An Experimental Comparative Study of Large-Sized Direct Solar Fryers for Injera Baking Applications

Abstract

1. Introduction

2. Materials and Methods

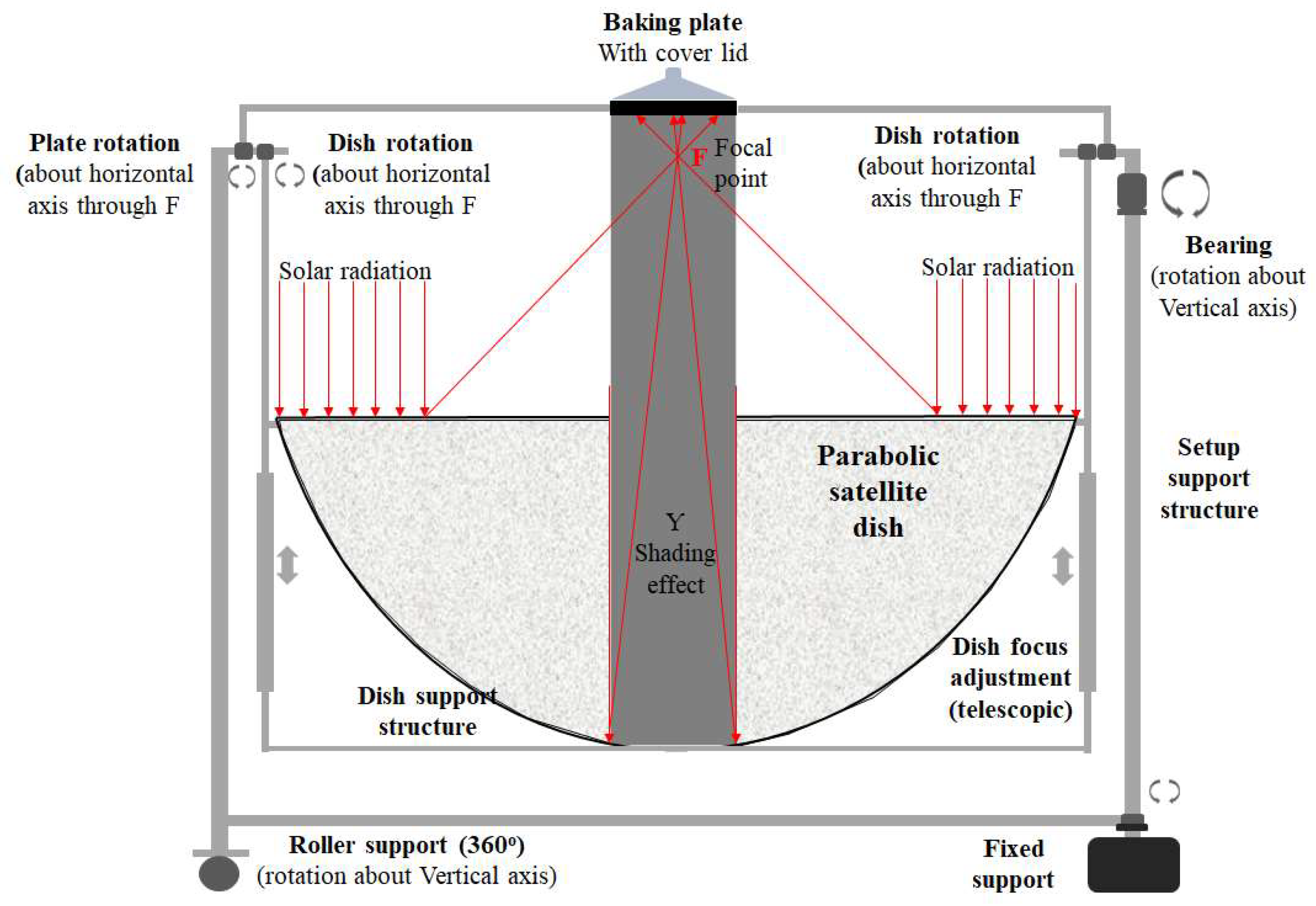

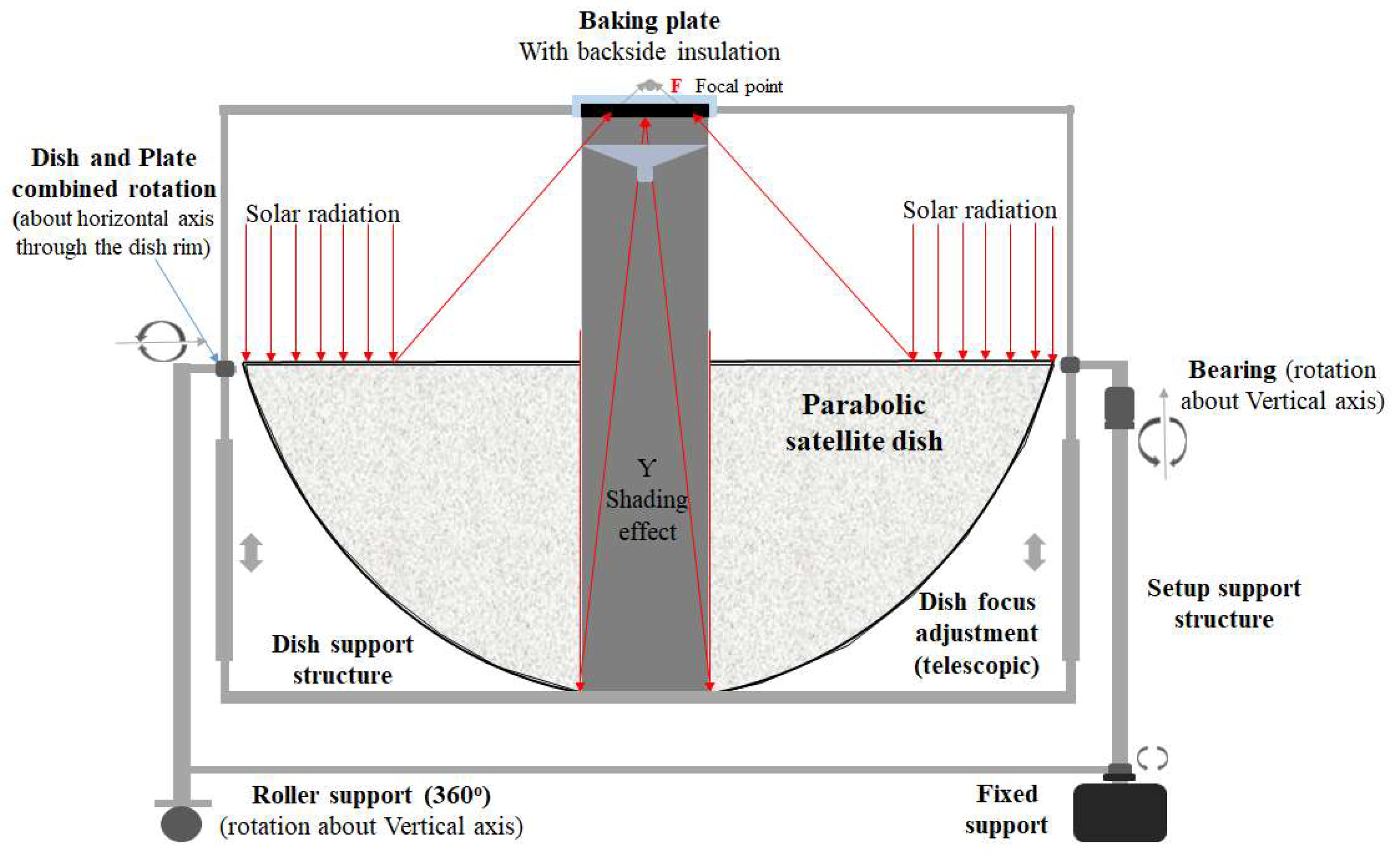

2.1. Design of the Direct Solar Fryer System

2.1.1. Geometrical Design

2.1.2. Thermal Design

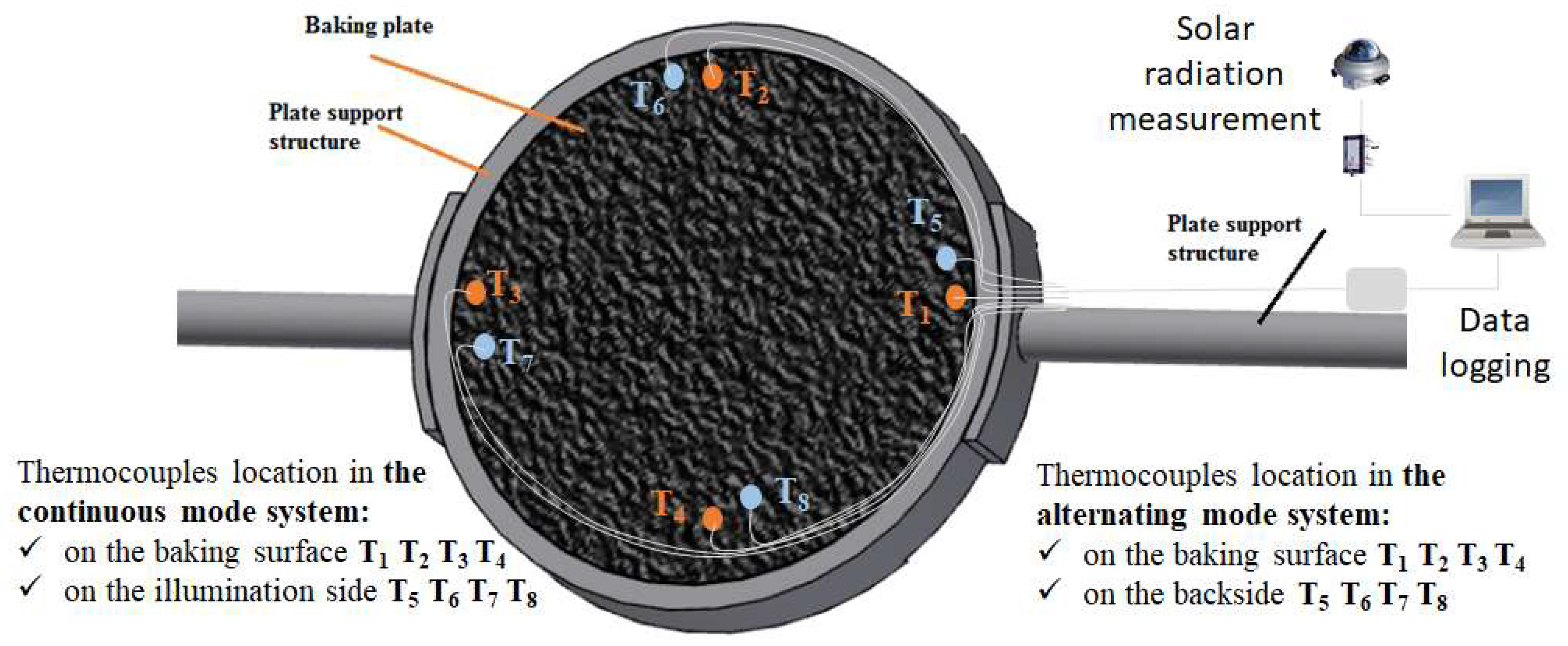

2.2. Experimental Methods and Materials

2.3. Comparative Performance Assessment

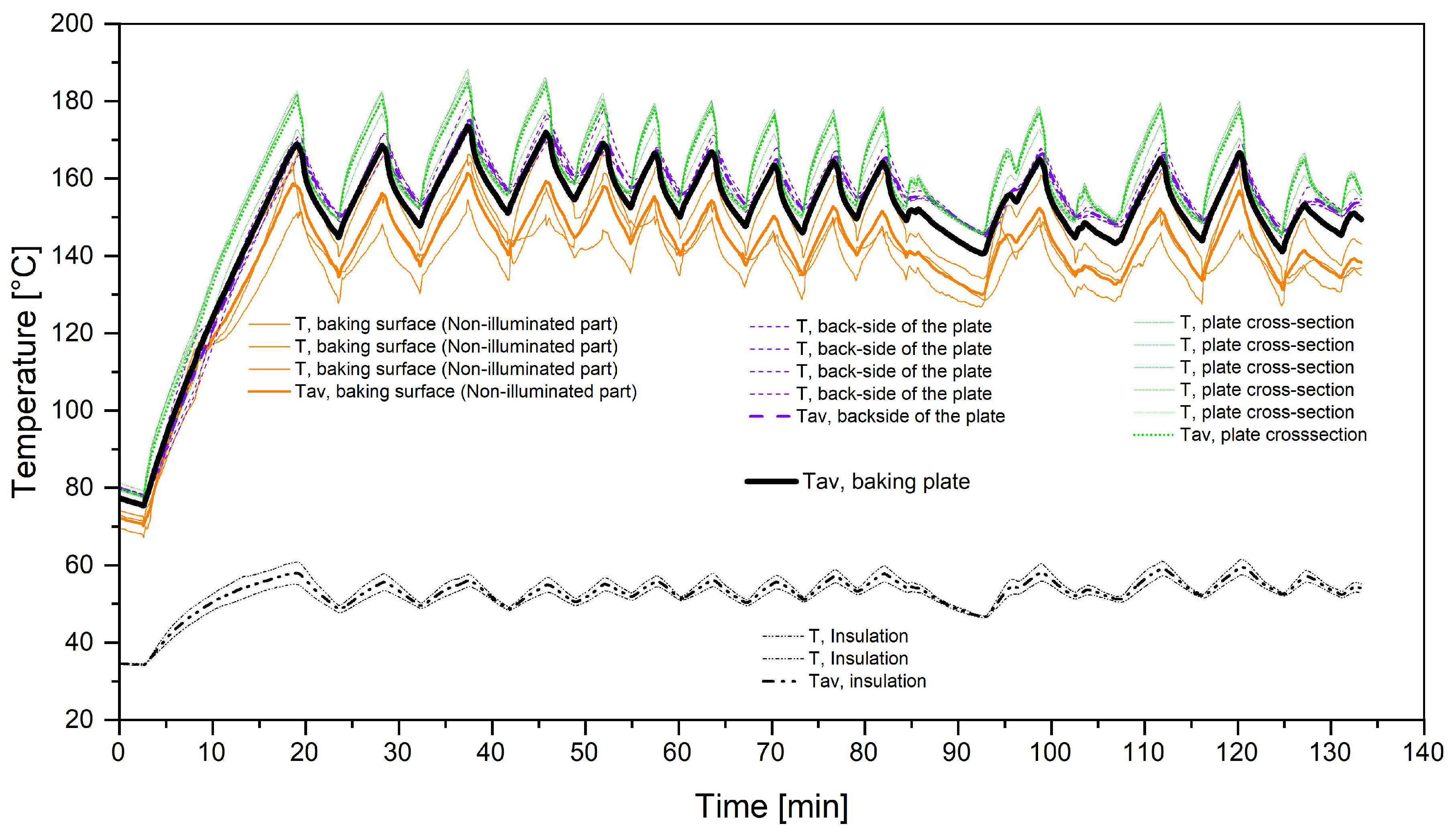

2.3.1. Temperature Achievement

2.3.2. Time for Initial Heating and Baking–Reheating Cycles

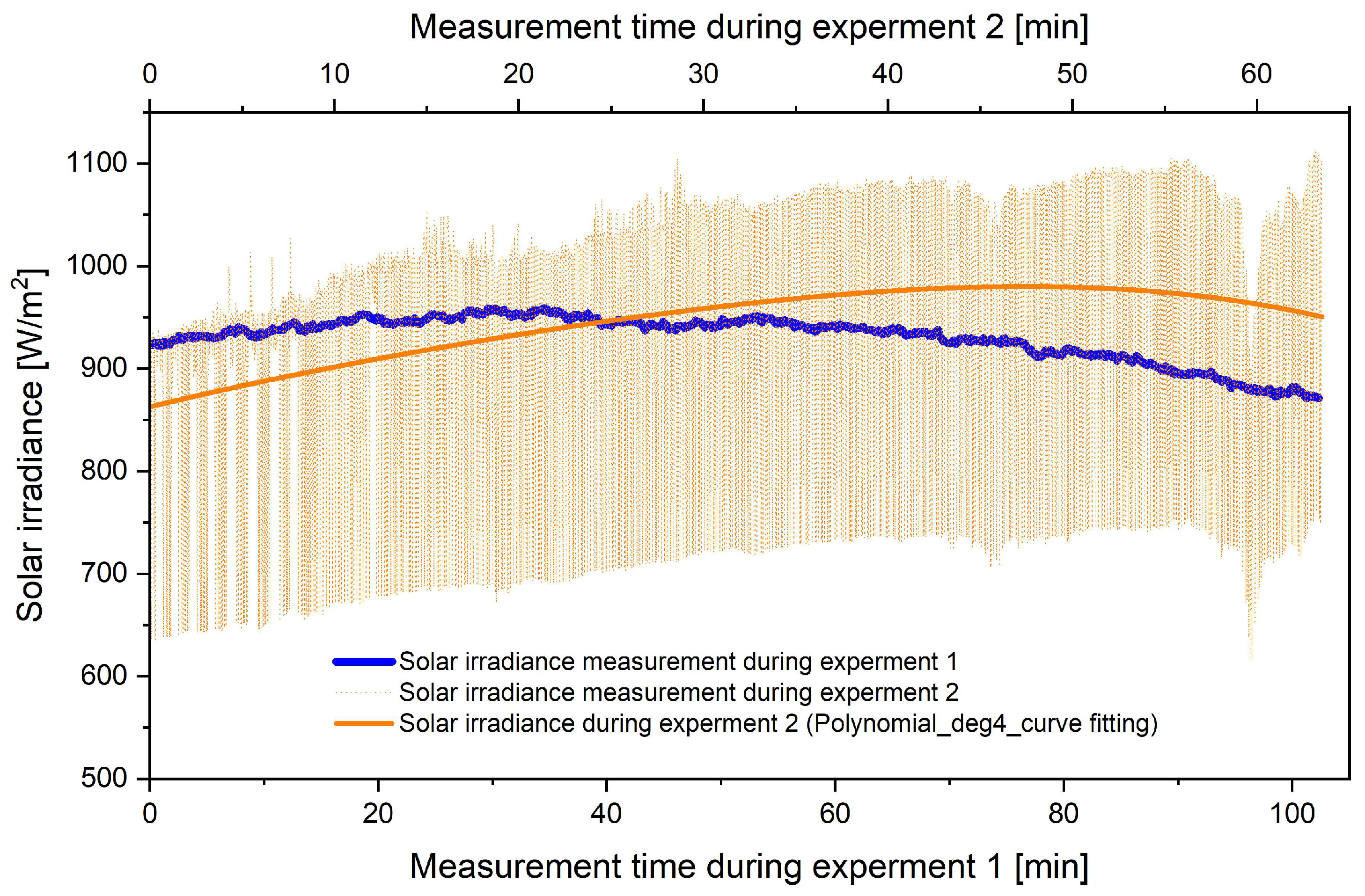

2.3.3. Input Solar Energy

2.3.4. Injera Quality Assessment

2.4. Estimating the Capital Cost of the Direct Fryer System

- Supporting structure: Human-made RHS and CHS pipes and sheet metal.

- Collector dish: A collector dish made of four to six strips is widely available and has a lower cost; however, such a dish is liable to geometrical inefficiencies. A dish manufactured from one complete sheet (i.e., without a strip) is more effective for solar concentrator applications. However, it is not commonly available in the market and has a higher cost.

- Solar reflecting sheet: This material is rarely available in the market, thus incurring a higher cost. Glass mirrors, which are widely and cheaply available, can also be used as a replacement; however, they come with reduced efficiency.

- Fryer plate: This component is locally manufactured by casting and machining.

- Insulation material: A small amount of insulation material is used for alternating-mode solar fryer systems.

- System manufacturing cost: A workshop activity for assembling the support structure, laminating the reflective material into the collector dish, and assembling the whole system are considered components of the system manufacturing cost.

