Enhanced Second-Order RC Equivalent Circuit Model with Hybrid Offline–Online Parameter Identification for Accurate SoC Estimation in Electric Vehicles under Varying Temperature Conditions

Abstract

:1. Introduction

- An enhanced second-order RC equivalent circuit model is proposed to identify internal parameters during both battery charging and discharging.

- Taking into full consideration both the accuracy and timeliness of SoC estimation, design an estimator that combines online and offline parameter identification.

- A comparison is made with the improved GRU-based transfer learning method, the traditional offline identification method, and the optimized online identification method.

- Verified by changing the battery’s surface temperature and conducting two different driving cycle tests.

- The results are verified through experiments, showing that the proposed method outperforms competing techniques.

2. Establish an Improved Lithium-Ion Battery Model

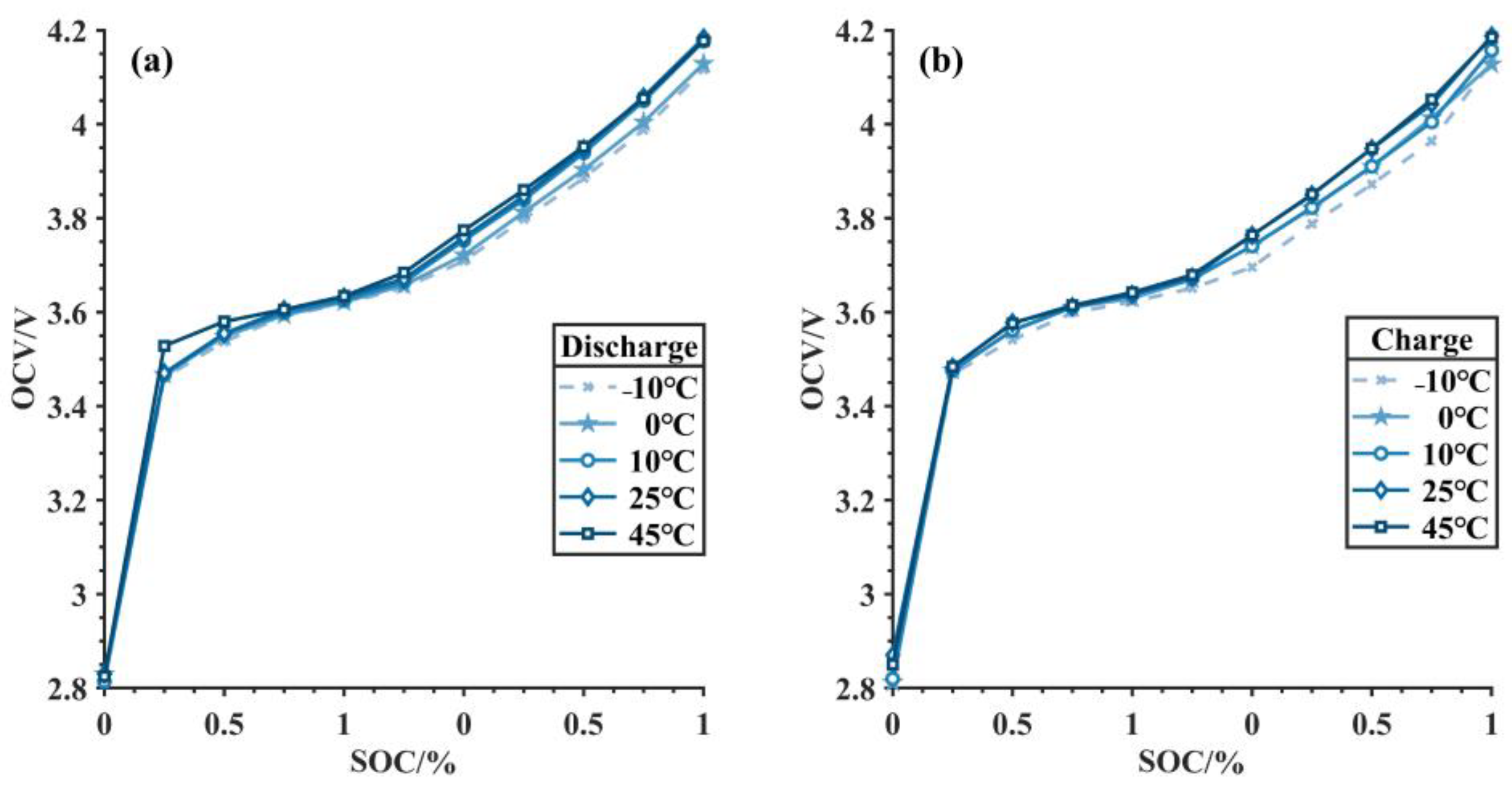

