Solid Flow in an Experimental Oxygen Blast Furnace Model: Effects of Recycled Gas and Raceway

Abstract

1. Introduction

2. Materials and Methods

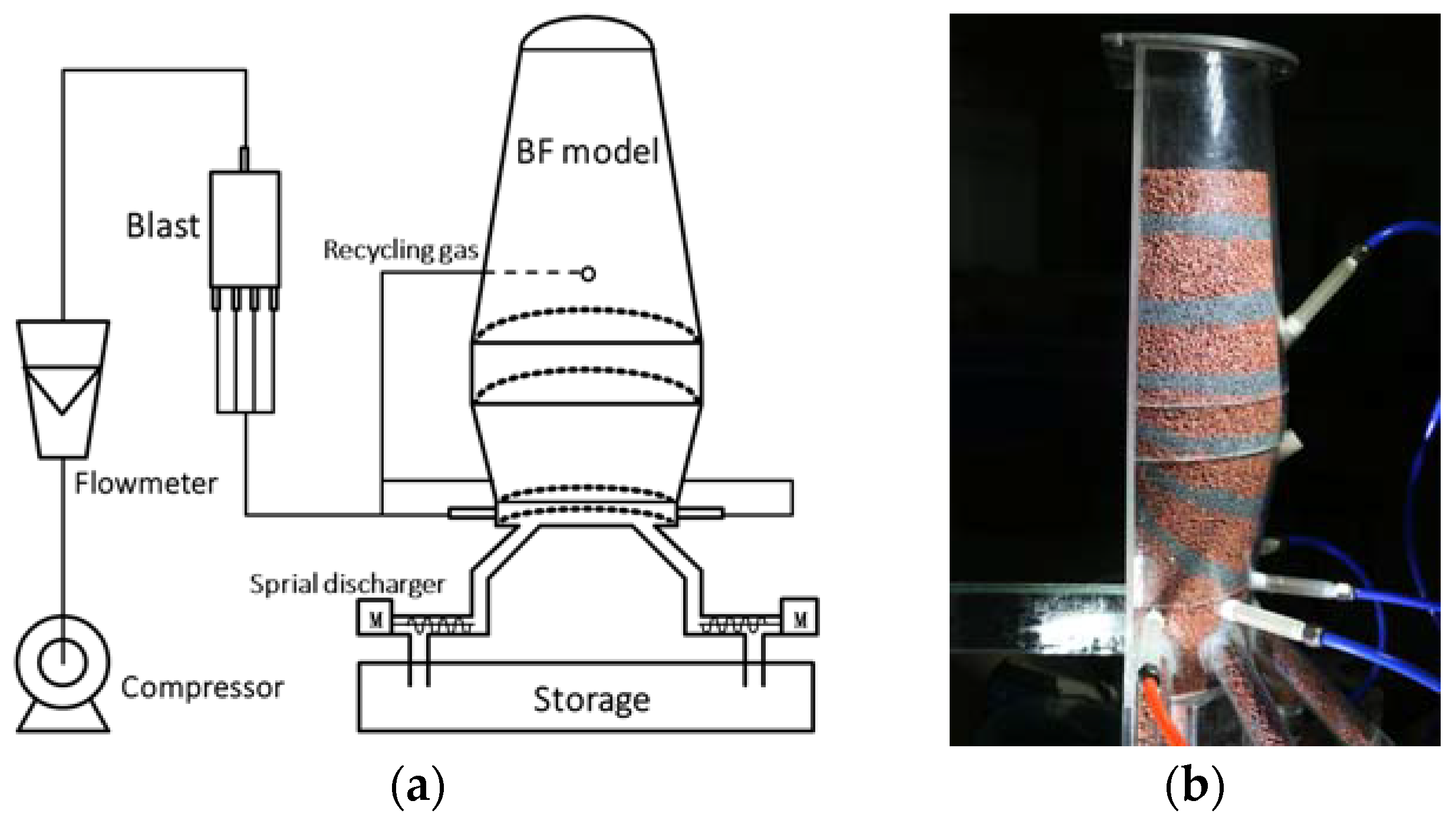

2.1. Experiment Setup

2.2. Particle Properties

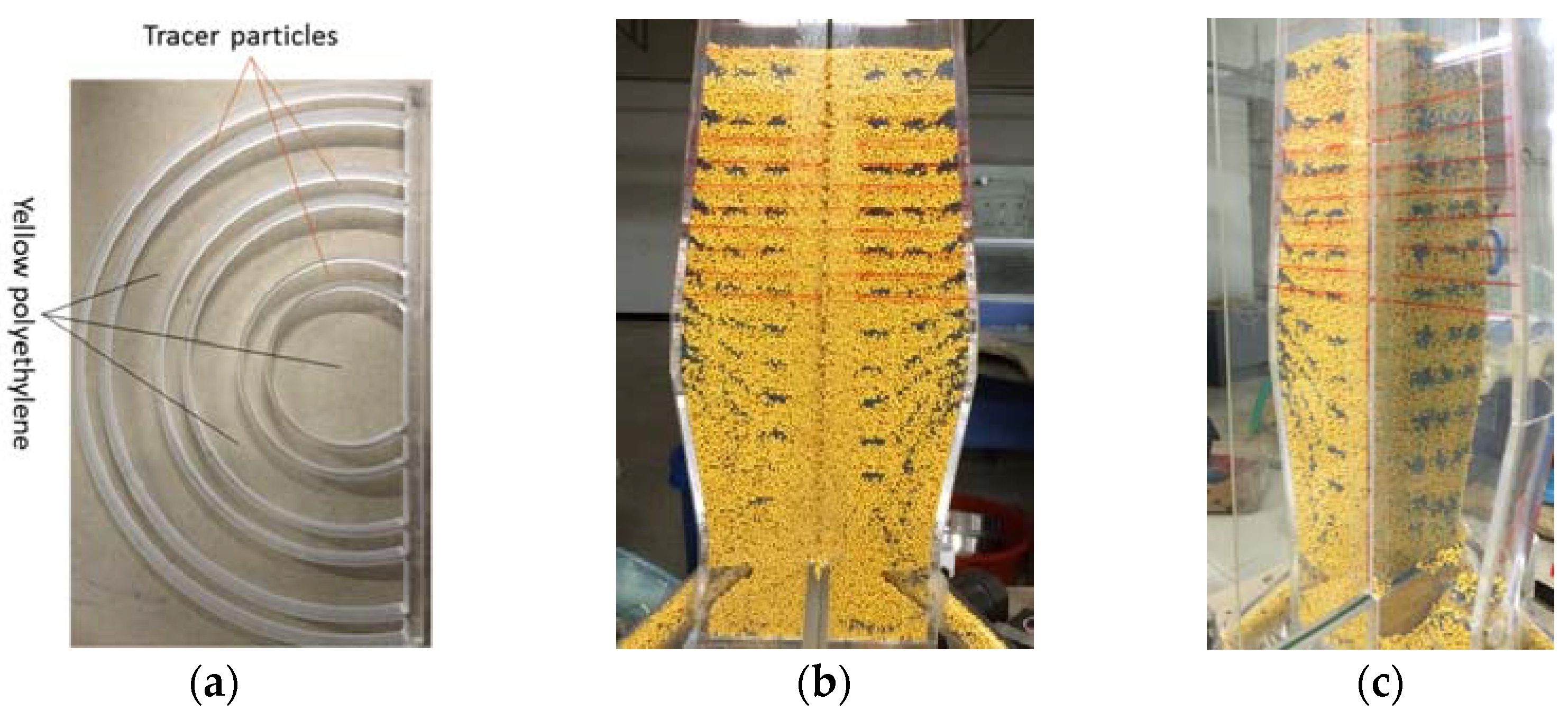

2.3. Experimental Procedure

- (1)

- Before the start of the experiment, adjust the motor speed and ensure that each motor has the same speed, so that each discharge speed is the same;

- (2)

- Fill the OBF model with red/yellow polyethylene particles, turn on the motor (spiral discharge device), and the solid flow decreases with the continuous discharge of particles;

