Abstract

Significant concerns over energy security and environmental impact reduction will drive all stakeholders to generate proper alternative energies. Biodiesel is a prospective cleaner-burning biofuel that can contribute on addressing these concerns globally. Presently, pure biodiesel (B100) application is still facing several obstacles, principally in terms of its cold flow properties. Improvement in cold flow behavior parameters is the solution to promoting biodiesel implementation at a higher percentage and wider environmental temperature range. This study provides a detailed review of several improvement methods, both physical, chemical, and biological, from various scientific sources, to elevate the cold fluidity characteristics of biodiesel. The investigated methods convincingly offer proper enhancement in the cold flow properties of biodiesel. Mostly, this improvement is accompanied by an alleviation in oxidation stability, cetane number, and/or viscosity. However, the skeletal isomerization method presents promising cold fluidity refinement with minimal reduction in other physical properties. Therefore, the continuous development of these methods promises global sustainable application of high-quality biodiesel.

1. Introduction

1.1. Global Energy Outlook

Global energy consumption is forecasted to rise continuously until 2050 due to world economic growth and rapid population increase [1]. This sharp rise will be led by the industrial sector and followed by the transportation sector. The high demand for industrial products and the energy efficiency of industrial processes at a low–medium level primarily determine the multiplication of energy utilization in the industrial sector. In the transportation sector, the better economic condition of society requires a more convenient transportation mode. Consequently, its energy consumption will be less efficient than that of the conventional mode. On the other side, the crisis of fossil fuel availability threatens all countries in the world and makes its price unaffordable [2,3]. This situation cannot be separated from the heavy dependence on fossil fuels, such as natural gas, petroleum, and coal, to meet their energy needs [4].

Furthermore, the excessive use of fossil fuel will promote adverse impacts on humans and the environment [5]. Emissions from this fossil fuel combustion consist of carbon dioxide (CO2), carbon monoxide (CO), hydrocarbon (HC), sulfur oxide (SOx), nitrogen oxide (NOx), and particulate matter (PM). These components cannot be completely degraded by the environment and, consequently, they will be accumulated in the atmosphere. The excessive appearance of CO2 causes the greenhouse gas (GHG) effect, leading to global warming and climate change phenomena [6]. The high concentration of CO2 and other released hazardous compounds (CO, HC, and PM) in the atmosphere also causes several health problems in humans [5]. Moreover, SOx and NOx emissions can trigger acid rain, which has damaging effects on the existing ecosystem [7].

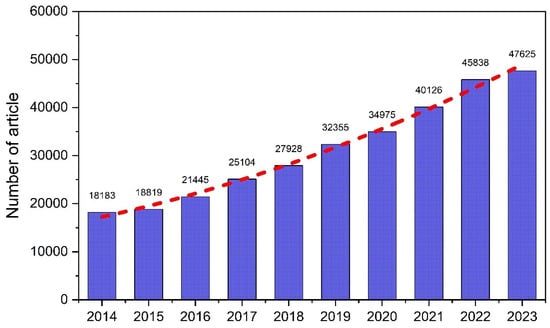

To anticipate those problems and provide energy security, all countries in the world have made efforts to meet their energy requirement with alternative energy for sustainable application. The share of non-fossil fuel utilization in all primary energy sources was reported at 20% in 2022 and predicted to be in the range of 25–35% in 2050 via various schemes [1]. The growth in alternative energy implementation is accompanied by the expansion in energy demand, which is estimated to increase by 30–50% in 2050 [1]. In line with this action, global researchers have also been continuously developing alternative energy on an industrial scale as a substitute for fossil fuels. Their works can be seen from the significant increase in scientific publications in this area, presented in Figure 1, in the last decade. No less than three thousand scientific articles on alternative energy have been published in this period. In fact, the number of related publications in 2023 reached more than 47,000 articles. Based on these articles, the most expected characteristics of the alternative energy are renewability, biodegradability, lower toxicity, less pollutant production, and being economically competitive [8,9,10]. Additionally, the compatibility of the investigated fuels and targeted machines must be examined and assessed to guarantee safety in their application [3].

Figure 1.

Number of published scientific articles on the alternative and renewable energy sector in the period of 2014–2023 (from Scopus accessed on 26 July 2024).

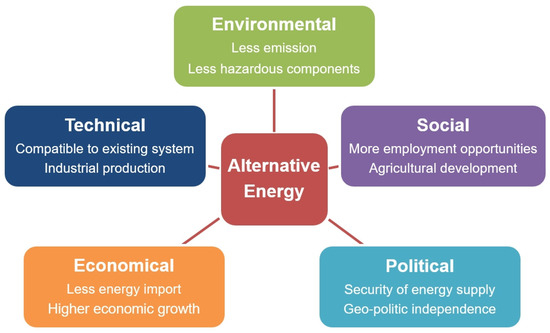

In addition to technical and environmental aspects, the increasing call for alternative energy for sustainable application is also driven by social, political, and economical aspects. In social aspects, the generation of alternative fuels can expand the employment opportunities and develop the advanced agricultural ecosystem [7,11]. Then, the political aspect considers the strengthening of energy supply security and the affirmation of geographically based political independence as the basis for enforcing the sustainable energy application [7,11]. Meanwhile, the economical point of view emphasizes the reason for energy import reduction and economic growth to functionalize self-produced environmentally friendly energy [3,12]. All considerations in every aspect are summarized in the diagram shown in Figure 2.

Figure 2.

Primary considerations of alternative energy application. Adapted and modified from Anwar and Garforth [7].

Based on the description above, the implementation of alternative energy has a very important role in the success of the 2030 Agenda for Sustainable Development. It greatly supports the achievement of several Sustainable Development Goals (SDGs). Mainly, this activity directly influences the realization of Affordable and Clean Energy (SDG-7), which targets the increasing use of new and renewable energies to substitute for fossil energy. Secondly, utilization of alternative energy provides cleaner emissions, which assists the goals of Climate Change (SDG-13), Good Health and Well-being (SDG-3), Responsible Consumption and Production (SDG-12), and Life on Land (SDG-15). Then, its massive production is required to be efficient in terms of land use. This point understandably contributes to SDG-12 and SDG-15. Afterward, it also correlates with the purposes of Decent Work and Economic Growth (SDG-8) and No Poverty (SDG-1). Those goals are reflected in the impact of alternative energy usage. Its attractiveness sufficiently drives economic growth, encourages expansion of decent work opportunities, and is highly expected to reduces poverty rates.

1.2. Biodiesel as an Alternative Energy Source

By observing the global map for alternative fuel development to date, biodiesel is a prospective cleaner-burning fuel to be widely implemented as a petro-diesel replacement fuel around the world. Biodiesel, for instance, shares several typical properties with petro-diesel, as shown in Table 1, although their chemical components are totally different. Petro-diesel is dominantly composed of long-chain alkanes and a small number of alkenes [12,13]. Meanwhile, biodiesel consists of long-chain hydrocarbons with ester functional groups [12,13]. However, both are insoluble in water (organic phase) [13]. Moreover, they are similar in some physical properties, such as kinematic viscosity, density, cetane number, flash point, and distillation temperature. Thus, they can technically replace each other or be blended to be a diesel fuel. Apart from being able to substitute for fossil diesel, biodiesel also has some other benefits in terms of renewability, sustainability, biodegradability, flammability, explosivity, toxicity, and emission [13,14].

Table 1.

Typical property comparison of petro-diesel and biodiesel.

Table 1.

Typical property comparison of petro-diesel and biodiesel.

| Properties | Unit | Petro-Diesel | Biodiesel | ||

|---|---|---|---|---|---|

| ASTM D975 [15,16] | EN 590 [16] | ASTM D6751 [17,18,19] | EN 14214 [13,20] | ||

| Chemical component [12,13] | - | Alkanes, alkenes (C10–C21) | Fatty acid alkyl esters (C8–C24 alkyl esters) | ||

| Phase [13] | - | Organic (insoluble in water) | Organic (insoluble in water) | ||

| Kinematic viscosity, at 40 °C | mm2/s | 1.9–4.1 | 2.0–4.5 | 1.9–6.0 | 3.5–5.0 |

| Density, at 15 °C | kg/m3 | n.s. *) | 820–845 | n.s. *) | 860–900 |

| Cetane number | - | ≥40 | ≥51 | ≥47 | ≥51 |

| Flash point | °C | ≥52 | ≥55 | ≥93 | ≥101 |

| Distillation temperature, at 90% | °C | 282–338 | n.s. *) | ≤360 | n.s. *) |

Note: *) n.s. = not specified.

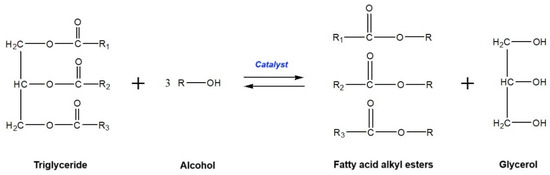

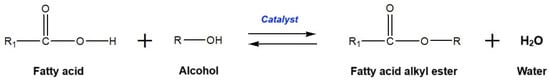

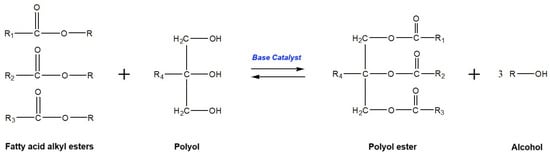

Generally, biodiesel is synthesized by transesterification or esterification processes. The former process generates biodiesel from triglyceride-rich feedstocks (such as vegetable oils, fats, and used cooking oils) and short-chain alcohols using a basic or acidic catalyst [21]. In this process, the glyceride-attached fatty acids are taken out, promoting alkyl ester monomers, and replaced by an alcohol functional group to form glycerol as a by-product. The general reaction formula of transesterification is presented in Figure 3. In the other method, the esterification process requires free fatty acid-rich feedstocks (such as fatty acid distillates) and short-chain alcohols to produce biodiesel in the existence of an acidic catalyst [22]. In this reaction, the activated methoxy component attacks the carboxylic acid functional group in the free fatty acid to produce a mono-alkyl ester and water as by-products. The appropriate formula of the esterification reaction is shown in Figure 4.

Figure 3.

General reaction formula of transesterification.

Figure 4.

General reaction formula of esterification.

Since its discovery in 1937 [7], biodiesel has been made from several categories of feedstocks, which were divided into four generations. The first-generation biodiesel was obtained from vegetable oil transesterification [23]. Palm [24], soybean [25], rapeseed [26], and sunflower oil [27] were the main oil-based crops used in this generation. However, the utilization of these feedstocks, with their future projection, potentially causes fundamental problems. Due to the use of edible materials, conflicts over their utilization in food and energy sector will occur to secure their supply in each sector [28]. The direct impact is higher commodity prices; hence, sectors with smaller purchasing power will experience an allocation shortage [29]. The global situation becomes even more dangerous when the food supply is obstructed. This will seriously threaten human life. Apart from economic and human life points of view, potential threats also arise from the environmental side in which the higher oil demand will require a larger plantation area [30].

The second-generation biodiesel was sourced from non-edible oils, animal fats, and wastes [28]. The primary non-edible sources used to produce biodiesel worldwide were jatropha [31], karanja [32], and jojoba oil [5,33]. Animal fat feedstocks used, for instance, were usually chicken fat [34] and beef tallow [35]. Then, the waste sources for biodiesel production were used cooking oils (UCOs) [36] and fatty acid distillates [14,37]. These low-cost materials were expected to overcome the problems in the first-generation feedstocks. However, the higher content of free fatty acid (FFA) and impurities in these sources generated fatty acid alkyl esters in a lower yield [38,39]. Moreover, the esters required more physical and chemical treatments to meet the biodiesel standard [12]. Consequently, the manufacturing cost of biodiesel was higher than that of the older generation [29].

