Unlocking Energy Efficiency: Debunking Myths on the Road to Decarbonization

Abstract

1. Introduction

2. Myth 1: My Plant Is ENERGY STAR Certified, or My Company Has Achieved the Energy-Savings Goal with Better Plants, So We Have Done Everything Possible for Energy Efficiency

2.1. The True Meaning of Some Certifications

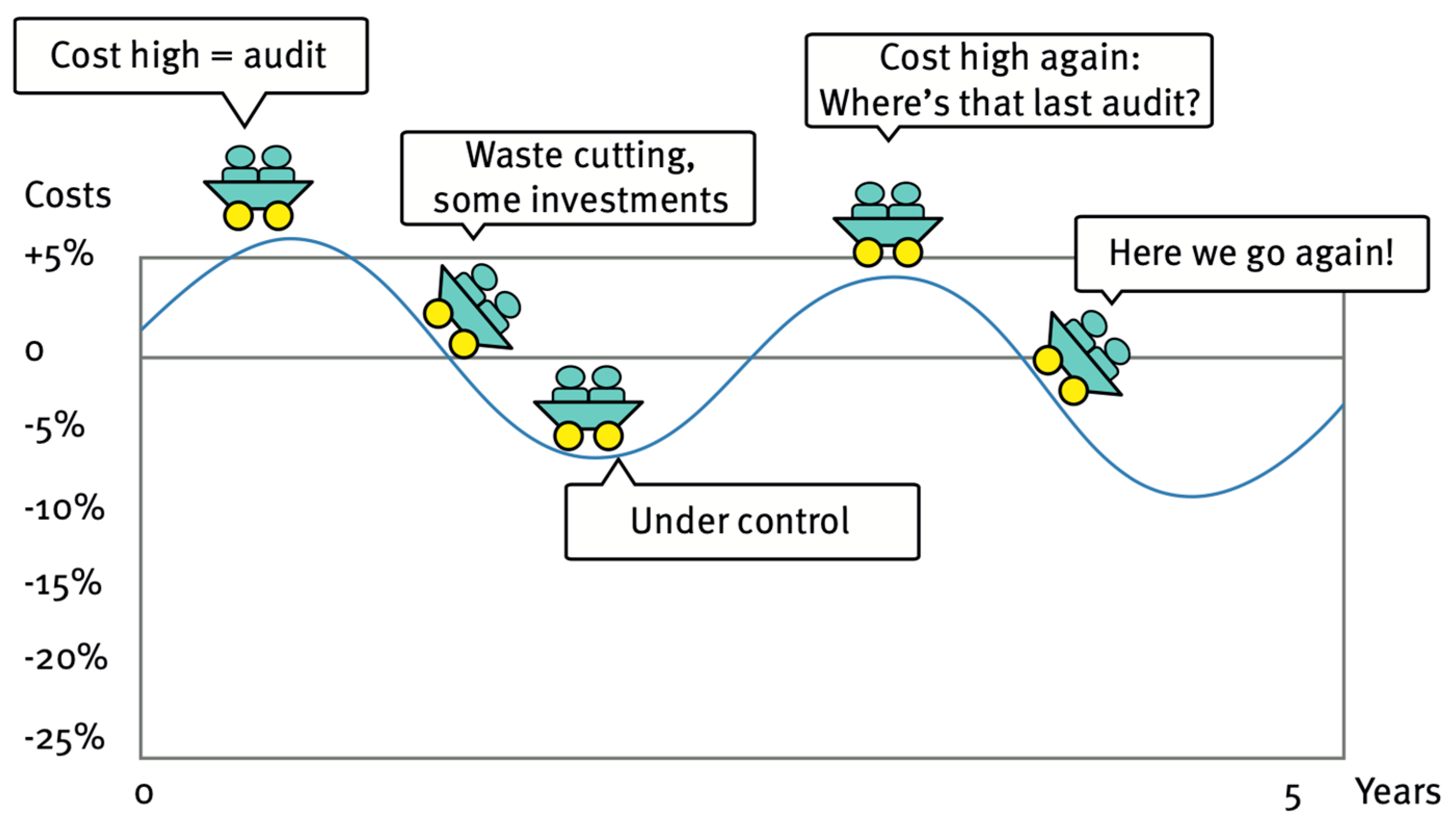

2.2. Reasons Why Energy-Savings Opportunities Always Exist

2.3. Smart Manufacturing Is the New Future of Energy Efficiency

3. Myth 2: Most Energy Efficiency Projects Are Capital Intensive and Have a Very Long Payback Period

3.1. Many Energy Efficiency Projects Are Low Cost and Have a Short Payback Period

3.2. Available Financial Resources from Utility Companies and State and Federal Governments

4. Myth 3: Energy Efficiency Projects Take Too Much Time and Companies Have No Qualified Staff to Identify and Implement

4.1. Free Technical Resources for Identifying Energy Efficiency Projects

4.2. Solution to Lack of Qualified Staff

5. Myth 4: We Are in Leased Space and Have Little Control over the Building Operation

5.1. Negotiate a Better Lease

5.2. Opportunities in Rented Spaces

6. Myth 5: Unbundled RECs Are More Attractive Compared with Energy Efficiency Measures

6.1. Prioritize Energy Efficiency over Unbundled REC Purchases

6.2. Combine Energy Efficiency with Renewable Energy Purchase for Higher Emissions Reduction Impact

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- The United Nations. The Paris Agreement; United Nations. Available online: https://www.un.org/en/climatechange/paris-agreement (accessed on 25 June 2024).

- Cresko, J.; Rightor, E.; Carpenter, A.; Peretti, K.; Elliott, N.; Nimbalkar, S.; Morrow Iii, W.; Hasanbeigi, A.; Hedman, B.; Supekar, S.; et al. U.S. Department of Energy’s Industrial Decarbonization Roadmap. 2022; p. DOE/EE--2635, 1961393. Available online: https://www.osti.gov/biblio/1961393 (accessed on 25 June 2024).

- 2022 Better Plants Progress Update—Final_0.Pdf. Available online: https://betterbuildingssolutioncenter.energy.gov/sites/default/files/attachments/2022%20Better%20Plants%20Progress%20Update%20-%20Final_0.pdf (accessed on 25 June 2024).

