Research on Inter-Fracture Gas Flooding for Horizontal Wells in Changqing Yuan 284 Tight Oil Reservoir

Abstract

1. Introduction

2. Modeling

2.1. Basic Parameters

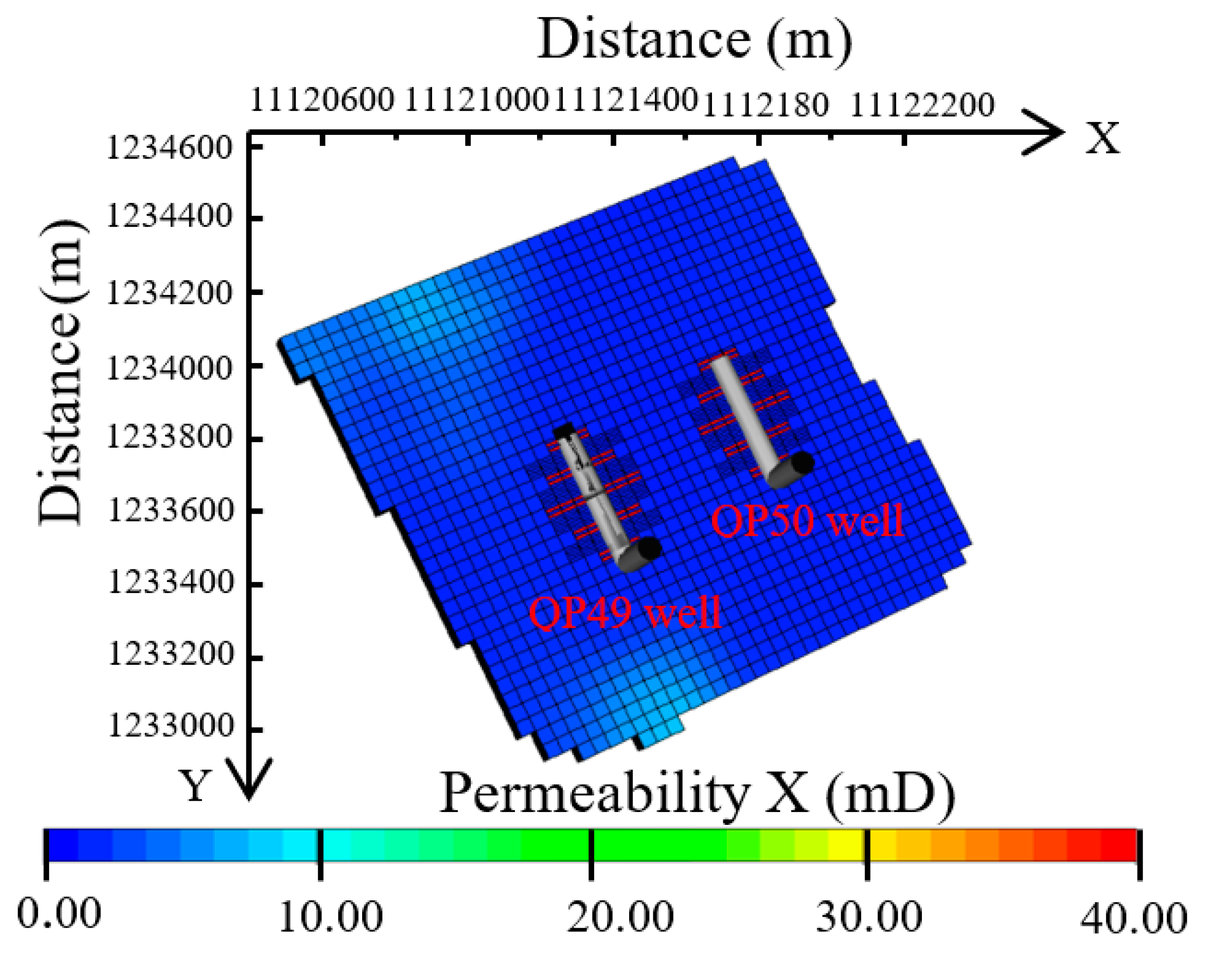