3. Results and Discussions

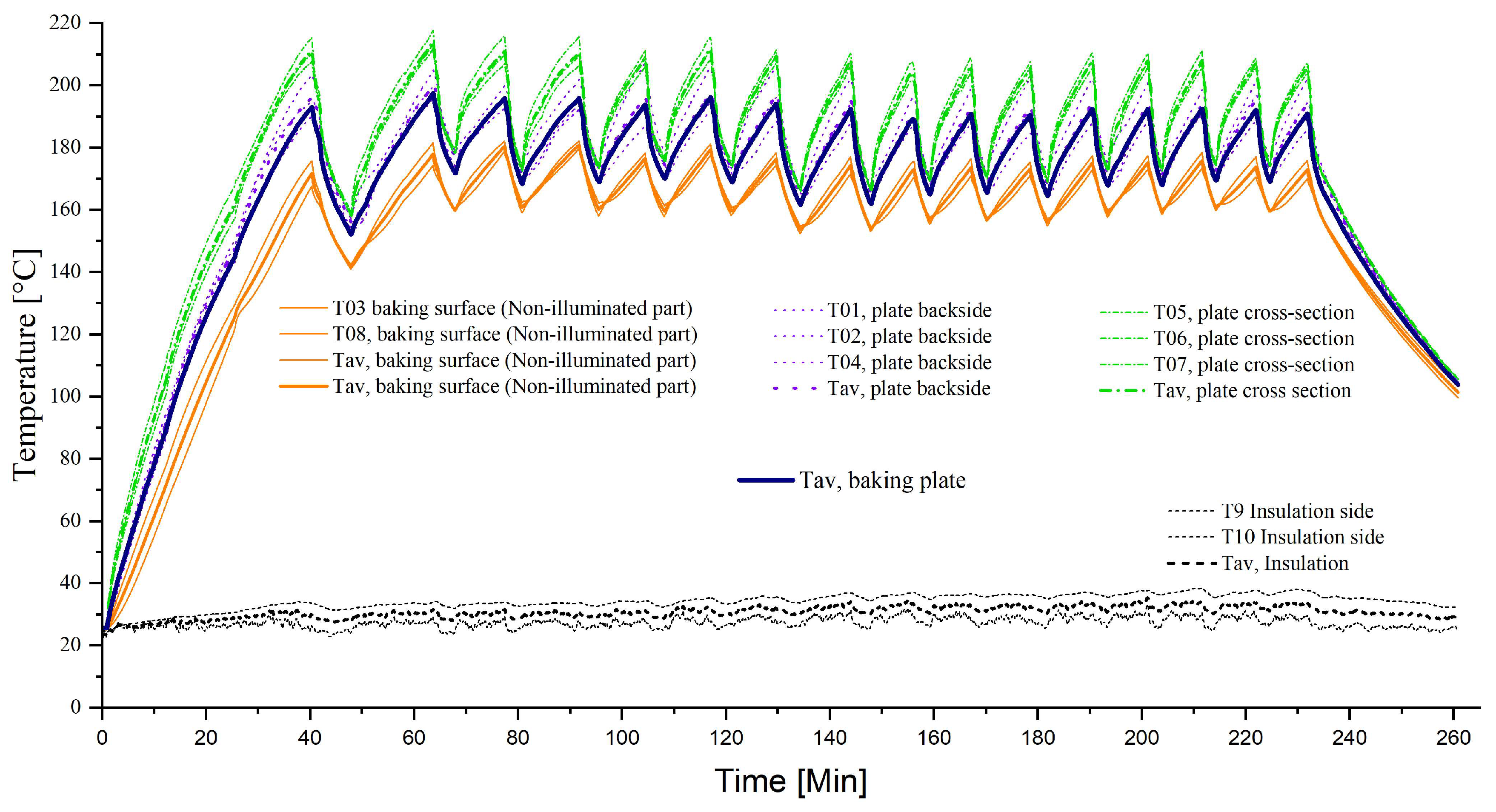

3.1. Performance Evaluation of the Alternating-Mode Solar Fryer Systems

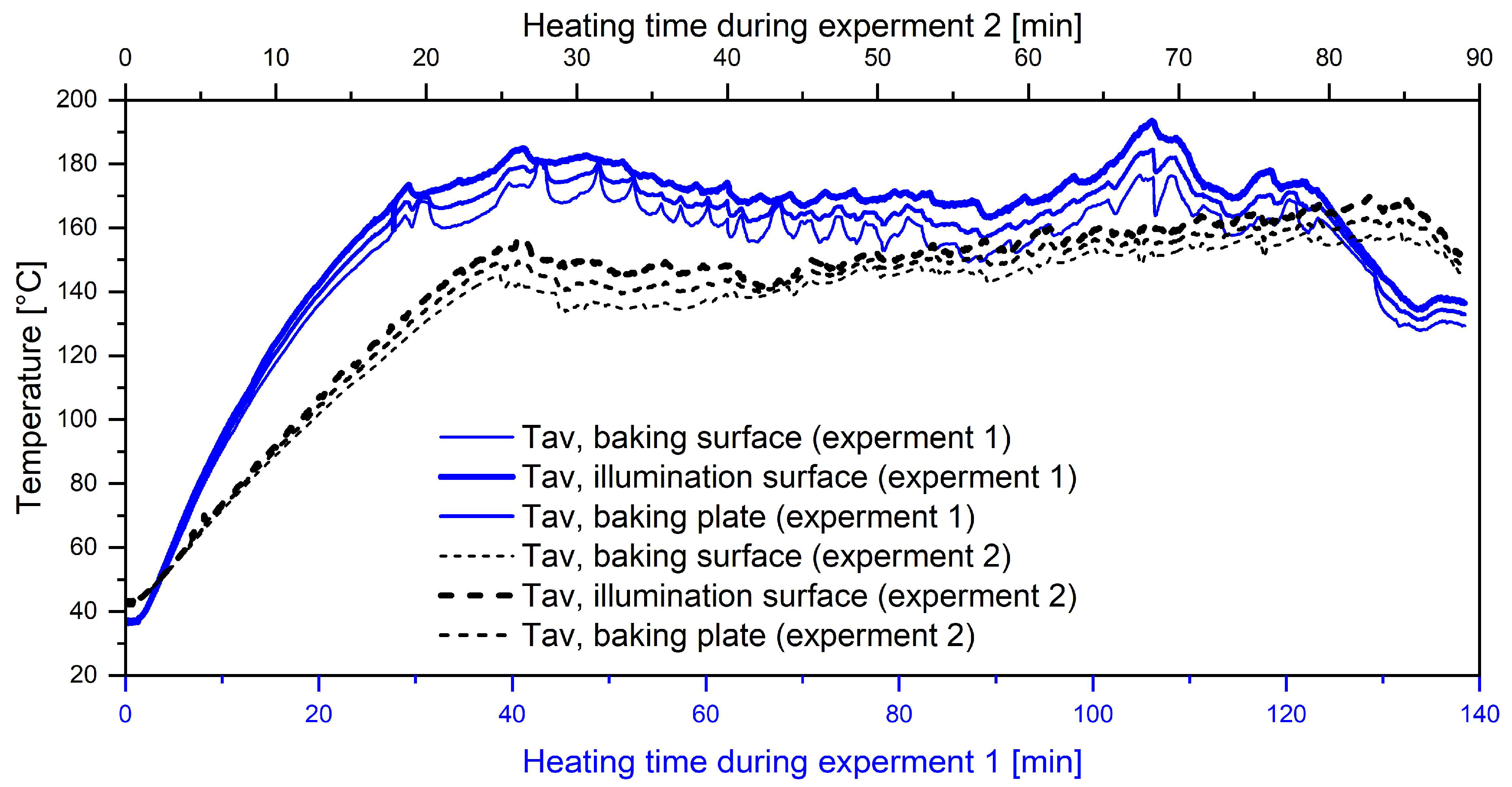

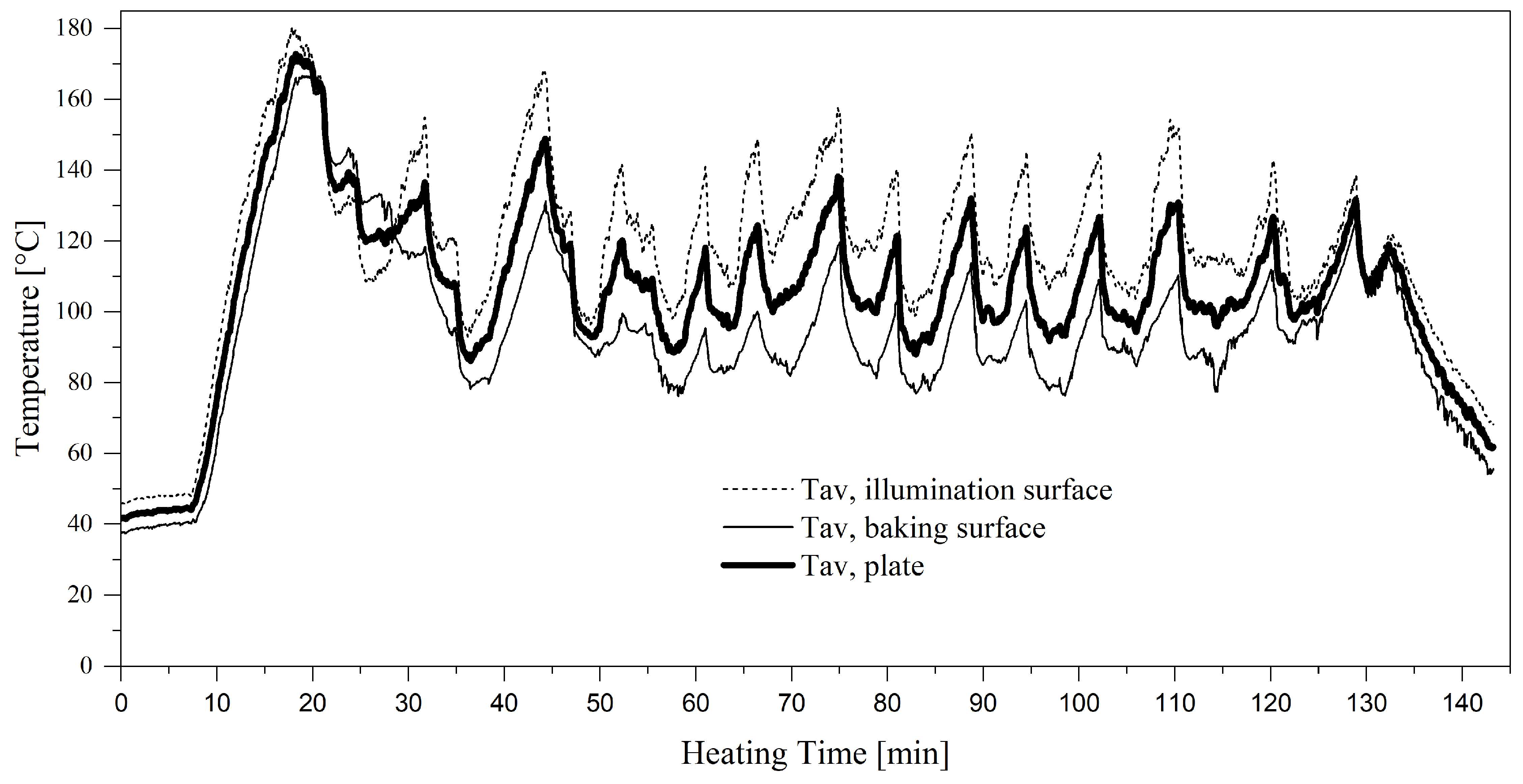