- (3)

- In order to maintain the dynamic balance of the burden layer, the upper part of the OBF model is constantly filled with polyethylene particles to maintain the stability of the burden layer’s height;

- (4)

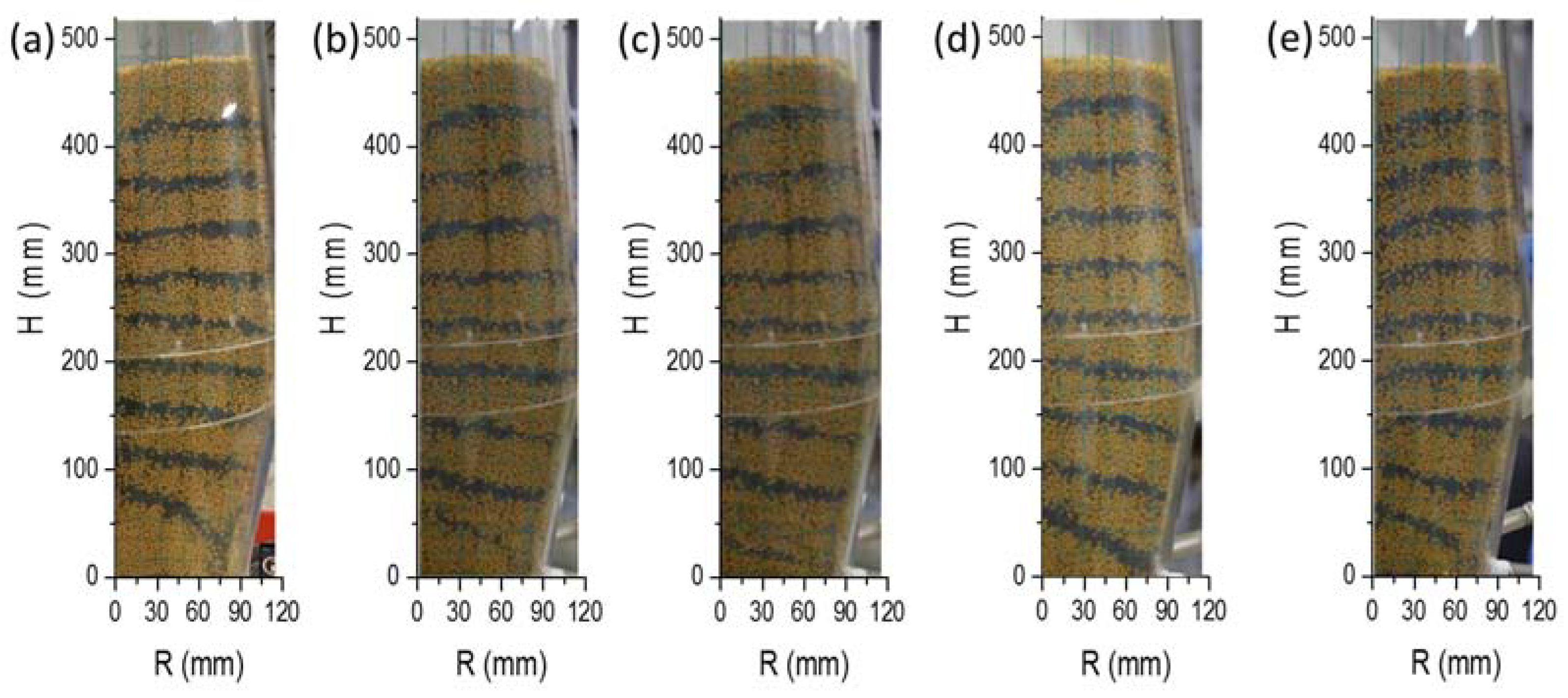

- In order to facilitate the observation of the timelines, 10 mm thick black tracer particles are loaded into the upper part of OBF model, and then polyethylene particles of a certain thickness are loaded. Polyethylene particles and black tracer particles are added at intervals, and the particles are loaded at the same time interval;

- (5)

- Stop the discharge until the first layer of tracer particles are discharged from the discharge port;

- (6)

- Cut the experimental products, observe the internal solid flow timelines, and take photos.

