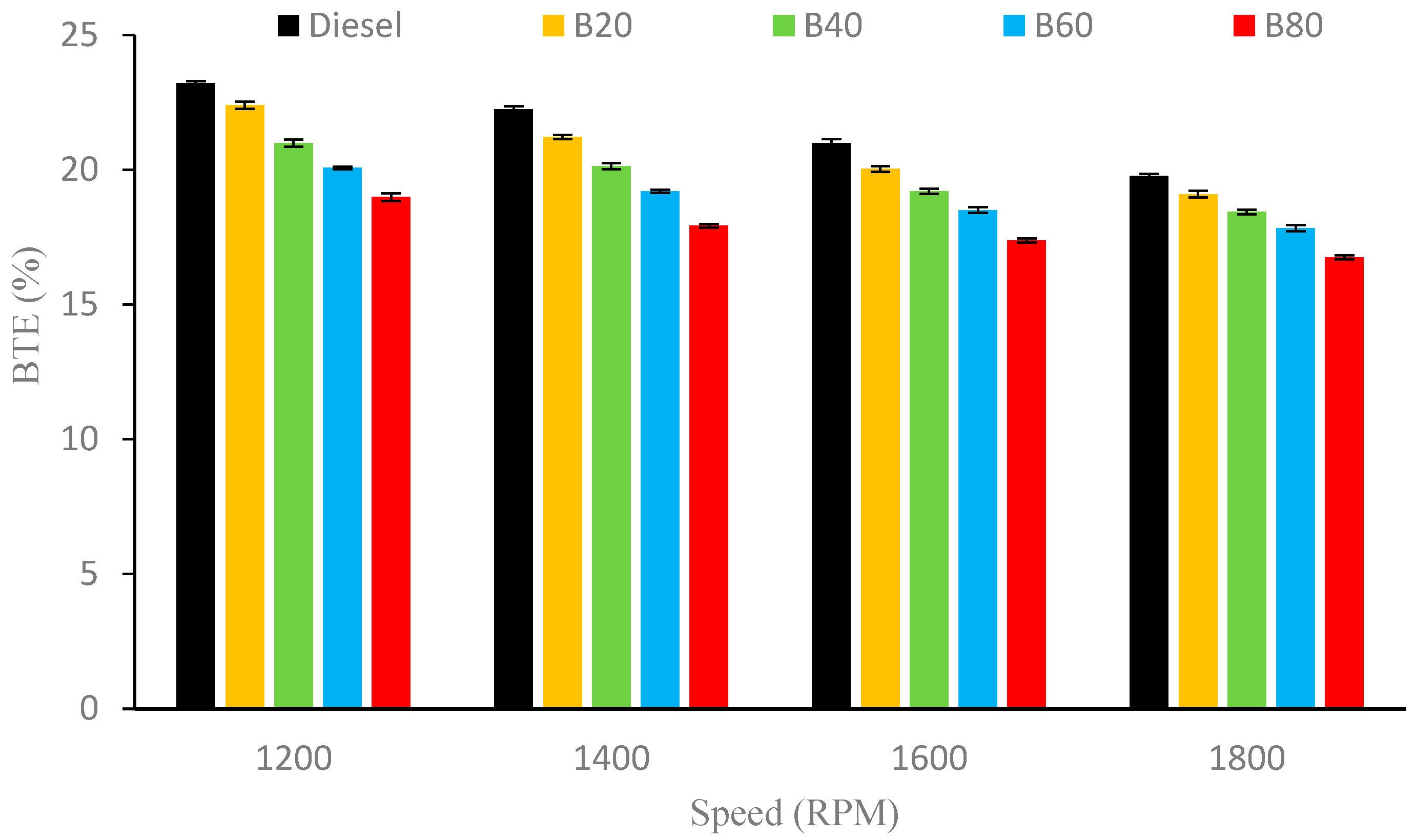

3.6. Brake Thermal Efficiency (BTE)

3.7. Brake Specific Fuel Consumption (BSFC)