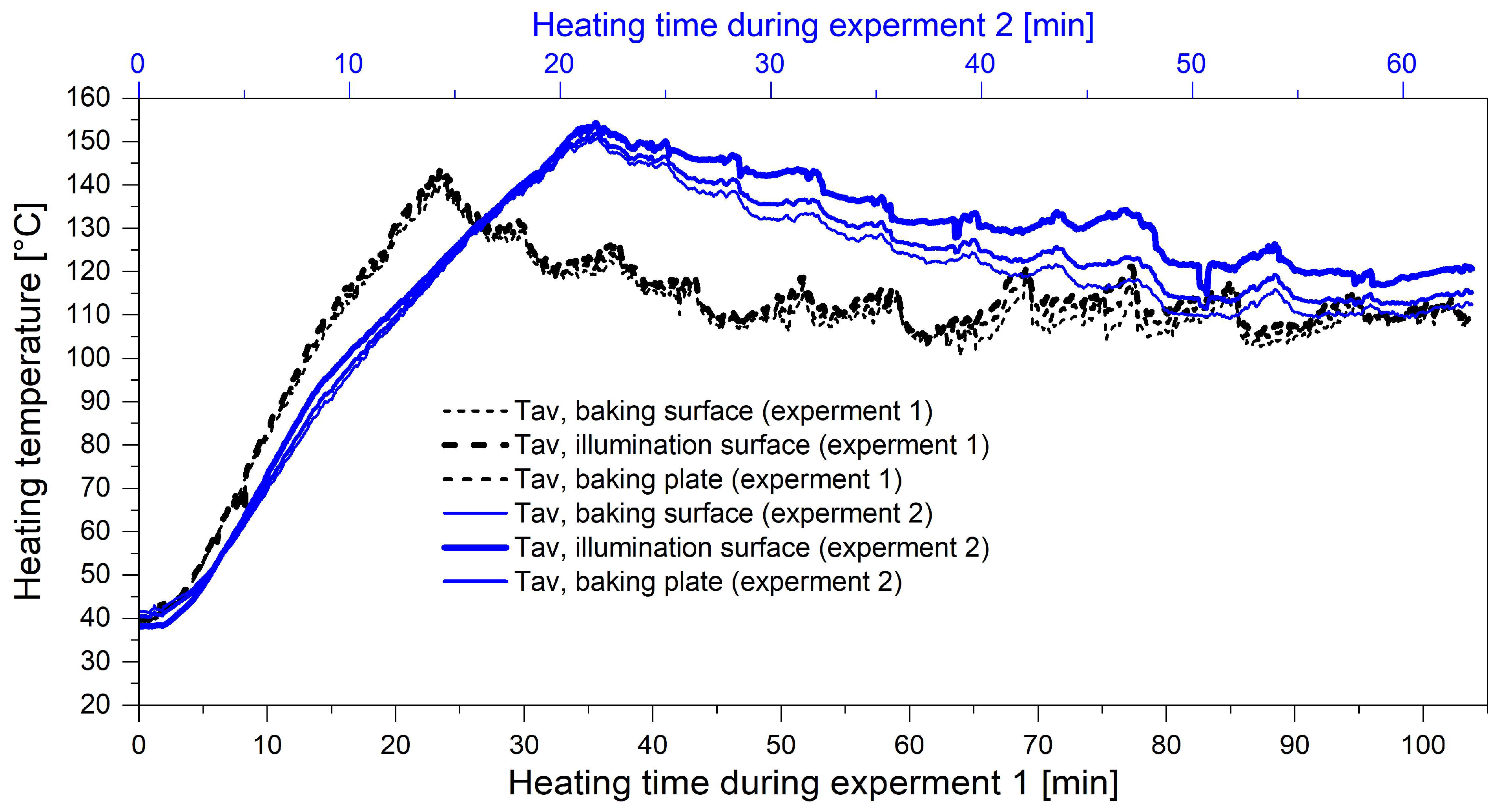

3.2. Performance Evaluation of the Continuous-Mode Solar Fryer Systems

3.3. Input Solar Energy Comparison

3.4. Baking Quality Assessment of the Solar Fryers

3.5. Estimated Capital Cost of the Direct Solar Fryer System

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- World Population Review. Available online: https://worldpopulationreview.com/countries (accessed on 2 August 2024).