2.2. Geological Model

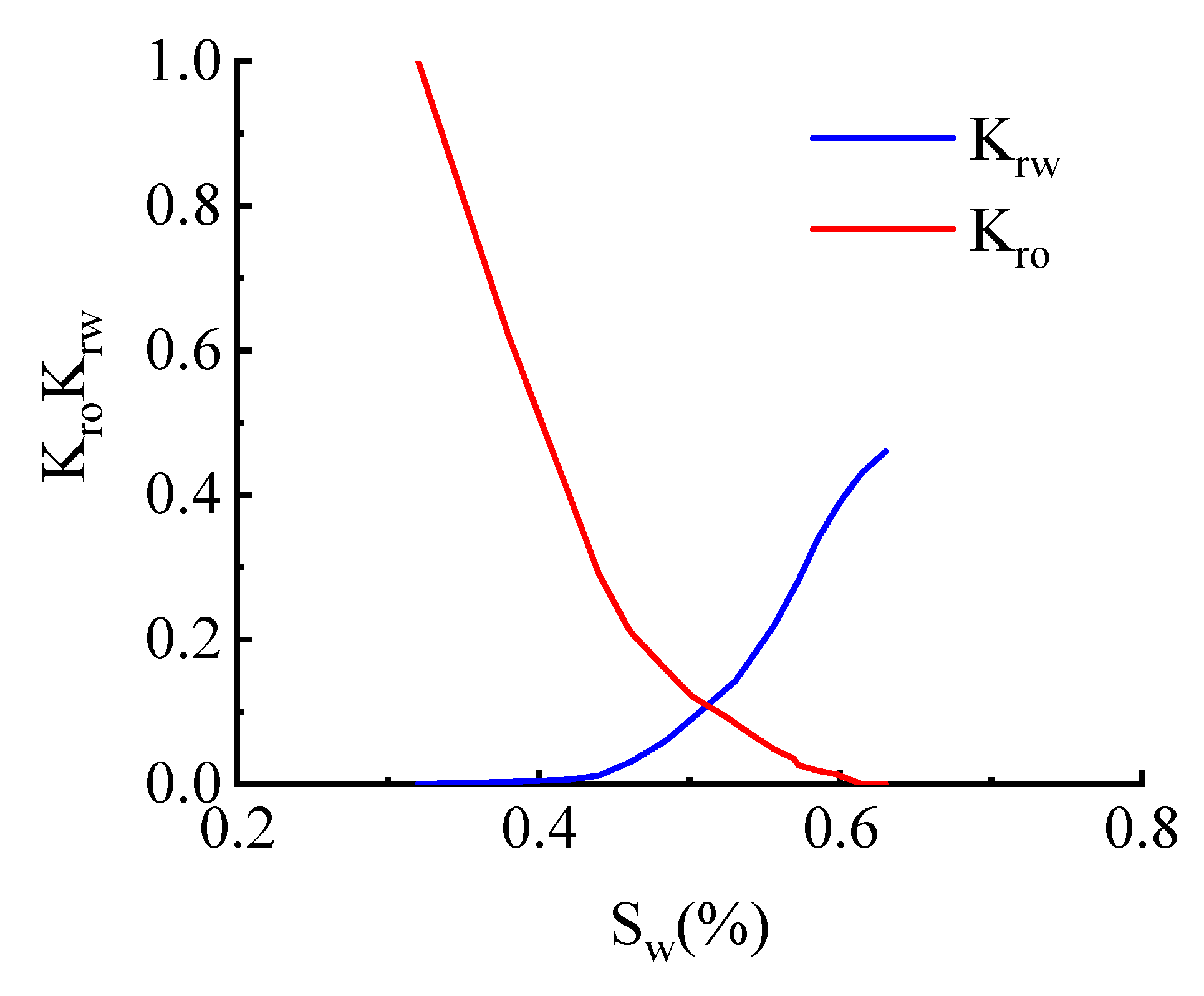

2.3. Oil–Water Relative Permeability and Oil–Gas Relative Permeability

2.4. Compositional Model

