Use of Extended Exergy Analysis to Quantify Advantages and Drawbacks of Decentralizing Industrial Production Lines

Abstract

1. Introduction

2. Analytical and Critical List of the Acknowledged Advantages and Disadvantages of Decentralized Production Systems

2.1. What Is Decentralization?

2.2. Advantages of Decentralisation (Most of the Points Discussed in This Section Have Been Extracted from [14])

- (a)

- Higher motivation of local workforce

- (b)

- Growth and Diversification

- (c)

- Quick Decision Making

- (d)

- Efficient Communication

- (e)

- Ease of Expansion

- (f)

- Better Supervision and Control

2.3. Disadvantages of Decentralization

- (a)

- Difficult To Coordinate

- (b)

- External Factors

- (c)

- Narrow Product Lines

- (d)

- Lack of Competence

- (e)

- Expensive

- (f)

- Inefficient use of resources

3. A Review of the Scientific Literature

4. Materials and Method

- i.

- Material flows are assigned an EE equal to their specific raw exergy (i.e., the exergy per unit mass they possess when in the earth litho-, atmo- or hydrosphere) augmented of all the exergy flows needed for their search, extraction, pre-treatment and transportation to the factory under analysis: this quantity was called Cumulative Exergy Consumption (”CExC”) by Szargut [39]. Since all the above processes involve externalities, proper values are calculated for the EE of capital, labor and environmental costs: the scheme for this calculation is described in detail in [3] and is briefly summarized under points (iii, iv and v) below.

- ii.

- Energy flows directly available in the environment are assigned their equivalent exergy value (in W). If, however, they are “processed” in some way (as when, for example, wind power is converted into electricity), again the EE of the externalities is added (Figure 1).

- iii.