- Hailu, M.H.; Kahsay, M.B.; Tesfay, A.H.; Dawud, O.I. Energy consumption performance analysis of electrical Mitad at Mekelle City. Momona Ethiop. J. Sci. (MEJS) 2017, 9, 43–65. [Google Scholar] [CrossRef]

- DANAS Electrical Engineering, Project Document Electric Injera Mitad Energy Efficiency Standards and Labeling. Available online: https://www.academia.edu/33020865 (accessed on 2 August 2024).

- Liyew, K.W.; Ejigu, N.A.; Habtu, N.G. Analysis of energy supply, energy policies, and the final energy end-use consumption of the residential sector in Ethiopia. Heliyon 2024, 10, e34809. [Google Scholar] [CrossRef] [PubMed]

- Beyene, G.E.; Kumie, A.; Edwards, R.; Troncoso, K. Opportunities for Transition to Clean Household Energy in Ethiopia: Application of the Household Energy Assessment Rapid Tool; World Health Organization: Geneva, Switzerland, 2018; Available online: https://www.who.int/publications/i/item/9789241514491 (accessed on 2 August 2024).

- Benti, N.E.; Gurmesa, G.S.; Argaw, T.; Aneseyee, A.B.; Gunta, S.; Kassahun, G.B.; Aga, G.S.; Asfaw, A.A. The current status, challenges and prospects of using biomass energy in Ethiopia. Biotechnol. Biofuels 2021, 14, 209. [Google Scholar] [CrossRef] [PubMed]

- Dumga, K.T.; Goswami, K. Energy choice and fuel stacking among rural households of Southern Ethiopia. Energy Sustain. Dev. 2023, 76, 101260. [Google Scholar] [CrossRef]

- Kyayesimira, J.; Muheirwe, F. Health concerns and use of biomass energy in households: Voices of women from rural communities in Western Uganda. Energy Sustain. Soc. 2021, 11, 42. [Google Scholar] [CrossRef]

- Downward, G.S.; van der Zwaag, H.P.; Simons, L.; Meliefste, K.; Tefera, Y.; Carreon, J.R.; Vermeulen, R.; Smit, L.A.M. Occupational exposure to indoor air pollution among bakery workers in Ethiopia; A comparison of electric and biomass cookstoves. Environ. Pollut. 2018, 233, 690–697. [Google Scholar] [CrossRef]

- Addis Alemayehu, Y. Status and Benefits of Renewable Energy Technologies in the Rural Areas of Ethiopia: A Case Study on Improved Cooking Stoves and Biogas Technologies. Int. J. Renew. Energy Dev. 2015, 4, 103–111. [Google Scholar] [CrossRef]

- Yalew, A.W. The Ethiopian energy sector and its implications for the SDGs and modeling. Renew. Sustain. Energy Transit. 2022, 2, 100018. [Google Scholar] [CrossRef]

- Tadesse, M. The Developmental Patterns of Injera Baking Stoves: Review on the Efficiency, and Energy Consumption in Ethiopia. SSRG Int. J. Mech. Eng. 2020, 7, 7–16. [Google Scholar] [CrossRef]

- Adem, K.D.; Ambie, D.A. A review of injera baking technologies in Ethiopia: Challenges and gaps. Energy Sustain. Dev. 2017, 41, 69–80. [Google Scholar] [CrossRef]

- Sood, D. Injera Electric Baking: Energy Use Impacts in Addis Ababa Ethiopia; The World Bank African Region: Washington, DC, USA, 2010. [Google Scholar]

- Gebreegziabher, Z. Urban Domestic Energy Problems in Ethiopia: An Overview; EDRI (Ethiopian Development Research Institute): Addis Ababa, Ethiopia, 2004. [Google Scholar]

- Gebreegziabher, Z. Household Fuel Consumption and Resource Use in Rural-Urban Ethiopia. Ph.D. Thesis, Department of Social Sciences, Wageningen University, Wageningen, The Netherlands, 2007. [Google Scholar]

- Moges, G. Electric Injera Mitad Energy, Efficiency Standards & Labeling, Challenges and Prospects; Vienna Energy Forum: Vienna, Austria, 2017. [Google Scholar]

- GIZ. The Development Intervention in Ethiopia, GiZ Energy Coordination Office Ethiopia (GiZ ECO Ethiopia), Report; GIZ: Addis Ababa, Ethiopia, 2011. [Google Scholar]

- Berhanu, H.; Bekele, A.; Venkatachalam, C.; Sivalingam, S. Performance improvement of an electric injera baking pan (Mitad) using copper powder as additive material. Energy Sustain. Dev. 2022, 68, 242–257. [Google Scholar] [CrossRef]

- RTPC, Rural Technology Promotion Center (RTPC). Biomass Stove (Mogogo Eton); Test Report; RTPC: Mekelle, Ethiopia, 1998. [Google Scholar]

- Tekle, A. Experimental Investigation on Performance Characteristics and Efficiency of Electric Injera Baking Pans (“Mitad”). Master’s Thesis, Addis Ababa University, Addis Ababa, Ethiopia, 2011. [Google Scholar]

- Saxena, A.; Norton, B.; Goel, V.; Singh, D.B. Solar cooking innovations, their appropriateness, and viability. Environ. Sci. Pollut. Res. 2022, 29, 58537–58560. [Google Scholar] [CrossRef] [PubMed]

- Aramesh, M.; Ghalebani, M.; Kasaeian, A.; Zamani, H.; Lorenzini, G.; Mahian, O.; Wongwises, S. A review of recent advances in solar cooking technology. Renew. Energy 2019, 140, 419–435. [Google Scholar] [CrossRef]

- Shrivastava, A.; Thombre, R.; Dutt, S. A Review Based Assessment of Solar Box-Type Cooker. IOSR J. Eng. (IOSRJEN) 2019, 19, 24–29. [Google Scholar]

