Experimental and Numerical Simulation Research on Different Shapes of Flame-Stabilizing Baffles in the Furnace

Abstract

1. Preface

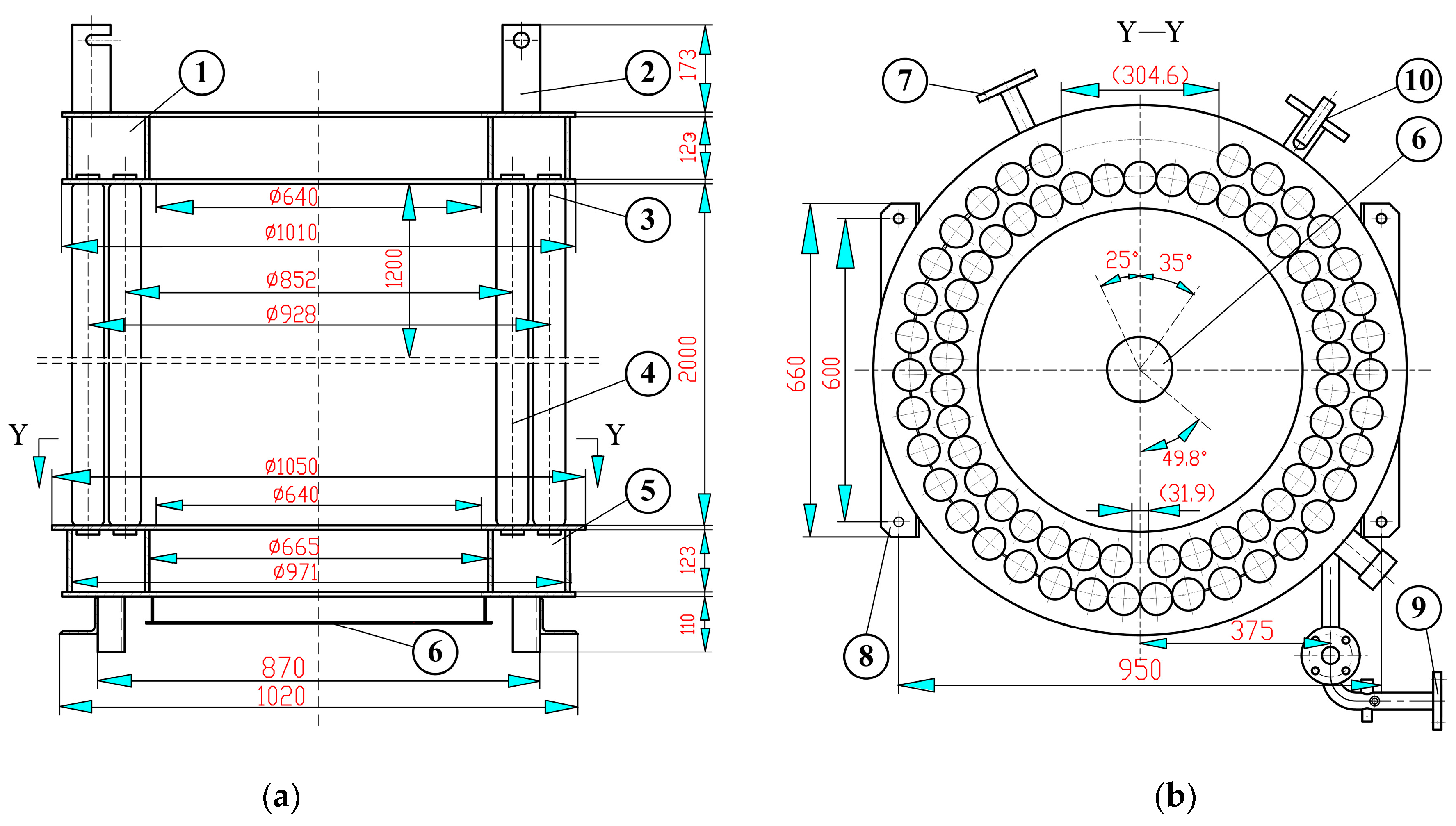

2. Surface Combustion and Aerodynamic Field Experiments

2.1. Boiler Experimental System Dimensions and Photos

2.2. Design of a Fully Premixed System

2.3. Full Premixed Combustion Experiment

3. Computational Details

3.1. Calculation Models and Equations

3.2. The Test Result of Grid Independence

4. Result and Discussion

4.1. Comparison of Experimental Values of Nonporous Baffles and Calculated Values of Various Baffles

4.1.1. Comparison of Experimental Values of O and CO When Installing Nonporous Baffles and without Baffles

4.1.2. Comparison of Calculated Values of CO Emissions

4.2. Comparison of Calculated Values of CO2 Emissions

4.3. Comparison of Calculated Values of Exhaust Gas Temperature

4.4. Comparison of Calculated Values of NOx Emissions

5. Conclusions

- (1)

