Heat Transfer Performance Factors in a Vertical Ground Heat Exchanger for a Geothermal Heat Pump System

Abstract

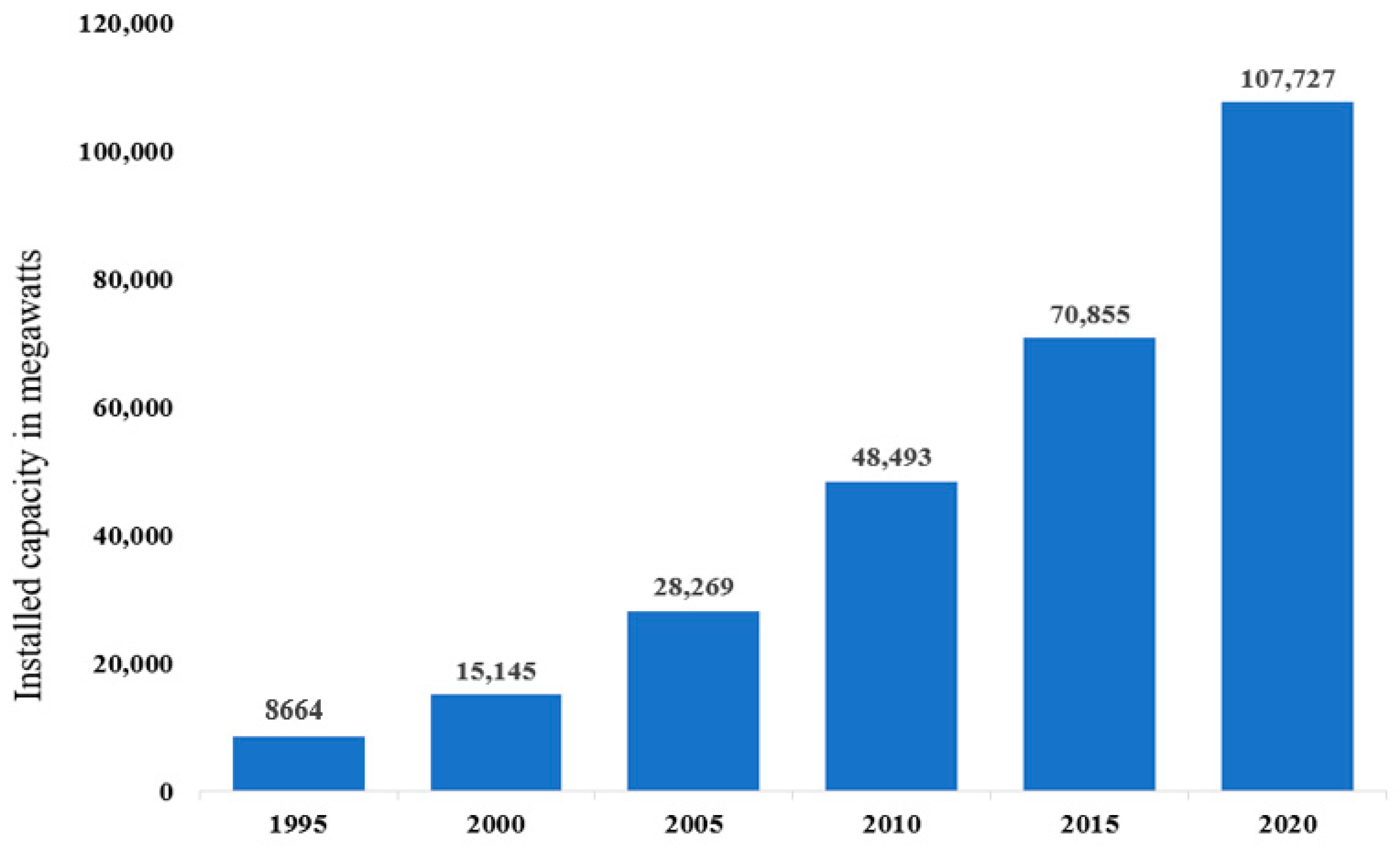

1. Introduction

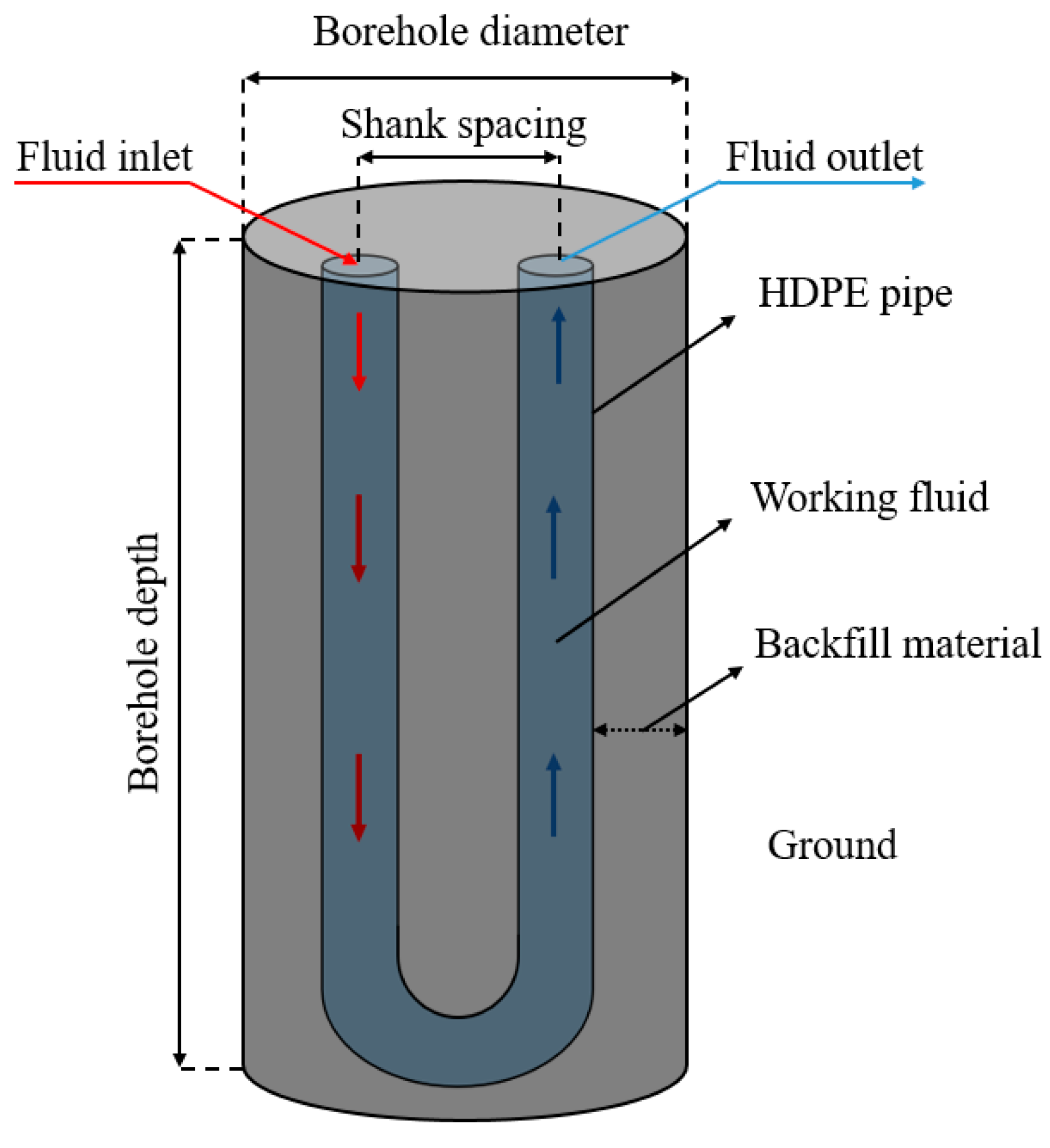

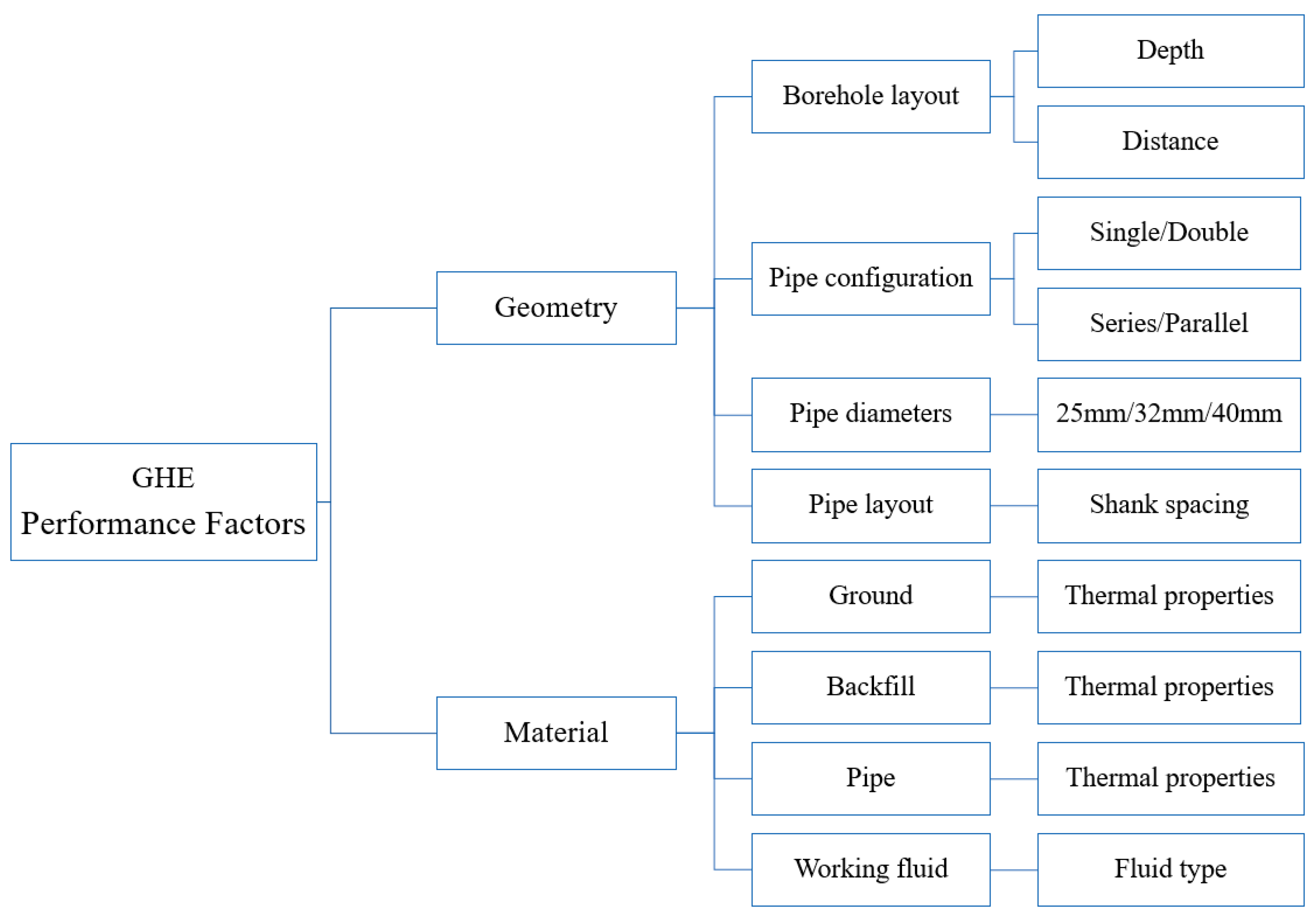

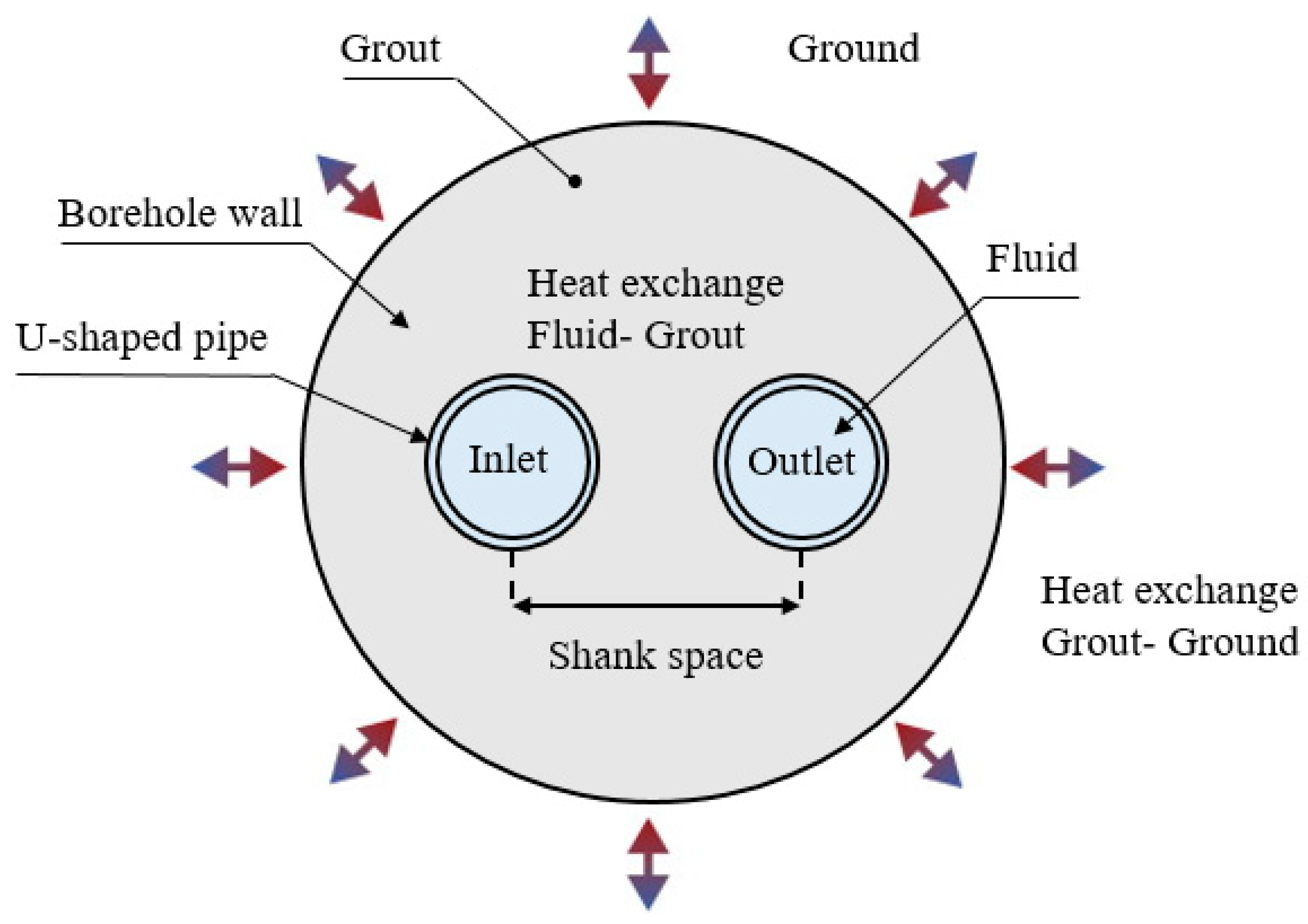

2. GHE Performance Factors

2.1. Soil Thermal Properties

2.2. Backfill Material Thermal Properties

2.2.1. Pure Material

2.2.2. Mixed Material

2.3. Borehole Layout

2.3.1. Borehole Depth

2.3.2. Borehole Diameter

2.3.3. Borehole Distance

2.3.4. Borehole Configuration

2.4. Pipe Thermal Properties

2.4.1. Pipe Material

2.4.2. Shank Spacing

2.5. Working Fluid Properties

2.5.1. Fluid Type

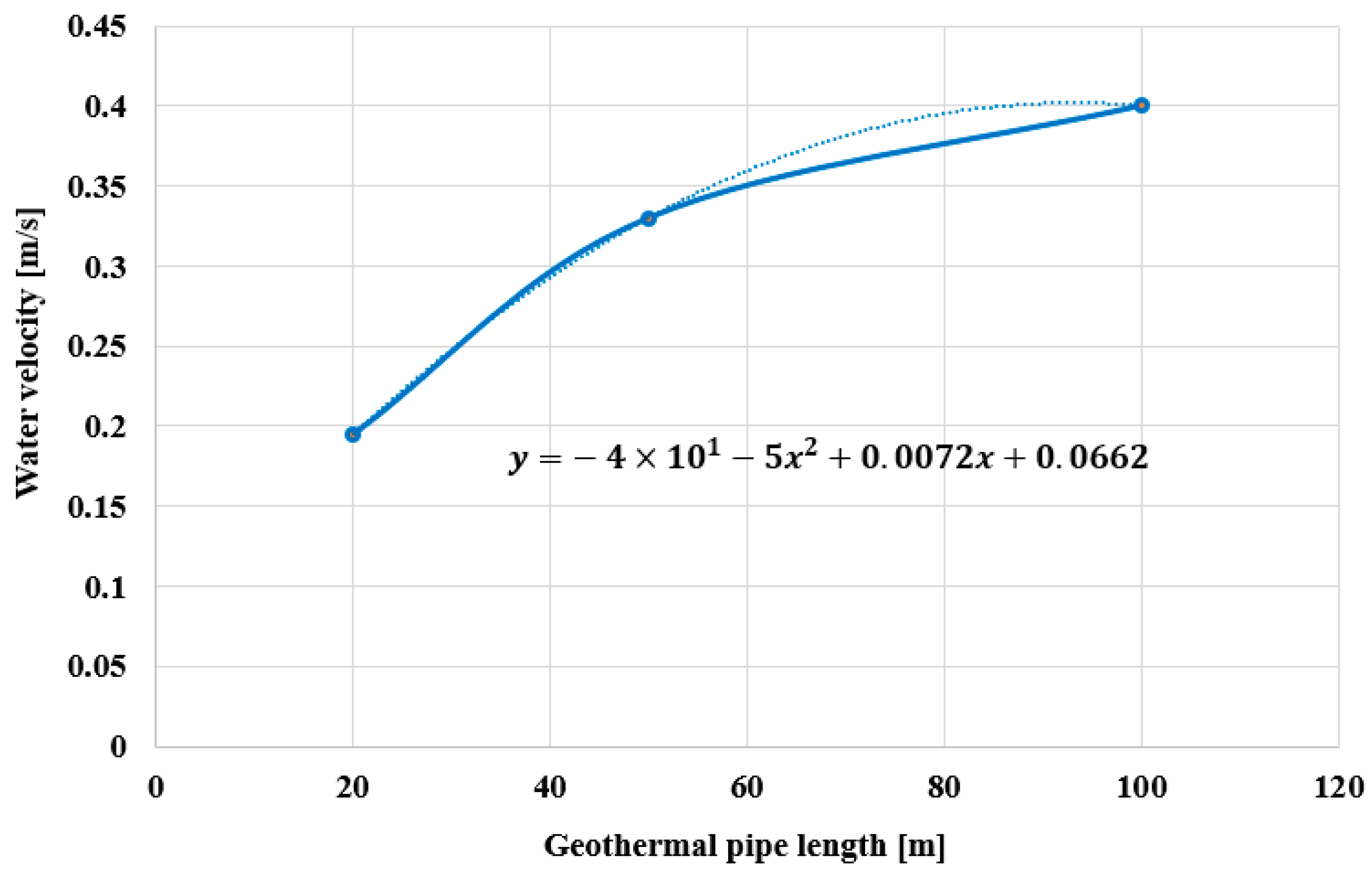

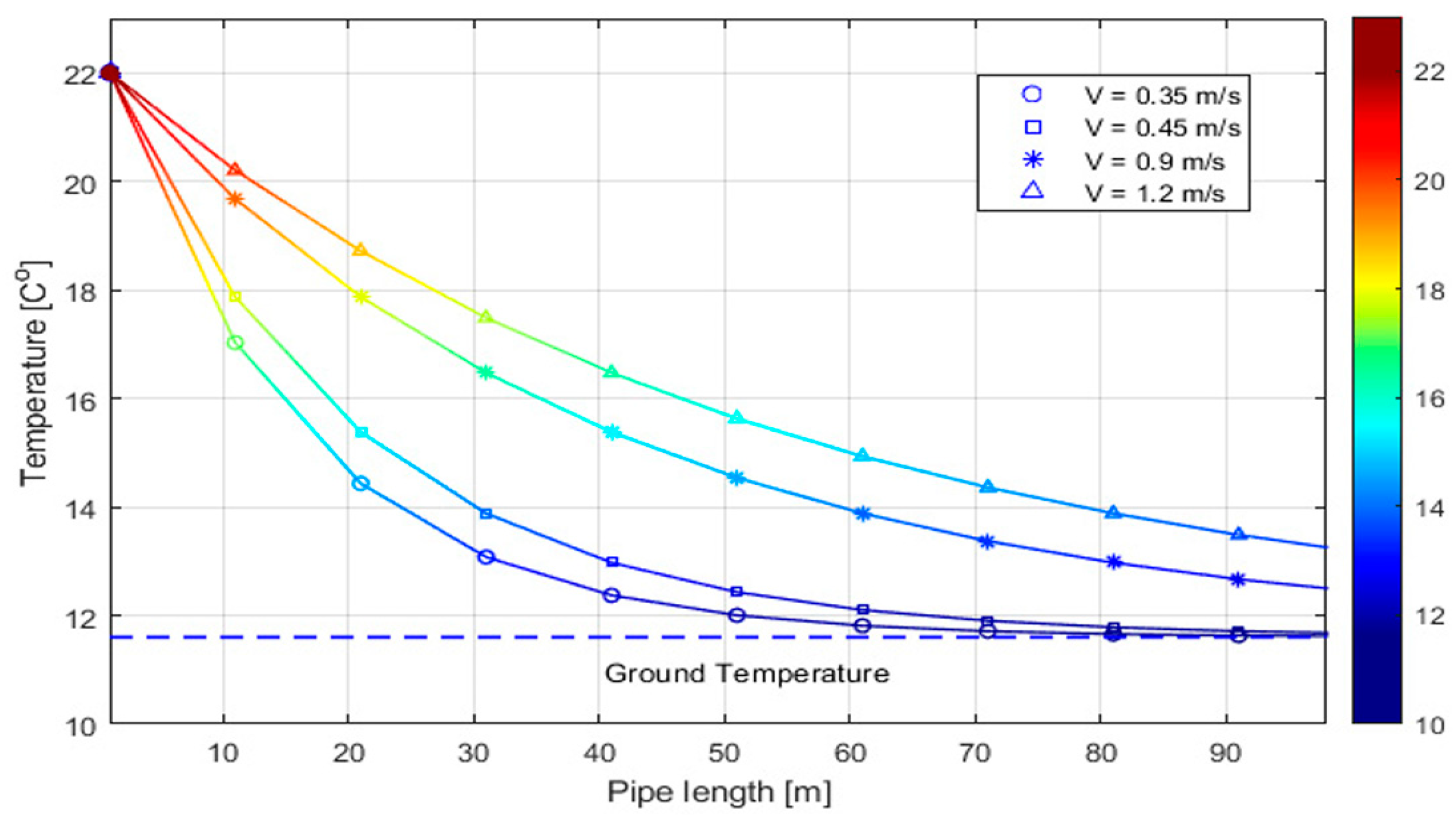

2.5.2. Fluid Velocity

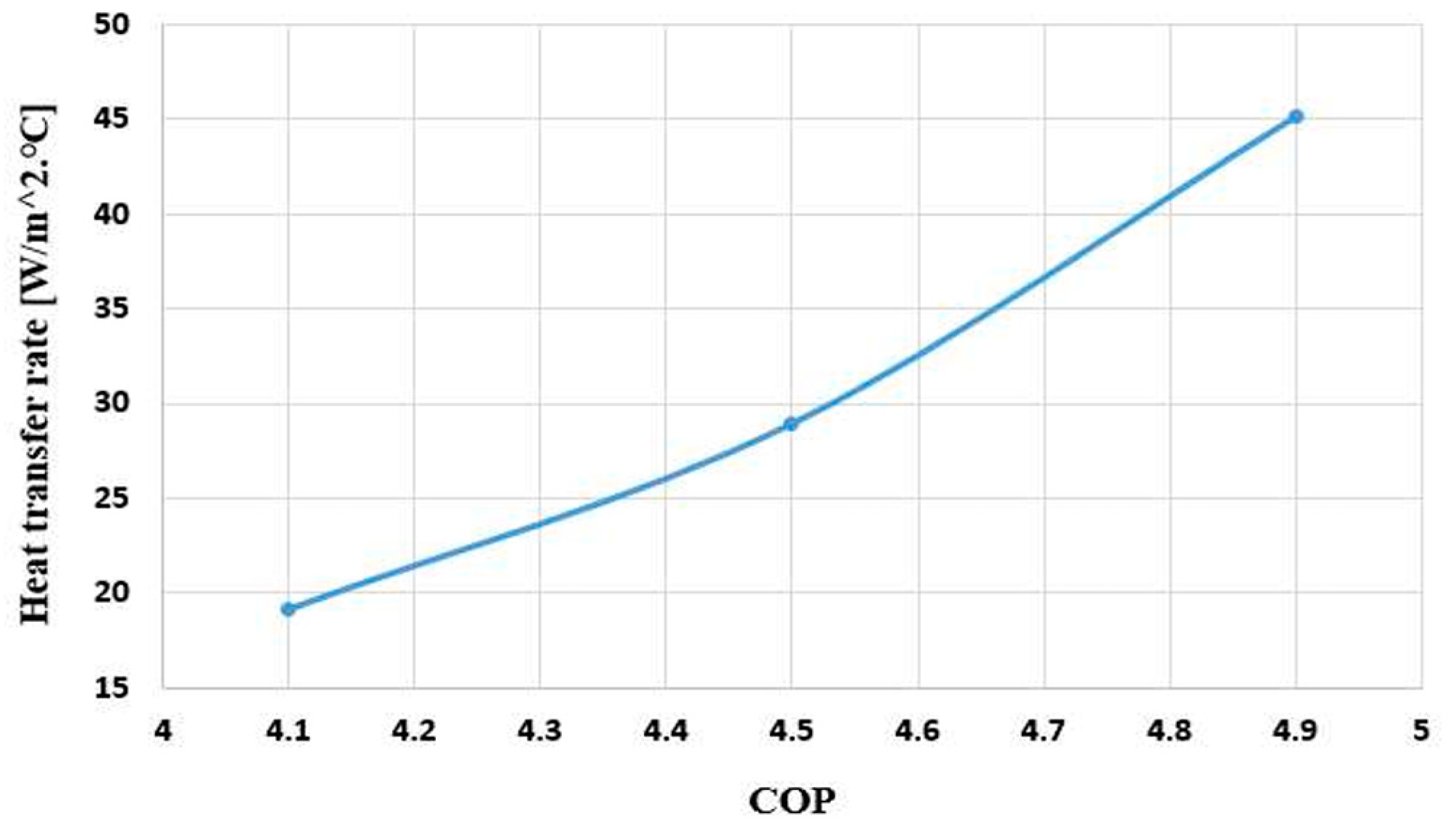

3. Discussion and Conclusions

Funding

Conflicts of Interest

Abbreviations

| BHE | Borehole heat exchanger |

| BTR | Borehole thermal resistance |

| CNT | Carbon nanotubes |

| COP | Coefficient of performance |

| DBHE | Deep borehole heat exchanger |

| GCHP | Ground-coupled heat pump |

| GHE | Ground heat exchanger |

| GHP | Geothermal heat pump |

| GHPS | Geothermal heat pump system |

| GSHP | Ground source heat pump |

| HDPE | High-density polyethylene |

| IEA | International Energy Agency |

| NF | Nanofluids |

References

