1. Introduction

Carbonate rocks are among the most significant oil and gas reservoir formations globally, accounting for approximately 50% of the world’s reserves, and contributing to over 60% of the total production. The Middle East, a pivotal region for global oil and gas resources, boasts carbonate reservoirs that account for 70% of its reserves and contribute to 80% of its overall production [

1,

2,

3,

4,

5]. Notably, the Mishrif Formation and the Asmari Formation are widely recognized as significant pay zones in the Middle East and serve as representative examples of thick and complex carbonate rocks. Consequently, there has been increasing attention devoted to study complex carbonate reservoirs along with approaches and technologies for their characterization and development. Extensive literature research reveals that previous studies have primarily focused on sedimentary evolution, rock classification, diagenesis, fracture prediction, and their impact on reservoir quality within the Middle East [

6,

7,

8,

9,

10,

11,

12,

13,

14]. Al-Dabbas et al. [

7] focused on southern Iraq, where they conducted a comprehensive study of eight subsurface sections and an extensive collection of thin sections from the Mishrif limestone in order to unravel the depositional facies and environments. By employing the principles of lithofacies association, they successfully developed a robust depositional model for the environment of the Mishrif Formation. Zhao et al. [

8] investigated and concluded that the sedimentary microenvironment and eogenetic karstification determine the macroscopic oiliness of the reservoir in the Mishrif Formation of the Halfaya Oilfield in Iraq. Lazim et al. [

9] studied the high resolution sequence stratigraphy of the Mishrif Formation at Zubair oilfield, southern Iraq. Zeng et al. [

10] revealed that a large number of tectonic shear fractures were formed in the Asmari Formation of the Zagros Basin under the action of three phases of tectonic stress: Late Cretace–Oligocene, Miocene, and Pliocene–Pleistocene. Han et al. [

11] proposed a new permeability calculation method for carbonate rocks involving classifying pore sizes by using the NMR T2 spectrum first and then calculating the permeability of different sizes of pores. Song et al. [

12] analyzed a number of developed carbonate reservoirs in the Middle East, and summarized three water injection development modes that are suitable for different types of reservoirs in the region. The aforementioned representative research on specific points provides a diverse range of technologies for the development of carbonate reservoirs. However, there remains a dearth of comprehensive case studies and systematic results encompassing reservoir characterization, fracture analysis, and injection-production strategies, as well as pattern optimization.

The M oilfield in Iraq is situated in the foreland of the Zagros Basin, characterized by a multilayer composite reservoir with diverse pore types and significant hydrocarbon reserves. In order to achieve the economic and efficient development of the M oilfield, the following key technical challenges need to be addressed: (1) The presence of an 800–1200 m thick gypsum-salt layer severely attenuates the seismic signal of the pre-salt target layer, making it difficult to establish the accuracy seismic interval velocity model. (2) The dolostones in Asmari Formation and limestones in the Mishrif Formation exhibit unique “porphyritic” oil-bearing characteristics, with significant variations in petrophysical properties both horizontally and vertically. The genetic mechanism behind these reservoirs is unclear, which complicates detailed reservoir characterization. (3) The Asmari reservoir displays significant heterogeneity as a fractured-porous system, with micro-fractures (fracture aperture < 100 μm) development that has weak responses to conventional logging. (4) Mishrif limestones present global challenges due to their considerable thickness (80~100 m), excess permeability layers within the reservoir, and intricate fluid flow mechanisms. (5) Initial depletion exploitation results in pressure dropping heavily within the formation, leading to asphaltene precipitation which significantly impacts crude oil output.

In response to the aforementioned challenges, this paper proposes targeted research methodologies and strategies: (1) The main research data for predicting the pre-salt geological structures are derived from seismic, logging, and lithology analysis, which have been innovatively utilized to dissect and model the seismic velocity of the gypsum-salt layer. (2) The genetic mechanism of high-quality carbonate reservoirs is explored and explained through core observation, thin section analysis, and experimental methods. (3) Advanced techniques such as formation anisotropy analysis and dipole shear wave long-distance imaging are employed to characterize micro-fractures. (4) Three-dimensional physical models and reservoir numerical simulation are conducted to propose an innovative mode of “bottom injection–top production” specifically designed for thick reservoirs. (5) After considering multiple factors, the relationship between optimal well pattern density and economic profit in overseas projects is examined using a mathematical model. Simultaneously, an innovative stepwise conversion composite well patterns approach was investigated through knowledge exploration and reservoir numerical simulation. (6) An innovative method is proposed to effectively characterize the influence of asphaltene precipitation on development indexes by combining experimental analysis, reservoir engineering, and the improved black oil numerical simulation.

2. Geological Setting and Reservoir Characteristics

2.1. Geological Setting

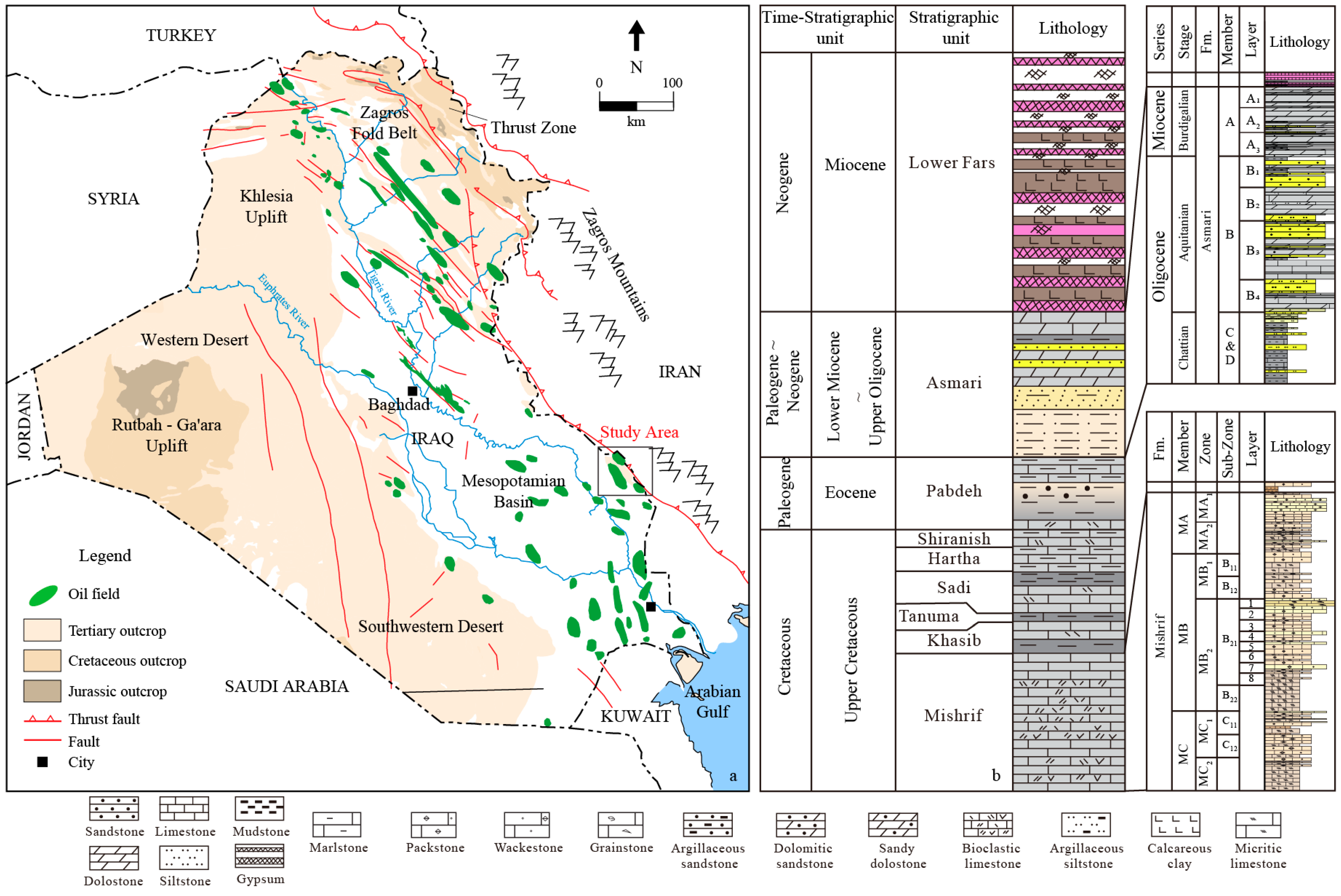

The M oilfield is located in the southwest margin of the Zagros Basin, tectonically in the central region of Mesopotamia at the junction with the Zagros Piedmonts depression (

Figure 1a). The southern part of Iraq is believed to be underlain by an Infra-Cambrian salt basin, which originated during Najd wrench faulting [

15]. Further episodes of tectonism coincided approximately with the Hercynian orogenic event and resulted in the development of an early NS-trending basin during Paleozoic times. Because the large NS-trending structures were uplifted during the mid-Carboniferous, sediments of this age were generally eroded. Throughout most of its subsequent geologic history, Iraq remained stable until the late Tertiary, when the area became tectonically active, with the formation of the Zagros Mountains. During the Mesozoic, most sediments were deposited in continental to moderately deep marine-shelf settings on the slowly subsiding passive margin of the Afro-Arabian Plate. In contrast, synorogenic sediments were restricted in time (early to middle Cretaceous and late Tertiary) and space (northeast Iraq). Several tectonic trends developed within the sedimentary basin, of which three are dominant: a NW–SE Zagros trend, a NE–SW trend, and an earlier NS Arabian trend [

16].

The M oilfield is a group of long and narrow anticlines in a NW–SE direction, mainly drilling into the Asmari Formation of the Oligocene–Miocene and the Mishrif Formation of the Upper Cretaceous. The Mesopotamia Foreland Basin in the Middle East is one of the most oil-rich areas in the world. Source rocks in the Mesopotamian Basin in Iraq entered the oil window in the Late Cretaceous and continuously generated oil and gas until the mid-Miocene [

17]. Generally, oil and gas migration in the Mesopotamia Foreland Basin involved vertical migration along major faults, accompanied by the lateral migration along unconformities or through porous reservoir rocks [

17,

18].