- The installation of Nonporous baffles in the furnace and combustion experiments were conducted. The results showed that when installing a Nonporous baffle in the furnace, considering parameters such as exhaust temperature, boiler efficiency, and NOx emissions, the optimal excess air coefficients were 1.9, 2.0, and 2.1, respectively. Under the optimal operating conditions, the experimental values of NOx emissions were all below 30 mg/m3, and the net heat efficiency of the boiler was above 80%.

- (2)

- A comparative combustion experiment was conducted without or with the addition of a Nonporous baffle. The experimental results showed that as the gas volume increased, the optimal oxygen consumption increased, and the net heat efficiency of the boiler slightly increased. Under minimum, middle, and maximum firing rates, the CO content in the flue gas decreases, indicating that adding baffle is more beneficial for combustion. For the Nonporous baffle, the calculated values were compared with experimental values, and it was found that the minimum CO emission value was below 20 ppm. The maximum error between the calculated value and the experimental value is 6.8%, and the minimum error is 2.2%, indicating high calculation accuracy. Comparing the calculated values of the four types of baffles, it was found that the CO values in the flue gas were the lowest when installing the Strip baffle, and the exhaust temperature was also the lowest when installing the Strip baffle.

- (3)

- Comparing the average temperature values on different cross-sections along the axis of flue gas flow in the furnace under calculation conditions, different airflow fields lead to different temperature distributions. Among them, when installing a Strip baffle, the flue gas temperature drops the most after crossing the baffle and reaches the lowest value among the four types of baffles at the furnace outlet. The calculated NOx emissions are also the lowest among the four operating conditions at the corresponding positions, and the optimal operating condition calculation values are all below 40 mg/m3.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| ρ | Fluid density; |

| k | Turbulent kinetic energy equation; |

| ε | Turbulent dissipation rate equation; |

| μ | Dynamic viscosity; |

| Mean fluid velocity; | |

| Nonporous | Without holes; |

| Strip | With bar holes; |

| Round | With annular holes; |

| Circular | With ring holes; |

| Gk | Average velocity gradient generation term; |

| Gb | Buoyancy generation term; |

| YM | Pulse generation term; |

| Yi | Component i pulse generation term; |

| C1ε | 1.44; |

| C2ε | 1.92; |

| C3ε | Emprical constant; |

| Sk/Sε | Souce items; |

| Ri | Net generation rate of chemical reaction of component I; |

| Si | The net generation rate obtained by adding the diffusion term to the user-defined source term; |

| Ji | The diffusion flow rate generated by the i-th component due to concentration gradient; |

| q | Water-cooled wall heat flux density, W/m2; |

| Tw | Water-cooled wall temperature, K; |

| Tf | Average flue gas temperature inside the furnace, K; |

| hf | Convective heat transfer coefficient between water-cooled wall and flue gas; |

| hint | Comprehensive heat transfer coefficient of convective radiation; |

| Tint | Convection radiation comprehensive heat transfer temperature, K; |

| qrad | Radiative heat transfer, W; |

| G | Average heat release of high-temperature flames, W; |

| εw | Surface emissivity of water-cooled walls. |

References

- Liu, J.; Zhao, J.; Zhu, Q.; Huo, D.; Li, Y.; Li, W. Methanol-based fuel boiler: Design, process, emission, energy consumption, and techno-economic analysis. Case Stud. Therm. Eng. 2024, 54, 103885. [Google Scholar] [CrossRef]

- Paniego-Alday, A.; Lopez-Ruiz, G.; Azkorra-Larrinaga, Z.; Uriondo-Arrue, Z.; Romero-Anton, N. Analysis and improvement of gas flow behaviour at the inlet duct of an industrial HRSG boiler through CFD modelling. Case Stud. Therm. Eng. 2024, 60, 104717. [Google Scholar] [CrossRef]