3. Results and Discussion

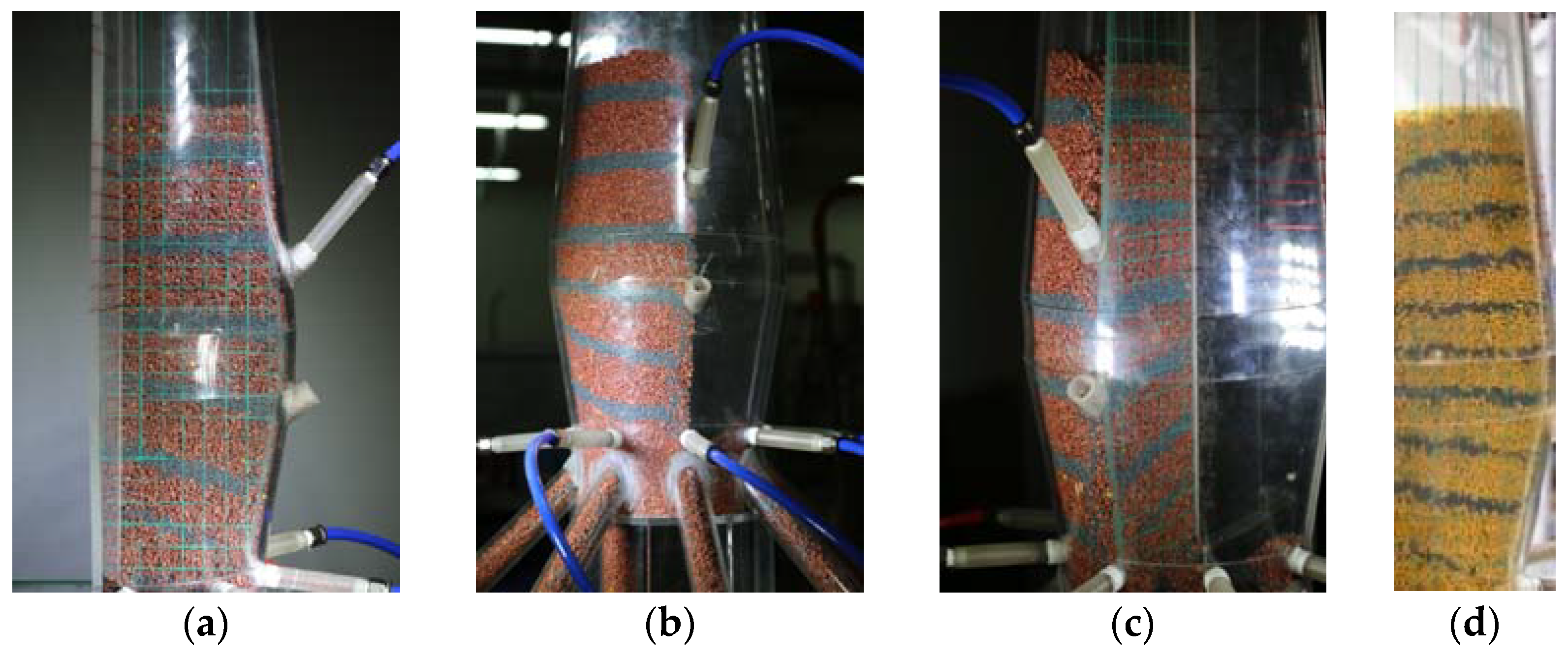

3.1. Effects of Recycled Gas

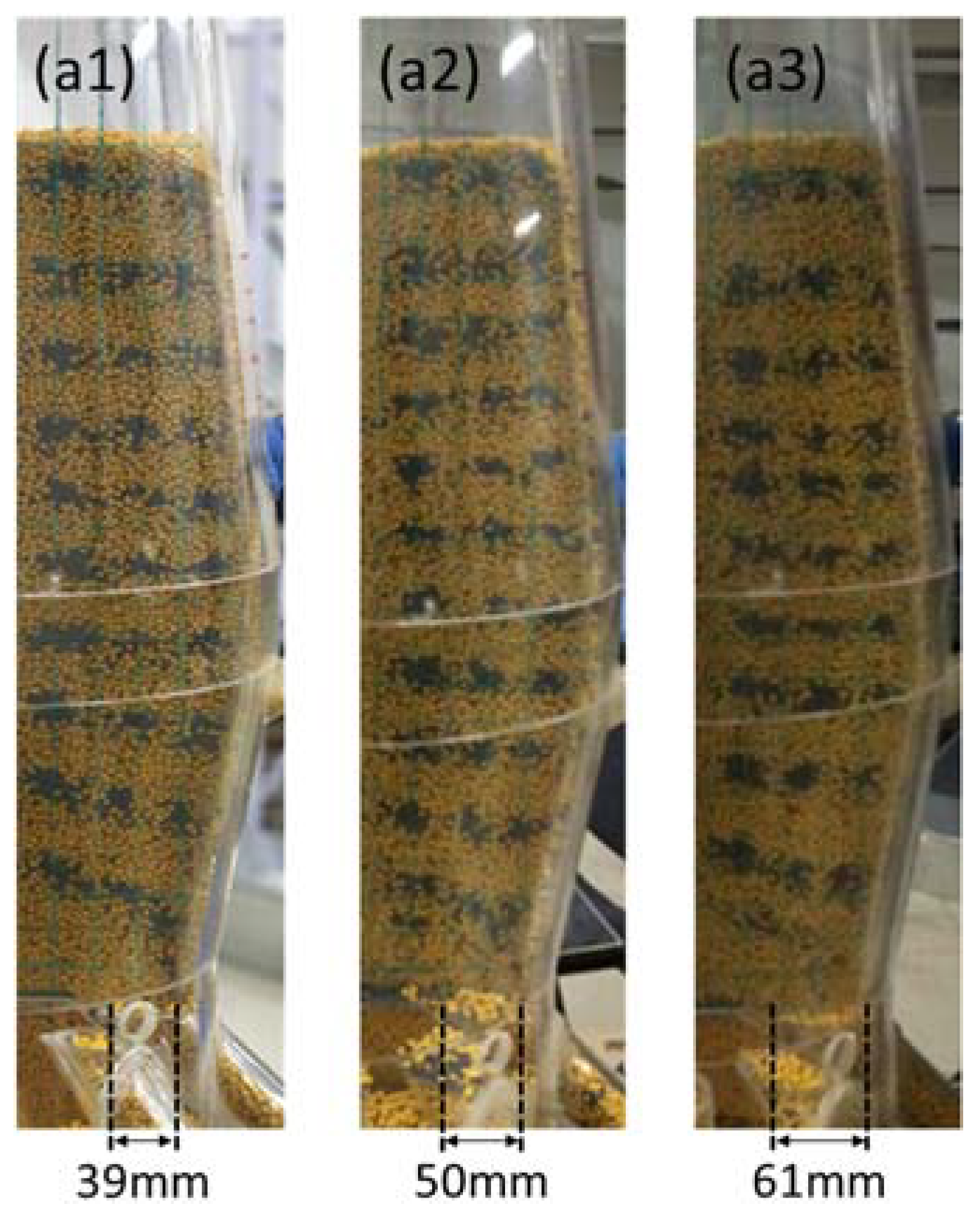

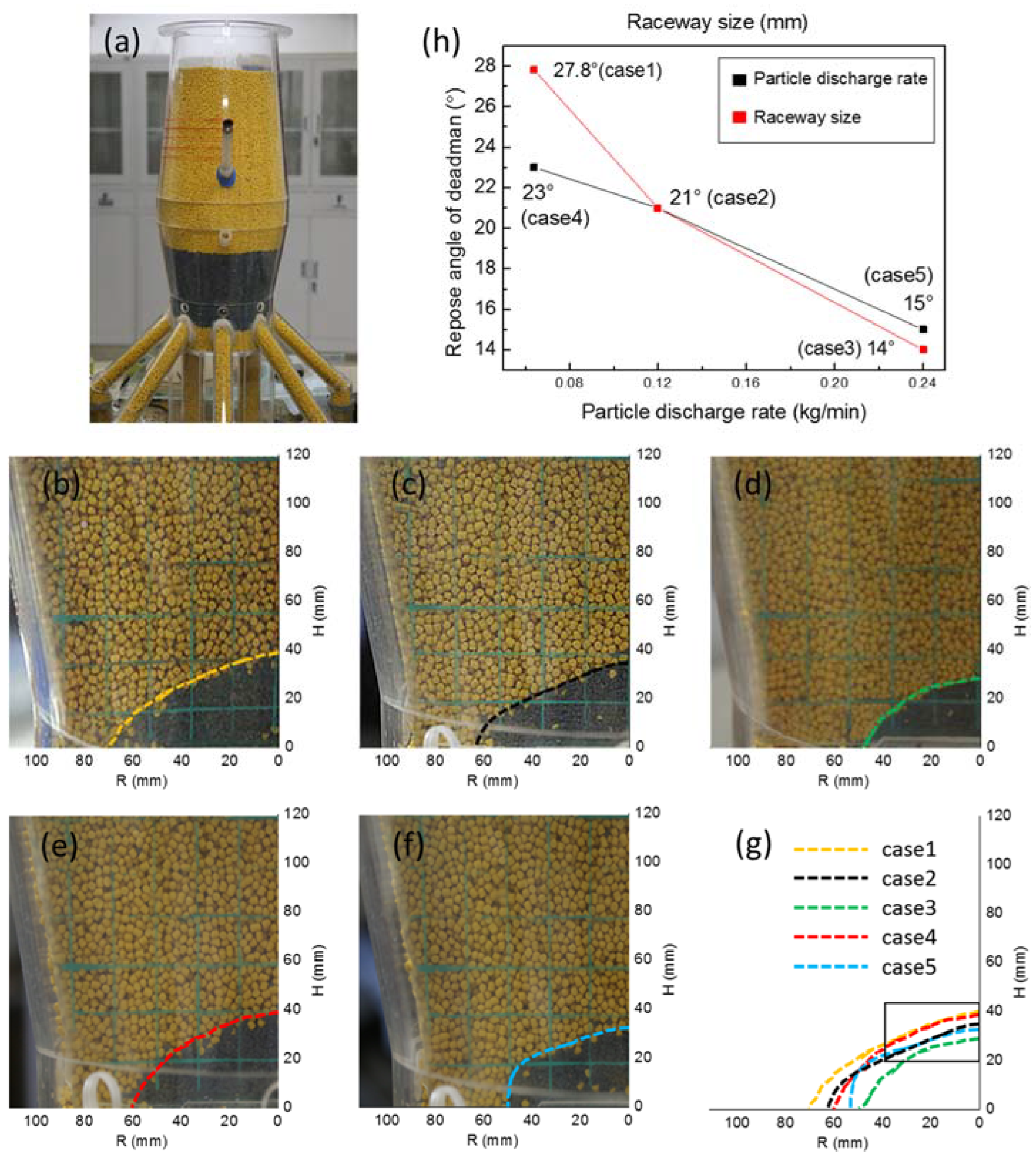

3.2. Effects of Raceway

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, L.; Jiang, Z.; Zhang, X.; Lu, Y.; He, J.; Wang, J.; Zhang, X. Effects of top gas recycling on in-furnace status, productivity, and energy consumption of oxygen blast furnace. Energy 2018, 163, 144–150. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, J.; Xue, Z. Exergy analyses of the oxygen blast furnace with top gas recycling process. Energy 2017, 121, 135–146. [Google Scholar] [CrossRef]

- Matsuura, M.; Mitsufuji, H.; Furukawa, T. Development of the Oxygen Blast Furnace Process. In Proceedings of the Sixth International Iron and Steel Congress, Nagoya, Japan, 21–26 October 1990. [Google Scholar]