2.2. Reservoir Characteristics

The Mishrif Formation sedimentary spread through the Mesopotamian Basin and the entire Arabian Peninsula, with a thickness of 100 to 400 m [

19,

20]. In the study area, the Mishrif Formation develops carbonate rocks formed as a carbonate ramp. The reservoir is mainly composed of high-energy bioclastic granular limestone, and the pore types mainly include inter-granular pores and intra-granular pores, as well as secondary pores formed by dissolution, without fractures. It is a typical porous carbonate reservoir. Under the dual control of sedimentation and diagenesis, the difference in primary deposition and the reconstruction of subsequent rocks are superimposed, leading to an extremely complex pore structure and diverse pore throat structure types in the interior of rocks and resulting in large differences in reservoir petrophysical properties. The permeability max–min ratio of core samplings with the same porosity can be up to three orders of magnitude, and the oil content on the cores shows the characteristics of “porphyritic”. The Mishrif reservoir, buried in M oilfield at a depth of 3800~4200 m, can be divided into three members, six corresponding zones, and six subzones according to sequence characteristics in the study area (

Figure 1b), of which the MB21 subzone is the main oil-bearing layer of the Mishrif Formation. According to the well logging characteristics, MB21 can be further divided into eight layers (I~VIII), and the reservoir petrophysical properties and oil saturation varies greatly from one sublayer to another. The core sampling and fluid testing indicate that the reservoir parameters are as follows: the original formation pressure of the reservoir is 6300 psi; the saturation pressure is 3200 psi; the average porosity is 15%; and the average permeability is 20 mD, which belongs to medium-low porosity and low permeability carbonate rocks. With a subsurface viscosity of 0.9 mPa·s and a relative density of 0.92, it has a low viscosity compared to medium-heavy crude oil.

The Asmari Formation was deposited during the transitional period from continental to marine facies and represents a large-scale multi-lithology mixed carbonate reservoir [

21,

22]. The lithology primarily comprises dolomite and limestone, with additional components of mudstone, sandstone, and anhydrite. The reservoir composition is complex and highly heterogeneous. Buried at a depth of 2800~3200 m with a strata thickness ranging from 200~400 m, the Asmari Formation is unconformably overlaid by the Lower Fars Formation—anhydrite deposited in an evaporite lake—which serves as an effective cap rock due to its significant thickness and tightness. Within the Asmari Formation are two oil-bearing pay zones: member A (upper Asmari) and member B (lower Asmari). Member B represents a set of semi-restricted platforms mixed with deltas that were deposited during the Oligocene period. It consists predominantly of mixed limestone, dolomite, and sandstone dominated by bioclastic and sandy-limestone components. With an average matrix porosity measuring at 16.78% and a permeability at 168.5 mD, respectively, member B can be classified as a medium-high poro-permeable reservoir. In contrast to member B’s higher matrix porosity compared to that of member A’s deposits, its fracture intensity is lower than what has been observed in member A’s deposits. Member A was deposited during the Miocene period within a restricted platform setting mainly composed of dolomite lithology, including micrite dolomites and bioclastic dolomites. Additionally, core observations often reveal clumps of anhydrite filling up the upper part of member A’s deposits. The average matrix porosity for member A stands at 8.72%, with an average permeability measuring at 2.6 mD, placing it within the low-medium poro-permeable reservoirs category. Although Asmari dolostones exhibit a massive and dense nature with limited primary reservoir properties, the introduction of fracturing and dolomitization processes significantly enhance productivity.

3. Characterization of Complex Carbonate Reservoirs

The study of reservoir quality and its geological structure plays a crucial role in oilfield development. Accurately predicting geological structures enhances reserve estimates, minimizes drilling risks and costs, and aids in geological modeling. However, predicting reservoir depth from seismic data is challenging due to the presence of thick gypsum-salt bodies with lateral velocity changes. Furthermore, understanding the formation mechanisms of Asmari and Mishrif is essential for strategic well placement and efficient development given their distinct physical properties and controlling factors.

3.1. Prediction of Pre-Salt Geological Structure

The seismic velocity modeling of gypsum-salt bodies is a key technical bottleneck for pre-salt reservoirs [

23,

24]. In the conventional approach, velocity interpolation combines the seismic velocity field and horizon constraints to construct a velocity model and structure map. However, the presence of thick gypsum-salt bodies often leads to substantial discrepancies between the observed geological structure in the seismic time domain and the actual formation due to variations in velocity and thickness of gypsum-salt rocks. This discrepancy is commonly referred to as the “see-saw” effect [

25]. It contradicts the traditional understanding that gypsum-salt rocks exhibit high seismic velocities, suggesting that increasing its thickness should result in deeper geological structural depth. However, drilling data indicate that instead, structural depth becomes shallower. Therefore, conventional seismic velocity modeling techniques struggle to accurately predict depths affected by gypsum-salt bodies, particularly in areas without well control. After conducting a comprehensive analysis of the seismic characteristics, velocity rules, and lithologies of the internal composition of the gypsum-salt bodies in the M oilfield, it is revealed that “low-velocity” zones with varying thickness within the gypsum-salt bodies are primarily responsible for the discrepancy between the seismic time domain and depth domain of the underlying target formation. As depicted in

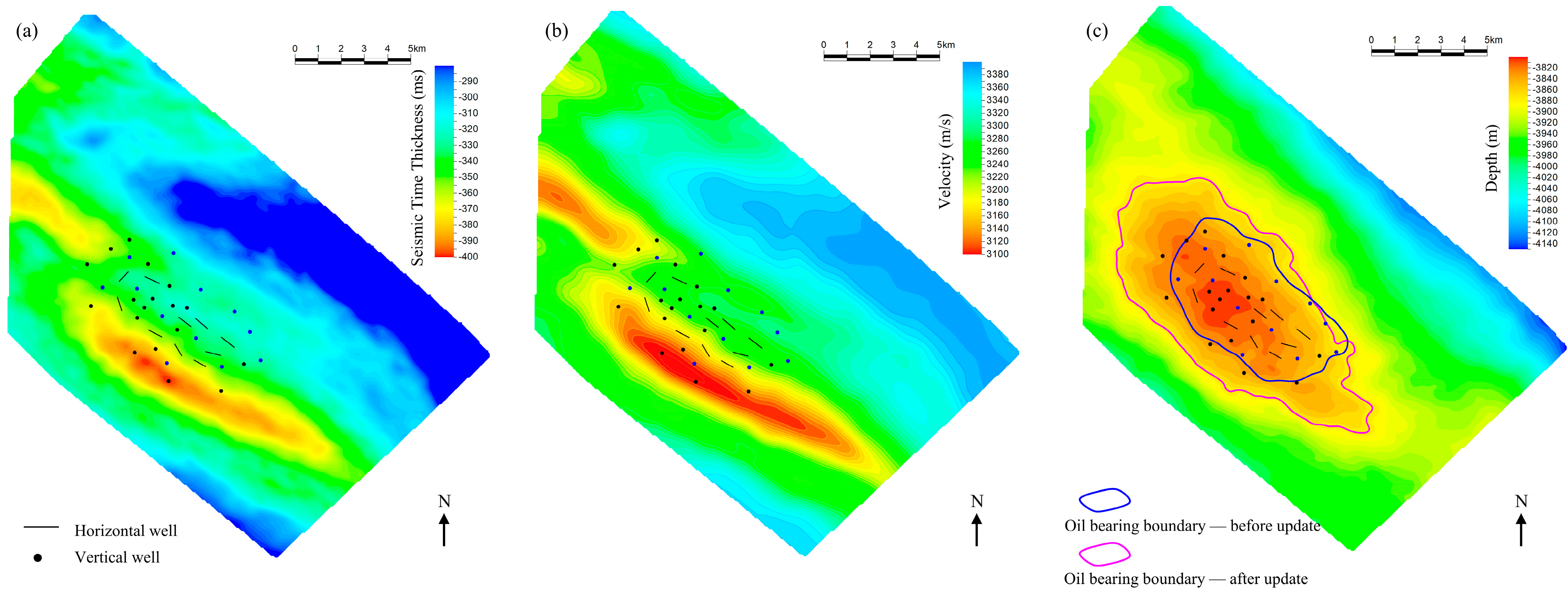

Figure 2a, the seismic time domain thickness distribution of the gypsum-salt layer (depicted as an orange-red stripe) in the oilfield exhibits a narrow, elongated band extending from southeast to northwest. Based on the new findings, a Fourier series reconstruction method has been employed to quantitatively characterize inter-well velocities (

Figure 2b) and address the challenge of predicting geological structure depth in regions lacking well control.

The specific steps of the new approach include the following: (1) Initial Stratigraphy Division: Utilizing lithological characteristics obtained from wells to preliminarily divide the overlying formations and establish initial stratigraphy structure units. (2) Well-Seismic Calibration: Conducting well-seismic calibration by employing spatial-variable wavelets, combined with seismic reflections, to acquire the acoustic wave velocity curve. Subsequently, decomposing this curve into multiple stratigraphic units through square-wave processing. (3) Analysis: Analyzing the thickness and velocity variations of each structural unit in order to identify key seismic “low-velocity” structural units that impact the geological structure depth of the target layer. (4) Seismic Time Thickness: Determining the time thickness distribution patterns of each interpreted horizon based on seismic reflection characteristics and changes in wave impedance. (5) Statistical Law: Collecting velocity data from all wells to determine the statistical characteristics of the velocity distribution and establish velocity control points. Comparing the time thickness distribution derived from well and seismic data, utilizing Fourier series approximation functions to calculate the relationship between seismic velocity and time thickness for each structural unit, enabling lateral interpolation of inter-well velocities. (6) Velocity Modeling: Constructing a formation velocity model based on interpolated interval velocities and interpreted horizons. The final geological structure depth of the target formation can be determined by summing up calculated each unit’s structural depths using the seismic velocity model, as depicted in

Figure 2c.

The new technology significantly reduced the depth prediction error compared to conventional methods, with a maximum error of 75.4 m (averaging at 28 m, where 23% of wells’ predictions exceeded this value) before study, achieving an accuracy within 5 m after extensive research. This improved precision effectively guided the successful implementation of 55 horizontal wells, with approximately 80% of them exhibiting predicted errors below 3 m. Notably, these advancements led to the discovery of around 300 million tons of additional petroleum reserves resulting from changes in geological structure.