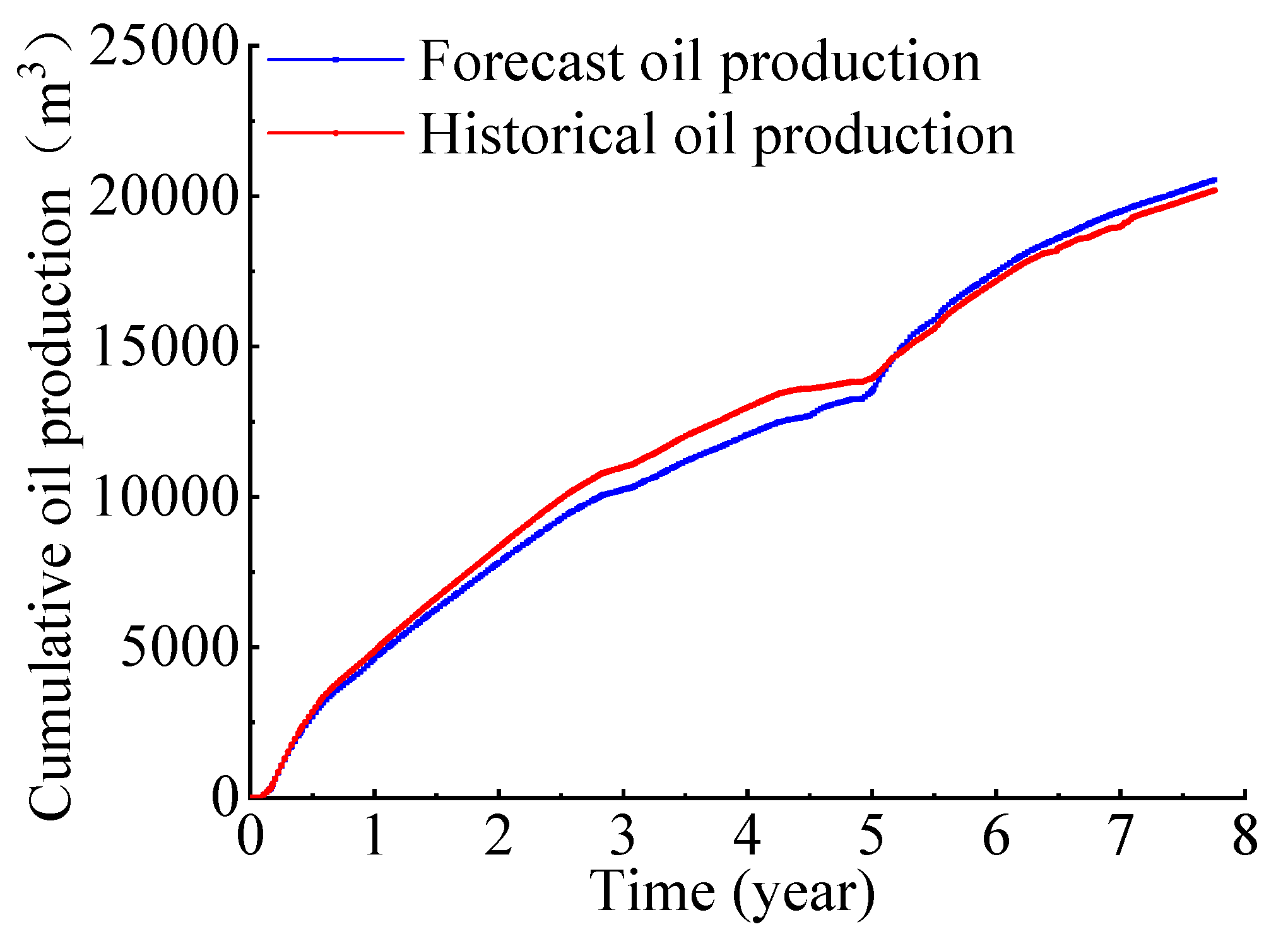

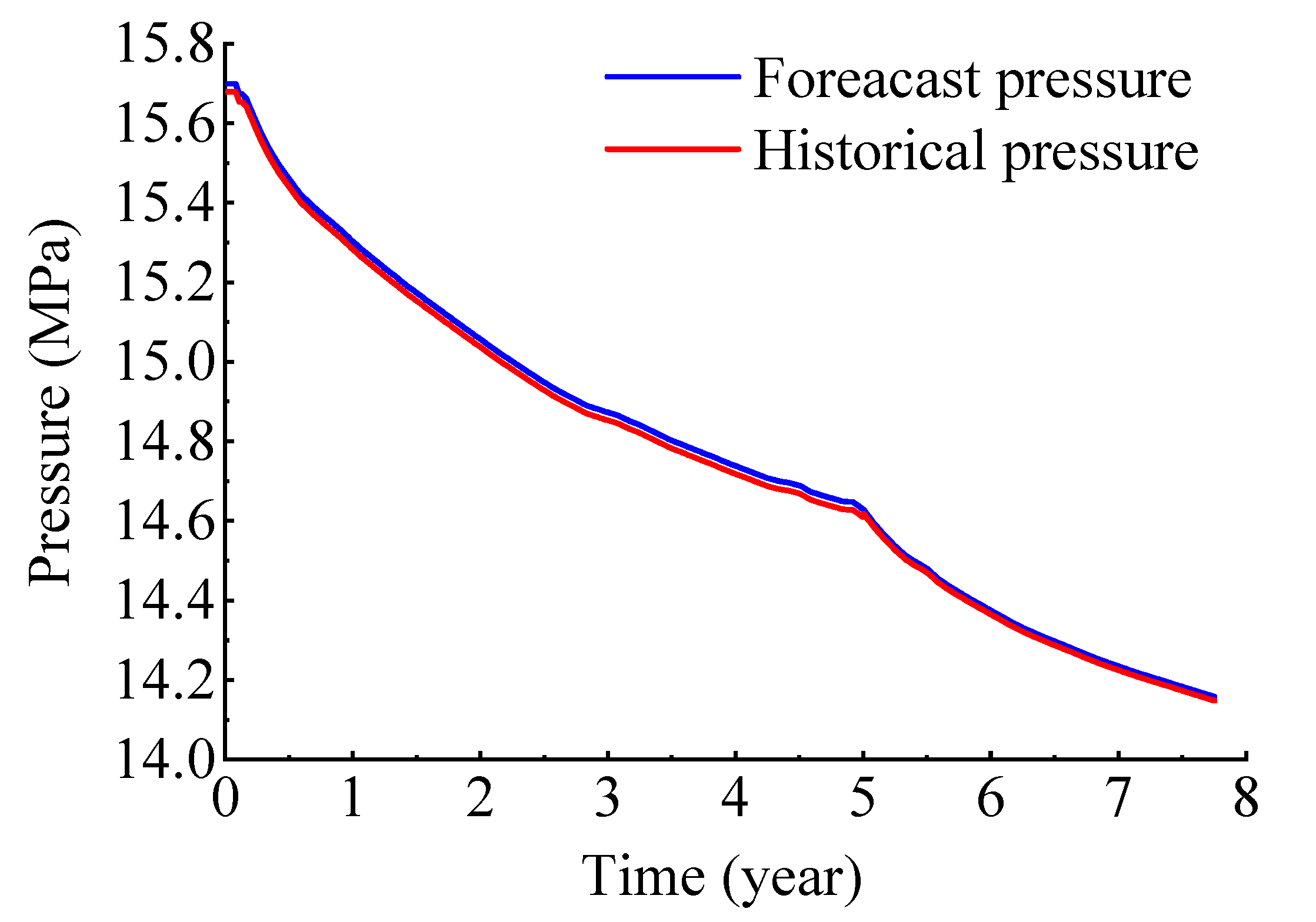

2.5. History Matching

3. Experimental Scheme

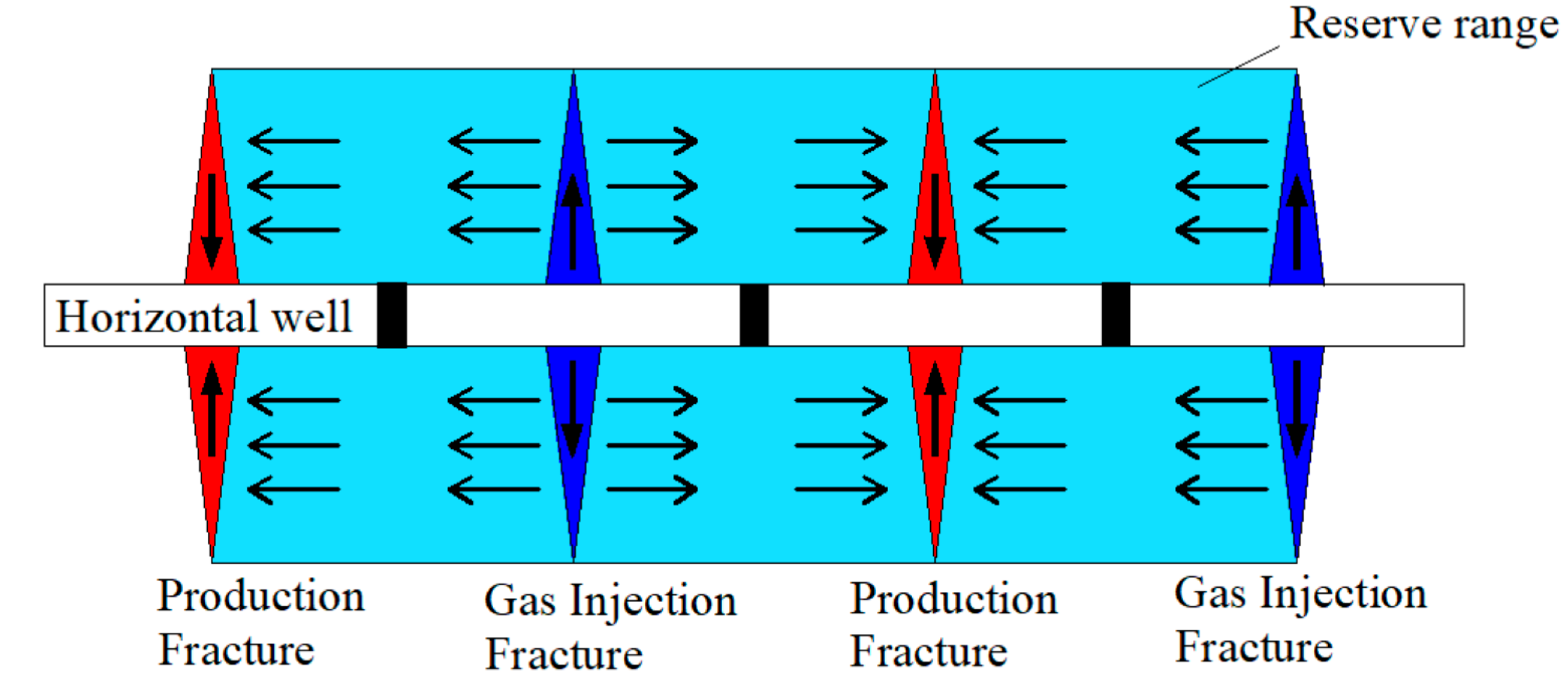

3.1. Development Modes

3.2. Injection Medium

