Comparison of the Energy Efficiency of Fixed and Tracking Home Photovoltaic Systems in Northern Poland

Abstract

1. Introduction

- First of all, there was a change in the status of new owners of photovoltaic installations in Poland. They stopped being prosumers with a quantitative settlement and were treated as energy producers with a financial settlement. This solution is less favorable for investors.

- Secondly, over the last five years, according to data from PSE (Polish Energy Networks), there has been a fivefold increase in the power installed in PV installations. The microgeneration market has been saturated with simple PV installations. New but much more expensive solutions have appeared (Smart Home Systems, PV tracking systems), and difference in investment costs for their use is not economically justified, which is partially shown in our article in relation to PV tracking systems.

- Thirdly, there has been a significant increase in the technical and economic awareness of potential investors. This translates into greater caution when investing in PV technology that is not supported by reliable technical information about the technology used.

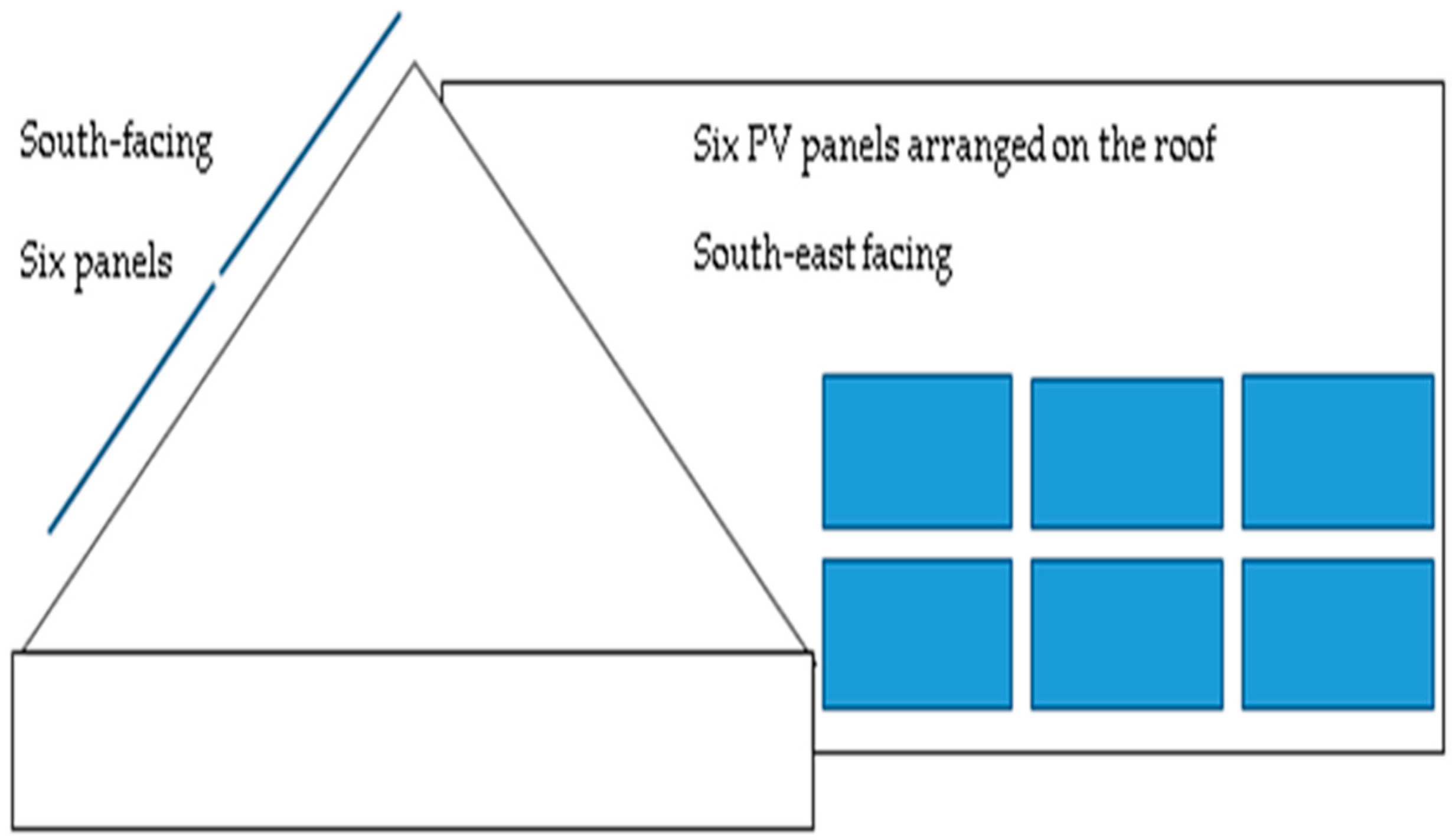

2. Specifications of the Tested Installations

- Roof installed, off grid—year of construction 2014;

- Roof installed, on grid—year of construction 2020;

- Dual-axis tracking system, on grid—year of construction 2020.

