Non-Exhaust Particulate Emissions from Road Transport Vehicles

Abstract

1. Introduction

2. Brake Wear Particulate Matter Emissions

2.1. Brake Wear Particulate Composition

2.2. Brake Wear Particulate Formation Mechanisms

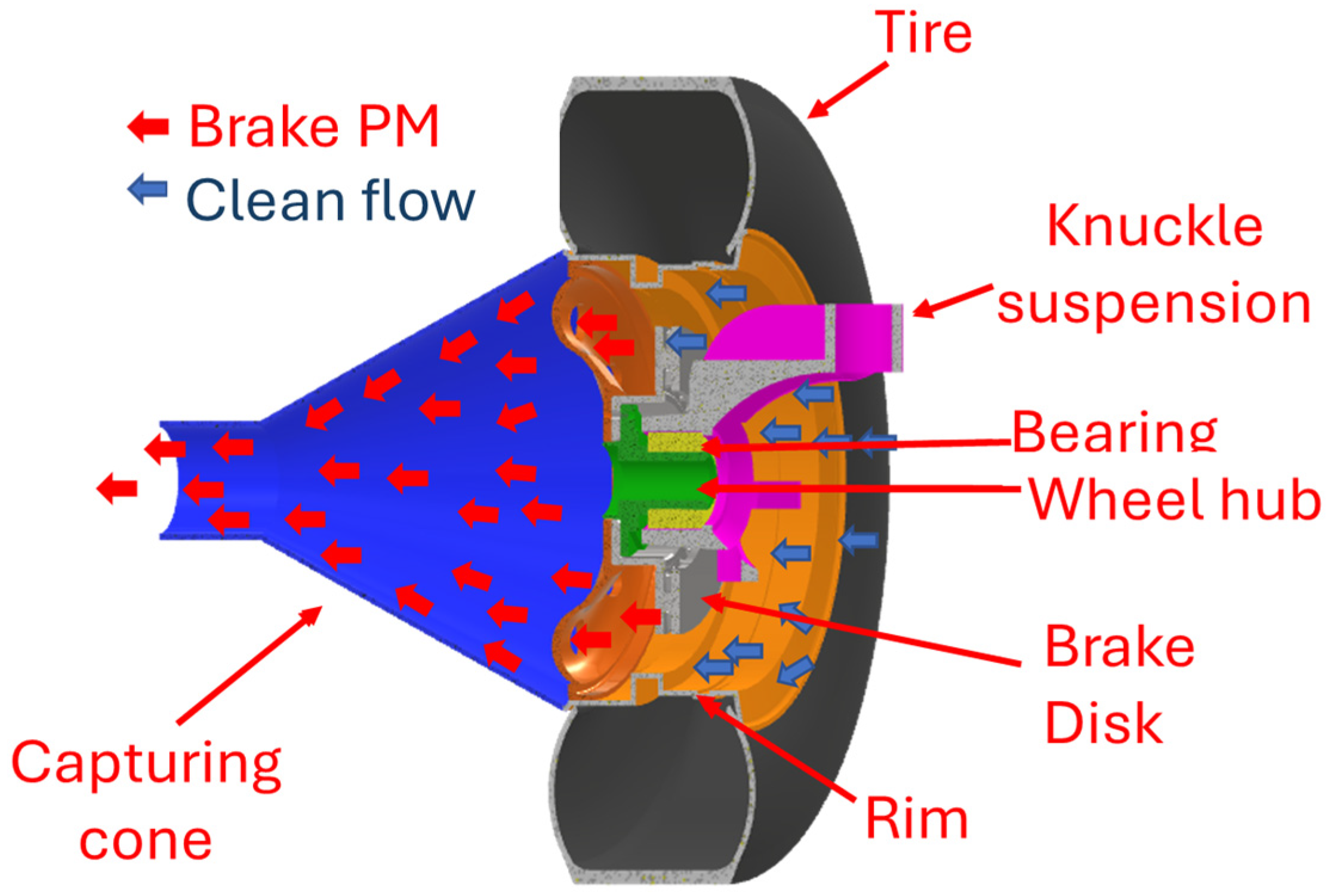

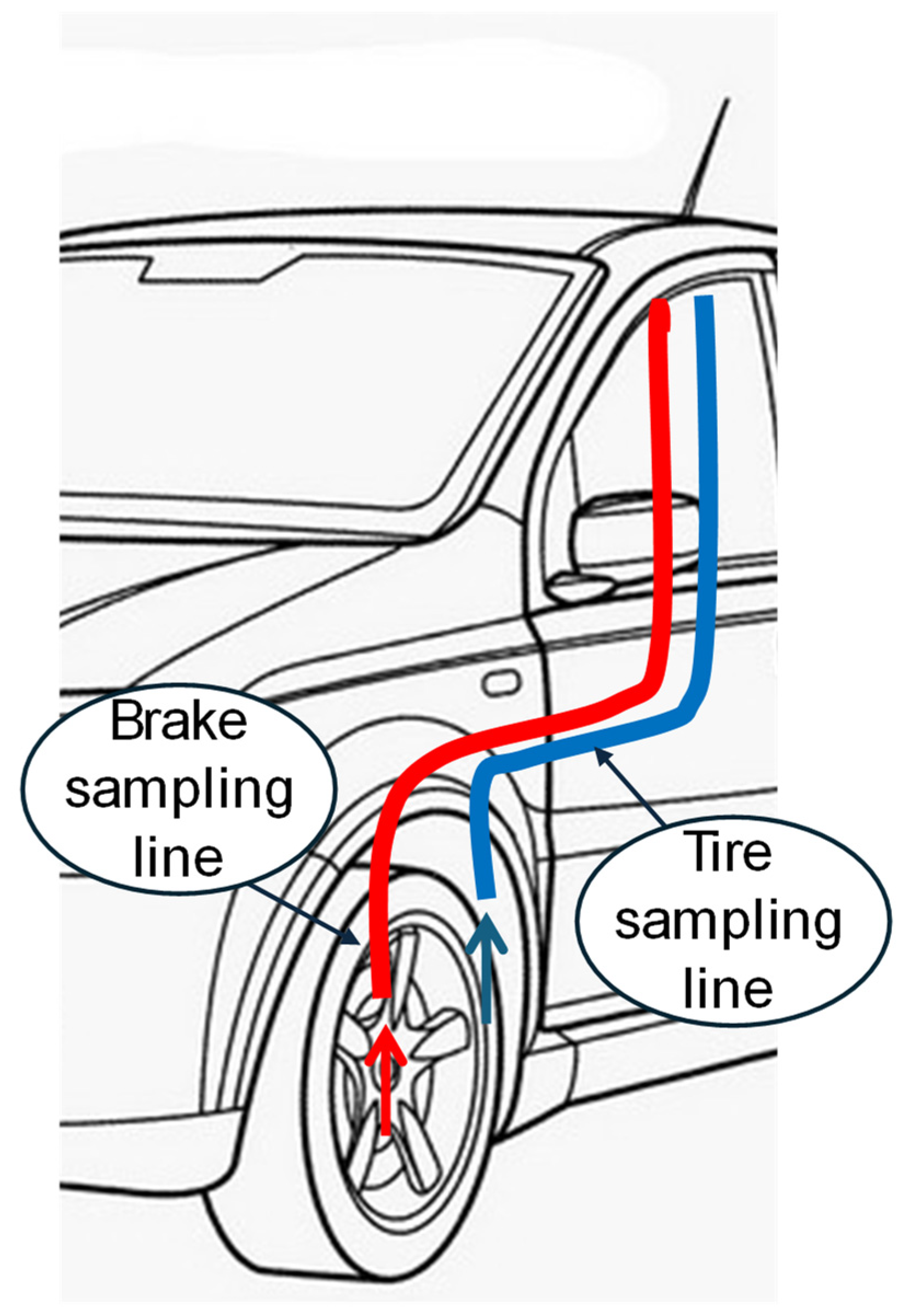

2.3. Brake Particulate Sampling Methodologies

2.4. Brake Wear Particulate Matter Emission Factors

3. Tire PM Emissions

3.1. Tire Wear Particulate Composition and Road Contribution

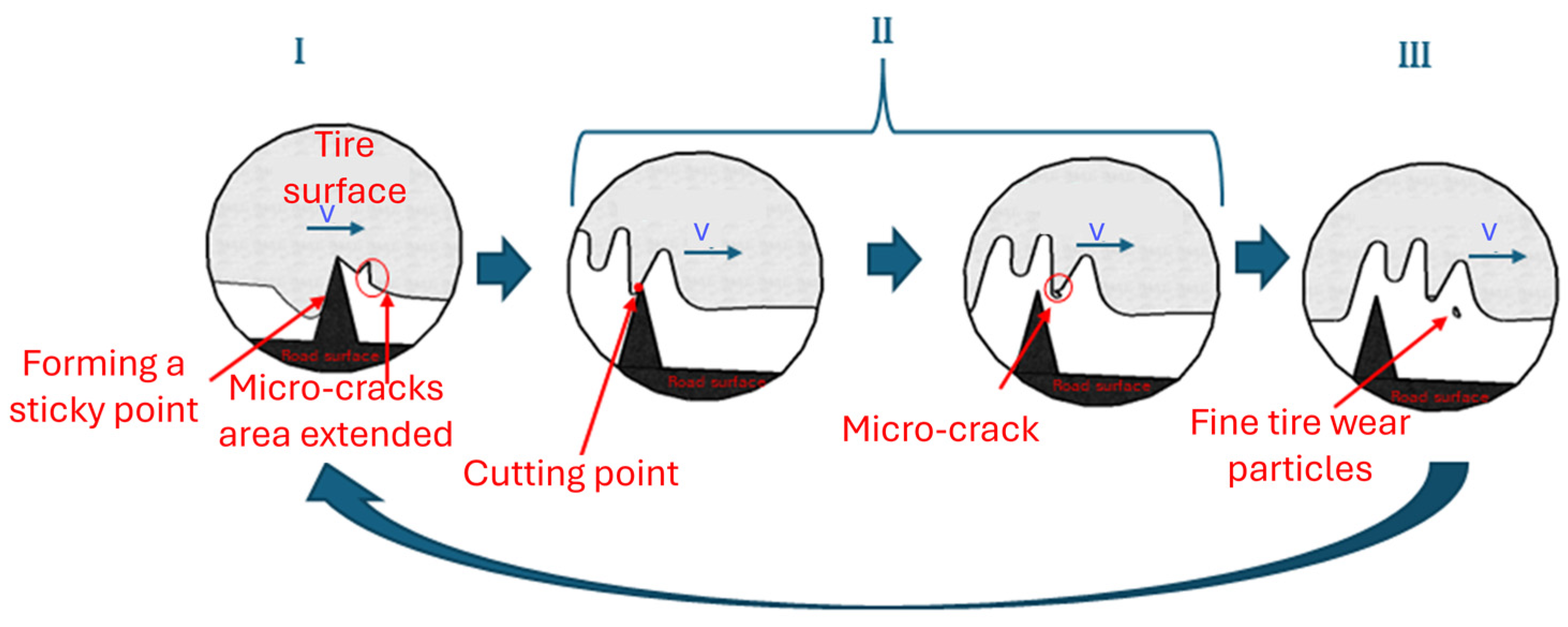

3.2. Tire Wear Particulate Formation Mechanisms

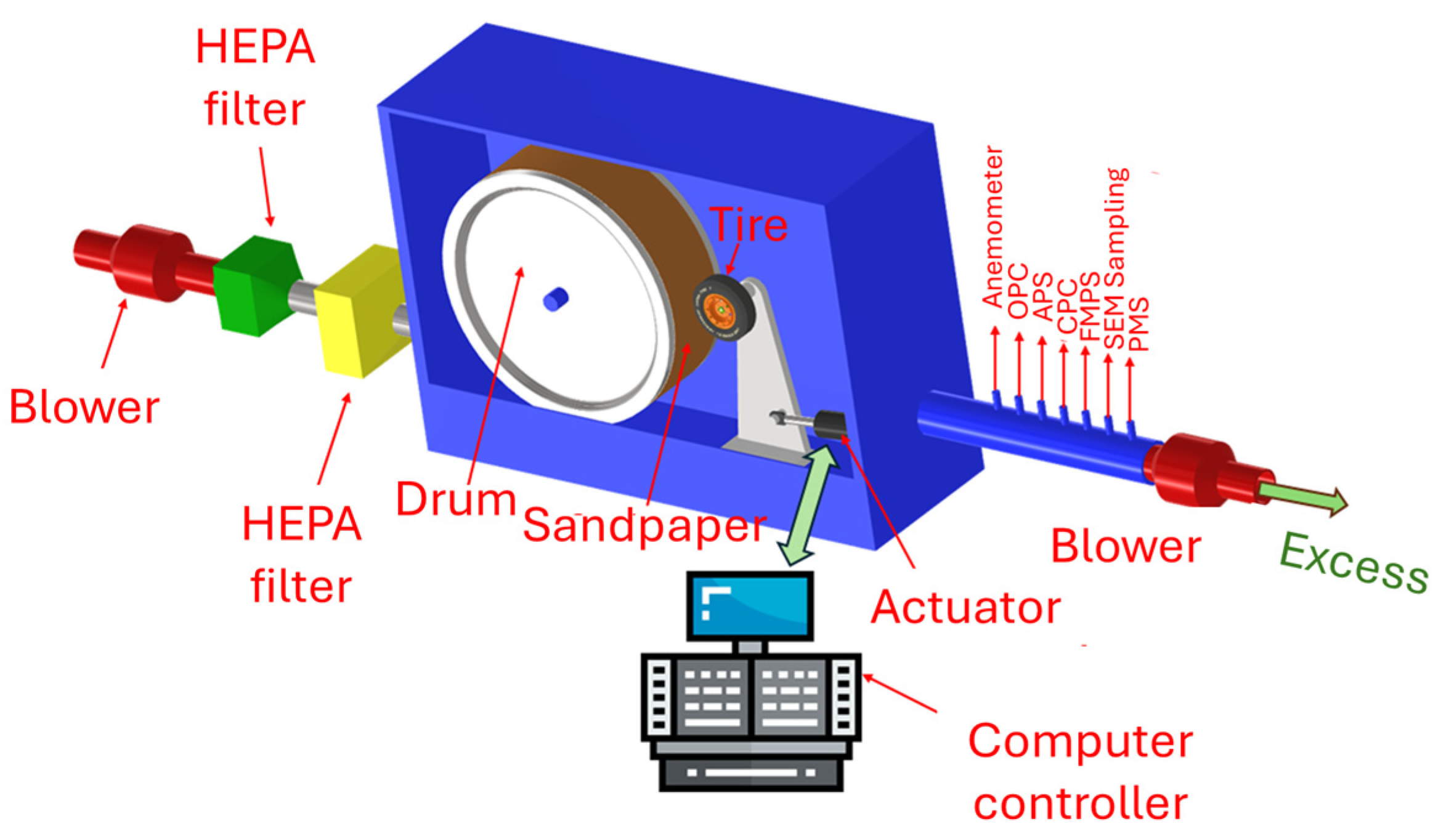

3.3. Tire Wear Particulate Sampling Methodologies

3.4. Tire Wear Particulate Matter Emission Factors

4. Resuspended Road Dust PM Emissions

