Research on Phase Change Cold Storage Materials and Innovative Applications in Air Conditioning Systems

Abstract

1. Introduction

| Specification | Water Cold Storage | Ice Cold Storage | Phase Change Cold Storage |

|---|---|---|---|

| Specific heat J/(kg·K) | 4.19 | 2.04 | - |

| Latent heat (kJ/kg) | - | 334 | 80~250 |

| Maintenance costs | Higher | Moderate | Moderate |

| Cold storage tank capacity | Larger | Smaller | Moderate |

| Power consumption | Lower | Higher | Lower |

| Initial investment | Lower | Moderate | High |

| Technical requirements and operating costs | High technical requirements and high operating costs | Low technical requirements and low operating costs | High technical requirements and low operating costs |

| Coefficient of performance | 5.0~5.9 | 2.9~4.1 | 5.0~5.9 |

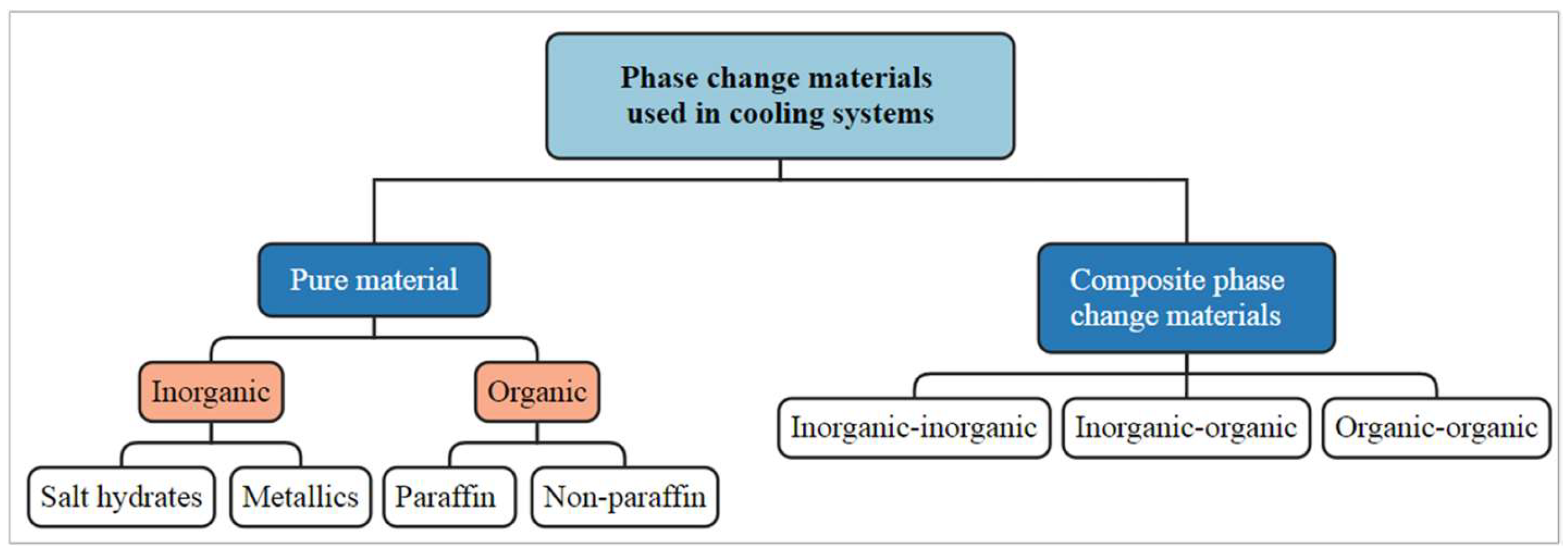

2. Phase Change Cold Storage Materials and Their Enhancement

2.1. Pure Phase Change Cold Storage Materials

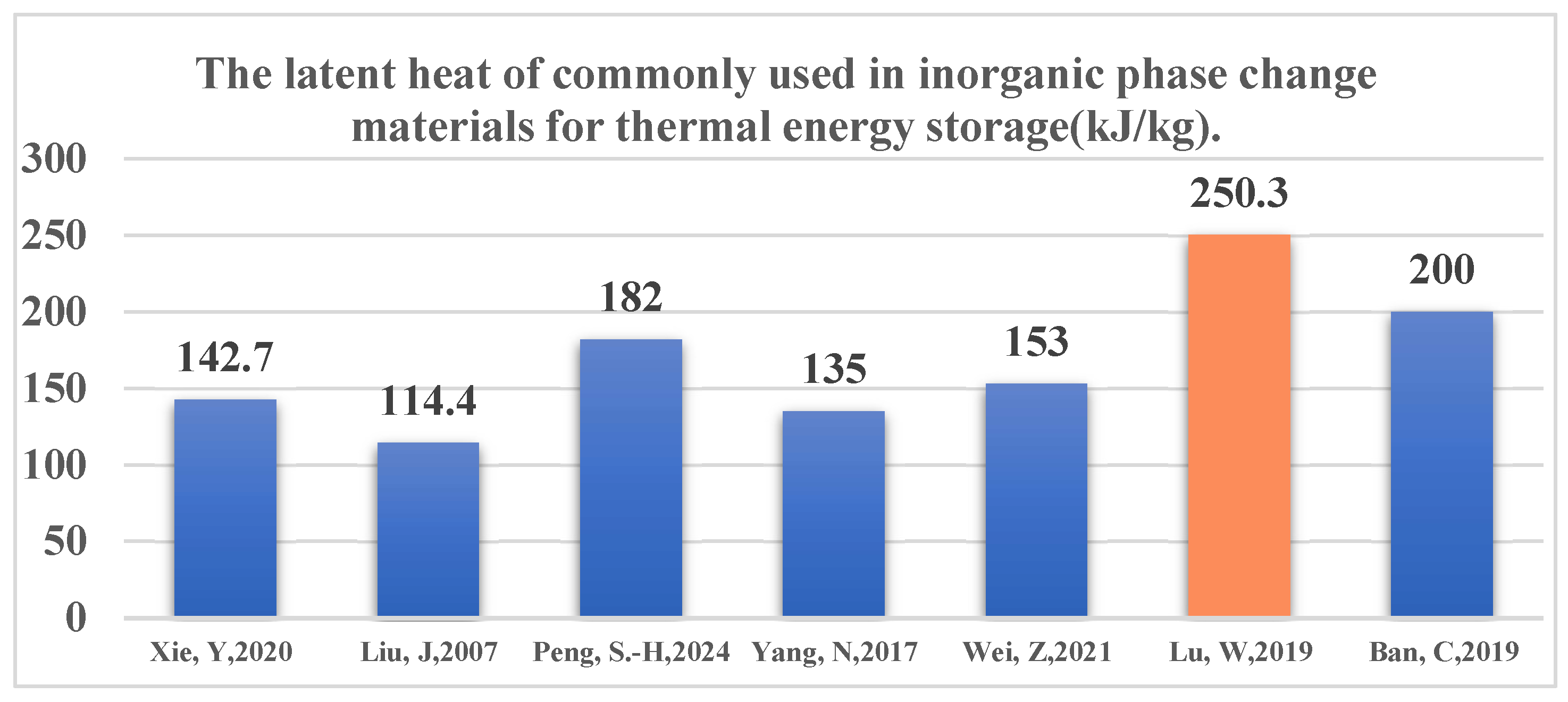

2.1.1. Inorganic Phase Change Cold Storage Materials

| PCM | Phase Change Temperature (°C) | Latent Heat (kJ/kg) | Application | References | Costs(CHF) |

|---|---|---|---|---|---|

| Na2SO4·10H2O (NH4Cl, borax, PAC) | 10.3 | 142.7 | Air conditioning | [26] | 278 |

| Na2SO4·10H2O (NH4Cl, KCl, K2SO4, CMC, sodium hexametaphosphate borax, and boric acid) | 8.25 | 114.4 | Air conditioning | [27] | 713 |

| Inorganic hydrates are encapsulated within high-density polyethylene (HDPE) cold storage plates | 8 | 182 | Air conditioning | [28] | 519 |

| Na2SO4·10H2O (NH4Cl, TiO2 nanoparticles, silica gel powder) | 7.33 | 135 | Air conditioning | [29] | 450 |

| A 15% solution of NaCl | −11 | 153 | Freezing cabinets | [30] | 165 |

| A mixture of sodium formate, potassium chloride, and distilled water with concentrations ratioed at 22%:8%:70% | −23.8 | 250.3 | Freezers | [31] | 722 |

| NaCl acts as the primary energy storage medium; K2CO3 and KCl are employed as cooling agents | −24 | 200 | Refrigerated transport | [32] | 324 |