4. Results

4.1. Development Modes

4.1.1. Oil Recovery

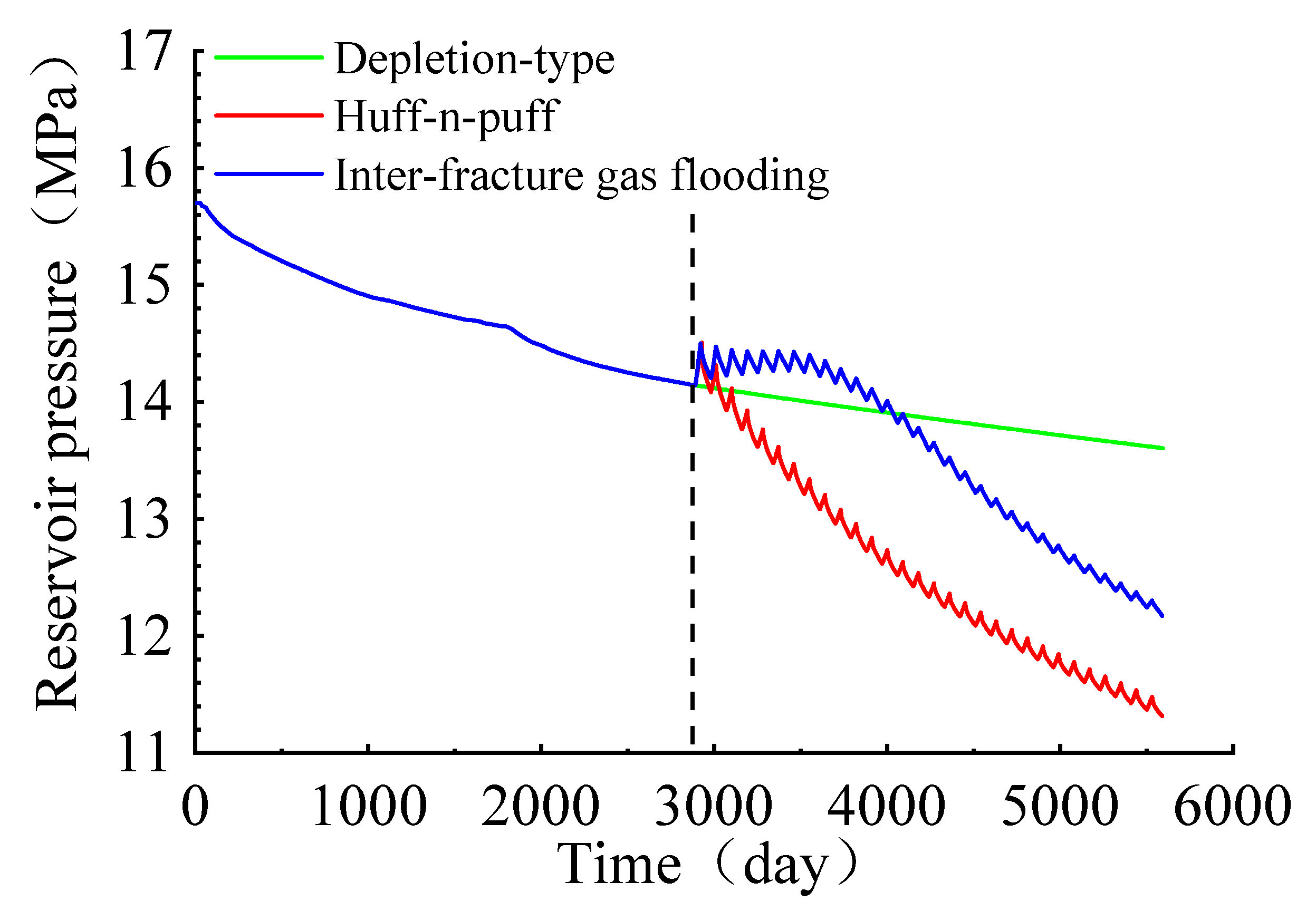

4.1.2. Pressure Change Pattern

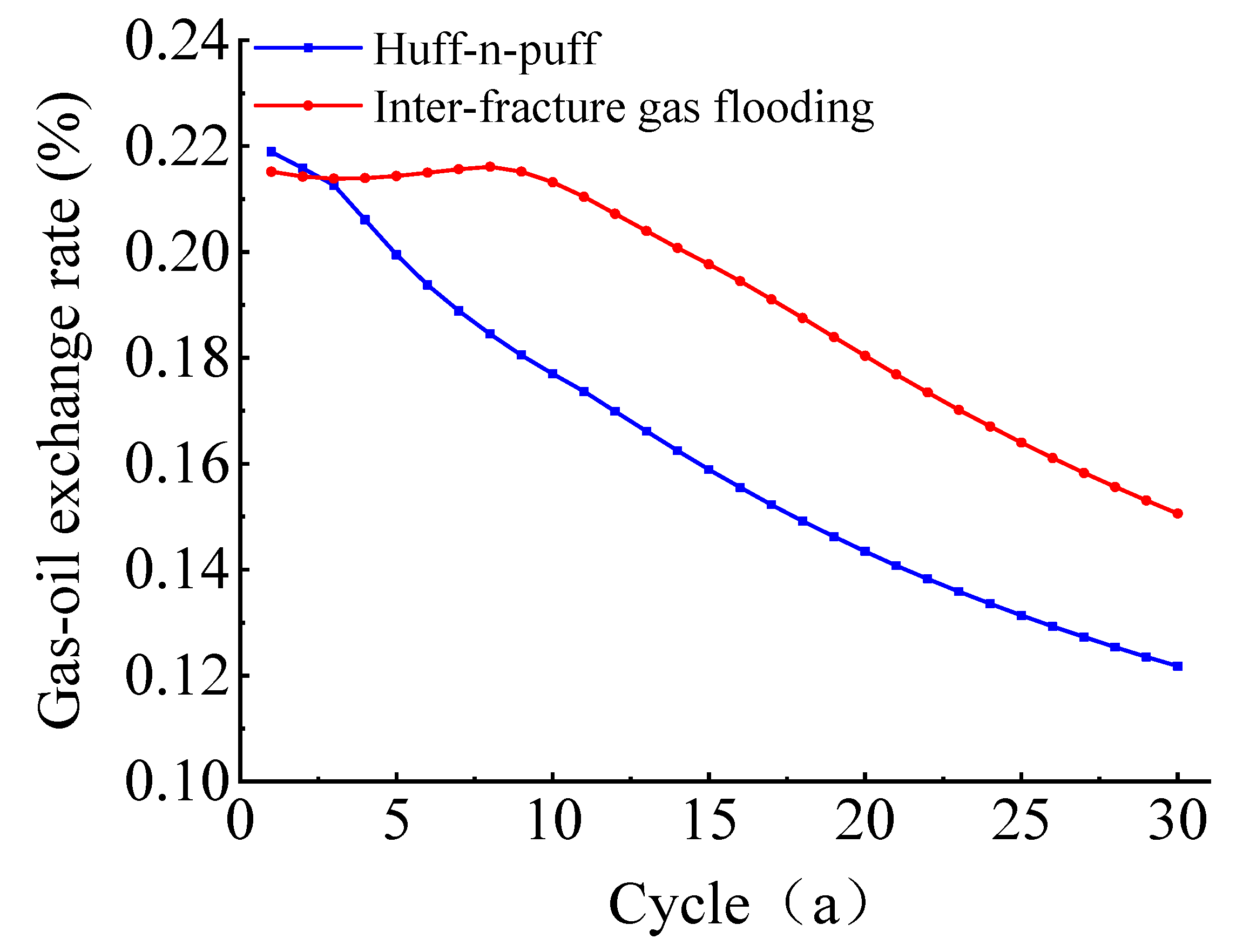

