Experimental Research and Improved Neural Network Optimization Based on the Ocean Thermal Energy Conversion Experimental Platform

Abstract

:1. Introduction

2. Materials and Methods

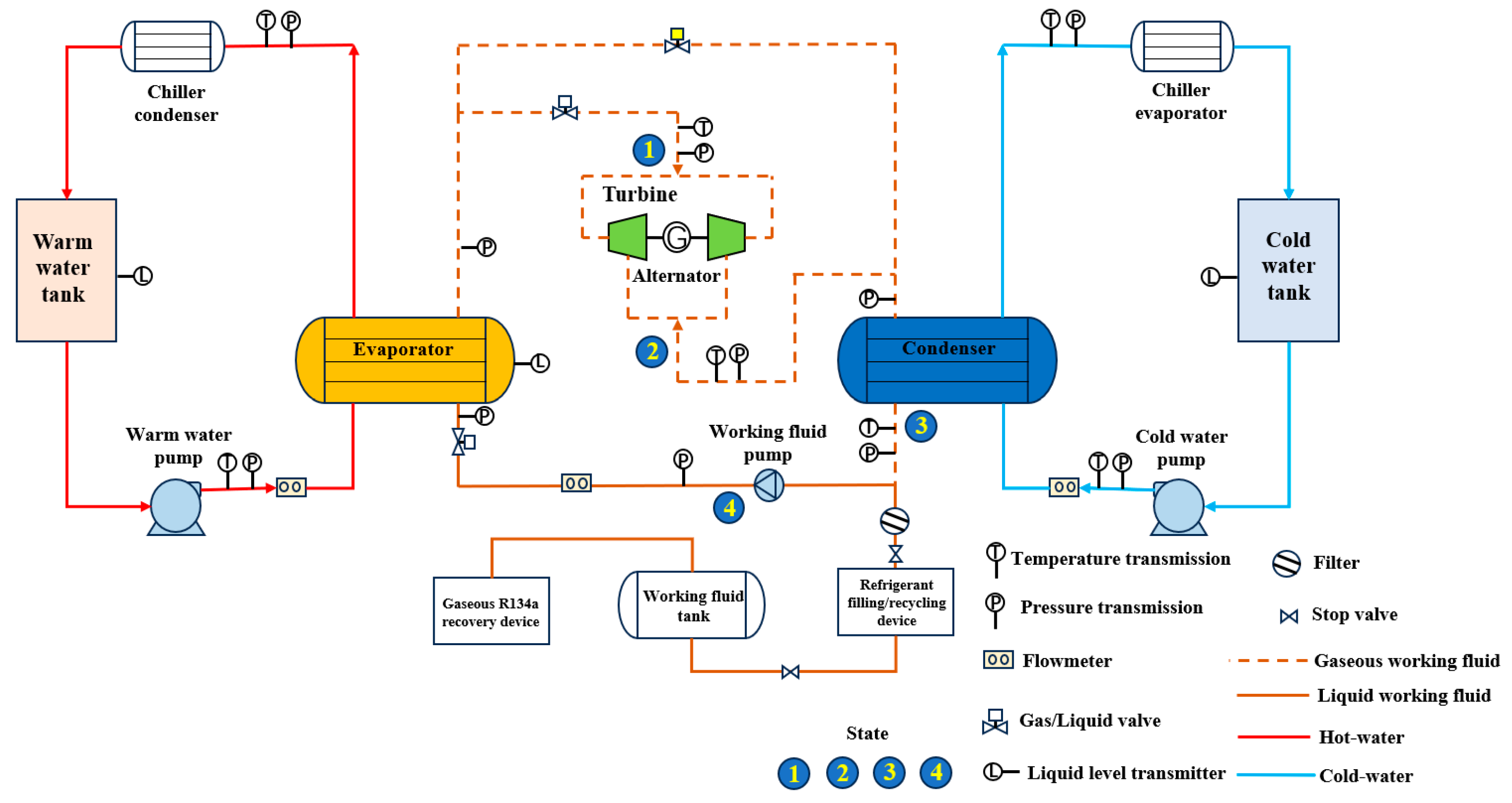

2.1. Description of the Test Bench

2.1.1. Warm and Cold Water Circuits

2.1.2. Dual Turbine OTEC Circuit

2.2. Measurement Device and Operating Method

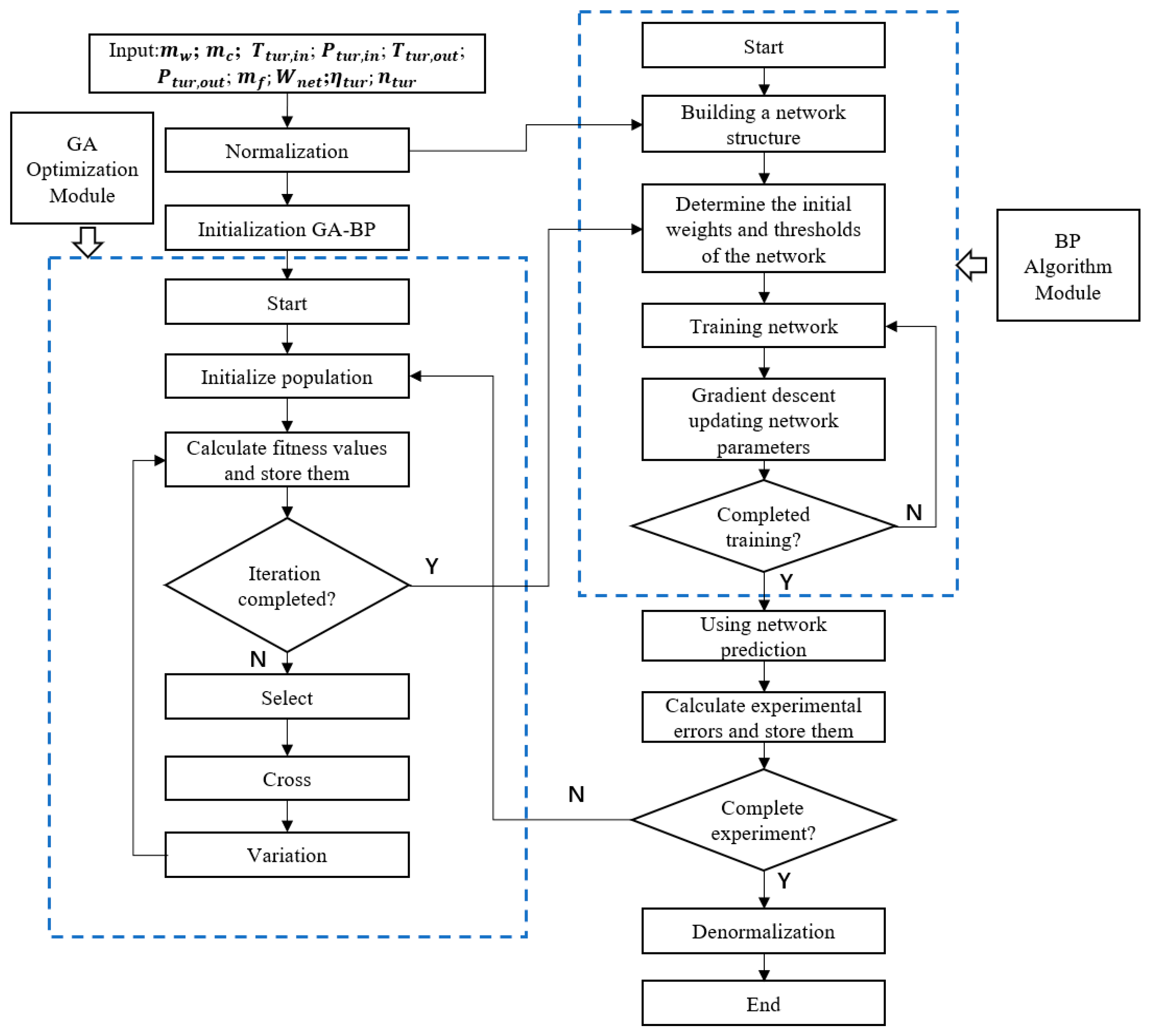

2.3. Algorithm Model

2.3.1. GA-BP Neural Network

2.3.2. GP-BP-OTEC Neural Network

2.3.3. GBO Neural Network Model Evaluation Indicators

3. Results and Discussion

3.1. Experimental Data Analysis

3.2. GBO Model Analysis

3.2.1. The Impact of the Training Function on the GBO Neural Network

3.2.2. Initial Parameter Selection

3.3. Model Accuracy Prediction and Evaluation

3.4. Multi-Objective Optimization

4. Conclusions

- The mass flow rate of warm and cold water, the inlet temperature and pressure of the turbine, and the grid-connected power of the turbine are positively correlated. The change in mass flow rate is consistent with the change in turbine output power. The outlet temperature and pressure of the turbine are negatively correlated with the grid-connected power of the turbine; the isentropic efficiency of the permeable is affected by the combined influence of seven operating parameters, all of which are essential, with the mass flow rate of the working fluid having the greatest impact.