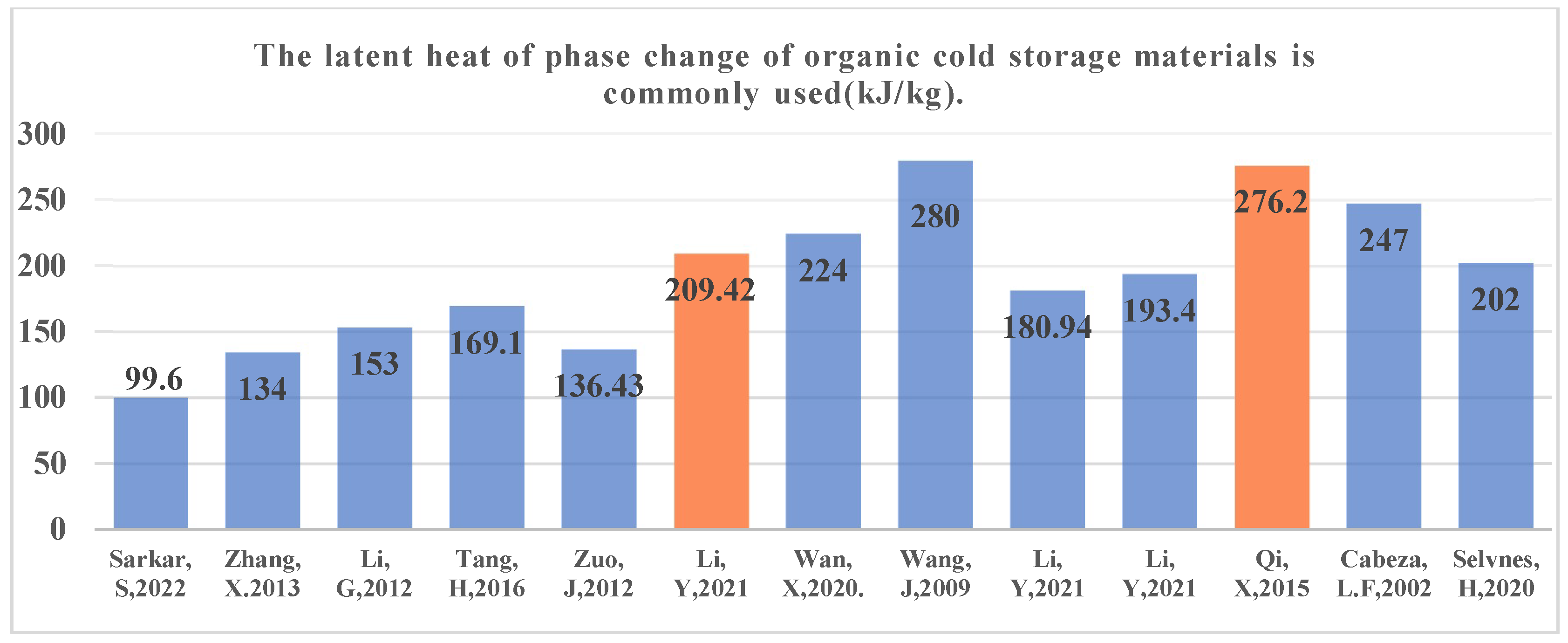

2.1.2. Organic Phase Change Cold Storage Materials

2.2. Composite Phase Change Cold Storage Materials

2.3. Cost–Benefit Analysis for PCMs

3. Case Study

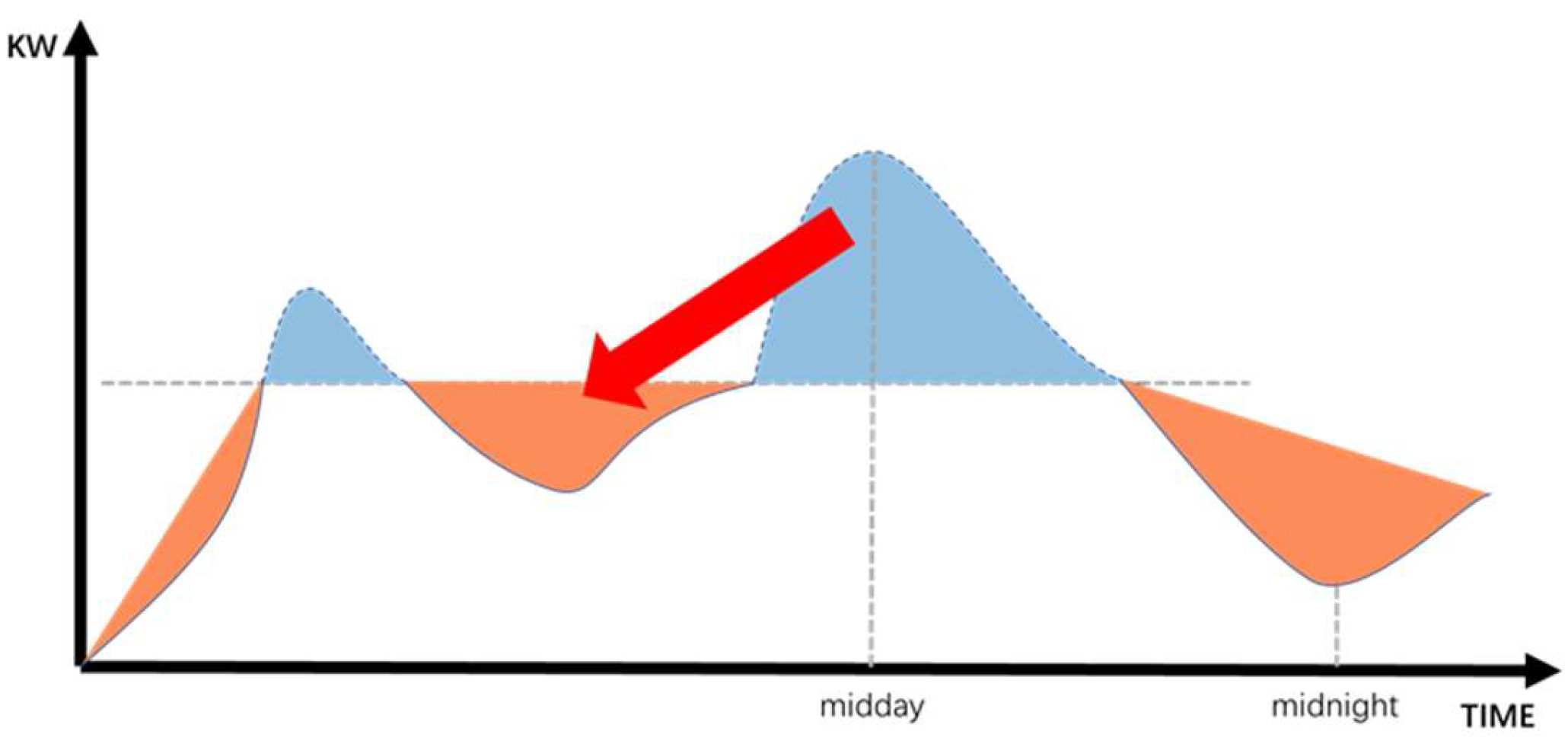

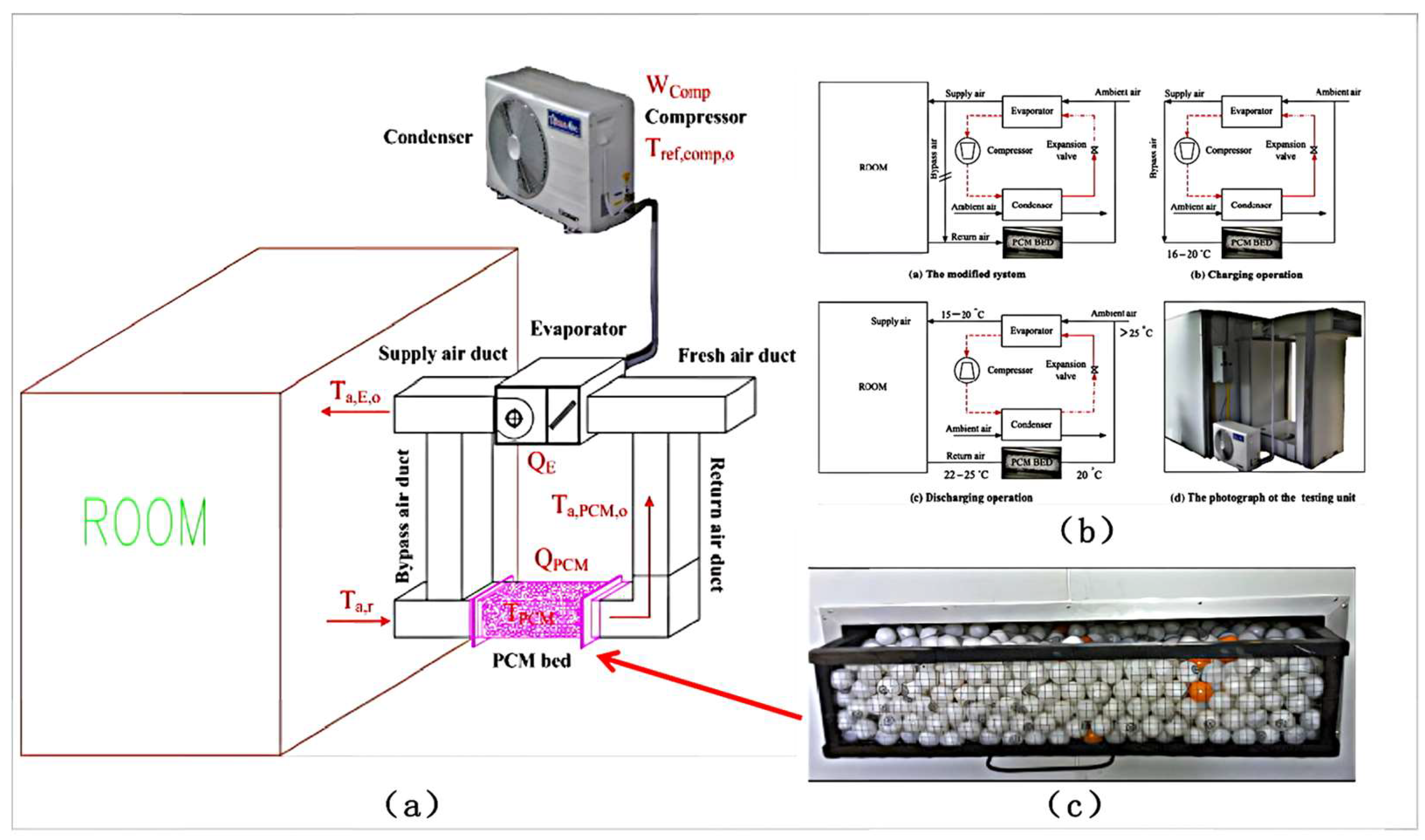

3.1. Vapor Compression Phase Change Cold Storage Air Conditioning System

3.1.1. PCM Applied in Condenser for Phase Change Cold Storage Air Conditioning Systems

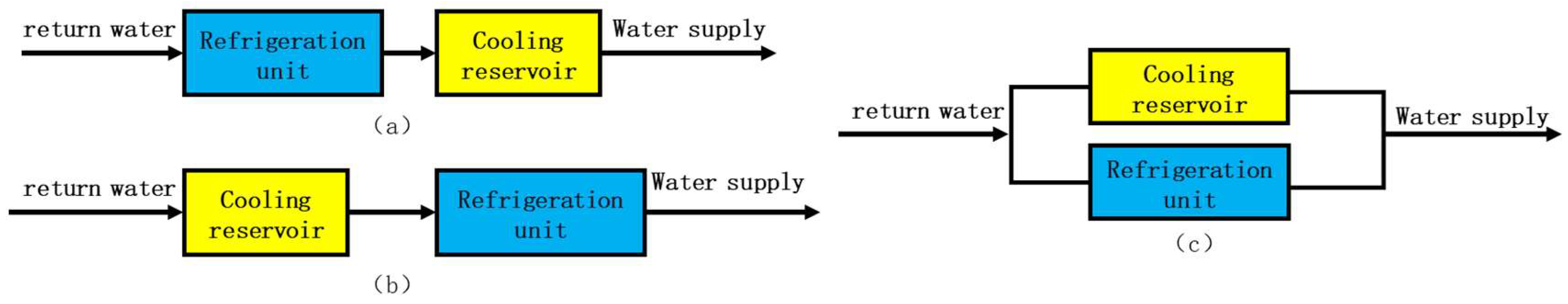

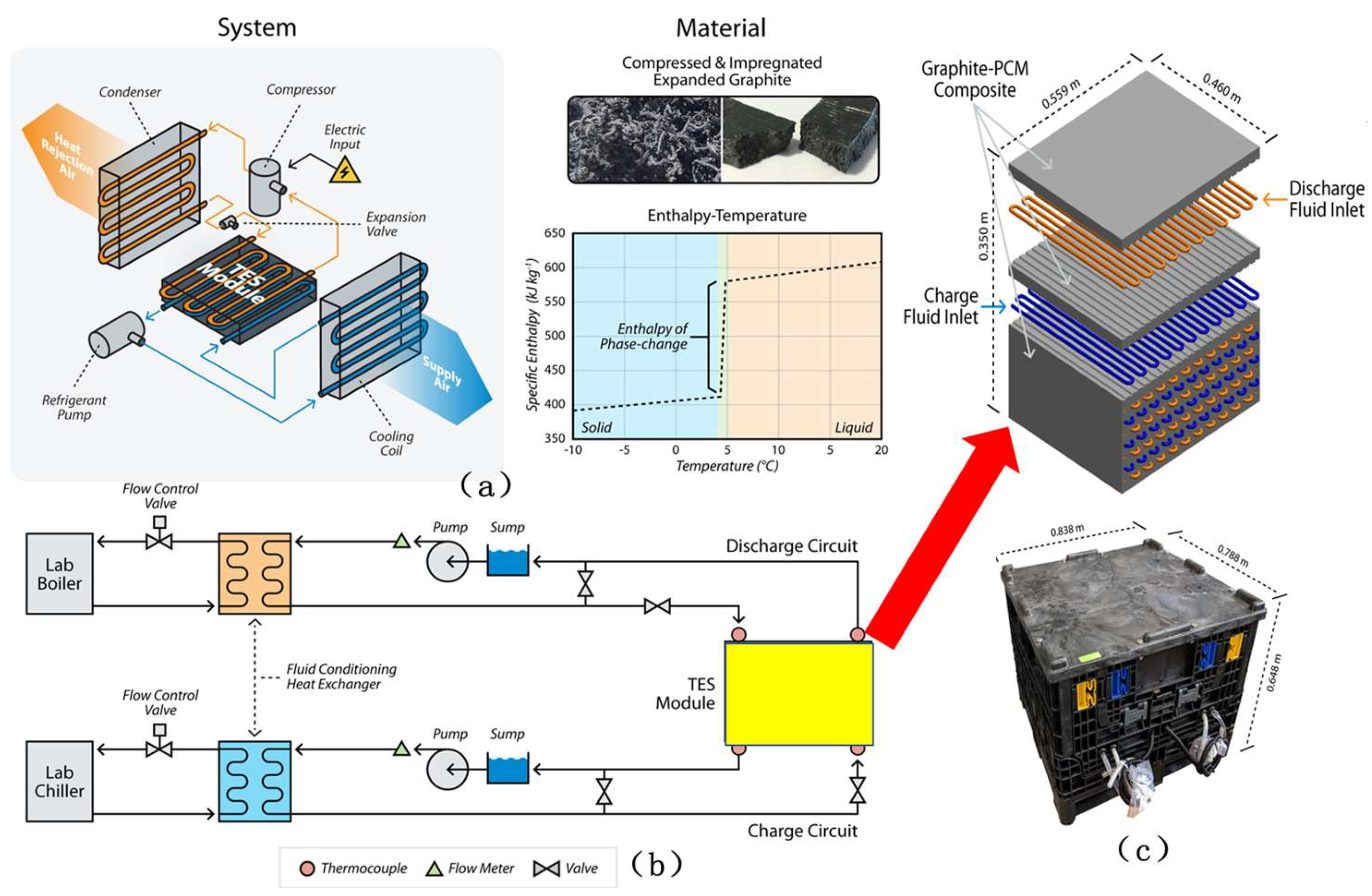

3.1.2. PCM Applied in Cold Storage Tank for Phase Change Cold Storage Air Conditioning Systems

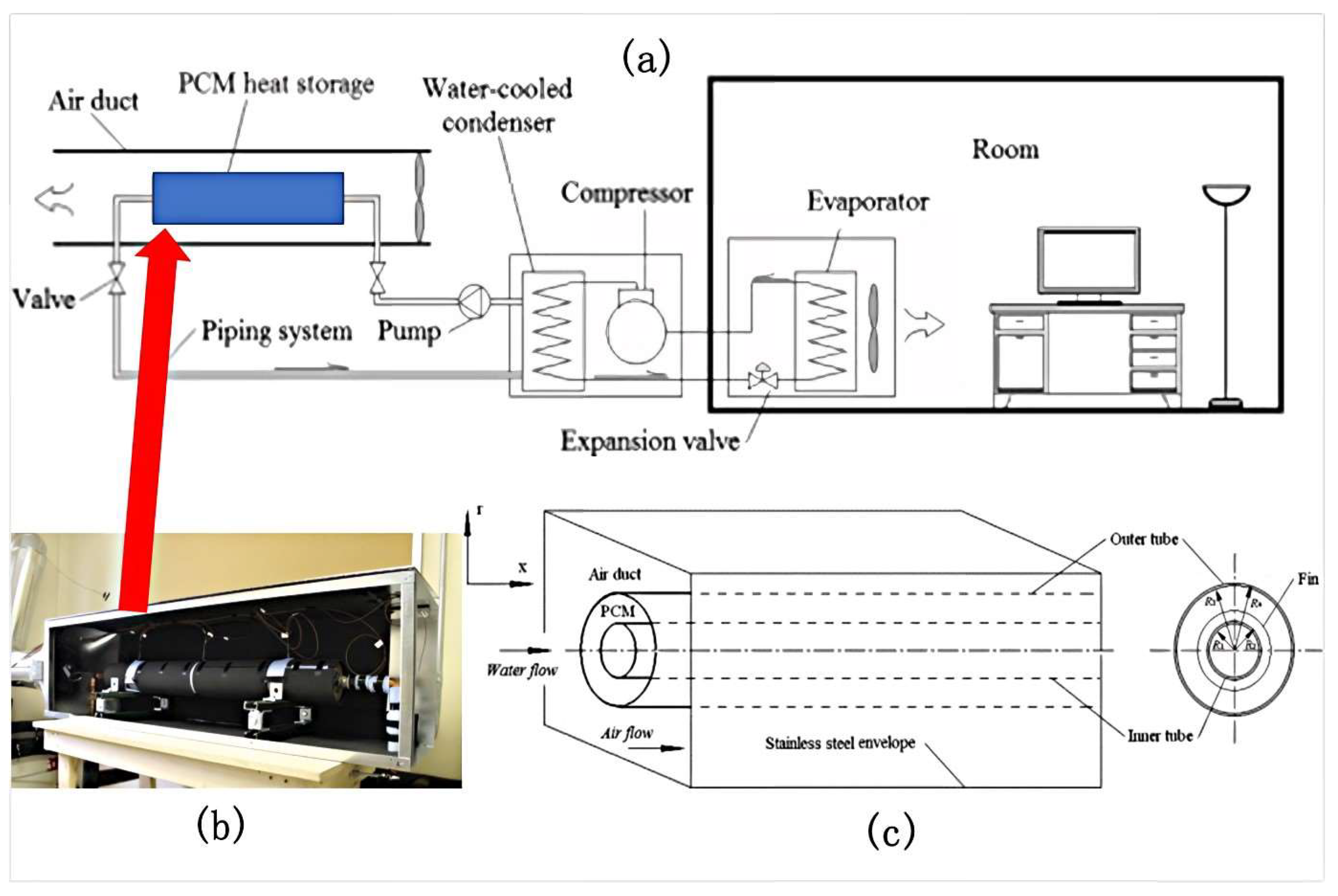