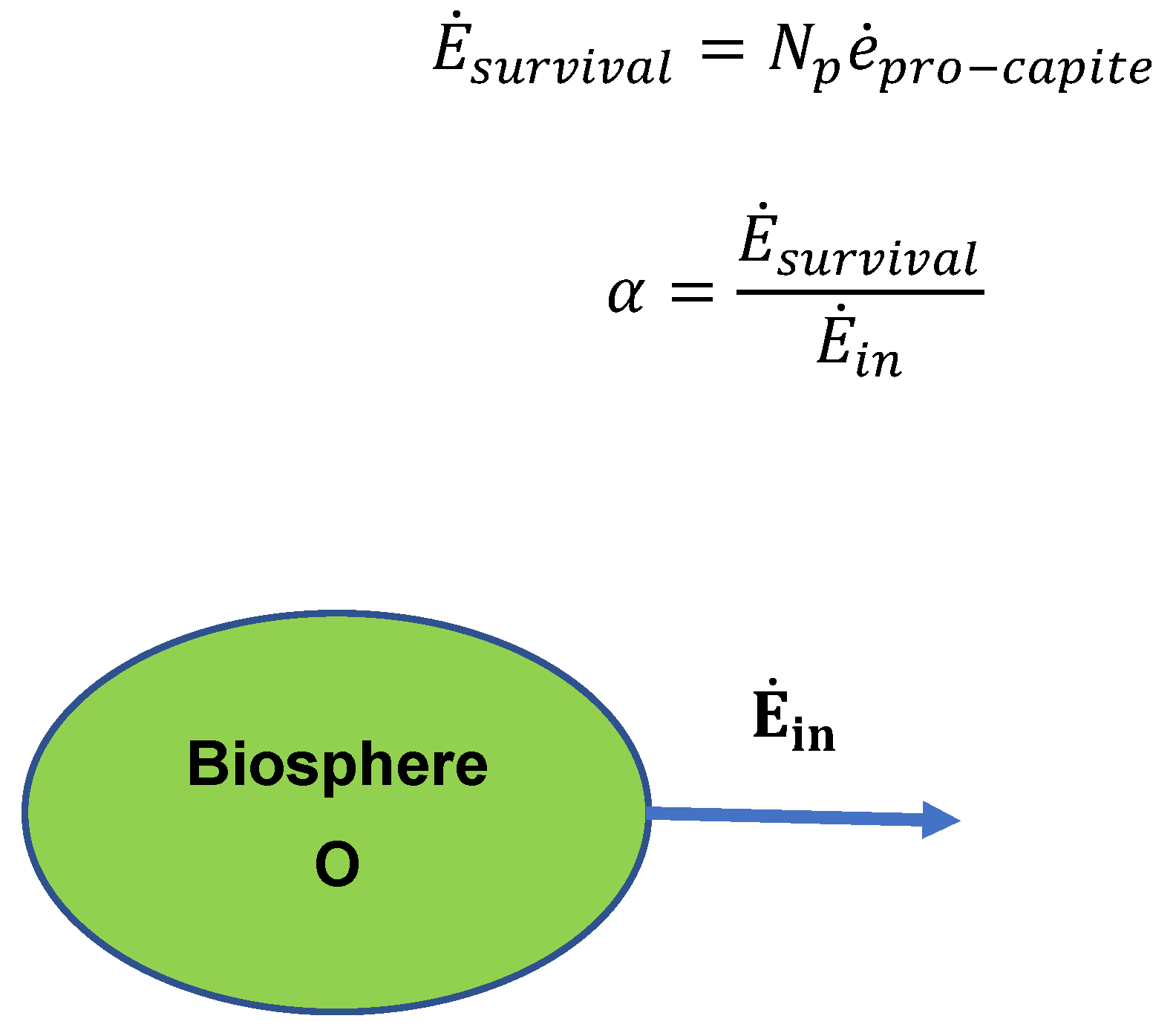

- The specific ee of labor, eeL (J/workhour), is calculated as the total amount of exergy necessary to the sustenance of the population divided by the number of workhours generated in the country: eeL = αEin/(Nw X wh). The econometric coefficient α (Figure 2) is assumed to be known for each country of interest [46]. Thus, the total EE of X workhours is EEL,X = eeL ∗ X (in W).

- iv.

- The EE of Capital, EEK (W), is assumed to be proportional to the Labor EEL, by a second econometric factor β assumed to be known for each country of interest [46]: EEK = βEEL = αβEin. The specific ee of Capital, eeK (J/EUR), is then eeK = αβEin/M2, where M2 (EUR/yr) is a monetary indicator (called “Money plus Quasi-Money”) published monthly/yearly by the Central Banks of all industrialized countries. As a result of the two above postulates, both Labor and Capital become Externalities as well.

- v.

- The environmental externality is calculated by assuming that a proper treatment plant is installed downstream of the system that reduces the physical exergy of the effluents to a value so low that it can be buffered by the biosphere [3,41]. The EEO = (EEM + EEH + EEL + EEK)O of this treatment system is then added to the EEin, and it results in an increase in the resource cost of the product (Figure 3).

- vi.

- Since EE is a “cost” (expressed in W of primary exergy), it obeys a cost conservation rule: the total EE in the input -including all externalities- is always equal to the total EE in the output. Assuming for the moment that the considered process generates N units of a single product, each unit shall be assigned an “extended exergy cost” equal to EEin/N. In the case of multiple products, proper allocation rules must be applied.

- vii.

- Since a correct evaluation of the system must include an exergy flow diagram, each of the N produced units has a unique and unambiguously calculated exergy content EN. Its Exergy Footprint is then a pure number calculated as ExF = EEin/EN: the higher this ratio, the more costly in terms of primary exergy resources the product is.

5. The Resource Cost of an Industrial Production Line or Settlement

- (a)

- The total amount of product is the same in the two cases: ΣPj = P;

- (b)

- The types of raw materials and of energy sources used in both cases are identical;

- (c)

- Due to the plant size (capacity) effect, the efficiency of the decentralized Sj is lower than that of the centralized S by a scaling factor that depends on technological and socio-economic reasons and that we shall assume known for each location: Ein,j/Pj = σjEin/P, the factors σj being higher than unity;

- (d)

- The capital costs are proportional to the size of the plant, but the CAPEX is affected by a cost scaling factor (ψj > 1) as well: ZK,j = ψjPj with ψj > ψ = ZK/P;

- (e)

- A similar reasoning applies to the labor- and maintenance costs (collectively referred to as “OPEX” hereinafter): ZL,j = λjPj with λj > λ = ZL/P. Here, λj > 1;

- (f)

- It is reasonable to assume that the environmental remediation costs scale proportionally to the size of the plant: ZO,j = ωjPj with ωj > ω = ZO/P;

- (g)

- Transportation costs of all inputs are solely proportional to the distance between the source and the plant, and distribution costs to the distance between the plant and the final user: EETR = Σ(τndn) and Σ(EETR,j) = Σ[Σ(τpdq)]j, where the factors τ are specific cost equivalents (W/km) that depend on the transport mode and schedule and on the fuel used (diesel, gasoline, electricity, biofuels…) and must also include their own and separately calculated environmental externality cost EEO,TR,j;

- (h)

- Salaries, interest rate, taxation, environmental regulations, etc., are the same for all locations.