2.1. Obtaining the External Characteristic Curve of the Battery

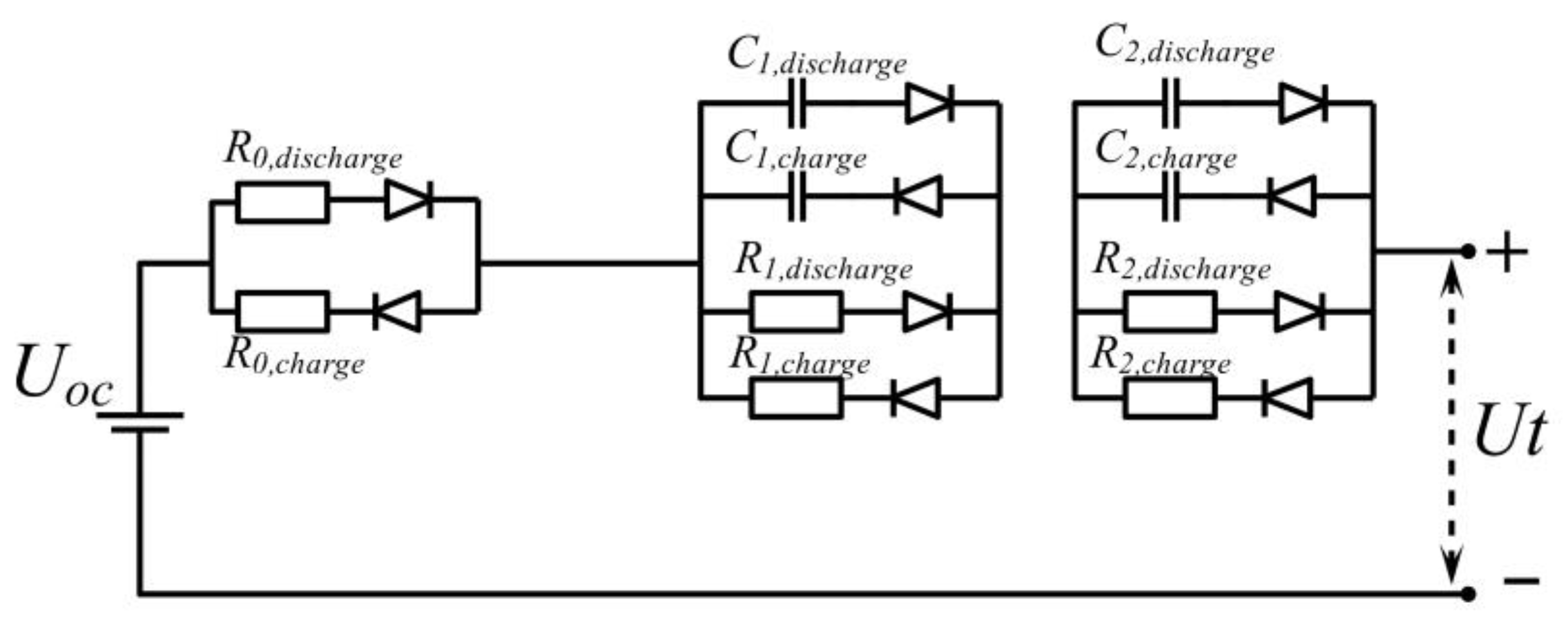

2.2. Optimized Equivalent Circuit Model

3. Acquisition of Battery Characteristic Parameters

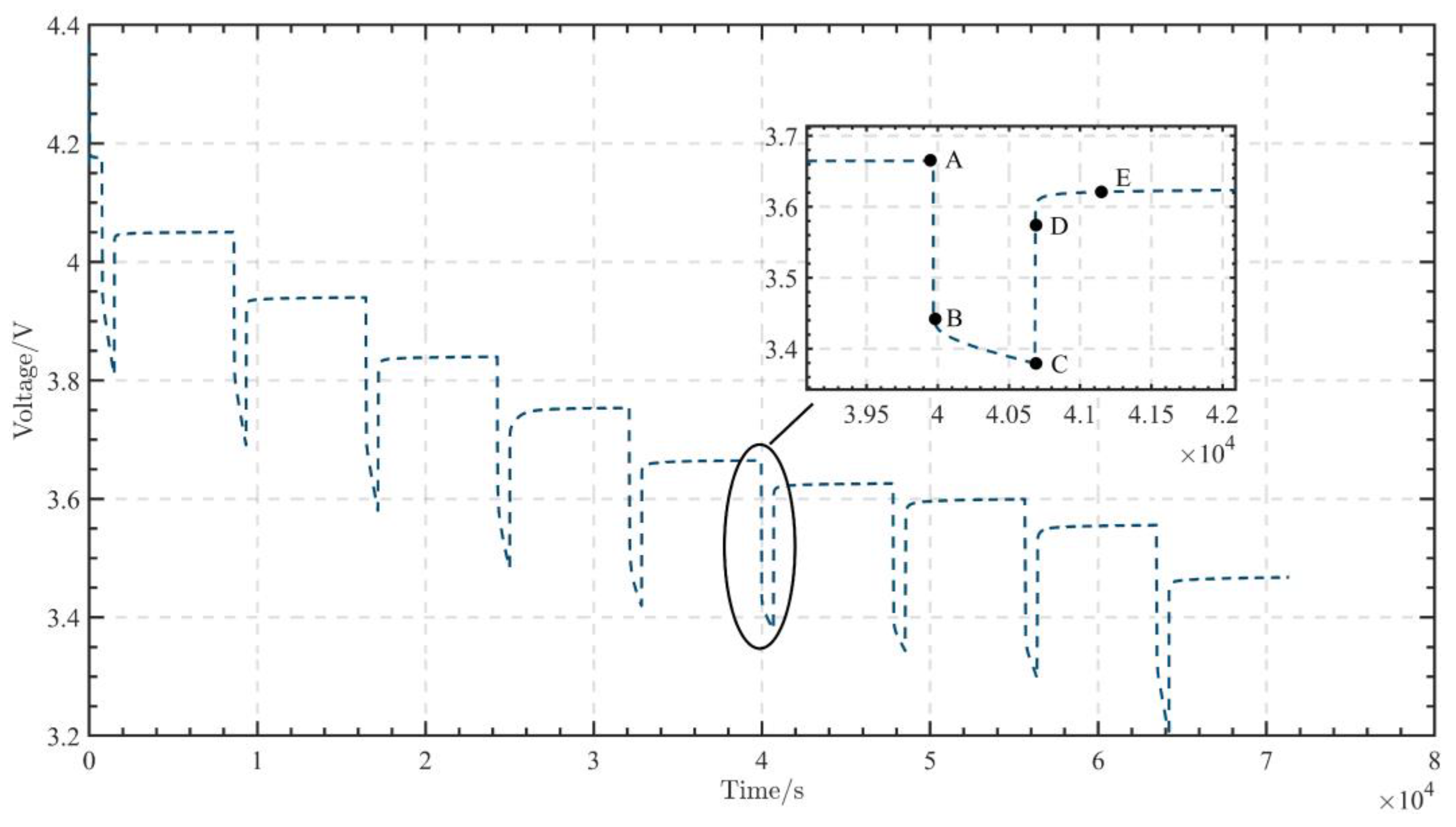

3.1. Offline Parameter Acquisition

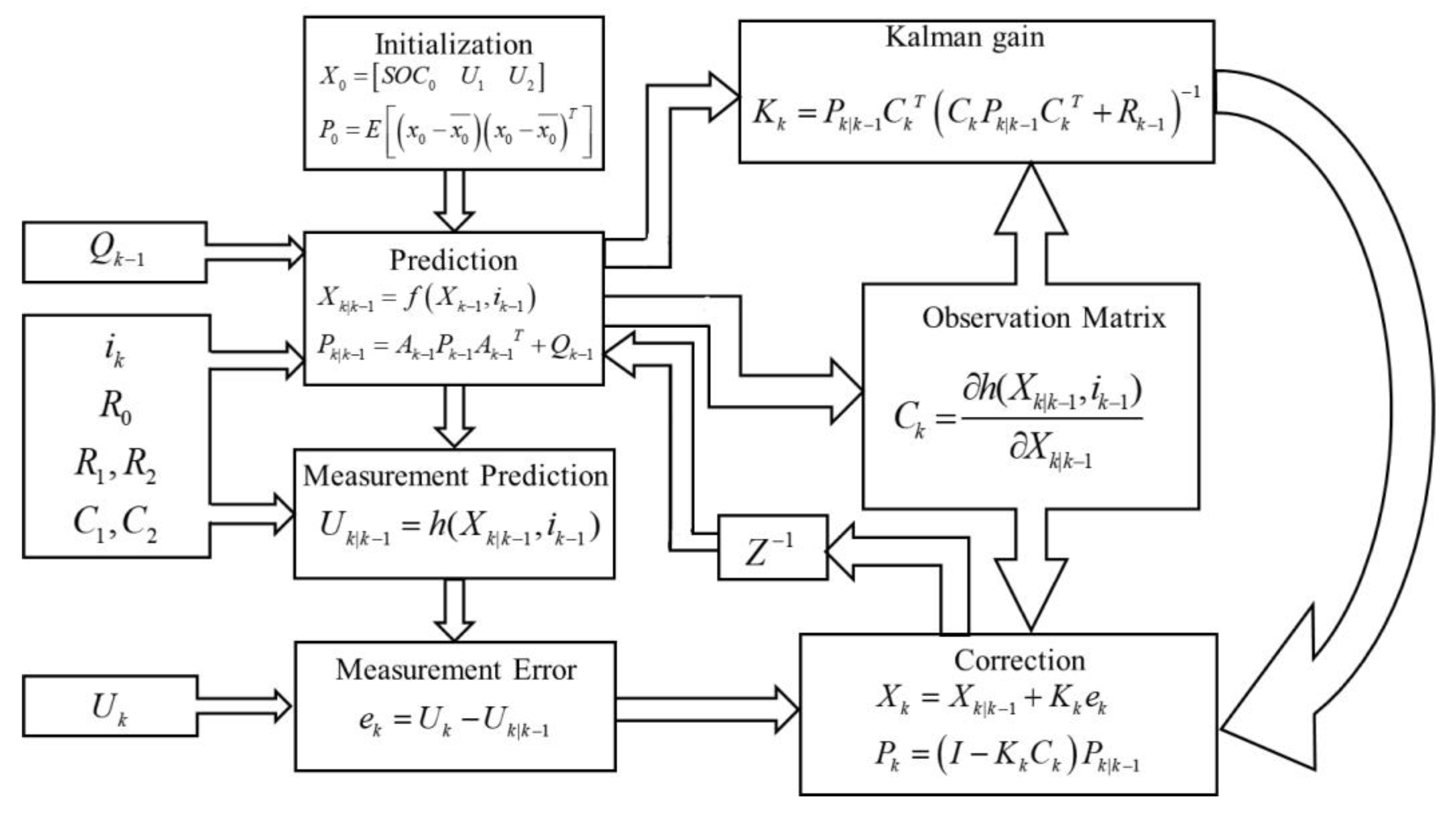

3.2. Online Parameter Acquisition

3.3. Offline Combined with Online Parameter Acquisition

4. Simulation and Comparison

5. Experiment Validation

6. Conclusions

- (1)

