Development Status and Prospects of Biomass Energy in China

Abstract

1. Introduction

2. Assessment of Biomass Resources and Potential in China

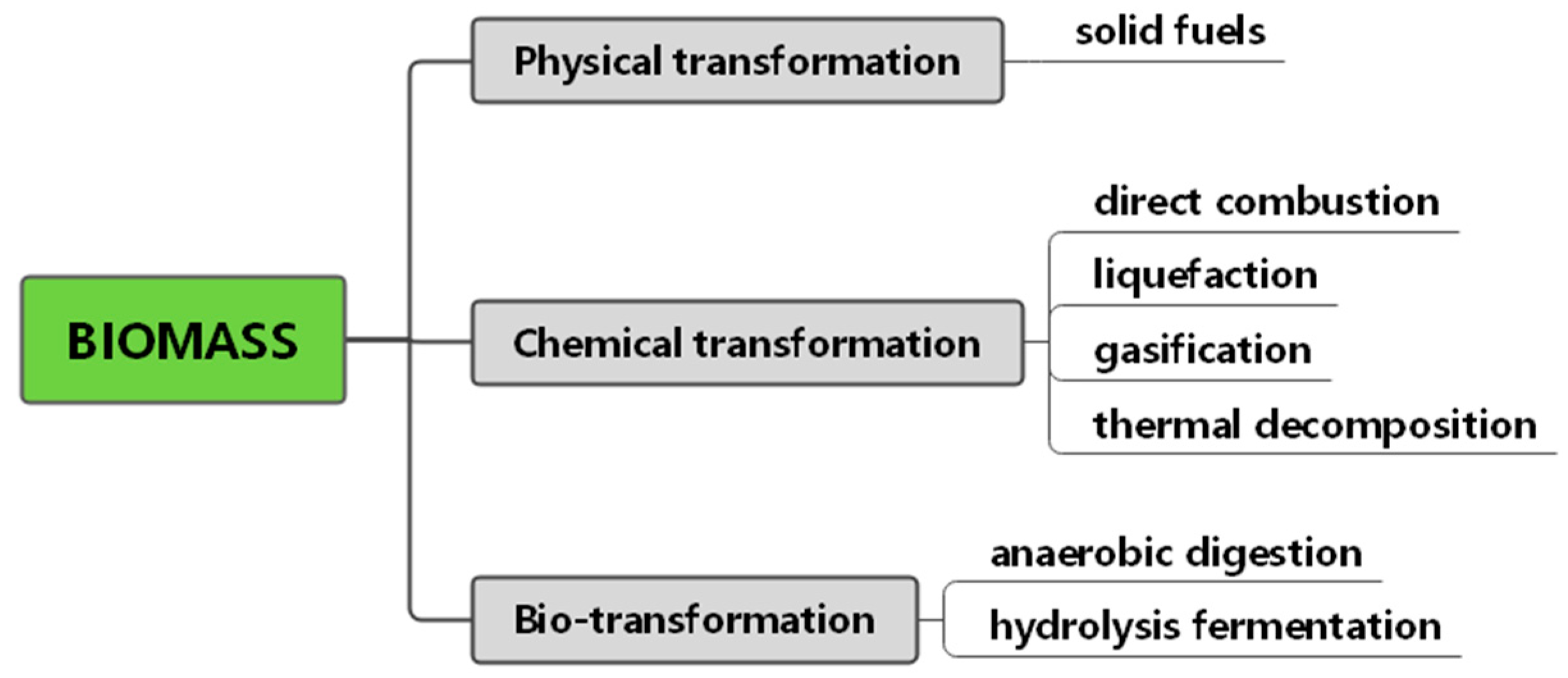

3. Biomass Conversion Technology

3.1. Physical Transformation

Solid Formed Fuel

3.2. Chemical Conversion

3.2.1. Direct Combustion

3.2.2. Biomass Gasification

3.2.3. Biomass Liquefaction

3.2.4. Biomass Pyrolysis

3.3. Biotransformation

3.3.1. Anaerobic Digestion

3.3.2. Pretreatment Hydrolysis Fermentation

4. Application Status of Biomass Energy in China

4.1. Biomass Power Generation and Heating

4.2. Biomass Gas Fuel

4.2.1. Biogas Production from Biomass

4.2.2. Hydrogen from Biomass

4.3. Biomass Liquid Fuels

4.3.1. Bioethanol

4.3.2. Biodiesel

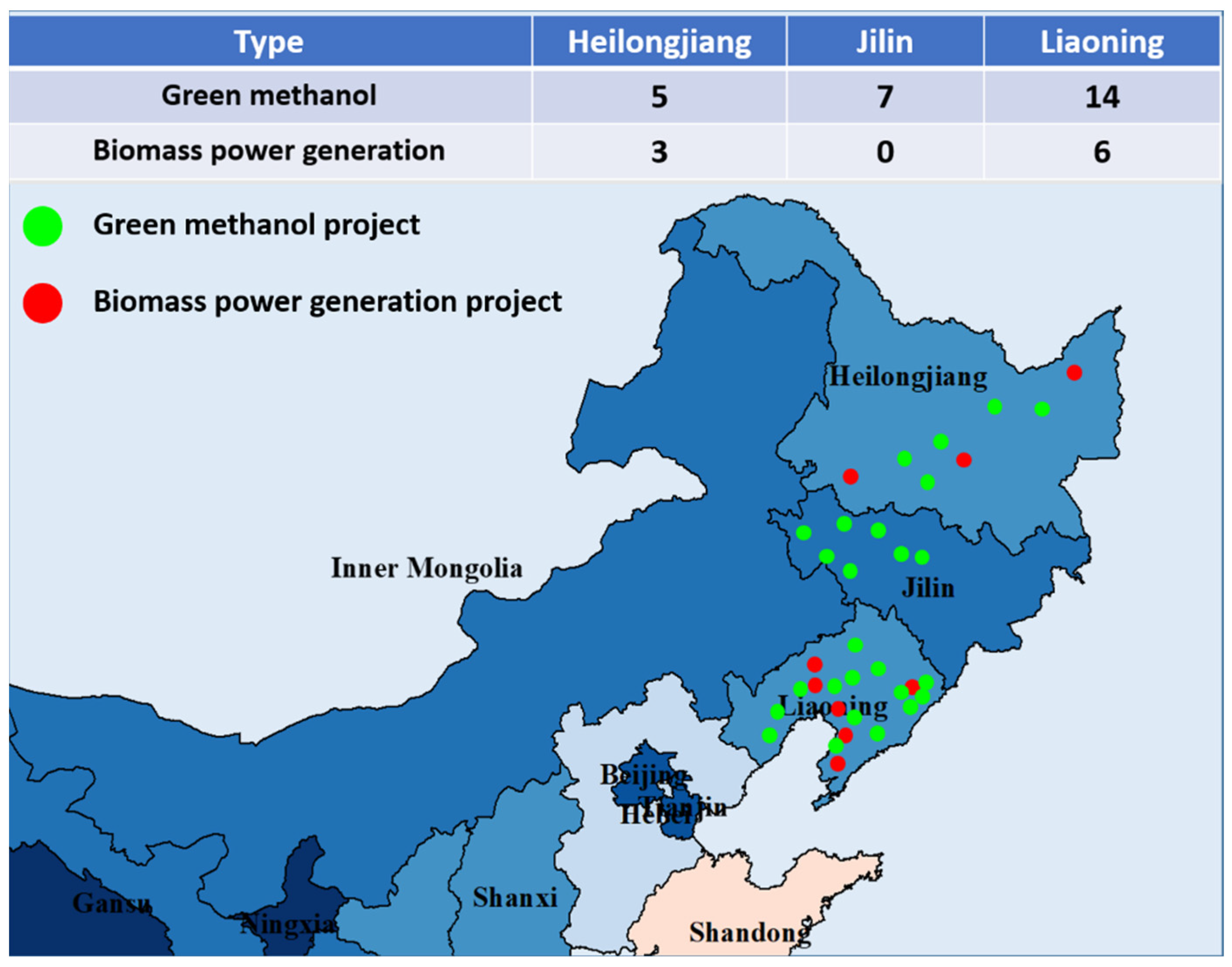

4.3.3. Bio-Methanol

4.3.4. Bio-Based Aviation Fuels

| Preparation Method | Catalyzer | Advantages and Disadvantages |

|---|---|---|

| Catalytic hydrogenation of vegetable oils | Pt, Pd, Ru, Rh, Ni, Co, Fe, and Mo | high fuel octane; low aromatic, oxygen, and sulfur content; expensive catalyst |