- Salhein, K.; Kobus, C.; Zohdy, M. Forecasting installation capacity for the top 10 countries utilizing geothermal energy by 2030. Thermo 2022, 2, 334–351. [Google Scholar] [CrossRef]

- Hadjadj, A.; Atia, A.; Ben haoua, B.; Arıcı, M.; Naili, N.; Kaddour, A. Energy and exergy analyses of a helicoidal water to air geothermal heat exchanger for arid regions. Energy Sources Part A Recovery Util. Environ. Eff. 2021, 1–16. [Google Scholar] [CrossRef]

- Akrouch, G. Energy Piles in Cooling Dominated Climates. Doctoral Dissertation, 2014. Available online: https://hdl.handle.net/1969.1/152552 (accessed on 19 August 2024).

- Office of Energy Efficiency & Renewable Energy. IEA 2020 U.S. Geothermal Report. 8 June 2021. Available online: https://www.energy.gov/eere/geothermal/articles/now-available-iea-2020-us-geothermal-report (accessed on 19 August 2024).

- Salhein, K.A.A. Modeling and Control of Heat Transfer in a Single Vertical Ground Heat Exchanger for a Geothermal Heat Pump System. Doctoral Dissertation, Oakland University, Rochester, MI, USA, 2023. [Google Scholar]

- Zhang, X.; Zeng, R.; Mu, K.; Liu, X.; Sun, X.; Li, H. Exergetic and exergoeconomic evaluation of co-firing biomass gas with natural gas in CCHP system integrated with ground source heat pump. Energy Convers. Manag. 2019, 180, 622–640. [Google Scholar] [CrossRef]