| Installation I3 kWp (2014) | Installation II5.2 kWp (2020) | Installation III4.8 kWp (2020) | ||

|---|---|---|---|---|

| Module type | (-) | MS250P-60 | SV120M.3.2-370 | SV120M.3.2-370 |

| Max. power | Pmax (W) | 250 | 370 | 370 |

| Open-circuit voltage | Uoc (V) | 37 | 40.9 | 40.9 |

| Max. power voltage | Umpp (V) | 26 | 34.3 | 34.3 |

| Short-circuit current | Isc (A) | 9.12 | 11.49 | 11.49 |

| Max. power current | Imppt (A) | 8.71 | 10.79 | 10.79 |

| Efficiency | (%) | 17.1 | 20.3 | 20.3 |

| Insolation [14] | (kWh/m2) | 1070 | 985 | 985 |

| Temperature coefficient of Pmax | %/°C | −0.407 | −0.36 | −0.36 |

| Installation I (2014) | Installation II (2020) | Installation III (2020) | ||

|---|---|---|---|---|

| Module type of inverter | (-) | Omega S1 | FroniusSymo5.0-3-M | FroniusSymo5.0-3-M |

| Max. input current | (A) | 7/15/24 | 16 | 16 |

| Min. input current | Umin (V) | 25 | 150 | 150 |

| Nominal input voltage | Unom (V) | 52 | 595 | 595 |

| Max. input voltage | Umax (V) | 90 | 1000 | 1000 |

| MPPT voltage range | (V) | 40–90 | 163–800 | 163–800 |

| Max. output current | (A) | 7/15/24 | 13.5 | 13.5 |

| Range of adjustable output voltage | (V) | 40–90 | 260–485 | 260–485 |

| Frequency | (Hz) | - | 50 | 50 |

| Internal night power consumption | (W) | <1 | <1 | <1 |

3. Energy Yields of the Considered PV Installations

- Efficiency was understood as an energy source operating in a specific geographic and time period;

- Cost effectiveness was understood as an investment with a specific depreciation;

- Operation was understood as a technical object subject to wear and tear over time.

4. Cost Efficiency of the Considered PV Installations

- The total (taking into account all elements) average price for electricity in the years 2014–2020 was—USD 0.15/kWh. Due to the abrupt increase in energy prices in 2023, a 5% linear annual increase in energy prices was assumed.

- Decrease in electricity production efficiency resulting from operational processes: 1.1%/year.

- Investment cost in year zero of individual photovoltaic installations: No. 1: USD 3578.5; No. 2: USD 6419.5; and No. 3: USD 13,456.6.

- The estimated, averaged annual electricity production of each tested photovoltaic installation, determined on the basis of measurements, is as follows: No. 1—1850 kWh; No. 2—3500 kWh; and No. 3—5200 kWh.

- Billing system for calculating profit for Installation II: 100% of the energy yield was used in the off-grid system. Installations II and III: an 80% on-grid prosumer system (80% user, 20% energy supplier for storage).

- The number of annual calculation periods is n = 25.

- The assumed rate of return based on the interest rate on long-term treasury bonds—CAGR (cumulative annual growth rate) [17,18]. For Installation I is used data for the first 8 years real exploatation, and for the other installations used forecast data with an r average (r average 5%). Note: If energy prices in a given country increase by more than the assumed 5%, the investment amortization time will shorten proportionally.

- The last column of Table 10 presents a simulation of the desired cost of the top-up installation, which will pay off at the same time as installations No. 1 and No. 2.

- Installation I financial flow: 10 years; discounted cash flow NPV: 13 years;

- Installation II financial flow: 10 years; discounted cash flow NPV: 13 years;

- Installation III financial flow: 13 years; discounted cash flow NPV: 19 years;

- Installation III financial flow: simulation of the desired cost of the tracking PV installation; discounted cash flow NPV: 13 years.

5. Discussion

5.1. Article 2: Energy Efficiency Analysis of 1 MW PV Farm Mounted on Fixed and Tracking Systems

5.2. Article 3: Environmental Life Cycle Analysis of a Fixed PV Energy System and a Two-Axis Sun Tracking PV Energy System in a Low-Energy House in Turkey

5.3. Article 4: Performance Comparison of a Double-Axis Sun Tracking Versus Fixed PV System

5.4. Article 5: Design and Simulation of a Solar Tracking System for PV

5.5. Article 6: Impact of PV System Tracking on Energy Production and Climate Change

5.6. Article 7: Innovative Sensorless Dual-Axis Solar Tracking System Using Particle Filter

5.7. Article 8: Comparison of Energy Production between Fixed-Mount and Tracking Systems of Solar PV Systems in Jakarta, Indonesia

5.8. Article 9: Comparative Performance Analysis between Static Solar Panels and Single-Axis Tracking System on a Hot Climate Region near to the Equator

5.9. Article 10: Performance Comparison between Fixed and Dual-Axis Sun-Tracking Photovoltaic Panels with an IoT Monitoring System in the Coastal Region of Ecuador

5.10. Article 11: Improvements of Photovoltaic Systems Using Solar Tracking in Equatorial Regions

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Directive (EU) 2018/2001 of the European Parliament and of the Council of 11 December 2018 on the Promotion of the Use of Energy from Renewable Sources (Recast). Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=uriserv:OJ.L_.2018.328.01.0082.01.ENG (accessed on 23 February 2024).

