The Time-Varying Characteristics of Relative Permeability in Oil Reservoirs with Gas Injection

Abstract

1. Introduction

2. Gas Drive/Oil Recovery Experiment

2.1. Materials

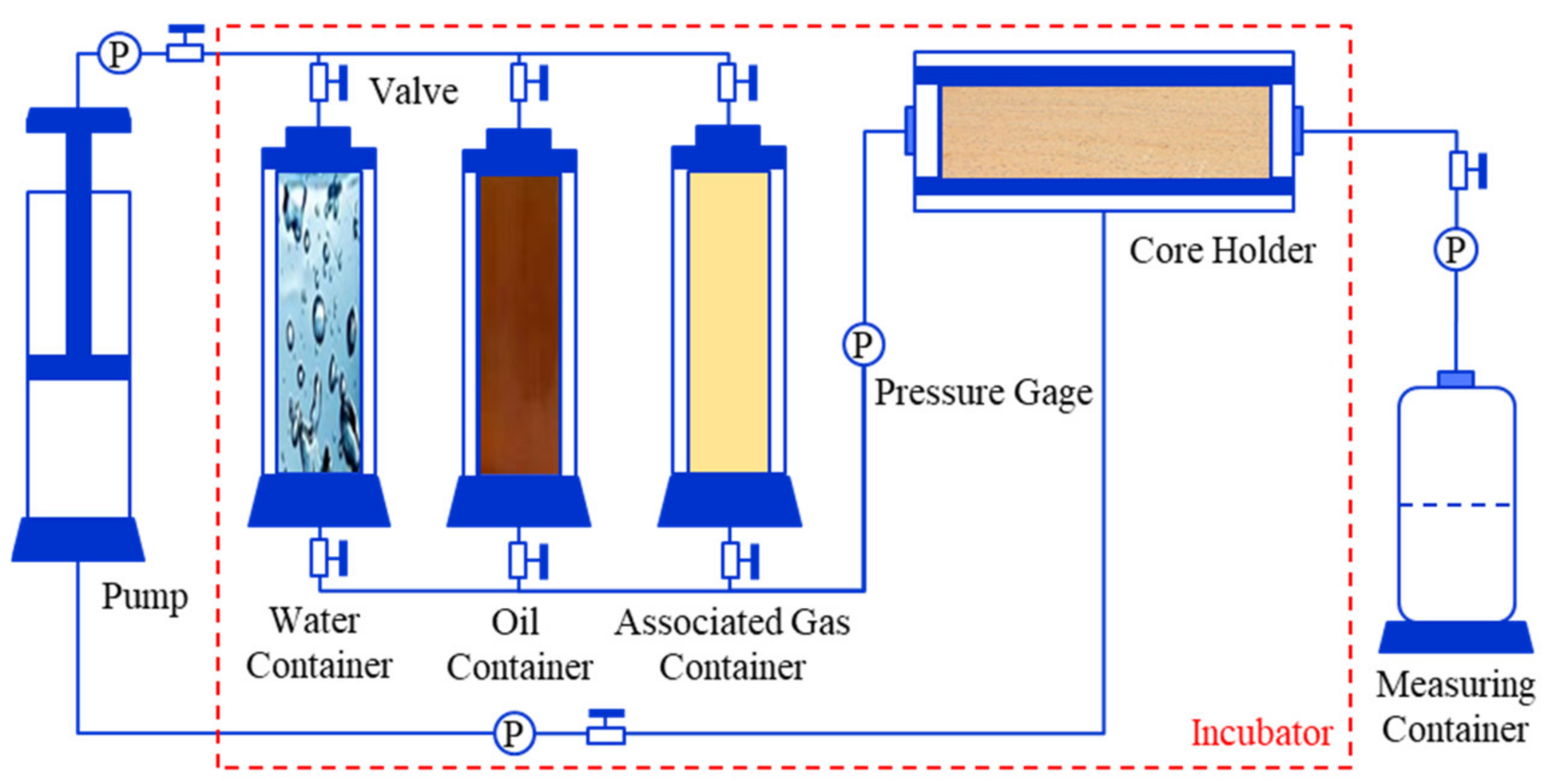

2.2. Experimental Apparatus

2.3. Experimental Procedure

- Saturate with formation water, establish a formation temperature of 140 °C and a pressure of 50 MPa, and record the amount of saturated formation water.