- Salhein, K.; Kobus, C.; Zohdy, M. Control of heat transfer in a vertical ground heat exchanger for a geothermal heat pump system. Energies 2022, 15, 5300. [Google Scholar] [CrossRef]

- Philippacopoulos, A.J.; Berndt, M.L. Influence of debonding in ground heat exchangers used with geothermal heat pumps. Geothermics 2001, 30, 527–545. [Google Scholar] [CrossRef]

- Heat, G. Geothermal Energy Outlook Limited for Some Uses but Promising for; United States General Accounting Office: Washington, DC, USA, 1994.

- Omer, A.M. Ground-source heat pumps systems and applications. Renew. Sustain. Energy Rev. 2008, 12, 344–371. [Google Scholar] [CrossRef]

- Parsons, J. What is Geothermal Energy And How Can I Heat/Cool My House With It? 2020. Available online: https://www.climatemaster.com/homeowner/news/geothermal-energy/geothermal-energy/2020-12-11-what-is-geothermal-energy-and-how-can-i-heat-cool-my-house-with-it (accessed on 5 June 2022).

- Alhawsawi, E.Y.; Salhein, K.; Zohdy, M.A. A Comprehensive Review of Existing and Pending University Campus Microgrids. Energies 2024, 17, 2425. [Google Scholar] [CrossRef]

- Zogg, M. History of Heat Pumps-Swiss Contributions and International Milestones; Swiss Federal Office of Energy: Berne, Switzerland, 2008.

- Energy Saver. Choosing and Installing Geothermal Heat Pumps. Available online: https://www.energy.gov/energysaver/choosing-and-installing-geothermal-heat-pumps (accessed on 23 August 2024).