- Szyja, P. Selected Aspects of Energy Efficiency in the Era of Shaping a Low-Carbon Economy in Poland; Difin: Warsaw, Poland, 2020; ISBN 978-83-8085-890-9. [Google Scholar]

- Wielewska, I. Impact of renewable energy sources on the environment in the opinion of the inhabitants of the Chojnice poviat. Ann. Pol. Assoc. Agric. Agribus. Econ. 2017, 19, 190–195. [Google Scholar] [CrossRef]

- Report 2020 KSE. Available online: https://www.pse.pl/dane-systemowe/funkcjonowanie-kse/raporty-roczne-z-funkcjonowania-kse-za-rok/raporty-za-rok-2020 (accessed on 16 March 2023).

- Economic Efficiency of the Functioning of Photovoltaic Micro-Installations Used by the Prosumer. Available online: https://pdgr.urk.edu.pl/zasoby/98/2017_z4_a08.pdf (accessed on 20 March 2023).

- Insolation in Poland. Available online: https://www.enis-pv.com/naslonecznienie-w-polsce.html (accessed on 16 March 2023).

- Rynek Elektryczny Pl. Available online: https://www.rynekelektryczny.pl/moc-zainstalowana-fotowoltaiki-w-polsce/12 (accessed on 16 March 2023).

- Report 2021 KSE. Available online: https://www.pse.pl/dane-systemowe/funkcjonowanie-kse/raporty-roczne-z-funkcjonowania-kse-za-rok/raporty-za-rok-2021 (accessed on 16 March 2023).

- National Plan for Energy and Climate for 2021–2030. Available online: https://powermeetings.eu/krajowy-plan-na-rzecz-energii-i-klimatu-na-lata-2021-2030/ (accessed on 3 November 2022).

- Nowak, T. Case Study—Based Experience Concerning Technical and Economical Effectiveness Resulting from the Operation of Photovoltaic Installations. Sci. J. Gdyn. Marit. Univ. 2021, 120, 7–21. [Google Scholar] [CrossRef]

- PN-HD 60364-4-41:2017-09 Standard; Low Voltage Electrical Installations—Part 4–41: Protection for Safety—Protection Against Electric Shock. The Polish Committee for Standardization (PKN): Warsaw, Poland, 2005.

- PN-EN 62305-4:2011 Standard; Lightning Protection—Part 4: Electrical and Electronic Equipment in Facilities. The Polish Committee for Standardization (PKN): Warsaw, Poland, 2013.

- Insolation Conditions in the Discussed Installations. Available online: https://ecosystemproject.pl/mapa-promieniowania-słonecznego-w-polsce,0,38.htm (accessed on 23 February 2024).

- Downer, M. Multi-Criteria Investment and Operational Analysis of a Selected System on Photovoltaic Panels in A Standard Version and a System that Adjusts the Appropriate Angle of Incidence of Sunlight; Gdynia City Hall: Gdynia, Poland, 2021. [Google Scholar]

- Solińska, M.; Soliński, I. Economic Effectiveness of Pro-Ecological Development Investments in Renewable Energy; UWND: Kraków, Poland, 2003; ISBN 83-89388-51-0. [Google Scholar]

- Methodology of Investment Profitability Analysis Photovoltaic. Available online: https://finanse-w-energetyce.cire.pl/pliki/2/20pstraspopr.pdf (accessed on 20 May 2021).

- Analysis since 2007: Rate of Return on Polish Treasury Bonds TBSP Index. Available online: https://www.michalstopka.pl/analiza-od-2007-roku-stopa-zwrotu-polskich-obligacji-skarbowych-indeks-tbsp-gpw/ (accessed on 20 February 2023).

- Lewandowski, W.M.; Klugmann-Radziemska, E. Pro-Ecological Renewable Energy Sources; PWN: Warsaw, Poland, 2022; ISBN 9788301190675. [Google Scholar]

- Trzasko, W. Performance analysis of a two-axis solar tracker system. Int. J. Online Biomed. Eng. 2018, 22, 11–17. [Google Scholar] [CrossRef]

- A Comparative Study of the Effectiveness of Stationary and Tracking Photovoltaic Systems. Available online: https://www.researchgate.net/publication/349103785 (accessed on 16 March 2023).