- Nadel, S.; Ungar, L. Halfway There: Energy Efficiency Can Cut Energy Use and Greenhouse Gas Emissions in Half by 2050. 2019. Available online: https://www.aceee.org/research-report/u1907#:~:text=Energy%20efficiency%20can%20slash%20US,up%20government%20policies%20and%20programs (accessed on 25 June 2024).

- ISO 50001:2018; Energy Management Systems—Requirements with Guidance for Use. International Organization for Standardization: Geneva, Switzerland, 2018.

- Sundaramoorthy, S.; Kamath, D.; Nimbalkar, S.; Price, C.; Wenning, T.; Cresko, J. Energy Efficiency as a Foundational Technology Pillar for Industrial Decarbonization. Sustainability 2023, 15, 9487. [Google Scholar] [CrossRef]

- Manufacturing Energy and Carbon Footprints (2018 MECS). Available online: https://www.energy.gov/eere/iedo/manufacturing-energy-and-carbon-footprints-2018-mecs (accessed on 11 June 2024).

- Nimbalkar, S.U.; Supekar, S.D.; Meadows, W.; Wenning, T.; Guo, W.; Cresko, J. Enhancing Operational Performance and Productivity Benefits by Implementing Smart Manufacturing Technologies in Breweries; Oak Ridge National Laboratory (ORNL): Oak Ridge, TN, USA, 2019. [Google Scholar]

- United States Department of Energy. Barriers to Industrial Energy Efficiency. 2015. Available online: https://www.energy.gov/sites/prod/files/2015/06/f23/EXEC-2014-005846_6%20Report_signed_0.pdf (accessed on 25 June 2024).

- United Nations. Overcoming Barriers to Investing in Energy Efficiency; ECE Energy Series; UN: New York, NY, USA, 2018; ISBN 978-92-1-363046-4. Available online: https://www.un-ilibrary.org/content/books/9789213630464 (accessed on 25 June 2024).

- Zuoza, A.; Pilinkienė, V. Barriers of Industrial Energy Efficiency. 2018. Available online: https://www.researchgate.net/publication/330359518_Barriers_of_industrial_energy_efficiency (accessed on 25 June 2024).

- Vaidyanathan, S.; Nadel, S.; Amann, J.; Bell, C.J.; Chittum, A.; Farley, K.; Hayes, S.; Vigen, M.; Young, R. Overcoming Market Barriers and Using Market Forces to Advance Energy Effciency; American Council for an Energy-Efficient Economy: Washington, DC, USA, 2013. [Google Scholar]

- DNV. Market Barriers to Energy Efficiency. 2023. Available online: http://www.energy.nh.gov/sites/g/files/ehbemt551/files/inline-documents/sonh/24-market-barriers-nh-energy-efficiency.pdf (accessed on 25 June 2024).