3.2. Genetic Mechanism and Evaluation of Complex Carbonate Reservoirs

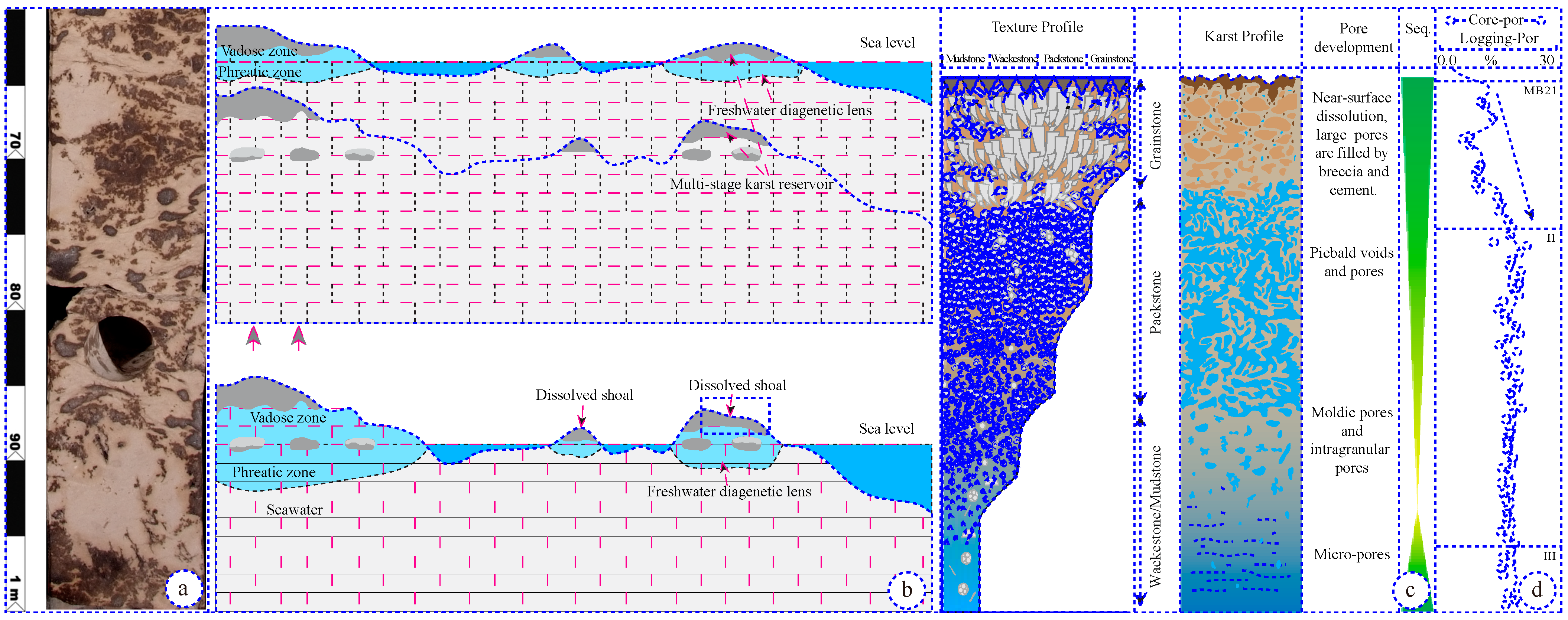

The cores from the Mishrif Formation and Asmari Formation exhibit a distinct “porphyritic” feature [

10], as illustrated in

Figure 3a, which is reflected in significant variations in measured petrophysical properties across different sections of the same core. To investigate the origin of this observation, we employed core descriptions, thin section observation, and the analysis of petrophysical properties combined with experiments on dissolution patterns and porosity evolution on carbonate rocks from the M oilfield [

26]. This paper elucidates the genetic mechanism influenced by both sedimentary micro-facies and eogenetic karstification on reef-shoal reservoirs. It has been determined that heterogeneity in reservoir space and pore-throat structure modified by diagenesis is primarily responsible for the “porphyritic” appearance of these reservoirs. Specifically, micro-facies control both the lateral and vertical extensions of grainstone shoals (

Figure 3b,c), while grain-supported porous carbonates develop interconnected and isolated reservoir spaces resulting in pronounced pore heterogeneity. During dissolution processes, fluids primarily migrate and react along interconnected pores, enlarging the size of the pore-throat structure and enhancing the petrophysical properties within the reservoirs. This process leads to variations in dissolution dominated by matrix porosity (

Figure 3c).

The Upper Asmari Formation, as illustrated in

Figure 4a, predominantly consists of karstic dolomite reservoirs with abundant anhydrite clumps deposited within the upper part’s dolostones. Contrary to the conventional understanding of the impact of karstification on reservoir petrophysical properties, the Asmari dolostones exhibit deteriorated petro-physical characteristics with intensified karstification [

27]. Sedimentological, petrological, and paleontological analysis, combined with measured petrophysical properties and production data, reveal that the Upper Asmari Formation was deposited in a shallow inner- to mid-ramp setting. This characteristic determines insufficient salinity for anhydrite precipitation; therefore, it is unlikely that the anhydrite clumps in the Upper Asmari Formation are synsedimentary. By analyzing both macroscopic types and microscopic textures characteristics of anhydrite clumps in the Asmari dolostones, we recognize that these anhydrite clumps originate from “dense brine refluxing” from the overlying Fars Formation (

Figure 4b). This process involves hypersaline water percolating downwards through underlying porous sediments from above, resulting in anhydrite cementation and clumps which subsequently reduce porosity in the upper reservoir. Additionally, microscopic observation reveals that in the Asmari dolostones, anhydrite primarily fills medium- to large-dissolution pores while small pores remain preserved (

Figure 4c). Pore size significantly controls mineral precipitation and cementation following a pattern of “large pores filled, small pores preserved”.

4. Quantitative Evaluation and Characterization of Natural Fractures

The dolostones of the Asmari Formation exhibit an extensive development of natural fractures. Core observations reveal that these fractures predominantly display structural shear characteristics with a dip angle ranging from 60 to 90 degrees. They typically manifest as micro-fractures with an aperture measuring between 50 and 100 micrometers. However, we have encountered limitations in the application of traditional fracture evaluation methods in the study area. Therefore, based on abundant cross-dipole acoustic logging data in the M oilfield and combined with rock mechanics and seismic inversion methods, this paper proposes an innovative technology for identifying and characterizing fractures to generate an integrated three-dimensional fracture characterization result.

4.1. Near-Wellbore Fractures Identification

The unique depositional setting and regional stress in the Middle East Asmari Formation give rise to micro-scale fracture characteristics compared to those in domestic carbonates, which presents challenges for traditional logging-based fracture identification [

28,

29]. The anisotropy of the fracture system is generally proportional to the intensity of fractures. Fractures with medium-high strike and dip angles result in Horizontal Transverse Isotropy (HTI) within the formation, enabling the use of cross-dipole acoustic logging (CDAL, i.e., XMAC tools) for the quantitative evaluation of near-wellbore fracture development. The analysis of the fast and slow flexural wave dispersion curves obtained from CDAL in the Asmari Formation revealed that fractures, rather than in situ stress, primarily contribute to formation anisotropy [

7,

30]. For fracture identification in the near-wellbore zone, firstly, compressional and shear interval transit time differences were determined from CDAL. Full waveform inversion was then employed using Alford rotation analysis to identify the orientation of the fast shear wave and determine formation anisotropy parameters. Subsequently, a directional fracture theoretical model was applied for inversion by combining time difference data, anisotropy parameters, compressional and shear velocities, as well as density logs. This process yielded quantitative evaluation parameters such as fracture intensity and fracture porosity. The application results (

Figure 5) demonstrate that the calculated outcomes align well with the fracture development trends interpreted from the image logs and core descriptions across the entire wellbore. Additionally, there exists a correlation between fracture intensity and production performance.

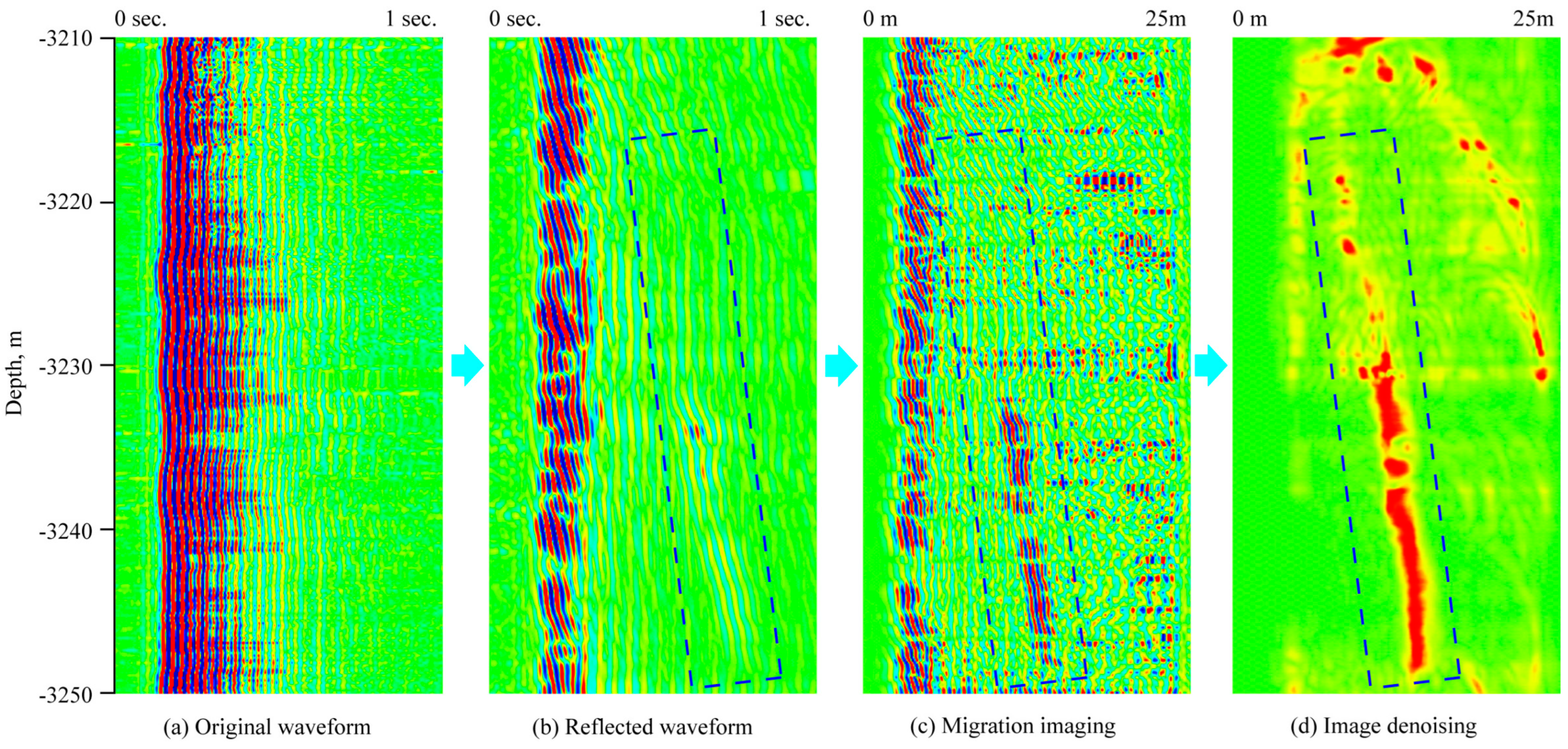

4.2. Remote-Wellbore Fracture Detection

Based on the inversion of fracture parameters using CDAL, a novel technique for detecting remote-wellbore fractures is proposed. This technique utilizes dipole shear wave remote reflection imaging to reduce noise and effectively overcomes the limitations associated with conventional logs and image log evaluations. As a result, it expands the detecting distance of formation fractures from 1 m around the wellbore to 20–30 m. The key steps involved in this technique are as follows: (1) Data Loading: Load four-component cross-dipole acoustic logging data. (2) Preprocessing: Apply filtering techniques to different waveform modes to eliminate low frequency, high frequency, and noise components while optimizing flexural wave duration through compression processing to enhance signal quality. (3) Imaging Processing: Separate compressed wavefield into direct and reflected waves, followed by applying migration imaging technology for the high-quality sub-surface imaging of reflected waves. (4) Imaging Filtering: Employ image denoising techniques to improve signal-to-noise ratio (SNR), effectively suppress interference noise, and clearly display effective reflectors (

Figure 6). The successful implementation of this technique has significantly enhanced accuracy and coverage in fracture detection within the study area, providing a new perspective for evaluating fractures located far from wellbores in carbonate reservoirs.