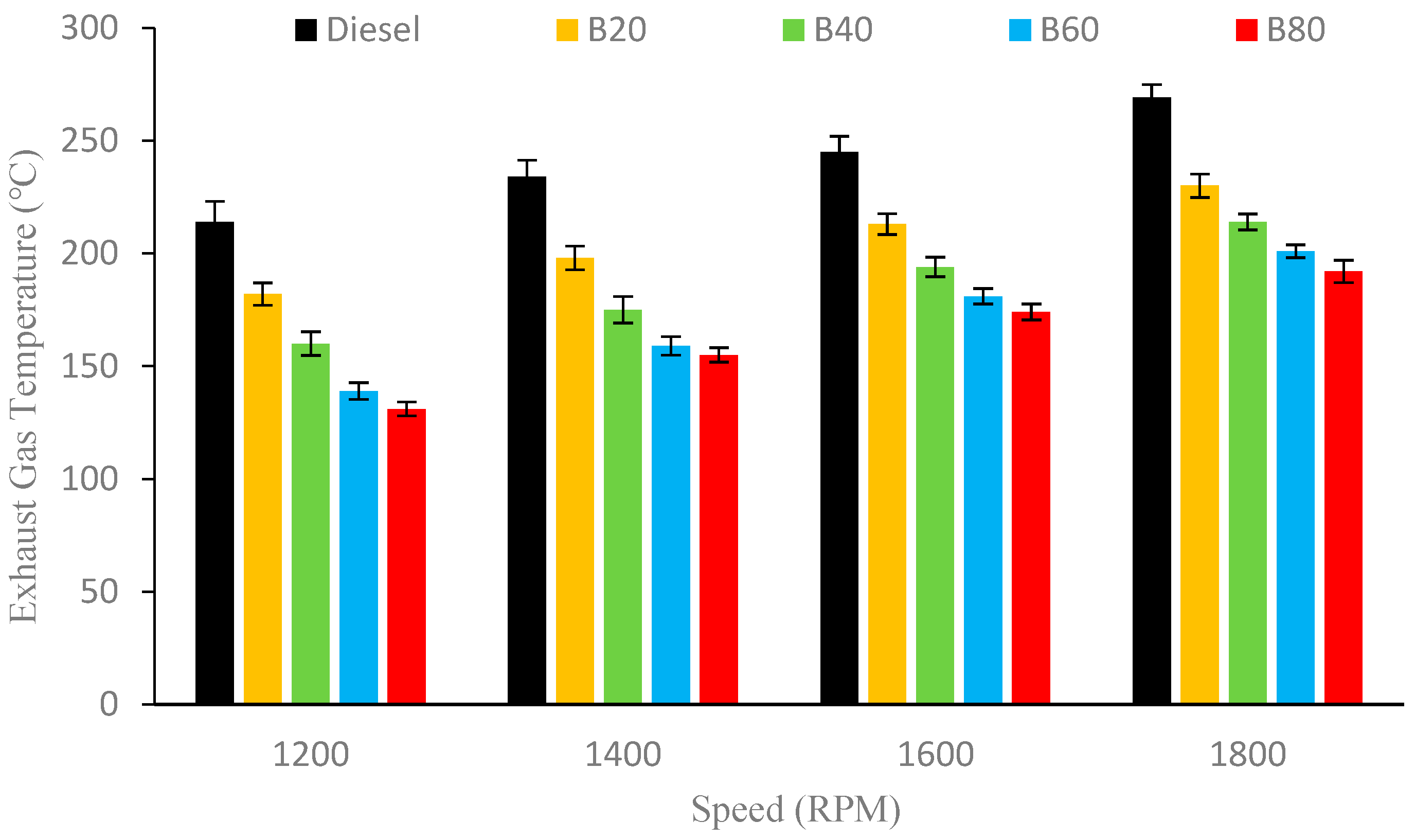

3.8. Exhaust Gas Temperature (EGT)

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| RPM | Revolutions Per Minute |