4.1.3. Gas–Oil Exchange Rate

4.2. Injection Media

4.2.1. Oil Recovery of Injection

4.2.2. Physical Property Change Laws of Fluids

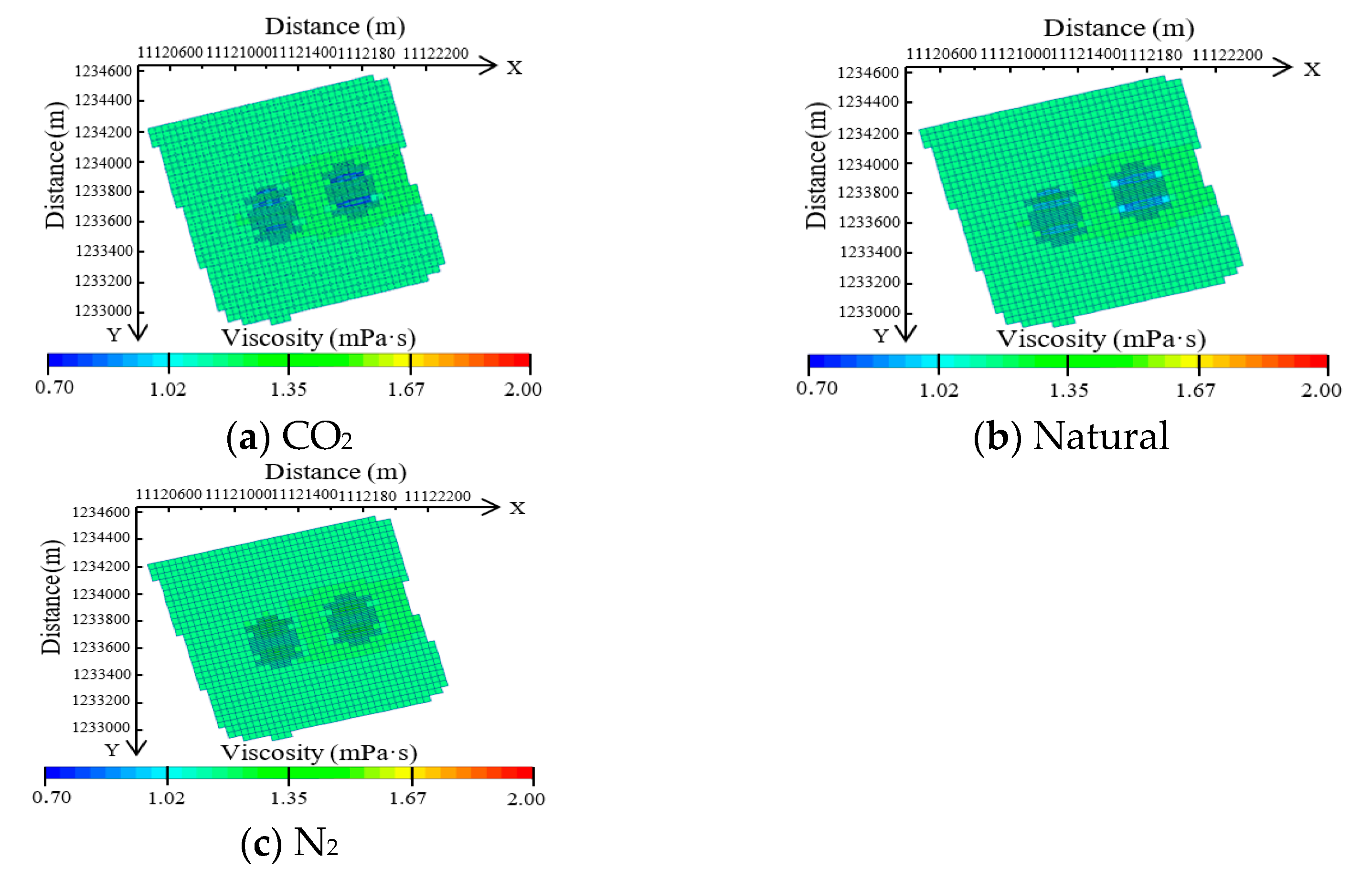

- (1)

- Viscosity

- (2)