- Salhein, K.; Ashraf, J.; Zohdy, M. Output temperature predictions of the geothermal heat pump system using an improved grey prediction model. Energies 2021, 14, 5075. [Google Scholar] [CrossRef]

- Zhou, H.; Lv, J.; Li, T. Applicability of the pipe structure and flow velocity of vertical ground heat exchanger for ground source heat pump. Energy Build. 2016, 117, 109–119. [Google Scholar] [CrossRef]

- Akpinar, E.K.; Hepbasli, A. A comparative study on exergetic assessment of two ground-source (geothermal) heat pump systems for residential applications. Build. Environ. 2007, 42, 2004–2013. [Google Scholar] [CrossRef]

- Lund, J.W.; Toth, A.N. Direct utilization of geothermal energy 2020 worldwide review. Geothermics 2021, 90, 101915. [Google Scholar] [CrossRef]

- Shtym, A.; Zhurmilova, I. Ground heat exchangers of geothermal heat pumps and analysis of their constructive features and types. In Proceedings of the 2017 International Conference on Industrial Engineering, Applications and Manufacturing (ICIEAM), St. Petersburg, Russia, 16–19 May 2017; pp. 1–4. [Google Scholar]

- Gultekin, A.; Aydin, M.; Sisman, A. Thermal performance analysis of multiple borehole heat exchangers. Energy Convers. Manag. 2016, 122, 544–551. [Google Scholar] [CrossRef]

- Energy Saver. Geothermal Heat Pumps. Available online: https://www.energy.gov/energysaver/geothermal-heat-pumps (accessed on 14 August 2024).

- Salhein, K.; Kobus, C.; Zohdy, M. Heat Transfer Control Mechanism in a Vertical Ground Heat Exchanger: A Novel Approach. In Fundamental Research and Application of Physical Science; B P International: London, UK, 2023; Volume 5, pp. 59–90. ISBN 978-81-19217-76-2. [Google Scholar]

- Alhajjaji, A.; Chiasson, A.; Aljabr, A. Simulation-based analysis of a novel CO2 ground source heat pipe (GSHP) to reduce temperature fluctuations in pavements in different climatic conditions. Energies 2022, 15, 3343. [Google Scholar] [CrossRef]

- Tarnawski, V.; Momose, T.; Leong, W. Assessing the impact of quartz content on the prediction of soil thermal conductivity. Géotechnique 2009, 59, 331–338. [Google Scholar] [CrossRef]

- Agrawal, K.K.; Misra, R.; Agrawal, G.D. Improving the thermal performance of ground air heat exchanger system using sand-bentonite (in dry and wet condition) as backfilling material. Renew. Energy 2020, 146, 2008–2023. [Google Scholar] [CrossRef]

- Barry-Macaulay, D.; Bouazza, A.; Singh, R.M.; Wang, B.; Ranjith, P. Thermal conductivity of soils and rocks from the Melbourne (Australia) region. Eng. Geol. 2013, 164, 131–138. [Google Scholar] [CrossRef]

- Malek, K.; Malek, K.; Khanmohammadi, F. Response of soil thermal conductivity to various soil properties. Int. Commun. Heat Mass Transf. 2021, 127, 105516. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, F.; Ma, Z.; Wang, X.; Wu, X. Research of heat and moisture transfer influence on the characteristics of the ground heat pump exchangers in unsaturated soil. Energy Build. 2016, 130, 140–149. [Google Scholar] [CrossRef]

- Tang, F.; Nowamooz, H. Factors influencing the performance of shallow Borehole Heat Exchanger. Energy Convers. Manag. 2019, 181, 571–583. [Google Scholar] [CrossRef]

- Choi, J.C.; Lee, S.R.; Lee, D.S. Numerical simulation of vertical ground heat exchangers: Intermittent operation in unsaturated soil conditions. Comput. Geotech. 2011, 38, 949–958. [Google Scholar] [CrossRef]

- Abu-Hamdeh, N.H.; Reeder, R.C. Soil thermal conductivity effects of density, moisture, salt concentration, and organic matter. Soil Sci. Soc. Am. J. 2000, 64, 1285–1290. [Google Scholar] [CrossRef]

- Aizzuddin, A.; Yusof, T.; Azmi, W. Investigation of pipe materials and thermal conductivity of soil on the performance of ground heat exchanger operating under Malaysia climate. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1078, 012030. [Google Scholar] [CrossRef]

- Choi, W.; Ooka, R. Effect of natural convection on thermal response test conducted in saturated porous formation: Comparison of gravel-backfilled and cement-grouted borehole heat exchangers. Renew. Energy 2016, 96, 891–903. [Google Scholar] [CrossRef]

- Smith, M.D.; Perry, R.L. Borehole grouting: Field studies and thermal performance testing. ASHRAE Trans. 1999, 105, 451. [Google Scholar]

- Dehkordi, S.E.; Schincariol, R.A. Effect of thermal-hydrogeological and borehole heat exchanger properties on performance and impact of vertical closed-loop geothermal heat pump systems. Hydrogeol. J. 2014, 22, 189. [Google Scholar] [CrossRef]

- Alberti, L.; Angelotti, A.; Antelmi, M.; La Licata, I. A numerical study on the impact of grouting material on borehole heat exchangers performance in aquifers. Energies 2017, 10, 703. [Google Scholar] [CrossRef]

- Saeidi, R.; Noorollahi, Y.; Esfahanian, V. Numerical simulation of a novel spiral type ground heat exchanger for enhancing heat transfer performance of geothermal heat pump. Energy Convers. Manag. 2018, 168, 296–307. [Google Scholar] [CrossRef]

- Carlson, S.W. GSHP bore field performance comparisons of standard and thermally enhanced grout. ASHRAE Trans. 2000, 106, 442. [Google Scholar]

- Jahanbin, A. Thermal performance of the vertical ground heat exchanger with a novel elliptical single U-tube. Geothermics 2020, 86, 101804. [Google Scholar] [CrossRef]

- Allan, M.; Philippacopoulos, A. Performance characteristics and modelling of cementitious grouts for geothermal heat pumps. In Proceedings of the Proceedings World Geothermal Congress, Tohoku, Japan, 28 May–10 June 2000; p. 2000. [Google Scholar]

- Song, X.-q.; Jiang, M.; Qin, P. Numerical investigation of the backfilling material thermal conductivity impact on the heat transfer performance of the buried pipe heat exchanger. IOP Conf. Ser. Earth Environ. Sci. 2019, 267, 042010. [Google Scholar] [CrossRef]

- Zhang, W.; Yang, H.; Lu, L.; Fang, Z. Investigation on influential factors of engineering design of geothermal heat exchangers. Appl. Therm. Eng. 2015, 84, 310–319. [Google Scholar] [CrossRef]

- Chang, K.S.; Kim, M.J. Thermal performance evaluation of vertical U-loop ground heat exchanger using in-situ thermal response test. Renew. Energy 2016, 87, 585–591. [Google Scholar] [CrossRef]

- Erol, S.; François, B. Efficiency of various grouting materials for borehole heat exchangers. Appl. Therm. Eng. 2014, 70, 788–799. [Google Scholar] [CrossRef]

- Cao, D.; Shi, B.; Loheide II, S.P.; Gong, X.; Zhu, H.-H.; Wei, G.; Yang, L. Investigation of the influence of soil moisture on thermal response tests using active distributed temperature sensing (A–DTS) technology. Energy Build. 2018, 173, 239–251. [Google Scholar] [CrossRef]

- Allan, M.L.; Kavanaugh, S.P. Thermal conductivity of cementitious grouts and impact on heat exchanger length design for ground source heat pumps. Hvac R Res. 1999, 5, 85–96. [Google Scholar] [CrossRef]

- Kara, Y.A. Experimental performance evaluation of a closed-loop vertical ground source heat pump in the heating mode using energy analysis method. Int. J. Energy Res. 2007, 31, 1504–1516. [Google Scholar] [CrossRef]

- Lee, C.; Park, S.; Lee, D.; Lee, I.-M.; Choi, H. Viscosity and salinity effect on thermal performance of bentonite-based grouts for ground heat exchanger. Appl. Clay Sci. 2014, 101, 455–460. [Google Scholar] [CrossRef]

- Pahud, D.; Matthey, B. Comparison of the thermal performance of double U-pipe borehole heat exchangers measured in situ. Energy Build. 2001, 33, 503–507. [Google Scholar] [CrossRef]

- Ahonen, L.; Korkeakoski, P.; Tiljander, M.; Kivikoski, H.; Laaksonen, R. Quality Assurance of the Bentonite Material (No. POSIVA-WR--08-33); Posiva Oy: Helsinki, Finland, 2008. [Google Scholar]

- Gökalp, Z.; Başaran, M.; Uzun, O. Compaction and swelling characteristics of sand-bentonite and pumice-bentonite mixtures. Clay Miner. 2011, 46, 449–459. [Google Scholar] [CrossRef]

- Suzuki, S.; Prayongphan, S.; Ichikawa, Y.; Chae, B.G. In situ observations of the swelling of bentonite aggregates in NaCl solution. Appl. Clay Sci. 2005, 29, 89–98. [Google Scholar] [CrossRef]

- Eckhart, F. Grouting Procedures for Ground-Source Heat Pump Systems; Ground Source Heat Pump Publications, Oklahoma State University: Stillwater, OK, USA, 1991. [Google Scholar]

- Li, H.; Chen, M.; Fu, B.; Liang, B. Evaluation on the thermal and moisture diffusion behavior of sand/bentonite. Appl. Therm. Eng. 2019, 151, 55–65. [Google Scholar] [CrossRef]

- Al-Ameen, Y.; Ianakiev, A.; Evans, R. Recycling construction and industrial landfill waste material for backfill in horizontal ground heat exchanger systems. Energy 2018, 151, 556–568. [Google Scholar] [CrossRef]

- Remund, C.P.; Lund, J.T. Thermal enhancement of bentonite grouts for vertical GSHP systems. In Proceedings of the Heat Pump and Refrigeration Systems, Design, Analysis, and Applications, ASME Winter Annual Meeting, New Orleans, LA, USA, 10 June 1993; pp. 95–106. [Google Scholar]

- Lee, C.; Lee, K.; Choi, H.; Choi, H.-P. Characteristics of thermally-enhanced bentonite grouts for geothermal heat exchanger in South Korea. Sci. China Ser. E Technol. Sci. 2010, 53, 123–128. [Google Scholar] [CrossRef]

- Wang, H.; Cui, Y.; Qi, C. Effects of sand–bentonite backfill materials on the thermal performance of borehole heat exchangers. Heat Transf. Eng. 2013, 34, 37–44. [Google Scholar] [CrossRef]

- Liang, B.; Chen, M.; Guan, J. Assessment on the thermal and moisture migration of sand-based materials coupled with kaolin additive. J. Therm. Anal. Calorim. 2022, 147, 10163–10176. [Google Scholar] [CrossRef]

- Lee, C.; Park, M.; Nguyen, T.-B.; Sohn, B.; Choi, J.M.; Choi, H. Performance evaluation of closed-loop vertical ground heat exchangers by conducting in-situ thermal response tests. Renew. Energy 2012, 42, 77–83. [Google Scholar] [CrossRef]

- Delaleux, F.; Py, X.; Olives, R.; Dominguez, A. Enhancement of geothermal borehole heat exchangers performances by improvement of bentonite grouts conductivity. Appl. Therm. Eng. 2012, 33, 92–99. [Google Scholar] [CrossRef]

- Agrawal, K.K.; Misra, R.; Agrawal, G.D. Thermal performance analysis of slinky-coil ground-air heat exchanger system with sand-bentonite as backfilling material. Energy Build. 2019, 202, 109351. [Google Scholar] [CrossRef]

- Liang, B.; Chen, M.; Fu, B.; Li, H. Investigation on the thermal and flow performances of a vertical spiral-tube ground heat exchanger in sand combined with kaolin additive. Energy Build. 2019, 190, 235–245. [Google Scholar] [CrossRef]

- Geothermal, G. Ground Loop Design Software; GLD2012. 2009. Available online: https://www.groundloopdesign.com/downloads/GLD_2012/ClimateMaster_GLD2012_Manual_FINAL.pdf (accessed on 19 August 2024).