- U.S. EPA. Celebrating 2023 Certified Plants. Available online: https://www.energystar.gov/industrial_plants/earn-recognition/plant-certification/list_certified_plants/certifiedplants2023 (accessed on 7 June 2024).

- U.S. EPA. ENERGY STAR Plant Certification. Available online: https://www.energystar.gov/industrial_plants/earn-recognition/plant-certification (accessed on 7 June 2024).

- Flowers Foods. Fourteen Flowers Foods Bakeries Achieve 2023 Energy Star Certification. Available online: https://flowersfoods.com/news/news-releases/2024/fourteen-flowers-foods-bakeries-achieve-2023-energy-starcertification/#:~:text=(NYSE%3A%20FLO)%20bakeries%20earned,Environmental%20Protection%20Agency%20(EPA) (accessed on 7 June 2024).

- Driver, L. Leveraging Tiered Incentive Rates from Utility Companies; Better Buildings, Better Plants Summit: Washington DC, USA, 2022. [Google Scholar]

- Shipley, A.M.; Elliott, R.N. Ripe for the Picking: Have We Exhausted the Low-Hanging Fruit in the Industrial Sector? American Council for an Energy-Efficient Economy: Washington, DC, USA, 2006. [Google Scholar]

- Zhang, A. Blast Freezing Process and Design Optimization; Better Buildings Better Plants Summit: Washington, DC, USA, 2020. [Google Scholar]

- Vora, J. First Facility Deployment of ATLAS, the Most Advanced Refrigeration Controls Platform; Better Buildings Better Plants Summit: Washington DC, USA, 2019. [Google Scholar]

- Nimbalkar, S.U.; Guo, W.; Wenning, T.; Cresko, J.; Graziano, D.; Morrow, W.R., III. Smart Manufacturing Technologies and Data Analytics for Improving Energy Efficiency in Industrial Energy Systems; Oak Ridge National Laboratory (ORNL): Oak Ridge, TN, USA, 2017. [Google Scholar]

- U.S. EIA. Average Price of Electricity to Ultimate Customers. Available online: https://www.eia.gov/electricity/annual/html/epa_02_04.html (accessed on 7 June 2024).

- U.S. EIA. United States Natural Gas Industrial Price. Available online: https://www.eia.gov/dnav/ng/hist/n3035us3a.htm (accessed on 7 June 2024).

- U.S. DOE Advanced Manufacturing Office. Improving Compressed Air System Performance: A Sourcebook for Industry, 3rd ed. Available online: https://www.energy.gov/sites/prod/files/2016/03/f30/Improving%20Compressed%20Air%20Sourcebook%20version%203.pdf (accessed on 25 June 2024).

- Muganyi, P.; Mbohwa, C. Proactive Maintenance Strategic Application to Advance Equipment Reliability. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Pretoria/Johannesburg, South Africa, 29 October–1 November 2018; pp. 3300–3309. [Google Scholar]

- United Nations Industrial Development Organization. Practical Guide for Implementing an Energy Management System. 2015. Available online: https://www.industrialenergyaccelerator.org/general/practical-guide-for-implementing-an-energy-management-system/ (accessed on 25 June 2024).

- de Boer, E.; Friligos, Y.; Giraud, Y.; Liang, D.; Malik, Y.; Mellors, N.; Shahani, R.; Wallace, J. Advanced Manufacturing and the Promise of Industry 4.0|McKinsey. Available online: https://www.mckinsey.com/capabilities/operations/our-insights/transforming-advanced-manufacturing-through-industry-4-0#/ (accessed on 23 July 2024).

- Lee, D.; Masterson, B.; Sartini, J.; Schlick, D.; YeeEe, B. IT@Intel: Expanding Low-Cost IIoT Manufacturing Use Cases. Available online: https://www.intel.com/content/dam/www/central-libraries/us/en/documents/2023-12/it-iiot-manufacturing-use-case-paper.pdf (accessed on 25 June 2024).

- OECD Case Study on Internet of Things in Manufacturing 2023. 2023. Available online: https://www.oecd-ilibrary.org/science-and-technology/measuring-the-internet-of-things_c4be2088-en (accessed on 25 June 2024).

- Roozbeh Nia, A.; Awasthi, A.; Bhuiyan, N. Industry 4.0 and Demand Forecasting of the Energy Supply Chain: A Literature Review. Comput. Ind. Eng. 2021, 154, 107128. [Google Scholar] [CrossRef]

- Dou, Z.; Sun, Y.; Zhang, Y.; Wang, T.; Wu, C.; Fan, S. Regional Manufacturing Industry Demand Forecasting: A Deep Learning Approach. Appl. Sci. 2021, 11, 6199. [Google Scholar] [CrossRef]

- U.S. DOE. IAC Recommendations. Available online: https://iac.university/searchRecommendations (accessed on 7 June 2024).