| Fischer–Tropsch synthesis | Ru, Fe, Co, Rh, and Ni | higher fuel thermal mass; lower energy density; lower aromatic content; higher production costs |

| Sugar conversion methods | basic catalyst; acid catalysts; acid-based bifunctional catalysts | complicated process; higher costs |

4.4. Bio-Based Material

4.5. Biofuel Cells

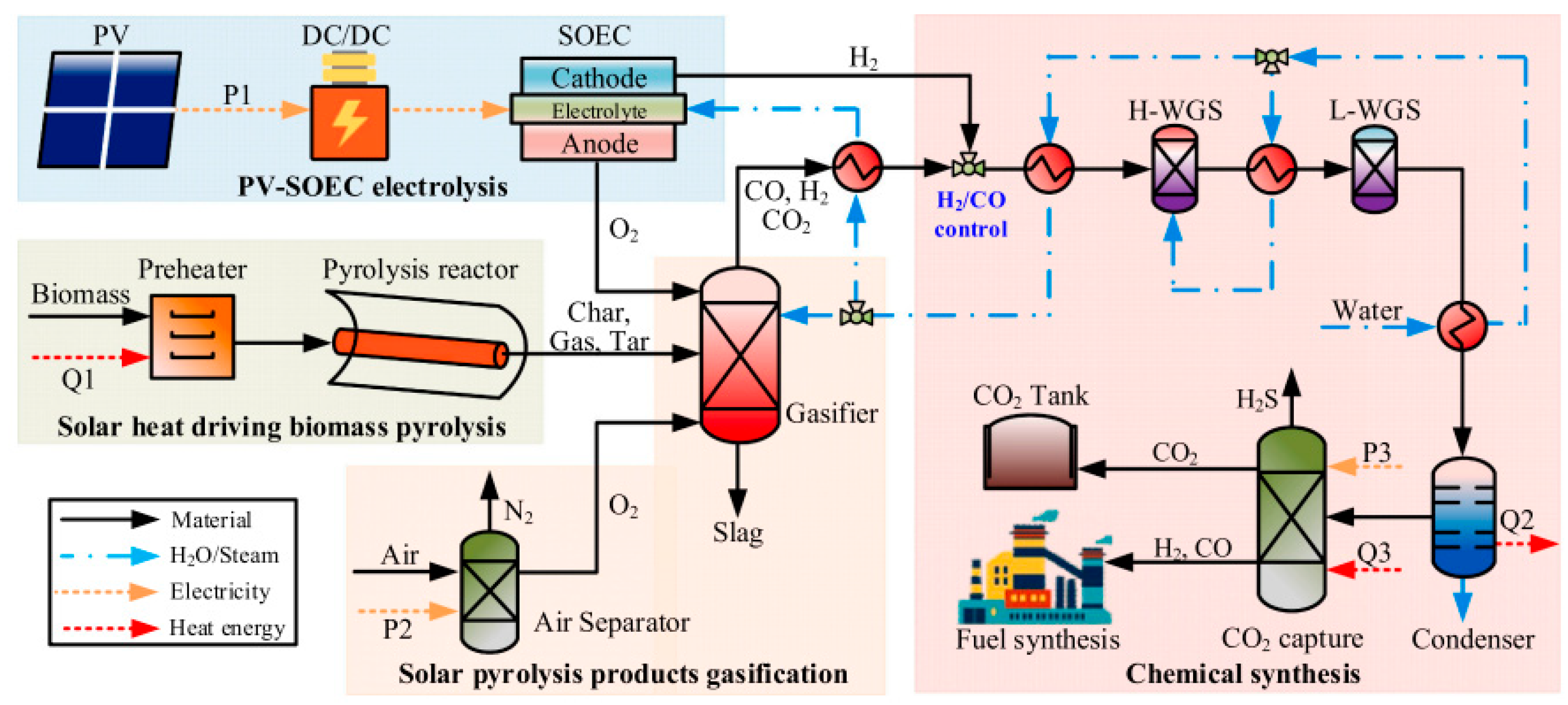

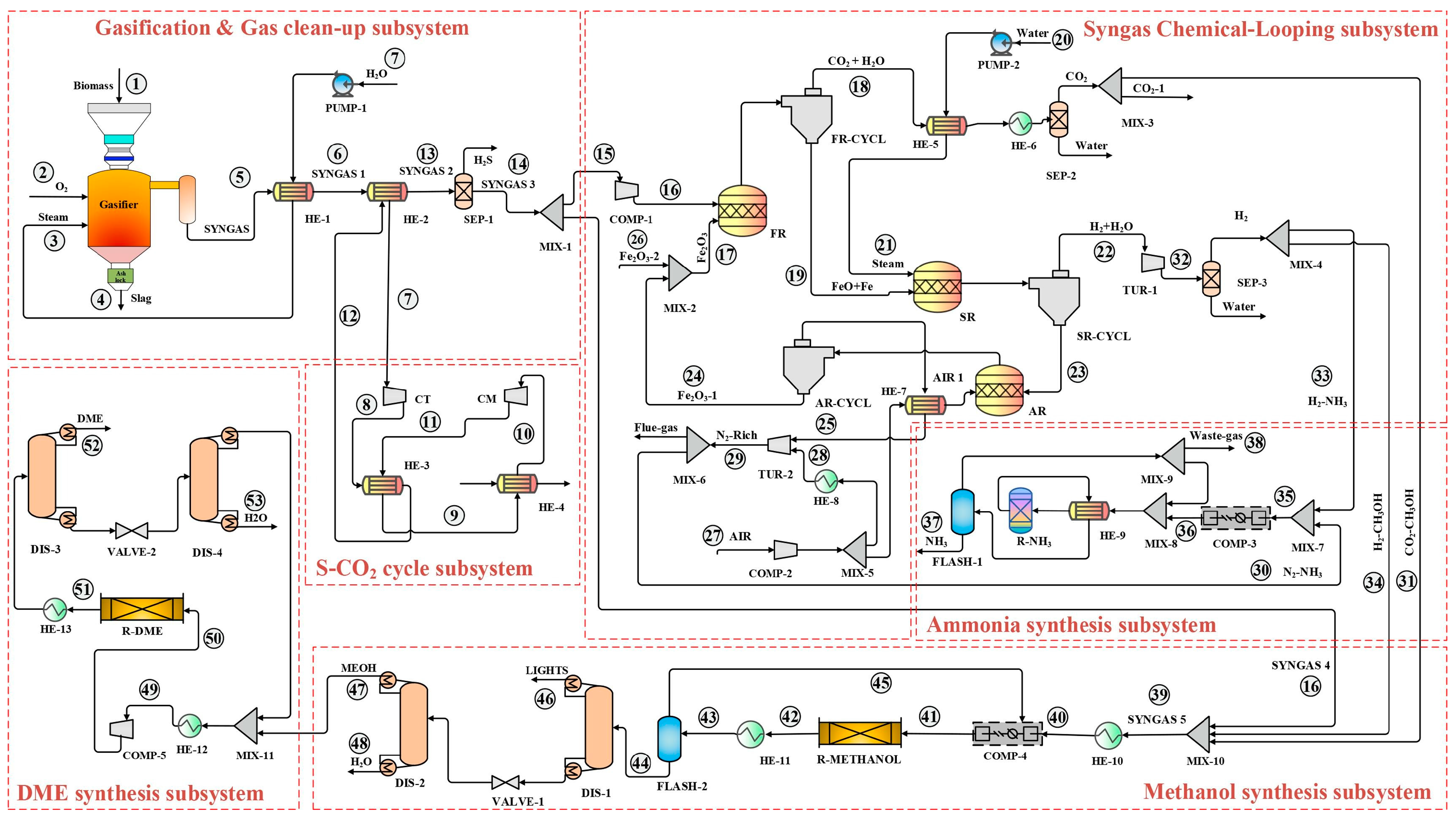

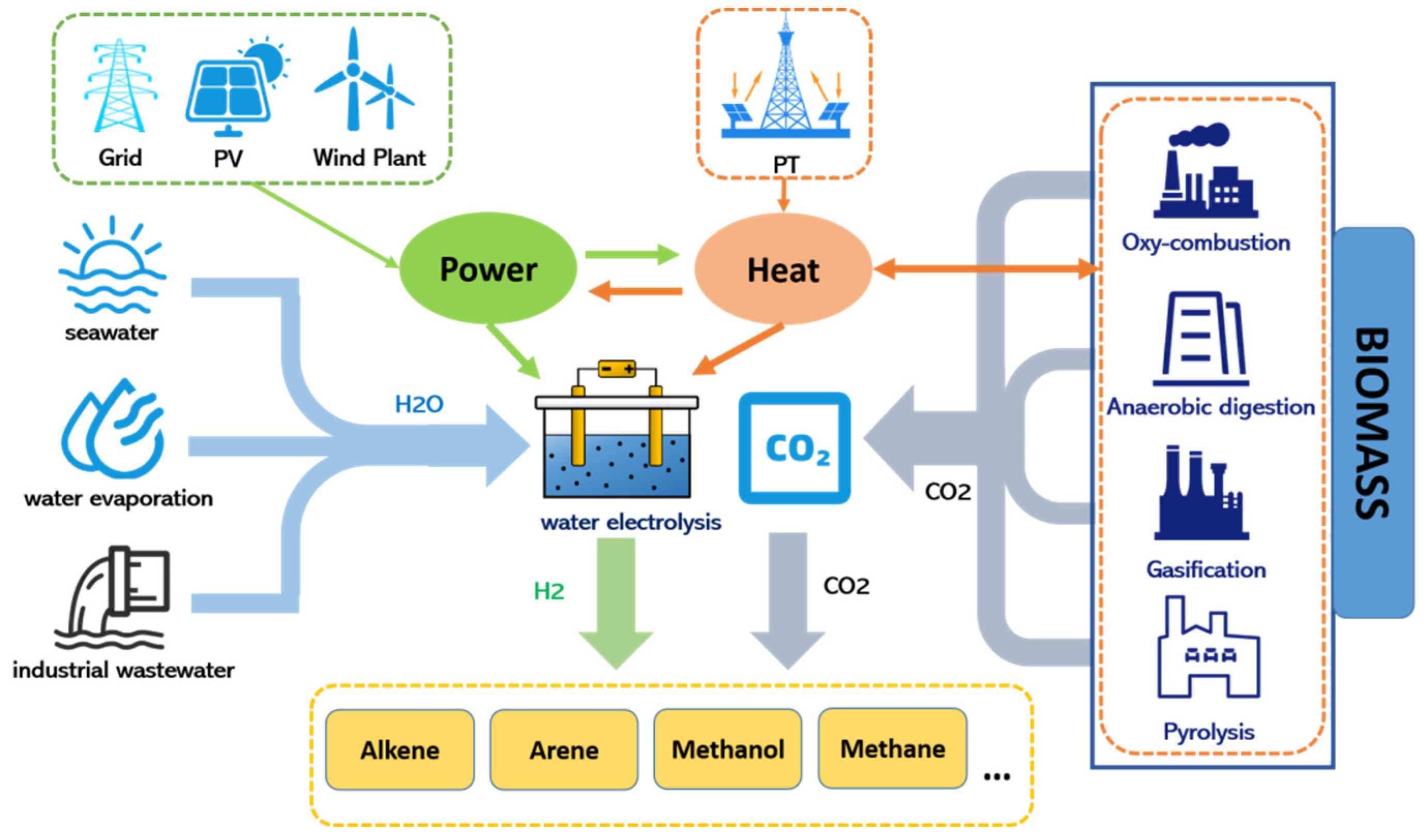

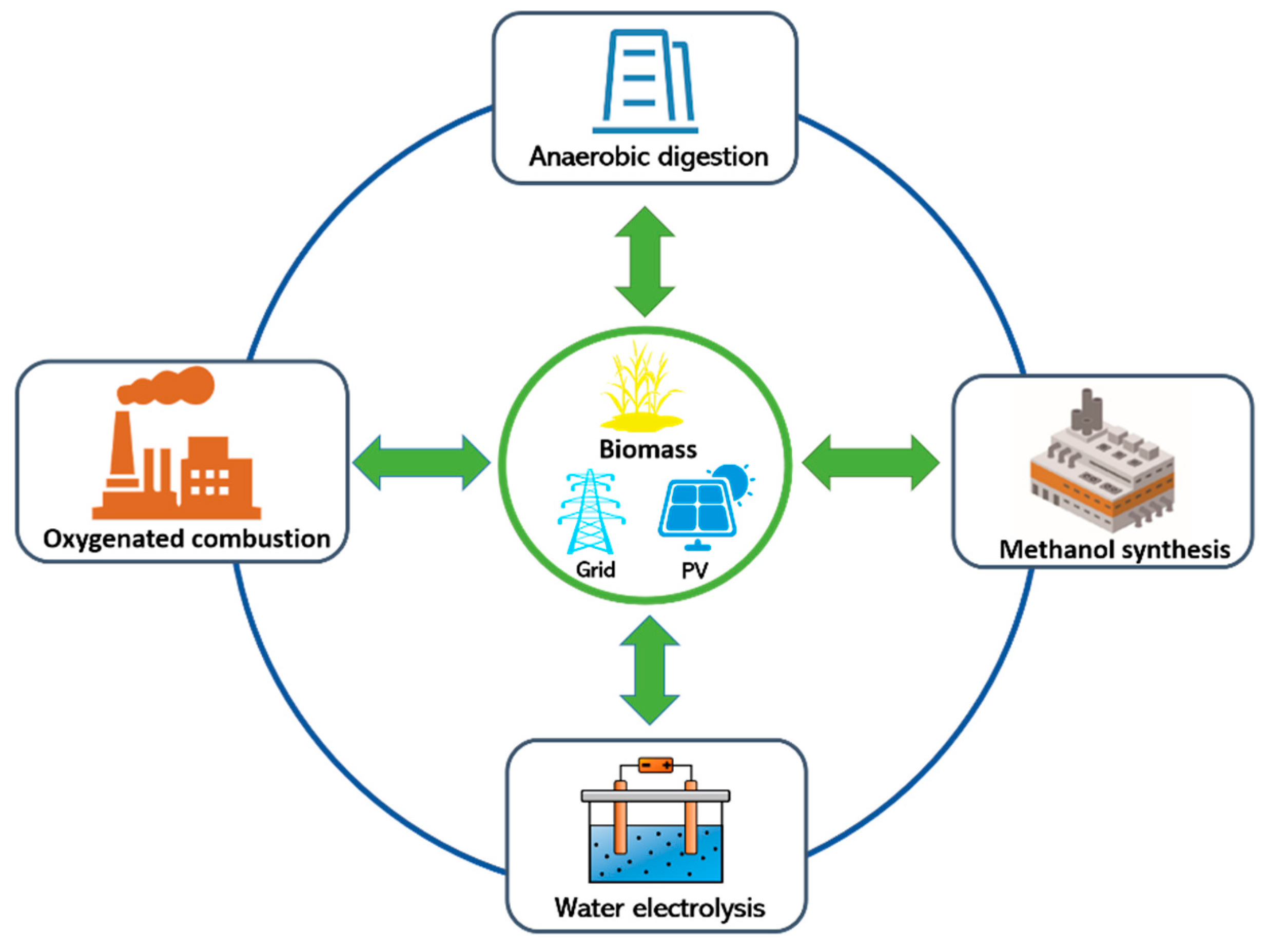

5. Progress in the Integrated Use of Biomass Energy in China

6. Conclusions

7. Future Development and Prospect

Funding

Conflicts of Interest

References

- Tu, W.; Zhang, L.; Zhou, Z.; Liu, X.; Fu, Z. The development of renewable energy in resource-rich region: A case in China. Renew. Sustain. Energy Rev. 2011, 15, 856–860. [Google Scholar] [CrossRef]

- Brad, P.; Guloren, T.; Alex, Z.; Lee, B.; Chris, C.; Ian, H.; Harry, L.; Patricia, L.; Annyna, S.; Eve, T.; et al. The Global Status of CCS 2019: Targeting Climate Change; Global CCS Institute: Canberra, Australia, 2019. [Google Scholar]

- The 12th Five-Year Plan for the Development of Biomass Energy Science and Technology; Ministry of Science and Technology: Beijing, China, 2012.

- Qu, M.; Lin, Y.; Liu, C.; Yao, S.; Cao, Y. Farmers’ perceptions of developing forest based bioenergy in China. Renew. Sustain. Energy Rev. 2016, 58, 581–589. [Google Scholar] [CrossRef]

- Han, J.; Mol, A.P.; Lu, Y.; Zhang, L. Small-scale bioenergy projects in rural China: Lessons to be learnt. Energy Policy 2008, 36, 2154–2162. [Google Scholar] [CrossRef]

- Zhang, B. Assessment of Biomass Feedstock Resources and Energy Potential in China; China Agricultural University: Beijing, China, 2018. [Google Scholar]

- Zhao, Z.-Y.; Yan, H. Assessment of the biomass power generation industry in China. Renew. Energy 2012, 37, 53–60. [Google Scholar] [CrossRef]