- Kuchmacz, J.; Mika, L. Description of development of prosumer energy sector in Poland. Energy Policy J. 2018, 21, 5–20. [Google Scholar] [CrossRef]

- Walichnowska, P.; Mroziński, A.; Idzikowski, A.; Fröhlich, S.R. Energy efficiency analysis of 1 MW PV farm mounted on fixed and tracking systems. Constr. Optim. Energy Potential 2022, 11, 75–83. [Google Scholar] [CrossRef]

- Tırmıkçı, C.A.; Yavuz, C. Environmental life cycle analysis of a fixed PV energy system and a two-axis sun tracking PV energy system in a low-energy house in Turkey. Smart Sustain. Built Environ. 2019, 8, 391–399. [Google Scholar] [CrossRef]

- Ponce-Jara, M.A.; Velásquez-Figueroa, C.; Reyes-Mero, M.; Rus-Casas, C. Performance Comparison between Fixed and Dual-Axis Sun-Tracking Photovoltaic Panels with an IoT Monitoring System in the Coastal Region of Ecuador. Sustainability 2022, 14, 1696. [Google Scholar] [CrossRef]

- Baouche, F.Z.; Abderezzak, B.; Ladmi, A.; Arbaoui, K.; Suciu, G.; Mihaltan, T.C.; Raboaca, M.S.; Hudișteanu, S.V.; Țurcanu, F.E. Design and Simulation of a Solar Tracking System for PV. Appl. Sci. 2022, 12, 9682. [Google Scholar] [CrossRef]

- Ahmed, W.; Sheikh, J.A.; Mahmud, M.A.P. Impact of PV System Tracking on Energy Production and Climate Change. Energies 2021, 14, 5348. [Google Scholar] [CrossRef]

- Pirayawaraporn, A.; Sappaniran, S.; Nooraksa, S.; Prommai, C.; Chindakham, N.; Jamroen, C. Innovative sensorless dual-axis solar tracking system using particle filter. Appl. Energy 2023, 338, 120946. [Google Scholar] [CrossRef]

- Tarigan, E. Comparison of Energy Production Between Fixed-Mount and Tracking Systems of Solar PV Systems in Jakarta, Indonesia. Future Cities Environ. 2023, 9, 3. [Google Scholar] [CrossRef]

- Vieira, R.G.; Guerra, F.K.; Vale, M.R.; Araújo, M.M. Comparative performance analysis between static solar panels and single-axis tracking system on a hot climate region near to the equator. Renew. Sustain. Energy Rev. 2016, 64, 672–681. [Google Scholar] [CrossRef]

- Vaca-Jiménez, S.; Morales, C.; Ordóñez, F. Improvements of photovoltaic systems by using solar tracking in equatorial regions. In Proceedings of the 33rd European Photovoltaic Solar Energy Conference and Exhibition, Amsterdam, The Netherlands, 25–29 September 2017. [Google Scholar]

- Available online: https://akademia-fotowoltaiki.pl/temperaturowy-wspolczynnik-mocy/ (accessed on 4 July 2024).

- Sanusi, Y.K.; Fajinmi, G.R.; Babatunde, E.B. Effects of Ambient Temperature on the Performance of a Photovoltaic Solar System in a Tropical Area. Pac. J. Sci. Technol. 2011, 12, 176–180. [Google Scholar]

- Gedik, E. Experimental Investigation of Module Temperature Effect on Photovoltaic Panels Efficiency. J. Polytech. 2016, 19, 569–576. [Google Scholar]

- Du, Y.; Fell, C.J.; Duck, B.; Chen, D.; Liffman, K.; Zhang, Y.; Gu, M.; Zhu, Y. Evaluation of photovoltaic panel temperature in realistic scenarios. Energy Convers. Manag. 2016, 108, 60–67. [Google Scholar] [CrossRef]

- Liu, S.H.; Simburger, E.J.; Matsumoto, J.; Garcia, A.; Ross, J.; Nocerino, J. Evaluation of thin-film solar cell temperature coefficients for space applications. Prog. Photovolt. Res. Appl. 2005, 13, 91–178. [Google Scholar] [CrossRef]

- Tytko, R. Renewable Energy Devices and Systems, NT; Eco Investment: Kraków, Poland, 2022; ISBN 978-83-8111-266-6. [Google Scholar]

- Klugmann-Radziemska, E. Photovoltaics in Theory and Practice; BTC Publish: Legionowo, Poland, 2020; pp. 34–35. [Google Scholar]

- Frydrychowicz Jastrzębska, G.; Bugała, A. Photovoltaic systems cooperating with concentrators. Electr. Eng. 2014, 79, 71–78. [Google Scholar]

- Szymański, B. Photovoltaic Installations; Globenergia: Kraków, Poland, 2023. [Google Scholar]

- ARE. Available online: https://www.are.waw.pl/ (accessed on 21 March 2022).