- Zhu, S.; Hui, J.; Lyu, Q.; Ouyang, Z.; Liu, J.; Zhu, J.; Zeng, X.; Zhang, X.; Ding, H.; Liu, Y.; et al. Experimental study on pulverized coal combustion preheated by a circulating fluidized bed: Preheating characteristics for peak shaving. Fuel 2022, 324, 124684. [Google Scholar] [CrossRef]

- Xie, Y.; Qin, C.; Guo, S.; Chen, Z. Experimental research of a small-scale industrial furnace with regenerative disc-flame burners. Case Stud. Therm. Eng. 2023, 41, 102613. [Google Scholar] [CrossRef]

- Han, B.; Lin, H.; Miao, Z. Numerical investigation on the optimized arrangement for high-temperature corrosion after low NOx transformation. J. Therm. Anal. Calorim. 2021, 146, 2183–2197. [Google Scholar] [CrossRef]

- Liu, H.; Li, S.; Xiang, X.; Gong, S.; Jia, C.; Wang, Q.; Sun, B. Simulation of biogas co-combustion in CFB boiler: Combustion analysis using the CPFD method. Case Stud. Therm. Eng. 2024, 59, 104610. [Google Scholar] [CrossRef]

- Liu, B.; Bao, B.; Wang, Y.; Xu, H. Numerical Simulation of Flow, Combustion and NO Emission of a Fuel-Staged Industrial Gas Burner. J. Energy Inst. 2017, 90, 441–451. [Google Scholar] [CrossRef]

- GB13271-2014; Emission Standard of Air Pollutants for Boiler. Ministry of Ecology and Environment of the People’s Republic of China: Beijing, China, 2014.

- Shi, H.-W.; Wang, H.-P. Research on Full Premixed Combustion and Emission Characteristics of Non-Electric Gas Boiler. Energies 2023, 16, 7409. [Google Scholar] [CrossRef]

- Bell, R.; Buckingham, F. An Overview of Technologies for Reduction of Oxides of Nitrogen from Combustion Furnaces; MPR Assoc Inc.: Alexandria, VA, USA, 2003. [Google Scholar]

- Najarnikoo, M.; Targhi, M.Z.; Pasdarshahri, H. Experimental study on the flame stability and color characterization of cylindrical premixed perforated burner of condensing boiler by image processing method. Energy 2019, 189, 116130. [Google Scholar] [CrossRef]

- Yu, B.; Kum, S.-M.; Lee, C.-E.; Lee, S. Combustion characteristics and thermal efficiency for premixed porous-media types of burners. Energy 2013, 53, 343–350. [Google Scholar] [CrossRef]

- Mujeebu, M.A.; Abdullah, M.Z.; Abu Bakar, M.Z.; Mohamad, A.A.; Muhad, R.M.N.; Abdullah, M.K. Combustion in porous media and its applications—A comprehensive survey. J. Environ. Manag. 2009, 90, 2287–2312. [Google Scholar] [CrossRef]

- Minutolo, P.; D’Anna, A.; Commodo, M.; Pagliara, R.; Toniato, G.; Accordini, C. Emission of Ultrafine Particles from Natural Gas Domestic Burners. Environ. Eng. Sci. 2008, 25, 1357–1364. [Google Scholar] [CrossRef]

- Keramiotis, C.; Stelzner, B.; Trimis, D.; Founti, M. Porous burners for low emission combustion: An experimental investigation. Energy 2012, 45, 213–219. [Google Scholar] [CrossRef]

- Yu, B.; Kum, S.-M.; Lee, C.-E.; Lee, S. Effects of exhaust gas recirculation on the thermal efficiency and combustion characteristics for premixed combustion system. Energy 2013, 49, 375–383. [Google Scholar] [CrossRef]

- Son, J.; Yang, H.; Kim, G.; Hwang, S.; You, H. Technology development for the reduction of NOx in flue gas from a burner-type vaporizer and its application. Korean J. Chem. Eng. 2017, 34, 1619–1629. [Google Scholar] [CrossRef]

- Hosseini, A.A.; Ghodrat, M.; Moghiman, M.; Pourhoseini, S.H. Numerical study of inlet air swirl intensity effect of a Methane-Air Diffusion Flame on its combustion characteristics. Case Stud. Therm. Eng. 2020, 18, 100610. [Google Scholar] [CrossRef]