- Xie, Y. An investigation of the current status and application of biomass energy development in China. Chem. Res. 2022, 33, 555–560. [Google Scholar]

- Hou, J.; Wang, W.; Zhang, L. Modern biomass energy technology system and its industrial application situation. Mod. Chem. Ind. 2022, 42, 7–13. [Google Scholar]

- GB 13223-2011; Emission Standards for Air Pollutants from Thermal Power Plants. Ministry of Ecological Environment of the People’s Republic of China: Beijing, China, 2011.

- Li, H.; Yuan, Z.; Ma, X. Modern Biomass Energy Utilisation Technology; Chemical Industry Press: Beijing, China, 2012. [Google Scholar]

- Bajwa, D.S.; Peterson, T.; Sharma, N.; Shojaeiarani, J.; Bajwa, S.G. A review of densified solid biomass for energy production. Renew. Sustain. Energy Rev. 2018, 96, 296–305. [Google Scholar] [CrossRef]

- Renewable Energy Policy Network for the 21st Century. Renewables 2020 Global Status Report [EB/OL]. 2021. Available online: https://ren21.net/gsr-2020 (accessed on 8 July 2024).

- Liu, H.C.; Wu, C.Z.; Xie, J.J.; Huang, Y.Q.; Lang, L.; Yang, W.S.; Yin, X.L. Status and development of technology and applications of biomass gasification. Adv. New Renew. Energy 2019, 7, 1–12. [Google Scholar]

- Cheng, X.W.; Liu, L.Z.; Wei, R. Analysis of gasification process and gasification characteristics of downdraft fixed bed gasifier. Biomass Chemieal Eng. 2021, 55, 9–15. [Google Scholar]

- Basu, P. Biomass Gasification, Pyrolysis and Torrefaction, 2nd ed.; Academic Press: Cambridge, MA, USA, 2013. [Google Scholar]

- Hanaoka, T.; Miyazawa, T.; Matsunaga, K. Development of conversion technology from cellulosic biomass to liquid fuel via syngas by biomass-to-liquid (BTL). J. Jpn. Inst. Energy 2011, 90, 33–36. [Google Scholar]