3.1.3. PCM Applied in Evaporator for Phase Change Cold Storage Air Conditioning Systems

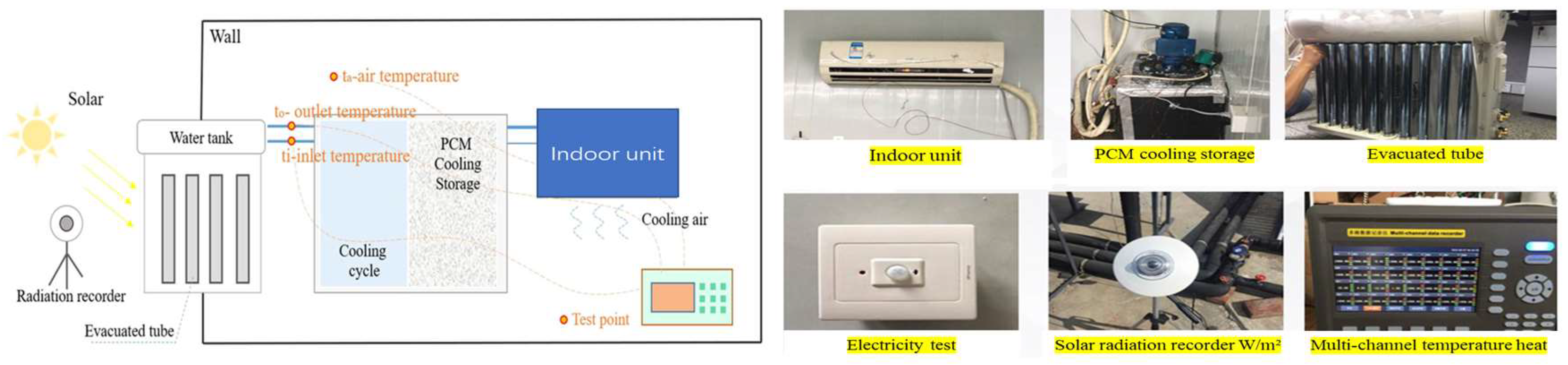

3.2. Natural Cooling Phase Change Cold Storage Air Conditioning Systems

3.3. Optimization of Phase Change Cold Storage Air Conditioning System

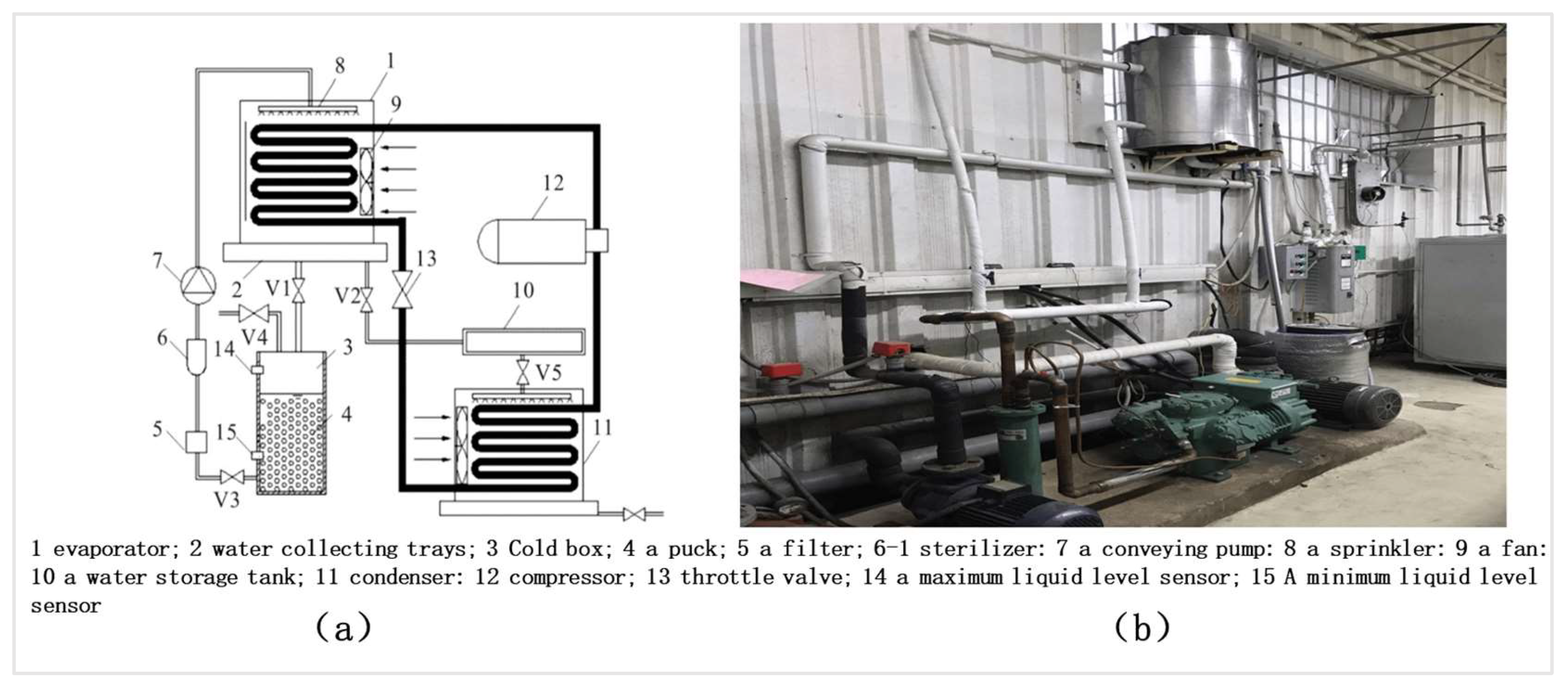

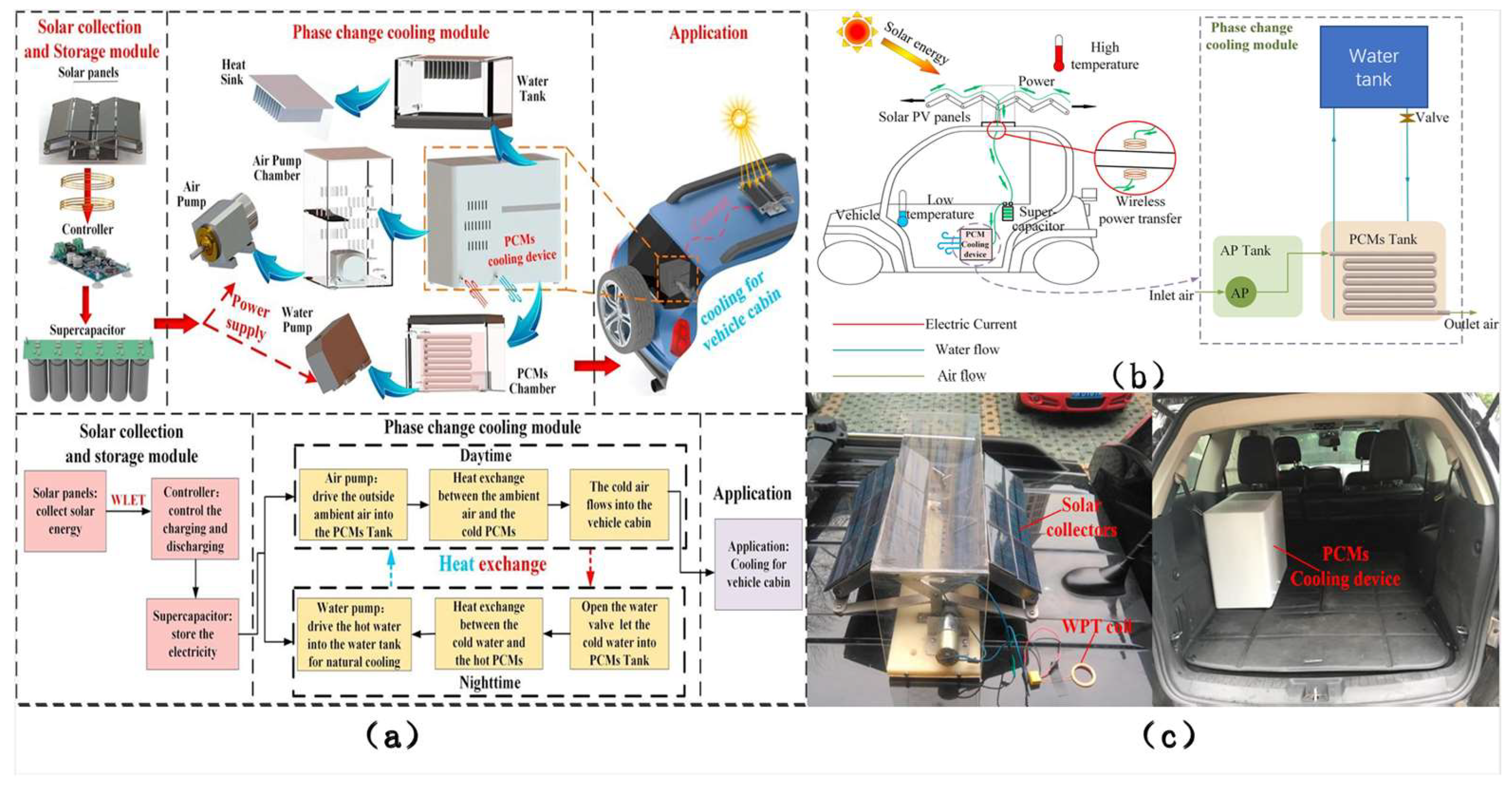

3.4. Application of Phase Change Cold Storage Air Conditioning

4. Discussion and Conclusions

- Latent heat cold storage holds greater research potential in air conditioning than sensible heat due to its high energy storage efficiency. Selecting appropriate phase change materials is essential, supercooling in inorganic materials can be mitigated with nucleating agents, and thickeners can prevent phase separation. Copper wires and ribs enhance the thermal conductivity of organic materials, while composite materials overcome the limitations of pure substances, pointing to a vital direction for future development. Vapor compression systems, which integrate phase change materials into condensers, storage tanks, and evaporators, are well established. Natural cooling systems leverage ambient conditions for low-energy cooling. Vapor compression is preferred for rapid, efficient cooling; however, natural cooling is ideal in suitable climates to minimize energy use.