- By considering the influence of battery charging and discharging states on battery parameters based on the traditional second-order RC battery model, the Ohmic resistance, polarization resistance, polarization capacitance, diffusion resistance, and diffusion capacitance during the charging and discharging process are discussed separately. This approach improves the accuracy and applicability of the model without increasing its computational complexity.

- (2)

- Traditional offline identification involves identifying parameters under specific conditions, but the characteristics of the battery may change over time, leading to inaccurate initial parameters. Additionally, traditional online SoC estimation methods often have low accuracy and efficiency. This paper proposes an SoC estimation method that combines online and offline identification, which not only greatly improves the efficiency of SoC estimation but also significantly enhances its accuracy and real-time performance. This method can take protective measures against overcharging, overdischarging, and other phenomena more quickly and accurately, which is crucial for improving BMS security.

- (3)

- By building an experimental platform, the feasibility of the proposed method is verified under FUDS (−10 °C to 45 °C, 80% battery level) and DST (−10 °C to 45 °C, 80% battery level) operating conditions. The experimental results show that the method proposed in this paper improves estimation accuracy by 16.28% and 28.2%, respectively, while achieving comparable estimation efficiency to the improved GRU-based transfer learning method.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lai, X.; Yuan, M.; Tang, X.; Yao, Y.; Weng, J.; Gao, F.; Ma, W.; Zheng, Y. Co-Estimation of State-of-Charge and State-of-Health for Lithium-Ion Batteries Considering Temperature and Ageing. Energies 2022, 15, 7416. [Google Scholar] [CrossRef]

- Liang, J.; Wu, T.; Wang, Z.; Yu, Y.; Hu, L.; Li, H.; Zhang, X.; Zhu, X.; Zhao, Y. Accelerating perovskite materials discovery and correlated energy applications through artificial intelligence. Energy Mater. 2022, 2, 200016. [Google Scholar] [CrossRef]

- Guo, F.; Wu, X.; Liu, L.; Ye, J.; Wang, T.; Fu, L.; Wu, Y. Prediction of remaining useful life and state of health of lithium batteries based on time series feature and Savitzky-Golay filter combined with gated recurrent unit neural network. Energy 2023, 270, 126880. [Google Scholar] [CrossRef]

- Fang, X.; Xu, M.; Fan, Y. SOC-SOH Estimation and Balance Control Based on Event-Triggered Distributed Optimal Kalman Consensus Filter. Energies 2024, 17, 639. [Google Scholar] [CrossRef]

- Hannan, M.A.; Lipu, M.S.H.; Hussain, A.; Mohamed, A. A review of lithium-ion battery state of charge estimation and management system in electric vehicle applications: Challenges and recommendations. Renew. Sustain. Energy Rev. 2017, 78, 834–854. [Google Scholar] [CrossRef]

- Sang, B.; Wu, Z.; Yang, B.; Wei, J.; Wan, Y. Joint Estimation of SOC and SOH for Lithium-Ion Batteries Based on Dual Adaptive Central Difference H-Infinity Filter. Energies 2024, 17, 1640. [Google Scholar] [CrossRef]

- Sangeetha, E.P.; Subashini, N.; Santhosh, T.K.; Lindiya, S.A.; Uma, D. Validation of EKF based SoC estimation using vehicle dynamic modelling for range prediction. Electr. Power Syst. Res. 2024, 226, 109905. [Google Scholar]

- Shi, N.; Chen, Z.; Niu, M.; He, Z.; Wang, Y.; Cui, J. State-of-charge estimation for the lithium-ion battery based on adaptive extended Kalman filter using improved parameter identification. J. Energy Storage 2022, 45, 103518. [Google Scholar] [CrossRef]

- Sun, H.; Pan, T.; Wu, D. Weighted Online Estimation of SOC Based on Adaptive Battery Model. J. Syst. Simul. 2017, 29, 1677–1684. [Google Scholar]

- Daowd, M.; Omar, N.; Van Mierlo, J.; Van Den Bossche, P. An Extended PNGV Battery Model for Electric and Hybrid Vehicles. Int. Rev. Electr. Eng.-IREE 2011, 6, 1692–1706. [Google Scholar]

- Kalikmanov, V.I.; Koudriachova, M.V.; de Leeuw, S.W. Lattice-gas model for intercalation compounds. Solid State Ion. 2000, 136, 1373–1378. [Google Scholar] [CrossRef]