- Equilibrate oil drives water to a connate water state and records the amounts of displaced formation water and connate water.

- Test the relative permeability of the oil phase under connate water conditions.

- Equilibrate associated gas drives oil to residual oil saturation, recording the relative permeabilities of the gas and oil phases under various water saturation conditions.

- Repeat steps 1 to 4, increasing gas drive speed and pressure.

2.4. Experiment on the Effect of Fluid Composition Changes on Relative Permeability

2.5. Experiment on the Effect of Gas Drive/Oil Operation Parameters on Relative Permeability

2.6. Brief Summary

3. Factors Influencing the Time-Varying Characteristics of Relative Permeability

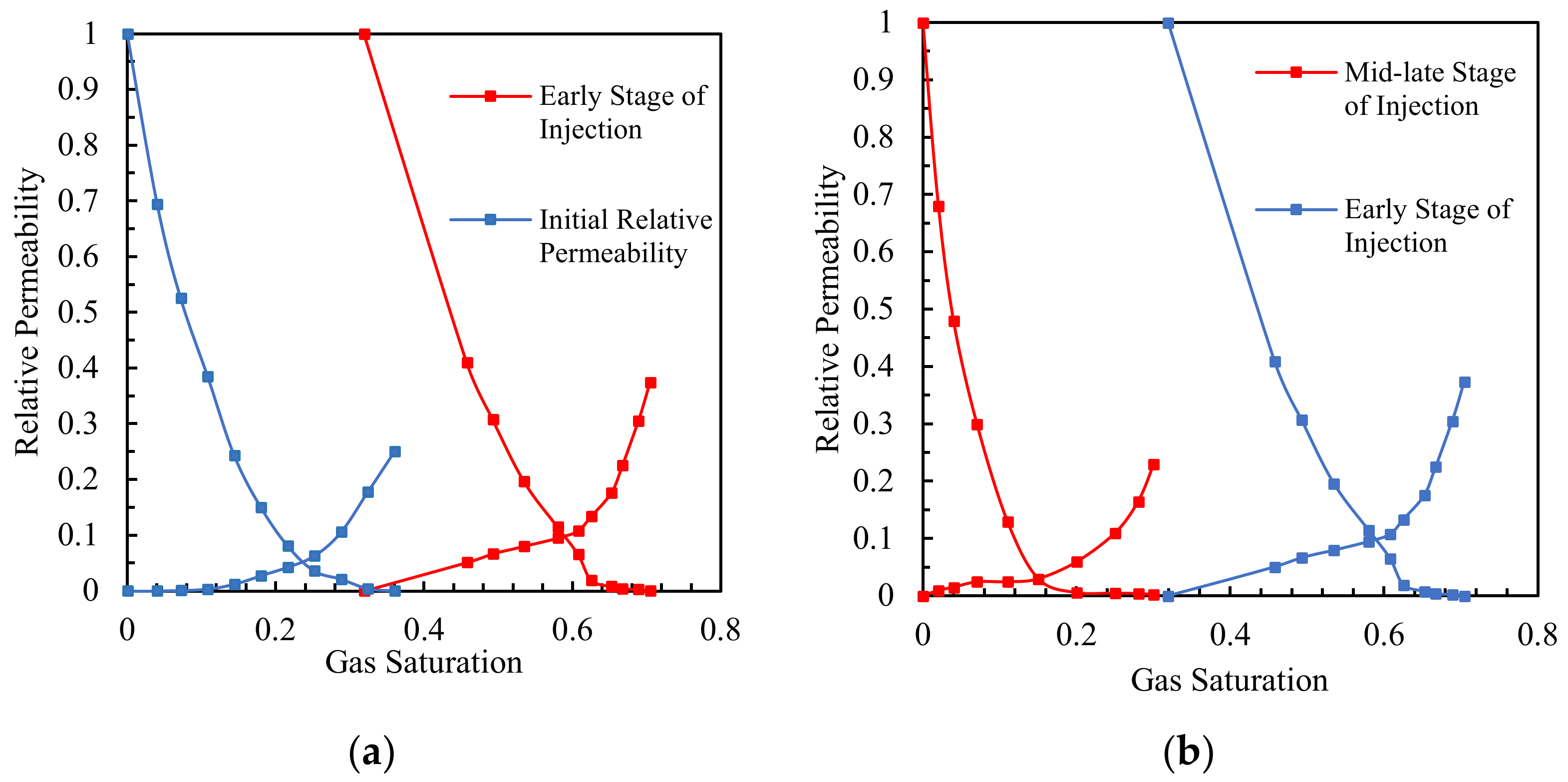

3.1. Effect of Fluid Composition Changes on Relative Permeability

3.2. Effect of Changes in Operating Parameters on Relative Permeability

4. Practical Application

4.1. Numerical Simulation Method of Reservoirs Considering Time-Varying Relative Permeability