4.3. Reservoir Fracture Characterization

Compared to conventional reservoirs, tight carbonate reservoirs are prone to developing fracture networks consisting of natural fractures with varying orientations due to their highly brittle nature and complex tectonic history. This poses a significant challenge for the three-dimensional quantitative characterization of fractures in carbonate rocks [

31,

32]. Focusing on the Asmari reservoir, this paper presents a technical workflow for predicting and characterizing reservoir fractures. The workflow encompasses near-wellbore fracture identification (

Figure 7a), inter-well fracture trend prediction (

Figure 7b), spatial fracture density characterization (

Figure 7c), and multiset fracture 3D network modeling (

Figure 7d). Accurate inter-well fracture trend prediction plays a crucial role in this process. The study commenced with a systematic analysis of the origin and primary controlling factors of fractures in the Asmari Formation within the M oilfield based on structural evolution, regional stress field analysis, and multiple geological data sources (e.g., imaging logs, cores, thin sections, and surface outcrops). Subsequently, fracture identification and evaluation were conducted in all wells utilizing advanced CDAL and imaging logging techniques. Moreover, the intelligent prediction of inter-well fracture trends was achieved through the integration of geomechanical numerical simulation, seismic attribute analysis, and machine learning inversion techniques. Finally, a co-sequential Gaussian simulation method was employed to construct a robust 3D fracture intensity model that incorporates both single-well fracture interpretation and inter-well fracture intensity constraints. The derived

P32 fracture density from this model enables the accurate quantitative characterization of fracture prediction in the Asmari reservoir. This proposed technology seamlessly integrates multisource information from geology, logging, seismic data, and artificial intelligence to significantly enhance the accuracy of predicting the spatial distribution of fractures in complex carbonate reservoirs (

Figure 7e,f). It achieves an impressive increase in single-well fracture identification accuracy to 86%, surpassing traditional techniques by 12%. The research outcomes effectively guide optimization strategies for well type selection, well placement optimization, and well pattern design in the Asmari reservoir, resulting in an expected recovery factor increase of 8.7%.

5. Stepwise Conversion of Spatial Well Patterns and Balanced Waterflood Development in Thick Carbonate Reservoir

Reef-shoal porous reservoirs in the Middle East are typically characterized by a substantial formation thickness, the extensive development of high-permeability layers, and pronounced reservoir heterogeneity [

33]. The conventional approach employed by International Oil Companies, involving commingled production and injection through vertical wells and a peripheral circular water injection mode, fails to efficiently exploit thick reservoirs in this region [

12,

34]. This paper investigates the water flooding mechanism of thick and highly heterogeneous carbonate reservoirs under a spatial injection-production mode using dynamic well testing response analysis, reservoir physical modeling, and numerical simulations. Considering the specificities of TSC in the Middle East, this research proposes an implementation strategy for horizontal well deployment along with a “bottom injection and top production” mode as well as the stepwise conversion of well patterns suitable for large integrated carbonate reservoirs.

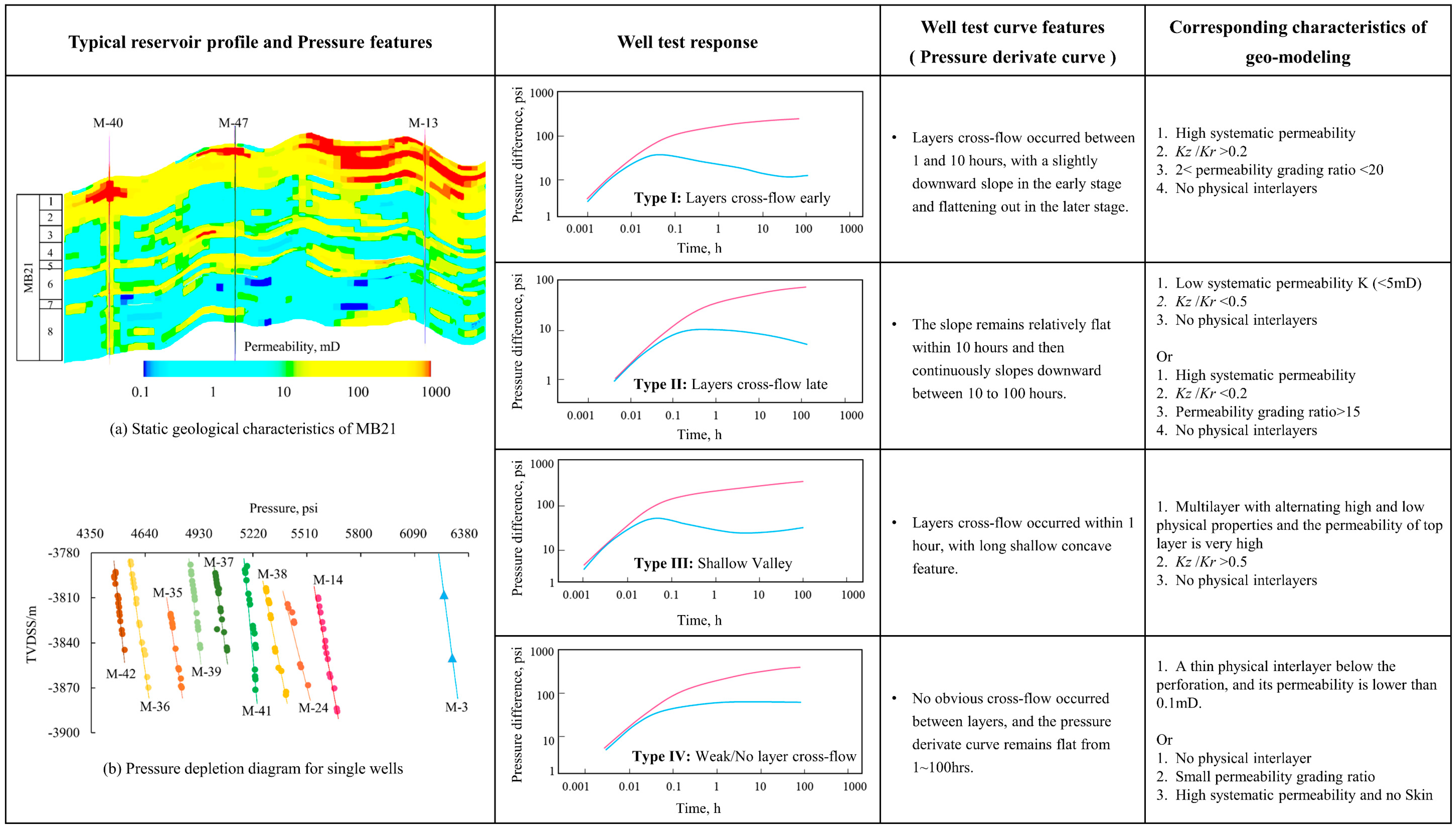

5.1. Dynamic Response Evaluation of Thick and Strongly Heterogeneous Reservoir

In the early development stage of MB21, a subzone denotes the principal pay zone within the Mishrif reservoir. The utilization of a vertical well partial-perforation technique is prevalent in high-permeability belts situated at the uppermost section of MB21. Well testing analysis reveals that under partial-perforation mode, the log–log curve does not exhibit typical hemispherical flow characteristics but instead displays a downward slope or shallow depression, indicating a distinctive seepage phenomenon. To investigate significant vertical heterogeneity in thick reservoirs, we have established a series of forward numerical well testing models. Furthermore, multi-parameter sensitivity analysis elucidates the impact of reservoir systematic permeability, permeability grading, the presence of interlayers, and the

Kz/

Kr ratio on well test curves. Our study demonstrates that production through partial-perforation in a MB21 thick reservoir primarily manifests as a vertical cross-flow between sublayers and can be further classified into four categories corresponding to different geological characteristics (

Figure 8).

The statistical results demonstrate that the majority of wells (90%) exhibit favorable vertical connectivity, except for a few located in lagoon facies or inter-beach facies which show inadequate vertical connectivity (e.g., Type IV with

Kz/

Kr kz/kr < 0.2). Moreover, the new well pressure monitoring results can also serve as a reliable indicator.

Figure 8b shows that the pressure distribution of well M-3 reflects the original reservoir condition (1976), while wells M-14 to M-42 represent the different years’ time span. Despite oil producers perforating within the top 10 m for production, there is a uniform and balanced decline in reservoir pressure throughout its entire thickness of 80~100 m, demonstrating good vertical connectivity. Through the comprehensive analysis of dynamic and static data from the reservoir, it is observed that this type of thick reservoir exhibits underdeveloped inner physical interlayers or only a local weak sealing of seepage flow. The main reason for the dip or shallow depression observed in well testing curves is attributed to vertical heterogeneity within sublayers causing cross-flow between them. This understanding provides crucial support for further research on the spatial injection-production mode in thick reservoirs.

5.2. Waterflooding Mechanism Simulation in Thick Carbonate Reservoir

The Mishrif reef-shoal reservoir is influenced by multi-stage sedimentation and diagenesis, resulting in the generation of a complex pore structure, particularly the hyperpermeability ‘thief zone’ at the top of the reservoir. This phenomenon can lead to rapid water breakthrough, which significantly impacts the development effect on the water-drive oilfield [

12,

35]. In this paper, we construct a large-scale macroscopic physical model (80 cm × 80 cm × 10.7 cm) to simulate the anisotropy and heterogeneity of the reservoir using similarity criteria and actual reservoir parameters. By conducting physical modeling on spatial water flooding along with numerical simulation studies on different well types, we reveal a pattern characterized by “horizontal breakthrough by hyper-permeability and vertical differentiation with gravity” during water flooding in thick reservoirs. Furthermore, we determine the path of water flooding under the spatial well pattern known as “bottom injection and top production”.