- This article ultimately chooses to use the trainlm training function and uses a Bayesian optimizer to optimize the hyperparameters of the GBO model. The number of hidden layer nodes is automatically determined by an improved BP algorithm, reducing training time and determining the number of hidden layer nodes to be 10;

- The trained GBO model has good fitting accuracy for the three output parameters, with the maximum of turbine grid-connected power reaching 0.99942, the of turbine entropy efficiency reaching 0.99906, and the of the turbine speed reaching 0.98764. The maximum errors of the three parameters are 0.246 kW, 0.00135, and 121 rpm, respectively, meeting the experimental accuracy requirements;

- Within a reasonable range of parameter variations, the grid-connected power and isentropic efficiency of the turbine cannot be optimized simultaneously. The Pareto frontier is obtained and normalized, and the optimal result obtained using the LINMAP method is a turbine grid-connected power of 40.1792 kW and an isentropic efficiency of 0.837439.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Mass flow rate, m3/h or kg/s | c | cold | |

| Rotational speed, rpm | w | warm | |

| Power; kW | f | working fluid | |

| Pressure, bar | Acronyms | ||

| Temperature, °C | OTEC | Ocean Thermal Energy Conversion | |

| Subscripts | ANN | Artificial Neural Network | |

| exp | expander | GA | Genetic Algorithm |

| con | condenser | BP | Back Propagation |

| tur | turbine | MSE | Mean Squared Error |

| in | inlet | R | Correlation coefficient |

| out | outlet | MAPE | Mean Average Percentage Error |

References

- Zhai, X.Y. Research on Ocean Thermoelectric Power Generation System and Its Heat Exchanger and Ejector. Master’s Thesis, Shandong University, Jinan, China, 2021. [Google Scholar] [CrossRef]

- Liu, W.M.; Chen, F.Y.; Ge, Y.Z.; Peng, J.P.; Liu, L.; Yang, X.; Song, J.Z.; Liu, K.L. Review of efficiency research on ocean thermal energy systems. Coast. Eng. 2022, 41, 441–450. [Google Scholar]

- Quoilin, S.; Van Den Broek, M.; Declaye, S.; Dewallef, P.; Lemort, V. Techno-economic survey of Organic Rankine Cycle (ORC) systems. Renew. Sustain. Energy Rev. 2013, 22, 168–186. [Google Scholar] [CrossRef]

- Yoon, J.I.; Son, C.H.; Baek, S.M.; Ye, B.H.; Kim, H.J.; Lee, H.S. Performance characteristics of a high-efficiency R717 OTEC power cycle. Appl. Therm. Eng. 2014, 72, 304–308. [Google Scholar] [CrossRef]

- Miljkovic, M. Injection power cycle applied in OTEC power plants. Energy Procedia 2017, 143, 823–828. [Google Scholar] [CrossRef]

- Kalina, A.I. Combined Cycle System with Novel Bottoming Cycle. ASME J. Eng. Turbines Power 1984, 106, 737–742. [Google Scholar] [CrossRef]