- Matsumoto, R.; Ozawa, M.; Terada, S.; Iio, T. Low NOx Combustion of DME by Means of Flue Gas Recirculation. J. Power Energy Syst. 2008, 2, 1074–1084. [Google Scholar] [CrossRef]

- Hinrichs, J.; Bortoli, S.D.; Pitsch, H. 3D modeling framework and investigation of pollutant formation in a condensing gas boiler. Fuel 2021, 300, 120916. [Google Scholar] [CrossRef]

- Liu, C.; Hu, X.; Chen, G. Temperature and NOx distribution characteristics of coal particles under high-temperature and low-oxygen environments simulating MILD oxy-coal combustion conditions. J. Energy Inst. 2022, 101, 73–86. [Google Scholar] [CrossRef]

- Khabbazian, G.; Aminian, J.; Khoshkhoo, R.H. Experimental and numerical investigation of MILD combustion in a pilot-scale water heater. Energy 2022, 239, 121888. [Google Scholar] [CrossRef]

- Huang, M.; Li, R.; Xu, J.; Cheng, S.; Deng, H.; Rong, Z.; Li, Y.; Zhang, Y. Effect of equivalence ratio and staging ratio on the methane MILD combustion in dual-stage combustor. Fuel 2022, 307, 121903. [Google Scholar] [CrossRef]

- Cai, S.; Yang, W.; Ding, Y.; Zeng, Q.; Wan, J. Hydrogen-air premixed combustion in a novel micro disc-burner with an annular step. Fuel 2022, 313, 123015. [Google Scholar] [CrossRef]

- Kuang, Y.; He, B.; Wang, C.; Tong, W.; He, D. Numerical analyses of MILD and conventional combustions with the Eddy Dissipation Concept (EDC). Energy 2021, 237, 121622. [Google Scholar] [CrossRef]

- Hu, F.; Li, P.; Zhang, T.; Zu, D.; Cheng, P.; Liu, Y.; Mi, J.; Liu, Z. Experimental investigation on co-firing residual char and pulverized coal under MILD combustion using low-temperature preheating air. Energy 2022, 244, 122574. [Google Scholar] [CrossRef]

- Boussetla, S.; Mameri, A.; Hadef, A. NO emission from non-premixed MILD combustion of biogas-syngas mixtures in opposed jet configuration ScienceDirect. Int. J. Hydrog. Energy 2021, 46, 37641–37655. [Google Scholar] [CrossRef]

- Westbrook, C.K.; Dryer, F.L. Chemical kinetics and modeling of combustion processes. Symp. Combust. 1981, 18, 749–767. [Google Scholar] [CrossRef]

- Jones, W.P.; Lindstedt, R.P. Global reaction schemes for hydrocarbon combustion. Combust. Flame 1988, 73, 233–249. [Google Scholar] [CrossRef]

- Shi, H.W.; Liu, Z.Q. Study on mixing characteristics of multichamber static mixer. Eng. Rep. 2023, 6, e12712. [Google Scholar] [CrossRef]

- Weng, Z. FLUENT 14.5 Flow Field Analysis from Beginner to Master; China Machine Press: Beijing, China, 2013; pp. 288–290. (In Chinese) [Google Scholar]

- Lee, P.H.; Hwang, S.S. Formation of Lean Premixed Surface Flame Using Porous Baffle Plate and Flame Holder. J. Therm. Sci. Technol. 2013, 8, 178–189. [Google Scholar] [CrossRef]

- Pierce, C.D.; Moin, P. Progress-variable approach for large-eddy simulation of non-premixed turbulent combustion. J. Fluid Mech. 2004, 504, 73–97. [Google Scholar] [CrossRef]

- Mittal, V.; Pitsch, H. A flamelet model for premixed combustion under variable pressure conditions. Proc. Combust. Inst. 2013, 34, 2995–3003. [Google Scholar] [CrossRef]

- Chang, J.; Wang, X.; Zhou, Z.; Chen, H.; Niu, Y. CFD modeling of hydrodynamics, combustion and NOx emission in a tangentially fired pulverized-coal boiler at low load operating conditions. Adv. Powder Technol. 2021, 32, 290–303. [Google Scholar] [CrossRef]

- Echi, S.; Bouabidi, A.; Driss, Z.; Abid, M.S. CFD simulation and optimization of industrial boiler. Energy 2019, 169, 105–114. [Google Scholar] [CrossRef]