The physical modeling results demonstrate (

Figure 9a) that during the initial stage of water injection, the injected water rapidly migrates towards the upper hyper-permeability layer in the near-wellbore region and subsequently advances, resulting in a dual-peak surge along with the bottom injected water. As the injected water progresses far away from the wellbore areas, there is a decrease in displacement pressure gradient and gravity differentiation becomes apparent. This causes the injected water to move downwards and breakthrough along secondary high-permeability streaks at lower positions, forming secondary bottom water and bottom water coning. This spatial injection-production mode effectively utilizes gravity differentiation to delay rising rates of water cut while enhancing the displacement effects of water flooding. Numerical simulation results (

Figure 9b) illustrate that conventional vertical wells employing commingled injection-production modes are susceptible to rapid breakthroughs of injected water reaching the production ends through hyper-permeability layers at reservoir tops, significantly diminishing their effectiveness as drivers for oil recovery from reservoirs. In contrast, horizontal injectors can effectively enhance injection efficiency and vertical displacement uniformity while achieving higher efficiency in driving out oil using water flooding methods as well as longer periods without producing significant amounts of formation waters or brines; they also achieve a higher ultimate recovery factor compared to conventional vertical wells with commingled injection-production modes. Therefore, a spatial injection-production mode (

Figure 9c) is proposed where injections are deployed at the bottom while productions are deployed at the top so as to substantially enhance development effects on oilfields; this mode is particularly suitable for composite well patterns used in thick and highly heterogeneous carbonate reservoirs.

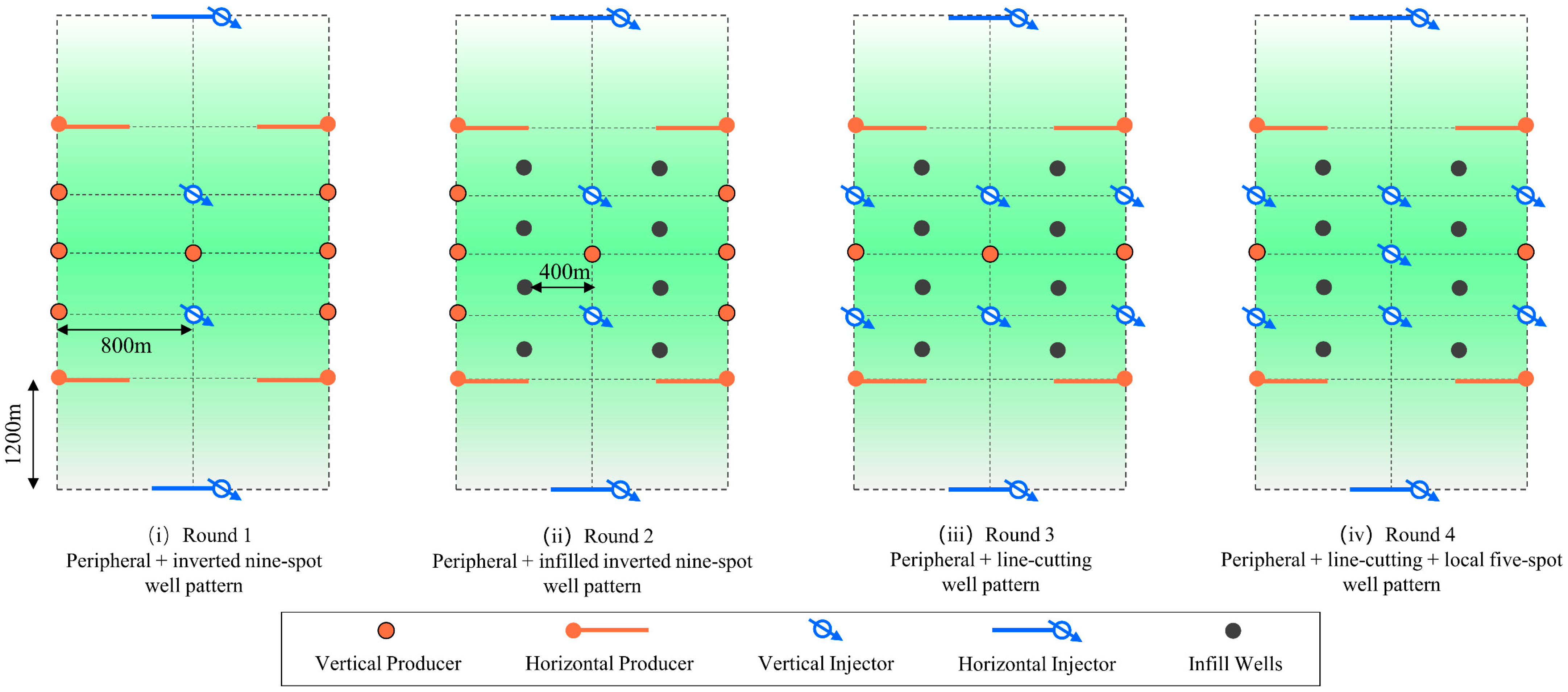

5.3. Stepwise Conversion Well Pattern Design of Integrated Carbonate Reservoir

This paper presents an optimization model for well spacing [

36] that fully incorporates economic profit considerations to address the challenges of achieving economic efficiency and rapid production ramp-up in the development of integrated carbonate reservoirs under TSC. The model considers key parameters such as oil displacement efficiency, investment, operating costs, and remuneration to evaluate the economic profits for both the resource-holder government and the leader contractor. It is observed that optimizing well spacing within a reasonable and cost-effective range set by the government can effectively enhance economic benefits for the leader contractor (

Figure 10). Furthermore, based on an analysis of reservoir connectivity and its favorable distribution patterns, this paper proposes a development approach called “interior and peripheral injecting simultaneously with stepwise conversion” using composite well patterns (

Figure 11).

The specific implementation strategy is divided into four stages: (1) In the initial stage, a peripheral circular injection and interior inverted nine-spot water flooding pattern is applied, primarily relying on converting old producers to quickly supplement formation energy. (2) In the second stage, infill oil producers are utilized to enhance the oil production rate and producing degree of the reserve in order to meet rapid production ramp-up requirements. Additionally, a water flooding strategy of “strengthening peripheral injection and coordinating interior injection” is proposed to mitigate the risk of fast water breakthrough in oil producers. (3) In the third stage, more interior producers are gradually converted into injectors, transforming the well pattern into a peripheral circular with interior line-cutting water injection. Moreover, an injection strategy of “peripheral strengthening and interior moderation” is implemented during this stage. Simultaneously, before converting oil producers, the production of the converted producer is increased to establish water streamline and balance the entire water drive flow-field. (4) In the final stage, local five-point converted injectors are employed to address uneven water drive in high-position producers, further enhancing the sweep degree of water flooding.

6. Quantitative Characterization of the Effects of Asphaltene Precipitation

The presence of asphaltene in crude oil leads to frequent issues such as precipitation and a decline in production. The conventional black oil model fails to accurately describe the damage caused by asphaltene deposition, while the component model involves numerous uncertain parameters and requires extensive calculation time. By utilizing laboratory data from the M oilfield, a novel model quantifies reservoir damage and integrates with a black oil simulator to assess the influence of asphaltene on production and field development.

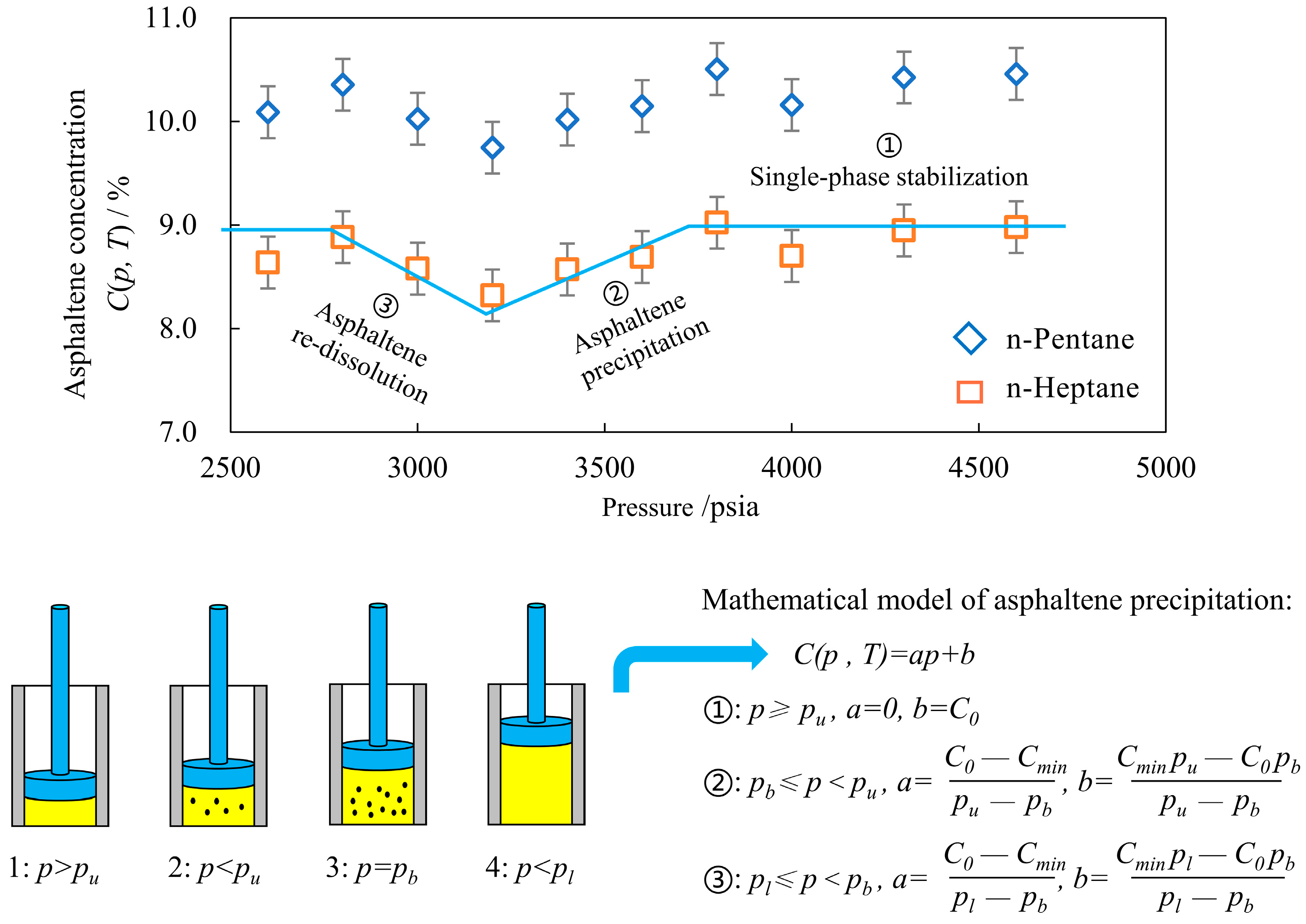

6.1. Experimental and Mathematical Model of Asphaltene Precipitation

The starting pressure of asphaltene precipitation and the change in asphaltene con-centration were determined by collecting typical crude oil samples in the field and con-ducting laboratory high temperature and high pressure experiments. The results (