- Uehara, H.; Ikegami, Y.; Nishida, T. Performance Analysis of OTEC System Using a Cycle with Absorption and Extraction Processes. Nihon Kikai Gakkai Ronbunshu B Hen Trans. Jpn. Soc. Mech. Eng. Part B 1998, 64, 2750–2755. [Google Scholar] [CrossRef]

- Xue, B. Performance Study of Karina Cycle and Upper Primary Cycle Marine Thermoelectric Power Generation Systems. Master’s Thesis, China University of Petroleum, Beijing, China, 2020. [Google Scholar]

- Liu, W.M.; Chen, F.Y.; Wang, Y.Q. Progress of Closed-Cycle OTEC and Study of a New Cycle of OTEC. Adv. Mater. Res. 2012, 354–355, 275–278. [Google Scholar] [CrossRef]

- Ge, Y.Z.; Peng, J.P.; Chen, F.Y.; Liu, L.; Liu, W.M. Design and performance impact of marine thermoelectric power generation turbines. Sci. Technol. Bull. 2021, 39, 96–101. [Google Scholar]

- Yang, X.; Liu, Y.; Chen, Y.; Zhang, L. Optimization Design of the Organic Rankine Cycle for an Ocean Thermal Energy Conversion System. Energies 2022, 15, 6683. [Google Scholar] [CrossRef]

- Yang, X.; Liu, Y.; Chen, Y.; Zhang, L. Operation Control and Performance Analysis of an Ocean Thermal Energy Conversion System Based on the Organic Rankine Cycle. Energies 2022, 15, 3971. [Google Scholar] [CrossRef]

- Chen, F.; Liu, L.; Peng, J.; Ge, Y.; Wu, H.; Liu, W. Theoretical and experimental research on the thermal performance of ocean thermal energy conversion system using the rankine cycle mode. Energy 2019, 183, 497–503. [Google Scholar] [CrossRef]

- Martins, M.; Sinama, F.; Lucas, F. Equivalent Gibbs systems for modelling an onshore OTEC experimental plant on Reunion Island. Int. J. Energy Res. 2013, 37, 1112–1121. [Google Scholar] [CrossRef]

- Present Study-Ocean Thermal Energy Conversion | Introduction of Each Division’s Researches | Research & Education | Institute of Ocean Energy Saga University Japant [EB/OL]. Available online: https://www.ioes.saga-u.ac.jp/en/research/ioes_present_study/otec_present_study (accessed on 17 September 2022).

- Chen, F.; Liu, L.; Peng, J. Theoretical analysis and testing of the performance of the Rankine cycle ocean thermoelectric power generation system. Sci. Technol. Rev. 2021, 39, 90–95. [Google Scholar]

- Liu, W. Research and Experimentation on 15 kW Thermoelectric Generator. China Sci. Technol. Achiev. 2014, 1, 17. [Google Scholar] [CrossRef]

- Peng, J.; Wu, H.; Ge, Y.; Chen, F.; Liu, L.; Liu, W. The experimental study of rankine cycle in ocean thermal energy conversion. Lop Conf. Ser. Mater. Sci. Eng. 2018, 381, 12126. [Google Scholar] [CrossRef]

- Journoud, A.; Sinama, F.; Lucas, F. Experimental Ocean Thermal Energy Conversion (OTEC) project on the Reunion Island. In Proceedings of the 4th International Conference on Ocean Energy, Dublin, Irland, 17–19 October 2012. [Google Scholar]

- Dijoux, A.; Sinama, F.; Marc, O.; Castaing-Lasvignottes, J. Modelling and experimentation of heat exchangers for Ocean Thermal Energy Conversion during transient operation. J. Procedia Manuf. 2019, 35, 298–303. [Google Scholar] [CrossRef]

- Dong, S.; Hu, X.; Huang, J.F.; Zhu, T.; Zhang, Y.; Li, X. Investigation on improvement potential of ORC system off-design performance by expander speed regulation based on theoretical and experimental exergy-energy analyses. Energy 2021, 220, 119753. [Google Scholar] [CrossRef]