- Wu, S.; Pan, W.; Zhu, M. A Collaborative Estimation Scheme for Lithium-Ion Battery State of Charge and State of Health Based on Electrochemical Model. J. Electrochem. Soc. 2022, 169, 090516. [Google Scholar] [CrossRef]

- Xing, Y.; He, W.; Pecht, M.; Tsui, K.L. State of charge estimation of lithium-ion batteries using the open-circuit voltage at various ambient temperatures. Appl. Energy 2014, 113, 106–115. [Google Scholar] [CrossRef]

- Chen, L.; Zeng, X.; Xia, X.; Sun, Y.; Yue, J. A modeling and state of charge estimation approach to lithium-ion batteries based on the state-dependent autoregressive model with exogenous inputs. Energy 2024, 300, 131626. [Google Scholar] [CrossRef]

- Yun, X.; Zhang, X.; Wang, C.; Fan, X. Online parameters identification and state of charge estimation for lithium-ion batteries based on improved central difference particle filter. J. Energy Storage 2023, 70, 107987. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, Y.; Wu, J.; Cheng, W.; Zhu, Q. SOC estimation for lithium-ion battery using the LSTM-RNN with extended input and constrained output. Energy 2023, 262, 125375. [Google Scholar] [CrossRef]

- Ahmed, R.; El Sayed, M.; Arasaratnam, I.; Tjong, J.; Habibi, S. Reduced-Order Electrochemical Model Parameters Identification and State of Charge Estimation for Healthy and Aged Li-Ion Batteries-Part II: Aged Battery Model and State of Charge Estimation. IEEE J. Emerg. Sel. Top. Power Electron. 2014, 2, 678–690. [Google Scholar] [CrossRef]

- Zhang, G.; Xia, B.; Wang, J.; Ye, B.; Chen, Y.; Yu, Z.; Li, Y. Intelligent state of charge estimation of battery pack based on particle swarm optimization algorithm improved radical basis function neural network. J. Energy Storage 2022, 50, 104211. [Google Scholar] [CrossRef]

- Salazar, D.; Garcia, M. Estimation and Comparison of SOC in Batteries Used in Electromobility Using the Thevenin Model and Coulomb Ampere Counting. Energies 2022, 15, 7204. [Google Scholar] [CrossRef]

- Zhang, R.; Xia, B.; Li, B.; Cao, L.; Lai, Y.; Zheng, W.; Wang, H.; Wang, W. State of the Art of Lithium-Ion Battery SOC Estimation for Electrical Vehicles. Energies 2018, 11, 1820. [Google Scholar] [CrossRef]

- Xie, S.; Xiong, R.; Zhang, Y.; He, H. The Estimation of State of Charge for Power Battery Packs used in Hybrid Electric Vehicle. In Proceedings of the 8th International Conference on Applied Energy (ICAE), Beijing, China, 8–11 October 2017; pp. 2678–2683. [Google Scholar]

- Wang, J.; Jia, Y.; Yang, N.; Lu, Y.; Shi, M.; Ren, X.; Lu, D. Precise equivalent circuit model for Li-ion battery by experimental improvement and parameter optimization. J. Energy Storage 2022, 52, 104980. [Google Scholar] [CrossRef]

- Charkhgard, M.; Farrokhi, M. State-of-Charge Estimation for Lithium-Ion Batteries Using Neural Networks and EKF. IEEE Trans. Ind. Electron. 2010, 57, 4178–4187. [Google Scholar] [CrossRef]

- Zhao, L.; Liu, Z.; Ji, G. Lithium-ion battery state of charge estimation with model parameters adaptation using H∞, extended Kalman filter. Control Eng. Pract. 2018, 81, 114–128. [Google Scholar] [CrossRef]

- Wu, S.; Zhang, S.; Li, H.; Cao, G.; Hu, Z.; Yu, Y.; Zhang, X. A totally coupled multi time-scale framework containing full parameters online identification and SOC real-time estimation of lithium-ion battery based on a fractional order model. J. Energy Storage 2023, 73, 109012. [Google Scholar] [CrossRef]

- Wang, Y.-X.; Chen, Z.; Zhang, W. Lithium-ion battery state-of-charge estimation for small target sample sets using the improved GRU-based transfer learning. Energy 2022, 244, 123178. [Google Scholar] [CrossRef]

- C. B. R. Group. CALCE Center for Advanced Life Cycle Engineering Lithium-Ion Battery Experimental Data [Online]. 2017. Available online: https://calce.umd.edu/battery-data (accessed on 11 May 2024).