6. A Formal, Resource-Based Cost/Benefit Calculation Procedure

7. Discussion

- (a)

- The efficiency scaling factors σj

- (b)

- The CAPEX scaling factors ψj

- (c)

- The OPEX scaling factors λj

- (d)

- The exhaust treatment scaling factors ωj

- (e)

- The transportation costs τj

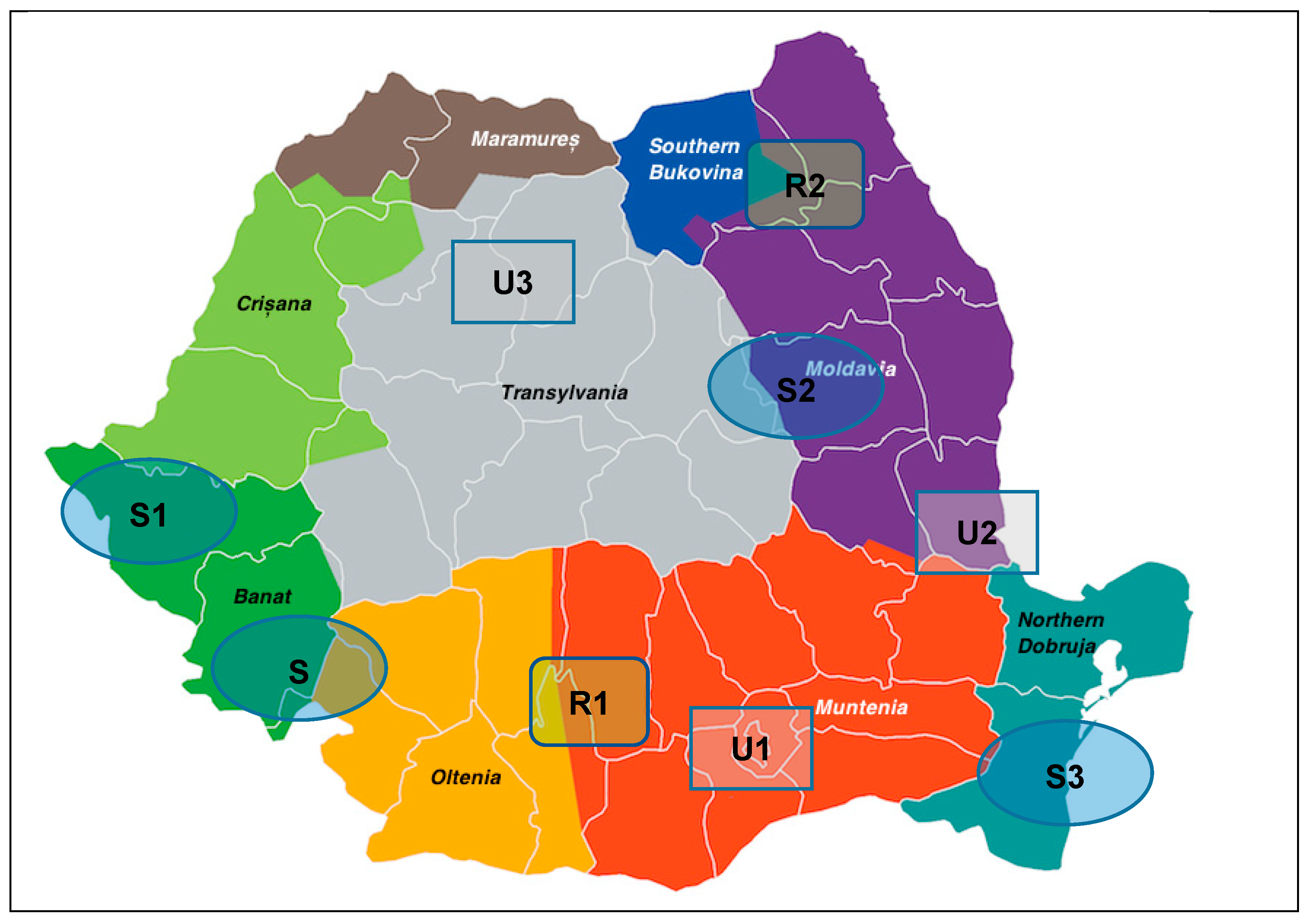

8. Illustrative Examples of Application

8.1. Three Smaller Coal-Fed Thermoelectric Plants Substitute for a Single Large One

- In the case of a single, 1000 MW powerplant, the Exergy Footprint ExF of the electrical energy received by the users is 3.42 kWh/kWh (Table 1). This means that for each final kWh, 3.42 kWh of primary resource (coal) have been consumed (and cannot be replaced, since we are dealing with a fossil source);