- Jin, Y.L.; Gao, N.P.; Zhu, T. Effect of resistive load characteristics on the performance of Organic Rankine cycle (ORC). Energy 2022, 246, 123407. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, X.; Cai, J.; He, Z.; Tian, H.; Shu, G.; Shi, L. Experimental study on operating parameters matching characteristic of the organic Rankine cycle for engine waste heat recovery. Energy 2022, 244, 122681. [Google Scholar] [CrossRef]

- Shao, L.; Ma, X.; Wei, X.; Hou, Z.; Meng, X. Design and experimental study of a small-sized organic Rankine cycle system under various cooling conditions. Energy 2017, 130, 236–245. [Google Scholar] [CrossRef]

- Li, J.; Li, R.; Miao, Z.; Xu, J. Experimental study on the influence of heat source temperature and flow rate on the operating characteristics of organic Rankine cycle systems. Therm. Power Gener. 2022, 51, 106–112. [Google Scholar]

- Feng, Y.Q.; Liu, Y.Z.; Wang, X.; He, Z.X.; Hung, T.C.; Wang, Q.; Xi, H. Performance prediction and optimization of an organic Rankine cycle (ORC) for waste heat recovery using back propagation neural network. Energy Convers. Manag. 2020, 226, 113552. [Google Scholar] [CrossRef]

- Gou, Y.; Li, L.; Min, H. Design and performance experiment of radial inflow turbine expander for organic Rankine cycle system. Int. J. Low-Carbon Technol. 2021, 16, 1202–1209. [Google Scholar] [CrossRef]

- Zhang, Y.F.; Li, M.J.; Ren, X.; Duan, X.Y.; Wu, C.J.; Xi, H.; Feng, Y.Q.; Gong, L.; Hung, T.C. Effect of heat source supplies on system behaviors of ORCs with different capacities: An experimental comparison between the 3 kW and 10 kW unit. Energy 2022, 254, 124267. [Google Scholar] [CrossRef]

- Hijriawan, M.; Pambudi, N.A.; Wijayanto, D.S.; Biddinika, M.K.; Saw, L.H. Experimental analysis of R134a working fluid on Organic Rankine Cycle (ORC) systems with scroll-expander. Eng. Sci. Technol. 2022, 29, 101036. [Google Scholar] [CrossRef]

- Arslan, O.; Yetik, O. ANN based optimization of supercritical ORC-Binary geothermal power plant: Simav case study. Appl. Therm. Eng. 2011, 31, 3922–3928. [Google Scholar] [CrossRef]

- Luo, X.; Wang, Y.; Liang, J.; Qi, J.; Su, W.; Yang, Z.; Chen, J.; Wang, C.; Chen, Y. Improved correlations for working fluid properties prediction and their application in performance evaluation of sub-critical Organic Rankine Cycle. Energy 2019, 174, 122–137. [Google Scholar] [CrossRef]

- Yang, F.; Cho, H.; Zhang, H.; Zhang, J.; Wu, Y. Artificial neural network (ANN) based prediction and optimization of an organic Rankine cycle (ORC) for diesel engine waste heat recovery. Energy Convers. Manag. 2018, 164, 15–26. [Google Scholar] [CrossRef]

- Rashidi, M.M.; Galanis, N.; Nazari, F.; Parsa, A.B.; Shamekhi, L. Parametric analysis and optimization of regenerative Clausius and organic Rankine cycles with two feedwater heaters using artificial bees colony and artificial neural network. Energy 2011, 36, 5728–5740. [Google Scholar] [CrossRef]

- Ziviani, D.; James, N.A.; Accorsi, F.A.; Braun, J.E.; Groll, E.A. Experimental and numerical analyses of a 5kWe oil-free open-drive scroll expander for small-scale organic Rankine cycle (ORC) applications. Appl. Energy 2018, 230, 1140–1156. [Google Scholar] [CrossRef]