- Song, J.; Jiang, Z.; Zhang, Y.; Han, Z.; Lu, Y.; Dong, H.; Zhang, Y. Economic Analysis of an Integrated Steel Plant Equipped with a Blast Furnace or Oxygen Blast Furnace. Sustainability 2023, 15, 11824. [Google Scholar] [CrossRef]

- Li, J.; Li, C.; Zhang, W.; Zhang, J.; Xue, Z. Material, energy and exergy flows of the oxygen blast furnace process with sintering flue gas injection. J. Clean. Prod. 2022, 371, 133294. [Google Scholar] [CrossRef]

- Zhang, H.-j.; She, X.-f.; Han, Y.-h.; Wang, J.-s.; Zeng, F.-b.; Xue, Q.-g. Softening and Melting Behavior of Ferrous Burden under Simulated Oxygen Blast Furnace Condition. J. Iron Steel Res. Int. 2015, 22, 297–303. [Google Scholar] [CrossRef]

- Li, H.; Chen, J. An Analysis of Long-Process Ironmaking in a Reduction Smelting Furnace with Hydrogen-Enriched Conditions. Metals 2023, 13, 1756. [Google Scholar] [CrossRef]

- Zhang, Z.; Tang, J.; Shi, Q.; Chu, M. Effects of Shaft Tuyere Parameters on Gas Movement Behavior and Burden Reduction in Oxygen Blast Furnace. Sustainability 2023, 15, 9159. [Google Scholar] [CrossRef]

- Yotaro, O.; Hirohisa, H.; Masahiro, M.; Hiroyuki, M.; Hiroshi, S.J.T.-t.-H. Development of Oxygen Blast Furnace Process with Preheating Gas Injection into Upper Shaft. Tetsu-to-Hagane 1989, 75, 1278–1285. [Google Scholar]

- Qin, M.S.; Qi, B.M. The full oxygen blast furnace (FOBF) process. In Proceedings of the Sixth International Iron and Steel Congress, Nagoya, Japan, 21–26 October 1990. [Google Scholar]

- Nijssen, T.M.J.; Hoeks, I.; Manjunath, V.; Kuipers, H.A.M.; van der Stel, J.; Adema, A.T.; Buist, K.A. Experiments and simulations on a cold-flow blast furnace hearth model. Chem. Eng. Sci. X 2022, 13, 100120. [Google Scholar] [CrossRef]

- Takahashi, H.; Tanno, M.; Katayama, J. Burden Descending Behaviour with Renewal of Deadman in a Two Dimensional Cold Model of Blast Furnace. ISIJ Int. 1996, 36, 1354–1359. [Google Scholar] [CrossRef]

- Kawai, H.; Takahashi, H.; Ichida, M. Segregation behavior for fine particles of sintered ores and coke supplied at the top of a two dimensional cold model of blast furnace. ISIJ Int. 2005, 45, 1112–1121. [Google Scholar] [CrossRef]

- Giuli, M.; Pinti, M.; Federico, G.; Salvatore, E. Investigation on burden descent in the blast furnace. In Proceedings of the IISC: The Sixth International Iron and Steel Congress, Nagoya, Japan, 21–26 October 1990; pp. 521–526. [Google Scholar]

- Wright, B.; Zulli, P.; Zhou, Z.; Yu, A. Gas–solid flow in an ironmaking blast furnace—I: Physical modelling. Powder Technol. 2011, 208, 86–97. [Google Scholar] [CrossRef]

- Perpiñán, J.; Bailera, M.; Peña, B.; Kannan, P.; Eveloy, V.; Romeo, L.M. Power to gas and top gas recycling integration in an oxygen blast furnace steelmaking industry. J. CO2 Util. 2023, 78, 102634. [Google Scholar] [CrossRef]

- Nishio, H.; Miyashita, T. On the top gas recycled reforming process and the injected gas Distribution. Tetsu-Hagané 1973, 59, 1506–1522. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Zhang, S.J.; Yu, A.B.; Zulli, P.; Wright, B.; Tüzün, U. Modelling of the Solids Flow in a Blast Furnace. ISIJ Int. 1998, 38, 1311–1319. [Google Scholar] [CrossRef]