- Energy consumption reduction can be approached from aspects such as refrigerant charge, enclosure structure, application of TES heat storage modules, PCM storage, inherent properties of PCM, and fins. The best phase change cold storage air conditioning performance is achieved when PCM is installed in spherical capsules or concave–convex plates and combined with the evaporator. However, further reducing the energy consumption of phase change cold storage air conditioning remains a crucial research topic for the future.

- Phase change materials often have issues such as leakage and corrosion. Therefore, good encapsulation is crucial for improving thermal reliability, good sealing, and strong resistance to thermal expansion. Composite phase change materials always perform better than pure materials. Ceramic-based composite phase change materials have excellent corrosion resistance and high thermal conductivity. Therefore, finding new composite phase change materials is a direction to solve the problems mentioned above.

- The practical application of phase change cold storage air conditioning systems at a large scale entails a careful evaluation of various factors, including cost-effectiveness, environmental impact, and the complexity of the processes involved. Despite the technological advancements in this field, the literature on these critical aspects remains sparse, indicating a clear gap that warrants further investigation. Furthermore, the research on using phase change cold storage air conditioning with new energy sources is relatively limited. While the integration with solar energy has been more extensively documented, a substantial opportunity exists for future development in the joint application of other renewable energy sources. This area of research holds promise for enhancing the sustainability and efficiency of cold storage air conditioning systems and, thus, deserves increased attention and exploration.

- Technological progress is set to usher intelligent features into phase change cold storage air conditioning systems. These systems will employ intelligent temperature control and thermal regulation, automatically adjusting the phase change and cooling output in response to environmental conditions and human activity, minimizing energy waste and cutting consumption. Integrating smart home ecosystems will allow for users to manage their air conditioning via mobile apps or voice commands, enhancing convenience and efficiency.

- Regarding phase change cold storage materials, research and development focusing on bio-based materials, such as plant and animal fats, could help reduce material costs. Combining shape memory alloys with PCMs to initiate phase change through shape alteration at specific temperatures shows promise. Using microchannel heat exchangers could boost heat transfer efficiency, creating modular, easy-to-maintain units. Features like fire protection, noise reduction, and air purification could further enhance system performance.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Taheri, S.; Amiri, A.J.; Razban, A. Real-world implementation of a cloud-based MPC for HVAC control in educational buildings. Energy Convers. Manag. 2024, 305, 118270. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, Y.; Liu, J.; Luo, X.; Wang, D.; Wang, Y.; Liu, J. Design and adaptability of photovoltaic air conditioning system based on office buildings. Sol. Energy 2020, 202, 17–24. [Google Scholar] [CrossRef]

- Selvnes, H.; Allouche, Y.; Manescu, R.I.; Hafner, A. Review on cold thermal energy storage applied to refrigeration systems using phase change materials. Therm. Sci. Eng. Prog. 2020, 22, 100807. [Google Scholar] [CrossRef]

- Wang, H.; Xie, B.; Li, C. Review on operation control of cold thermal energy storage in cooling systems. Energy Built Environ. 2024, in press. [Google Scholar] [CrossRef]

- Serale, G.; Baronetto, S.; Goia, F.; Perino, M. Characterization and Energy Performance of a Slurry PCM-based Solar Thermal Collector: A Numerical Analysis. Energy Procedia 2014, 48, 223–232. [Google Scholar] [CrossRef]

- Liu, Z.; Quan, Z.; Zhao, Y.; Zhang, W.; Yang, M.; Shi, J.; Bai, Z. Dynamic modelling and performance prediction of a novel direct-expansion ice thermal storage system based multichannel flat tube evaporator plus micro heat pipe arrays storage module. Renew. Energy 2023, 217, 119153. [Google Scholar] [CrossRef]

- Wang, X.; Qu, X.; Wang, C.; Zhu, B. Review on Phase Change Cool Storage in Air-conditioning System. Build. Sci. 2013, 29, 98–106. [Google Scholar] [CrossRef]

- Feng, X. Research on Operation Strategy and Application of Phase Change Cool Storage Air Conditioning System. Master’s Thesis, Beijing University of Civil Engineering and Architecture, Beijing, China, 2020. [Google Scholar] [CrossRef]

- Yang, J. Preparation and Performance Study of Phase Change Material with Hydrated Salt for Cold Storage in Air Conditioning. Master’s Thesis, Southeast University, Nanjing, China, 2022. [Google Scholar] [CrossRef]

- Riahi, A.; Shafii, M.B. Parametric study of a vapor compression refrigeration system integrated with a PCM storage tank for increasing condenser sub-cooled temperature. Case Stud. Therm. Eng. 2023, 47, 103100. [Google Scholar] [CrossRef]

- Ma, Y. Study on Application of Phase Change Microcapsule in Solar Composite Air Conditioning System. Master’s Thesis, Zhongyuan University of Technology, Zhengzhou, China, 2020. [Google Scholar] [CrossRef]

- Zhao, D.; Tan, G. Experimental evaluation of a prototype thermoelectric system integrated with PCM (phase change material) for space cooling. Energy 2014, 68, 658–666. [Google Scholar] [CrossRef]

- Abdolmaleki, L.; Berardi, U. Single and Multi-phase Change Materials Used in Cooling Systems. Int. J. Thermophys. 2022, 43, 61. [Google Scholar] [CrossRef]

- Peng, S.-H.; Lo, S.-L. Hybrid (Optimal) Selection Model for Phase Change Materials Used in the Cold Energy Storage of Air Conditioning Systems. Energies 2023, 17, 63. [Google Scholar] [CrossRef]

- Tang, R.; Gui, S.; Yan, J.; Li, D. Research Progress of Phase Change Materials Applied in Air-Conditioning Cold Storage. J. Build. Energy Effic. 2020, 48, 57–61. [Google Scholar] [CrossRef]

- Zhang, W.; Zhao, C. Examining the Performance of Portable Cold-storage Box Based on Phase-change Technology. J. Refrig. 2024, 45, 145–157. [Google Scholar] [CrossRef]

- Lin, N.; Li, C.; Zhang, D.; Li, Y.; Chen, J. Emerging phase change cold storage materials derived from sodium sulfate decahydrate. Energy 2022, 245, 123294. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, D.; Yang, X.; Chen, G.; Zhang, Y.; Chen, B. Analysis of Thermal Characteristics of Eutectic Salt Phase Change Materials for Air Conditioning. In Proceedings of the 11th National Conference on Energy and Thermal Engineering NCETE, The Chinese Society for Metals, Maanshan City, China, 14–16 July 2021; pp. 292–296. [Google Scholar] [CrossRef]

- Liu, F.; Liu, X. Preparation and properties study of phase change materials for fruits and vegetables preservation. J. Hebei Univ. Sci. Technol. 2018, 39, 540–545. [Google Scholar] [CrossRef]

- Yang, J.; Yin, Y. Research Progress of Phase Change Materials for Cold Thermal Energy Storage in Air-conditioners. J. Refrig. 2022, 43, 37–44. [Google Scholar]

- Wang, Y.; Xing, M.; Jing, D.; Zhang, H.; Wang, R. Study on the Performance of CNT Based Phase Change Cold Storage Air Conditioning; China Academic Journal Electronic Publishing House: Ningbo, China, 2023; pp. 1032–1036. [Google Scholar] [CrossRef]

- Yan, W.-M.; Huang, C.-Y.; Gao, K.-E.; Amani, M.; Chien, L.-H.; Homayooni, A. Study on the performance enhancement of ice storage and melting processes in an ice-on-coil thermal energy storage system. J. Energy Storage 2023, 72, 108410. [Google Scholar] [CrossRef]

- Liu, K.; He, Z.; Lin, P.; Zhao, X.; Chen, Q.; Su, H.; Luo, Y.; Wu, H.; Sheng, X.; Chen, Y. Highly-efficient cold energy storage enabled by brine phase change material gels towards smart cold chain logistics. J. Energy Storage 2022, 52, 104828. [Google Scholar] [CrossRef]

- Li, M.; Chen, P.; Lv, Z.; Chen, Z. Preparation and Modification of Composite Inorganic Salt Phase Change Materials for Cold Storage. J. Refrig. 2021, 42, 106–115. [Google Scholar]

- Jiao, F.; Li, X.; Ma, Z.; Ma, K.; Li, J.; Lv, G.; Yu, Z. Review on Research Progress and Applications of Phase Change Materials for Cold Storage. J. Refrig. Technol. 2023, 46, 71–79. [Google Scholar] [CrossRef]

- Xie, Y.; Shi, B.; Feng, Y. Experimental Study on Thickening Characteristics of Eutectic Salt Cold Storage Material for Air Conditioning. J. Build. Energy Effic. 2020, 48, 9–13, 32. [Google Scholar]

- Liu, J.; Liu, R.; Wang, C.; Liang, Y. Thermodynamics test of Na2SO4·10H2O phase change compound system. Energy Conserv. 2007, 2007, 13–14. [Google Scholar]

- Peng, S.-H.; Lo, S.-L. An Economic Analysis of Energy Saving and Carbon Mitigation by the Use of Phase Change Materials for Cool Energy Storage for an Air Conditioning System—A Case Study. Energies 2024, 17, 912. [Google Scholar] [CrossRef]

- Yang, N.; Wang, J.; Liu, J.; Zhang, Z. Experimental Study on Eutectic Salt Air Conditioning Thermal Energy Storage Material with Added Nanoparticles. Build. Energy Effic. 2017, 45, 10–13, 18. [Google Scholar]

- Wei, Z.; Liu, X.; Liu, Z. Research on performance of phase change cold storage supermarket freezing cabinet. J. Appl. Sci. Technol. 2021, 2021, 59–63. [Google Scholar] [CrossRef]

- Lu, W.; Liu, G.; Xing, X.; Wang, H. Investigation on Ternary Salt-Water Solutions as Phase Change Materials for Cold Storage. Energy Procedia 2019, 158, 5020–5025. [Google Scholar] [CrossRef]