- Hu, X.J.; Yang, T.; Liu, S.J.; Liu, J.; Zhang, S.J.; Li, Y.R. Effect of gasification temperature of circulating fluidized bed on solid product feature of rice husk gasification. Biomass Chemieal Eng. 2021, 55, 23–28. [Google Scholar]

- Zhang, S.; Liao, X.; Zhang, X.; Chen, Y.Q.; Shao, J.A.; Wang, X.H.; Yang, H.P.; Chen, H.P. Current status, development and options for boiler industry of biomass fuel conversion and utilisation technology. Ind. Boil. 2019, 02, 001. [Google Scholar]

- Tursi, A. A review on biomass: Importance, chemistry, classification, and conversion. Biofuel Res. J. 2019, 6, 962–979. [Google Scholar] [CrossRef]

- Wang, F.; Harindintwali, J.D.; Yuan, Z.; Wang, M.; Wang, F.; Li, S.; Yin, Z.; Huang, L.; Fu, Y.; Li, L.; et al. Technologies and perspectives for achieving carbon neutrality. Innovation 2021, 2, 100180. [Google Scholar] [CrossRef] [PubMed]

- Bridgwater, T. Challenges and Opportunities in Fast Pyrolysis of Biomass: Part I Introduction to the technology, feedstocks and science behind a promising source of fuels and chemicals. Johns. Matthey Technol. Rev. 2018, 62, 118–130. [Google Scholar] [CrossRef]

- Jonsson, E. Slow Pyrolysis in Brista: An Evaluation of Heat and Biochar Production in Sweden (Dissertation); KTH Royal Institute of Technology: Stockholm, Sweden, 2016. [Google Scholar]

- Kan, T.; Strezov, V.; Evans, T. Catalytic pyrolysis of coffee grounds using nicu-impregnated catalysts. Energy Fuels 2014, 28, 228–235. [Google Scholar] [CrossRef]

- Gitzhofer, F. A review on plasma technologies applied to thermo-chemical biomass conversion. In Biorefnery I: Chemicals and Materials from Thermo-Chemical Biomass Conversion and Related Processes; Engineering Conferences International Symposium Series: Chania, Greece, 2015; Available online: https://www.proceedings.com/29588.html (accessed on 10 July 2024).