- Nkhonjera, L.; Bello-Ochende, T.; John, G.; King’ondu, C.K. A review of thermal energy storage designs, heat storage materials and cooking performance of solar cookers with heat storage. Renew. Sustain. Energy Rev. 2017, 75, 157–167. [Google Scholar] [CrossRef]

- Sedighi, M.; Zakariapour, M. A Review of Direct and Indirect Solar Cookers. Sustain. Energy 2014, 2, 44–51. [Google Scholar]

- Cuce, E.; Cuce, P.M. A comprehensive review on solar cookers. Appl. Energy 2013, 102, 1399–1421. [Google Scholar] [CrossRef]

- Schwarzer, K.; da Silva, M.E.V. Characterisation and design methods of solar cookers. Sol. Energy 2008, 82, 157–163. [Google Scholar] [CrossRef]

- Liyew, K.W.; Habtu, N.G.; Louvet, Y.; Guta, D.D.; Jordan, U. Technical design, costs, and greenhouse gas emissions of solar Injera baking stoves. Renew. Sustain. Energy Rev. 2021, 149, 111392. [Google Scholar] [CrossRef]

- Ebersviller, S.M.; Jetter, J.J. Evaluation of performance of household solar cookers. Sol. Energy 2020, 208, 166–172. [Google Scholar] [CrossRef]

- Gallagher, A. A solar fryer. Sol. Energy 2011, 85, 496–505. [Google Scholar] [CrossRef]

- Hailu, M.H.; Kahsay, M.B.; Tesfay, A.H.; Neydal, O.J. A Direct Solar fryer for Injera baking application. In Proceedings of the SWC International Solar Energy Society (ISES) Solar World Congress SHC IEA SHC Solar Heating and Cooling Conference, Abu Dhabi, United Arab Emirates, 29 October–2 November 2017; SWC2017/SHC2017 Proceedings. pp. 1475–1485. [Google Scholar]

- Hailu, M.H.; Kahsay, M.B.; Tesfay, A.H.; Neydal, O.J. An oil based indirect Solar fryer for Injera baking application. In Proceedings of the SOLARTR Solar Conference and Exhibition, Istanbul, Turkey, 9 May 2018; SOLARTR Proceeding Book. pp. 109–118. [Google Scholar]

- Hassen, A.A.; Amibe, D.A.; Nydal, O.J. Performance investigation of solar powered injera baking oven for indoor cooking. In Proceedings of the ISES Solar World Congress Proceedings, Kassel, Germany, 28 August–2 September 2011; pp. 186–196. [Google Scholar] [CrossRef]

- Tesfay, A.H.; Kahsay, M.B.; Nydal, O.J. Design and Development of Solar Thermal Injera Baking: Steam Based Direct Baking. Energy Procedia 2014, 57, 2946–2955. [Google Scholar] [CrossRef]

- Jemal, T.; Fatoba, O.; Shimels, S.; Tegenaw, Y. Design and experimental Analyses of enhanced heat transfer performance in solar powered Injera baking pan using Cu/Oil and A12O2/Oil nanofluids. Mater. Today Proc. 2022, 62 Pt 6, 2839–2848. [Google Scholar] [CrossRef]

- Younes, S.; Claywell, R.; Muneer, T. Quality control of solar radiation data: Present status and proposed new approaches. Energy 2005, 30, 1533–1549. [Google Scholar] [CrossRef]

- Girma, T.; Bultosa, G.; Bussa, N. Effect of grain tef [Eragrostis tef (Zucc.) Trotter] flour substitution with flaxseed on quality and functionality of injera. Int. J. Food Sci. Technol. 2013, 48, 350–356. [Google Scholar] [CrossRef]

- Merkato Online Retailer, Construction Material Prices. Available online: https://con.2merkato.com/ (accessed on 15 September 2024).

- Commercial Bank of Ethiopia, Exchange Rate. Available online: https://combanketh.et/en/exchange-rate/ (accessed on 15 September 2024).

| Cost Component | Description | Quantity | Price (USD) 1 |

|---|---|---|---|

| Supporting structure | RHS pipe, 50 mm × 50 mm × 1.5 mm × 6 m | 2 pc | 43.33 |

| CHS pipe, 50 mm × 1.5 mm | 2 m | 11.67 | |

| Sheet metal, 0.88 mm | 0.4 m2 | 9.17 | |

| Reflective material | Reflective glass, 4 mm thick | 5.34 m2 | 70.5 |

| Collector dish | 1.8 m rim diameter, 64.8 cm focal length | 1 pc | 37.5 |

| Fryer plate | Casting, 45 cm diameter, 3 cm thick | 1 pc | 37.5 |

| Machining process | 1 pc | 41.67 | |

| Insulation material | Locally available material | LS | 4.17 |

| Manufacturing | Supporting structure | LS | 25.0 |

| Reflective material lamination | LS | 25.0 | |

| System assembly | LS | 25.0 | |

| Sub total | 330.51 USD | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hailu, M.H.; Kahsay, M.B.; Tesfay, A.H.; Nydal, O.J. An Experimental Comparative Study of Large-Sized Direct Solar Fryers for Injera Baking Applications. Energies 2024, 17, 4949. https://doi.org/10.3390/en17194949

Hailu MH, Kahsay MB, Tesfay AH, Nydal OJ. An Experimental Comparative Study of Large-Sized Direct Solar Fryers for Injera Baking Applications. Energies. 2024; 17(19):4949. https://doi.org/10.3390/en17194949

Chicago/Turabian StyleHailu, Mesele Hayelom, Mulu Bayray Kahsay, Asfafaw Haileslassie Tesfay, and Ole Jørgen Nydal. 2024. "An Experimental Comparative Study of Large-Sized Direct Solar Fryers for Injera Baking Applications" Energies 17, no. 19: 4949. https://doi.org/10.3390/en17194949

APA StyleHailu, M. H., Kahsay, M. B., Tesfay, A. H., & Nydal, O. J. (2024). An Experimental Comparative Study of Large-Sized Direct Solar Fryers for Injera Baking Applications. Energies, 17(19), 4949. https://doi.org/10.3390/en17194949