- Zhao, X.; Sun, B.; Zhang, W.; He, X.; Ma, S.; Zhang, J.; Liu, X. Error theory study on EKF-based SOC and effective error estimation strategy for Li-ion batteries. Appl. Energy 2024, 353, 121992. [Google Scholar] [CrossRef]

| Type | Parameter | Value |

|---|---|---|

| Panasonic NCR18650B | Rated capacity of battery | 2500 mAh |

| Normal voltage | 3.6 V | |

| Max/Min voltage | Vmin: 2.8 V/Vmax: 4.2 V |

| Step | Procedure |

|---|---|

| 1 | After sufficient resting, discharge the battery at 1 C until the discharge cutoff voltage is reached. |

| 2 | Rest for 2 h, then charge the battery with constant current and voltage to SoC = 100%. Set the charging current to 1 C, the charging voltage to 4.2 V, and the cutoff condition to a current of 0.05 C. |

| 3 | Rest for 12 h to activate the battery, then measure and record the terminal voltage. |

| 4 | Discharge at a constant current of 1 C for 6 min and rest for 1 h. |

| 5 | After 10 cycles in step 4, let the battery rest for 2 h. |

| 6 | Charge at a constant current of 1 C for 6 min and rest for 1 h. |

| 7 | After 10 cycles in step 6, let the battery rest for 2 h. |

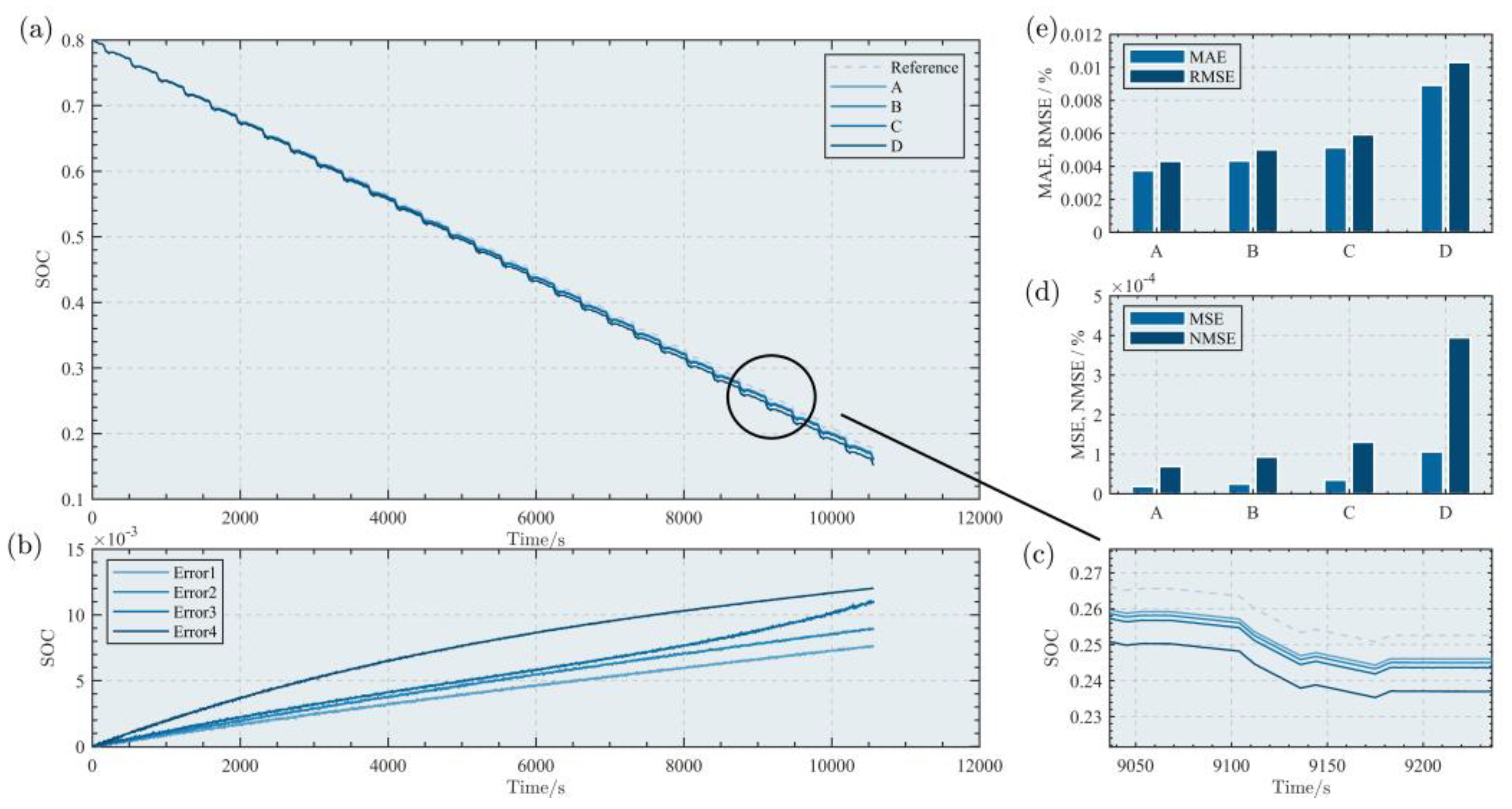