- Mettler, M.S.; Vlachos, D.G.; Dauenhauer, P.J. Top ten fundamental challenges of biomass pyrolysis for biofuels. Energy Environ. Sci. 2012, 5, 7797–7809. [Google Scholar] [CrossRef]

- Ansari Khursheed, B.; Arora Jyotsna, S.; Wei, C.J.; Dauenhauer Paul, J.; Mushrif Samir, H. Fast Pyrolysis of Cellulose, Hemicellulose, and Lignin: Effect of operating Temperature on Bio-oil Yield and Composition and Insights into the Intrinsic Pyrolysis Chemistry. Ind. Eng. Chem. Res. 2019, 58, 15838–15852. [Google Scholar] [CrossRef]

- Kadam, R.; Panwar, N.L. Recent advancement in biogas enrichment and its applications. Renew. Sustain. Energy Rev. 2017, 73, 892–903. [Google Scholar] [CrossRef]

- Wang, X.; Yang, G.; Feng, Y.; Ren, G.; Han, X. Optimizing feeding composition and carbon-nitrogen ratios for improved methane yield during anaerobic co-digestion of dairy, chicken manure and wheat straw. Bioresour. Technol. 2012, 120, 78–83. [Google Scholar] [CrossRef]

- Katinas, V.; Marčiukaitis, M.; Perednis, E.; Dzenajavičienė, E.F. Analysis of bio-de-gradable waste use for energy generation in Lithuania. Renew. Sustain. Energy Rev. 2019, 101, 559–567. [Google Scholar] [CrossRef]

- Chen, S.; Yong, Q.; Xu, Y.; Zhu, J.; Yu, S. Effect of dilute acid pretreatment on fiber composition and structure of corn stover. Chin. J. Grain Oil 2011, 26, 13–19. [Google Scholar]

- Hua, X. Optimization of Hydrolysis and Fermentation of Cellulose Waste for Fuel Ethanol Production. Master’s Thesis, Shanghai Jiao Tong University, Shanghai, China, 2012. [Google Scholar]

- Zeng, F.; Jiang, J.; Wei, M.; Chen, Y.R. Research progress of biomass hydrolysis and fermentation to produce fuel ethanol. Biomass Chem. Eng. 2009, 43, 43–48. [Google Scholar]

- Vohra, M.; Manwar, J.; Manmode, R.; Padgilwar, S.; Patil, S. Bioethanol production: Feedstock and current technologies. J. Environ. Chem. Eng. 2014, 2, 573–584. [Google Scholar] [CrossRef]

- Ma, L.; Tang, Z.; Wang, C.; Sun, Y.; Lü, X.; Chen, Y. Current status of biomass energy research and future development strategy. Scaled Util. Renew. Energy 2019, 34, 04. [Google Scholar] [CrossRef]

- Xu, J. Overview of China’s energy and power development in 2023. Energy 2024, 3, 29–35. [Google Scholar]

- Liu, J.; Li, G.; Wang, J. Current Situation and Development Trend of Biomass Power Generation Technology. In Proceedings of the Fifth International Conference on Mechatronics and Computer Technology Engineering, Chongqing, China, 19–21 August 2022. [Google Scholar]

- Wu, T.; Liu, K.; Cheng, X.; Zhang, J. Analysis of energy, carbon emissions and economics during the life cycle of biomass power generation: Case comparison from China. Biomass Bioenergy 2024, 182, 107098. [Google Scholar] [CrossRef]

- Yun, H.; Dai, J.; Li, H.; Bi, X. Economic and environmental assessment of biomass coupled coal-fired power generation. CIESC J. 2021, 72, 6311–6327. [Google Scholar]

- Xu, Y.; Yang, K.; Zhou, J.; Zhao, G. Coal-biomass Co-firing power generation technology: Current status, challenges and policy implications. Sustainability 2020, 12, 3692. [Google Scholar] [CrossRef]

- Huang, Y.; Zhao, Y.-J.; Hao, Y.-H.; Wei, G.-Q.; Feng, J.; Li, W.-Y.; Yi, Q.; Mohamed, U.; Pourkashanian, M.; Nimmo, W. A feasibility analysis of distributed power plants from agricultural residues resources gasification in rural China. Biomass Bioenergy 2019, 121, 1–12. [Google Scholar] [CrossRef]

- Wylock, C.E.; Budzianowski, W.M. Performance evaluation of biogas upgrading by pressurized water scrubbing via modelling and simulation. Chem. Eng. Sci. 2017, 170, 639–652. [Google Scholar] [CrossRef]

- Gkotsis, P.; Kougias, P.; Mitrakas, M.; Zouboulis, A. Biogas upgrading technologies-Recent advances in membrane-based processes. Int. J. Hydrogen Energy 2023, 48, 3965–3993. [Google Scholar] [CrossRef]

- Baena-Moreno, F.M.; Le Saché, E.; Pastor-Perez, L.; Reina, T.R. Memberane-based technologies for biogas upgrading: A review. Environ. Chem. Lett. 2020, 18, 1649–1658. [Google Scholar] [CrossRef]

- Tang, Z.; Li, Z. Progress of carbon dioxide separation and utilisation technology in biogas. China Biogas 2023, 41, 10–17. [Google Scholar]

- Da Silva Veras, T.; Mozer, T.S.; da Costa Rubim Messeder dos Santos, D.; da Silva César, A. Hydrogen: Trends, production and characterization of the main process worldwide. Int. J. Hydrogen Energy 2017, 42, 2018–2033. [Google Scholar] [CrossRef]

- Li, L.; Peng, J.; Fu, B.; Huang, Y.; Jiang, H.; Qi, H. Analysis of the development trend and application prospect of green hydrogen production technology under the vision of carbon neutralization. J. Sol. Energy 2022, 43, 508–520. [Google Scholar]

- Zhang, Y.; Xu, S.; Zhang, Q.; Li, Y. Metal nanoparticles in dark fermentation biological hydrogen production. Appl. Chem. 2021, 50, 1922–1926. [Google Scholar]

- Parthasarathy, P.; Narayanan, K.S. Hydrogen production from steam gasification of biomass: Influence of process parameters on hydrogen yield—A review. Renew. Energy 2014, 66, 570–579. [Google Scholar] [CrossRef]

- Arregi, A.; Amutio, M.; Lopez, G.; Bilbao, J.; Olazar, M. Evaluation of thermochemical routes for hydrogen production from biomass: A review. Energy Convers. Manag. 2018, 165, 696–719. [Google Scholar] [CrossRef]

- Ye, L.; Huang, L.; Duan, X.; Yuan, Y.; Xie, S. Degradable polyglycolic acid was prepared from coal by syngas technical progress. Clean Coal Technol. 2022, 28, 110–121. [Google Scholar]

- Wang, X.; Wei, Q.; Ren, X. Study on the preparation and separation of glycolic acid and polyglycolic acid Progress. Chem. Prog. 2018, 37, 8. [Google Scholar]

- Li, H. Biomass liquid fuels move towards large-scale application. Sci. Technol. Dly. 2024. [Google Scholar] [CrossRef]

- Sharma, B.; Larroche, C.; Dussap, C.-G. Comprehensive assessment of 2G bioethanol production. Bioresour. Technol. 2020, 313, 123630. [Google Scholar] [CrossRef]

- Gong, C.; Cao, L.; Fang, D.; Zhang, J.; Awasthi, M.K.; Xue, D. Genetic manipulation strategies for ethanol production from bioconversion of lignocellulose waste. Bioresour. Technol. 2022, 352, 127105. [Google Scholar] [CrossRef] [PubMed]