Figure 12) show that the precipitation trends in the two types of asphaltenes separated from n-pentane and n-heptane are consistent. The experiment revealed that the starting pressure for asphaltene precipitation is approximately 3800 psi, and when the pressure drops to around 3200 psi, the remaining fluid’s asphaltene decreases to a minimum amount. As the pressure further decreases, the asphaltene redissolves and its concentration stabilizes at 2800 psi, which is consistent with the initial condition. Based on the analysis of lab experiment results, it was found that within the range of the asphaltene precipitation envelope, there is an approximately linear relationship between dissolved asphaltenes’ concentration in crude oil and pressure. A mathematical model for solid phase precipitation process of asphalt particles was established. With increasing pressure changes, variations in asphaltene concentration can be divided into four processes: firstly, when formation pressure drops from initial value

pi to upper limit precipitation pressure

pu, the mass fraction of asphaltenes remains stable; then, as pressure continues to drop to bubble point

pb, asphaltene components gradually precipitate causing a decrease in mass fraction; next, when continuing to drop down to lower limit precipitation

pl, the precipitated asphaltenes redissolve partially recovering mass fraction; finally, when dropping below lower limit

pl, the mass fraction of asphaltenes remains stable.

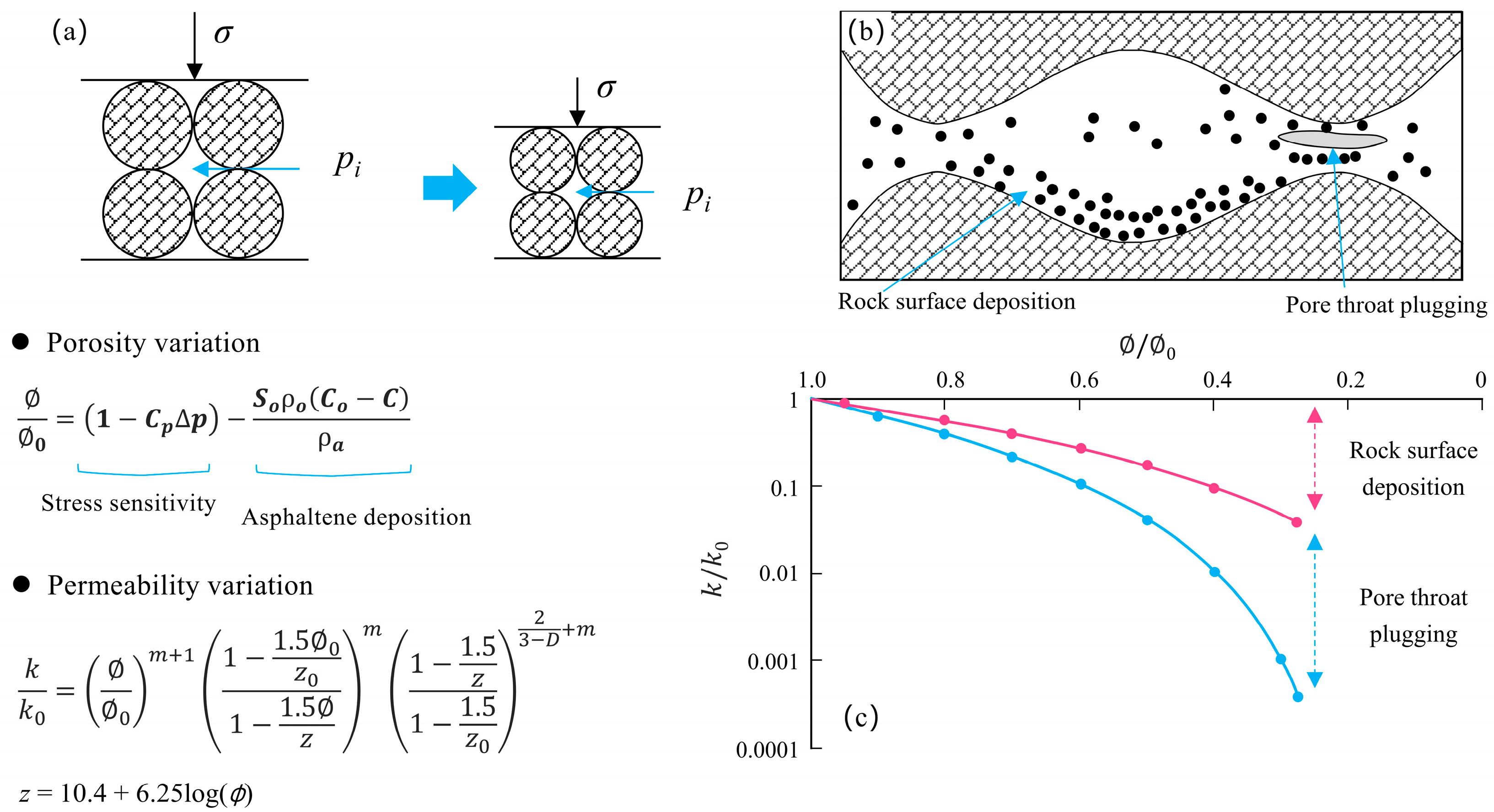

6.2. Influence of Asphaltene Deposits on Reservoir Petrophysical Properties

The variation in reservoir pressure will have a significant impact on the oilfield development. When the reservoir pressure decreases significantly, the reservoir is not only affected by the stress sensitive behavior of the rock but is also influenced by asphaltene precipitation, resulting in particle adhesion on the rock surface and the blockage of pore throats. The conventional capillary bundle theory model struggles to fully describe these complex seepage phenomena. Building upon the Critical Percolation Theory [

37], this paper has developed a porosity-permeability evaluation model that comprehensively considers the combined effects of stress sensitive behavior and solid-phase precipitation of asphaltene particles in carbonate reservoirs (

Figure 13). By quantitatively analyzing reductions in pore radius and blockages in pore throats, this model effectively characterizes permeability loss caused by asphaltene precipitation on rock surfaces and blockages in pore throats.

6.3. Effect of Asphaltene Precipitation on Reservoir Seepage

Asphaltene precipitation not only causes physical damage to reservoirs but also significantly alters reservoir wettability, thereby impacting fluid saturation distribution and seepage characteristics [

38,

39]. In this paper, lab experiments were conducted to comprehensively investigate the effects of different concentrations of asphaltene precipitation on rock wetting angle and relative permeability curve. The experimental results demonstrate (

Figure 14a) that continuous asphaltene precipitation in a water-wet reservoir condition (initial wetting angle

θ = 30°) gradually increases the oil-wet tendency of the rock surface. This leads to an increase in the wetting angle of the water phase, a decrease in irreducible water saturation, an increase in the oil phase index, a decrease in the water phase index, and ultimately enhances flow capacity of the water phase resulting in a rapid rise in water cut.

Building upon the Gibbs isothermal adsorption theory, this paper further derives a mathematical model that describes how asphaltene precipitation influences relative permeability curves under changing formation pressures [

40]. By incorporating time-elapsed features of reservoir rock petro-physical properties and fluid properties into black oil simulator architecture through programming techniques, we account for solid-phase asphaltene particle precipitation and effectively simulate its impact on formation seepage characteristics during actual oilfield development. Compared with conventional numerical simulation technology, this approach significantly improves prediction accuracy for key indicators related to oilfield development (

Figure 14b), increasing fitting rate by 25% for well productivity estimation and enhancing prediction accuracy for the relation curve between water cut and recovery factor.

7. Development Effect of M Oilfield

The M oilfield in Iraq’s development plan, enhanced by theoretical insights and key technologies, employs a spatial injection-production layout with a stepwise well pattern across 547 wells. The plan forecasts a 38.5% oil recovery rate after 25 years, exceeding previous estimates. The highlights are as follows: (1) An innovative seismic velocity model improves geological prediction accuracy in under-explored areas, guiding eight appraisal wells and uncovering 300 million tons of new reserves. (2) The paper uncovers the genetic mechanism of karstification in the Mishrif Formation, identifying optimal reservoir zones 4–8 m below sequence interfaces of MB21, which has optimized over 100 horizontal wells, doubling individual well productivity. (3) Advances in Asmari reservoir fracture characterization have led to a dual-porosity model, enhancing water cut prediction accuracy and providing reliable fracture data. (4) A top-bottom interlaced spatial injection-production strategy for horizontal wells has efficiently managed water injection in thick reservoirs. Seven years of water injection have significantly maintained reservoir pressure and reduced the natural decline rate and water cut rise. Compared to other similar oilfields in the Middle East, the M oilfield has achieved high-level development goals.

8. Discussion

The technical achievements have positively impacted the M oilfield’s development. Yet, oilfield development is complex, requiring detailed reservoir characterization and evolving geological insights for effective guidance. For example, identifying low-velocity lithologic intervals in the gypsum-salt bodies is key for accurate seismic velocity modeling. Moreover, some other technologies have practical limitations. For instance, anisotropy, which measures formation anisotropy to assess fracture development, can be less effective when fractures align with stratification or intersect at small angles, potentially causing interference. This method is also inadequate for evaluating fracture density in complex networks. The “bottom injection and top production” waterflooding method used in the Mishrif Formation is suitable for reservoirs with vertical connectivity and reverse-rhythm behavior in thick layers. Still, it must be modified and adapted for reservoirs with internal interlayers and high permeability zones. Each technical method has its limitations, so optimizing oilfield development and enhancing ultimate recovery require improving reservoir characterization. This process guides the selection of the best practices and boosts development efficiency.

9. Conclusions

- (1)

Seismic velocity modeling: Discrepancies between conventional seismic inversion and actual geological structures are attributed to concealed low-velocity zones in thick gypsum-salt rocks. A Fourier series reconstruction technique has been developed for precise seismic velocity modeling in pre-salt formations.