| PPM | Parts Per Million |

| KOH | Potassium Hydroxide |

| NaOH | Sodium Hydroxide |

| BTE | Brake Thermal Efficiency |

| EGT | Exhaust Gas Temperature |

| BSFC | Brake Specific Fuel Consumption |

| NOx | Nitrogen Oxide |

| CO | Carbon Monoxide |

| CO2 | Carbon Dioxide |

| HC | Hydrocarbon |

| B80 | 80% Biodiesel + 20% Diesel |

| B60 | 60% Biodiesel + 40% Diesel |

| B40 | 40% Biodiesel + 60% Diesel |

| B20 | 20% Biodiesel + 80% Diesel |

References

- Winangun, K.; Setiyawan, A.; Sudarmanta, B.; Puspitasari, I.; Dewi, E.L. Investigation on the properties of a biodiesel-hydrogen mixture on the combustion characteristics of a diesel engine. Case Stud. Chem. Environ. Eng. 2023, 8, 100445. [Google Scholar] [CrossRef]

- Mohite, A.; Bora, B.J.; Sharma, P.; Medhi, B.J.; Barik, D.; Balasubramanian, D.; Nguyen, V.G.; Femilda Josephin, J.S.; Le, H.C.; Kamalakannan, J.; et al. Maximizing efficiency and environmental benefits of an algae biodiesel-hydrogen dual fuel engine through operational parameter optimization using response surface methodology. Int. J. Hydrogen Energy 2024, 52, 1395–1407. [Google Scholar] [CrossRef]

- Gad, M.S.; Ismail, M.A. Effect of waste cooking oil biodiesel blending with gasoline and kerosene on diesel engine performance, emissions and combustion characteristics. Process Saf. Environ. Prot. 2021, 149, 1–10. [Google Scholar] [CrossRef]

- Gad, M.S.; EL-Seesy, A.I.; Radwan, A.; He, Z. Enhancing the combustion and emission parameters of a diesel engine fueled by waste cooking oil biodiesel and gasoline additives. Fuel 2020, 269, 117466. [Google Scholar] [CrossRef]

- Shrivastava, P.; Verma, T.N. An experimental investigation into engine characteristics fueled with Lal ambari biodiesel and its blends. Therm. Sci. Eng. Prog. 2020, 17, 100356. [Google Scholar] [CrossRef]

- Bukkarapu, K.R.; Krishnasamy, A. Support vector regression approach to optimize the biodiesel composition for improved engine performance and lower exhaust emissions. Fuel 2023, 348, 128604. [Google Scholar] [CrossRef]

- Aslan, V. Fuel characterization, engine performance characteristics and emissions analysis of different mustard seed biodiesel: An overview. J. Biotechnol. 2023, 370, 12–30. [Google Scholar] [CrossRef]

- Aydin, H.; İlkılıç, C. Effect of ethanol blending with biodiesel on engine performance and exhaust emissions in a CI engine. Appl. Therm. Eng. 2010, 30, 1199–1204. [Google Scholar] [CrossRef]

- Yaşar, F. Biodiesel production via waste eggshell as a low-cost heterogeneous catalyst: Its effects on some critical fuel properties and comparison with CaO. Fuel 2019, 255, 115828. [Google Scholar] [CrossRef]

- Lin, C.-Y.; Lu, C. Development perspectives of promising lignocellulose feedstocks for production of advanced generation biofuels: A review. Renew. Sustain. Energy Rev. 2021, 136, 110445. [Google Scholar] [CrossRef]

- Carmona-Cabello, M.; Sáez-Bastante, J.; Pinzi, S.; Dorado, M.P. Optimization of solid food waste oil biodiesel by ultrasound-assisted transesterification. Fuel 2019, 255, 115817. [Google Scholar] [CrossRef]

- de Souza, T.A.Z.; Pinto, G.M.; Julio, A.A.V.; Coronado, C.J.R.; Perez-Herrera, R.; Siqueira, B.O.P.S.; da Costa, R.B.R.; Roberts, J.J.; Palacio, J.C.E. Biodiesel in South American countries: A review on policies, stages of development and imminent competition with hydrotreated vegetable oil. Renew. Sustain. Energy Rev. 2022, 153, 111755. [Google Scholar] [CrossRef]

- da Silva César, A.; Conejero, M.A.; Ribeiro, E.C.B.; Batalha, M.O. Competitiveness analysis of “social soybeans” in biodiesel production in Brazil. Renew. Energy 2019, 133, 1147–1157. [Google Scholar] [CrossRef]