- Chu, D.; Xin, Y.; Zhao, C. Preparation of bioethanol from corn stover by continuous hydrogenolysis. Chin. J. Catal. 2021, 42, 844–854. [Google Scholar] [CrossRef]

- Hou, J.; Zhang, X.; Zhang, S.; Hu, W.; Kang, Z.; Yi, G.; Zhou, Y.; Huang, Y.; Zhang, Q. Improvement of bioethanol production using a new fermentation system: The process analysis and micro-mechanisms study. Process Saf. Environ. Prot. 2022, 162, 837–845. [Google Scholar] [CrossRef]

- Liu, F.; Guo, X.; Wang, Y.; Chen, G.; Hou, L. Process simulation and economic and environmental evaluation of a corncob-based biorefinery system. Clean. Prod. 2021, 329, 129707. [Google Scholar] [CrossRef]

- Yang, Q.; Huo, D.; Han, X.; Gu, C.; Hou, Q.; Zhang, F.; Si, C.; Liu, Z.; Ni, Y. Improvement of fermentable sugar recovery and bioethanol production from eucalyptus wood chips with the combined pretreatment of NH4Cl impregnation and refining. Ind. Crops Prod. 2021, 167, 113503. [Google Scholar] [CrossRef]

- Zhang, F.; Wang, J.; Liu, S.; Zhang, S.; Sutherland, J.W. Integrating GIS with optimization method for a biofuel feedstock supply chain. Biomass Bioenergy 2017, 98, 194–205. [Google Scholar] [CrossRef]

- Leng, L.; Han, P.; Yuan, X.; Li, J.; Zhou, W. Biodiesel microemulsion upgrading and thermogravimetric study of bio-oil produced by liquefaction of different sludges. Energy 2018, 153, 1061–1072. [Google Scholar] [CrossRef]

- Sundus, F.; Fazal, M.; Masjuki, H. Tribology with biodiesel: A study on enhancing biodiesel stability and its fuel properties. Renew. Sustain. Energy Rev. 2017, 70, 399–412. [Google Scholar] [CrossRef]

- Sajjadi, B.; Raman, A.A.A.; Arandiyan, H. A comprehensive review on properties of edible and non-edible vegetable oil-based biodiesel: Composition, specifications and prediction models. Renew. Sustain. Energy Rev. 2016, 63, 62–92. [Google Scholar] [CrossRef]

- Yadav, C.; Saini, A.; Bera, M.; Maji, P.K. Thermo-analytical characterizations of biodiesel produced from edible and non-edible oils. Fuel Process. Technol. 2017, 167, 395–403. [Google Scholar] [CrossRef]

- Ayhan, D. New liquid biofuels from vegetable oils via catalytic pyrolysis. Energy Educ. Sci. Technol. 2008, 21, 1–59. [Google Scholar]

- Innovation Outlook: Renewable Methanol; International Renewable Energy Agency, IRENA AND METHANOL INSTITUTE: Abu Dhabi, United Arab Emirates, 2021.

- Wang, X.; Demirel, Y. Feasibility of power and methanol production by an entrained flow coal gasification system. Energy Fuels 2018, 32, 7595–7610. [Google Scholar] [CrossRef]

- Chen, Z.; Shen, Q.; Sun, N.; Wei, W. Life cycle assessment of typical methanol production routes: The environmental impacts analysis and power optimization. Clean. Prod. 2019, 220, 408–416. [Google Scholar] [CrossRef]

- Zakaria, Z.; Kamarudin, S. Direct conversion technologies of methane to methanol: An overview. Renew. Sustain. Energy Rev. 2016, 65, 250–261. [Google Scholar] [CrossRef]

- Osman, A.I.; Mehta, N.; Elgarahy, A.M.; Al-Hinai, A.; Al-Muhtaseb, A.H.; Rooney, D.W. Conversion of biomass to biofuels and life cycle assessment: A review. Environ. Chem. Lett. 2021, 19, 4075–4118. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, X.; Chen, Y.; Cheng, H.; Zhu, Z.; Zhong, L. Economics of Methanol From Waste Biomass. Ref. Modul. Chem. Mol. Sci. Chem. Eng. 2024. [Google Scholar] [CrossRef]

- Singh, N.B.; Kumar, A.; Rai, S. Potential production of bioenergy from biomass in an Indian perspective. Renew. Sustain. Energy Rev. 2014, 39, 65–78. [Google Scholar] [CrossRef]

- Wang, S.; Li, C.; Hu, Y.-J.; Wang, H.; Xu, G.; Zhao, G.; Wang, S. Assessing the prospect of bio-methanol fuel in China from a life cycle perspective. Fuel 2024, 358, 130255. [Google Scholar] [CrossRef]

- Christian, B.; Esther, L.F. Commercialization of low carbon methanol. ATZextra Worldw. 2016, 21, 22–25. [Google Scholar]

- Li, C.; Hao, Q.; Wang, H.; Hu, Y.-J.; Xu, G.; Qin, Q.; Wang, X.; Negnevitsky, M. Assessing green methanol vehicles’ deployment with life cycle assessment-system dynamics model. Appl. Energy 2024, 363, 123055. [Google Scholar] [CrossRef]

- Yang, S.; Li, B.; Zheng, J.; Kankala, R.K. Biomass-to-Methanol by dual-stage entrained flow gasification: Design and techno-economic analysis based on system modeling. Clean. Prod. 2018, 205, 364–374. [Google Scholar] [CrossRef]

- Fargione, J.; Hill, J.; Tilman, D.; Polasky, S.; Hawthorne, P. Land clearing and the biofuel carbon debt. Science 2008, 319, 1235–1238. [Google Scholar] [CrossRef]

- Fan, M.; Jiang, P.; Bi, P.; Deng, S.; Yan, L.; Zhai, Q.; Wang, T.; Li, Q. Directional synthesis of ethylbenzene througu catalytic transformation of lignin. Bioresour. Technol. 2013, 143, 59–67. [Google Scholar] [CrossRef]

- Liu, X.; Li, T.; Wu, S.; Ma, H.; Yin, Y. Structural characterization and comparison of enzymatic and deep eutectic solvents isolated lignin from various green processes: Toward lignin valorization. Bioresour. Technol. 2020, 310, 123460. [Google Scholar] [CrossRef]

- Ly, H.V.; Park, J.W.; Kim, S.-S.; Hwang, H.T.; Kim, J.; Woo, H.C. Catalytic pyrolysis of bamboo in a bubbling fluidized-bed reactor with two different catalysts: HZSM-5 and red mud for upgrading bio-oil. Renew. Energy 2020, 149, 1434–1445. [Google Scholar] [CrossRef]

- Wang, K.; Kim, K.H.; Brown, R.C. Catalytic pyrolysis of individual components of lignocellulosic biomass. Green Chem. 2014, 16, 727–735. [Google Scholar] [CrossRef]

- Zheng, Y.; Wang, J.; Liu, C.; Lu, Y.; Lin, X.; Li, W.; Zheng, Z. Efficient and stable Ni-Cu catalysts for ex situ catalytic pyrolysis vapor upgrading of oleic acid into hydrocarbon: Effect of catalyst support, process parameters and Ni-to-Cu mixed ratio. Renew. Energy 2020, 154, 797–812. [Google Scholar] [CrossRef]

- Wang, F.; Zhang, W.; Jiang, J.; Xu, J.; Zhai, Q.; Wei, L.; Long, F.; Liu, C.; Liu, P.; Tan, W.; et al. Nitrogen-rich carbon-supported ultrafine MoC nanoparticles for the hydrotreatment of oleic acid into diesel-like hydrocarbons. Chem. Eng. J. 2020, 382, 122464. [Google Scholar] [CrossRef]