- (2)

Carbonate rock heterogeneity: The paper clarifies lithofacies and petrophysical properties as key to understanding karst differential dissolution in carbonates, explaining the “porphyritic” core observations and the selective preservation of small pores in dolostones due to dense brine reflux. This provides a basis for high-quality reservoir prediction and well placement.

- (3)

Fracture evaluation: Utilizing the characteristics of middle- to high-angle fractures causing anisotropy in the M oilfield, cross-dipole acoustic logging is proposed for fracture characterization and remote detection, addressing fracture evaluation challenges in the Middle East.

- (4)

Fluid flow mechanism in carbonates: The seepage mechanism in thick carbonate reservoirs with exceptional vertical connectivity is described, providing insights for the “bottom injection and top production” strategy in Mishrif reservoirs to manage rapid water flooding and improve water drive swept volume.

- (5)

Well pattern innovation: To tackle rapid production scaling and ensure economic viability, an innovative stepwise conversion composite well pattern is proposed to balance waterflooding and mitigate large-scale investment risks.

- (6)

Asphaltene precipitation model: A new model for asphaltene precipitation and its impact on development indices is developed using lab experiments combined with reservoir engineering and numerical simulation, addressing practical issues in the M oilfield, Iraq.

Author Contributions

Methodology, K.T. and J.H.; validation, Y.T. and P.C.; software, C.L. and P.C.; investigation, K.T. and J.H.; resources, W.D.; writing—original draft, K.T., J.W. and P.C.; writing—review and editing, F.S., C.L., P.C., S.R. and J.W.; supervision, K.T., J.H. and J.W.; project administration, K.T.; funding acquisition, J.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Major Science and Technology Project of CNOOC, grant No. KJGG2022-0905.

Data Availability Statement

Data are contained within the article.

Acknowledgments

The author would like to express sincere appreciation to all the members of the Asia-Pacific technical team from CNOOC International Limited.

Conflicts of Interest

Authors Kaijun Tong, Juan He, Peiyuan Chen, Changyong Li, Weihua Dai, Futing Sun, Yi Tong, and Su Rao were employed by the company CNOOC International Limited. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Wei, C.J.; Song, H.Q.; Li, Y.; Zhang, Q.; Song, B.B.; Wang, J.L. Production characteristics with different superimposed modes using variogram: A case study of a super-giant carbonate reservoir in the Middle East. Energies 2017, 10, 250. [Google Scholar] [CrossRef]

- Aljuboori, F.A.; Lee, J.H.; Elraies, K.A.; Stephen, K.D. Gravity drainage mechanism in naturally fractured carbonate reservoirs; review and application. Energies 2019, 12, 3699. [Google Scholar] [CrossRef]

- Zhao, Z.Q.; Li, Y.; Jiang, T.W.; Hu, D.D.; Zhang, L.X.; Ma, R.C. Analysis and application of horizontal well test in low permeability porous carbonate reservoir. Processes 2022, 10, 1545. [Google Scholar] [CrossRef]

- Guo, J.; Ling, Z.; Xu, X.; Zhao, Y.; Yang, C.; Wei, B.; Zhang, Z.; Zhang, C.; Tang, X.; Chen, T.; et al. Saturation determination and fluid identification in carbonate rocks based on well logging data: A Middle Eastern case study. Processes 2023, 11, 1282. [Google Scholar] [CrossRef]

- Fathy, D.; El-Balkiemy, A.F.; Maled, W.A.; Hosny, A.M. Organic geochemical signals of Paleozoic rocks in the southern Tethys, Siwa basin, Egypt: Implications for source rock characterization and petroleum system. Phys. Chem. Earth 2023, 130, 103393. [Google Scholar] [CrossRef]

- Flügel, E. Microfacies of Carbonate Rocks: Analysis, Interpretation and Application, 2nd ed.; Springer: New York, NY, USA, 2010; Volume 2, pp. 1–10. [Google Scholar]

- Wang, H.; Shi, K.B.; Ma, Y.S.; Liu, B.; Song, X.M.; Ge, Y.Z.; Liu, H.Y.; Hoffmann, R.; Immenhauser, A. Control of depositional and diagenetic processes on the reservoir properties of the Mishrif Formation in the AD oilfield, Central Mesopotamian Basin, Iraq. Mar. Pet. Geol. 2021, 132, 105202. [Google Scholar] [CrossRef]

- Zhao, L.M.; Zhou, W.; Guo, R.; Jin, Z.M.; Chen, Y.T. Control factors of reservoir oil-bearing difference of Cretaceous Mishrif Formation in the H oilfield, Iraq. Pet. Explor. Dev. 2019, 46, 314–323. [Google Scholar] [CrossRef]

- Lazim, A.A.; Ismail, M.J.; Mahdi, M.M. High resolution sequence stratigraphy of the Mishrif Formation (Cenomanian-Early Turonian) at zubair oilfield (al-rafdhiah dome), southern Iraq. Pet. Res. 2024, 9, 61–71. [Google Scholar] [CrossRef]

- Zeng, L.B. Genesis Mechanism Analysis and Characterization of Fractures in Carbonate Reservoirs; Scientific report; CNOOC International Limited: Beijing, China, 2021. [Google Scholar]

- Han, Y.J.; Zhou, C.C.; Fan, Y.R.; Li, C.L.; Yuan, C.; Cong, Y.H. A new permeability calculation method using nuclear magnetic resonance logging based on pore sizes: A case study of bioclastic limestone reservoirs in the A oilfield of the Mid-East. Pet. Explor. Dev. 2018, 45, 183–192. [Google Scholar] [CrossRef]

- Song, X.M.; Li, Y. Optimum development options and strategies for water injection development of carbonate reservoirs in the Middle East. Pet. Explor. Dev. 2018, 45, 679–689. [Google Scholar] [CrossRef]

- Yang, Y.; Liu, H.Q.; Wang, J.; Zhang, Z.X.; Chen, Q.Y.; Cheng, H. Determination of flow units in carbonate reservoir with multiscale karst morphology. J. Energy Resour. Technol. 2016, 138, 032908. [Google Scholar] [CrossRef]

- Chen, L.X.; Jiang, Z.X.; Sun, C.; Ma, B.S.; Su, Z.; Wan, X.G.; Han, J.F.; Wu, G.H. An overview of the differential carbonate reservoir characteristic and exploitation challenge in Tarim Basin (NW China). Energies 2023, 16, 5586. [Google Scholar] [CrossRef]

- Alsharhan, A.S.; Nairn, A.E.M. Sedimentary Basins and Petroleum Geology of the Middle East, 2nd ed.; Elsevier Science: Amsterdam, The Netherlands, 2003; Volume 6, pp. 691–715. [Google Scholar]

- Al-Gailani, M. Iraq’s significant hydrocarbon potential remains relatively undeveloped. Oil Gas J. 1996, 94, 108–112. [Google Scholar]

- Pitman, J.K.; Steinshouer, D.; Lewan, M.D. Petroleum generation and migration in the Mesopotamian Basin and Zagros Fold Belt of Iraq: Results from a basin-modeling study. GeoArabia 2004, 9, 41–72. [Google Scholar] [CrossRef]

- Al-Shahristani, H.; Al-Atyia, M.J. Vertical migration of oil in Iraqi oil fields: Evidence based on vanadium and nickel concentrations. Geochim. Cosmochim. Acta 1972, 36, 929–938. [Google Scholar] [CrossRef]

- Aqrawi, A.A.M.; Thehni, G.A.; Sherwani, G.H.; Kareem, B.M.A. Mid-Cretaceous rudist-bearing carbonates of the Mishrif Formation: An important reservoir sequence in the Mesopotamian basin, Iraq. J. Petrol. Geol. 1998, 21, 57–82. [Google Scholar] [CrossRef]

- Al-Sherwani, G.H. Lithostratigraphy and environmental considerations of cenomanian-early turonian shelf carbonates (Rumaila and Mishrif Formation) of Mesopotamian basin. AAPG Bull. 1988, 71, 614. [Google Scholar]

- Karami, S.; Ahmadi, V.; Sarooe, H.; Bahrami, M. Facies analysis and depositional environment of the Oligocene-Miocene Asmari Formation, in Interior Fars (Zagros Basin, Iran). Carbonates Evaporites 2020, 35, 88–98. [Google Scholar] [CrossRef]

- Seyrafian, A. Microfacies and depositional environments of the Asmari Formation, at Dehdez area (a correlation across central Zagros basin). Carbonates Evaporites 2000, 15, 121–129. [Google Scholar] [CrossRef]

- Maul, A.; Bulcao, A.; Dias, R.M.; Pereira-Dias, B.; Teixeira, L.; Borges, F.; Gonzalez, M.; Guizan, C.; Cetale, M. Benefits of inserting salt stratification to detail velocity model prior to least-squares reverse-time migration. J. Appl. Geophys. 2021, 195, 104469. [Google Scholar] [CrossRef]

- Di, H.; Gao, D.L.; AlRegib, G. Developing a seismic texture analysis neural network for machine-aided seismic pattern recognition and classification. Geophys. J. Int. 2019, 218, 1262–1275. [Google Scholar] [CrossRef]

- Zuo, Z.H.; Jiang, L.Q.; Zhang, H.Y.; Chen, W.X.; Cai, J.Y. Analysis of Neogene straum velocity anomaly in Bohai oilfield. Prog. Geophys. 2019, 34, 2128–2132. [Google Scholar]

- She, M.; Shou, J.F.; Sheng, A.J.; Pan, L.Y.; Hu, Y.Y. Experimental simulation of dissolution law and porosity evolution of carbonate rock. Pet. Explor. Dev. 2016, 43, 564–572. [Google Scholar] [CrossRef]

- Luo, S.C.; Tan, X.C.; Chen, L.; Li, F.; Chen, P.Y.; Xiao, D. Dense brine refluxing: A new genetic interpretation of widespread anhydrite lumps in the Oligocene–Lower Miocene Asmari Formation of the Zagros foreland basin, NE Iraq. Mar. Pet. Geol. 2019, 101, 373–388. [Google Scholar] [CrossRef]

- Aghli, G.; Moussavi-Harami, R.; Tokhmechi, B. Integration of sonic and resistivity conventional logs for identification of fracture parameters in the carbonate reservoirs (A case study, Carbonate Asmari Formation, Zagros Basin, SW Iran). J. Pet. Sci. Eng. 2020, 186, 106728. [Google Scholar] [CrossRef]

- Seyed, S.; Yazdjerdi, K.; Asadi, A.; Tabatabaei, H. Image log analysis of Asmari reservoir fractures in a Southwest Iranian oil field. Carbonates Evaporites 2022, 37, 5–13. [Google Scholar] [CrossRef]