The third-generation biodiesel feedstocks were microorganism-based oil or lipid. The prominent lipid-rich microorganism candidate was microalgae [29]. Microalgae are high-efficiency photosynthetic microorganisms containing a lot of essential components, such as carbohydrates, protein, lipids, vitamins, and bio-active compounds [40,41]. Compared to conventional oil crops, the main benefits of microalgae were a faster growth rate and higher lipid productivity [42,43,44]. The previous study by Chisti [45] reported that open microalgae cultivation per plantation area could potentially produce in the range of five to twenty times more oil than oil palm. Moreover, the environment-related superiorities of microalgae were high CO2 capture capability and adaptability in low-grade cultivation media [46,47]. Microalgae have been successfully cultivated with a CO2 supply from CO2-rich industrial flue gas [48]. Additionally, they could be cultured in various waste media, such as glycerol wastewater [49], palm oil mill effluent (POME) [17], waste molasses [50], and mining wastewater [51]. All the microalgae benefits stated above were expected to supply the energy requirement while minimizing impacts on the environment. Nevertheless, high FFA and fuel-based contamination contents in microalgal oil were challenges of using microalgae as biodiesel feedstocks [12].

Furthermore, the fourth-generation biodiesel feedstocks were proposed by genetically engineering the microorganisms used in the third-generation materials [28]. The functions of genetic modification were to improve the biomass growth rate, oil content, and adaptability to the culture medium [12]. The development of this generation, however, is still in the preliminary stage [3,28]. Thus, it requires further study to determine the optimum fuel-supporting genetic formula [12,28]. The classification of all biodiesel feedstocks discussed above is summarized in Table 2.

Table 2.

Summary of biodiesel feedstock classification and its distinctive characteristics.

Table 2.

Summary of biodiesel feedstock classification and its distinctive characteristics.

| Generation | Category | Feedstocks | Distinctive Characteristics | |

|---|---|---|---|---|

| First generation | Edible oils |

|

|

|

| Second generation | Non-edible oils |

|

|

|

| Animal fats |

|

| ||

| Wastes |

|

| ||

| Third generation | Microalgae |

|

|

|

| Fourth generation | Genetically modified microorganism |

|

| |

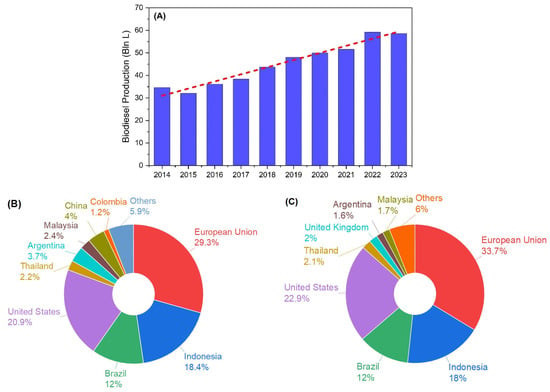

In the past decade, alkyl ester-based biofuel production has grown continuously to meet the increasing demand for diesel fuel, especially in the transportation sector [164]. Figure 5A demonstrates worldwide biodiesel production in 2014–2023. In this period, the quantity of commercial biodiesel manufacturing continued to increase significantly, reaching 58.59 billion liters in 2023 [165]. It was prominently produced from vegetable oils, with a percentage of ~70%-v [164]. The three largest shares were palm (29%-v), soybean (23%-v), and rapeseed biodiesel (14%-v) [164]. The remaining percentage was yielded from UCOs and animal fats [164].

Figure 5.

Current situation of biodiesel: (A) global biodiesel production in 2014–2023 (red line is production trendline); (B) distribution of biodiesel producers in 2023; (C) distribution of biodiesel consumers in 2023 (data were obtained from [164,165]).

As shown in Figure 5B, the big four vegetable biodiesel producers in 2023 were the European Union (EU), United States (US), Indonesia, and Brazil. They dominated global vegetable oil-based biodiesel production, with a combined share of 80.6%-v. They were also declared as the four largest biodiesel consuming countries/regions in the world, as presented in Figure 5C. As the biggest country/region for biodiesel generation and utilization in 2023, the European Union, nowadays, relies on rapeseed oil supply as the main biodiesel feedstock [164]. Nevertheless, the biodiesel production and consumption in the EU are predicted to decrease in the future because of a palm biodiesel reduction and an electrification policy in the transportation sector [164]. In this situation, Indonesia took advantage of its excess palm oil availability to generate palm biodiesel [164]. The increasing palm biodiesel production was used by the Indonesian Government to support the implementation of B30 (blend of biodiesel 30%-v and petro-diesel 70%-v) in 2020 [164,166] and B35 (blend of biodiesel 35%-v and petro-diesel 65%-v) in 2023 [167]. Moreover, it has proposed to drive biodiesel applications at a higher level for the next few years [168]. Then, Brazil and the United States of America implemented biodiesel synthesis primarily from soybean oil [164]. Brazil is forecasted to face a multiplication in biodiesel demand in line with the growth in diesel vehicles in the coming years [164]. Meanwhile, the future outlook for biodiesel application in USA is mostly like that of the EU, with biodiesel production declining due to decreased consumption in fueled transportation [164].

2. Physicochemical Properties of Biodiesel

2.1. Physical Properties of Biodiesel

Worldwide biodiesel production is supplied with numerous types of feedstocks, which have different components and composition. This fact leads to the distinction in biodiesel characteristics depending on the raw material. However, the primary application of biodiesel as a petro-diesel replacement fuel in common diesel machines requires it to be standardized. The standardization of biodiesel quality serves to guarantee its safe operation and normal emissions [7]. Currently, there are two main standards of biodiesel specifications that are used as references throughout the world. These are ASTM D6751, defined by the American standardization institution, and EN 14214, issued by the European standardization committee [7]. The specification details of both reference standards and other standards in several biodiesel producer countries (Indonesia, Malaysia, Brazil, and India) are demonstrated in Table 3. Although referring to the international standards, each country or relevant authority can adjust the value of crucial parameters to suit their purposes and needs of biodiesel. For example, Indonesia has applied a tighter standard for the cold filter plugging point, monoglyceride content, and water content than the international standards. This regulation is set to support a higher biodiesel volumetric percentage in diesel fuel for domestic consumption and wider utilization in low-temperature areas.

2.2. Chemical Properties of Biodiesel

Generally, biodiesel feedstocks can be obtained from various resources depending on their abundance in a region or country. The amazing diversity in biodiesel feedstocks can be seen in Table 2, which is divided into several generation and categories. Each feedstock has a specific fatty acid profile and these differ from each other [7], as shown in Table 4. These fatty acids can be classified into two categories, namely saturated fatty acid (SFA) and unsaturated fatty acid (UFA) [169]. SFA is defined as a fatty acid component without a double bond in the carbon chain. It is generally symbolized with Cx:0 (x denotes the number of carbon chains and 0 indicates there is no double bond in the carbon chain). The major SFAs found in vegetable oils are palmitic acid (C16:0) and stearic acid (C18:0). Furthermore, UFA represents a double-bond fatty acid component and its acronym is Cx:y (y indicates the number of double bonds in the carbon chain). Then, UFA is divided again into two sub-categories, mono-unsaturated fatty acid (MUFA) for a single double-bond fatty acid component and poly-unsaturated fatty acid (PUFA) for more than one double bond in the fatty acid carbon chain [169]. The examples of MUFA compounds in biodiesel feedstocks are oleic acid (C18:1) and palmitoleic acid (C16:1). Meanwhile, linoleic acid (C18:2) and linolenic acid (C18:3) are the top two PUFA components mostly found in the fatty acid ester feedstocks.

Table 3.

Physical properties of biodiesel based on American Standard (ASTM D6751), European Standard (EN 14214), Indonesian Standard (KEPDIRJEN 195.K/EK.05/DJE/2022), Malaysian Standard (MS 2008:2014), Brazilian Standard (ANP N° 920/2023), and Indian Standard (IS 15607).

Table 3.

Physical properties of biodiesel based on American Standard (ASTM D6751), European Standard (EN 14214), Indonesian Standard (KEPDIRJEN 195.K/EK.05/DJE/2022), Malaysian Standard (MS 2008:2014), Brazilian Standard (ANP N° 920/2023), and Indian Standard (IS 15607).

| Properties | Unit | Method | American Standard (ASTM D6751) [7,17,18,19] | European Standard (EN 14214) [7,13,20] | Indonesian Standard (195.K/EK.05/DJE/2022) [170] | Malaysian Standard (MS 2008:2014) [17,171] | Brazilian Standard (ANP N° 920/2023) [172] | Indian Standard (IS 15607) [173] | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | |||

| Density at 15 °C | kg/m3 | EN 12185/ ISO 3675 | - | - | 860 | 900 | - | - | 860 | 900 | 850 a | 900 a | 860 | 900 |

| Density at 40 °C | kg/m3 | D4052 | - | - | - | - | 850 | 890 | - | - | - | - | - | - |

| Kinematic viscosity at 40 °C | mm2/s | D445/ EN ISO 3104 | 1.9 | 6.0 | 3.5 | 5.0 | 2.3 | 6.0 | 3.5 | 5.0 | 3.0 | 5.0 | 3.0 | 6.0 |

| Cetane number | - | D613/ EN ISO 5165 | 47 | - | 51 | - | 51 | - | 51 | - | report | - | 51 | - |

| Flash point (close cup) | °C | D93/ EN ISO 3679 | 93 | - | 101 | - | 130 | - | 120 | - | 100 | - | 120 | - |

| Cloud point | °C | D2500 | −3 | 12 | - | - | - | - | - | - | - | - | - | - |

| Pour point | °C | D97/ISO 3016 | −15 | 10 | - | - | - | - | - | - | - | - | - | - |

| Cold filter plugging point | °C | D6371/EN 116 | - | - | - | report | - | 15 | - | 15 | - | report | - | - |

Carbon residue

| wt% | D4530 D4530/ EN ISO 10370 | - - | 0.05 - | - - | - 0.3 | - - | 0.05 0.3 | - - | 0.05 0.3 | - - | - - | - - | 0.05 - |

| Copper strip corrosion, 3 h at 50 °C | Rating | D130/ EN ISO 2160 | - | No. 3 | Class 1 | Class 1 | Class 1 | Class 1 | Class 1 | |||||

| Distillation temperature, at 90% | °C | D1160 | - | 360 | - | - | - | 360 | - | - | - | - | - | - |

| Acid number | mg KOH/g | D664/ EN14104 | - | 0.5 | - | 0.5 | - | 0.4 | - | 0.5 | - | 0.5 | - | 0.5 |

| Iodine number | g I /100 g | EN14111/ AOCS Cd 1-25 | - | - | - | 120 | - | 115 | - | 110 | - | - | - | report |

| Oxidation stability, at 110 °C | h | EN14112/ EN15751 | 3 | - | 8 | - | 11 | - | 10 | - | 13 | - | 6 | - |

| Ester content | wt% | EN14103/ SNI 7182:2015 | - | - | 96.5 | - | 96.5 | - | 96.5 | - | 96.5 | - | 96.5 | - |

| Linolenic acid methyl ester | wt% | EN14103 | - | - | - | 12 | - | - | - | 12 | - | - | - | - |

| Polyunsaturated (≥4 double bonds) methyl esters | wt% | EN14103 | - | - | - | 1 | - | - | - | 1 | - | - | - | - |

| Methanol content | wt% | EN14110 | - | 0.2 | - | 0.2 | - | - | - | 0.2 | - | 0.2 | - | - |

| Monoglyceride content | wt% | D6584/ EN14105 | - | - | - | 0.7 | - | 0.525 | - | 0.7 | - | 0.5 | - | - |

| Diglyceride content | wt% | EN14105 | - | - | - | 0.2 | - | - | - | 0.2 | - | 0.2 | - | - |

| Triglyceride content | wt% | EN14105 | - | - | - | 0.2 | - | - | - | 0.2 | - | 0.2 | - | - |