- Palagi, L.; Sciubba, E.; Tocci, L. A neural network approach to the combined multi-objective optimization of the thermodynamic cycle and the radial inflow turbine for Organic Rankine cycle applications. Appl. Energy 2019, 237, 210–226. [Google Scholar] [CrossRef]

- Emadi, M.A.; Mahmoudimehr, J. Modeling and thermo-economic optimization of a new multi-generation system with geothermal heat source and LNG heat sink. Energy Convers. Manag. 2019, 189, 153–166. [Google Scholar] [CrossRef]

- Wang, W.; Deng, S.; Zhao, D.; Zhao, L.; Lin, S.; Chen, M. Application of machine learning into organic Rankine cycle for prediction and optimization of thermal and exergy efficiency. Energy Convers. Manag. 2020, 210, 112700. [Google Scholar] [CrossRef]

- Peng, Y.; Lin, X.; Liu, J.; Su, W.; Zhou, N. Machine learning prediction of ORC performance based on properties of working fluid. Appl. Therm. Eng. 2021, 195, 117184. [Google Scholar] [CrossRef]

- Chen, W.; Liang, Y.; Luo, X.; Chen, J.; Yang, Z.; Chen, Y. Artificial neural network grey-box model for design and optimization of 50 MWe-scale combined supercritical CO2 Brayton cycle-ORC coal-fired power plant. Energy Convers. Manag. 2021, 249, 114821. [Google Scholar] [CrossRef]

- Rumelhart, D.E.; McClelland, J.L. Parallel Distributed Processing; IEEE: Piscataway, NJ, USA, 1998. [Google Scholar]

| Month | Temperature/°C | Month | Temperature/°C | Month | Temperature/°C |

|---|---|---|---|---|---|

| 1 | 25 | 5 | 29.7 | 9 | 29.1 |

| 2 | 24.6 | 6 | 30.1 | 10 | 28.8 |

| 3 | 25.6 | 7 | 29.9 | 11 | 27.8 |

| 4 | 27.9 | 8 | 29.5 | 12 | 26.4 |

| State | Temperature (°C) | Pressure (kPa) | Density (kg/m3) | Specific Enthalphy (kJ/kg) | Specific Entropy (kJ/kg·K) |

|---|---|---|---|---|---|

| 1 | 24 | 645.78 | 31.389 | 411.82 | 1.7166 |

| 2 | 7.999 | 387.61 | 19.115 | 401.39 | 1.7166 |

| 2′ | 7.999 | 387.61 | 18.961 | 402.95 | 1.7222 |

| 3 | 8 | 387.61 | 1267.9 | 210.84 | 1.0388 |

| 4 | 8.1070 | 645.78 | 1268.6 | 211.03 | 1.0388 |

| Parameter | Value | Unit | |

|---|---|---|---|

| Warm water pump | Mass flow | 191.5 | kg/s |

| Temperature | 28 | °C | |

| Cold water pump | Mass flow | 184 | kg/s |

| Temperature | 4 | °C | |

| Warm water insulation water tank | Volume | 30 | m3 |

| Cold water insulation water tank | Volume | 30 | m3 |

| Parameter | Value | Unit | |

|---|---|---|---|

| Evaporator | Heat exchange | 1608.56 | kW |

| Evaporation temperature | 24 | °C | |

| Evaporation pressure | 645.78 | kPa | |

| Warm water mass flow rate | 191.5 | kg/s | |

| Condenser | Heat exchange | 1545.68 | kW |

| Condensation temperature | 8 | °C | |

| Condensation pressure | 387.61 | kPa | |

| Cold water mass flow rate | 184 | kg/s | |

| Working fluid pump | Working fluid mass flow rate | 8 | kg/s |

| Operating temperature | 7.9 | °C | |

| Inlet pressure | 384.86 | kPa | |

| Outlet pressure | 650.99 | kPa | |

| Turbine | Inlet temperature | 24 | °C |

| Inlet pressure | 632.23 | kPa | |

| Outlet temperature | 9 | °C | |

| Outlet pressure | 393.96 | kPa | |

| Instrument Name | Specification Parameters |

|---|---|

| Temperature transmitter | accuracy class: A-level ±(0.15 + 0.002|t|) °C; −50~200 °C |