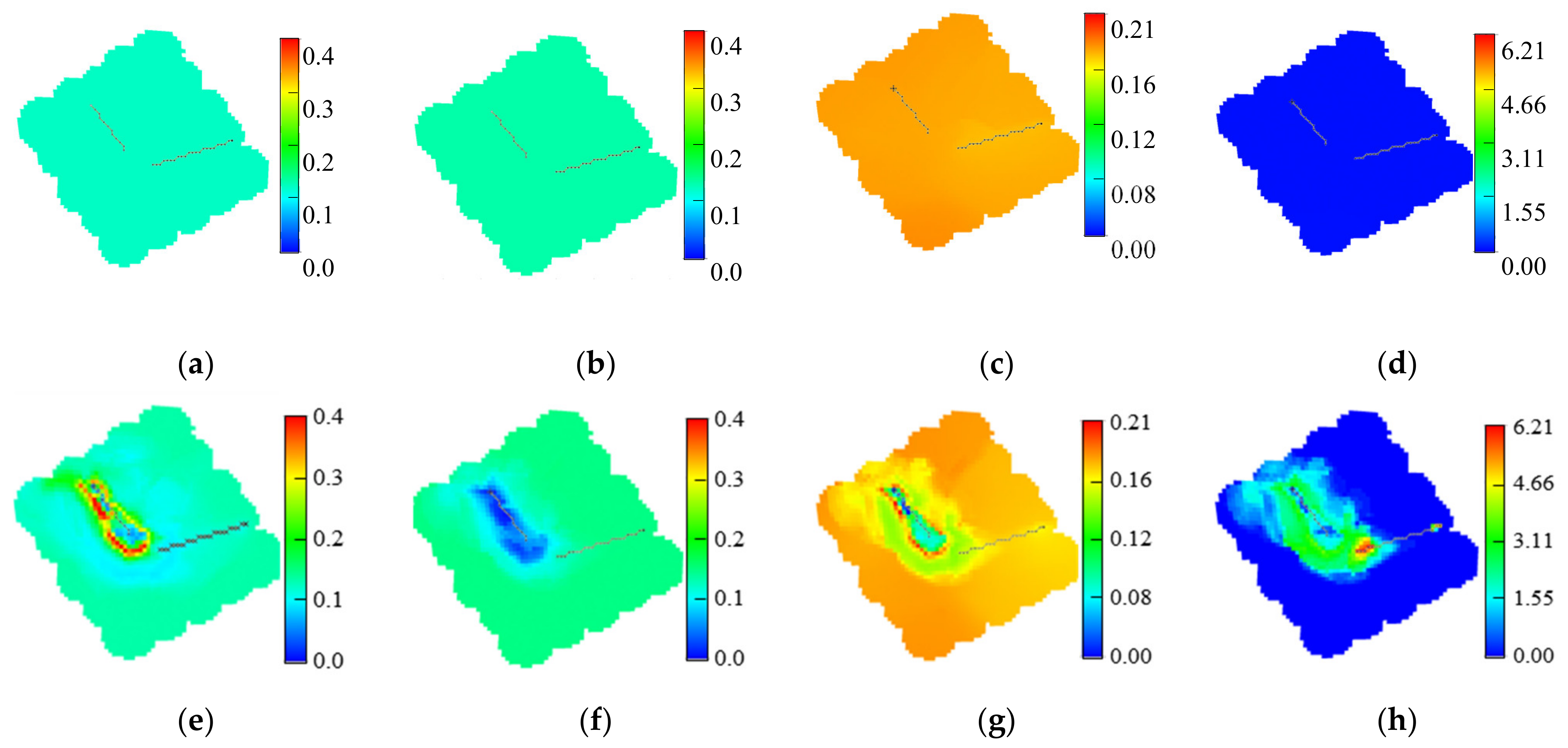

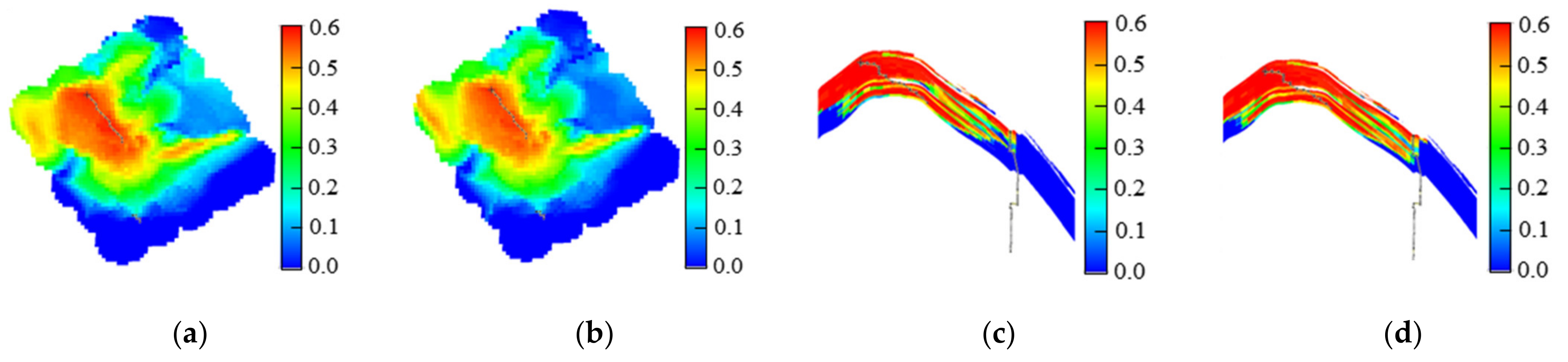

4.2. Reservoir Numerical Simulation Based on Time-Varying Relative Permeability

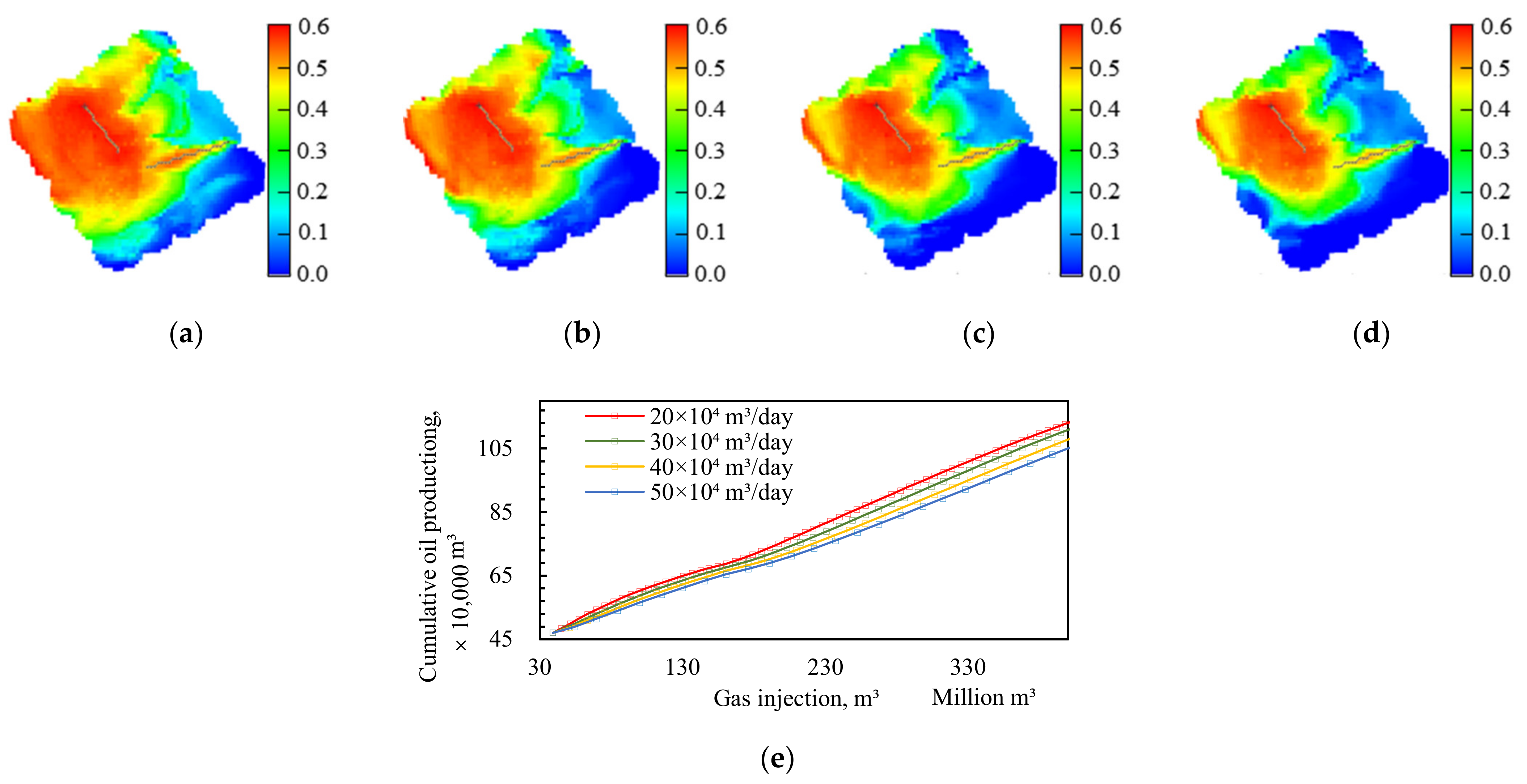

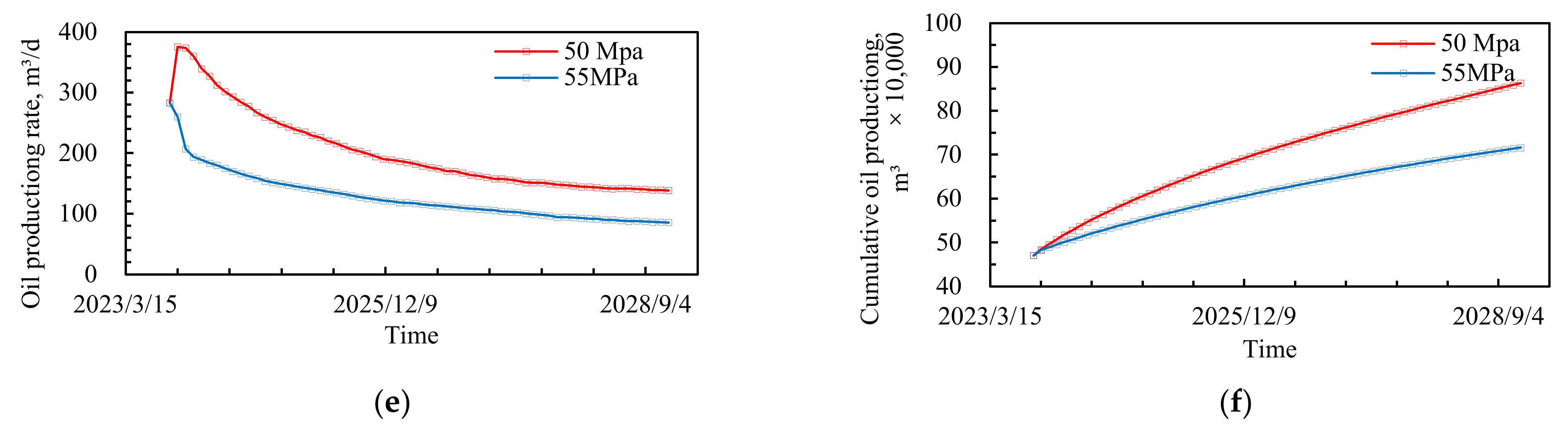

4.3. Effect of Gas Injection Parameters on Development Efficiency Considering Time-Varying Relative Permeability

5. Conclusions

- During the process of gas injection in reservoirs, changes in reservoir properties, fluid composition, and operating parameters cause the relative permeability of oil and gas to exhibit significant time-varying characteristics. In the early stages of gas injection, most of the reservoir is at the gas injection front, resulting in a leftward shift in the relative permeability of oil and gas. In the mid–late stages of gas injection, the reservoir is at the trailing edge of gas injection, resulting in a leftward shift in the relative permeability of oil and gas.