| Free glycerol | wt% | D6584/ EN14105 | - | 0.02 | - | 0.02 | - | 0.02 | - | 0.02 | - | 0.02 | - | 0.02 |

| Total glycerol | wt% | D6584/ EN14105 | - | 0.24 | - | 0.25 | - | 0.24 | - | 0.25 | - | 0.20 | - | 0.25 |

| Alkaline metals (Na + K) | ppm | EN 14538 | - | 5 | - | 5 | - | 5 | - | 5 | - | 2.5 | - | report |

| Alkaline earth metals (Ca + Mg) | ppm | EN 14538 | - | 5 | - | 5 | - | 5 | - | 5 | - | 2.5 | - | report |

| Sulphur content | ppm | D5453/ EN ISO 20846 | - | - | - | 10 | - | 10 | - | 10 | - | 10 | - | 50 |

| Sulphur (S 15 Grade) | ppm | D5463 | - | 15 | - | - | - | - | - | - | - | - | - | - |

| Sulphur (S 500 Grade) | ppm | D5463 | - | 500 | - | - | - | - | - | - | - | - | - | - |

| Sulphated ash content | wt% | D874/ ISO 3987 | - | 0.02 | - | 0.02 | - | 0.02 | - | 0.02 | - | 0.02 | - | 0.02 |

| Phosphorus content | ppm | D4951/EN14107/AOCS Ca 12-55 | - | 10 | - | 4 | - | 4 | - | 4 | - | 3.0 | - | 10 |

| Water and sediment | %-v | D2709 | - | 0.05 | - | - | - | - | - | - | - | - | - | - |

| Water content | ppm | D6304/ EN ISO 12937 | - | - | - | 500 | - | 340 | - | 500 | - | 200 | - | 500 |

| Total contamination | ppm | D6217/EN12662 | - | - | - | 24 | - | 20 b | - | 24 | - | 24 | - | 24 |

| Cold soak filterability | s | Annex to D6751 | - | 360 | - | - | - | - | - | - | - | - | - | - |

Note: a measured at 20 °C; b unit: mg/L.

Table 4.

Profiles of fatty acids in several fatty acid-rich feedstocks (wt%) and its influence on selected biodiesel physical properties.

Table 4.

Profiles of fatty acids in several fatty acid-rich feedstocks (wt%) and its influence on selected biodiesel physical properties.

| Fatty Acids | Composition (wt%) and Physical Property Value | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| P | S | R | SN | SF | CN | CS | C | J | JB | K | CI | UC | CF | BT | MS | MC | MT | ||

| Caprylic | C8:0 | - | - | - | - | - | 6.5 | - | - | - | - | - | - | - | - | - | - | - | - |

| Capric | C10:0 | - | - | - | - | - | 5.6 | - | - | - | - | - | - | - | - | 0.1 | - | - | - |

| Lauric | C12:0 | 0.2 | - | - | - | - | 46.9 | - | - | - | - | - | - | 0.4 | 0.1 | 0.2 | - | 9.8 | 3.1 |

| Myristic | C14:0 | 1.0 | 0.1 | - | 0.1 | - | 18.7 | 0.7 | - | 0.1 | 1.1 | - | - | 0.9 | 0.7 | 2.4 | 3.6 | - | - |

| Palmitic | C16:0 | 43.0 | 10.9 | 2.8 | 7.0 | 6.1 | 9.7 | 25.9 | 11.8 | 17.7 | 2.6 | 9.7 | 14.7 | 36.6 | 24.1 | 24.4 | 14.9 | 7.2 | 1.6 |

| Palmitoleic | C16:1 | - | 0.1 | 0.3 | 0.1 | - | 0.1 | 0.3 | 0.1 | 0.8 | - | - | 0.3 | 0.2 | 5.7 | 2.7 | 1.0 | 24.5 | 10.1 |

| Margaric | C17:0 | - | 0.1 | - | - | - | - | - | - | - | - | - | - | - | 0.2 | 0.9 | - | - | - |

| Stearic | C18:0 | 4.6 | 4.2 | 1.3 | 4.5 | 2.5 | 2.8 | 1.7 | 2.1 | 6.4 | 5.1 | 7.1 | 13.2 | 4.2 | 6.4 | 19.1 | 28.1 | 9.5 | 4.3 |

| Oleic | C18:1 | 40.0 | 25.0 | 64.4 | 18.7 | 29.6 | 6.8 | 15.9 | 27.3 | 41.8 | 45.8 | 52.4 | 46.1 | 42.4 | 41.4 | 41.7 | 5.4 | 11.6 | 16.8 |

| Linoleic | C18:2 | 10.1 | 52.7 | 22.3 | 67.5 | 59.2 | 2.2 | 55.1 | 57.6 | 32.9 | 31.5 | 16.5 | 24.7 | 9.9 | 18.8 | 5.9 | 1.1 | 3.2 | 1.2 |

| Linolenic | C18:3 | 0.3 | 6.2 | 7.3 | 0.8 | 0.7 | - | 0.2 | 0.6 | 0.2 | 6.1 | 5.2 | 0.2 | 0.2 | 1.1 | 0.7 | - | 0.7 | 1.1 |

| Arachidic | C20:0 | 0.4 | 0.3 | 0.6 | 0.4 | - | 0.1 | 0.2 | 0.3 | 0.1 | - | - | 0.8 | 0.3 | 0.1 | 0.4 | 32.4 | - | - |

| Eicosenoic | C20:1 | - | 0.1 | 1.0 | 0.1 | - | - | 0.1 | 0.3 | - | - | 3.5 | - | 0.2 | 0.4 | 0.5 | 1.9 | - | - |

| Eicosadienoic | C20:2 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | 1.0 | - | - |

| Eicosatetraenoic | C20:4 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | 1.9 | 0.6 |

| Eicosapentaenoic | C20:5 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | 5.3 | 1.7 |

| Behenic | C22:0 | - | 0.3 | - | 0.7 | - | - | 0.1 | - | - | - | 4.2 | - | - | 0.3 | 0.03 | 6.7 | - | - |

| Erucic | C22:1 | - | - | - | - | - | - | - | - | - | - | - | - | - | 0.4 | 0.06 | - | - | - |

| Docosapentaenoic | C22:5 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | 8.1 | 0.9 |

| Docosahexaenoic | C22:6 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | 6.2 | 0.7 |

| Total saturated (wt%) | 49.2 | 15.9 | 4.7 | 12.7 | 8.6 | 90.4 | 28.6 | 14.2 | 24.3 | 8.9 | 22.4 | 28.7 | 42.4 | 32.1 | 47.7 | 89.6 | 26.5 | 8.9 | |

| Total unsaturated (wt%) | 50.4 | 84.1 | 95.3 | 87.2 | 89.5 | 9.2 | 71.5 | 85.8 | 75.7 | 83.5 | 77.6 | 71.3 | 52.8 | 67.8 | 51.5 | 9.4 | 61.5 | 33.1 | |

| Total mono-unsaturated (wt%) | 40.0 | 25.2 | 65.7 | 18.9 | 29.6 | 6.9 | 16.3 | 27.6 | 42.6 | 45.8 | 55.9 | 46.4 | 42.7 | 47.9 | 44.8 | 8.3 | 36.1 | 26.9 | |

| Total poly-unsaturated (wt%) | 10.4 | 58.9 | 29.6 | 68.3 | 59.9 | 2.2 | 55.2 | 58.2 | 33.1 | 37.6 | 21.8 | 24.9 | 10.1 | 19.9 | 6.6 | 1.1 | 25.4 | 6.2 | |

| Pour point (°C) | 6 | −3.2 | −11 | −2 | −12 | −3.8 | −0.2 | −5.1 | 2 | −6.2 | 1 | 13 | −6.5 | 4.4 | 10 | −9 | n.a. | n.a. | |

| Cloud point (°C) | 6 | 0 | −3.5 | 1.3 | n.a. | −1.2 | 1.2 | −3 | 3 | 5.8 | 6 | 12 | n.a. | 7.5 | 13.8 | −3 | 6.2 | 10.6 | |

| CFPP (°C) | 4 | −2 | −11.3 | −2 | −11 | −4.7 | 4.8 | −7.5 | n.a. | n.a. | −7 | 11 | n.a. | 2.7 | 12.2 | n.a. | n.a. | n.a. | |

| Oxidation stability (h) | 20.3 | 4.08 | 7.4 | 1.3 | 1.4 | 11 | 1.8 | 3 | 3.1 | 15.5 | 4.1 | 6.1 | 3 | 8.7 | 0.45 | n.a. | n.a. | n.a. | |

| Cetane number | 61.2 | 51.8 | 54.1 | 51.9 | 54.8 | 61 | 53.3 | 52.5 | 53.5 | 54.4 | 55.4 | n.a. | 56.2 | 57 | 60.9 | 70 | 46.2 | 46.2 | |

| Reference | [54,69] | [13,69] | [13,69] | [13,69] | [64] | [69] | [69] | [69] | [85] | [33] | [32,69] | [91] | [69,129] | [69] | [69] | [146] | [145] | [145] | |

Notes: P—palm; S—soybean; R—rapeseed; SN—sunflower; SF—safflower; CN—coconut; CS—cottonseed; C—corn; J—jathropha; JB—jojoba; K—karanja; CI—polanga (Calophyllum inophyllum); UC—used cooking oil; CF—chicken fat; BT—beef tallow; MS—microalgae Spirulina platensis; MC—microalgae Chlorella vulgaris; MT—microalgae Tetraselmis chuii; n.a.—not available.

3. Cold Flow Properties of Biodiesel

3.1. Parameters of Cold Flow Properties

Cold flow properties (CFPs) of biodiesel are defined as behaviors or characteristics of biodiesel flow in low-temperature condition [174]. These properties are commonly indicated by the parameters of pour point, cloud point, and cold filter plugging point. Pour point (PP) is a physical property used to measure the lowest temperature at which the fuel can still flow from one point to another [175]. Starting at this point and lower, the crystalline solids are agglomerated to form a gel phase; thus, the fuel loses its fluidity and stops flowing [13,69]. It is commonly related to the freezing or melting point of a fluid mixture [7]. The international standard testing procedures of the pour point parameter are ASTM D97 and EN ISO 3016 [13,20].

Cloud point (CP) is the temperature at which the formation of a crystalline solid starts to show a cloudy appearance after being exposed to low temperature [175]. In other words, the wax crystals formed by low temperature exposure begin to be visible at this point [13]. Below this point, molecule solidification will be greater and more crystals are created. Consequently, it increases fuel viscosity and significantly reduces its pumping ability [175]. The CP parameter can be determined using ASTM D2500 as a standard testing procedure [17,18,19].

Cold filter plugging point (CFPP) is a cold flow property used to indicate the lowest temperature at which a certain volume of biodiesel (20 mL) successfully flows through a standard filter (4.5 × 10−2 mm) in a specified flow time (≤60 s) [13]. An operating temperature below this point causes clogging in filtration devices. This parameter is widely used to accurately evaluate the low-temperature flow performance of biodiesel [7]. The CFPP parameter can be quantified using ASTM D6371 and EN 116 as international standard testing procedures [174].