- U.S. DOE. Better Plants In-Plant Trainings. Available online: https://betterbuildingssolutioncenter.energy.gov/better-plants/plant-trainings-inplts (accessed on 7 June 2024).

- Guo, W.; Wenning, T.; Nimbalkar, S.U.; Travis, J.; Levine, E. US DOE In-Plant Trainings to Develop Expertise and Replicate Success; Oak Ridge National Lab. (ORNL): Oak Ridge, TN, USA, 2019. [Google Scholar]

- U.S. DOE. Industrial Research and Assessment Center Implementation Grants. Available online: https://www.energy.gov/mesc/industrial-research-and-assessment-center-implementation-grants (accessed on 7 June 2024).

- U.S. DOE. Qualifying Advanced Energy Project Credit (48C) Program. Available online: https://www.energy.gov/infrastructure/qualifying-advanced-energy-project-credit-48c-program (accessed on 7 June 2024).

- U.S. DOE. Funding and Incentives Resource Hub. Available online: https://betterbuildingssolutioncenter.energy.gov/funding-incentives-hub (accessed on 7 June 2024).

- U.S. DOE. Financing Navigator. Available online: https://betterbuildingssolutioncenter.energy.gov/financing-navigator/about (accessed on 7 June 2024).

- U.S. DOE. Industrial Assessment Centers (IACs). Available online: https://www.energy.gov/mesc/industrial-assessment-centers-iacs (accessed on 8 June 2024).

- Better Buildings Solution Center Arcelormittal USA: Power of 1 Contest Increases Employee Engagement and Generates Low- and No-Cost Project Ideas. Available online: https://betterbuildingssolutioncenter.energy.gov/implementation-models/arcelormittal-usa-power-1-contest-increases-employee-engagement-and-generates (accessed on 8 June 2024).

- Guo, W.; Wenning, T.; Nimbalkar, S.U.; Travis, J.; O’Neill, J.; Lung, B. US Department of Energy Better Plants Program’s Approach to Manufacturing Workforce Development; Oak Ridge National Laboratory (ORNL): Oak Ridge, TN, USA, 2023. [Google Scholar]

- Better Buildings Solution Center Occidental Chemical Corporation: Incorporating The Better Plants Steam System In-Plant Training into Corporate Training and Energy Management Best Practices. Available online: https://betterbuildingssolutioncenter.energy.gov/implementation-models/occidental-chemical-corporation-incorporating-better-plants-steam-system (accessed on 8 June 2024).

- Better Buildings Solution Center Tyson Foods: DOE’s Virtual In-Plant Trainings on Industrial Refrigeration Uncover Big Savings. Available online: https://betterbuildingssolutioncenter.energy.gov/showcase-projects/tyson-foods-does-virtual-plant-trainings-industrial-refrigeration-uncover-big (accessed on 8 June 2024).

- Better Buildings Solution Center Celanese Corporation: Raising Energy Engagement in Plant Operations Teams with “Energy Sparks” Training Tools. Available online: https://betterbuildingssolutioncenter.energy.gov/implementation-models/celanese-corporation-raising-energy-engagement-plant-operations-teams-energy (accessed on 25 June 2024).

- Better Buildings Solution Center 3M: Energy Manual 81 For Project Design Requirements and Guidelines. Available online: https://betterbuildingssolutioncenter.energy.gov/implementation-models/3m-energy-manual-81-project-design-requirements-and-guidelines (accessed on 8 June 2024).

- Better Buildings Solution Center Bentley Mills: Reducing Risk and Liability in Energy Upgrades Through Efficiency-As-A-Service Financing (EaaS). Available online: https://betterbuildingssolutioncenter.energy.gov/implementation-models/bentley-mills-reducing-risk-and-liability-energy-upgrades-through-efficiency (accessed on 8 June 2024).

- Better Buildings Solution Center General Motors Funds Energy Conservation Projects Through an Energy Performance Contracting Model. Available online: https://betterbuildingssolutioncenter.energy.gov/implementation-models/general-motors-funds-energy-conservation-projects-through-energy-performance (accessed on 8 June 2024).

- ULI Tenant Energy Optimization Program. Available online: https://tenantenergy.uli.org/ (accessed on 11 June 2024).