- Song, X.; Wen, Z.; Si, J. CFD numerical simulation of a U-tube ground heat exchanger used in ground source heat pumps. Chin. J. Eng. 2007, 29, 329–333. [Google Scholar]

- Li, Z.; Zheng, M. Development of a numerical model for the simulation of vertical U-tube ground heat exchangers. Appl. Therm. Eng. 2009, 29, 920–924. [Google Scholar] [CrossRef]

- Chen, J.; Xia, L.; Li, B.; Mmereki, D. Simulation and experimental analysis of optimal buried depth of the vertical U-tube ground heat exchanger for a ground-coupled heat pump system. Renew. Energy 2015, 73, 46–54. [Google Scholar] [CrossRef]

- Rybach, L.; Sanner, B. Ground source heat pump systems, the European experience. GHC Bull. 2000, 21, 16–26. [Google Scholar]

- Zeng, H.; Diao, N.; Fang, Z. Efficiency of vertical geothermal heat exchangers in the ground source heat pump system. J. Therm. Sci. 2003, 12, 77–81. [Google Scholar] [CrossRef]

- Li, M.; Lai, A.C. Review of analytical models for heat transfer by vertical ground heat exchangers (GHEs): A perspective of time and space scales. Appl. Energy 2015, 151, 178–191. [Google Scholar] [CrossRef]

- Hellstrom, G.A.J. Ground Heat Storage: Thermal Analyses of Duct Storage Systems; I. Theory (1992): 0662-0662. Doctoral Dissertation, Lunds Universitet, Lund, Sweden, 1992. [Google Scholar]

- Pulat, E.; Coskun, S.; Unlu, K.; Yamankaradeniz, N. Experimental study of horizontal ground source heat pump performance for mild climate in Turkey. Energy 2009, 34, 1284–1295. [Google Scholar] [CrossRef]

- Casasso, A.; Sethi, R. Efficiency of closed loop geothermal heat pumps: A sensitivity analysis. Renew. Energy 2014, 62, 737–746. [Google Scholar] [CrossRef]

- Sani, A.K.; Singh, R.M.; Amis, T.; Cavarretta, I. A review on the performance of geothermal energy pile foundation, its design process and applications. Renew. Sustain. Energy Rev. 2019, 106, 54–78. [Google Scholar] [CrossRef]

- Residential Geothermal Heating & Cooling. Available online: https://dandelionenergy.com/resources/vertical-ground-loop (accessed on 15 August 2024).

- Adebayo, P.; Beragama Jathunge, C.; Shor, R.; Mohamad, A.; Mwesigye, A. A Comparative Study of the Long-Term Performance of Vertical U-Tube Borehole Heat Exchanger and Foundation Piles in a Cold Climate. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, New Orleans, LA, USA, 29 October–2 November 2023; p. V007T008A011. [Google Scholar]

- Zanchini, E.; Jahanbin, A. Effects of the temperature distribution on the thermal resistance of double u-tube borehole heat exchangers. Geothermics 2018, 71, 46–54. [Google Scholar] [CrossRef]

- Focaccia, S.; Tinti, F. An innovative Borehole Heat Exchanger configuration with improved heat transfer. Geothermics 2013, 48, 93–100. [Google Scholar] [CrossRef]

- Madani, H.; Claesson, J.; Lundqvist, P. Capacity control in ground source heat pump systems: Part I: Modeling and simulation. Int. J. Refrig. 2011, 34, 1338–1347. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, Y.; Liu, Y.; Kong, X.; Wang, Q. Computational methods for ground thermal response of multiple borehole heat exchangers: A review. Renew. Energy 2018, 127, 461–473. [Google Scholar] [CrossRef]

- Diersch, H.-J.; Bauer, D. Analysis, modeling and simulation of underground thermal energy storage (UTES) systems. In Advances in Thermal Energy Storage Systems; Elsevier: Amsterdam, The Netherlands, 2015; pp. 149–183. [Google Scholar]

- Sliwa, A.; Rosen, M.; Gonet, A.; Sliwa, T. Deep borehole heat exchangers—A conceptual review. Int. J. Air-Cond. Refrig. 2016, 24, 1630001. [Google Scholar] [CrossRef]

- Yang, L.; Zhang, B.; Klemeš, J.J.; Liu, J.; Song, M.; Wang, J. Effect of buried depth on thermal performance of a vertical U-tube underground heat exchanger. Open Phys. 2021, 19, 327–330. [Google Scholar] [CrossRef]

- Aljabr, A.; Chiasson, A. Numerical modeling of the effects of the radial and axial location of added micro-encapsulated phase change materials in vertical borehole heat exchangers. Geothermics 2023, 110, 102684. [Google Scholar] [CrossRef]

- Johnson, D. Ground Source Heat Pumps: Horizontal Collectors vs. Vertical Boreholes. Available online: https://www.mesh-energy.com/insights/ground-source-heat-pumps-horizontal-collectors-vs-vertical-boreholes (accessed on 15 August 2024).

- Aljabr, A. Investigation on the influence of mixed borehole depths in vertical ground heat exchanger systems. Geothermics 2024, 119, 102971. [Google Scholar] [CrossRef]

- Li, Y.; An, Q.; Liu, L.; Zhao, J. Thermal performance investigation of borehole heat exchanger with different U-tube diameter and borehole parameters. Energy Procedia 2014, 61, 2690–2694. [Google Scholar] [CrossRef]

- Li, Y.; Mao, J.; Geng, S.; Han, X.; Zhang, H. Evaluation of thermal short-circuiting and influence on thermal response test for borehole heat exchanger. Geothermics 2014, 50, 136–147. [Google Scholar] [CrossRef]

- Chen, S.; Mao, J.; Han, X. Heat transfer analysis of a vertical ground heat exchanger using numerical simulation and multiple regression model. Energy Build. 2016, 129, 81–91. [Google Scholar] [CrossRef]

- Sandler, S.; Zajaczkowski, B.; Bialko, B.; Malecha, Z.M. Evaluation of the impact of the thermal shunt effect on the U-pipe ground borehole heat exchanger performance. Geothermics 2017, 65, 244–254. [Google Scholar] [CrossRef]

- Zhai, X.; Cheng, X.; Wang, R. Heating and cooling performance of a minitype ground source heat pump system. Appl. Therm. Eng. 2017, 111, 1366–1370. [Google Scholar] [CrossRef]

- Mehrpooya, M.; Hemmatabady, H.; Ahmadi, M.H. Optimization of performance of Combined Solar Collector-Geothermal Heat Pump Systems to supply thermal load needed for heating greenhouses. Energy Convers. Manag. 2015, 97, 382–392. [Google Scholar] [CrossRef]

- Loveridge, F.; Powrie, W. 2D thermal resistance of pile heat exchangers. Geothermics 2014, 50, 122–135. [Google Scholar] [CrossRef]

- Dehkordi, S.E.; Schincariol, R.A.; Reitsma, S. Thermal performance of a tight borehole heat exchanger. Renew. Energy 2015, 83, 698–704. [Google Scholar] [CrossRef]

- Luo, J.; Rohn, J.; Bayer, M.; Priess, A.; Wilkmann, L.; Xiang, W. Heating and cooling performance analysis of a ground source heat pump system in Southern Germany. Geothermics 2015, 53, 57–66. [Google Scholar] [CrossRef]

- Luo, J.; Rohn, J.; Bayer, M.; Priess, A. Thermal performance and economic evaluation of double U-tube borehole heat exchanger with three different borehole diameters. Energy Build. 2013, 67, 217–224. [Google Scholar] [CrossRef]

- Yang, H.; Cui, P.; Fang, Z. Vertical-borehole ground-coupled heat pumps: A review of models and systems. Appl. Energy 2010, 87, 16–27. [Google Scholar] [CrossRef]

- Tarrad, A.H. A Brief Review and Evaluation of Available 1-Dimensional Models for the Borehole Thermal Performance Prediction in a Ground-Coupled Heat Pump System. Curr. Approaches Sci. Technol. Res. 2021, 13, 145–170. [Google Scholar]

- Janssen, H.; Carmeliet, J.; Hens, H. The influence of soil moisture transfer on building heat loss via the ground. Build. Environ. 2004, 39, 825–836. [Google Scholar] [CrossRef]

- Pei, G.; Zhang, L. Heat transfer analysis of underground U-type heat exchanger of ground source heat pump system. SpringerPlus 2016, 5, 1863. [Google Scholar] [CrossRef]

- Boban, L.; Miše, D.; Herceg, S.; Soldo, V. Application and design aspects of ground heat exchangers. Energies 2021, 14, 2134. [Google Scholar] [CrossRef]

- Zhang, H.; Han, Z.; Li, X.; Ji, M.; Zhang, X.; Li, G.; Yang, L. Study on the influence of borehole spacing considering groundwater flow and freezing factors on the annual performance of the ground source heat pump. Appl. Therm. Eng. 2021, 182, 116042. [Google Scholar] [CrossRef]

- Self, S.J.; Reddy, B.V.; Rosen, M.A. Geothermal heat pump systems: Status review and comparison with other heating options. Appl. Energy 2013, 101, 341–348. [Google Scholar] [CrossRef]

- Sagia, Z.; Stegou, A.; Rakopoulos, C. Borehole resistance and heat conduction around vertical ground heat exchangers. Open Chem. Eng. J. 2012, 6, 32–40. [Google Scholar] [CrossRef]

- Signorelli, S.; Kohl, T.; Rybach, L. Sustainability of production from borehole heat exchanger fields. In Proceedings of the Proceedings World Geothermal Congress 2005, Antalya, Turkey, 24–29 April 2005; pp. 1–6. [Google Scholar]

- Han, Z.; Li, B.; Zhang, S.; Bai, C.; Hu, H. Study on design error of ground source heat pump system and its influencing factors. Appl. Therm. Eng. 2018, 144, 1030–1036. [Google Scholar] [CrossRef]