4.1. Measurement Methodologies for Resuspended PM

4.2. Resuspended Road Dust Particulate Matter Emission Factors

| Reference | Environment/Sampling System | Measurement Method | Results |

|---|---|---|---|

| Alves et al., 2020 [78] | Northern Portugal city Direct sampling and resuspension of PM10 | Empirical correlation by Amato et al., 2011 [79] | Asphalt roads: 41.2 mg/km_veh Roads paved with cobblestones: 340 mg/km_veh |

| Amato et al., 2010 [73] | Barcelona 3 mobile labs | Linear regression between increases in traffic, PM10 and NOx at two different sites | 97 mg/km_veh |

| Padoan et al., 2018 [80] | Turin, Barcelona Direct sampling and resuspension of PM10 | Empirical correlation by Amato et al., 2011 [79] | Turin: 27 mg/km_veh Barcelona: 20 mg/km_veh |

| Mathissen et al., 2012 [81] | Germany Monitoring with instrumented vehicle and trailer | Measured concentration multiplied by the section and the vehicle speed and divided by the distance | 20–60 mg/km |

| Zhang et al., 2020 [82] | Cina Measurements in urban tunnels | Source apportionment via mass balance | 33.8 mg/km_veh |

| Alshetty et Nagendra, 2022 [83] | India Continuous sampling of PM10 and PM25 Road dust sampling | USEPA | PM2.5: 23–556 mg/km_veh PM10: 95–2299 mg/km_veh |

| Rienda et al., 2023 [84] | Portugal Direct sampling and resuspension of PM10 | Empirical correlation by Amato et al., 2011 [79] | 18.9–210.8 mg/km_veh |

5. Conclusions

- Brake wear particle emissions have been found to be strongly influenced by the type of brake pad and operating conditions, such as brake test type and vehicle weight, as well as type of test and the sampling system;

- Tire wear particle Emission factors are often correlated with the mass consumption. However, the mass loss of a tire does not precisely correspond to the emission into the atmosphere. Resuspended particles affect on-road TWP measurements, while laboratory tests are limited by their inability to fully replicate tire wear similar to that of real-world road conditions;

- Emission factors for resuspended road dust particulate matter are less reliant on measurement methodologies but are strongly influenced by meteorological conditions, traffic patterns, road maintenance, and cleaning practices.