- Ban, C.; Lv, L.; Pan, L. Preparation and performance evaluation of freeze type composite phase change material. New Chem. Mater. 2019, 47, 218. [Google Scholar]

- Lv, Y. Organic Phase Change Cold Storage Material for Air Conditioning of Regular Working Condition Research. Master’s Thesis, TianJin University, Tianjin, China, 2017. [Google Scholar]

- Rodríguez, A.T.; Gálvez, D.M.; Kerdan, I.G.; Casarín, R.S. A Comparison of a Transparent Thermal Insulation System Filled with Refrigerants and a Pig-Fat Based PCM. Energies 2023, 16, 3630. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, Q.; Zhai, Z.; Qiu, J. Performance of a cold storage air-cooled heat pump system with phase change materials for space cooling. Energy Build. 2020, 228, 110405. [Google Scholar] [CrossRef]

- Sarkar, S.; Mestry, S.; Mhaske, S.T. Developments in phase change material (PCM) doped energy efficient polyurethane (PU) foam for perishable food cold-storage applications: A review. J. Energy Storage 2022, 50, 104620. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, Y. Preparation and cycling performance of lauric acid-caprylic acid as cool storage phase change material. Chem. Eng. J. 2013, 41, 10–13. [Google Scholar]

- Li, G.; Hwang, Y.; Radermacher, R. Review of cold storage materials for air conditioning application. Int. J. Refrig. 2012, 35, 2053–2077. [Google Scholar] [CrossRef]

- Tang, H.; Wu, W.; Miao, P.; Zhang, H. Theoretical prediction and experimental research of binary organic phase change storage materials used for air-conditioning system. New Chem. Mater. 2016, 44, 121–123, 126. [Google Scholar]

- Zuo, J.; Li, W.; Xu, S. Thermal Properties of Caprylic Acid and Lauric Acid as Phase Change Cool Storage Material. Acta Energiae Solaris Sin. 2012, 33, 131–134. [Google Scholar]

- Li, Y. Preparation and Performance Study of Organic Phase Change Coolant Used in Cold Chain. Master’s Thesis, Xi’an University of Technology, Xi’an, China, 2021. [Google Scholar] [CrossRef]

- Wan, X.; Chen, C.; Tian, S.; Guo, B. Thermal characterization of net-like and form-stable ML/SiO2 composite as novel PCM for cold energy storage. J. Energy Storage 2020, 28, 101276. [Google Scholar] [CrossRef]

- Wang, J.; Xie, H.; Xin, Z. Thermal properties of paraffin based composites containing multi-walled carbon nanotubes. Thermochim. Acta 2009, 488, 39–42. [Google Scholar] [CrossRef]

- Qi, X. Development of Phase-Changing Coolant and Its Application on Preservation of Fruit and Vegetables. Master’s Thesis, Zhejiang University, Hangzhou, China, 2015. [Google Scholar]

- Cabeza, L.F.; Mehling, H.; Hiebler, S.; Ziegler, F. Heat transfer enhancement in water when used as PCM in thermal energy storage. Appl. Therm. Eng. 2002, 22, 1141–1151. [Google Scholar] [CrossRef]

- Waqas, A.; Ji, J.; Ali, M.; Alvi, J.Z. Effectiveness of the phase change material-based thermal energy storage integrated with the conventional cooling systems of the buildings—A review. Proc. Inst. Mech. Eng. Part A J. Power Energy 2018, 232, 735–766. [Google Scholar] [CrossRef]

- Ma, Z.; Lin, W.; Sohel, M.I. Nano-enhanced phase change materials for improved building performance. Renew. Sustain. Energy Rev. 2016, 58, 1256–1268. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Castell, A.; Barreneche, C.; De Gracia, A.; Fernández, A.I. Materials used as PCM in thermal energy storage in buildings: A review. Renew. Sustain. Energy Rev. 2011, 15, 1675–1695. [Google Scholar] [CrossRef]

- Alehosseini, E.; Jafari, S.M. Nanoencapsulation of phase change materials (PCMs) and their applications in various fields for energy storage and management. Adv. Colloid Interface Sci. 2020, 283, 102226. [Google Scholar] [CrossRef] [PubMed]

- Chang, Y.; Yao, X.; Chen, Y.; Huang, L.; Zou, D. Review on ceramic-based composite phase change materials: Preparation, characterization and application. Compos. Part B Eng. 2023, 254, 110584. [Google Scholar] [CrossRef]

- Mosaffa, A.H.; Talati, F.; Rosen, M.A.; Basirat-Tabrizi, H. Green’s function solution for transient heat conduction in annular fin during solidification of phase change material. Appl. Math. Mech.-Engl. Ed. 2012, 33, 1265–1274. [Google Scholar] [CrossRef]

- Fashandi, M.; Leung, S.N. Preparation and characterization of 100% bio-based polylactic acid/palmitic acid microcapsules for thermal energy storage. Mater. Renew. Sustain. Energy 2017, 6, 14. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, W.; Dong, Z.; Wang, H.; Pan, Y. Preparation and thermal performance of new composite phase change storage materials for refrigerator car. New Chem. Mater. 2013, 41, 41–43. [Google Scholar]

- Liu, Z.; Zhao, D.; Wang, Q.; Chi, Y.; Zhang, L. Performance study on air-cooled household refrigerator with cold storage phase change materials. Int. J. Refrig. 2017, 79, 130–142. [Google Scholar] [CrossRef]

- Jia, P.; Wu, W.; Wang, Y. Preparation of 0 °C phase change material and its cold storage performance in cold-chain logistics. Chem. Ind. Eng. Prog. 2019, 38, 2862–2869. [Google Scholar] [CrossRef]

- Kong, Q.; Mu, H.; Han, Y.; Wu, W.; Fang, X.; Liu, R.; Chen, H.; Gao, H. Preparation of Composite Phase Change Cold Storage Material and Its Effect on Storage Quality of Lentinula edodes. Food Sci. 2020, 41, 238–246. [Google Scholar]

- Wang, L.; Lu, W.; Xing, X. Investigation of New Low Temperature Composite Phase Change Materials for Cold Storage. Guangzhou Chem. 2021, 46, 50–56. [Google Scholar] [CrossRef]

- Wang, M.; Lei, M.; Wei, Y.; Yin, P. Study on composite phase change cold storage material for refrigerator freezer. Heilongjiang Sci. 2018, 9, 22–23. [Google Scholar]

- Li, J.; Xie, R.; Liu, G.; Foster, A. Development of New Low-temperature Phase Change Material and Equipment Used in Refrigerated Transportation. J. Refrig. 2018, 39, 32–37. [Google Scholar]

- Said, M.A.; Hassan, H. Impact of energy storage of new hybrid system of phase change materials combined with air-conditioner on its heating and cooling performance. J. Energy Storage 2021, 36, 102400. [Google Scholar] [CrossRef]

- Singh, P.C.; Halder, P. Performance Assessment of an Air-Conditioning System Utilizing a PCM-Based Annulus Cylindrical Latent Heat Storage. Arab. J. Sci. Eng. 2023, 49, 1759–1770. [Google Scholar] [CrossRef]

- Gao, X. Study on Cool Storage and Discharging Characteristic of Direct-contact Cool Storage Device at Conventional Air-Conditioning. Master’s Thesis, Harbin University of Commerce, Harbin, China, 2014. [Google Scholar]

- Zeng, X.; Wang, H.; Han, B. Performance test on cooling process of phase change cool storage device for air conditioning of rail vehicle. New Chem. Mater. 2020, 48, 230–233+238. [Google Scholar] [CrossRef]

- Wang, S.; Wang, H.; Sun, H.; Zeng, X. Numerical simulation on cooling process of phase change cool storage device for rail vehicle air conditioning. New Chem. Mater. 2020, 48, 152–156. [Google Scholar] [CrossRef]

- Jia, J.; Lee, W.L. Experimental investigations on using phase change material for performance improvement of storage-enhanced heat recovery room air-conditioner. Energy 2015, 93, 1394–1403. [Google Scholar] [CrossRef]

- Zhao, D.; Tan, G. Numerical analysis of a shell-and-tube latent heat storage unit with fins for air-conditioning application. Appl. Energy 2015, 138, 381–392. [Google Scholar] [CrossRef]

- Wan, Z.; Su, C.; Li, X.; Cheng, L.; Lu, Y. Feasibility Study on a New Cooling Storage System of Phase Change with Condensate in Air Conditioning. J. Green Sci. Technol. 2019, 195–197. [Google Scholar] [CrossRef]

- Nguyen, X.V. Fabrication and Performance Evaluation of Cold Thermal Energy Storage Tanks Operating in Water Chiller Air Conditioning System. Energies 2021, 14, 4159. [Google Scholar] [CrossRef]

- Loem, S.; Asanakham, A.; Deethayat, T.; Vorayos, N.; Kiatsiriroat, T. Testing of solar inverter air conditioner with PCM cool storage and sizing of photovoltaic modules. Therm. Sci. Eng. Prog. 2023, 38, 101671. [Google Scholar] [CrossRef]

- Loem, S.; Deethayat, T.; Asanakham, A.; Kiatsiriroat, T. Study on phase change material thermal characteristics during air charging/discharging for energy saving of air-conditioner. Heat Mass Transf. 2020, 56, 2121–2133. [Google Scholar] [CrossRef]

- Chaiyat, N. Energy and economic analysis of a building air-conditioner with a phase change material (PCM). Energy Convers. Manag. 2015, 94, 150–158. [Google Scholar] [CrossRef]

- Wonorahardjo, S.; Sutjahja, I.M.; Tunçbilek, E.; Achsani, R.A.; Arıcı, M.; Rahmah, N. PCM-based passive air conditioner in urban houses for the tropical climates: An experimental analysis on the stratum air circulation. Build. Environ. 2021, 192, 107632. [Google Scholar] [CrossRef]