- Faba, E.M.S.; Ferrero, G.O.; Ferrero, G.O.; Eimer, G.A. Alternative Raw Materials to Produce Biodiesel through Alkaline Heterogeneous Catalysis. Catalysts 2019, 9, 690. [Google Scholar] [CrossRef]

- Vijayan, S.; Sathyamurthy, R.; Mokheimer, E.M.A.; Kumar, R.S. Performance enhancement and emission reduction of CRDI diesel engine fueled using Manilkara Zapota biodiesel blend with TiO2 nanoadditive. Fuel Process. Technol. 2023, 248, 107842. [Google Scholar] [CrossRef]

- Leo, G.M.L.; Jayabal, R.; Srinivasan, D.; Das, M.C.; Ganesh, M.; Gavaskar, T. Predicting the performance and emissions of an HCCI-DI engine powered by waste cooking oil biodiesel with Al2O3 and FeCl3 nano additives and gasoline injection—A random forest machine learning approach. Fuel 2024, 357 Pt B, 129914. [Google Scholar]

- Sousa, N.L.; Cabral, G.B.; Vieira, P.M.; Baldoni, A.B.; Aragão, F.J.L. Bio-detoxification of ricin in castor bean (Ricinus communis L.) seeds. Sci. Rep. 2017, 7, 15385. [Google Scholar] [CrossRef] [PubMed]

- Badra, J.; Zubail, A.; Sim, J. Numerical Investigation into Effects of Fuel Physical Properties on GCI Engine Performance and Emissions. Energy Fuels 2019, 33, 10267–10281. [Google Scholar] [CrossRef]

- Deep, A.; Sandhu, S.S.; Chander, S. Experimental investigations on castor biodiesel as an alternative fuel for single cylinder compression ignition engine. Environ. Prog. Sustain. Energy 2017, 36, 1139–1150. [Google Scholar] [CrossRef]

- Çalhan, R.; Ergani, S.K.; Uslu, S. Synthesis of Fe–Ni–TiO2/activated carbon nanoparticles and evaluation of catalytic activity in a palm oil/diesel fuel blended diesel engine and optimization with RSM. Sci. Technol. Energy Transit. 2023, 78, 16. [Google Scholar] [CrossRef]

- Kivevele, T.T.; Mbarawa, M.M.; Bereczky, A.; Laza, T.; Madarasz, J. Impact of antioxidant additives on the oxidation stability of biodiesel produced from Croton Megalocarpus oil. Fuel Process. Technol. 2011, 92, 1244–1248. [Google Scholar] [CrossRef]

- Rana, Q.U.A.; Irfan, M.; Ahmed, S.; Hasan, F.; Shah, A.A.; Khan, S.; Rehman, F.U.; Khan, H.; Ju, M.; Li, W.; et al. Bio-catalytic transesterification of mustard oil for biodiesel production. Biofuels 2022, 13, 69–76. [Google Scholar] [CrossRef]

- Attia, A.M.A.; Kulchitskiy, A.R.; Nour, M.; El-Seesy, A.I.; Nada, S.A. The influence of castor biodiesel blending ratio on engine performance including the determined diesel particulate matters composition. Energy 2022, 239 Pt A, 121951. [Google Scholar] [CrossRef]

- Kondaiah, A.; Rao, Y.S.; Satishkumar; Kamitkar, N.D.; Ibrahim, S.J.A.; Chandradass, J.; Kannan, T.T.M. Influence of blends of castor seed biodiesel and diesel on engine characteristics. Mater. Today Proc. 2021, 45 Pt 7, 7043–7049. [Google Scholar] [CrossRef]

- Arunkumar, M.; Kannan, M.; Murali, G. Experimental studies on engine performance and emission characteristics using castor biodiesel as fuel in CI engine. Renew. Energy 2019, 131, 737–744. [Google Scholar] [CrossRef]