3.2. Effect of Fatty Acid Profiles on Cold Flow Properties

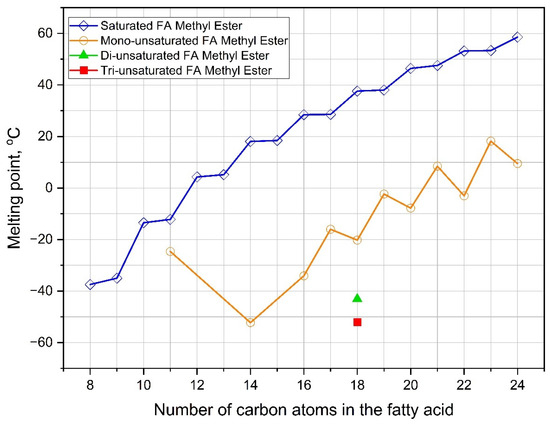

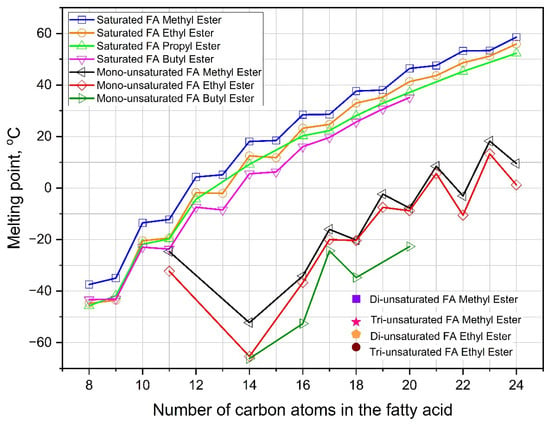

The variety of fatty acid profiles in the parent oil feedstocks experimentally has effects on the low-temperature flow behavior of biodiesel. As shown in Table 4, the biodiesel with a high SFA content has problems regarding the cold flow properties. The values of PP, CP, and/or CFPP are too high. This correlation can be seen in palm biodiesel (P), polanga biodiesel (CI), chicken fat biodiesel (CF), beef tallow biodiesel (BT), microalgae Chlorella vulgaris biodiesel (MC), and microalgae Tetraselmis chuii biodiesel (MT). On the other hand, biodiesel having a high UFA content provides better cold flow behavior, such as soybean biodiesel (S), rapeseed biodiesel (R), sunflower biodiesel (SN), safflower biodiesel (SF), corn biodiesel (C), and jojoba biodiesel (JB). To ensure this correlation, the melting data comparison of primary saturated and unsaturated fatty acid methyl esters (FAMEs) is shown in Table 5. As previously discussed, the pour point of a component can refer to its melting point [7]. For the same carbon chain, the unsaturated FAME component has a significantly lower melting point than the saturated component. Moreover, the greater number of double bonds also provides a lower melting point or better cold flow properties. Therefore, the higher SFA content promotes poor cold flow properties, and vice versa.

Table 5.

Data tabulation of additive effects on the biodiesel cold flow properties.

Table 5.

Data tabulation of additive effects on the biodiesel cold flow properties.

| Biodiesel | Additives | PP (°C) | CP (°C) | CFPP (°C) | Ref. | ||||

|---|---|---|---|---|---|---|---|---|---|

| Before | After | Before | After | Before | After | ||||

| Palm biodiesel | B100 | Diethyl ether (5 vol%) | 16 | 10 | - | - | - | - | [176] |

| Ethanol (5 vol%) | 16 | 11 | - | - | - | - | |||

| n-butanol (5 vol%) | 16 | 12 | - | - | - | - | |||

| Palm biodiesel | B100 | Glycerol ketals (5 vol%) | 14 | 9 | 16 | 11 | - | - | [177] |

| Glycerol acetates (5 vol%) | 14 | 9 | 16 | 11 | - | - | |||

| Palm fatty acid isopropyl esters (5 vol%) | 14 | 10 | 16 | 11 | - | - | |||

| Palm fatty acid isobutyl esters (5 vol%) | 14 | 10 | 16 | 12 | - | - | |||

| Palm fatty acid 2-butyl esters (5 vol%) | 14 | 8 | 16 | 10 | - | - | |||

| Palm biodiesel | B100 | Ozonized palm oil (1 wt%) | 12 | 10 | 18 | 12 | - | - | [178] |

| Ozonized sunflower oil (1 wt%) | 12 | 11 | 18 | 13 | - | - | |||

| Ozonized soybean oil (1 wt%) | 12 | 13 | 18 | 13 | - | - | |||

| Ozonized rapeseed oil (1 wt%) | 12 | 13 | 18 | 13 | - | - | |||

| Soybean biodiesel | B100 | Oleyl alcohol (10 wt%) | - | - | 0 | −4 | - | - | [179] |

| Tert-butyl alcohol (10 wt%) | - | - | 0 | −4 | - | - | |||

| Soybean biodiesel | B10 | Tetradecyl methacrylate-citric anhydride-styrene co-polymer (0.15 wt%) | −13 | −24 | 0 | −3 | −1 | −8 | [180] |

| B20 | Tetradecyl methacrylate-citric anhydride-styrene co-polymer (0.15 wt%) | −13 | −23 | 1 | −3 | −1 | −9 | [180] | |

| B30 | Tetradecyl methacrylate-citric anhydride-styrene co-polymer (0.15 wt%) | −12 | −22 | 1 | −3 | 0 | −10 | ||

| Soybean biodiesel | B100 | Ozonized palm oil (1 wt%) | −2 | −10 | 1 | −2 | - | - | [178] |

| Ozonized sunflower oil (1 wt%) | −2 | −9 | 1 | 1 | - | - | |||

| Ozonized soybean oil (1 wt%) | −2 | −12 | 1 | 1 | - | - | |||

| Ozonized rapeseed oil (1 wt%) | −2 | −11 | 1 | −1 | - | - | |||

| Rapeseed biodiesel | B100 | Ozonized palm oil (1 wt%) | −13 | −10 | −4 | −6 | - | - | [178] |

| Ozonized sunflower oil (1 wt%) | −13 | −30 | −4 | −6 | - | - | |||

| Ozonized soybean oil (1 wt%) | −13 | −28 | −4 | −4 | - | - | |||

| Ozonized rapeseed oil (1 wt%) | −13 | −30 | −4 | −3 | - | - | |||

| Canola biodiesel | B100 | Oleyl alcohol (10 wt%) | - | - | −13 | −18 | - | - | [179] |

| Tert-butyl alcohol (10 wt%) | - | - | −13 | −16 | - | - | |||

| Sunflower biodiesel | B100 | Ozonized palm oil (1 wt%) | −5 | −15 | 1 | −2 | - | - | [178] |

| Ozonized sunflower oil (1 wt%) | −5 | −24 | 1 | 0 | - | - | |||

| Ozonized soybean oil (1 wt%) | −5 | −22 | 1 | 0 | - | - | |||

| Ozonized rapeseed oil (1 wt%) | −5 | −20 | 1 | 1 | - | - | |||

| Coconut biodiesel | B10 | Methyl acrylate polymer (0.03 wt%) | −13 | −21 | −3 | −11 | −5 | −16 | [181] |

| B20 | Methyl acrylate polymer (0.03 wt%) | −13 | −22 | −3 | −11 | −4 | −16 | ||

| B30 | Methyl acrylate polymer (0.03 wt%) | −10 | −12 | −3 | −7 | −4 | −9 | ||

| Polanga (Calophyllum inophyllum) biodiesel | B10 | Methyl acrylate polymer (0.03 wt%) | −2 | −9 | −1 | −5 | 0 | −8 | [181] |

| B20 | Methyl acrylate polymer (0.03 wt%) | 1 | −4 | 4 | −2 | 5 | −1 | ||

| B30 | Methyl acrylate polymer (0.03 wt%) | 4 | −3 | 7 | 1 | 5 | −2 | ||

| Used cooking biodiesel | B100 | Methyl acrylate polymer (0.04 wt%) | −11 | −19 | −8 | −9 | −9 | −15 | [182] |

| Ethylene vynil acetate co-polymer (0.04 wt%) | −11 | −17 | −8 | −8 | −9 | −11 | |||

| α-olefin polymer (0.04 wt%) | −11 | −14 | −8 | −9 | −9 | −10 | |||

| Maleic anhydride polymer (0.08 wt%) | −11 | −11 | −8 | −9 | −9 | −10 | |||

| Used cooking biodiesel | B100 | α-olefin polymer (0.06 wt%) | 5 | 2 | 7 | 5 | 6 | 3 | [183] |

| B20 | α-olefin polymer (0.04 wt%) | −10 | −17 | −2 | −9 | −1 | −11 | ||

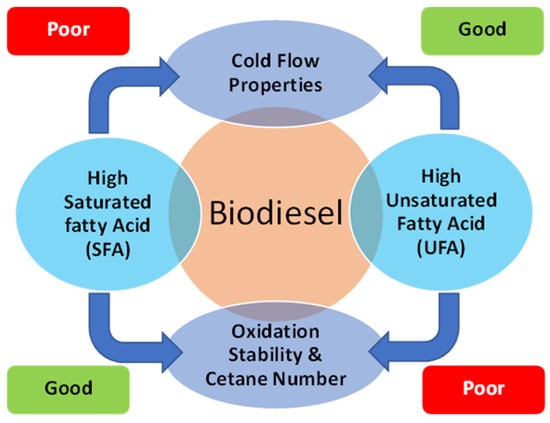

Nevertheless, the fatty acid composition inversely influences the oxidation stability and cetane number properties. Oxidation stability is a major physical property that indicates the potential reactivity with oxygen, which can change the fuel properties [91]. Meanwhile, the cetane number is used to identify the auto-ignition and ignition delay of the fuel [69]. According to the data in Figure 6, biodiesel having a higher SFA content leads to longer oxidation stability and a higher cetane number. In comparison, biodiesel dominated by UFA content has lower oxidation stability and a lower cetane number. The higher unsaturation degree will also cause lower oxidation stability and a lower cetane number [7]. The summary of fatty acid composition effects on biodiesel cold flow properties, oxidation stability, and cetane number is visualized in Figure 7.

Figure 6.

Melting point comparison of major saturated and unsaturated FAMEs from vegetable oils [7,184].

Figure 7.

Effect of fatty acid composition on biodiesel cold flow properties, oxidation stability, and cetane number (adapted from [185]).

3.3. Influence of Cold Flow Properties on Biodiesel Application

Cold flow properties (CFPs) have a prominent meaning for biodiesel application. These properties provide normal diesel fuel combustion, especially in low-temperature areas [169]. The utilization of low-CFP biodiesel, more SFA content, and less UFA content, in a low-temperature environment, will promote some operability problems in terms of molecule crystallization, causing blockages in the fuel flow line, filter, or injector [13]. It also becomes thicker and loses its flow characteristic [186]. This situation inhibits fuel supply into the combustion chamber, causing significant losses in power output, fuel consumption efficiency, and initial engine starting ability in low-temperature conditions [13]. For long-term application, it causes wear in and even damage to the engine [186].

However, the low-CFP biodiesel with a high SFA content has good oxidation stability and cetane number properties [7]. High oxidation stability provides more stable fuel and prevents property changes during distribution, storage, and use [169]. Fuel with a high cetane number ensures normal ignition time (the required time to start the combustion after fuel injection) [69]. Often, a high cetane number is correlated with the lower NOx emissions [69,169].

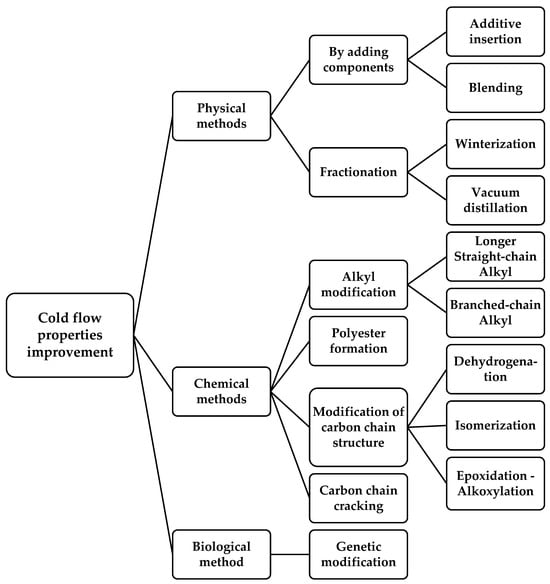

4. Methods for Improving Cold Flow Properties

The biodiesel that has problems associated with cold flow properties requires treatments to improve its quality and enable its application in a higher percentage of commercial fuel. As mentioned in the previous section, the main reason for this is the high SFA content in biodiesel products. Generally, the proposed methods for improving cold flow properties can be classified into three categories: (i) physical methods; (ii) chemical methods; and (iii) biological methods. Then, these categories can be divided into several sub-categories based on the process. The detailed classification chart of methods used to improve cold flow properties is depicted in Figure 8.