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| 3h-LACT | Three Hours-Los Angeles City Traffic |

| BEV | Battery Electric Vehicles |

| BR | Butadiene Rubber |

| Cr | Rolling Resistance Coefficient |

| EU | European Union |

| FTP | Federal Test Procedure |

| GTR24 | Global Technical Regulation |

| NEDC | New European Driving Cycle |

| NHTSA | National Highway Traffic Safety Administration |

| NR | Natural Rubber |

| PMxx | Particulate Matter xx microns |

| PM | Particle Matter |

| PN | Particle Number |

| SBR | Styrene-Butadiene Rubber |

| sL | Silt Loading |

| SUV | Sport Utility Vehicles |

| TRWP | Tire and Road Wear Particles |

| TWP | Tire Wear Particles |

| US-EPA | US Environmental Protection Agency |

| UTQGS | Uniform Tire Quality Grading Standards |

| WHO | World Health Organization |

| WLTP | Worldwide Harmonised Light Vehicle Test Procedure |

References

- Environmental European Agency—EEA. Europe’s Air Quality Status 2023; Korean Society of Environmental Engineers (KSEE): Seoul, Republic of Korea, 2023; ISBN 978-92-9480-554-6. [Google Scholar] [CrossRef]

- Zhang, M.; Yin, H.; Tan, J.; Wang, X.; Yang, Z.; Hao, L.; Du, T.; Niu, Z.; Ge, Y. A comprehensive review of tyre wear particles: Formation, measurements, properties, and influencing factors. Atmos. Environ. 2023, 297, 119597. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Grigoratos, T.; Dilara, P.; Karageorgiou, T.; Ntziachristos, L.; Samaras, Z. Light-Duty Vehicle Brake Emission Factors. Atmosphere 2024, 15, 97. [Google Scholar] [CrossRef]

- Roy, A.; Mandal, M.; Das, S.; Kumar, M.; Popek, R.; Awasthi, A.; Giri, B.S.; Mondal, K.C.; Sarkar, A. Non-exhaust particulate pollution in Asian countries: A comprehensive review of sources, composition, and health effects. Environ. Eng. Res. 2024, 29, 230384. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, H.; Wu, S.; Gao, J.; Li, Y.; An, Z.; Mao, B.; Tu, R.; Li, T. Impact of vehicle type, tyre feature and driving behaviour on tyre wear under real-world driving conditions. Sci. Total Environ. 2022, 842, 156950. [Google Scholar] [CrossRef]

- Gulia, S.; Goyal, P.; Goyal, S.K.; Kumar, R. Re-suspension of road dust: Contribution, assessment and control through dust suppressants—A review. Int. J. Environ. Sci. Technol. 2019, 16, 1717–1728. [Google Scholar] [CrossRef]

- GTR, U. Proposal for a New UN GTR on Laboratory Measurement of Brake Emissions for Light–Duty Vehicles. UNECE (United Nations Economic Comission for Europe), Informal Working Group on Particulate Measurement Programme, Eighty–Seventh Session, Geneve. 2023. Available online: https://unece.org/sites/default/files/2023-07/ECE-TRANS-180-Add.24.pdf (accessed on 5 August 2024).

- Perricone, G.; Matejka, V.; Alemani, M.; Wahlström, J.; Olofsson, U. A Test Stand Study on the Volatile Emissions of a Passenger Car Brake Assembly. Atmosphere 2019, 10, 263. [Google Scholar] [CrossRef]

- Borawski, A. Conventional and unconventional materials used in the production of brake pads–review. Sci. Eng. Compos. Mater. 2020, 27, 374–396. [Google Scholar] [CrossRef]

- Lopez, B.; Wang, X.; Chen, L.W.A.; Ma, T.; Mendez-Jimenez, D.; Cobb, L.C.; Frederickson, C.; Fang, T.; Hwang, B.; Shiraiwa, M.; et al. Metal contents and size distributions of brake and tire wear particles dispersed in the near-road environment. Sci. Total Environ. 2023, 883, 163561. [Google Scholar] [CrossRef]

- Woo, S.H.; Jang, H.; Na, M.Y.; Chang, H.J.; Lee, S. Characterization of brake particles emitted from non-asbestos organic and low-metallic brake pads under normal and harsh braking conditions. Atmos. Environ. 2022, 278, 119089. [Google Scholar] [CrossRef]

- Sanderson, P.; Delgado-Saborit, J.M.; Harrison, R.M. A review of chemical and physical characterisation of atmospheric metallic nanoparticles. Atmos. Environ. 2014, 94, 353–365. [Google Scholar] [CrossRef]

- Gietl, J.K.; Lawrence, R.; Thorpe, A.J.; Harrison, R.M. Identification of brake wear particles and derivation of a quantitative tracer for brake dust at a major road. Atmos. Environ. 2010, 44, 141–146. [Google Scholar] [CrossRef]