- Interfacial tension

4.2.3. Pressure Change Pattern of Injection

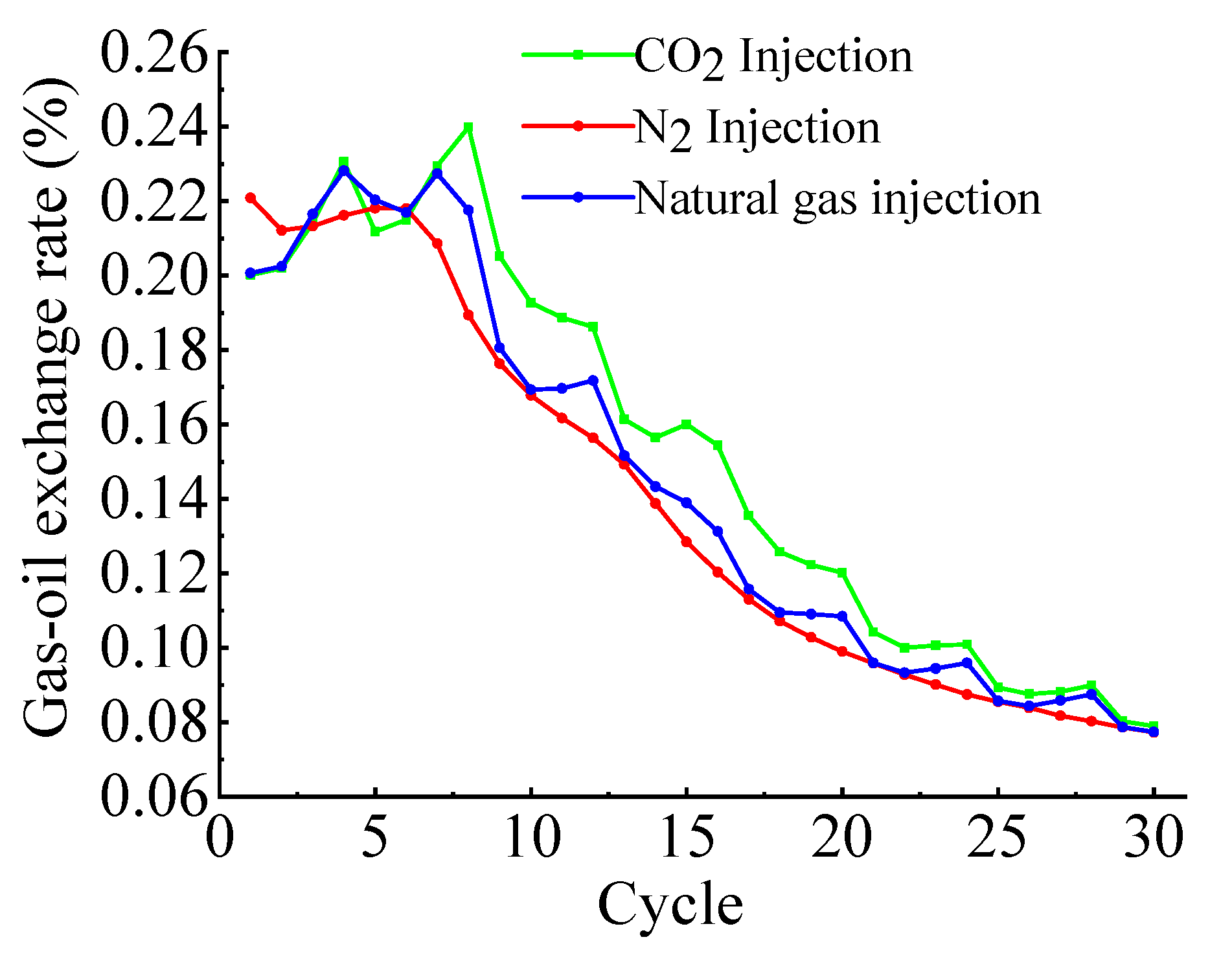

4.2.4. Gas–Oil Exchange Rate of Injection

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, Q.; Wang, Y.; Wang, F.; Ning, X.; Chuanbao, Z.; Zhang, J.; Zhang, C. Factor analysis and mechanism disclosure of supercritical CO2 filtration behavior in tight shale reservoirs. Environ. Sci. Pollut. Res. 2022, 29, 17682–17694. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Liu, J.; Wang, S.; Guo, Y.; Han, X.; Li, Q.; Cheng, Y.; Dong, Z.; Li, X.; Zhang, X. Numerical insights into factors affecting collapse behavior of horizontal wellbore in clayey silt hydrate-bearing sediments and the accompanying control strategy. Ocean Eng. 2024, 297, 117029. [Google Scholar] [CrossRef]

- Khan, W.A.; Rui, Z.; Hu, T.; Liu, Y.; Zhang, F.; Zhao, Y. Application of Machine Learning and Optimization of Oil Recovery and CO2 Sequestration in the Tight Oil Reservoir. SPE J. 2024, 29, 2772–2792. [Google Scholar] [CrossRef]

- Du, S.; Shi, Y. Nanostructures in tight oil reservoirs: Multiple perspectives. Int. J. Hydrogen Energy 2024, 49, 884–896. [Google Scholar] [CrossRef]

- Zhou, X.; Wei, J.; Zhao, J.; Zhang, X.; Fu, X.; Shamil, S.; Abdumalik, G.; Chen, Y.; Wang, J. Study on pore structure and permeability sensitivity of tight oil reservoirs. Energy 2024, 288, 129632. [Google Scholar] [CrossRef]

- Storosten, H.B. US light tight oil supply flexibility-A multivariate dynamic model for production and rig activity. Energy Econ. 2024, 131, 107386. [Google Scholar] [CrossRef]

- Sheng, J.J. Enhanced oil recovery in shale reservoirs by gas injection. J. Nat. Gas Sci. Eng. 2015, 22, 252–259. [Google Scholar] [CrossRef]

- Yang, Y.; Xiong, W.; Liao, G.Z.; Gao, S.; Shen, R.; Zhang, J.; Li, Q. Flow mechanism of production decline during natural depletion after hydraulic fracturing of horizontal wells in tight oil reservoirs. Pet. Sci. Technol. 2022, 40, 383–400. [Google Scholar] [CrossRef]

- Thi Huong Vuong, G.; Nguyen, M.H.; Hoang, K. Oil price uncertainty, oil pricing reform, and corporate profitability: The case of China. PLoS ONE 2024, 19, e0297554. [Google Scholar] [CrossRef]

- Alharthy, N.; Teklu, T.W.; Kazemi, H.; Graves, R.M.; Hawthorne, S.B.; Braunberger, J.; Kurtoglu, B. Enhanced oil recovery in liquid-rich shale reservoirs: Laboratory to field. SPE Reserv. Eval. Eng. 2018, 21, 137–159. [Google Scholar] [CrossRef]

- Yu, H.; Fu, W.; Zhang, Y.; Lu, X.; Cheng, S.; Xie, Q.; Qu, X.; Yang, W.; Lu, J. Experimental study on EOR performance of CO2-based flooding methods on tight oil. Fuel 2021, 290, 119988. [Google Scholar] [CrossRef]

- Bhargav, B.J.; Economides, C.E. Simultaneous Multiple Plane to Plane Waterflooding in Fractured Tight Reservoirs. In Abu Dhabi International Petroleum Exhibition & Conference; Society of Petroleum Engineers: Richardson, TX, USA, 2017. [Google Scholar]

- Jiang, Z.; Liu, Z.; Zhao, P.; Chen, Z.; Mao, Z. Evaluation of tight waterflooding reservoirs with complex wettability by NMR data: A case study from Chang 6 and 8 members, Ordos Basin, NW China. J. Pet. Sci. Eng. 2022, 213, 110436. [Google Scholar] [CrossRef]

- Liang, T.; Zhao, X.; Yuan, S.; Zhu, J.; Liang, X.; Li, X.; Zhou, F. Surfactant-EOR in tight oil reservoirs: Current status and a systematic surfactant screening method with field experiments. J. Pet. Sci. Eng. 2021, 196, 108097. [Google Scholar] [CrossRef]

- He, Y.; Qiao, Y.; Qin, J.; Tang, Y.; Wang, Y.; Chai, Z. A Novel Method to Enhance Oil Recovery by Inter-Fracture Injection and Production Through the Same Multi-Fractured Horizontal Well. J. Energy Resour. Technol. 2021, 144, 043005. [Google Scholar] [CrossRef]