- Problems in the Cooperation of Photovoltaics with the Power Grid. Available online: https://czysteogrzewanie.pl/jak-to-sie-robi/fotowoltaika-jak-uruchomic-wlasna-instalacje-krok-po-kroku/problemy-we-wspolpracy-fotowoltaiki-z-siecia-energetyczna/ (accessed on 20 March 2023).

| Installation I (2014) (Module Power 250W) | Installation II (2020) (Module Power 370W) | Installation III (2020) (Module Power 370W) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Name | IU | Quantity | Price per Item (USD) | Price (USD) | Quantity | Price per Item (USD) | Price (USD) | Quantity | Price per Item (USD) | Price (USD) |

| Photovoltaic module | pcs. | 12 | 135.4 | 1625.3 | 14 | 149.2 | 2088.9 | 13 | 149.2 | 1939.7 |

| Inverter | pcs. | 1 | 270.9 | 270.9 | 1 | 1079 | 1079 | 1 | 1079 | 1079 |

| Cables, supporting structure, and other elements | set | 1 | 1489.8 | 1489.8 | 1 | 1607.2 | 1607.2 | 1 | 819.2 | 819.2 |

| Dual-axis tracking system with motors | set | - | - | - | - | - | - | 1 | 6366.8 | 6366.8 |

| No. | Year of Energy Production | Energy Produced (kWh) | Total Energy Produced (kWh) |

|---|---|---|---|

| 1 | 2014 | 6.2 | 6.2 |

| 2 | 2015 | 2201 | 2207 |

| 3 | 2016 | 1798 | 4005 |

| 4 | 2017 | 2016 | 6021 |

| 5 | 2018 | 1849 | 7870 |

| 6 | 2019 | 1646 | 9516 |

| 7 | 2020 | 1832 | 11,348 |

| 8 | 2021 | 1728 | 13,076 |

| 9 | 2022 | 1569 | 14,645 |

| Month | Installation I (2014)(kWh) | Installation II (2020)(kWh) | Installation III (2020)(kWh) |

|---|---|---|---|

| July | 610.3 | 705.8 | 914.0 |

| August | 476.1 | 665.7 | 947.0 |

| September | 381.7 | 493.9 | 695.2 |

| October | 204.9 | 278.4 | 363.4 |

| November | 87.5 | 116.9 | 188.7 |

| December | 43.0 | 45.2 | 110.3 |

| Total | 1803.5 | 2305.9 | 3218.6 |

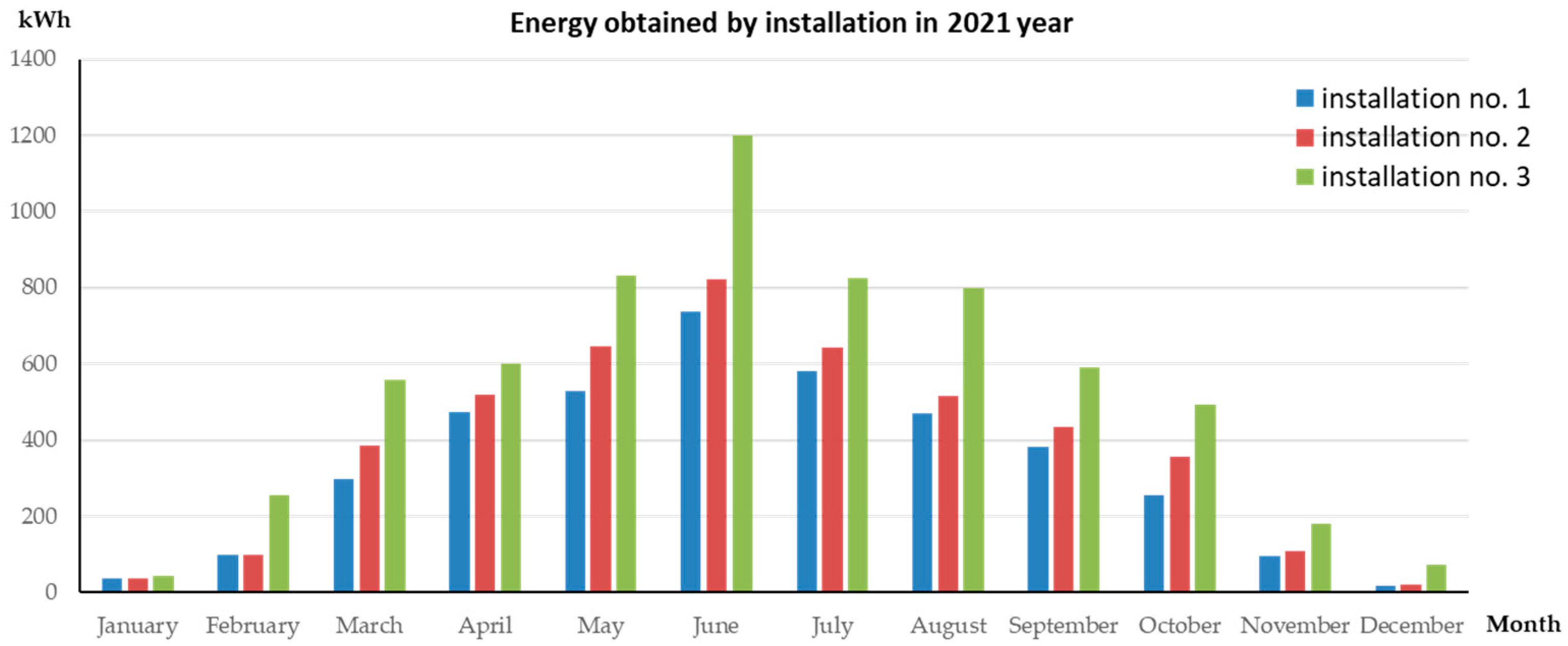

| Month | Installation I (2014) (kWh) | Installation II (2020) (kWh) | Installation III (2020) (kWh) |