- A reservoir numerical simulation model considering time-varying the relative permeability of oil and gas better matches production conditions and can more accurately reflect the distribution characteristics of oil and gas and the dynamic changes in production.

- During reservoir gas injection, it is necessary to optimize the injection rate and injection pressure to improve the development efficiency. Excessively high injection rates and pressures may increase the microscopic oil displacement efficiency but can also cause premature gas channeling, reducing the sweep efficiency and negatively impacting reservoir development.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ding, Y.; Duan, H.; Tang, X.; Ren, K.; Yang, Z.; Lan, Z.; Liu, S. Exploring China’s oil consumption pathways toward 2060 under different climate targets. Environ. Impact Assess. Rev. 2023, 103, 107233. [Google Scholar] [CrossRef]

- Pan, X.; Wang, L.; Dai, J.; Zhang, Q.; Peng, T.; Chen, W. Analysis of China’s oil and gas consumption under different scenarios toward 2050: An integrated modeling. Energy 2020, 195, 116991. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, Y.; Zou, R.; Zou, R.; Huang, L.; Liu, Y.; Meng, Z.; Wang, Z.; Lei, H. A systematic review of CO2 injection for enhanced oil recovery and carbon storage in shale reservoirs. Int. J. Hydrogen Energy 2023, 48, 37134–37165. [Google Scholar] [CrossRef]

- Bai, J.; Feng, Q.; Yang, G.; Ai, X.; Cheng, S.; Pan, Y.; Lu, Y. Research Progress of Friendly Carbon Dioxide Expansion Flooding: A Review. Chem. Technol. Fuels Oils 2024, 60, 119–131. [Google Scholar] [CrossRef]

- Kang, W.-L.; Zhou, B.-B.; Issakhov, M.; Gabdullin, M. Advances in enhanced oil recovery technologies for low permeability reservoirs. Pet. Sci. 2022, 19, 1622–1640. [Google Scholar] [CrossRef]

- Alvarado, V.; Manrique, E. Enhanced Oil Recovery: An Update Review. Energies 2010, 3, 1529–1575. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, S.; Zhao, W.; Yan, H.; Guo, P.; Zhang, J.; Bai, Z.; Wang, Z.; Ou, L. Multi-dimensional Experimental Study of Hydrocarbon Gas-Assisted Gravity Drainage. Arab. J. Sci. Eng. 2023, 48, 17031–17048. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, H.X.; Ma, L.Y.; Liu, Y.; Zhang, L. Performance evaluation and mechanism with different CO2 flooding modes in tight oil reservoir with fractures. J. Pet. Sci. Eng. 2020, 188, 106950. [Google Scholar] [CrossRef]

- Pu, W.; Fan, H.; Du, D.; Zhao, S.; Liu, Z.; Li, Y.; Jin, F. High pressure air injection in ultra-low permeability reservoirs: Effects of physical and chemical reactions on oil recovery. Chem. Eng. Res. Des. 2023, 195, 323–331. [Google Scholar] [CrossRef]

- Seyyedi, M.; Mahmud, H.K.B.; Verrall, M.; Giwelli, A.; Esteban, L.; Ghasemiziarani, M.; Clennell, B. Pore structure changes occur during CO2 injection into carbonate reservoirs. Sci. Rep. 2020, 10, 3624. [Google Scholar] [CrossRef]

- Xiong, R.; Guo, J.; Kiyingi, W.; Luo, H.; Li, S. Asphaltene deposition under different injection gases and reservoir conditions. Chem. Eng. Res. Des. 2023, 194, 87–94. [Google Scholar] [CrossRef]

- Zhou, W.; Niu, M.-y.; Luo, W.-j.; Liu, X.-t. Research Progress on Enhanced Oil Recovery by CO2 Flooding in Low Permeability Reservoirs. In Proceedings of the International Field Exploration and Development Conference, Wuhan, China, 20–22 September 2023; pp. 343–366. [Google Scholar]

- Zheng, Z.-g.; Wang, Y.-h.; Xiong, W.-l.; Gou, C.-b.; Wang, J.-h.; Zhan, J. Research on Gas Channeling Identification Technology for CO2 Flooding in Ultra-low Permeability Reservoirs. In Proceedings of the International Field Exploration and Development Conference, Qingdao, China, 20–22 October 2021; pp. 2653–2663. [Google Scholar]