- Xiao, Z.; Ding, W.; Hao, S.; Taleghani, A.D.; Wang, X.; Zhou, X.; Sun, Y.; Liu, J.; Gu, Y. Quantitative analysis of tight sandstone reservoir heterogeneity based on rescaled range analysis and empirical mode decomposition: A case study of the Chang 7 reservoir in the Dingbian oilfield. J. Pet. Sci. Eng. 2019, 182, 106326. [Google Scholar] [CrossRef]

- Hu, J.; Sun, R.; Zhang, Y. Investigating the horizontal well performance under the combination of micro-fractures and dynamic capillary pressure in tight oil reservoirs. Fuel 2020, 269, 117375. [Google Scholar] [CrossRef]

- Yang, Y.; Liao, G.; Xiong, W.; Shen, R.; Zhang, J.; Li, Q.; Wang, S.; Zhang, J.; Tan, L.; Shao, G. Physical and numerical simulation of inter-fracture flooding in heterogeneous tight oil reservoirs. Energy Rep. 2022, 8, 12970–12978. [Google Scholar] [CrossRef]

- Yang, Y.; Liao, G.; Xiong, W.; Zhang, J.; Gao, S.; Shen, R.; Wang, S.; Zhang, J.; Tan, L.; Liu, Y. Evaluation of Enhanced Oil Recovery Potential using Interfracture Water Flooding in a Tight Oil Reservoir. Lithosphere 2022, 2022 (Special 12), 6606336. [Google Scholar] [CrossRef]

- Fu, X.; Bonifas, P.; Finley, A.; Lemaster, J.; He, Z.; Venepalli, K. Tight Oil EOR through Inter-Fracture Gas Flooding within a Single Horizontal Well. In Proceedings of the SPE Annual Technical Conference and Exhibition, Calgary, AB, Canada, 30 September–2 October 2019. [Google Scholar] [CrossRef]

- Lu, X.; Cao, B.; Xie, K.; Cao, W.; Liu, Y.; Zhang, Y.; Wang, X.; Zhang, J. Enhanced oil recovery mechanisms of polymer flooding in a heterogeneous oil reservoir. Pet. Explor. Dev. 2021, 48, 169–178. [Google Scholar] [CrossRef]

- Wang, J.; Song, H.; Wang, Y. Investigation on the micro-flow mechanism of enhanced oil recovery by low-salinity water flooding in carbonate reservoir. Fuel 2020, 266, 117156. [Google Scholar] [CrossRef]

- Gao, S.; Yang, Y.; Liao, G.; Xiong, W.; Liu, H.; Shen, R.; Ye, L.; Zhu, W.; An, W. Experimental research on inter-fracture asynchronous injection-production cycle for a horizontal well in a tight oil reservoir. J. Pet. Sci. Eng. 2022, 208, 109647. [Google Scholar] [CrossRef]

- Zhu, P.; Balhoff, M.T.; Mohanty, K.K. Simulation of fracture-to-fracture gas injection in an oil-rich shale. In Proceedings of the SPE Annual Technical Conference and Exhibition. Society of Petroleum Engineers, Houston, TX, USA, 28–30 September 2015. [Google Scholar] [CrossRef]

- Cheng, S.; Wang, Y.; Lang, H.; Yu, H.; Zhu, C.; Yang, B.; Zhang, H.; Sun, Z. feasibility of inter-fracture injection and production for the same multi-stage fractured horizontal. Acta Pet. Sin. 2017, 38, 1411–1419. [Google Scholar]

- Pu, H.; Li, Y. Novel capillarity quantification method in IOR process in Bakken shale oil reservoirs. In Proceedings of the SPE Improved Oil Recovery Conference, Tulsa, OK, USA, 11–13 April 2016; SPE: New York, NY, USA, 2016. [Google Scholar] [CrossRef]

- Han, B.; Cui, G.; Wang, Y.; Zhang, J.; Zhai, Z.; Shi, Y.; Yan, F.; Li, W. Effect of fracture network on water injection huff-puff for volume stimulation horizontal wells in tight oil reservoir: Field test and numerical simulation study. J. Pet. Sci. Eng. 2021, 207, 109106. [Google Scholar] [CrossRef]

- He, Y.; Cheng, S.; Sun, Z.; Chai, Z.; Rui, Z. Improving oil recovery through fracture injection and production of multiple fractured horizontal wells. J. Energy Resour. Technol. 2020, 142, 053002. [Google Scholar] [CrossRef]

- Abdulwarith, A.; Sinha, U.; Gautam, S.; Dindoruk, B. A New Physics-Based CO2 EOR Screening Tool for Offshore Applications. In Proceedings of the SPE Improved Oil Recovery Conference, Tulsa, OK, USA, 22–25 April 2024; SPE: New York, NY, USA, 2024; p. D031S022R001. [Google Scholar]

- Miłek, K.; Szott, W.; Tyburcy, J.; Lew, A. Reservoir Simulations of Hydrogen Generation from Natural Gas with CO2 EOR: A Case Study. Energies 2024, 17, 2321. [Google Scholar] [CrossRef]

- Roozbahani, A.; Soofivand, F.; Al-Tameemi, A.S.H.; Abdollahi, H.; Saatchi, S.; Ansari, A. A contrasting analysis of CO2 and N2 foam flood for enhanced oil recovery and geological storage of CO2. Pet. Res. 2024, 9, 55–60. [Google Scholar] [CrossRef]

- Wang, Z.; Lu, H.; Zhao, C.; Zhu, E. Investigating phase dynamics of reservoir fluids in CO2 huff-n-puff enhanced oil recovery. Geoenergy Sci. Eng. 2024, 238, 212925. [Google Scholar] [CrossRef]

- He, Y.; Cheng, S.; Chai, Z.; Patil, S.; Rui, R.; Yu, H. Application of Inter-Fracture Injection and Production in a Cluster Well to Enhance Oil Recovery. In Proceedings of the SPE Annual Technical Conference and Exhibition, Calgary, AB, Canada, 30 September–2 October 2019; OnePetro: Richardson, TX, USA, 2019. [Google Scholar] [CrossRef]

- Tang, W.; Zhou, F.; Zheng, X.; Wang, Q.; Wang, Y.; Hu, L.; Sheng, J.J.; Wang, X. Evaluation of matrix energization effect of pre-fracturing method in tight reservoirs—A comparative study of CO2, N2, and water. Geoenergy Sci. Eng. 2024, 233, 212535. [Google Scholar] [CrossRef]

- Páez, D.E. Natural gas production associated to oil from oil and gas reservoirs. In Advances in Natural Gas; Elsevier: Amsterdam, The Netherlands, 2024; pp. 125–168. [Google Scholar]