|---|---|---|---|

| January | 38.2 | 36.8 | 43.2 |

| February | 98.1 | 98.2 | 256.4 |

| March | 299.0 | 385.4 | 558.5 |

| April | 473.5 | 520.6 | 599.7 |

| May | 527.2 | 645.7 | 832.0 |

| June | 736.4 | 820.5 | 1199.7 |

| July | 582.4 | 643.4 | 826.3 |

| August | 469.1 | 517.1 | 799.6 |

| September | 381.7 | 434.8 | 591.8 |

| October | 255.8 | 357 | 491.4 |

| November | 95.5 | 108.4 | 180.9 |

| December | 18.0 | 20.9 | 72.3 |

| Total | 3974.9 | 4588.8 | 6451.8 |

| Month | Installation I (2014) (kWh) | Installation II (2020) (kWh) | Installation III (2020) (kWh) |

|---|---|---|---|

| January | 42.8 | 23.9 | 86.6 |

| February | 148.0 | 88.4 | 474.3 |

| March | 464.3 | 412.6 | 501.5 |

| April | 472.1 | 448.9 | 581.8 |

| May | 471.7 | 554.9 | 878.3 |

| June | 497.7 | 813.1 | 1227.7 |

| July | 473.8 | 545.5 | 819.1 |

| August | 514.0 | 586.6 | 703.3 |

| September | 276.5 | 351.2 | 607.3 |

| October | 192.7 | 298.9 | 434.6 |

| November | 47.0 | 92.9 | 152.1 |

| December | 8.7 | 15.5 | 64.8 |

| Total | 3609.3 | 4232.4 | 6531.4 |

| Period of Operation | Comparison of Installations | ||

|---|---|---|---|

| Installation I/II (%) | Installation III/II (%) | Installation III/I (%) | |

| 1 July–31 December 2020 | −21.8 | 39.6 | 78.5 |

| 1 January–30 June 2021 | −15.4 | 39.2 | 60.6 |

| 1 July–31 December 2021 | −15.5 | 42.3 | 64.3 |

| 2021 | −15.4 | 40.6 | 62.3 |

| 1 January–30 June 2022 | −11.7 | 60.1 | 78.9 |

| 1 July–31 December 2022 | −25 | 47.1 | 83.9 |

| 2022 | −17.3 | 54.3 | 81 |

| Strengths: | SWOT Installation I | Weaknesses: |

| Simple uncomplicated installation. Simple operational supervision. Consistent comparable (despite the time of) operation energy. Off-grid installation heating with a heat exchanger and cooperation with the UPS. | Potential for internal failures resulting from aging structural and electronic components subjected to environmental conditions. | |

| Opportunities: | Threats: | |

| Good weather gives higher energy yields. Operation during power outages. | Bad weather, rapid wear and tear of installations due to environmental impacts, and technological advances. | |

| Strengths: | SWOT Installation II | Weaknesses: |

| Simple uncomplicated installation. Simple operational supervision. Consistent comparable (despite the time of) operation energy. On-grid installation and cooperation with the power grid. | Potential for internal failures resulting from aging structural and electronic components subjected to environmental conditions. No operation in the event of a power outage to the power grid. | |

| Opportunities: | Threats: | |

| Good weather gives higher energy yields. | Bad weather, rapid wear and tear of installations due to environmental impacts, and technological advances. | |

| Strengths: | SWOT Installation III | Weaknesses: |

| Gain some electricity independence. On-grid installation and cooperation with the power grid. | Complicated installation requiring technical supervision. Potential for internal failures resulting from aging structural and electronic components subjected to environmental conditions. No operation in the event of a power outage to the power grid. | |

| Opportunities: | Threats: | |

| Good weather gives higher energy yields. Excellent energy matching. | Bad weather, rapid wear and tear of the installation resulting from environmental impacts, and technological advances. |

| Year (Years) | Current and Estimated Price per 1 kWh (USD) | Installation I (2014) | Installation II (2020) | Installation III (2020) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Current and Estimated Energy Production (kWh) | Financial Gain (USD) | Financial Flow (USD) | Discounted Cash Flow NPV (USD) | Current and Estimated Energy Production (kWh) | Financial Gain (USD) | Financial Flow (USD) | Discounted Cash Flow NPV (USD) | Current and Estimated Energy Production (kWh) | Financial Gain (USD) | Financial Flow (USD) | Discounted Cash Flow NPV (USD) | Desired Installation Cost (USD) | ||