- Liu, B. ANSYS Fluent 2020 Comprehensive Application Case Explanation; Tinghua University Press: Beijing, China, 2015; pp. 253–255. [Google Scholar]

- Hassan, G.; Pourkashanian, M.; Ingham, D.; Ma, L.; Taylor, S. Reduction in Pollutants Emissions From Domestic Boilers—Computational Fluid Dynamics Study. J. Therm. Sci. Eng. Appl. 2009, 1, 011007. [Google Scholar] [CrossRef]

- Lamioni, R.; Bronzoni, C.; Folli, M.; Tognotti, L.; Galletti, C. Feeding H2-admixtures to domestic condensing boilers: Numerical simulations of combustion and pollutant formation in multi-hole burners. Appl. Energy 2022, 309, 118379. [Google Scholar] [CrossRef]

| Items | CH4 | C2H6 | C3H8 | N2 | Density /kg·Nm−3 | Wobbe Number /KJ·m−3 | Explosion Limit/% | Combustion Index | Calorific Value /MJ·Nm−3 |

|---|---|---|---|---|---|---|---|---|---|

| Natural gas | 95.346 | 2.936 | 0.535 | 1.183 | 0.74 | 52.44 | 5.0–15.1 | 39.3 | 35.7 |

| Premixed Gas | Flue Gas Emission Index | Boiler Output and Efficiency | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Natural Gas Temperature /m3·h−1 | O2 /% | CO /ppm | CO2 /% | NO /mg·m−3 | NO2 /% | NOx /mg·m−3 | Exhaust Gas Temperature/°C | Smoke Pressure /pa | Steam Flow Rate /L·min−1 | Gross Efficiency /effg% | Net Efficiency /effn% |

| 100/ Minmum firing rate | 1.9 | 24 | 10.77 | 33 | 6 | 35.2 | 151.4 | 2.8 | 0.57 | 90.2 | 81.9 |

| 2.2 | 33 | 10.65 | 35 | 5 | 37.8 | 158.2 | 5.3 | 0.59 | 92.7 | 84.1 | |

| 2.4 | 32 | 10.37 | 40 | 5 | 42.6 | 160.3 | 16.8 | 0.57 | 92.8 | 84.2 | |

| 161/ Middle firing rate | 1.2 | 31 | 11.22 | 31 | 7 | 39.3 | 185.1 | 15 | 0.57 | 92.8 | 82.2 |

| 2 | 9 | 10.77 | 25.9 | 9 | 36.1 | 180.5 | 23 | 0.56 | 91.4 | 82.9 | |

| 2.2 | 24 | 10.65 | 35 | 4 | 38 | 205.2 | 57.2 | 0.57 | 90.6 | 82.1 | |

| 199/ Maximum firing rate | 2.1 | 9 | 12.82 | 21.2 | 5 | 26.9 | 200.8 | 58 | 0.55 | 90.4 | 82 |

| 2.2 | 12 | 12.16 | 31 | 6 | 33 | 211 | 63.1 | 0.56 | 90.3 | 81.9 | |

| 2.7 | 15 | 12.47 | 27 | 7 | 29 | 207 | 60 | 0.56 | 90.1 | 80.6 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, H.; Yin, X.; Wang, C.; Wang, H. Experimental and Numerical Simulation Research on Different Shapes of Flame-Stabilizing Baffles in the Furnace. Energies 2024, 17, 4253. https://doi.org/10.3390/en17174253

Shi H, Yin X, Wang C, Wang H. Experimental and Numerical Simulation Research on Different Shapes of Flame-Stabilizing Baffles in the Furnace. Energies. 2024; 17(17):4253. https://doi.org/10.3390/en17174253

Chicago/Turabian StyleShi, Hongwei, Xiao Yin, Chunming Wang, and Haipeng Wang. 2024. "Experimental and Numerical Simulation Research on Different Shapes of Flame-Stabilizing Baffles in the Furnace" Energies 17, no. 17: 4253. https://doi.org/10.3390/en17174253

APA StyleShi, H., Yin, X., Wang, C., & Wang, H. (2024). Experimental and Numerical Simulation Research on Different Shapes of Flame-Stabilizing Baffles in the Furnace. Energies, 17(17), 4253. https://doi.org/10.3390/en17174253