Figure 8.

Classification chart of methods used to improve cold flow properties.

4.1. By Adding Components

4.1.1. Additive Insertion

This method is implemented by adding chemical compounds in small amounts to biodiesel to prevent the plugging phenomenon in the diesel engine system. The selection stage of additives also needs to consider the negative effects on the other physical parameters, such as fuel kinematic viscosity and density, to maintain biodiesel quality [13,174]. There are two types of additives proposed for improving cold flow properties: pour point depressant and wax crystalline modifier [187]. The first mentioned additive category has the function of inhibiting crystal enlargement at low temperatures, thereby preventing agglomerate formation [174]. The second additive type is mixed with biodiesel to obstruct the organization of formed crystals at low temperatures [13]. In other words, this compound becomes a shield between crystalline solids, avoiding gel formation and maintaining the flow ability of the fuel.

In this method, the additives commonly used to improve cold flow properties are non-aromatic chemicals with a low freezing point and low molecular weight [13,179]. Based on these characteristics, numerous potential chemical groups have been evaluated as additives: short-chain alcohols [179], low-molecular-weight co-polymers [180,181,182], glycerol derivatives [177], fatty acid branched-chain alkyl esters [177], branched fatty acid alkyl esters [188], diethyl ether [176], and ozonized vegetable oils [178]. The effects of these proposed additives on the cold flow properties of various fatty esters are tabulated in Table 5. According to Table 5, low-molecular-weight polymers and co-polymers show the best performance in terms of improving biodiesel cold flow properties. The addition of a small amount of these components, in the range of 0.03–0.15 wt%, significantly decreases PP, CP, and CFPP of biodiesel. Meanwhile, short-chain alcohols and diethyl ether must be mixed with biodiesel in an amount of at least 5 wt% to achieve a remarkable impact.

4.1.2. Blending

Blending is proposed to mix poor-CFP biodiesel with good-CFP components in a certain ratio. It is the simplest method used to elevate cold flow properties of biodiesel. Primarily, the blending component is a biodiesel with a high UFA content [189]. The utilization of high-UFA biodiesel as a blending agent is not without problems. Based on the reciprocal effect of SFA and UFA components, mixing poor- and good-CFP biodiesel needs optimization to control the negative elevation of oxidation stability and the cetane number [13]. Besides that, biodiesel cold flow properties can also be lifted using fossil diesel or kerosene; however, this reduces the sustainability and environmentally friendly aspect of biodiesel products [190]. Then, other chemicals used for blending agents are short-chain fatty acid methyl ester [174], branched-chain fatty acid methyl ester [188], fatty acid longer-chain alkyl ester [184], and short-chain alcohol [191]. The effects of these proposed blending agents on the cold flow properties of various fatty esters are presented in Table 6. According to Table 6, the utilization of blending agents successfully decreases the value of PP, CP, and/or CFPP with various degrees of effectiveness. Different from others, the application of branched-chain saturated fatty acid methyl ester shows minimum effects on the other physical properties. This is because branched-chain saturated fatty acid methyl ester provides better cold flow properties than its parent compound, but it presents an insignificant change in oxidation stability and the cetane number [188]. However, the commercial production of this component still requires further technological development and feasibility evaluation.

Table 6.

Data tabulation of blending agent effects on the biodiesel cold flow properties.

Table 6.

Data tabulation of blending agent effects on the biodiesel cold flow properties.

| Biodiesel | Blending Agent | PP (°C) | CP (°C) | CFPP (°C) | Ref. | |||

|---|---|---|---|---|---|---|---|---|

| Before | After | Before | After | Before | After | |||

| Palm biodiesel | Soybean biodiesel (20 wt%) | - | - | - | - | 10 | 8 | [192] |

| Soybean biodiesel (40 wt%) | - | - | - | - | 10 | 5 | ||

| Soybean biodiesel (60 wt%) | - | - | - | - | 10 | 0 | ||

| Rapeseed biodiesel (20 wt%) | - | - | - | - | 10 | 7 | ||

| Rapeseed biodiesel (40 wt%) | - | - | - | - | 10 | 2 | ||

| Rapeseed biodiesel (60 wt%) | - | - | - | - | 10 | −3 | ||

| Soybean biodiesel (20 wt%) Rapeseed biodiesel (20 wt%) | - | - | - | - | 10 | 3 | ||

| Soybean biodiesel (40 wt%) Rapeseed biodiesel (20 wt%) | - | - | - | - | 10 | −2 | ||

| Soybean biodiesel (20 wt%) Rapeseed biodiesel (40 wt%) | - | - | - | - | 10 | −3 | ||

| Palm biodiesel | Methyl iso-stearat (25 wt%) | 16.7 | 10.3 | 14.2 | 8.6 | - | - | [188] |

| Methyl iso-stearat (50.1 wt%) | 16.7 | 4 | 14.2 | 3.1 | - | - | ||

| Methyl iso-oleat (25 wt%) | 16.7 | 11 | 14.2 | 8.7 | - | - | ||

| Methyl iso-oleat (49.8 wt%) | 16.7 | 4 | 14.2 | 2.2 | - | - | ||

| Soybean biodiesel | Rapeseed biodiesel (20 wt%) | - | - | - | - | −3 | −2 | [192] |

| Rapeseed biodiesel (40 wt%) | - | - | - | - | −3 | −4 | ||

| Rapeseed biodiesel (60 wt%) | - | - | - | - | −3 | −8 | ||

| Soybean biodiesel | Methyl iso-stearat (25 wt%) | 0.3 | −4.3 | 0.6 | −3.5 | - | - | [188] |

| Methyl iso-stearat (50 wt%) | 0.3 | −10 | 0.6 | −7.3 | - | - | ||

| Methyl iso-oleat (25 wt%) | 0.3 | −4 | 0.6 | −3.4 | - | - | ||

| Methyl iso-oleat (49.8 wt%) | 0.3 | −9.7 | 0.6 | −7.3 | - | - | ||

| Canola biodiesel | Methyl iso-stearat (24.7 wt%) | −10.7 | −14.7 | −2.5 | −5.7 | - | - | [188] |

| Methyl iso-stearat (49.8 wt%) | −10.7 | −17 | −2.5 | −10.1 | - | - | ||

| Methyl iso-oleat (24.9 wt%) | −10.7 | −18 | −2.5 | −5.7 | - | - | ||

| Methyl iso-oleat (48.5 wt%) | −10.7 | −27 | −2.5 | −8.7 | - | - | ||

| Rapeseed biodiesel | N-butanol (10 vol%) | - | - | −6 | −7 | −10 | −11 | [191] |

| N-butanol (20 vol%) | - | - | −6 | −8 | −10 | −13 | ||

| N-butanol (50 vol%) | - | - | −6 | −9 | −10 | −17 | ||

| Rapeseed biodiesel (butyl esters) | N-butanol (10 vol%) | - | - | −7 | −8 | −14 | −16 | [191] |

| N-butanol (20 vol%) | - | - | −7 | −8 | −14 | −16 | ||

| N-butanol (50 vol%) | - | - | −7 | −9 | −14 | −17 | ||

| Jatropha biodiesel | Petro-diesel (20 vol%) | 18 | 16.5 | 20.2 | 17 | - | - | [193] |

| Petro-diesel (40 vol%) | 18 | 15.5 | 20.2 | 17 | - | - | ||

| Petro-diesel (60 vol%) | 18 | 15 | 20.2 | 15.5 | - | - | ||

| Kerosene (20 vol%) | 18 | 14 | 20.2 | 15 | - | - | ||

| Kerosene (40 vol%) | 18 | 10 | 20.2 | 12 | - | - | ||

| Kerosene (60 vol%) | 18 | 7 | 20.2 | 8 | - | - | ||

| Used cooking palm biodiesel | Used cooking coconut biodiesel (50 vol%) | 12 | 4 | 13 | 5 | - | - | [194] |

| Used cooking sunflower biodiesel (50 vol%) | 12 | 3 | 13 | 4 | - | - | ||

4.2. Fractionation

4.2.1. Cold Fractionation (Winterization)

Cold fractionation, or commonly called winterization, is a method used to separate components in a mixture based on the melting point differences of its components [195]. This process is carried out by cooling biodiesel slowly until reaching a desired temperature (crystallization temperature) and filtering it into split solid and liquid phases [13]. The solid phase consists of higher-melting-point or poor-CFP components, which are associated with saturated fatty esters [174]. In contrast, the liquid phase is dominated by lower-melting-point or good-CFP components, which are identical to unsaturated fatty acid alkyl esters [196]. By removing saturated fatty esters, the biodiesel product is expected to have better cold flow properties than the crude product. However, the main adverse effects of winterization are loss in biodiesel yield, reduction in oxidation stability, and downgrade in the cetane number [13,193]. The latter effect directly corresponds to diesel engine performance in terms of poorer ignitability and higher NOx emissions [169,187].

Biodiesel winterization can be conducted with or without additional chemicals. Dry winterization is operated naturally without additional chemicals. This process typically requires a longer time and produces a lower yield [187]. The other methods are detergent and solvent winterization [174,197]. They use detergent and solvent, respectively, as additional chemicals to enhance the winterization process. Both chemicals play roles in separating the trapped liquid from solids and elevating liquid-phase recovery in low-temperature exposure [198]. The detailed effects of the winterization process on improving biodiesel cold flow properties are summarized in Table 7.

Table 7.

Data tabulation of winterization effects on the biodiesel cold flow properties.

Table 7.

Data tabulation of winterization effects on the biodiesel cold flow properties.

| Biodiesel | Winterization Agent | PP (°C) | CP (°C) | CFPP (°C) | Biodiesel Yield (wt%) | Ref. | |||

|---|---|---|---|---|---|---|---|---|---|

| Before | After | Before | After | Before | After | ||||

| Palm biodiesel | No agent | 7 | 5.5 | 7.5 | 6.5 | - | - | 65.5 | [199] |

| Palm biodiesel | Sorbitan palmitate (0.5 wt%) | - | - | 16 | 8.5 | - | - | 74.4 | [200] |

| Palm biodiesel-like mixture | Sorbitan palmitate (1 wt%) | - | - | 17 | 10 | - | - | 41.6 | [198] |

| Sorbitan monostearate (0.75%) | - | - | 17 | 12 | - | - | 73.4 | ||

| Sorbitan tristearate (1 wt%) | - | - | 17 | 11 | - | - | 50.5 | ||

| L-ascorbyl palmitate (1 wt%) | - | - | 17 | 14 | - | - | 42.9 | ||

| L-ascorbyl di-palmitate (1 wt%) | - | - | 17 | 16 | - | - | 35.6 | ||

| Cholesterol palmitate (1 wt%) | - | - | 17 | 16 | - | - | 56.9 | ||

| Soybean biodiesel | No agent | −2 | −21 | −0.3 | −20 | - | - | 33.4 | [201] |

| Isopropanol (0.2 wt%) | −2 | −9 | −0.3 | −8.7 | - | - | 86.0 | ||

| n-hexane (0.2 wt%) | −2 | −11.3 | −0.3 | −10.3 | - | - | 78.4 | ||

| Soybean biodiesel | Sorbitan palmitate (0.5 wt%) | - | - | −1.5 | −4.5 | - | - | 76.6 | [200] |

| Rice biodiesel | Sorbitan palmitate (0.5 wt%) | - | - | 1 | 0 | - | - | 23.1 | [200] |

| Cottonseed biodiesel | Sorbitan palmitate (0.5 wt%) | - | - | 1.5 | −4 | - | - | 46.0 | [200] |

| Jatropha biodiesel | No agent | 18 | 16.5 | 20.2 | 17.8 | - | - | - | [193] |

| Karanja biodiesel | No agent | 9 | 3 | 16 | 9 | - | - | 91.33 | [196] |

| Peanut biodiesel | No agent (one stage) | 15 | −3 | 20 | 12 | 17 | 6 | 91.46 | [202] |

| No agent (three stages) | 15 | −3 | 20 | 2 | 17 | −3 | 90.51 | ||

| Methanol (mass ratio 4:1; one stage) | 15 | −6 | 20 | 0 | 17 | −8 | 91.07 | ||

| Used cooking biodiesel | No agent | 13.7 | 10.6 | 14.5 | 11.5 | - | - | - | [193] |

| Used cooking biodiesel | Sodium dodecylsulfate (0.3 wt%) Magnesium sulfate (1 wt%) | - | - | - | - | −10 | −17 | 73.1 | [197] |

4.2.2. Vacuum Distillation

Distillation is a separation method used to purify products from impurities by utilizing vapor pressure (corresponds to volatility) or boiling point differences of components [203]. This method can be implemented to modify fatty ester composition in biodiesel and obtain better cold flow properties [204]. The desired components are unsaturated fatty esters, which have a lower melting point and higher boiling point than the unfavorable saturated fatty esters [205]. However, the characteristics of these unsaturated components are lower oxidation stability and a lower cetane number than in their saturated form. Hence, implementation of this process requires optimization of saturated fatty ester removal.