| 0 | Investment cost > | −3578.4 | −3578.4 | Investment cost > | −6419.5 | −6419.5 | Investment cost > | −13,456.6 | −13,456.6 | −9456.6 | ||||

| 1 | 0.152 | 2201 | 335.2 | −3243.2 | −3265.2 | 3670 | 558.9 | −5860.7 | −5887.3 | 5162 | 786.1 | −12,670.4 | −12,708 | −8709.3 |

| 2 | 0.159 | 1798 | 286.1 | −2957.3 | −3010.7 | 3386 | 538.6 | −5322 | −5398.6 | 5229 | 831.8 | −11,838.6 | −11,953.4 | −7955.2 |

| 3 | 0.167 | 2016 | 336.8 | −2620.4 | −2721.4 | 3489 | 583 | −4739.1 | −4895.2 | 5138 | 858.2 | −10,980.4 | −11,212 | −7214.0 |

| 4 | 0.175 | 1849 | 324.1 | −2296.4 | −2456.8 | 3451 | 604.8 | −4134.5 | −4397.7 | 5081 | 890.4 | −10,090 | −10,479.5 | −6482.5 |

| 5 | 0.182 | 1646 | 299.3 | −1997.3 | −2223.4 | 3413 | 620.4 | −3513.9 | −3911.6 | 5025 | 913.6 | −9176.4 | −9763.6 | −5765.9 |

| 6 | 0.191 | 1832 | 349.8 | −1647.5 | −1962.5 | 3375 | 644.3 | −2869.5 | −3430.7 | 1129.5 | 948.9 | −8227.5 | −9055.4 | −5057.8 |

| 7 | 0.200 | 1728 | 346.4 | −1301.1 | −1719.5 | 3338 | 669.1 | −2200.4 | −2955.2 | 4915 | 985.2 | −7242 | −8355.2 | −4359.2 |

| 8 | 0.210 | 1569 | 330.2 | −970.9 | −1478.2 | 3301 | 694.8 | −1505.7 | −2485 | 4861 | 1023.2 | −6219.1 | −7662.7 | −3668.3 |

| 9 | 0.221 | 1809 | 399.5 | −571.1 | −1220.7 | 3265 | 721.4 | −784.3 | −2020 | 4808 | 1062 | −5156.8 | −6978.2 | −2983.4 |

| 10 | 0.232 | 1789 | 414.8 | −156.6 | −966.1 | 3229 | 748.6 | −35.7 | −1560.4 | 4755 | 1102.3 | −4054.5 | −6301.4 | −2306.1 |

| 11 | 0.243 | 1769 | 430.2 | 273.6 | −714.5 | 3194 | 776.6 | 740.9 | −1106.4 | 4703 | 1143.6 | −2910.9 | −5632.7 | −1637.9 |

| 12 | 0.254 | 1750 | 445.4 | 719.1 | −466.6 | 3159 | 804.1 | 1545 | −658.6 | 4651 | 1183.9 | −1727 | −4973.6 | −980.1 |

| 13 | 0.267 | 1730 | 462.3 | 1181.6 | −221.4 | 3124 | 835 | 2379.8 | −215.9 | 4600 | 1229.3 | −497.7 | −4321.6 | −328.8 |

| 14 | 0.280 | 1711 | 479.8 | 1661.4 | 21.1 | 3089 | 866.4 | 3246.4 | 221.8 | 4549 | 1275.9 | 778.2 | −3677.3 | 314.5 |

| 15 | 0.294 | 1693 | 498.2 | 2159.8 | 260.7 | 3055 | 899.3 | 4145.7 | 654.3 | 4499 | 1324.1 | 2102.5 | −3040.2 | 950.8 |

| 16 | 0.309 | 1674 | 517 | 2676.6 | 497.7 | 3022 | 933.4 | 5078.9 | 1082 | 4450 | 1374.3 | 3476.8 | −2410.7 | 1580.7 |

| 17 | 0.324 | 1656 | 536.6 | 3213.4 | 731.8 | 2989 | 968.6 | 6047.5 | 1504.5 | 4401 | 1426.4 | 4902.9 | −1788.4 | 2202.8 |

| 18 | 0.340 | 1637 | 557 | 3770.4 | 963.2 | 2956 | 1005.7 | 7053.2 | 1922.5 | 4352 | 1480.9 | 6383.9 | −1173 | 2817.7 |

| 19 | 0.357 | 1619 | 558 | 4348.4 | 1192 | 2923 | 1043.6 | 8096.8 | 2335.4 | 4304 | 1536.8 | 7920.7 | −564.8 | 3425.7 |

| 20 | 0.375 | 1601 | 600 | 4948.4 | 1418.2 | 2891 | 1083.4 | 9180.4 | 2743.9 | 4257 | 1595.4 | 9516.1 | 36.6 | 4027.4 |