- Desideri, U.; Sorbi, N.; Arcioni, L.; Leonardi, D. Feasibility study and numerical simulation of a ground source heat pump plant, applied to a residential building. Appl. Therm. Eng. 2011, 31, 3500–3511. [Google Scholar] [CrossRef]

- Sailer, E.; Taborda, D.M.; Keirstead, J. Assessment of design procedures for vertical borehole heat exchangers. In Proceedings of the PROCEEDINGS, Fortieth Workshop on Geothermal Reservoir Engineering, Stanford, CA, USA, 26–28 January 2015. [Google Scholar]

- Staiti, M.; Angelotti, A. Design of borehole heat exchangers for ground source heat pumps: A comparison between two methods. Energy Procedia 2015, 78, 1147–1152. [Google Scholar] [CrossRef]

- Zheng, Z.; Wang, W.; Ji, C. A study on the thermal performance of vertical U-tube ground heat exchangers. Energy Procedia 2011, 12, 906–914. [Google Scholar] [CrossRef]

- Guo, M.; Diao, N.; Man, Y.; Fang, Z. Research and development of the hybrid ground-coupled heat pump technology in China. Renew. Energy 2016, 87, 1033–1044. [Google Scholar] [CrossRef]

- Zeng, H.; Diao, N.; Fang, Z. Heat transfer analysis of boreholes in vertical ground heat exchangers. Int. J. Heat Mass Transf. 2003, 46, 4467–4481. [Google Scholar] [CrossRef]

- Cai, Y.; Xu, H.; Chen, S. Testing and analysis of the influence factors for the ground thermal parameters. Appl. Therm. Eng. 2016, 107, 662–671. [Google Scholar] [CrossRef]

- Qi, D.; Pu, L.; Ma, Z.; Xia, L.; Li, Y. Effects of ground heat exchangers with different connection configurations on the heating performance of GSHP systems. Geothermics 2019, 80, 20–30. [Google Scholar] [CrossRef]

- Florides, G.A.; Christodoulides, P.; Pouloupatis, P. Single and double U-tube ground heat exchangers in multiple-layer substrates. Appl. Energy 2013, 102, 364–373. [Google Scholar] [CrossRef]

- Zarrella, A.; Emmi, G.; De Carli, M. A simulation-based analysis of variable flow pumping in ground source heat pump systems with different types of borehole heat exchangers: A case study. Energy Convers. Manag. 2017, 131, 135–150. [Google Scholar] [CrossRef]

- Miyara, A.; Tsubaki, K.; Inoue, S.; Yoshida, K. Experimental study of several types of ground heat exchanger using a steel pile foundation. Renew. Energy 2011, 36, 764–771. [Google Scholar]

- Darkwa, J.; Su, W.; Chow, D. Heat dissipation effect on a borehole heat exchanger coupled with a heat pump. Appl. Therm. Eng. 2013, 60, 234–241. [Google Scholar] [CrossRef]

- Exchange, T.P. 2024. Available online: https://www.theplasticsexchange.com/ (accessed on 26 August 2024).

- Araújo, J.; Waldman, W.; De Paoli, M. Thermal properties of high density polyethylene composites with natural fibres: Coupling agent effect. Polym. Degrad. Stab. 2008, 93, 1770–1775. [Google Scholar] [CrossRef]

- Pip’s Island Home. What Is High Density Polyethylene Pipe? (Usage, Pros & Cons). Available online: https://www.pipsisland.com/what-is-high-density-polyethylene-pipe/ (accessed on 26 August 2022).

- Travaš, L.; Rujnić Havstad, M.; Pilipović, A. Optimization of Thermal Conductivity and Tensile Properties of High-Density Polyethylene by Addition of Expanded Graphite and Boron Nitride. Polymers 2023, 15, 3645. [Google Scholar] [CrossRef]

- Bassiouny, R.; Ali, M.R.; Hassan, M.K. An idea to enhance the thermal performance of HDPE pipes used for ground-source applications. Appl. Therm. Eng. 2016, 109, 15–21. [Google Scholar] [CrossRef]

- Raymond, J.; Frenette, M.; Léger, A.; Magni, É.; Therrien, R. Numerical Modeling of Thermally Enhanced Pipe Performances in Vertical Ground Heat Exchangers. ASHRAE Trans. 2011, 117, 899. [Google Scholar]

- Bouhacina, B.; Saim, R.; Oztop, H.F. Numerical investigation of a novel tube design for the geothermal borehole heat exchanger. Appl. Therm. Eng. 2015, 79, 153–162. [Google Scholar] [CrossRef]

- Narei, H.; Fatehifar, M.; Ghasempour, R.; Noorollahi, Y. In pursuit of a replacement for conventional high-density polyethylene tubes in ground source heat pumps from their composites—A comparative study. Geothermics 2020, 87, 101819. [Google Scholar] [CrossRef]

- Guo, Y.; Cao, C.; Luo, F.; Huang, B.; Xiao, L.; Qian, Q.; Chen, Q. Largely enhanced thermal conductivity and thermal stability of ultra high molecular weight polyethylene composites via BN/CNT synergy. RSC Adv. 2019, 9, 40800–40809. [Google Scholar] [CrossRef] [PubMed]

- Quiles-Díaz, S.; Martínez-Rubí, Y.; Guan, J.; Kim, K.S.; Couillard, M.; Salavagione, H.J.; Gómez-Fatou, M.n.A.; Simard, B. Enhanced thermal conductivity in polymer nanocomposites via covalent functionalization of boron nitride nanotubes with short polyethylene chains for heat-transfer applications. ACS Appl. Nano Mater. 2018, 2, 440–451. [Google Scholar] [CrossRef]

- Li, X.; Sheng, X.; Guo, Y.; Lu, X.; Wu, H.; Chen, Y.; Zhang, L.; Gu, J. Multifunctional HDPE/CNTs/PW composite phase change materials with excellent thermal and electrical conductivities. J. Mater. Sci. Technol. 2021, 86, 171–179. [Google Scholar] [CrossRef]

- Sobolciak, P.; Abdulgader, A.; Mrlik, M.; Popelka, A.; Abdala, A.A.; Aboukhlewa, A.A.; Karkri, M.; Kiepfer, H.; Bart, H.J.; Krupa, I. Thermally conductive polyethylene/expanded graphite composites as heat transfer surface: Mechanical, thermo-physical and surface behavior. Polymers 2020, 12, 2863. [Google Scholar] [CrossRef]

- Klonos, P.A.; Papadopoulos, L.; Kourtidou, D.; Chrissafis, K.; Peoglos, V.; Kyritsis, A.; Bikiaris, D.N. Effects of Expandable Graphite at Moderate and Heavy Loadings on the Thermal and Electrical Conductivity of Amorphous Polystyrene and Semicrystalline High-Density Polyethylene. Appl. Nano 2021, 2, 31–45. [Google Scholar] [CrossRef]

- Muratov, D.S.; Stepashkin, A.A.; Anshin, S.M.; Kuznetsov, D.V. Controlling thermal conductivity of high density polyethylene filled with modified hexagonal boron nitride (hBN). J. Alloys Compd. 2018, 735, 1200–1205. [Google Scholar] [CrossRef]

- Rasul, M.G.; Kiziltas, A.; Hoque, M.S.B.; Banik, A.; Hopkins, P.E.; Tan, K.-T.; Arfaei, B.; Shahbazian-Yassar, R. Improvement of the thermal conductivity and tribological properties of polyethylene by incorporating functionalized boron nitride nanosheets. Tribol. Int. 2022, 165, 107277. [Google Scholar] [CrossRef]

- Zhang, X.; Wu, H.; Guo, S. Effect of interfacial interaction on morphology and properties of polyethylene/boron nitride thermally conductive composites. Polym.-Plast. Technol. Eng. 2015, 54, 1097–1105. [Google Scholar] [CrossRef]

- Chen, B.; Gong, J.; Huang, W.; Gao, N.; Deng, C.; Gao, X. Constructing a parallel aligned shish kebab structure of HDPE/BN composites: Toward improved two-way thermal conductivity and tensile strength. Compos. Part B Eng. 2023, 259, 110699. [Google Scholar] [CrossRef]

- Yang, X.; Song, X.; Hu, Z.; Li, C.; Guo, T. Improving comprehensive properties of high-density polyethylene matrix composite by boron nitride/coconut shell carbon reinforcement. Polym. Test. 2022, 115, 107728. [Google Scholar] [CrossRef]

- Jing, J.; Chen, Y.; Shi, S.; Yang, L.; Lambin, P. Facile and scalable fabrication of highly thermal conductive polyethylene/graphene nanocomposites by combining solid-state shear milling and FDM 3D-printing aligning methods. Chem. Eng. J. 2020, 402, 126218. [Google Scholar] [CrossRef]

- Shemelya, C.; De La Rosa, A.; Torrado, A.R.; Yu, K.; Domanowski, J.; Bonacuse, P.J.; Martin, R.E.; Juhasz, M.; Hurwitz, F.; Wicker, R.B. Anisotropy of thermal conductivity in 3D printed polymer matrix composites for space based cube satellites. Addit. Manuf. 2017, 16, 186–196. [Google Scholar] [CrossRef]

- Chen, B.; Yang, H.; Shen, K.; Fu, Q.; Gao, X. The effect of high-temperature annealing on thermal properties and morphology of polyethylene pipes prepared by rotational shear. Polymer 2020, 204, 122770. [Google Scholar] [CrossRef]

- Zong, Z.; Ren, F.; Guo, Z.; Lu, Z.; Jin, Y.; Zhao, Y.; Ren, P. Dual-functional carbonized loofah@ GNSs-CNTs reinforced by cyanate ester composite with highly efficient electromagnetic interference shielding and thermal management. Compos. Part B Eng. 2021, 223, 109132. [Google Scholar] [CrossRef]

- Yang, W.; Wang, Y.; Li, Y.; Gao, C.; Tian, X.; Wu, N.; Geng, Z.; Che, S.; Yang, F.; Li, Y. Three-dimensional skeleton assembled by carbon nanotubes/boron nitride as filler in epoxy for thermal management materials with high thermal conductivity and electrical insulation. Compos. Part B Eng. 2021, 224, 109168. [Google Scholar] [CrossRef]

- Ahn, H.J.; Eoh, Y.J.; Park, S.D.; Kim, E.S. Thermal conductivity of polymer composites with oriented boron nitride. Thermochim. Acta 2014, 590, 138–144. [Google Scholar] [CrossRef]

- Wagner, V.; Bayer, P.; Kübert, M.; Blum, P. Numerical sensitivity study of thermal response tests. Renew. Energy 2012, 41, 245–253. [Google Scholar] [CrossRef]

- Jun, L.; Xu, Z.; Jun, G.; Jie, Y. Evaluation of heat exchange rate of GHE in geothermal heat pump systems. Renew. Energy 2009, 34, 2898–2904. [Google Scholar] [CrossRef]