- He, Y.; Chai, Z.; Huang, J.; Li, P.; Cheng, S.; Killough, J. Simulation of Inter-Fracture Injection and Production in Tight Reservoirs Based on Compartmental Embedded Discrete Fracture Model. In Proceedings of the SPE Reservoir Simulation Conference, Galveston, TX, USA, 10–11 April 2019; OnePetro: Richardson, TX, USA, 2019. [Google Scholar] [CrossRef]

- Kang, S.; Pu, C.; Wang, K.; Ding, Q.; Jin, X. Study on mechanisms and influencing factors of the inter-fracture asynchronous huff-n-puff technology of horizontal well in the tight oil reservoir. In IOP Conference Series: Earth and Environmental Science, Proceedings of the Asia Conference on Geological Research and Environmental Technology, Kamakura, Japan, 21–22 August 2021; IOP Publishing: Bristol, UK, 2021; Volume 859, p. 012018. [Google Scholar] [CrossRef]

- Wang, G.; Chang, X.; Yin, W.; Li, Y.; Song, T. Impact of diagenesis on reservoir quality and heterogeneity of the Upper Triassic Chang 8 tight oil sandstones in the Zhenjing area, Ordos Basin, China. Mar. Pet. Geol. 2017, 83, 84–96. [Google Scholar] [CrossRef]

- Xu, Z.; Liu, L.; Wang, T.; Wu, K.; Dou, W.; Song, X.; Feng, C.; Li, X.; Ji, H.; Yang, Y.; et al. Characteristics and controlling factors of lacustrine tight oil reservoirs of the Triassic Yanchang Formation Chang 7 in the Ordos Basin, China. Mar. Pet. Geol. 2017, 82, 265–296. [Google Scholar] [CrossRef]

- Zhao, J. Sedimentary characteristics and development pattern of turbidity event of Chang 6 and Chang 7 oil reservoirs in the southern Ordos Basin. Acta Pet. Sin. 2008, 29, 389–394. [Google Scholar]

- Zhu, H.; Song, Y.; Lei, Z.; Tang, X. 4D-stress evolution of tight sandstone reservoir during horizontal wells injection and production:A case study of Yuan 284 block, Ordos Basin, NW China. Pet. Explor. Dev. 2022, 49, 156–169. [Google Scholar] [CrossRef]

- Shi, Y.; Wu, B.; Wang, H.; Li, Y.; Liu, Z.; Xu, C.; Qin, J.; Li, Y.; Song, Z.; Liu, H. Insights into CO2 huff-n-puff mechanisms from laboratory experiment and single-well pilot test in the Lucaogou tight oil reservoir, Jimsar sag, China. Geoenergy Sci. Eng. 2024, 232, 212456. [Google Scholar] [CrossRef]

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Reservoir depth | −2200 m | Initial formation pressure | 15.8 MPa |

| Crude oil density | 0.72 g/cm3 | Reservoir temperature | 69.7 °C |

| Formation oil viscosity | 0.97 cp | Formation oil compressibility | 13.9 × 10−4 MPa−1 |

| Compressibility of formation water | 1.95 × 10−4 MPa−1 | Formation water viscosity | 0.7 cp |

| Component | Content Fraction | Composition (mol%) | Molar Mass (g·mol−1) | Critical Pressure (MPa) | Critical Temperature (K) | Deviation Factor |

|---|---|---|---|---|---|---|

| N2 | 0.0744658 | 7.44658 | 28.013 | 3.3944 | 126.2 | 0.04 |

| CO2 | 0.00343 | 0.343 | 44.01 | 7.3866 | 304.7 | 0.225 |

| C1 | 0.1126342 | 11.26342 | 16.043 | 4.8042 | 190.6 | 0.013 |

| C2 | 0.059 | 5.9 | 30.07 | 4.6839 | 305.43 | 0.0986 |

| C3 | 0.03843 | 3.843 | 44.097 | 4.2455 | 369.8 | 0.1524 |

| C4 | 0.01696 | 1.696 | 58.124 | 3.747 | 419.5 | 0.1956 |

| C5+ | 0.0395 | 3.95 | 77.009 | 3.216 | 482.96 | 0.26496 |

| C7+ | 0.17185 | 17.185 | 124.15 | 2.5798 | 607.7 | 0.35834 |

| C11+ | 0.48373 | 48.373 | 275.03 | 13 | 1000 | 0.4 |

| Development Mode | Gas Injection Time per Cycle (d) | Gas Production Time per Cycle (d) | Cycles | Injection Medium | Injection Rate (m3/d) |

|---|---|---|---|---|---|

| Depletion | — | — | — | — | — |

| Huff-n-puff | 30 | 60 | 30 | CO2 | 30,000 |

| Inter-fracture Gas flooding | 30 | 60 | 30 | CO2 | 30,000 |

| Injection Medium | Gas Injection Time per Cycle (d) | Gas Production Time per Cycle (d) | Injection-Production Ratio | Cycles | Injection Rate (m3/d) |

|---|---|---|---|---|---|

| CO2 | 30 | 60 | 0.5 | 30 | 30,000 |

| N2 | 30 | 60 | 0.5 | 30 | 30,000 |

| Natural gas | 30 | 60 | 0.5 | 30 | 30,000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tan, L.; Yang, Y.; Xiong, W.; Shen, R.; Xiong, Y.; Qi, Y.; Sun, Z. Research on Inter-Fracture Gas Flooding for Horizontal Wells in Changqing Yuan 284 Tight Oil Reservoir. Energies 2024, 17, 4254. https://doi.org/10.3390/en17174254

Tan L, Yang Y, Xiong W, Shen R, Xiong Y, Qi Y, Sun Z. Research on Inter-Fracture Gas Flooding for Horizontal Wells in Changqing Yuan 284 Tight Oil Reservoir. Energies. 2024; 17(17):4254. https://doi.org/10.3390/en17174254

Chicago/Turabian StyleTan, Lingfang, Yi Yang, Wei Xiong, Rui Shen, Yu Xiong, Yuanhang Qi, and Zewei Sun. 2024. "Research on Inter-Fracture Gas Flooding for Horizontal Wells in Changqing Yuan 284 Tight Oil Reservoir" Energies 17, no. 17: 4254. https://doi.org/10.3390/en17174254

APA StyleTan, L., Yang, Y., Xiong, W., Shen, R., Xiong, Y., Qi, Y., & Sun, Z. (2024). Research on Inter-Fracture Gas Flooding for Horizontal Wells in Changqing Yuan 284 Tight Oil Reservoir. Energies, 17(17), 4254. https://doi.org/10.3390/en17174254