- The decentralization scheme of Case A (Table 1) is not convenient since the ExF of all users is higher than that of the centralized solution. This effect depends on the scale factors for the CAPEX and OPEX of smaller plants (that increase their respective EEK), on their lower efficiency (that increases the mass of coal used to generate a single kWh) and on their relatively costlier exhaust treatments (higher EEO);

- Optimizing the capacity allocation as in Case B helps (Table 2) but does not solve the problem: the ExF of the decentralized system is still higher than that of the centralized one. Possible optimal sets of solutions may exist and can be sought after by performing an optimization w.r.t. the source-to-plant and plant-to-user distances;

- A convenient solution is that of adopting a better technology for the smaller plants, i.e., raising their efficiency as in Case C (Table 2), because the decrease in environmental costs (lower mass flowrate of coal) more than compensates for the increased CAPEX.

8.2. Three Smaller RDF Incineration Plants Substitute a for Single Large One

9. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Symbol and Units | Meaning | Greek Symbols | |

| c EUR/ton | Specific cost of coal | α | Econometric coefficient |

| CExC (W), cexc | Cumulative exergy consumption | β | Econometric coefficient |

| d km | Distance | δ | EE evaluation factor |

| E (W) | Exergy flow | ε | 2nd Law efficiency |

| EE (W), ee (W/unit) | Extended Exergy | λ | OPEX scaling factor |

| ExF (W/W) | Exergy Footprint | ψ | CAPEX scaling factor |

| fsz | Szargut exergy factor | σ | Efficiency scaling factor |

| GHG | Greenhouse gas | τ | Transportation scaling |

| i (EUR/(EURyear) | Yearly Interest rate | ω | Effluent treatment scaling |

| LHV (kWh/kg) | Lower Heating Value | Suffixes | |

| M2 | Money + Quasi-money | Coal, RDF | Indicated the used fuel |

| NW | Number of Workers | d | Exergy destruction |

| P | Product | F | Fuel |

| PF (h/yr) | Plant factor | H | Energy |

| R | Capital recovery rate | in | input |

| S (MW) | Plant Capacity | L | Labor |

| t | Tons of material | M | Material |

| TIC (EUR) | Installation cost | O | Environmental |

| wh | Number of workhours | TR | Transportation |

| Z | Cost rate | ||

Appendix A

| σ1 | 1.1 | ψ1 | 1.15 | λ1 | 1.15 | ω1 | 1.2 | τ1 | 0.25 |

| σ2 | 1.05 | ψ2 | 1.1 | λ2 | 1.1 | ω2 | 1.15 | τ2 | 0.35 |

| σ3 | 1.03 | ψ3 | 1.05 | λ3 | 1.1 | ω3 | 1.1 | τ3 | 0.4 |

| dR1-S | 200 | dR2-S | 663 | dS-U1 | 300 | dS-U2 | 550 | dS-U3 | 350 |

| dR1-S1 | 424 | dR2-S1 | 607 | dS1-U1 | 500 | dS1-U2 | 650 | dS1-U3 | 300 |

| dR1-S2 | 413 | dR2-S2 | 150 | dS2-U1 | 250 | dS2-U2 | 150 | dS2-U3 | 325 |

| dR1-S3 | 354 | dR2-S3 | 527 | dS3-U1 | 200 | dS3-U2 | 200 | dS3-U3 | 650 |

| ΣdS-U | 1200 | ΣdS1-U | 1450 | ΣdS2-U | 725 | ΣdS3-U | 1050 | PF | 0.628 |

| S | 1000 | S1 | 250 | S2 | 350 | S3 | 400 | eeK | 1.7 |

| TICS | 2.1 × 109 | R(i,30) | 0.06 | εS | 0.39 | kgCO2/kWh | 0.75 | cexc | 1.25 |

| ZF,S | 1.145 | ZK,S | 4 | ZL,S | 0.07 | ZO,S | 4.58 | ed,tr | 0.00008 |

| Eel,S | 174.40 | Ein,S | 447.19 | EEin,S | 558.99 | EEin,tot,S | 577.1 | ccoal | 20 |