- Attia, A.M.A.; Nour, M.; Nada, S.A. Study of Egyptian castor biodiesel-diesel fuel properties and diesel engine performance for a wide range of blending ratios and operating conditions for the sake of the optimal blending ratio. Energy Convers. Manag. 2018, 174, 364–377. [Google Scholar] [CrossRef]

- Aengchuan, P.; Wiangkham, A.; Klinkaew, N.; Theinnoi, K.; Sukjit, E. Prediction of the influence of castor oil–ethanol–diesel blends on single-cylinder diesel engine characteristics using generalized regression neural networks (GRNNs). Energy Rep. 2022, 8 (Suppl. S15), 38–47. [Google Scholar] [CrossRef]

- Tacias-Pascacio, V.G.; Torrestiana-Sánchez, B.; Magro, L.D.; Virgen-Ortíz, J.J.; Suárez-Ruíz, F.J.; Rodrigues, R.C.; Fernandez-Lafuente, R. Comparison of acid, basic and enzymatic catalysis on the production of biodiesel after RSM optimization. Renew. Energy 2019, 135, 1–9. [Google Scholar] [CrossRef]

- Sukpancharoen, S.; Katongtung, T.; Rattanachoung, N.; Tippayawong, N. Unlocking the potential of transesterification catalysts for biodiesel production through machine learning approach. Bioresour. Technol. 2023, 378, 28961. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, C.; Luo, B.; He, P.; Zhang, L.; Wu, G. Efficient and economic transesterification of waste cooking soybean oil to biodiesel catalyzed by outer surface of ZSM-22 supported different Mo catalyst. Biomass Bioenergy 2022, 167, 106646. [Google Scholar] [CrossRef]

- Bahadorian, A.; Sadrameli, S.M.; Pahlavanzadeh, H.; Kashkouli, M.N.I. Optimization study of linseed biodiesel production via in-situ transesterification and slow pyrolysis of obtained linseed residue. Renew. Energy 2023, 203, 10–19. [Google Scholar] [CrossRef]

- Maleki, B.; Talesh, S.S.A.; Mansouri, M. Comparison of catalysts types performance in the generation of sustainable biodiesel via transesterification of various oil sources: A review study. Mater. Today Sustain. 2022, 18, 100157. [Google Scholar] [CrossRef]

- Suzihaque, M.U.H.; Syazwina, N.; Alwi, H.; Ibrahim, U.K.; Abdullah, S.; Haron, N. A sustainability study of the processing of kitchen waste as a potential source of biofuel: Biodiesel production from waste cooking oil (WCO). Mater. Today Proc. 2022, 63 (Suppl. S1), S484–S489. [Google Scholar] [CrossRef]

- Karkal, S.S.; Jamadar, A.S.; Kudre, T.G. Valorization of marine fishmeal industry oil as feedstock and calcined shrimp and crab shells as catalysts for production of biodiesels and evaluation of their fuel properties, engine combustion, performance and gas emission characteristics. Process Saf. Environ. Prot. 2023, 182, 443–455. [Google Scholar] [CrossRef]

- Chidambaranathan, B.; Gopinath, S.; Aravindraj, R.; Devaraj, A.; Krishnan, S.G.; Jeevaananthan, J.K.S. The production of biodiesel from castor oil as a potential feedstock and its usage in compression ignition Engine: A comprehensive review. Mater. Today Proc. 2020, 33 Pt 1, 84–92. [Google Scholar] [CrossRef]

- Khujamberdiev, R.; Cho, H.M.; Mahmud, M.I. Experimental Investigation of Single-Cylinder Engine Performance Using Biodiesel Made from Waste Swine Oil. Energies 2023, 16, 7891. [Google Scholar] [CrossRef]

- Kareemullah, M.; Afzal, A.; Rehman, K.F.; Shahapurkar, K.; Khan, H.; Akram, N. Performance and emission analysis of compression ignition engine using biodiesels from Acid oil, Mahua oil, and Castor oil. Heat Transf. 2019, 49, 858–871. [Google Scholar] [CrossRef]

- Qenawy, M.; Khalaf, M.; Wang, J.; Tian, J.; Zuo, L.; Mustafa, H.M.M.; Esmail, M.F.C. Performance and emission of extracted biodiesel from mixed Jatropha-Castor seeds. Fuel 2024, 357 Pt C, 130060. [Google Scholar] [CrossRef]