| 21 | 0.393 | 1585 | 623.6 | 5572 | 1641.8 | 2859 | 1124.8 | 10,305.2 | 3147.5 | 4210 | 1656.4 | 11,172.5 | 631.1 | 4621.3 |

| 22 | 0.413 | 1567 | 647 | 6219.1 | 1863.2 | 2828 | 1167.7 | 11,473 | 3546.8 | 4164 | 1719.5 | 12,892 | 1218.9 | 5209.2 |

| 23 | 0.433 | 1549 | 671.4 | 6890.4 | 2081.6 | 2797 | 1212 | 12,685.2 | 3941.4 | 4118 | 1784.8 | 14,677 | 1800 | 5789.7 |

| 24 | 0.454 | 1532 | 696.4 | 7586.8 | 2297.7 | 2766 | 1257.3 | 13,942.5 | 4331.4 | 4073 | 1851.4 | 16,528.2 | 2374 | 6363.0 |

| 25 | 0.477 | 1516 | 723.6 | 8310.2 | 2511.4 | 2736 | 1305.7 | 15,248 | 4716.8 | 4028 | 1922.5 | 18,450.7 | 2941.8 | 6930.4 |

| No | Title of the Article | Energy (MWh) | Difference (%), Localization | |

|---|---|---|---|---|

| Fixed | Tracker | |||

| 1. | This article: Comparison of the Energy Efficiency of Fixed and Tracking Home Photovoltaic Systems in Northern Poland | 4.45 | 6.48 | 2.5 years of measurement for Installations I and II and >8 years for Installation I: from 39.2 to 60.1 (average 46) Poland: Installation I 54.6° N, Installations II and III 53.8° N |

| 2. | Energy efficiency analysis of 1 MW PV farm mounted on fixed and tracking systems [22] | 1080 | 1293 | 16.5 Kuyavian-Pomeranian Voivodeship, Poland, latitude 53° N |

| 3. | Environmental life cycle analysis of a fixed PV energy system and a two-axis sun tracking PV Energy system in a low-energy house in Turkey [23] | 1.34 | 2.13 | Only July (max): 35.1, July–December: 31 Sakarya, Turkiye, latitude 41° N |

| 4. | Performance comparison of a double-axis sun tracking versus fixed PV system [24] | 11.53 | 15.98 | 30.8, Muğla, Turkiye, latitude 37° N |

| 5. | Design and Simulation of a Solar Tracking System for PV [25] | - | - | From 22 to 56 Northern Algeria, latitude 36° N |

| 6. | Impact of PV System Tracking on Energy Production and Climate Change [26] | 1710 | 2171 2234 | 21.2 fixed vs. one axis 23.5 fixed vs. dual axis 2.8 one axis vs. dual axis Townsville, Australia, latitude 19° S |

| 7. | Innovative sensorless dual-axis solar tracking system using particle filter [27] | 0.017 | 0.02 | 60 days: average 20.1, max. 38.5 Bangkok, Thailand, latitude 12.8° N |

| 8. | Comparison of Energy Production Between Fixed-Mount and Tracking Systems of Solar PV Systems in Jakarta, Indonesia [28] | 1.38 | 1.67 | 15–29, average 21, Jakarta, Indonesia, latitude 6° S |

| 9. | Comparative performance analysis between static solar panels and single-axis tracking system on a hot climate region near to the equator [29] | 0.00117 | 0.00131 | 13–20 July 2014: 11.5, one-axis PV Mossoro, Brazil, latitude 5.2° S |

| 10. | Performance Comparison between Fixed and Dual-Axis Sun-Tracking Photovoltaic Panels with an IoT Monitoring System in the Coastal Region of Ecuador [24] | 0.04 | 0.047 | 21 days: 19.6, Manabí, Ecuador, latitude 1° S |

| 11. | Improvements of photovoltaic systems by using solar tracking in equatorial regions [30] | 1.9 | 2.5 | 27.3 fixed vs. one axis 31 fixed vs. dual axis max. 6.5 average for one axis vs. dual axis Quito, Ecuador, latitude 0.2° S |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Listewnik, K.J.; Nowak, T. Comparison of the Energy Efficiency of Fixed and Tracking Home Photovoltaic Systems in Northern Poland. Energies 2024, 17, 4410. https://doi.org/10.3390/en17174410

Listewnik KJ, Nowak T. Comparison of the Energy Efficiency of Fixed and Tracking Home Photovoltaic Systems in Northern Poland. Energies. 2024; 17(17):4410. https://doi.org/10.3390/en17174410

Chicago/Turabian StyleListewnik, Karol Jakub, and Tomasz Nowak. 2024. "Comparison of the Energy Efficiency of Fixed and Tracking Home Photovoltaic Systems in Northern Poland" Energies 17, no. 17: 4410. https://doi.org/10.3390/en17174410

APA StyleListewnik, K. J., & Nowak, T. (2024). Comparison of the Energy Efficiency of Fixed and Tracking Home Photovoltaic Systems in Northern Poland. Energies, 17(17), 4410. https://doi.org/10.3390/en17174410