- Yang, J.; Hou, J. Experimental study on gas channeling characteristics of nitrogen and foam flooding in 2-D visualized fractured-vuggy model. J. Pet. Sci. Eng. 2020, 192, 107334. [Google Scholar] [CrossRef]

- Wang, J.; Sun, L. The Time-Varying Regulation of Reservoir Physical Properties and the Study of Core Numerical Simulation. In Proceedings of the International Field Exploration and Development Conference 2020, Chengdu, China, 23–25 September 2020; pp. 3296–3304. [Google Scholar]

- Jie, J.; Zijun, H.; Ruxiang, G.; Jibo, R.; Gaoming, Y.; Yu, Z. Time-varying Numerical Simulation Of Reservoir Physical Properties Based On Surface Flux. J. Phys. Conf. Ser. 2021, 1894, 012077. [Google Scholar] [CrossRef]

- Jiang, R.; Zhang, W.; Zhao, P.; Jiang, Y.; Cai, M.; Tao, Z.; Zhao, M.; Ni, T.; Xu, J.; Cui, Y.; et al. Characterization of the reservoir property time-variation based on ‘surface flux’ and simulator development. Fuel 2018, 234, 924–933. [Google Scholar] [CrossRef]

- Okhovat, M.R.; Hassani, K.; Rostami, B.; Khosravi, M. Experimental studies of CO2-brine-rock interaction effects on permeability alteration during CO2-EOR. J. Pet. Explor. Prod. Technol. 2020, 10, 2293–2301. [Google Scholar] [CrossRef]

- Yang, Y.-B.; Xiao, W.-L.; Zheng, L.-L.; Lei, Q.-H.; Qin, C.-Z.; He, Y.-A.; Liu, S.-S.; Li, M.; Li, Y.-M.; Zhao, J.-Z.; et al. Pore throat structure heterogeneity and its effect on gas-phase seepage capacity in tight sandstone reservoirs: A case study from the Triassic Yanchang Formation, Ordos Basin. Pet. Sci. 2023, 20, 2892–2907. [Google Scholar] [CrossRef]

- Pan, H.; Jiang, Y.; Guo, G.; Yang, C.; Deng, H.; Zhu, X.; Zeng, Q.; Song, L.; Cao, J.; Wang, Z.; et al. Pore-throat structure characteristics and fluid mobility analysis of tight sandstone reservoirs in Shaximiao Formation, Central Sichuan. Geol. J. 2023, 58, 4243–4256. [Google Scholar] [CrossRef]

- Huang, X.; Zhang, Y.; He, M.; Li, X.; Yang, W.; Lu, J. Asphaltene precipitation and reservoir damage characteristics of CO2 flooding in different microscopic structure types in tight light oil reservoirs. Fuel 2022, 312, 122943. [Google Scholar] [CrossRef]

- Yang, Y.; Yao, J.; van Dijke, M.I. Effect of reservoir rock wettability on microcosmic distribution of residual oil after gas displacement. Shiyou Xuebao/Acta Pet. Sin. 2010, 31, 467–470. [Google Scholar]

- Liu, Q.; Wu, K.; Li, X.; Tu, B.; Zhao, W.; He, M.; Zhang, Q.; Xie, Y. Effect of displacement pressure on oil–water relative permeability for extra-low-permeability reservoirs. ACS Omega 2021, 6, 2749–2758. [Google Scholar] [CrossRef]

- Eydinov, D.; Gao, G.; Li, G.; Reynolds, A. Simultaneous estimation of relative permeability and porosity/permeability fields by history matching production data. J. Can. Pet. Technol. 2009, 48, 13–25. [Google Scholar] [CrossRef]

- Zhang, N.; Yao, J.; Huang, Z.; Wang, Y. Accurate multiscale finite element method for numerical simulation of two-phase flow in fractured media using discrete-fracture model. J. Comput. Phys. 2013, 242, 420–438. [Google Scholar] [CrossRef]

- Fang, T.; Wang, M.; Gao, Y.; Zhang, Y.; Yan, Y.; Zhang, J. Enhanced oil recovery with CO2/N2 slug in low permeability reservoir: Molecular dynamics simulation. Chem. Eng. Sci. 2019, 197, 204–211. [Google Scholar] [CrossRef]