| Eδ,S | 5.54 | EU,S | 168.86 | EEU,S | 577.1 | eeel,S | 3.42 |

| ES1-U1 | 8.37 | ES1-U2 | 0.00 | ES1-U3 | 34.04 |

| ES2-U1 | 25.64 | ES2-U2 | 25.65 | ES2-U3 | 8.49 |

| ES3-U1 | 30.89 | ES3-U2 | 30.89 | ES3-U3 | 6.61 |

| εS1 | 0.379 | εS2 | 0.382 | εS3 | 0.386 |

| σ1 | 1.01 | ψ1 | 1 | λ1 | 1.15 | ω1 | 1.2 | τ1 | 1 |

| σ2 | 1.02 | ψ2 | 1 | λ2 | 1.1 | ω2 | 1.15 | τ2 | 1 |

| σ3 | 1.03 | ψ3 | 1 | λ3 | 1.1 | ω3 | 1.1 | τ3 | 1 |

| dR1-S | 233 | dR2-S | 663 | dS-U1 | 300 | dS-U2 | 550 | dS-U3 | 350 |

| dR1-S1 | 424 | dR2-S1 | 607 | dS1-U1 | 500 | dS1-U2 | 650 | dS1-U3 | 300 |

| dR1-S2 | 413 | dR2-S2 | 150 | dS2-U1 | 250 | dS2-U2 | 150 | dS2-U3 | 325 |

| dR1-S3 | 354 | dR2-S3 | 527 | dS3-U1 | 200 | dS3-U2 | 200 | dS3-U3 | 650 |

| ΣdS-U | 1200 | ΣdS1-U | 1450 | ΣdS2-U | 725 | ΣdS3-U | 1050 | PF | 0.41 |

| EU1 | 19 | EU2 | 16.5 | EU3 | 14.5 | cexc | 1 | eeK | 1.7 |

| S | 50 | S1 | 25 | S2 | 15 | S3 | 10 | fsz,RDF | 1.2 |

| ES1-U1 | 0.57 | ES1-U2 | 0.00 | ES1-U3 | 2.28 | emistr | 0.15 | ed,tr | 0.00008 |

| ES2-U1 | 0.80 | ES2-U2 | 0.57 | ES2-U3 | 0.34 | LHVRDF | 20,000 | CO2 tax | 35 |

| ES3-U1 | 0.57 | ES3-U2 | 0.46 | ES3-U3 | 0.11 | kgCO2/kWh | 0.6 | eeel, S | 3.90 |

| tRDF,R1-S | 60,000 | tRDF,R2-S | 60,000 | tCO2,R1-S | 2097 | tCO2,R2-S | 5967 | zconferral | 15 |

| TICS | 2.95 × 108 | R(i,30) | 0.06 | ZK,S | 0.56 | ZL,S | 0.04 | ZO,S | 0.13 |

| εS | 0.27 | Ein,S | 21.09 | EEin,S | 21.09 | EEin,tot, S | 21.53 | ||

| Eel S | 5.69 | Eδ,S | 0.18 | EU,S | 5.51 | EEU,S | 21.53 |

References

- Ruiz-Villaverde, A. Editor’s Introduction: The Growing Failure of the Neoclassical Paradigm in Economics. Am. J. Econ. Sociol. 2019, 78, 13–34. [Google Scholar] [CrossRef]

- Sylos Labini, F. Science and the Economic Crisis; Springer International Pub.: Cham, Switzerland, 2016; ISBN 978-3-319-29527-5. [Google Scholar]

- Sciubba, E. A Thermodynamic Measure of Sustainability. Front. Sustain. 2021, 2, 739395. [Google Scholar] [CrossRef]

- Wall, G.; Gong, M. Exergy and sustainable development, Part 1: Conditions and concepts. Int. J. Exergy 2001, 1, 128–145. [Google Scholar] [CrossRef]

- Dewulf, J.; van Langenhove, H.; Muys, B.; Bruers, S.; Bakshi, B.R.; Grubb, G.F.; Paulus, D.M.; Sciubba, E. Exergy: Its potential and limitations. Environ. Sci. Technol. 2008, 42, 2221–2232. [Google Scholar] [CrossRef] [PubMed]

- Kotas, T. The Exergy Method of Thermal Plant Analysis, Butterworths; Academic Press: London, UK, 1985. [Google Scholar]