Application of this process at atmospheric pressure is hampered by the high boiling point of fatty esters, rendering high energy consumption and low energy efficiency. Besides that, high temperature distillation above 200 °C potentially degrades fatty esters before thermal separation occurs, causing a significant alteration in the physical properties of biodiesel [205,206,207]. To overcome these problems, vacuum distillation is then proposed to provide a lower operating temperature. The lower temperature condition is associated with a reduction in energy consumption, but it is not linear. This process still requires additional energy for negative-pressure conditioning, but its energy requirement is relatively smaller than that required for high-temperature heating. Moreover, the application of vacuum distillation can also minimize fatty ester decomposition [205]. This ensures that there are no drastic changes in the physical properties of biodiesel.

Finally, this method is reported to be able to improve biodiesel CFP. As presented in Table 8, vacuum application in the distillation is verified to decrease PP, CP, and/or CFPP. Yeong et al. proved that vacuum distillation alleviated PP, CP, and CFPP of palm fatty acid distillate biodiesel by 6–8 °C [205]. Iakovlieva et al. applied vacuum conditions to distill rapeseed biodiesel with PP depression up to 2 °C [207]. Furthermore, Table 8 also shows that the negative-pressure implementation reduces the operating temperature to the range of 165–259 °C. Normally, biodiesel distillation is carried out at temperature above 332 °C to separate methyl palmitate from biodiesel [206], whereas methyl stearate removal requires a distillation temperature of more than 353 °C at atmospheric pressure. In the future, temperature and pressure optimization will be two major topics for further development of vacuum distillation for biodiesel CFP refinement [206].

Table 8.

Results of vacuum distillation applications for improving cold flow properties.

Table 8.

Results of vacuum distillation applications for improving cold flow properties.

| Biodiesel | Pressure (kPa) | Temperature (°C) | PP (°C) | CP (°C) | CFPP (°C) | Biodiesel Yield (wt%) | Ref. | |||

|---|---|---|---|---|---|---|---|---|---|---|

| Before | After | Before | After | Before | After | |||||

| Rapeseed biodiesel (methyl ester) | 0.4–0.7 | 165–215 | −16 | −18.5 | - | - | - | - | - | [207] |

| Rapeseed biodiesel (ethyl ester) | 0.4–0.7 | 165–215 | −17 | −19 | - | - | - | - | - | [207] |

| Palm fatty acid distillate (PFAD) biodiesel | 1 | 194.8 | 15 | 9 | 20 | 13 | 19 | 11 | 59.6 | [205] |

| Microalgae Nannochloropsis oceania biodiesel | 5 | 255–259 | - | - | - | - | - | 5 | 57.8 | [204] |

4.3. Alkyl Modification

Generally, a fatty ester molecule is composed of a fatty acid and short-chain alkyl from methyl or ethyl alcohol. The application of this fatty ester typically does not cause any problems in a small-percentage mixture and a room-temperature environment. However, it will be a serious obstacle when running with a high-level content and in cold conditions [13]. One solution is to replace methanol or ethanol as transesterification reactants with longer straight- or branched-chain alcohols [174]. Some of the proposed longer straight-chain alcohols are 1-propanol and 1-butanol. According to Figure 9 and Table 9, fatty ester products from these alcohols have a lower melting point than methyl or ethyl esters. Meanwhile, the limit of the alcohol carbon chain length is four atoms, because alcohols with more carbon atoms potentially promote fatty esters having a higher pour point [169]. This phenomenon, in which n-butyl ester has a lower PP than n-pentyl ester, is also presented in Table 9. Other benefits of using longer carbon chain alcohols are improving oxidation stability [208], elevating fuel ignitability [174], reducing heat emission [169], and suppressing smoke generation [169]. However, the weaknesses of using these alcohols are greater expense [13], higher ester viscosity [209,210], lower reactivity during transesterification [174], and more coke formation in the fuel injector [169]. The third weakness correlates with increasing concerns regarding monoglycerol content in the biodiesel product [209].

Figure 9.

Melting points of various fatty acid straight-chain alkyl esters [7,184].

Furthermore, the prospective reactants from branched-chain alcohol moieties are isopropanol, 2-butanol, isobutanol, and isopentanol. As demonstrated in Table 9, the utilization of these alcohols as reactants in biodiesel production successfully decreases PP, CP, and/or CFPP. In other words, this alcohol group renders better low-temperature fluidity than methanol and ethanol. Nonetheless, it potentially deteriorates oxidation stability and cetane number [211]. Other potential frailties of branched-chain alcohols are the same as those of the straight-chain moiety in terms of commodity price [13], viscosity of ester products [209,210], reactivity [174], and coke formation [169]. Even though they both have shortcomings in terms of reactivity, the branched-chain alcohol is still better than the straight-chain alcohols [174], while the other comparable weaknesses are almost the same for both alcohols.

Table 9.

Results of alkyl modification for improving cold flow properties.

Table 9.

Results of alkyl modification for improving cold flow properties.

| Feedstock | Alcohol | Alkyl Ester | PP (°C) | CP (°C) | CFPP (°C) | Ref. |

|---|---|---|---|---|---|---|

| Palm oil | Methanol | Methyl ester | 14 | - | - | [209] |

| Ethanol | Ethyl ester | 8 | - | - | ||

| n-propanol | n-propyl ester | 6 | - | - | ||

| n-butanol | n-butyl ester | 4 | - | - | ||

| Isobutanol | Isobutyl ester | 0 | - | - | ||

| n-pentanol | n-pentyl ester | 4 | - | - | ||

| Isopentanol | Isopentyl ester | 2 | - | - | ||

| n-hexanol | n-hexyl ester | 6 | - | - | ||

| n-heptanol | n-heptyl ester | 10 | - | - | ||

| n-octanol | noctyl ester | 12 | - | - | ||

| Palm oil | Methanol | Methyl ester | 12 | 16 | - | [212] |

| Isopropanol | Isopropyl ester | −3 | 6 | - | ||

| 2-butanol | 2-butyl ester | −6 | 7 | - | ||

| Isobutanol | Isobutyl ester | −3 | 7 | - | ||

| Isopentanol | Isopentyl ester | −9 | 8 | - | ||

| Soybean oil | Methanol | Methyl ester | - | 0 | - | [213] |

| Isopropanol | Isopropyl ester | - | −10 | - | ||

| Soybean oil | Methanol | Methyl ester | −3 | −2 | - | [214] |

| Ethanol | Ethyl ester | −6 | −2 | |||

| Isopropanol | Isopropyl ester | −12 | −9 | - | ||

| 2-butanol | 2-butyl ester | −15 | −12 | |||

| Soybean oil | Methanol | Methyl ester | −2 | 0 | - | [187] |

| Ethanol | Ethyl ester | −4 | 1 | - | ||

| Isopropanol | Isopropyl ester | −12 | −9 | - | ||

| n-butanol | n-butyl ester | −7 | −3 | - | ||

| 2-butanol | 2-butyl ester | −15 | −12 | - | ||

| Rapeseed oil | Methanol | Methyl ester | −9 | −4 | −14 | [211] |

| Ethanol | Ethyl ester | −15 | −1 | −6 | ||

| Biobutanol | Butyl ester | −18 | −8 | −21 | ||

| Canola oil | Methanol | Methyl ester | −9 | 1 | - | [187] |

| Ethanol | Ethyl ester | −6 | −1 | - | ||

| Isopropanol | Isopropyl ester | −12 | 7 | - | ||

| n-butanol | n-butyl ester | −16 | −6 | - | ||

| Safflower oil | Methanol | Methyl ester | −6 | - | - | [187] |

| Ethanol | Ethyl ester | −6 | −6 | - | ||

| Sunflower oil | Methanol | Methyl ester | −3 | 2 | - | [187] |

| Ethanol | Ethyl ester | −5 | −1 | - | ||

| Beef tallow | Methanol | Methyl ester | 15 | 17 | - | [187] |

| Ethanol | Ethyl ester | 12 | 15 | - | ||

| n-propanol | n-propyl ester | 9 | 12 | - | ||

| Isopropanol | Isopropyl ester | 0 | 8 | - | ||

| n-butanol | n-butyl ester | 6 | 9 | - | ||

| Isobutanol | Isobutyl ester | 3 | 8 | - | ||

| Waste cooking oil | Methanol | Methyl ester | 2 | −3 | −3 | [211] |

| Ethanol | Ethyl ester | −0.5 | −3 | −1 | ||

| Biobutanol | Butyl ester | −8 | −3 | −9 |

4.4. Polyester Formation

Polyester formation is a transesterification process used to transform monoester biodiesel into polyester biodiesel by using polyol as an additional reactant [215]. This method is the opposite to the common transesterification process used for biodiesel production. In general transesterification, triglyceride (polyester) reacts with alcohol to produce monoester as the main product and glycerol (polyol) as a by-product, whereas this process converts monoester and other polyols into polyester as the main product and alcohol as a by-product. Fundamentally, polyol is defined as a chemical compound that has more than one hydroxyl group (–OH), such as glycerol [174]. In this case, the desired polyols are glycerol analog compounds that have three hydroxyl groups, but they do not have β-hydrogen attached to the middle carbon of glycerol [216]. The absence of β-hydrogen elevates both molecule and thermal stability during oxidation [215]. Notably, thermal devastation due to the presence of β-hydrogen will potentially eliminate the ester group in the polyester, generating a free fatty acid and undesired ester (enol acetate) [216].

Figure 10 shows the overall reversible reaction formula of polyester formation from mono-fatty esters and polyol. In detail, the process of inserting the monoester into the polyol backbone takes place gradually, one-by-one. The appearance of alkyl (R4) instead of β-hydrogen in the β position is proven to enhance biodiesel cold flow properties. The evidence of the polyester effect on biodiesel cold fluidity is demonstrated in Table 10. Of all data available in Table 10, trymethylolpropane (TMP) is a polyol widely used for polyester production. This compound has an ethyl group attached to the middle polyol backbone [215]. The formation of trymethylolpropane ester (TMPE) from TMP and monoesters reduces the PP of biodiesel to below 0 °C. Other polyols that can be used to create polyester are pentaerythritil monomethyl ether, pentaerythritil monoethyl ether, pentaerythritil monobutyl ether, pentaerythritil monophenyl ether, and 3,3-bis(hydroxymethyl)-oxetane.

Figure 10.

Reaction scheme of polyester formation (adapted and modified from [174]).

Besides the astonishing results in pour point reduction and the benefits in terms of oxidation and thermal stability, polyester also presents a remarkable increase in kinematic viscosity [216]. According to Table 10, kinematic viscosities of polyester biodiesel exhibit an increase of up to ten times compared to those of the monoester biodiesel. Therefore, the polyester yield must be limited to a low value to minimize its negative impact on biodiesel quality. Another way is to use polyester as an additive or blending agent of biodiesel to refine cold flow properties.