- Piscitello, A.; Bianco, C.; Casasso, A.; Sethi, R. Non-exhaust traffic emissions: Sources, characterization, and mitigation measures. Sci. Total Environ. 2021, 766, 144440. [Google Scholar] [CrossRef]

- Polajnar, M.; Kalin, M.; Thorbjornsson, I.; Thorgrimsson, J.T.; Valle, N.; Botor-Probierz, A. Friction and wear performance of functionally graded ductile iron for brake pads. Wear 2017, 382, 85–94. [Google Scholar] [CrossRef]

- Andersson, J.; Campbell, M.; Marshall, I.; Kramer, L.; Norris, J. Measurements of Brake and Tyre Wear, Report for UK Department for Transport; Ricardo Energy & Environment: Harwell, UK, 2023. [Google Scholar]

- Kukutschová, J.; Filip, P. Review of brake wear emissions: A review of brake emission measurement studies: Identification of gaps and future needs. In Non-Exhaust Emissions; Amato, F., Ed.; Academic Press: Cambridge, MA, USA, 2018; pp. 123–146. [Google Scholar]

- Verma, P.C.; Ciudin, R.; Bonfanti, A.; Aswath, P.; Straffelini, G.; Gialanella, S. Role of the friction layer in the high-temperature pin-on-disc study of a brake material. Wear 2016, 346, 56–65. [Google Scholar] [CrossRef]

- Münchhoff, J. Initial Input of Audi to Brake Particle Emissions, Presented at the in 35th PMP IWG Meeting. 2015. Available online: https://wiki.unece.org/download/attachments/25264603/PMP-35-17%20AUDI%20Presentation.pdf?api=v2 (accessed on 5 August 2024).

- Hagen, F.H.F.Z.; Mathissen, M.; Grabiec, T.; Hennicke, T.; Rettig, M.; Grochowicz, J.; Vogt, R.; Benter, T. On-road vehicle measurements of brake wear particle emissions. Atmos. Environ. 2019, 217, 116943. [Google Scholar] [CrossRef]

- Dornoff, J.; Rodriguez, F. Euro 7: The New Emission Standard for Light- and Heavy-Duty Vehicles in the European Union. International Council on Clean Transportation. 2024. Available online: https://theicct.org/publication/euro-7-emission-standard-ldv-hdv-eu-mar24/ (accessed on 5 August 2024).

- Grigoratos, T.; Mamakos, A.; Vedula, R.; Arndt, M.; Lugovyy, D.; Hafenmayer, C.; Moisio, M.; Agudelo, C.; Giechaskiel, B. Characterization of laboratory particulate matter (PM) mass setups for brake emission measurements. Atmosphere 2023, 14, 516. [Google Scholar] [CrossRef]

- Mathissen, M.; Grigoratos, T.; Lahde, T.; Vogt, R. Brake wear particle emissions of a passenger car measured on a chassis dynamometer. Atmosphere 2019, 10, 556. [Google Scholar] [CrossRef]

- Kwak, J.-h.; Kim, H.; Lee, J.; Lee, S. Characterization of non-exhaust coarse and fine particles from on-road driving and laboratory measurements. Sci. Total Environ. 2013, 458–460, 273–282. [Google Scholar]

- Oroumiyeh, F.; Zhu, Y. Brake and tire particles measured from on-road vehicles: Effects of vehicle mass and braking intensity. Atmos. Environ. X 2021, 12, 100121. [Google Scholar] [CrossRef]

- Grigoratos, T.; Martini, G. Brake wear particle emissions: A review. Environ. Sci. Pollut. Res. 2015, 22, 2491–2504. [Google Scholar] [CrossRef]

- Feo, M.L.; Torre, M.; Tratzi, P.; Battistelli, F.; Tomassetti, L.; Petracchini, F.; Guerriero, E.; Paolini, V. Laboratory and on-road testing for brake wear particle emissions: A review. Environ. Sci. Pollut. Res. 2023, 30, 100282–100300. [Google Scholar] [CrossRef]

- Woo, S.H.; Kim, Y.; Lee, S.; Choi, Y.; Lee, S. Characteristics of brake wear particle (BWP) emissions under various test driving cycles. Wear 2021, 480, 203936. [Google Scholar] [CrossRef]

- Seo, H.; Joo, B.; Park, J.; Kim, Y.C.; Lee, J.J.; Jang, H. Effect of disc material on particulate matter emissions during high-temperature braking. Tribol. Int. 2021, 154, 106713. [Google Scholar] [CrossRef]