- Green Lease Leaders. Refernce Guide for Tenants. Available online: https://greenleaseleaders.com/resource/tenant-reference-guide/ (accessed on 25 June 2024).

- U.S. DOE. Energy Efficiency &Renewable Energy. Energy Efficiency in Separate Tenant Spaces—A Feasibility Study. Available online: https://www.energy.gov/sites/default/files/2016/04/f30/DOE%20-%20Energy%20Efficiency%20in%20Separate%20Tenant%20Spaces_0.pdf (accessed on 25 June 2024).

- O’Shaughnessy, E.; Jena, S.; Sumner, J. Status and Trends in the U.S. Voluntary Green Power Market: 2022 Data. 2024. Available online: https://www.nrel.gov/analysis/assets/pdfs/status-and-trends-2022-data.pdf (accessed on 25 June 2024).

- Wilson, A.; Lenoir, T. US Renewable Energy Credit Market Size to Double to $26 Billion by 2030. Available online: https://www.spglobal.com/marketintelligence/en/news-insights/research/us-renewable-energy-credit-market-size-to-double-to-26-billion-by-2030 (accessed on 25 June 2024).

| Energy Conservation Measure | Average of Simple Payback (Years) |

|---|---|

| Reduce the pressure of compressed air to the minimum required | 0.3 |

| Eliminate leaks in compressed air lines/valves | 0.6 |

| Upgrade controls on compressors | 0.9 |

| Eliminate or reduce compressed air used for cooling, agitating liquids, moving products, or drying | 1.3 |

| Energy Conservation Measure | Average of Simple Payback (Years) |

|---|---|

| Repair or replace steam traps | 0.2 |

| Insulate steam/hot water lines | 0.5 |

| Flash condensate to produce lower-pressure steam | 0.9 |

| Optimize boiler controls strategy | 0.9 |

| Install steam turbine | 1.8 |

| Install economizer | 2.9 |

| Energy Conservation Measure | Average of Simple Payback (Years) |

|---|---|

| Remove throttle valves | 0.0 |

| Replace existing pumps | 2.0 |

| Install variable frequency drive | 2.6 |

| Best Practices in a Standard Lease Form, Corporate Policies, or Other Documentations |

|---|

|

|

|

|

|

|

|

|

|

|

|

| Energy Efficiency Measure | % Energy Reduction | Cost |

|---|---|---|

| High-efficiency lighting | 30–60% | $54/m2 ($5/ft2) |

| Lighting control technologies | 24–38% | $22/m2($2/ft2) |

| Daylighting | 20–80% | ≤$54/m2 ($5/ft2) |

| ENERGY STAR Certified appliances and office equipment | 10–40% | $538–$2152/m2 ($50–$200/ft2) |

| Plug and process load inventory and reduction strategies | 20–50% | Based on equipment |

| High-efficiency HVAC units for above-standard operations | 5–20% | $100–$180/ton |

| Point-of-use domestic water heating | 27–50% | Based on equipment |

| Energy-management and information systems | 10–15% | $3.2–$11.4/m2 ($0.30–$1.06/ft2) * |

| Optimization of outside air volumes according to tenant occupancy | Varies based on building occupancy | $0.54–$10.8/m2 ($0.05–$1/ft2) |

| Data centers and IT server room best practices | 80% | $276,000–$770,000 |

| Improving building envelope performance | Varies based on building age | NA |

| HVAC zoning | Depends on current controls | $32–$65/m2 ($3–$6/ft2) |

| Window attachments | 5–17% | ≤$21/m2 ($2/ft2) |

| Utility metering and submetering | NA | $700–$5000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nandy, P.; Guo, W.; Wenning, T. Unlocking Energy Efficiency: Debunking Myths on the Road to Decarbonization. Energies 2024, 17, 4390. https://doi.org/10.3390/en17174390

Nandy P, Guo W, Wenning T. Unlocking Energy Efficiency: Debunking Myths on the Road to Decarbonization. Energies. 2024; 17(17):4390. https://doi.org/10.3390/en17174390

Chicago/Turabian StyleNandy, Paulomi, Wei Guo, and Thomas Wenning. 2024. "Unlocking Energy Efficiency: Debunking Myths on the Road to Decarbonization" Energies 17, no. 17: 4390. https://doi.org/10.3390/en17174390

APA StyleNandy, P., Guo, W., & Wenning, T. (2024). Unlocking Energy Efficiency: Debunking Myths on the Road to Decarbonization. Energies, 17(17), 4390. https://doi.org/10.3390/en17174390