- Li, J.; Yang, G.; Yoneyama, Y.; Vitidsant, T.; Tsubaki, N. Jet fuel synthesis via Fischer-Tropsch synthesis with varied 1-olefins as additives using Co/ZrO2-SiO2 bimodal catalyst. Fuel 2016, 171, 159–166. [Google Scholar] [CrossRef]

- Li, X.; He, J.; Meng, M.; Yoneyama, Y.; Tsubaki, N. One-step synthesis of H-β zeolite enwrapped Co/Al2O3 fischer-tropsch catalyst with high spatial selectivity. J. Catal. 2008, 265, 26–34. [Google Scholar] [CrossRef]

- Anbarasan, P.; Baer, Z.C.; Sreekumar, S.; Gross, E.; Binder, J.B.; Blanch, H.W.; Clark, D.S.; Toste, F.D. Integration of chemical catalysis with extractive fermentation to produce fuels. Nature 2012, 491, 235–239. [Google Scholar] [CrossRef] [PubMed]

- Briassoulis, D.; Giannoulis, A. Evaluation of the functionality of bio- based plastic mulching films. Polym. Test. 2018, 67, 99–109. [Google Scholar] [CrossRef]

- Jiang, H.; Li, X.; Gao, Q.; Zhang, H. Analysis of Bio-based Materials Development and R&D Trend. Chin. Biotechnol. 2024, 44, 142–151. [Google Scholar]

- Sun, K.; Zhang, L.; Hu, S.; Liu, Y. The high performance of bio-based plastics should be fully utilized. China Pet. Chem. Ind. Obs. 2024, 04, 41–42. [Google Scholar]

- Ma, Y. Vigorously develop bio-based material industry to accelerate the formation of new quality productivity. Forw. Forum 2024, 3, 62–64. [Google Scholar]

- Kumar, M.; Oyedun, A.O.; Kumar, A. A review on the current status of various hydrothermal technologies on biomass feedstock. Renew. Sustain. Energy Rev. 2017, 81, 1742–1770. [Google Scholar] [CrossRef]

- Wu, J.; Xia, M.; Zhang, X.; Chen, Y.; Sun, F.; Wang, X.; Yang, H.; Chen, H. Hierarchical porous carbon derived from wood tar using crab as the template: Performance on supercapacitor. J. Power Sources 2020, 455, 25–39. [Google Scholar] [CrossRef]

- Zhu, J.; Jia, J.; Kwong, F.L.; Ng, D.H.L.; Tjong, S.C. Synthesis of multiwalled carbon nanotubes from bamboo charcoal and the roles of minerals on their growth. Biomass Bioenergy 2012, 36, 12–19. [Google Scholar] [CrossRef]

- Wang, X.; Lu, J. Research progress of biofuel cell. Shandong Chem. Ind. 2017, 46, 61–63+66. [Google Scholar]

- Wu, G.; Yao, Z.; Fei, B.; Gao, F. An enzymatic ethanol biosensor and ethanol/air biofuel cell using liquid-crystalline cubic phases as hosting matrices to co-entrap enzymes and mediators. J. Electrochem. Soc. 2017, 164, G82–G86. [Google Scholar] [CrossRef]

- Shoji, K.; Akiyama, Y.; Suzuki, M.; Nakamura, N.; Ohno, H.; Morishima, K. Biofuel cell backpacked insect and its application to wireless sensing. Biosens. Bioelectron. 2016, 78, 390–395. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Lv, P.; Yao, Y.; Feng, Q.; Mensah, A.; Li, D.; Wei, Q. A novel single-enzymatic biofuel cell based on highly flexible conductive bacterial cellulose electrode utilizing pollutants as fuel. Chem. Eng. J. 2020, 379, 122316. [Google Scholar] [CrossRef]

- Sahoo, U.; Kumar, R.; Pant, P.; Chaudhary, R. Development of an innovative polygeneration process in hybrid solar-biomass system for combined power, cooling and desalination. Appl. Therm. Eng. 2017, 120, 560–567. [Google Scholar] [CrossRef]

- Baldelli, M.; Bartolucci, L.; Cordiner, S.; D’andrea, G.; De Maina, E.; Mulone, V. Biomass to H2: Evaluation of the Impact of PV and TES Power Supply on the Performance of an Integrated Bio-Thermo-Chemical Upgrading Process for Wet Residual Biomass. Energies 2023, 16, 2966. [Google Scholar] [CrossRef]

- Cappiello, F.L.; Cimmino, L.; D’accadia, M.D.; Vicidomini, M. A solar-assisted liquefied biomethane production by anaerobic digestion: Dynamic simulations for harbors. Renew. Sustain. Energy Rev. 2024, 189, 114066. [Google Scholar] [CrossRef]

- Irshad, A.S.; Zakir, M.N.; Rashad, S.S.; Lotfy, M.E.; Mikhaylov, A.; Elkholy, M.; Pinter, G.; Senjyu, T. Comparative analyses and optimizations of hybrid biomass and solar energy systems based upon a variety of biomass technologies. Energy Convers. Manag.-X 2024, 23, 100640. [Google Scholar] [CrossRef]

- Liu, Y.; Bi, D.; Yin, M.; Zhang, K.; Liu, H.; Liu, S. Modeling and exergy-economy analysis of residential building energy supply systems combining torrefied biomass gasification and solar energy. Therm. Sci. Eng. Prog. 2024, 50, 102584. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhang, C.; Yan, M.; Liu, Z.; Li, W.; Li, H.; Wang, Y. Biomass-fired combined heat, cool and power system incorporating organic Rankine cycle and single-effect lithium bromide absorption refrigeration integrated with CO2 capture: Thermo-economic analysis. Energy 2024, 304, 132096. [Google Scholar] [CrossRef]

- Zhu, C.; Wang, M.; Guo, M.; Deng, J.; Du, Q.; Wei, W.; Zhang, Y.; Mohebbi, A. An innovative process design and multi-criteria study/optimization of a biomass digestion-supercritical carbon dioxide scenario toward boosting a geothermal-driven cogeneration system for power and heat. Energy 2024, 292, 130408. [Google Scholar] [CrossRef]

- Zhu, C.; Wang, M.; Guo, M.; Deng, J.; Du, Q.; Wei, W. Design and multi-aspect analysis of a geothermal and biomass dual-source power, cooling, heating, and hybrid freshwater production system. Energy 2024, 293, 130532. [Google Scholar] [CrossRef]

- Zhao, H.; Lu, R.; Zhang, T. Thermodynamic and economic performance study of SOFC combined cycle system using biomass and LNG coupled with CO2 recovery. Energy Convers. Manag. 2023, 280, 116817. [Google Scholar] [CrossRef]

- Xin, Y.; Xing, X.; Li, X.; Hong, H. A biomass-solar hybrid gasification system by solar pyrolysis and PV-Solid oxide electrolysis cell for sustainable fuel production. Appl. Energy 2024, 356, 122419. [Google Scholar] [CrossRef]

- Guo, S.; Zhang, D.; Li, X.; He, X.; Wang, H.; Deng, J.; Zhang, X.; Tian, W.; Qiu, S.; Su, G. Exergy analysis of biomass and nuclear hydrogen production system. Int. J. Hydrogen Energy 2024, 57, 1354–1363. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, Y.; Zhang, Y.; Wu, Q.; Xin, L.; Zhou, Y.; Yin, K.; Wang, Y.; Li, X.; Cui, P. A novel power, DME, and ammonia polygeneration system using Aspen plus based on the integration of biomass gasification and syngas chemical looping. Energy Convers. Manag. 2024, 299, 117808. [Google Scholar] [CrossRef]