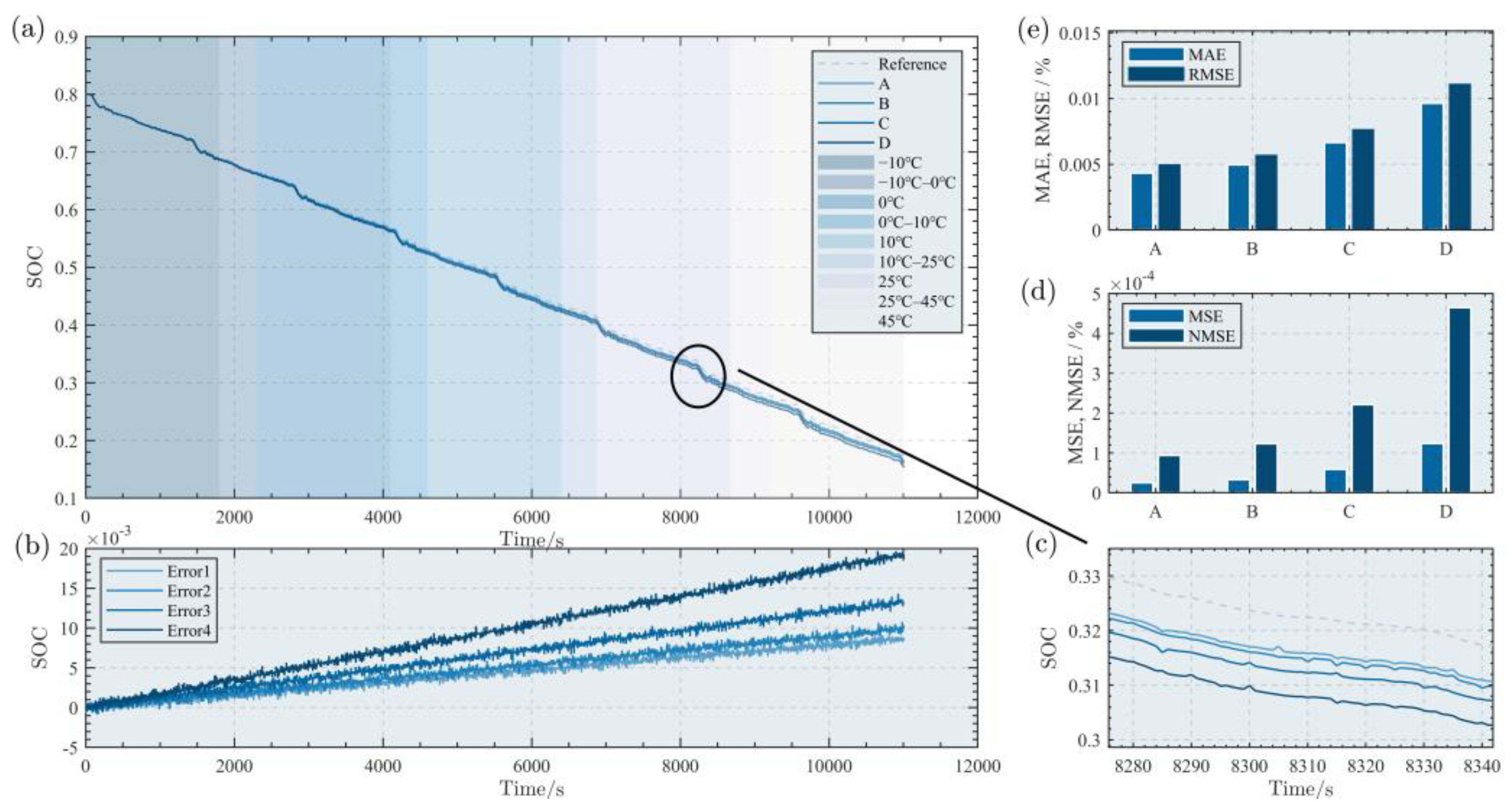

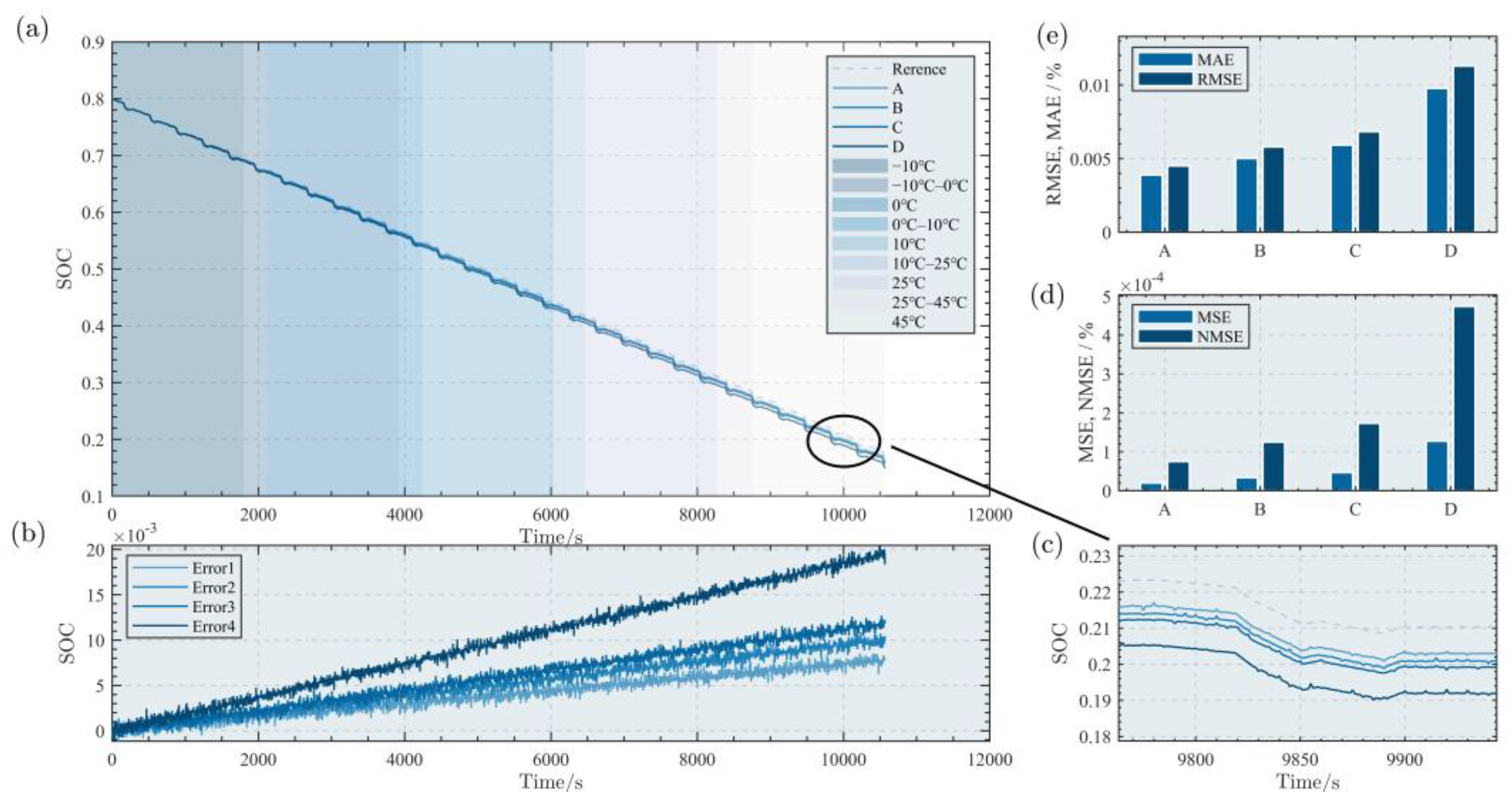

| Method | FUDS (25 °C, 80% Battery Level) | DST (25 °C, 80% Battery Level) | ||||

|---|---|---|---|---|---|---|

| MAE (%) | RMSE (%) | MAX (%) | MAE (%) | RMSE (%) | MAX (%) | |

| A | 0.4166 | 0.4811 | 4.1089 | 0.39 | 0.45 | 4.7506 |

| B | 0.5084 | 0.587 | 5.0140 | 0.5 | 0.58 | 5.9928 |

| C | 0.533 | 0.647 | 5.5272 | 0.63 | 0.65 | 6.6621 |

| D | 0.97 | 1.126 | 9.6109 | 0.98 | 1.13 | 11.1377 |

| Method | FUDS (25 °C, 80% Battery Level) | DST (25 °C, 80% Battery Level) | ||||||

|---|---|---|---|---|---|---|---|---|

| MAE (%) | RMSE (%) | MAX (%) | Time * (ms) | MAE (%) | RMSE (%) | MAX (%) | Time * (ms) | |

| A | 0.4166 | 0.4811 | 4.1089 | 91.27 | 0.39 | 0.45 | 4.7506 | 107.68 |

| B | 0.5084 | 0.587 | 5.0140 | 94.29 | 0.5 | 0.58 | 5.9928 | 103.65 |

| C | 0.533 | 0.647 | 5.5272 | 53.5 | 0.63 | 0.65 | 6.6621 | 59.85 |

| D | 0.97 | 1.126 | 9.6109 | 247.68 | 0.98 | 1.13 | 11.1377 | 214.38 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, H.; He, Q.; Li, Y.; Wang, Y.; Wang, D.; Xie, Y. Enhanced Second-Order RC Equivalent Circuit Model with Hybrid