- Moran, M.J.; Sciubba, E. Exergy analysis-principles and practice. JERT 1994, 116, 1994. [Google Scholar] [CrossRef]

- Colombo, E.; Rocco, M.; Sciubba, E. Advances in exergy analysis: A novel assessment of the Extended Exergy Accounting method. Appl. Energy 2013, 113, 1405–1420. [Google Scholar]

- Sciubba, E. Beyond Thermoeconomics? The concept of Extended Exergy Accounting and its application to the analysis and design of Thermal Systems. Exergy Int. J. 2001, 1, 68–84. [Google Scholar] [CrossRef]

- Coote, D. The Benefits of Decentralized Energy; News Corp Australia: Surry Hills, Australia, 2021. [Google Scholar]

- Hagemann, T. Five Reasons to Switch to Decentralised Electricity Generation. The Governance Post, 6 April 2017. [Google Scholar]

- ISGF—India Smart Grid Forum. Characteristics of Smart Grid? How Is It Different from the Existing Grid? Available online: https://indiasmartgrid.org/sgg2.php (accessed on 4 September 2021).

- Siraganyan, K.; Dasun-Perera, A.T.; Scartezzini, J.-L.; Mauree, D. Eco-Sim: A parametric Tool to Evaluate the Environmental and Economic Feasibility of Decentralized Energy Systems. Energies 2019, 12, 776. [Google Scholar] [CrossRef]

- TOPPR Tutorials. Available online: https://www.toppr.com/guides/fundamentals-of-economics-and-management/organising/advantages-and-disadvantages-of-decentralisation/ (accessed on 2 September 2021).

- Alstone, S.; Gershenson, D.; Kammen, D. Decentralized energy systems for clean electricity access. Nat. Clim. Chang. 2015, 5, 305–314. [Google Scholar] [CrossRef]

- Bohn, D. Decentralised energy systems: State of the art and potentials. Int. J. Energy Technol. Policy 2005, 3, 1–11. [Google Scholar] [CrossRef]

- Schütz, T.; Hu, X.-L.; Fuchs, M.; Müller, D. Optimal design of decentralized energy conversion systems for smart microgrids using decomposition methods. Energy 2018, 156, 250–263. [Google Scholar] [CrossRef]

- Sujarwoto, S. Why decentralization works and does not work? A systematic literature review. JSAS 2017, 1, 1–10. [Google Scholar]

- Bolton, S.; Farrell, J. Decentralization, Duplication and Delay. J. Political Econ. 1990, 98, 803–826. [Google Scholar] [CrossRef]

- Adil, A.M.; Ko, Y. Socio-technical evolution of Decentralized Energy Systems: A critical review and implications for urban Planning and Policy. Renew. Sustain. Energy Rev. 2016, 57, 1025–1037. [Google Scholar] [CrossRef]

- Tan, L.-M.; Arbabi, H.; Densley-Tingley, D.; Brockway, S.E.; Mayfield, M. Mapping resource effectiveness across urban systems. Npj Urban Sustain. 2021, 1, 20. [Google Scholar] [CrossRef]

- Henderson, J.V. Locational pattern of heavy industries: Decentralization is more efficient. J. Policy Model. 1988, 10, 569–580. [Google Scholar] [CrossRef]

- Karger, C.R.; Hennings, W. Sustainability evaluation of decentralized electricity generation. Renew. Sustain. Energy Rev. 2009, 13, 583–593. [Google Scholar] [CrossRef]

- UN-ESCAP. Low Carbon Green Growth Roadmap for Asia and the Pacific:Fact Sheet- Decentralized Energy System. Available online: https://www.unescap.org (accessed on 9 September 2021).

- Fukuizumi, Y. 3 Trends That Will Transform the Energy Industry. 2020. Available online: https://spectra.mhi.com/3-trends-that-will-transform-the-energy-industry (accessed on 4 September 2021).

- Egger, G.; Chaltsev, D.; Giusti, A.; Matt, D.T. A deployment-friendly decentralized scheduling approach for cooperative multi-agent systems in production systems. Procedia Manuf. 2020, 52, 127–132. [Google Scholar] [CrossRef]

- Suvarna, M.; YaS, K.S.; Yang, W.; Li, J.; Ng, Y.T.; Wang, X. Cyber-physical production systems for data-driven, decentralized, and secure manufacturing—A perspective. Engineering 2021. Available online: https://www.sciencedirect.com (accessed on 24 July 2021).