- Cui, Y.; Zhu, J. 3D transient heat transfer numerical analysis of multiple energy piles. Energy Build. 2017, 134, 129–142. [Google Scholar] [CrossRef]

- Qi, D.; Pu, L.; Sun, F.; Li, Y. Numerical investigation on thermal performance of ground heat exchangers using phase change materials as grout for ground source heat pump system. Appl. Therm. Eng. 2016, 106, 1023–1032. [Google Scholar] [CrossRef]

- Ruiz-Calvo, F.; Cervera-Vázquez, J.; Montagud, C.; Corberán, J.M. Reference data sets for validating and analyzing GSHP systems based on an eleven-year operation period. Geothermics 2016, 64, 538–550. [Google Scholar] [CrossRef]

- Leidel, J. Human Health Science Building Geothermal Heat Pump Systems; Oakland University: Rochester, MI, USA, 2014. [Google Scholar]

- Vella, C.; Borg, S.P.; Micallef, D. The effect of shank-space on the thermal performance of shallow vertical U-tube ground heat exchangers. Energies 2020, 13, 602. [Google Scholar] [CrossRef]

- Bauer, D.; Heidemann, W.; Müller-Steinhagen, H.; Diersch, H.J. Thermal resistance and capacity models for borehole heat exchangers. Int. J. Energy Res. 2011, 35, 312–320. [Google Scholar] [CrossRef]

- Dada, M.; Benchatti, A. Assessment of heat recovery and recovery efficiency of a seasonal thermal energy storage system in a moist porous medium. Int. J. Heat Technol 2016, 34, 701–708. [Google Scholar] [CrossRef]

- Mohamad, Z.; Fardoun, F.; Meftah, F. A review on energy piles design, evaluation, and optimization. J. Clean. Prod. 2021, 292, 125802. [Google Scholar] [CrossRef]

- Neuberger, P.; Adamovský, R.; Šeďová, M. Temperatures and heat flows in a soil enclosing a slinky horizontal heat exchanger. Energies 2014, 7, 972–987. [Google Scholar] [CrossRef]

- Emmi, G.; Zarrella, A.; De Carli, M.; Donà, M.; Galgaro, A. Energy performance and cost analysis of some borehole heat exchanger configurations with different heat-carrier fluids in mild climates. Geothermics 2017, 65, 158–169. [Google Scholar] [CrossRef]

- Duangthongsuk, W.; Wongwises, S. An experimental study on the heat transfer performance and pressure drop of TiO2-water nanofluids flowing under a turbulent flow regime. Int. J. Heat Mass Transf. 2010, 53, 334–344. [Google Scholar] [CrossRef]

- Serrano, E.; Rus, G.; Garcia-Martinez, J. Nanotechnology for sustainable energy. Renew. Sustain. Energy Rev. 2009, 13, 2373–2384. [Google Scholar] [CrossRef]

- Saidur, R.; Leong, K.; Mohammed, H.A. A review on applications and challenges of nanofluids. Renew. Sustain. Energy Rev. 2011, 15, 1646–1668. [Google Scholar] [CrossRef]

- Diglio, G.; Roselli, C.; Sasso, M.; Channabasappa, U.J. Borehole heat exchanger with nanofluids as heat carrier. Geothermics 2018, 72, 112–123. [Google Scholar] [CrossRef]

- Asadi, A. A guideline towards easing the decision-making process in selecting an effective nanofluid as a heat transfer fluid. Energy Convers. Manag. 2018, 175, 1–10. [Google Scholar] [CrossRef]

- Narei, H.; Ghasempour, R.; Noorollahi, Y. The effect of employing nanofluid on reducing the bore length of a vertical ground-source heat pump. Energy Convers. Manag. 2016, 123, 581–591. [Google Scholar] [CrossRef]

- Alim, M.A.; Abdin, Z.; Saidur, R.; Hepbasli, A.; Khairul, M.A.; Rahim, N.A. Analyses of entropy generation and pressure drop for a conventional flat plate solar collector using different types of metal oxide nanofluids. Energy Build. 2013, 66, 289–296. [Google Scholar] [CrossRef]

- Tsai, C.; Chien, H.; Ding, P.; Chan, B.; Luh, T.Y.; Chen, P. Effect of structural character of gold nanoparticles in nanofluid on heat pipe thermal performance. Mater. Lett. 2004, 58, 1461–1465. [Google Scholar] [CrossRef]

- Wen, D.; Ding, Y. Experimental investigation into convective heat transfer of nanofluids at the entrance region under laminar flow conditions. Int. J. Heat Mass Transf. 2004, 47, 5181–5188. [Google Scholar] [CrossRef]

- Pak, B.C.; Cho, Y.I. Hydrodynamic and heat transfer study of dispersed fluids with submicron metallic oxide particles. Exp. Heat Transf. Int. J. 1998, 11, 151–170. [Google Scholar] [CrossRef]

- Heris, S.Z.; Etemad, S.G.; Esfahany, M.N. Experimental investigation of oxide nanofluids laminar flow convective heat transfer. Int. Commun. Heat Mass Transf. 2006, 33, 529–535. [Google Scholar] [CrossRef]

- Heris, S.Z.; Esfahany, M.N.; Etemad, S.G. Experimental investigation of convective heat transfer of Al2O3/water nanofluid in circular tube. Int. J. Heat Fluid Flow 2007, 28, 203–210. [Google Scholar] [CrossRef]

- Li, Q.; Xuan, Y. Convective heat transfer and flow characteristics of Cu-water nanofluid. Sci. China Ser. E Technolgical Sci. 2002, 45, 408–416. [Google Scholar] [CrossRef]

- Xuan, Y.; Li, Q. Investigation on convective heat transfer and flow features of nanofluids. J. Heat Transf. 2003, 125, 151–155. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, Z.G.; Grulke, E.A.; Anderson, W.B.; Wu, G. Heat transfer properties of nanoparticle-in-fluid dispersions (nanofluids) in laminar flow. Int. J. Heat Mass Transf. 2005, 48, 1107–1116. [Google Scholar] [CrossRef]

- Ding, Y.; Alias, H.; Wen, D.; Williams, R.A. Heat transfer of aqueous suspensions of carbon nanotubes (CNT nanofluids). Int. J. Heat Mass Transf. 2006, 49, 240–250. [Google Scholar] [CrossRef]

- He, Y.; Jin, Y.; Chen, H.; Ding, Y.; Cang, D.; Lu, H. Heat transfer and flow behaviour of aqueous suspensions of TiO2 nanoparticles (nanofluids) flowing upward through a vertical pipe. Int. J. Heat Mass Transf. 2007, 50, 2272–2281. [Google Scholar] [CrossRef]

- Nguyen, C.T.; Roy, G.; Gauthier, C.; Galanis, N. Heat transfer enhancement using Al2O3–water nanofluid for an electronic liquid cooling system. Appl. Therm. Eng. 2007, 27, 1501–1506. [Google Scholar] [CrossRef]

- Chein, R.; Chuang, J. Experimental microchannel heat sink performance studies using nanofluids. Int. J. Therm. Sci. 2007, 46, 57–66. [Google Scholar] [CrossRef]

- Duangthongsuk, W.; Wongwises, S. Effect of thermophysical properties models on the predicting of the convective heat transfer coefficient for low concentration nanofluid. Int. Commun. Heat Mass Transf. 2008, 35, 1320–1326. [Google Scholar] [CrossRef]

- Duangthongsuk, W.; Wongwises, S. Heat transfer enhancement and pressure drop characteristics of TiO2–water nanofluid in a double-tube counter flow heat exchanger. Int. J. Heat Mass Transf. 2009, 52, 2059–2067. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, F.; Liu, J.; Ma, Z.; Han, E.; Song, M. Field test and numerical investigation on the heat transfer characteristics and optimal design of the heat exchangers of a deep borehole ground source heat pump system. Energy Convers. Manag. 2017, 153, 603–615. [Google Scholar] [CrossRef]

- You, S.; Cheng, X.; Guo, H.; Yao, Z. In-situ experimental study of heat exchange capacity of CFG pile geothermal exchangers. Energy Build. 2014, 79, 23–31. [Google Scholar] [CrossRef]

- Bouhacina, B.; Saim, R.; Benzenine, H.; Oztop, H.F. Analysis of thermal and dynamic comportment of a geothermal vertical U-tube heat exchanger. Energy Build. 2013, 58, 37–43. [Google Scholar] [CrossRef]

- Casasso, A.; Sethi, R. Sensitivity analysis on the performance of a ground source heat pump equipped with a double U-pipe borehole heat exchanger. Energy Procedia 2014, 59, 301–308. [Google Scholar] [CrossRef]

- Zhu, L.; Chen, S.; Yang, Y.; Sun, Y. Transient heat transfer performance of a vertical double U-tube borehole heat exchanger under different operation conditions. Renew. Energy 2019, 131, 494–505. [Google Scholar] [CrossRef]

| Aspect | Advantages | Disadvantages | Refs |

|---|---|---|---|

| Popularity | GHPSs have grown in popularity worldwide, especially in colder regions, due to their efficiency and cost savings. | — | [5] |

| Global Adoption | As of 2021, around 6.46 million GSHP units were operational in about 30 countries, with 1.7 million in the U.S. | — | [4] |

| Energy Consumption | GHPSs can reduce cooling bills by 20% to 50% and heating bills by 30% to 60% compared to conventional systems. | — | [8,9] |

| Heating Efficiency | GHPSs are more efficient than traditional systems, particularly in winter, as they do not burn fuel and transfer existing heat. GHPSs provide heating efficiency 30% to 70% higher than traditional systems and 20% to 50% higher than air conditioning systems. | — | [5,10,11] |

| Availability | GHPSs are available year-round and not affected by weather conditions, ensuring stable energy output. | — | [1,5,12] |

| Environmental Impact | GHPSs can reduce GHG emissions by 66% and CO2 emissions by 50% compared to fossil-fuel-based systems. | — | [13] |

| Lifespan | GHPSs typically have a longer lifespan compared to conventional systems; HDPE pipes last up to 50 years and heat pump systems up to 25 years. | — | [14] |

| Maintenance | GHPSs require minimal maintenance. | — | [5] |

| Installation Cost | — | Installation can be expensive; vertical systems require extensive borehole drilling; and horizontal systems need large land areas. Initial capital cost is approximately 30–50% higher than that of traditional heating and cooling systems. | [16,17] |

| Parameters | Density (kg/m3) | Specific Heat Capacity (J/kg·K) | Thermal Conductivity (W/m·K) |