- Lyu, Y.; Leonardi, M.; Wahlström, J.; Gialanella, S.; Olofsson, U. Friction, wear and airborne particle emission from Cu-free brake materials. Tribol. Int. 2020, 141, 105959. [Google Scholar] [CrossRef]

- Kim, S.H.; Jeong, M.H.; Kim, J.; Shim, W.; Kwon, S.U.; Lee, J.-J.; Huh, S.H.; Pee, J.-H.; Kim, J.Y. Dynamometric investigation on airborne particulate matter (Pm) from friction materials for automobile: Impact of abrasive and lubricant on pm emission factor. Lubricants 2021, 9, 118. [Google Scholar] [CrossRef]

- Zhang, Q.; Fang, T.; Men, Z.; Wei, N.; Peng, J.; Du, T.; Zhang, X.; Ma, Y.; Wu, L.; Mao, H. Direct measurement of brake and tire wear particles based on real-world driving conditions. Sci. Total Environ. 2024, 906, 167764. [Google Scholar] [CrossRef]

- Beji, A.; Deboudt, K.; Muresan, B.; Khardi, S.; Flament, P.; Fourmentin, M.; Lumiere, L. Physical and chemical characteristics of particles emitted by a passenger vehicle at the tire-road contact. Chemosphere 2023, 340, 139874. [Google Scholar] [CrossRef]

- Sommer, F.; Dietze, V.; Baum, A.; Sauer, J.; Gilge, S.; Maschowski, C.; Gieré, R. Tire abrasion as a major source of microplastics in the environment. Aerosol Air Qual. Res. 2018, 18, 2014–2028. [Google Scholar] [CrossRef]

- Guo, Q.; Men, Z.; Liu, Z.; Niu, Z.; Fang, T.; Liu, F.; Wu, L.; Peng, J.; Mao, H. Chemical characteristics of fine tire wear particles generated on a tire simulator. Environ. Pollut. 2023, 336, 122399. [Google Scholar] [CrossRef]

- Fussell, J.C.; Franklin, M.; Green, D.C.; Gustafsson, M.; Harrison, R.M.; Hicks, W.; Kelly, F.J.; Kishta, F.; Miller, M.R.; Mudway, I.S.; et al. A Review of Road Traffic-Derived Non-Exhaust Particles: Emissions, Physicochemical Characteristics, Health Risks, and Mitigation Measures. Environ. Sci. Technol. 2022, 56, 6813–6835. [Google Scholar] [CrossRef]

- Milad, A.; Ali, A.S.B.; Babalghaith, A.M.; Memon, Z.A.; Mashaan, N.S.; Arafa, S.; Yusoff, N.I.M. Utilisation of waste-based geopolymer in asphalt pavement modification and construction—A review. Sustainability 2021, 13, 3330. [Google Scholar] [CrossRef]

- Bae, S.H.; Chae, E.; Park, Y.S.; Lee, S.W.; Yun, J.H.; Choi, S.S. Characteristics of tire-road wear particles (TRWPs) and road pavement wear particles (RPWPs) generated through a novel tire abrasion simulator based on real road pavement conditions. Sci. Total Environ. 2024, 944, 173948. [Google Scholar] [CrossRef] [PubMed]

- Murph, D.; Liu, J.; Liu, J. Designs of abrasion resistant and durable concrete pavements made with SCMs for cold climates. J. Transp. Eng. Part B Pavements 2022, 148, 04022017. [Google Scholar] [CrossRef]

- Gustafsson, M.; Blomqvist, G.; Gudmundsson, A.; Dahl, A.; Swietlicki, E.; Bohgard, M.; Lindbom, J.; Ljungman, A. Properties and toxicological effects of particles from the interaction between tyres, road pavement and winter traction material. Sci. Total Environ. 2008, 393, 226–240. [Google Scholar] [CrossRef]

- Fiala, M.; Hwang, H.M. Influence of highway pavement on metals in road dust: A case study in Houston, Texas. Water Air Soil Pollut. 2021, 232, 185. [Google Scholar] [CrossRef]

- Kreider, M.L.; Panko, J.M.; McAtee, B.L.; Sweet, L.I.; Finley, B.L. Physical and chemical characterization of tire-related particles: Comparison of particles generated using different methodologies. Sci. Total Environ. 2010, 408, 652–659. [Google Scholar] [CrossRef]

- Ambient Air—Determination of the Mass Concentration of Tire and Road Wear Particles (TRWP)—Pyrolysis-GC-MS Method. Available online: https://www.iso.org/standard/68470.html (accessed on 5 August 2024).