- Clarke-Sather, A.R. Decentralized or Centralized Production: Impacts to the Environment, Industry, and the Economy. Ph.D. Thesis, Western Michigan University, Kalamazoo, MI, USA, 2009. [Google Scholar]

- Lin, J.-Y.; Tao, R.; Liu, M.-X. Decentralization and Local Governance in China’s Economic Transition. In Rise of Local Governments in Developing Countries; London School of Economics: London, UK, 2003. [Google Scholar] [CrossRef]

- Agrawal, A.; Ostrom, E. Collective Action, Property Rights, and Decentralization in Resource Use in India and Nepal. Politics Soc. 2001, 29, 485–514. [Google Scholar] [CrossRef]

- Bardhan, P.; Mookherjee, D. Decentralization and Local Governance in Developing Countries: A Comparative Perspective; MIT Press: Cambridge, MA, USA, 2006; Volume 1. [Google Scholar]

- Ribot, J.C. Waiting for Democracy: The Politics of Choice in Natural Resource Decentralization; World Resources Institute: Washington, DC, USA, 2004. [Google Scholar]

- Litvack, J.; Ahmad, J.; Bird, R. Rethinking Decentralization at the World Bank: A Discussion Paper; World Bank Pub: Washington, DC, USA, 2010. [Google Scholar]

- Crook, R.; Sverrisson, A. To What Extent Can Decentralised Forms of Government Enhance the Development of Pro-Poor Policies and Improve Poverty-Alleviation Outcomes? IDS Working Paper 130; Inst. Development Studies: Brighton, UK, 2001. [Google Scholar]

- Bienen, H.; Kapur, D.; Parks, J.; Riedinger, J. Decentralization in Nepal. World Dev. 1990, 18, 61–75. [Google Scholar] [CrossRef]

- Sarker, M.A.; Itohara, Y. Farmers’ perception about the extension services and extension workers: The case of organic agriculture extension program by PROSHIKA. Am. J. Agric. Biol. Sci. 2008, 4, 332–337. [Google Scholar] [CrossRef]

- Blanchard, O.; Shleifer, A. Federalism with and without Political Centralization: China versus Russia; National Bureau of Economic Research: Cambridge, MA, USA, 2000; NBER Paper 7616. [Google Scholar]

- Treisman, D. Decentralization and the Quality of Government, Preliminary Draft Dated November 20, 2000. Available online: https://www.imf.org (accessed on 2 October 2021).

- Szargut, J.; Morris, D.R.; Steward, F.R. Exergy Analysis of Thermal, Chemical, and Metallurgical Processes; Hemisphere Pub.: New York, NY, USA, 1988. [Google Scholar]

- El Sayed, Y.M. The Thermo-Economics of Energy Conversion; Elsevier: Amsterdam, The Netherlands, 2003. [Google Scholar]

- Szargut, J.; Ziębik, A.; Stanek, W. Depletion of the Unrestorable Natural Exergy Resources as a Measure of the Ecological Cost. Energy Convers. Manag. 2002, 43, 1149–1163. [Google Scholar] [CrossRef]

- Tsatsaronis, G. Combination of Exergetic and Economic Analysis in Energy-Conversion Processes. In Proceedings of the European Congress Energy Economics & Management in Industry, Algarve, Portugal, 2–5 April 1984; Pergamon Press: Oxford, UK, 1984; Volume 1, pp. 151–157. [Google Scholar]

- Valero, A.; Lozano, M.A.; Muñoz, M. A general theory of exergy savings-1. On the exergetic cost. Comput.-Aided Eng. Energy Syst. Second Law Anal. Model. 1986, 3, 1–8. [Google Scholar]

- Yantovsky, E.I. Energy and Exergy Currents (An Introduction to Exergonomics); Nova Science Pub.: New York, NY, USA, 1994. [Google Scholar]

- Sciubba, E. A novel exergetic costing method for determining the optimal allocation of scarce resources. In Proceeding Contemporary Problems in Thermal Engineering; Rudnicki, G., Stanek, W., Nowak, A., Eds.; Polytechnica Slaska Publication: Gliwice/Katowice/Zabrze/Rybnik, Poland, 1998; pp. 311–324. [Google Scholar]

- Sciubba, E. A revised calculation of the econometric factors α- and β for the Extended Exergy Accounting method. Ecol. Model. 2011, 222, 1060–1066. [Google Scholar] [CrossRef]