| Pressure transmitter | accuracy class: ±0.1%; −0.1~1.6 Mpa |

| Flow transmitter | accuracy class: ±0.5% |

| Speed transmitter | accuracy class: ±0.2% |

| Test Point | (m3/h) | (m3/h) | (°C) | (bar) | (°C) | (bar) | (kg/s) | (kW) | (rpm) | |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 648.000 | 559.51 | 22.27286 | 4.71991 | 12.86531 | 3.19965 | 6.782315 | 30.00000 | 0.80288 | 9389.46777 |

| 2 | 720.49 | 558.07 | 22.25116 | 4.72512 | 12.64106 | 3.20197 | 6.567218 | 30.10000 | 0.83069 | 9389.46777 |

| 3 | 738.37 | 556.77 | 22.24031 | 4.75232 | 12.71340 | 3.20544 | 6.895445 | 30.70000 | 0.79951 | 9382.23340 |

| … | … | … | … | … | … | … | ||||

| 211 | 825.35 | 807.86 | 24.02705 | 5.05671 | 12.10576 | 3.14120 | 7.389667 | 41.50000 | 0.83746 | 10,264.75684 |

| 212 | 822.53 | 823.22 | 24.01982 | 5.04688 | 12.08044 | 3.14120 | 7.292357 | 41.30000 | 0.84615 | 10,275.60742 |

| 213 | 822.23 | 825.61 | 24.02344 | 5.05035 | 12.15278 | 3.14410 | 7.374606 | 41.30000 | 0.83812 | 10,384.11523 |

| Parameters | Initial | Min | Max |

|---|---|---|---|

| Learning rate | 0.1 | 0.01 | 0.8 |

| Population size | 50 | 30 | 120 |

| Crossover probability | 0.8 | 0.6 | 0.9 |

| Mutation probability | 0.02 | 0.01 | 0.2 |

| Parameters | Value |

|---|---|

| Learning rate | 0.1 |

| Train function | trainlm |

| Population | 70 |

| Number of hidden layer nodes | 10 |

| Crossover probability | 0.8 |

| Mutation probability | 0.2 |

| Training precision | 0.00001 |

| Hidden layer function | tansig |

| Output layer function | purelin |

| Parameter | Value |

|---|---|

| Population size | 50 |

| Iterations | 100 |

| Crossover probability | 0.8 |

| Mutation probability | 0.1 |

| Parameter | Numerical Value | Unit |

|---|---|---|

| 760.8 | m3/h | |

| 665 | m3/h | |

| 24 | °C | |

| 5 | bar | |

| 11.01 | °C | |

| 3.14 | bar | |

| 7.95 | kg/s | |

| 40.1792 | kW | |

| 0.83749 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, Y.; Tian, M.; Liu, Y.; Lu, B.; Chen, Y. Experimental Research and Improved Neural Network Optimization Based on the Ocean Thermal Energy Conversion Experimental Platform. Energies 2024, 17, 4310. https://doi.org/10.3390/en17174310

Yu Y, Tian M, Liu Y, Lu B, Chen Y. Experimental Research and Improved Neural Network Optimization Based on the Ocean Thermal Energy Conversion Experimental Platform. Energies. 2024; 17(17):4310. https://doi.org/10.3390/en17174310

Chicago/Turabian StyleYu, Yanni, Mingqian Tian, Yanjun Liu, Beichen Lu, and Yun Chen. 2024. "Experimental Research and Improved Neural Network Optimization Based on the Ocean Thermal Energy Conversion Experimental Platform" Energies 17, no. 17: 4310. https://doi.org/10.3390/en17174310

APA StyleYu, Y., Tian, M., Liu, Y., Lu, B., & Chen, Y. (2024). Experimental Research and Improved Neural Network Optimization Based on the Ocean Thermal Energy Conversion Experimental Platform. Energies, 17(17), 4310. https://doi.org/10.3390/en17174310