- Wu, D.; Zhang, Q.; Chen, X.; Liao, S.; Sha, Z. Experimental Study on the Performance of Small-sized Cool Storage Air Conditioning with Phase Change Materials. Build. Sci. 2017, 33, 62–67. [Google Scholar] [CrossRef]

- Zhou, G.; Yang, Y.; Xu, H. Energy performance of a hybrid space-cooling system in an office building using SSPCM thermal storage and night ventilation. Sol. Energy 2011, 85, 477–485. [Google Scholar] [CrossRef]

- Nie, B.; Du, Z.; Chen, J.; Zou, B.; Ding, Y. Performance enhancement of cold energy storage using phase change materials with fumed silica for air-conditioning applications. Int. J. Energy Res. 2021, 45, 16565–16575. [Google Scholar] [CrossRef]

- Goyal, A.; Kozubal, E.; Woods, J.; Nofal, M.; Al-Hallaj, S. Design and performance evaluation of a dual-circuit thermal energy storage module for air conditioners. Appl. Energy 2021, 292, 116843. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, Q.; Zhai, Z.J.; Ma, X. Potential of ventilation systems with thermal energy storage using PCMs applied to air conditioned buildings. Renew. Energy 2019, 138, 39–53. [Google Scholar] [CrossRef]

- Marani, A.; Nehdi, M.L. Integrating phase change materials in construction materials: Critical review. Constr. Build. Mater. 2019, 217, 36–49. [Google Scholar] [CrossRef]

- Almeshaal, M.A.; Sakr, R.Y. Numerical study of encapsulated nanoparticles enhanced phase change material in thermal energy cool storage packed bed system. J. Energy Storage 2023, 68, 107837. [Google Scholar] [CrossRef]

- Ismail, M.; Zahra, W.K.; Hassan, H. Numerical investigation of the air conditioning system performance assisted with energy storage of capsulated concave/convex phase change material. J. Energy Storage 2023, 68, 107651. [Google Scholar] [CrossRef]

- Parameshwaran, R.; Kalaiselvam, S. Energy conservative air conditioning system using silver nano-based PCM thermal storage for modern buildings. Energy Build. 2014, 69, 202–212. [Google Scholar] [CrossRef]

- Deng, S.; Nie, C.; Jiang, H.; Ye, W.-B. Evaluation and optimization of thermal performance for a finned double tube latent heat thermal energy storage. Int. J. Heat Mass Transf. 2019, 130, 532–544. [Google Scholar] [CrossRef]

- Jamekhorshid, A.; Sadrameli, S.M.; Farid, M. A review of microencapsulation methods of phase change materials (PCMs) as a thermal energy storage (TES) medium. Renew. Sustain. Energy Rev. 2014, 31, 531–542. [Google Scholar] [CrossRef]

- Memon, S.A. Phase change materials integrated in building walls: A state of the art review. Renew. Sustain. Energy Rev. 2014, 31, 870–906. [Google Scholar] [CrossRef]

- Li, X.-Y.; Li, L.; Yu, J.-W.; Liu, J.-Q.; Wu, Y.-Y. Investigation of the dynamic characteristics of a storage tank discharging process for use in conventional air-conditioning system. Sol. Energy 2013, 96, 300–310. [Google Scholar] [CrossRef]

- Li, S.; Peng, J.; Li, H.; Zou, B.; Song, J.; Ma, T.; Ji, J. Zero energy potential of PV direct-driven air conditioners coupled with phase change materials and load flexibility. Renew. Energy 2022, 200, 419–432. [Google Scholar] [CrossRef]

- Li, S.; Peng, J.; Zou, B.; Li, B.; Lu, C.; Cao, J.; Luo, Y.; Ma, T. Zero energy potential of photovoltaic direct-driven air conditioners with considering the load flexibility of air conditioners. Appl. Energy 2021, 304, 117821. [Google Scholar] [CrossRef]

- Qi, L.; Pan, H.; Zhu, X.; Zhang, X.; Salman, W.; Zhang, Z.; Li, L.; Zhu, M.; Yuan, Y.; Xiang, B. A portable solar-powered air-cooling system based on phase-change materials for a vehicle cabin. Energy Convers. Manag. 2017, 150, 148–158. [Google Scholar] [CrossRef]

- Sun, B. The Numerical Simulation of Radiant Floor Cooling and Heating System with Double Phase Change Energy Storage and the Thermal Performance. Master’s Thesis, Northeast Petroleum University, Daqing, Chinna, 2022. [Google Scholar] [CrossRef]

- Zheng, L.; Zhang, W.; Xie, L.; Wang, W.; Tian, H.; Chen, M. Experimental study on the thermal performance of solar air conditioning system with MEPCM cooling storage. Int. J. Low-Carbon Technol. 2019, 14, 83–88. [Google Scholar] [CrossRef]

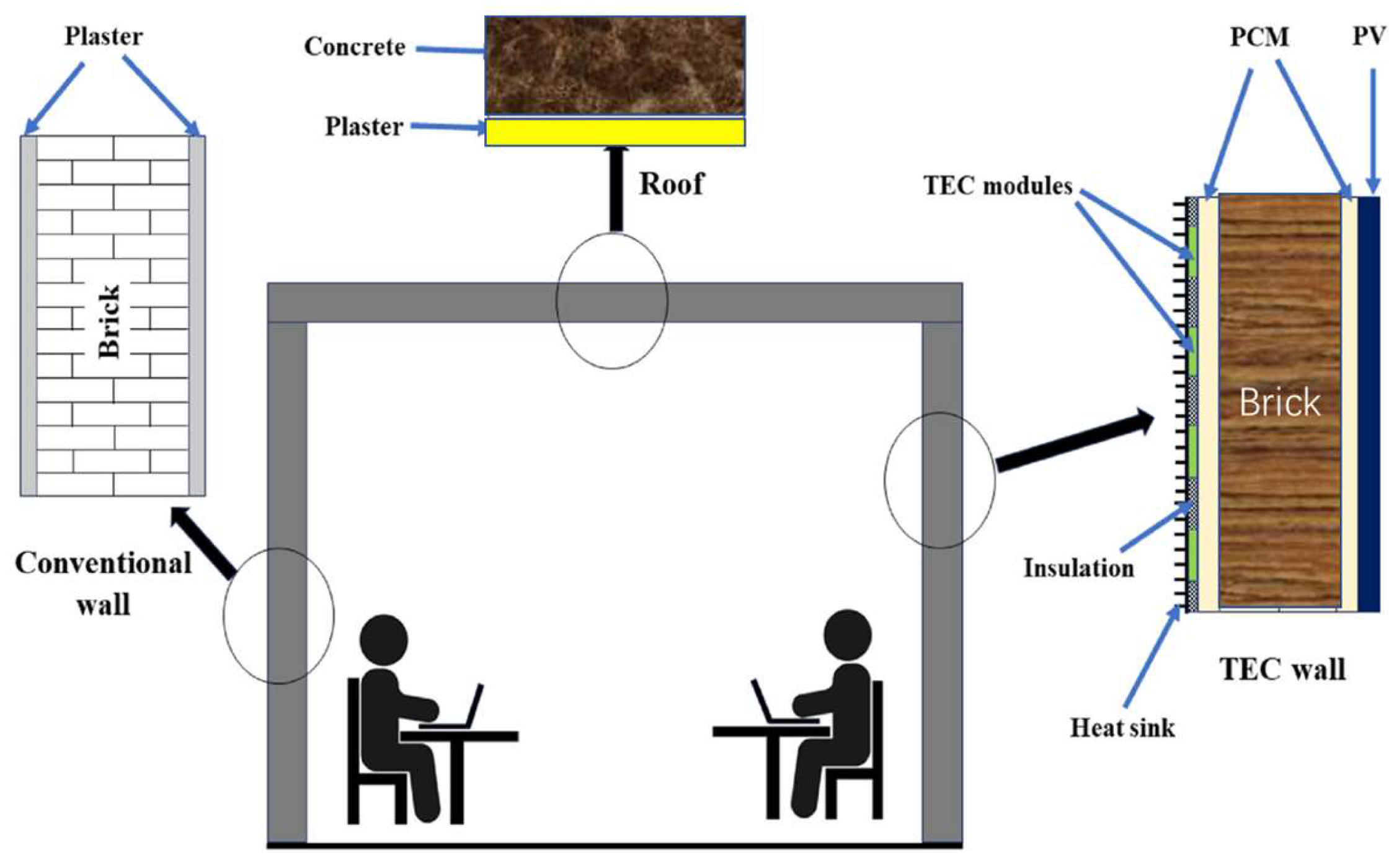

- Ahmed, H.A.; Megahed, T.F.; Nada, S.; Mori, S.; Hassan, H. Impact of modules number of thermoelectric cooler coupled with PV panels and phase change material on building air conditioning. J. Build. Eng. 2024, 86, 108914. [Google Scholar] [CrossRef]

- Maiorino, A.; Petruzziello, F.; Aprea, C. Refrigerated Transport: State of the Art, Technical Issues, Innovations and Challenges for Sustainability. Energies 2021, 14, 7237. [Google Scholar] [CrossRef]