- Zhou, Z.; Zhu, H.; Wright, B.; Yu, A.; Zulli, P. Gas–solid flow in an ironmaking blast furnace—II: Discrete particle simulation. Powder Technol. 2011, 208, 72–85. [Google Scholar] [CrossRef]

- Zhou, Z.; Zhu, H.; Yu, A.; Zulli, P. Numerical Investigation of the Transient Multiphase Flow in an Ironmaking Blast Furnace. ISIJ Int. 2010, 50, 515–523. [Google Scholar] [CrossRef]

- Lu, Y.; Jiang, Z.; Zhang, X.; Wang, J.; Zhang, X. Vertical section observation of the solid flow in a blast furnace with a cutting method. Metals 2019, 9, 127. [Google Scholar] [CrossRef]

- Ichida, M.; Nishihara, K.; Tamura, K.; Sugata, M.; Ono, H. Influence of Ore/Coke Distribution on Descending and Melting Behavior of Burden in Blast Furnace. ISIJ Int. 1991, 31, 505–514. [Google Scholar] [CrossRef]

- Yang, W.; Zhou, Z.; Yu, A. Discrete particle simulation of solid flow in a three-dimensional blast furnace sector model. Chem. Eng. J. 2015, 278, 339–352. [Google Scholar] [CrossRef]

- Hou, Q.; Dianyu, E.; Kuang, S.; Li, Z.; Yu, A. DEM-based virtual experimental blast furnace: A quasi-steady state model. Powder Technol. 2017, 314, 557–566. [Google Scholar] [CrossRef]

- An, X.-W.; Wang, J.-S.; Lan, R.-Z.; Han, Y.-H.; Xue, Q.-G. Softening and Melting Behavior of Mixed Burden for Oxygen Blast Furnace. J. Iron Steel Res. Int. 2013, 20, 11–16. [Google Scholar] [CrossRef]

| Parameters | Value |

|---|---|

| Diameter of hearth, mm | 213 |

| Diameter of belly, mm | 267 |

| Diameter of throat, mm | 200 |

| Height of hearth, mm | 213 |

| Height of bosh, mm | 160 |

| Height of belly, mm | 054 |

| Height of shaft, mm | 333 |

| Height of throat, mm | 100 |

| Tuyere diameter, mm | 10 |

| Depth of raceway, mm | 39, 50 *, 61 |

| Height of raceway, mm | 50 |

| Average particle diameter, mm | 4 |

| Average tracer particles diameter, mm | 2.5 |

| Total particle discharge rate, kg/min | 0.034, 0.08 *, 0.16, 0.24 * |

| Parameters | Raceway Depth | Discharging Rate |

|---|---|---|

| Case 1 | 39 mm | 0.08 kg/min |

| Case 2 * | 50 mm | 0.08 kg/min |

| Case 3 | 61 mm | 0.08 kg/min |

| Case 4 | 50 mm | 0.04 kg/min |

| Case 5 | 50 mm | 0.16 kg/min |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, Y.; Jiang, Z.; Zhang, X.; E, D. Solid Flow in an Experimental Oxygen Blast Furnace Model: Effects of Recycled Gas and Raceway. Energies 2024, 17, 309. https://doi.org/10.3390/en17020309

Lu Y, Jiang Z, Zhang X, E D. Solid Flow in an Experimental Oxygen Blast Furnace Model: Effects of Recycled Gas and Raceway. Energies. 2024; 17(2):309. https://doi.org/10.3390/en17020309

Chicago/Turabian StyleLu, Yuanxiang, Zeyi Jiang, Xinru Zhang, and Dianyu E. 2024. "Solid Flow in an Experimental Oxygen Blast Furnace Model: Effects of Recycled Gas and Raceway" Energies 17, no. 2: 309. https://doi.org/10.3390/en17020309

APA StyleLu, Y., Jiang, Z., Zhang, X., & E, D. (2024). Solid Flow in an Experimental Oxygen Blast Furnace Model: Effects of Recycled Gas and Raceway. Energies, 17(2), 309. https://doi.org/10.3390/en17020309