- Tong, K.J.; He, J.; Dong, S.Q.; Sun, F.T.; Chen, P.Y.; Tong, Y. Fracture characterization of Asmari Formation carbonate reservoirs in G Oilfield, Zagros Basin, Middle East. Energy Geosci. 2023, 4, 100178. [Google Scholar] [CrossRef]

- Yasin, O.; Ding, Y.; Baklouti, S.; Boateng, C.; Du, Q.Z.; Golsanami, N. An integrated fracture parameter prediction and characterization method in deeply-buried carbonate reservoirs based on deep neural network. J. Pet. Sci. Eng. 2022, 208, 109346. [Google Scholar] [CrossRef]

- Abdolvahab, A.; Behnam, R.; Reza, M.H.; Mohammad, S.; Wang, Q.Q.; John, N.H. Open fracture clustering: Integrating subsurface and outcrop analogues, Asmari Formation, SW Iran. J. Struct. Geol. 2023, 176, 104962. [Google Scholar]

- Shirnkin, D.; Kochnev, A.; Krivoshchekov, S.; Putilov, I.; Botalov, A.; Kozyrev, N.; Ozhgibesov, E. High permeability streak identification and modeling approach for carbonate reef reservoir. Energies 2024, 17, 236. [Google Scholar] [CrossRef]

- Zahid, B.; Shahin, N.; Mohamed, S. Screening of field development options by simulation study to improve recovery from lower southern units of complex carbonate reservoir. In Proceedings of the SPE Abu Dhabi International Petroleum Exhibition & Conference, Abu Dhabi, United Arab Emirates, 5–8 November 2006. [Google Scholar]

- Li, F.F.; Li, L.; Chen, J.H. Characteristics of high flow zones and a balanced development strategy of a thick bioclastic limestone reservoir in the Mishrif Formation in X oilfield, Iraq. Energies 2023, 16, 1451. [Google Scholar] [CrossRef]

- Li, C.Y.; He, J.; Zhang, Y. The method and strategy to optimize well density for oilfield development projects in technical service contract framework. In Proceedings of the SPE Abu Dhabi International Petroleum Exhibition & Conference, Abu Dhabi, United Arab Emirates, 9–12 November 2020. [Google Scholar]

- Antonio, C. Permeability-porosity relationship: A reexamination of the Kozeny-Carman equation based on a fractal pore-space geometry assumption. Geophys. Res. Lett. 2006, 33, 1–5. [Google Scholar]

- Hamid, R.L.; Xu, Y.F.; Kamy, S. Modeling dynamic wettability alteration effect based on contact angle. In Proceedings of the SPE Improved Oil Recovery Conference, Tulsa, OK, USA, 11–13 April 2016. [Google Scholar]

- Jober, T.S.; Mahyar, R.K.; Akram, S.; Ali, E.; Mohammad, A.K.; Hamid, S. Wettability alteration by surface adsorption of asphaltene molecular in carbonate porous media. J. Mol. Liq. 2022, 345, 118128. [Google Scholar]

- Li, C.Y. Reservoir simulation assessment for the effect of asphaltene deposition on water flooding in B oilfield. In Proceedings of the International Petroleum Technology Conference, Bangkok, Thailand, 1–3 March 2023. [Google Scholar]

Figure 1.

Geological map: (a) regional location map; (b) comprehensive column of Asmari and Mishrif Formation in M Oilfield, Iraq.

Figure 1.

Geological map: (a) regional location map; (b) comprehensive column of Asmari and Mishrif Formation in M Oilfield, Iraq.

Figure 2.

Seismic velocity and time thickness map of gypsum-salt layer and structure depth map of target formation in the study area: (a) seismic time thickness map of gysum-salt layer; (b) seismic velocity map of gypsum-salt layer; (c) structural depth map of target formation.

Figure 2.

Seismic velocity and time thickness map of gypsum-salt layer and structure depth map of target formation in the study area: (a) seismic time thickness map of gysum-salt layer; (b) seismic velocity map of gypsum-salt layer; (c) structural depth map of target formation.

Figure 3.

Differential mechanisms of “porphyritic” carbonate rocks: (a) the “porphyritic” core sample from the Mishrif Formation; (b) reservoir development controlled by microfacies; (c) differential dissolution during diagenesis due to heterogeneity; (d) core and logging porosity.

Figure 3.

Differential mechanisms of “porphyritic” carbonate rocks: (a) the “porphyritic” core sample from the Mishrif Formation; (b) reservoir development controlled by microfacies; (c) differential dissolution during diagenesis due to heterogeneity; (d) core and logging porosity.

Figure 4.

Genetic model of anhydrite clumps and its filling features in the Asmari dolostones.

Figure 4.

Genetic model of anhydrite clumps and its filling features in the Asmari dolostones.

Figure 5.

Diagram of fracture integrated interpretation results of Well G33, Asmari Formation.

Figure 5.

Diagram of fracture integrated interpretation results of Well G33, Asmari Formation.

Figure 6.

Dipole shear wave remote reflection imaging workflow.

Figure 6.

Dipole shear wave remote reflection imaging workflow.

Figure 7.

Process and result map of fracture prediction and integrated characterization under multisource information fusion: (a) fracture intensity interpretation based on CDAL; (b) inter-well fracture trend prediction based on integration of reservoir geomechanics and seismic attributes; (c) inter-well fracture density modeling; (d) fracture network modeling; (e) section of the fracture development intensity model; (f) section of the discrete fracture network model.

Figure 7.

Process and result map of fracture prediction and integrated characterization under multisource information fusion: (a) fracture intensity interpretation based on CDAL; (b) inter-well fracture trend prediction based on integration of reservoir geomechanics and seismic attributes; (c) inter-well fracture density modeling; (d) fracture network modeling; (e) section of the fracture development intensity model; (f) section of the discrete fracture network model.

Figure 8.

Well test features of vertical well partial-perforation mode in thick carbonate reservoir.

Figure 8.

Well test features of vertical well partial-perforation mode in thick carbonate reservoir.

Figure 9.

Water flooding mechanism of a thick carbonate reservoir under spatial injection-production mode: (a) saturation field at different time (physical simulation experiments); (b) comparison of waterflood front of different well type (numerical simulation); (c) “bottom injection and top production” streamlines under composite well types.

Figure 9.

Water flooding mechanism of a thick carbonate reservoir under spatial injection-production mode: (a) saturation field at different time (physical simulation experiments); (b) comparison of waterflood front of different well type (numerical simulation); (c) “bottom injection and top production” streamlines under composite well types.

Figure 10.

Relationship chart between the economic profit and well pattern density under TSC contract (government vs. the leader contractor). Where N is original oil in place, 106 m3; ED is displacement factor, fraction of volume; B is well pattern index, fraction; S is well density, km2/well; α is tax rate, fraction; I is investment per well excluding operating expense, USD MM; O is operating expense per well, USD MM; A is oil-bearing area, km2; RT is recovery factor of recoverable reserves, fraction; λsp is equity ratio of state partner, fraction; λc is equity ratio of contractor, fraction; P is oil price, USD/m3; Prf is remuneration fee per barrel, USD/m3; y3 is income of the contractor, USD MM; y4 is expenditure of the contractor, USD MM; Sgr is economic reasonable well density for the government, km2/well.

Figure 10.

Relationship chart between the economic profit and well pattern density under TSC contract (government vs. the leader contractor). Where N is original oil in place, 106 m3; ED is displacement factor, fraction of volume; B is well pattern index, fraction; S is well density, km2/well; α is tax rate, fraction; I is investment per well excluding operating expense, USD MM; O is operating expense per well, USD MM; A is oil-bearing area, km2; RT is recovery factor of recoverable reserves, fraction; λsp is equity ratio of state partner, fraction; λc is equity ratio of contractor, fraction; P is oil price, USD/m3; Prf is remuneration fee per barrel, USD/m3; y3 is income of the contractor, USD MM; y4 is expenditure of the contractor, USD MM; Sgr is economic reasonable well density for the government, km2/well.

Figure 11.

Schematic diagram of the areal well pattern with “edge-to-inner combination and stepwise conversion”.

Figure 11.

Schematic diagram of the areal well pattern with “edge-to-inner combination and stepwise conversion”.

Figure 12.

Mathematical model for process controlling of asphaltene precipitation. Where C is the dissolved asphaltene content in the oil phase, wt%; p is the oil phase pressure, psi (Pa); pu is the upper AOP, psi (Pa); pb is the bubble point pressure, psi (Pa); pl is the lower AOP, psi (Pa); C0 and Cmin are the original and minimum dissolved asphaltene contents, wt%; a and b is the constant factor.

Figure 12.

Mathematical model for process controlling of asphaltene precipitation. Where C is the dissolved asphaltene content in the oil phase, wt%; p is the oil phase pressure, psi (Pa); pu is the upper AOP, psi (Pa); pb is the bubble point pressure, psi (Pa); pl is the lower AOP, psi (Pa); C0 and Cmin are the original and minimum dissolved asphaltene contents, wt%; a and b is the constant factor.

Figure 13.

Variation of rock permeability under the coupling effect of stress sensitivity and asphalt precipitation: (a) stress sensitivity conceptual model; (b) asphaltene deposition model; (c) k/k0 versus. ∅/∅0. Where ∅ is the local dynamic porosity, fraction; ∅0 denotes the initial porosity, fraction; k is the formation permeability, mD (10−3 μm2); k0 is the initial formation permeability, mD (10−3 μm2); Cp is the rock compressibility, psi−1 (Pa−1); ∆p is the pressure difference, psi (Pa); So is oil saturation, fraction; ρo is oil density, g/cm3; ρa is asphaltene density, g/cm3; m and D is constant factor; z = A + B log (∅), both A and B are constants. A is 10.4 and B is 6.25.

Figure 13.

Variation of rock permeability under the coupling effect of stress sensitivity and asphalt precipitation: (a) stress sensitivity conceptual model; (b) asphaltene deposition model; (c) k/k0 versus. ∅/∅0. Where ∅ is the local dynamic porosity, fraction; ∅0 denotes the initial porosity, fraction; k is the formation permeability, mD (10−3 μm2); k0 is the initial formation permeability, mD (10−3 μm2); Cp is the rock compressibility, psi−1 (Pa−1); ∆p is the pressure difference, psi (Pa); So is oil saturation, fraction; ρo is oil density, g/cm3; ρa is asphaltene density, g/cm3; m and D is constant factor; z = A + B log (∅), both A and B are constants. A is 10.4 and B is 6.25.

Figure 14.

Influence of asphaltene precipitation on oil-water relative permeability curve and reservoir development index during water flooding: (a) relative permeability curves, (b) history matching results.

Figure 14.

Influence of asphaltene precipitation on oil-water relative permeability curve and reservoir development index during water flooding: (a) relative permeability curves, (b) history matching results.

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).