- Shafiei, S.E.; Alleyne, A. Model predictive control of hybrid thermal energy systems in transport refrigeration. Appl. Therm. Eng. 2015, 82, 264–280. [Google Scholar] [CrossRef]

| PCM | Phase Change Temperature (°C) | Latent Heat (kJ/kg) | Thermal Conductivity W/(m·K) | Application | References | Costs |

|---|---|---|---|---|---|---|

| Paraffin RT11HC | 10~12 | 0.2 | Air-cooled heat pump system | [35] | 161 | |

| Polyethylene Glycol E-40 | 8 | 99.6 | 0.18 (L) | Food cold storage | [36] | 104 |

| Lauric acid, capric acid with a mass ratio of 21:79 | 7.73 | 134 | Air conditioning | [37] | 435 | |

| S7, S8, S10 | 7–10 | 150–155 | Air conditioning | [38] | ||

| OA/nutmeg alcohol with a mass ratio of 73.7:26.3 | 6.9 | 169.1 | Air conditioning | [39] | 782 | |

| OA,LA | 6.2 | 136.43 | [40] | 540 | ||

| Lauric acid/tetradecane with a molar ratio of 21:79 | 5.51 | 209.42 | Cold chain | [41] | 508 | |

| Methyl laurate | 5.48 | 224 | [42] | 633 | ||

| Tetrahydrofuran | 5 | 280 | [43] | 914 | ||

| Decanoic acid/decanol with a molar ratio of 36:64 | 3.8 | 180.94 | Cold chain | [41] | 504 | |

| Decanoic acid/methyl laurate with a molar ratio of 30:70 | 1.62 | 193.4 | Cold chain | [41] | 575 | |

| Mannitol aqueous solution | −3~−3.5 | 276.2 | Preservation of fruit and vegetables | [44] | 455 | |

| Teg | −7 | 247 | [45] | 123 | ||

| Paraffin RT-9HC | −9~10 | 202 | Liquid 0.174 Solid 0.309 | Refrigeration systems | [3] | 419 |

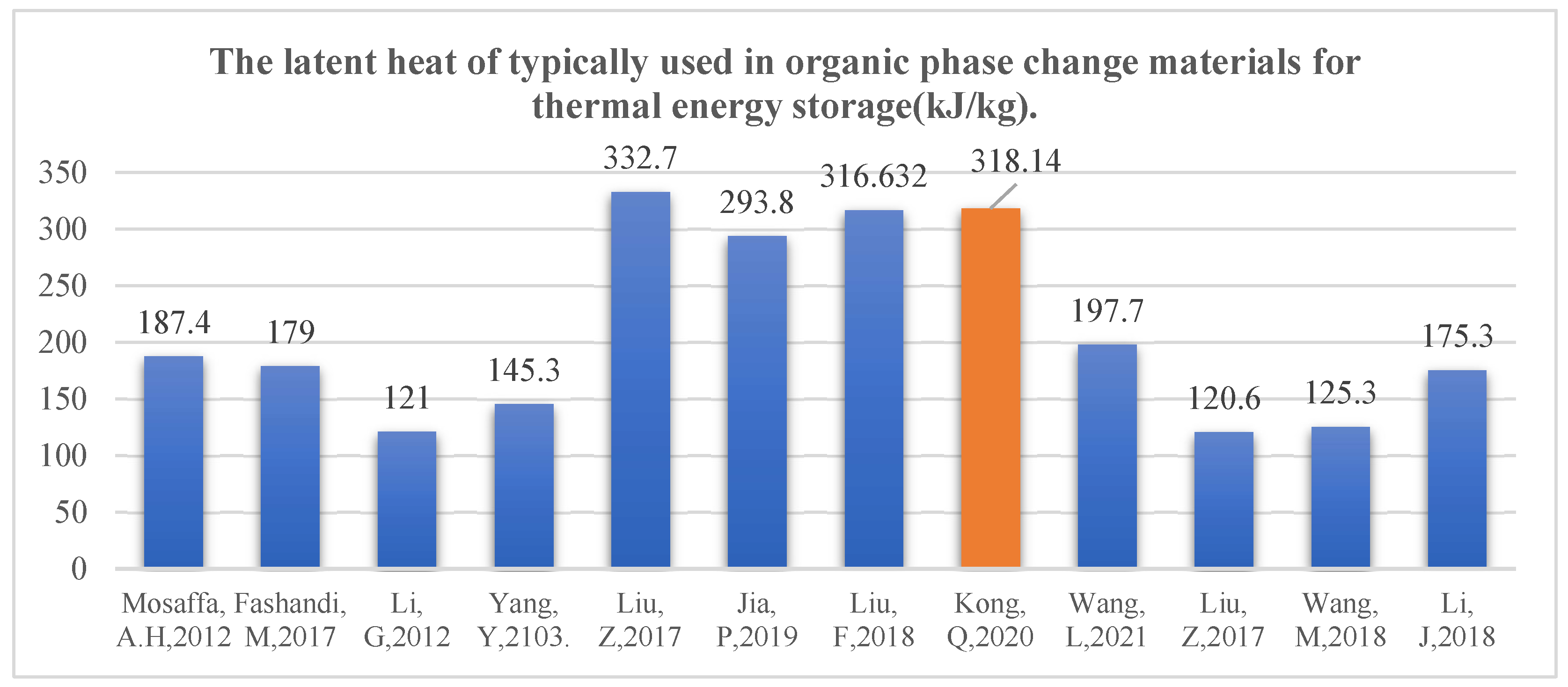

| PCM | Phase Change Temperature (°C) | Latent Heat (kJ/kg) | Application | References | Costs |

|---|---|---|---|---|---|

| CaCl2, H2O | 29.7 | 187.4 | [51] | 96 | |

| Na2B4O7·10H2O, NH4Br | 9.5–10 | 179 | Bio-based polymeric shell | [52] | 345 |

| Na2SO4, H2O, NaCl, NH4Cl | 7.5 | 121 | Air conditioning | [38] | 255 |

| Decanoic acid, tetradecane, and graphite with a mass fraction of 74%, 26%, and 6% | 6.6 | 145.3 | Refrigerator car | [53] | 532 |

| Deionized water (softened water) with 1% superabsorbent polymer (SAP) and 0.03% diatomaceous earth added | 0.41 | 332.7 | Air-cooled household refrigerator | [54] | |

| A 5% sorbitol aqueous solution with 0.40% TiO2 and 1.0% sodium polyacrylate | −2.9 | 293.8 | Cold-chain logistics | [55] | 782 |

| Sodium benzoate, water, and 0.1% diatomaceous earth | −4.06 | 316.632 | Fruits and vegetables preservation | [19] | 149 |

| A mixture with a mass fraction of 2% potassium chloride, 1.37% glycine, and 3.37% SAP | −6.08 | 318.14 | Storage Quality of Lentinula edodes | [56] | |

| Propanetriol: ammonium chloride: water = 1:2:7 | −17.6 | 197.7 | [57] | 700 | |

| An 18% sodium chloride solution with 5% SAP and 0.03% diatomaceous earth | −18.98 | 120.6 | Air-cooled household refrigerator | [54] | |

| Propanetriol, sodium chloride, and water with a mass ratio of 15%, 10%, 75% | −21.4 | 125.3 | Freezer refrigerator | [58] | 609 |

| A mixture of 20% sodium chloride solution and 50% propanetriol solution with a mass ratio of 2.5:7.5 | −31.5 | 175.3 | Refrigerated transportation | [59] | 590 |

| Matrix | Advantages | Disadvantages |

|---|---|---|

Ceramic matrix | 1. High sensible heat storage capacity | Frangibility |

| 2. Good dimensional stability | ||

| 3. High wettable with PCMs | ||

| 4. Excellent chemical and thermal stability | ||

| 5. High corrosion resistance | ||

| 6. Low cost | ||

Carbon matrix | Excellent thermal conductivity | 1. High cost |

| 2. Poor high-temperature thermal stability | ||

| 3. Complexity of preparation | ||

| Metallic matrix | 1. Excellent thermal conductivity | 1. High cost |

| 2. Good mechanical strength | 2. Corrosion issue | |

| 3. High porosity | 3. Insufficient wetting to PCMs | |

| 4. Excellent thermal stability |

| AC Systems | Parameters | Description | 0 | 1 | 2 | 3 | 10 | Present Value (CHF) |

|---|---|---|---|---|---|---|---|---|

| Without phase change material storage | K | Investment cost | 507,021.76 | 507,021.76 | ||||

| C1 | Operation costs | 60,136.69 | 60,136.69 | 60,136.69 | 60,136.69 | 60,136.69 | 368,820.14 | |

| C2 | Maintenance costs | 25,374.04 | 25,374.04 | 25,374.04 | 25,374.04 | 25,374.04 | 153,354.23 | |

| B1 | Electricity bill | 45,675.08 | ||||||

| B2 | Savings | 17,600.63 | ||||||

| D | Salvage value | 45,337.71 | 652,469 | |||||

| With phase change material storage | K | Investment cost | 441,000.66 | 441,000.66 | ||||

| C1 | Operation costs | 52,723.29 | 52,723.29 | 52,723.29 | 52,723.29 | 52,723.29 | 305,275.74 | |

| C2 | Maintenance costs | 39,843.53 | 39,843.53 | 39,843.53 | 39,843.53 | 39,843.53 | 261,305.83 | |

| B1 | Electricity bill | 2,000,000.00 | ||||||

| B2 | Savings | 325,471.13 | 325,471.13 | 325,471.13 | 325,471.13 | 325,471.13 | 15,000.00 | |

| D | Salvage value | 39,469.17 | 15,217.07 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Sha, Y.; Zhang, X. Research on Phase Change Cold Storage Materials and Innovative Applications in Air Conditioning Systems. Energies 2024, 17, 4365. https://doi.org/10.3390/en17174365

Li Z, Sha Y, Zhang X. Research on Phase Change Cold Storage Materials and Innovative Applications in Air Conditioning Systems. Energies. 2024; 17(17):4365. https://doi.org/10.3390/en17174365

Chicago/Turabian StyleLi, Zhengjing, Yishun Sha, and Xuelai Zhang. 2024. "Research on Phase Change Cold Storage Materials and Innovative Applications in Air Conditioning Systems" Energies 17, no. 17: 4365. https://doi.org/10.3390/en17174365

APA StyleLi, Z., Sha, Y., & Zhang, X. (2024). Research on Phase Change Cold Storage Materials and Innovative Applications in Air Conditioning Systems. Energies, 17(17), 4365. https://doi.org/10.3390/en17174365