Table 10.

Results of polyester formation for improving cold flow properties.

Table 10.

Results of polyester formation for improving cold flow properties.

| Feedstock | Polyol | PP (°C) | CP (°C) | Kinematic Viscosity at 40 °C (cSt) | Ref. |

|---|---|---|---|---|---|

| Palm oil | Trymethylolpropane | −1 | - | 49.7 | [217] |

| High oleic palm oil | Trymethylolpropane | −9–−37 | - | 45.5–50.7 | [217] |

| Canola oil | Trymethylolpropane | −66 | −27 | 40.5 | [218] |

| Palm kernel oil | Di-trymethylolpropane | −6 | - | 111.7 | [219] |

| Used cooking oil | Trymethylolpropane | −8 | - | 38.6 | [220] |

| Oleic acid | Trymethylolpropane | −51 | −21 | 48.9 | [218] |

| Oleic acid | Trymethylolpropane | −35 a | - | 47.4 | [216] |

| Pentaerythritil monophenyl ether | −19 a | - | 67.9 | ||

| Pentaerythritil monomethyl ether | −15 a | - | 47.8 | ||

| Pentaerythritil monoethyl ether | −35 a | - | 46.3 | ||

| Pentaerythritil monobutyl ether | −33 a | - | 45.9 | ||

| 3,3-bis(hydroxymethyl)-oxetane | −28 a | - | 35.4 |

Note: a melting point.

4.5. Modification of Carbon Chain Structure

4.5.1. Dehydrogenation

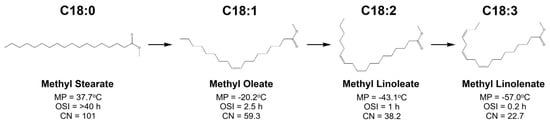

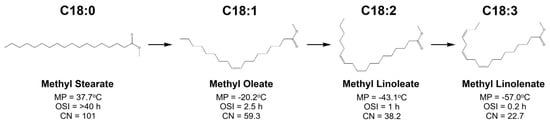

Dehydrogenation, usually called desaturation, is a hydrogen removal process used to create a double bond in the carbon chain or generate hydrocarbons having a greater unsaturation degree [7]. This process is specifically considered to lift biodiesel cold flow properties by transforming saturated fatty esters into unsaturated components, as visualized in Figure 11. Based on this chart, components having a greater unsaturation degree are favorable to meet a high level of cold flow properties. However, a higher unsaturated fatty ester content in biodiesel will contribute to a remarkable alleviation in the oxidation stability index (OSI) and cetane number (CN). Therefore, application of fatty ester desaturation to enhance biodiesel cold flow properties must be followed by refinement actions for both properties. Consequently, this will multiply production cost.

Based on the authors’ best effort, the reports on fatty ester dehydrogenation are inadequate. Macias et al. [221] conducted a catalytic reaction of methyl oleate using a mesoporous gallium-niodium oxide solid catalyst. This catalyst has driven isomerization, cracking, dehydrogenation, and dimerization reactions for a wide range of selectivity. The dehydrogenation reaction was detected at a reaction temperature of 220 °C, based on the presence of methyl linoleate and linolenate in the product. This was also indicated by positive iodine value differences between the products and feedstock. In this case, observational dehydrogenation successfully reduced the pour point of biodiesel. Additionally, this paper also concluded that dehydrogenation of biodiesel was inversely correlated with the acidity strength and the amount of impregnated gallium in the acid catalyst. The lower acidity strength and doped-gallium content in the catalyst presented a higher catalyst performance in the dehydrogenation reaction.

Figure 11.

Desaturation steps of C18 fatty ester with melting point (MP), oxidation stability index (OSI), and cetane number (CN) characteristics (adapted and modified from [7,184,222]).

4.5.2. Isomerization

Isomerization is a process that modifies the carbon chain structure in a hydrocarbon molecule, thereby producing an isomeric product. In this method, the structure of the carbon chain is rearranged to create a new structure, but its chemical formula is still the same as that of the parent component [7]. There are five types of isomerization: skeletal, positional, functional, geometric, and optical isomerization [223]. For the first type, the isomeric product has a different chain structure than the feed, such as straight-chain and branched-chain hydrocarbon. Functional isomerization will change the position of the double-bond, triple-bond, or functional group in the hydrocarbon, for example, 1-butene and 2-butene. Functional isomerization generates an isomeric product with a different functional group, for example, 1-hexene and cyclo-hexane. The last two isomerization categories are specified as stereo isomerization, which produces different geometric (cis- and trans-) and spatial arrangements of the asymmetric carbon atom (D- and L-), respectively.

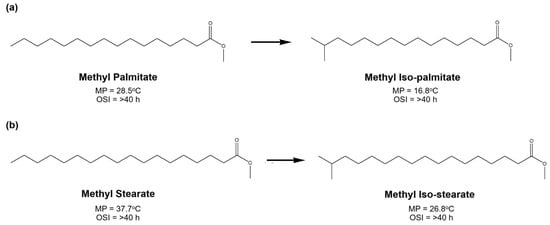

Regarding biodiesel, the discussion is focused on skeletal isomerization to generate fatty esters having a lower melting point, which correlates with better cold flow properties. In other words, this section specifically talks about the transformation process of natural straight-chain fatty esters into branched-chain fatty esters as isomeric products. The primary targeted components are saturated straight-chain fatty esters, such as palmitate ester and stearate ester. Figure 12 shows that methyl palmitate and methyl stearate can be commonly isomerized into methyl iso-palmitate and methyl iso-stearate, respectively. These isomeric products provide a lower melting point (MP) than the natural products. As illustrated in Figure 12, the branching of linear-chain fatty esters preferably occurs at the second-last carbon (iso-branch form), opposing the ester functional group. Branching may also take place at the third-last carbon (anteiso- branch form) or closer to the middle carbon, which generally results in a lower melting point than the iso- branching [7]. However, its formation is difficult due to the effects of the ester group molecule. To see more details, the tabulation of biodiesel isomerization results for CFP improvement is presented in Table 11.

Figure 12.

Skeletal isomerization of saturated straight-chain fatty esters: (a) methyl palmitate; and (b) methyl stearate (adapted and modified from [7,184]).

For other fuel properties, the appearance of branched-chain fatty esters in the biodiesel has insignificant effects on the oxidation stability. Based on the data available in Figure 12, the oxidation stability index (OSI) of branched-chain fatty acids in the saturated form is still higher than forty hours, while for the cetane number, the existence of isomerized fatty esters has a slight consequence. Although they both have a saturated structure, the linear-chain ester has a slightly better cetane number that the branched form [224]. Therefore, the effect of branched-chain ester components on the biodiesel cetane number also needs to be considered for commercial application.

Table 11.

Results of fatty ester isomerization for improving cold flow properties.

Table 11.

Results of fatty ester isomerization for improving cold flow properties.

| Biodiesel | Catalyst | PP (°C) | CP (°C) | Ref. | ||

|---|---|---|---|---|---|---|

| Before | After | Before | After | |||

| Palm biodiesel | Pt/β-zeolite | 15 | 9 | 17.5 | 12.8 | [225] |

| Coconut biodiesel | Pt/β-zeolite | 9 | −3 | 14.2 | −2.3 | [225] |

| Soybean biodiesel | SO42−/ZrO2 | - | - | 5.2 | −1.5 | [226] |

| H-mordenite zeolite | - | - | 5.2 | 0 | ||

| Methyl palmitate | Pt/β-zeolite | - | - | 30 | 20 | [227] |

| Methyl stearate | H-ferrierite zeolite | 37.7 a | −25 | n.a. | −13.9 | [188] |

| Methyl oleate | H-ferrierite zeolite | −20.2 a | −34 | n.a. | −18.5 | [188] |

| Methyl oleate | H-ferrierite zeolite | −20.2 a | −34 | n.a. | −16 | [228] |

| Methyl oleate | β-zeolite | −15.6 | −15.2 | [229] | ||

| Methyl palmitate-methyl oleate mixture | Pt/β-zeolite | - | - | 17 | 9.5 | [230] |

Note: a approximated by melting point.

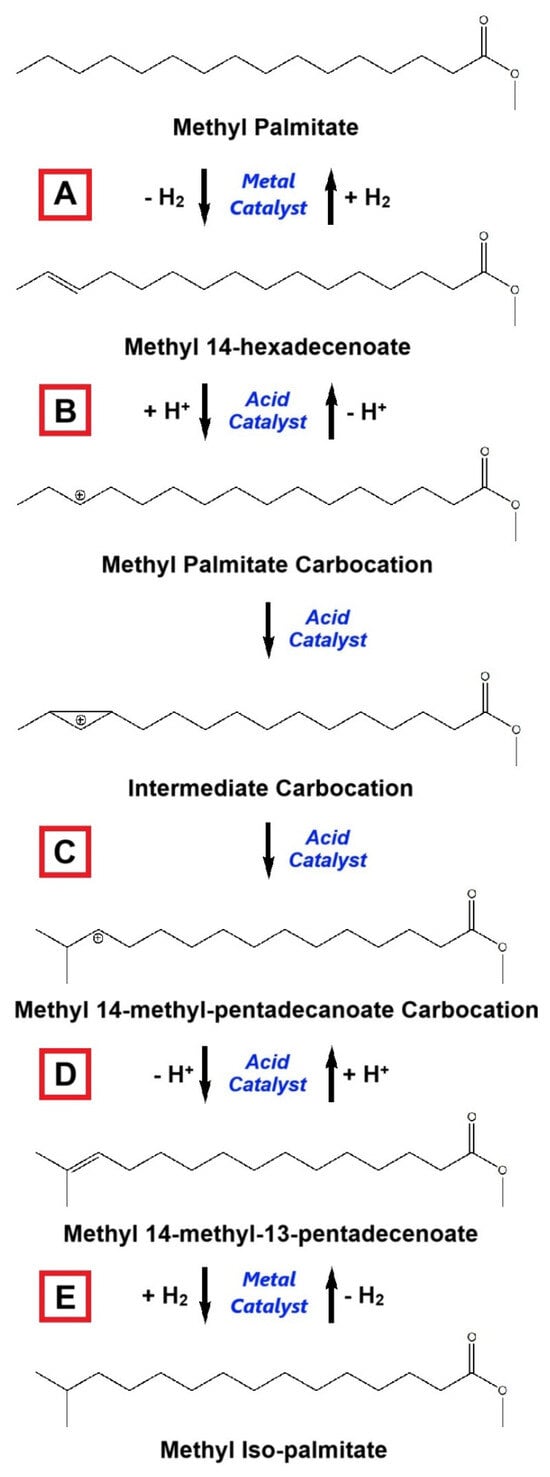

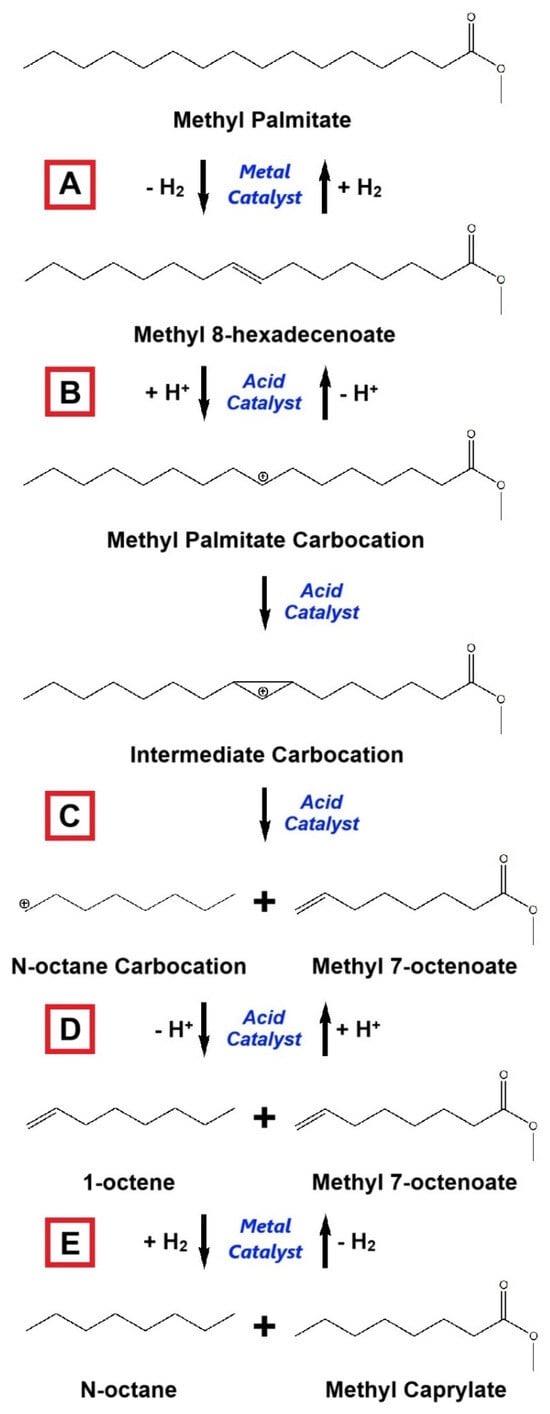

The isomerization reaction for saturated hydrocarbon branching generally occurs through a five-step process, as illustrated in Figure 13. The reaction mechanism is explained as follows [7,225]:

- -

- Dehydrogenation of saturated linear-chain fatty ester using a metal catalyst to generate an unsaturated fatty ester. In this step, no branching is formed.