|---|---|---|---|

| Clay | 1700 | 1800 | 1.2 |

| Sand | 1500 | 1710 | 1.26 |

| Sandy-silt | 1845 | 1200 | 1.3 |

| Sandy-clay | 1960 | 1200 | 2.1 |

| Refs. | Material or Additions | Results |

|---|---|---|

| [33] | Gravel and cement | Gravel reduced borehole thermal resistance more effectively The heat transfer rate almost doubled The BTR of gravel-backfilled and cement-grouted BHEs decreased by 9.8% and 8.7%, respectively |

| [34,39,40,42] | Backfill material with high thermal conductivity | Improved heat transfer rate and raised GHE heat capacity Increased borehole surface temperature; reduced thermal resistance Strong connection between pipe wall and surrounding ground Reduced GHE pipe length, especially for double U-tube pipes |

| [35] | Backfill material (3 W/m·K) | Increased heat extraction by more than 10% |

| [36] | Backfill material (0.7 W/m·K to 2.3 W/m·K) | Lowered borehole thermal resistance from 0.135 to 0.054 m·K/W |

| [37] | Backfill material (0.5 to 2 W/m·K) | Increased heat transfer rate by 40–48% |

| [38] | Bentonite-based materials | Reduced borehole length by 10% |

| [49] | Quartz sand instead of bentonite | Lowered borehole thermal resistance by 30% |

| [59] | Sand/kaolin mixture | Reduced moisture migration and improved heat diffusion |

| [57] | Silica sand and graphite in bentonite grout | Increased thermal conductivity up to 3.5 W/m·K and increased viscosity |

| [61] | Graphite flakes in bentonite | Increased backfill material thermal conductivity to 5 W/m·K |

| [60] | Cement with silica sand and graphite | Increased backfill material thermal conductivity to 2.6 W/m·K |

| [43] | Graphite with silica sand and bentonite | Increased viscosity and enhanced backfill material thermal conductivity |

| [54,56,58] | Quartzite or graphite in sand/bentonite Quartzite sand in bentonite-based grout Bentonite to sand mixture | Improved thermal conductivity of sand/bentonite blend |

| [55] | Metallic parts in grout | Increased GHE thermal performance by up to 77% |

| [63] | Kaolin/sand | Enhanced the GHE thermal performance |

| [62] | Wet sand–bentonite | Reduced required pipe length by 20% |

| [64] | 20% Bentonite 30% Bentonite Cement mortar Concrete (50% quartz sand) | Increased the backfill material thermal conductivity to up to 0.73 W/m·K Increased the backfill material thermal conductivity to up to 0.74 W/m·K Increased the backfill material thermal conductivity to up to 0.78 W/m·K Increased the backfill material thermal conductivity to up to 1.9 W/m·K |

| Refs | Additives | Results |

|---|---|---|

| [123] | 2 mm and 3 mm aluminum wires | Thermal conductivity increased by 25% with 2 mm wires and 150% with 3 mm wires compared to the original HDPE pipe |

| [124] | Additives mixed into polymer resin during extrusion | Thermal conductivity increased by 75% (from 0.4 to 0.7 W/m·K); borehole thermal resistance reduced by 24% |

| [125] | Longitudinal fins on the pipe’s inner surface | Heat extraction increased by about 7% compared to pure HDPE pipe |

| [126] | Graphite | The borehole length reduced by 12.76% compared to the original HDPE pipe |

| [127] | 40% boron nitride sheets and 7 wt.% carbon nanotubes | Achieved a thermal conductivity of 2.38 W/m·K |

| [128] | Covalent functionalization of BNNTs with short polyethylene chains | Increased thermal conductivity by up to 250% compared to pure HDPE matrix |

| [122] | Metallic and non-metallic additives, including expanded graphite (EG) and boron nitride (BN) particles | Enhanced thermal and tensile properties; reduced yield strain from 8.5% (pure HDPE) to 1.8%, depending on additives and BN particle size |

| [129] | Carbon nanotubes (CNTs) in porous scaffolds | Increased thermal conductivity of HDPE/CNTs/PW-3:7 by 2.94 times and electrical conductivity by 13 orders of magnitude compared to HDPE/PW-3:7 |

| [130] | 50 wt.% EG | Achieved a thermal conductivity of 2.18 W/m·K; tensile strength decreased by 40% compared to pure HDPE. |

| [122] | 15 wt.% EG and 25 wt.% mBN | Achieved a thermal conductivity of 3 W/m·K; tensile strength 24.37 MPa |

| [131] | 55 wt.% EG | Achieved a thermal conductivity of 1.97 W/m·K |

| [132] | 50 wt.% micro-sized hexagonal BN | Thermal conductivity: 2.08 W/m·K (non-treated); 0.9 W/m·K (titanate-treated) |

| [133] | 5 wt.% BN nanosheets | Thermal conductivity: 0.96 W/m·K (with silane coupling agent) |

| [134] | BN treated with PE-g-MAH | Thermal conductivity: 2.6 W/m·K (treated) vs. 2.2 W/mK (non-treated) |

| [135] | Boron Nitride (BN) filler in HDPE | Achieved a maximum thermal conductivity of 1.26 W/m·K with 35 vol% BN loading and a tensile strength of 40 MPa |

| [136,137,138] | 5 wt.% graphene nanoplatelets (GNPs) | Increased thermal conductivity from 0.45 to 0.65 W/m·K |

| [139] | 30 wt.% Boron Nitride (BN) | Increased HDPE thermal conductivity to 0.93 W/m·K |

| [140,141,142] | 5-30 wt.% Boron Nitride (BN) | Enhanced thermal conductivity of polymers; increased thermal conductivity from 0.479 to 0.93 W/m·K |

| Refs | Additives | Results |

|---|---|---|

| [73] | 20% calcium chloride, 25% and 33% propylene glycol, 24% ethanol | 20% calcium chloride solution is more effective than the other solutions |

| [154] | Pure water, 25% ethylene glycol/water mixture | Pure water produces a lower fluid temperature in a ground heat exchanger compared to the ethylene glycol mixture |

| [155] | TiO2-water nanofluid (21 nm, 0.2% to 2% concentration) | Improved heat transfer coefficient by 26% at lower concentrations, but decreased by 14% at 2% concentration |

| [158] | Copper nanofluid (0.1% to 1% concentration) | Copper nanofluid reduced thermal resistance by up to 3.8% at 1% concentration but increased pressure drop significantly |

| [159] | MWCNT-ZnO nanoparticles | Increased convective heat transfer coefficients by 42%, recommended for enhancing heat transfer performance |

| [160] | Al2O3/water nanofluid | Achieved less than 1.3% reduction in borehole length compared to pure water; backfill material has a greater impact |

| [161] | Al2O3, CuO, SiO2, TiO2 nanoparticles in water | Water/CuO nanofluid reduced entropy generation by 4.34% and increased heat transfer by 22.15% with a slight increase in pumping power |

| [162] | Gold-DI water nanofluids | Significant reduction in thermal resistance compared to DI water |

| [164] | γ-Al2O3, TiO2 nanoparticles dispersed in water | Nusselt number increased with Reynolds number and particle concentration; convective heat transfer coefficient with 3 vol.% nanoparticles was 12% lower than pure water |

| [165,166] | Al2O3-water, CuO-water nanofluids | Heat transfer coefficient increased with Peclet number and particle concentration; CuO-water showed less enhancement than Al2O3-water |

| [167,168] | Cu-water nanofluids | Enhanced heat transfer performance; friction factor matched water; proposed new correlations for laminar and turbulent flow |

| [163] | Al2O3-DI water nanofluids | Local heat transfer coefficient increased with Reynolds number and particle concentration |

| [169] | Graphite nanoparticles in two liquids | Heat transfer coefficient increased with Reynolds number and particle concentration; different sources of nanoparticles showed varying results |

| [170] | CNT-distilled water nanofluids | Local heat transfer coefficient significantly higher than pure water; enhancement depended on flow conditions, CNT concentration, and pH value; aspect ratio is important |

| [171] | TiO2-distilled water nanofluids | Local heat transfer coefficient increased with nanoparticle concentration; pressure drops similar to the base fluid |

| [172] | Al2O3 nanoparticles in water | Higher heat transfer coefficient compared to base liquid; 36 nm particles performed better than 47 nm particles |

| [173] | CuO-water nanofluids | Greater energy absorption at low flow rates; no added benefit at high flow rates |

| [174,175] | 0.2 vol.% TiO2 nanoparticles in water | Thermophysical models had minimal effect on predicted Nusselt number; heat transfer coefficient slightly greater than water (6–11%); minimal penalty in pressure drop |

| Refs | Type of Pipe | Length (m) | Optimal Flow Rate (m/s) |

|---|---|---|---|

| [16] | Single U-tube, Double U-tube | — | 0.4–0.6 (32 mm), 0.4–0.5 (25 mm), 0.3–0.4 (32 mm). |

| [88] | Single U-tube | — | 0.4–0.7 |

| [5] | Single U-tube | 50, 20 | 0.28–0.38 (50 m), 0.17–0.22 (20 m). |

| [5,7,22] | Single U-tube | 98 | 0.33–0.43 (25 mm), 0.35–0.45 (32 mm), 0.38–0.48 (40mm). |

| [176] | Deep Borehole | 2000 | 0.3–0.7 |

| [177] | U-tube | — | 0.5–0.6 |

| [83] | U-tube | — | 0.4–1.0 |

| [178] | U-tube | — | 0.3–0.4 |

| [180] | Double U-tube | — | 0.3 |

| [145] | U-tube | — | 0.3–0.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salhein, K.; Kobus, C.J.; Zohdy, M.; Annekaa, A.M.; Alhawsawi, E.Y.; Salheen, S.A. Heat Transfer Performance Factors in a Vertical Ground Heat Exchanger for a Geothermal Heat Pump System. Energies 2024, 17, 5003. https://doi.org/10.3390/en17195003

Salhein K, Kobus CJ, Zohdy M, Annekaa AM, Alhawsawi EY, Salheen SA. Heat Transfer Performance Factors in a Vertical Ground Heat Exchanger for a Geothermal Heat Pump System. Energies. 2024; 17(19):5003. https://doi.org/10.3390/en17195003

Chicago/Turabian StyleSalhein, Khaled, C. J. Kobus, Mohamed Zohdy, Ahmed M. Annekaa, Edrees Yahya Alhawsawi, and Sabriya Alghennai Salheen. 2024. "Heat Transfer Performance Factors in a Vertical Ground Heat Exchanger for a Geothermal Heat Pump System" Energies 17, no. 19: 5003. https://doi.org/10.3390/en17195003

APA StyleSalhein, K., Kobus, C. J., Zohdy, M., Annekaa, A. M., Alhawsawi, E. Y., & Salheen, S. A. (2024). Heat Transfer Performance Factors in a Vertical Ground Heat Exchanger for a Geothermal Heat Pump System. Energies, 17(19), 5003. https://doi.org/10.3390/en17195003