Offline–Online Parameter Identification for Accurate SoC Estimation in Electric Vehicles under Varying Temperature Conditions. Energies 2024, 17, 4397. https://doi.org/10.3390/en17174397

Zhou H, He Q, Li Y, Wang Y, Wang D, Xie Y. Enhanced Second-Order RC Equivalent Circuit Model with Hybrid Offline–Online Parameter Identification for Accurate SoC Estimation in Electric Vehicles under Varying Temperature Conditions. Energies. 2024; 17(17):4397. https://doi.org/10.3390/en17174397

Chicago/Turabian StyleZhou, Hao, Qiaoling He, Yichuan Li, Yangjun Wang, Dongsheng Wang, and Yongliang Xie. 2024. "Enhanced Second-Order RC Equivalent Circuit Model with Hybrid Offline–Online Parameter Identification for Accurate SoC Estimation in Electric Vehicles under Varying Temperature Conditions" Energies 17, no. 17: 4397. https://doi.org/10.3390/en17174397

APA StyleZhou, H., He, Q., Li, Y., Wang, Y., Wang, D., & Xie, Y. (2024). Enhanced Second-Order RC Equivalent Circuit Model with Hybrid Offline–Online Parameter Identification for Accurate SoC Estimation in Electric Vehicles under Varying Temperature Conditions. Energies, 17(17), 4397. https://doi.org/10.3390/en17174397