- Wu, Z.; Zhang, Z.; Xu, G.; Ge, S.; Xue, X.; Chen, H. Thermodynamic and economic analysis of a new methanol synthesis system coupled with a biomass integrated gasification combined cycle. Energy 2024, 300, 131647. [Google Scholar] [CrossRef]

- de Fournas, N.; Wei, M. Techno-economic assessment of renewable methanol from biomass gasification and PEM electrolysis for decarbonization of the maritime sector in California. Energy Convers. Manag. 2022, 257, 115440. [Google Scholar] [CrossRef]

- Harris, K.; Grim, R.G.; Huang, Z.; Tao, L. A comparative techno-economic analysis of renewable methanol synthesis from biomass and CO2: Opportunities and barriers to commercialization. Appl. Energy 2021, 303, 117637. [Google Scholar] [CrossRef]

- Zhang, Q.; Chen, H.; Li, B.; Pan, P.; Xu, G.; Zhao, Q.; Jiang, X. A novel system integrating water electrolysis and supercritical CO2 cycle for biomass to methanol. Appl. Therm. Eng. 2023, 225, 120234. [Google Scholar] [CrossRef]

- Cappiello, F.L.; Cimmino, L.; D’accadia, M.D.; Vicidomini, M. Dynamic simulation and thermoeconomic analysis of a power to gas system. Renew. Sustain. Energy Rev. 2023, 187, 113759. [Google Scholar] [CrossRef]

| Technical | Advantages | Disadvantages | Percentage of Application |

|---|---|---|---|

| membrane separation | CH4 content of 90.3%; low operating costs; environmentally friendly; simple equipment and operation; small footprint | membrane elements are fragile, short-lived, and costly | 25% |

| water washing | CH4 content of 96.1%; good regeneration | high investment and operating costs; large footprint; difficult CO2 recovery | 31% |

| variable pressure adsorption | CH4 content of 95.8%; low energy consumption; good regeneration; simultaneous removal of H2S | high CH4 loss rate; high cost; complex process; prone to fouling | 14% |

| cryogenic separation | High CO2 separation; liquid CH4 can be produced | high energy consumption; high investment and operating costs; complex equipment | 1% |

| chemical absorption | CH4 content of 94.6%; simple process; high efficiency; high product purity | high investment costs; high absorbent toxicity; difficult to dispose of waste | 21% |

| biotransformation | CH4 content of 94%; low cost and low energy consumption; environmentally friendly | requires the addition of microbial nutrients; volatile acids tend to accumulate | 8% |

| Primary Classification | Secondary Classification | Strengths and Weaknesses |

|---|---|---|

| thermochemical hydrogenation | gasification | high reaction temperature; catalyst required; tar difficult to control |

| pyrolytic reforming | low reaction temperature; simple process; tar is difficult to control | |

| supercritical water conversion | no tar; high conversion rate; high-temperature and high-pressure environment; clogging and coke problems | |

| chemical chain | high hydrogen purity; high-temperature and high-pressure environment; high- performance oxygen carriers are expensive | |

| biological method for producing hydrogen | photolytic water | O2 in the product; low light energy conversion |

| optical fermentation | no O2 generation; high conversion rate; complex system | |

| dark fermentation | high economy; fast hydrogen production rate; good stability; volatile acids tend to accumulate | |

| light–dark fermentation | high energy conversion efficiency; low carbon dioxide emissions; high hydrogen production rate; complex technology and high cost |

| Generation | Material | Production Process | Vantage | Drawbacks |

|---|---|---|---|---|

| 1 | oilseeds, plant refined oil, and edible-crop refined oil (such as soybeans, rapeseed, peanuts, etc.) | ester exchange | mature technology; simple process; the most mature development | poor low-temperature fluidity; not suitable for long-term storage; increases food security |

| 2 | non-food crops, agricultural biomass waste, forestry waste biomass (such as wampee, mango, animal fats, rubber seeds, etc.) | hydrogenation of fats and oils | no food security issues; high carbon emission reduction effects | purification separation; purification is more difficult and costly |

| 3 | microalgae, microorganisms (such as autotrophic microalgae, heterotrophic microalgae, yeast, etc.) | photosynthesis | no pretreatment is required; high lipid production; the breeding method is simple and rapid; sewage purification | high cost; need a lot of water resources; may be toxic; poor fluidity at low temperatures |

| Production Route | Material | Technological Route | Advantages and Disadvantages |

|---|---|---|---|

| Methanol from biomass gasification | Biomass, H2 | pretreatment → gasification → syngas treatment → methanol synthesis, distillation | higher thermochemical efficiency; difficult to scale up |

| Methanol from biomass biogas | Biomass, O2 | biogas → pretreatment → methane reforming → syngas compression → methanol synthesis and distillation | slow process; low biomass energy density; difficult disposal of waste residues |

| First Classification | Secondary Classification | |

|---|---|---|

| Bio-based material | Bio-based chemicals | ethanol, lactic acid, 1,3-propanediol, etc. |

| Bio-based plastics | non-biodegradable bio-based plastics (polylactic acid, polycaprolactone, polybutylene terephthalate, starch-based plastics, etc.) | |

| biodegradable bio-based plastics (polyethylene, polyamide, polyethylene terephthalate and modified natural polymers, etc.) | ||

| Bio-based chemical fibers | polylactic acid fiber | |

| bio-based polyamide fibers | ||

| polyterephthalate (PTT) fibers | ||

| chitin fiber | ||

| seaweed fiber | ||

| protein-modified fibers | ||

| Bio-based elastomers | bio-based rubber | |

| other elastomers | ||

| Bio-based material additives | bio-based plasticisers | |

| bio-based combustion agents | ||

| bio-based adhesives | ||

| bio-based lubricants | ||

| bio-based cleaners | ||

| bio-based surfactants | ||

| bio-based other additives | ||

| Bio-based coatings | bio-based anticorrosion coatings | |

| bio-based light-curing coatings | ||

| other bio-based coatings | ||

| Bio-based Composites | wood-based composite materials | |

| bamboo-based composite materials | ||

| starch-based composite materials |

| Classification | Type | Advantages and Disadvantages |

|---|---|---|

| Catalyst type | microbial fuel cell | Wide range of raw materials Mild operating environment No pollution and low cost Low output power density |

| enzyme fuel cell | High catalyst selectivity Catalysts are costly, prone to deactivation and have poor stability | |

| Electronic transfer method | direct biofuel cell | Low current and power density |

| indirect biofuel cells | High efficiency of electronic transfer |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, T.; Zhou, T.; Li, C.; Song, Q.; Zhang, M.; Yang, H. Development Status and Prospects of Biomass Energy in China. Energies 2024, 17, 4484. https://doi.org/10.3390/en17174484

Wang T, Zhou T, Li C, Song Q, Zhang M, Yang H. Development Status and Prospects of Biomass Energy in China. Energies. 2024; 17(17):4484. https://doi.org/10.3390/en17174484

Chicago/Turabian StyleWang, Tong, Tuo Zhou, Chaoran Li, Qiang Song, Man Zhang, and Hairui Yang. 2024. "Development Status and Prospects of Biomass Energy in China" Energies 17, no. 17: 4484. https://doi.org/10.3390/en17174484

APA StyleWang, T., Zhou, T., Li, C., Song, Q., Zhang, M., & Yang, H. (2024). Development Status and Prospects of Biomass Energy in China. Energies, 17(17), 4484. https://doi.org/10.3390/en17174484