- Hassan, T.; Rahman, M.M.; Adib, A.R.; Meraz, R.M.; Rahman, M.A.; Tushar, M.S.H.K. Effect of Ni and Al nanoadditives on the performance and emission characteristics of a diesel engine fueled with diesel-castor oil biodiesel-n-butanol blends. Case Stud. Chem. Environ. Eng. 2023, 8, 100531. [Google Scholar] [CrossRef]

- Haq, M.U.; Jafry, A.T.; Ahmad, S.; Cheema, T.A.; Kamran, M.; Ajab, H.; Masjuki, H.H. Macroscopic spray behavior in pressurized chamber alongside thermal performance of quaternary castor biodiesel with butanol and 1-butoxybutane. Energy 2023, 282, 128912. [Google Scholar] [CrossRef]

- Umeuzuegbu, J.C.; Okiy, S.; Nwobi-Okoye, C.C.; Onukwuli, O.D. Computational modeling and multi-objective optimization of engine performance of biodiesel made with castor oil. Heliyon 2021, 7, e06516. [Google Scholar] [CrossRef] [PubMed]

| Parameters | Description |

|---|---|

| Engine Type | Single-cylinder water-cooled 4-stroke |

| Manufacture | Daedong Ltd., Daegu City, Republic of Korea |

| Bore (mm) | 95 |

| Rated Power Output (kW) | 7.4 |

| Injection Pressure (kg cm−2) | 200 |

| Displacement (cc) | 673 |

| Compression Ratio | 21 |

| Stroke Length (mm) | 95 |

| Property | Castor Biodiesel | B20 | B40 | B60 | B80 | Diesel |

|---|---|---|---|---|---|---|

| Calorific Value (MJ/kg) | 38.156 | 44.121 | 43.855 | 41.564 | 40.152 | 45.512 |

| Density at 15 °C (kg/m3) | 896 | 831 | 843 | 851 | 869 | 820 |

| Flash Point (°C) | 102 | 75 | 79 | 85 | 93 | 58 |

| Kinematic Viscosity at 40 °C (mm2/s) | 7.35 | 3.34 | 4.61 | 5.42 | 5.94 | 2.87 |

| Cetane Number | 62 | 50 | 53 | 56.5 | 59 | 48.7 |

| Oxygen Content (%) | 12.34 | 2.53 | 4.96 | 7.42 | 9.91 | 0.11 |

| Exhaust Emission | Error Range | Unit | Measurement Range |

|---|---|---|---|

| CO | ±0.01% | % | 0.00–10.00 |

| HC | ±1 ppm | ppm | 0–10,000 |

| O2 | ±0.1% | % | 0.00–25.00 |

| NOx | ±1 ppm | ppm | 0–5000 |

| CO2 | ±0.1% | % | 0.0–20.0 |

| Thermocouple (K-Type) | ±0.1 °C | °C | 0–1200 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, F.; Cho, H.M. The Effect of Different Mixing Proportions and Different Operating Conditions of Biodiesel Blended Fuel on Emissions and Performance of Compression Ignition Engines. Energies 2024, 17, 344. https://doi.org/10.3390/en17020344

Zheng F, Cho HM. The Effect of Different Mixing Proportions and Different Operating Conditions of Biodiesel Blended Fuel on Emissions and Performance of Compression Ignition Engines. Energies. 2024; 17(2):344. https://doi.org/10.3390/en17020344

Chicago/Turabian StyleZheng, Fangyuan, and Haeng Muk Cho. 2024. "The Effect of Different Mixing Proportions and Different Operating Conditions of Biodiesel Blended Fuel on Emissions and Performance of Compression Ignition Engines" Energies 17, no. 2: 344. https://doi.org/10.3390/en17020344

APA StyleZheng, F., & Cho, H. M. (2024). The Effect of Different Mixing Proportions and Different Operating Conditions of Biodiesel Blended Fuel on Emissions and Performance of Compression Ignition Engines. Energies, 17(2), 344. https://doi.org/10.3390/en17020344