- Lin, B.; Wei, Y.; Gao, S.; Ye, L.; Liu, H.; Zhu, W.; Zhang, J.; Han, D. Current Progress and Development Trend of Gas Injection to Enhance Gas Recovery in Gas Reservoirs. Energies 2024, 17, 1595. [Google Scholar] [CrossRef]

- Shafiei, M.; Kazemzadeh, Y.; Escrochi, M.; Cortés, F.B.; Franco, C.A.; Riazi, M. A comprehensive review direct methods to overcome the limitations of gas injection during the EOR process. Sci. Rep. 2024, 14, 7468. [Google Scholar] [CrossRef] [PubMed]

- GB/T 28912-2012; Test method for two phase relative permeability in rock. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China, Standardization Administration of the People’s Republic of China: Beijing, China, 2012.

| Property | Various Displacement Stages | ||

|---|---|---|---|

| Initial Gas Injection | Early Gas Injection | Mid–Late Gas Injection | |

| Displacement Rate (mL/min) | 0.01 | 0.01 | 0.01 |

| Displacement Pressure (MPa) | 50 | 50 | 50 |

| Length (cm) | 4.93 | 6.08 | 6.08 |

| Diameter (cm) | 2.46 | 2.45 | 2.45 |

| Porosity (%) | 18.94 | 20.62 | 20.62 |

| Permeability (mD) | 54.47 | 54.38 | 54.38 |

| Minimum Gas Saturation (%) | 0 | 31.88 | 28.94 |

| Residual Oil Saturation (%) | 64.00 | 29.58 | 69.86 |

| Fluid Properties | Various Gas Injection Stages | |||

|---|---|---|---|---|

| November 2014 | November 2021 | November 2023 | ||

| Well Stream Composition (%) | C1 + N2 | 10.18 | 69.14 | 82.61 |

| C2–C6 + CO2 | 69.14 | 11.86 | 19 | |

| C7+ | 82.61 | 2.83 | 14.56 | |

| Injected Gas Composition | Nitrogen gas | Associated gas | Associated gas | |

| Viscosity (mPa·s) | 2.20 | 0.63 | 1.41 | |

| Core Sample | Baseline Core | High-Permeability Core | Increased Pressure Displacement | Increased Rate Displacement |

|---|---|---|---|---|

| Displacement Rate (mL/min) | 0.01 | 0.01 | 0.01 | 0.02 |

| Displacement Pressure (MPa) | 50 | 50 | 55 | 50 |

| Length (cm) | 6.08 | 6.85 | 6.08 | 6.08 |

| Diameter (cm) | 2.45 | 2.45 | 2.45 | 2.45 |

| Porosity (%) | 20.62 | 21.16 | 20.62 | 20.62 |

| Permeability (mD) | 54.38 | 126.85 | 54.38 | 54.38 |

| Connate Water Saturation (%) | 28.24 | 28.6 | 28.39 | 28.65 |

| Residual Oil Saturation (%) | 28.94 | 27.45 | 26.17 | 28.04 |

| Gas drive/oil Efficiency (%) | 59.67 | 61.55 | 63.46 | 60.70 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liao, H.; Liu, X.; He, X.; Li, Y.; Jiang, Z.; Li, K.; Wu, K. The Time-Varying Characteristics of Relative Permeability in Oil Reservoirs with Gas Injection. Energies 2024, 17, 4512. https://doi.org/10.3390/en17174512

Liao H, Liu X, He X, Li Y, Jiang Z, Li K, Wu K. The Time-Varying Characteristics of Relative Permeability in Oil Reservoirs with Gas Injection. Energies. 2024; 17(17):4512. https://doi.org/10.3390/en17174512

Chicago/Turabian StyleLiao, Hengjie, Xinzhe Liu, Xianke He, Yuansheng Li, Zhehao Jiang, Kaifen Li, and Keliu Wu. 2024. "The Time-Varying Characteristics of Relative Permeability in Oil Reservoirs with Gas Injection" Energies 17, no. 17: 4512. https://doi.org/10.3390/en17174512

APA StyleLiao, H., Liu, X., He, X., Li, Y., Jiang, Z., Li, K., & Wu, K. (2024). The Time-Varying Characteristics of Relative Permeability in Oil Reservoirs with Gas Injection. Energies, 17(17), 4512. https://doi.org/10.3390/en17174512