- -

- Attachment of protons (protonation) to the unsaturated linear-chain fatty ester to produce fatty ester carbocation. This step requires an acid-based catalyst to accelerate protonation.

- -

- Fatty ester carbocation is transformed into intermediate carbocation, and the carbon chain structure is then rearranged to create a new structure with branching (saturated branched-chain fatty ester carbocation). In this stage, the type of acid catalyst determines the reaction rate and product selectivity.

- -

- Release of protons (deprotonation) from branched-chain fatty ester carbocation to establish an unsaturated branched-chain fatty ester.

- -

- Hydrogenation of the unsaturated branched-chain fatty ester to promote the saturated form of the branched-chain fatty ester.

Figure 13.

General mechanism of hydro-isomerization for saturated fatty esters, represented by methyl palmitate: (A) Dehydrogenation; (B) Protonation; (C) Isomerization; (D) Deprotonation; and (E) Hydrogenation (adapted and modified from [7,231]).

This mechanism is also called hydro-isomerization because of the involvement of the hydrogenation–dehydrogenation process [174]. The branching process of unsaturated hydrocarbon at the location of the double bond does not involve a dehydrogenation (A) and hydrogenation step (E), producing branched-chain unsaturated hydrocarbon. Hereinafter, when the process implicates dehydrogenation–hydrogenation, the unsaturated hydrocarbon will be branched at the single-bonded carbon atom.

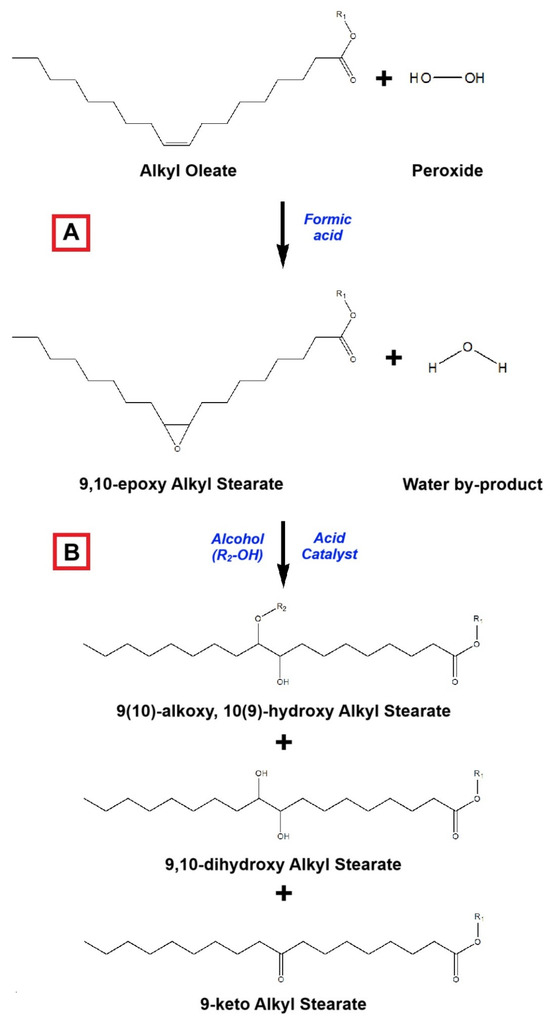

4.5.3. Epoxidation–Alkoxylation

Epoxidation–alkoxylation is a combination process proffered to bring down cold fluidity parameters (PP, CP, and/or CFPP) of biodiesel by reducing the double bond in the fatty ester and converting it into an alkoxy product [232]. Different from other methods, the targeted components in this method are unsaturated fatty esters [233]. Although the unsaturated fatty ester has good low-temperature flow behavior, its cetane number and oxidation stability are not as expected [174,234]. Therefore, the combination of epoxidation and alkoxylation is offered to improve oxidation stability, cetane number, and also cold fluidity characteristics [235]. This method will change the carbon chain pattern of fatty ester from an unsaturated-linear pattern into a saturated-branched pattern a with lower PP and/or CP [174].

Generally, the reaction scheme of epoxidation–alkoxylation for fatty ester branching is illustrated in Figure 14. Initially, the double bond in the unsaturated fatty ester molecule is epoxidized using peroxide and formic acid to create an oxirane ring or cyclic ether functional group. The first process is called epoxidation (A). Afterward, the oxirane ring is opened by a strong acid catalyst and it will bind an alkoxy molecule [174]. The alkoxy molecule originates from alcohol, which is activated by a strong acid catalyst, such as sulfuric acid and boron trifluoride [236,237]. The process integrating ring opening and alkoxy attachment in the epoxidized fatty ester is well known as alkoxylation (B). Ultimately, three products result from the alkoxylation stage: (i) alkoxy-hydroxy saturated fatty ester (main product); (ii) dihydroxy saturated fatty ester; and (iii) keto saturated fatty ester.

Figure 14.

Reaction scheme of epoxidation–alkoxylation, represented by methyl oleate: (A) Epoxidation; and (B) Alkoxylation (adapted and modified from [232,235,236,237]).

The results of fatty ester epoxidation–alkoxylation have been previously reported for improving cold flow properties, as presented in Table 12. Of all data introduced in Table 12, the longer carbon chain or higher molecular weight of alkoxy will reduce the PP and/or CP of biodiesel. This phenomenon has been explicitly explained by Smith et. al. [236] as the bigger molecule of alkoxy hindering the formation of tidy and compact fatty ester molecules. It will bend the primary carbon chain and interrupt crystal formation, thus definitely decreasing the melting point. This reason also clarifies the remarkable decline in the melting point from high- to low-saturation-degree fatty esters. In addition to the superiorities stated above, the alkoxylated fatty esters also have some drawbacks: (i) higher kinematic viscosity; (ii) slightly lower higher-heating value (HHV); and (iii) higher corrosive properties than the normal fatty esters [232,234,235,237]. The last two weaknesses are specifically due to the higher presence of oxygen in the alkoxylated fatty esters. Hence, the implementation of this treatment for biodiesel CFP improvement must be properly controlled to optimize alkoxylation conversion and achieve the desired quality.

Table 12.

Results of fatty ester epoxidation–alkoxylation for improving cold flow properties.

Table 12.

Results of fatty ester epoxidation–alkoxylation for improving cold flow properties.

| Biodiesel | Alkoxy | PP (°C) | CP (°C) | Ref. | ||

|---|---|---|---|---|---|---|

| Before | After | Before | After | |||

| Canola butyl ester | Methoxy | - | - | −3 | −4 | [236] |

| Canola butyl ester | n-buthoxy | - | - | −3 | −5 | [233] |

| Canola butyl ester | n-pentoxy | −12 | −12 | −3 | −5 | [235] |

| n-hexoxy | −12 | −12 | −3 | −5 | ||

| n-octoxy | −12 | −12 | −3 | −5 | ||

| 2-ethylhexoxy | −12 | −12 | −3 | −6 | ||

| Poultry fat methyl ester | Tert-butoxy | −3 | −3 | 2 | 3 | [234] |

| Used cooking methyl ester | 2-ethylhexoxy | 10 | −14 | - | - | [238] |

| High oleic acid methyl ester | Methoxy | 0 | −1 | 2 | 3 | [237] |

| Ethoxy | 0 | −4 | 2 | −2 | ||

| n-propoxy | 0 | −6 | 2 | −3 | ||

| Isopropoxy | 0 | −10 | 2 | −3 | ||

| n-butoxy | 0 | −6 | 2 | −4 | ||

| Isobutoxy | 0 | −8 | 2 | −4 | ||

| n-hexoxy | 0 | −10 | 2 | −7 | ||

| n-octoxy | 0 | −10 | 2 | −7 | ||

| n-decoxy | 0 | −14 | 2 | −11 | ||

| High oleic acid isopropyl ester | n-butoxy | −12 a | −22 | −9 b | −21 | [239] |

| Isobutoxy | −12 a | −23 | −9 b | −21 | ||

| n-hexoxy | −12 a | −23 | −9 b | −23 | ||

| n-octoxy | −12 a | −23 | −9 b | −23 | ||

| 2-ethylhexoxy | −12 a | −24 | −9 b | −23 | ||

| n-decoxy | −12 a | −24 | −9 b | −23 | ||

Note: a pour point of soybean isopropyl ester. b cloud point of soybean isopropyl ester.

4.6. Carbon Chain Cracking

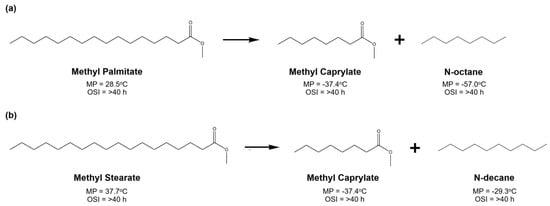

Carbon chain cracking, usually called hydrocracking, is a thermal process used to break carbon chains into two or more shorter carbon chain molecules. In this topic, hydrocracking is proposed to particularly break down the carbon chain saturated fatty esters, hence probably producing lighter fatty esters and alkane hydrocarbons [7]. As depicted in Figure 15, both probable products show considerable melting point (MP) reduction compared to their parent fatty esters. The positive point is that their oxidation stability index (OSI) can be maintained at high values. However, these desired products have problems in terms of the cetane number, which proportionally corresponds to fuel ignitability in diesel engines [230]. Therefore, the optimum composition of basic fatty esters and cracked products should be considered in the final product to maintain the quality of biodiesel.

Reviewing further, the general hydrocracking mechanism of saturated hydrocarbon is described as follows [7,240]:

- -

- Dehydrogenation of saturated hydrocarbon to promote double-bond-containing hydrocarbon;

- -

- Protonation of unsaturated hydrocarbon to stimulate carbenium ion formation;

- -

- Carbenium ions are dissociated into shorter carbon chain carbocation and unsaturated hydrocarbon;

- -

- Deprotonation of carbocation to generate unsaturated hydrocarbon;

- -

- Unsaturated molecules are then hydrogenated to become saturated hydrocarbons.

Figure 15.

Hydrocracking (expected) of saturated straight-chain fatty esters: (a) methyl palmitate; and (b) methyl stearate (adapted and modified from [7,184,241]).