- Biondi, A.; Sciubba, E. Extended Exergy Analysis (EEA) of Italy, 2013–2017, Energies, Extended Exergy Analysis (EEA) of Italy, 2013–2017. Energies 2021, 14, 2767. [Google Scholar] [CrossRef]

- Dai, J.; Chen, B.; Sciubba, E. Ecological accounting for China based on Extended Exergy—A sustainability perspective. Renew. Sustain. Energy Rev. 2014, 37, 334–347. [Google Scholar]

- Estervåg, I. Energy, exergy, and extended-exergy analysis of the Norwegian society. Energy 2003, 30, 649–675. [Google Scholar]

- Seçkin, C.; Sciubba, E.; Bayulken, A.R. An application of the Extended Exergy Accounting method to the Turkish Society, year 2006. Energy 2012, 40, 151–163. [Google Scholar] [CrossRef]

- Ha, G.-H.; Kim, S.H. Cost Scaling Factor according to Power Plant Capacity Change. J. Energy Eng. 2013, 22, 283–286. [Google Scholar] [CrossRef]

- Celikbilek, O. An Experimental and Numerical Approach for Tuning the Cathode for High Performance IT-SOFC. Ph.D. Thesis, Imperial College London, London, UK, 2006. [Google Scholar]

- Hendricks, T.J.; Yee, S.; LeBlanc, S. Cost Scaling of a Real-World Exhaust Waste Heat Recovery Thermoelectric Generator: A Deeper Dive. J. Electron. Mater. 2016, 45, 1751–1761. [Google Scholar] [CrossRef]

- European Environmental Agency. Greenhouse Gas Emissions from Transport in Europe. 2020. Available online: https://www.eea.europa.eu (accessed on 2 October 2021).

- Posada, F.; Chambliss, S.; Blumberg, K. Costs of Emission Reduction Technologies For Heavy-Duty Diesel Vehicles; ICCT paper; World Resources Institute: Washington, DC, USA, 2016. [Google Scholar]

- Pavičić, I.; Holjevac, N.; Ivanković, I.; Brnobić, D. Model for 400 kV Transmission Line Power Loss Assessment Using the PMU Measurements. Energies 2021, 14, 5562. [Google Scholar] [CrossRef]

- ISPRA. GHG Atmospheric Emission Factors in the Electric Sector in European Countries; TR. 317/2020; ISPRA: Roma, Italy, 2020. (In Italian) [Google Scholar]

- Wu, J.S.-Y. Capital Cost Comparison of Waste-to-Energy (WTE) Facilities in China and the U.S. Ph.D. Thesis, Columbia University, New York, NY, USA, 2016. [Google Scholar]

| S-(U1 + U2U3) Centralized | S1-(U1 + U2 + U3) | S2-(U1 + U2 + U3) | S3-(U1 + U2 + U3) |

|---|---|---|---|

| 3.42 | 4.15 | 3.72 | 3.75 |

| ExF Centralized | Decentralized, Case A | Decentralized, Case B | Decentralized, Case C |

|---|---|---|---|

| 3.42 | U1: 4.15 | U1: 3.47 | U1: 3.37 |

| U2: 3.72 | U2: 3.44 | U2: 3.36 | |

| U3: 3.75 | U3: 3.59 | U3: 3.40 |

| S-(U1 + U2 + U3) Centralized | S1-(U1 + U2 + U3) | S2-(U1 + U2 + U3) | S3-(U1 + U2 + U3) |

|---|---|---|---|

| 4.57 | 4.716 | 4.719 | 4.712 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sciubba, E. Use of Extended Exergy Analysis to Quantify Advantages and Drawbacks of Decentralizing Industrial Production Lines. Energies 2024, 17, 4173. https://doi.org/10.3390/en17164173

Sciubba E. Use of Extended Exergy Analysis to Quantify Advantages and Drawbacks of Decentralizing Industrial Production Lines. Energies. 2024; 17(16):4173. https://doi.org/10.3390/en17164173

Chicago/Turabian StyleSciubba, Enrico. 2024. "Use of Extended Exergy Analysis to Quantify Advantages and Drawbacks of Decentralizing Industrial Production Lines" Energies 17, no. 16: 4173. https://doi.org/10.3390/en17164173

APA StyleSciubba, E. (2024). Use of Extended Exergy Analysis to Quantify Advantages and Drawbacks of Decentralizing Industrial Production Lines. Energies, 17(16), 4173. https://doi.org/10.3390/en17164173