- Charbouillot, T.; Cettour Janet, D.; Schaal, P.; Beynier, I.; Boulat, J.-M. Methodology for the direct measurement of tire emission factors. Sci. Total Environ. 2023, 863, 160853. [Google Scholar] [CrossRef] [PubMed]

- Park, I.; Kim, H.; Lee, S. Characteristics of tire wear particles generated in a laboratory simulation of tire/road contact conditions. J. Aerosol Sci. 2018, 124, 30–40. [Google Scholar] [CrossRef]

- Woo, S.H.; Jang, H.; Mun, S.H.; Lim, Y.; Lee, S. Effect of treadwear grade on the generation of tire PM emissions in laboratory and real-world driving conditions. Sci. Total Environ. 2022, 838, 156548. [Google Scholar] [CrossRef]

- Yan, H.; Zhang, L.; Liu, L.; Wen, S. Investigation of the external conditions and material compositions affecting the formation mechanism and size distribution of tire wear particles. Atmos. Environ. 2021, 244, 118018. [Google Scholar] [CrossRef]

- Xuan, S.; Huang, H.; Liu, J.; Liu, Q.; Lu, X. Investigation of tire wear particle paths based on analytical method. China Mech. Eng. 2017, 28, 1002–1007. [Google Scholar]

- Cho, J.R.; Choi, J.H.; Kim, Y.S. Abrasive wear amount estimate for 3D patterned tire utilizing frictional dynamic rolling analysis. Tribol. Int. 2011, 44, 850–858. [Google Scholar] [CrossRef]

- Pirjola, L.; Kupiainen, K.J.; Perhoniemi, P.; Tervahattu, H.; Vesala, H. Nonexhaust emission measurement system of the mobile laboratory SNIFFER. Atmos. Environ. 2009, 43, 4703–4713. [Google Scholar] [CrossRef]

- Tonegawa, Y.; Sasaki, S. Development of tire-wear particle emission measurements for passenger vehicles. Emiss. Control. Sci. Technol. 2021, 7, 56–62. [Google Scholar] [CrossRef]

- Kim, G.; Lee, S. Characteristics of tire wear particles generated by a tire simulator under various driving conditions. Environ. Sci. Technol. 2018, 52, 12153–12161. [Google Scholar] [CrossRef]

- Etyemezian, V.; Kuhns, H.; Gillies, J.; Green, M.; Pitchford, M.; Watson, J. Vehicle based road dust emission measurement: I—methods and calibration. Atmos. Environ. 2003, 37, 4559–4571. [Google Scholar] [CrossRef]

- Park, I.; Lee, J.; Lee, S. Laboratory study of the generation of nanoparticles from tire tread. Aerosol. Sci. Technol. 2017, 51, 188–197. [Google Scholar] [CrossRef]

- Milani, M.; Pucillo, F.P.; Ballerini, M.; Camatini, M.; Gualtieri, M.; Martino, S. First evidence of tyre debris characterization at the nanoscale by focused ion beam. Mater. Charact. 2004, 52, 283–288. [Google Scholar] [CrossRef]

- ADAC. Tyre Wear Particles in the Environment. 2021. Available online: https://assets.adac.de/image/upload/v1639663105/ADAC-eV/KOR/Text/PDF/Tyre_wear_particles_in_the_environment_zkmd3a.pdf (accessed on 5 August 2024).

- Pohrt, R. Tire wear particle hot spots—Review of influencing factors. Facta Univ. Mech. Eng. 2019, 17, 17–27. [Google Scholar] [CrossRef]

- Councell, T.B.; Duckenfield, K.U.; Landa, E.R.; Callender, E. Tire-wear particles as a source of zinc to the environment. Environ. Sci. Technol. 2004, 38, 4206–4214. [Google Scholar] [CrossRef]

- Mennekes, D.; Nowack, B. Tire wear particle emissions: Measurement data where are you? Sci. Total Environ. 2022, 830, 154655. [Google Scholar] [CrossRef]

- Grigoratos, T.; Gustafsson, M.; Eriksson, O.; Martini, G. Experimental investigation of tread wear and particle emission from tyres with different treadwear marking. Atmos. Environ. 2018, 182, 200–212. [Google Scholar] [CrossRef]

- Candeias, C.; Vicente, E.; Tome, M.; Rocha, F.; Ávila, P.; Alves, C. Geochemical, mineralogical and morphological characterization of road dust and associated health risks. Int. J. Environ. Res. Public Health 2020, 17, 1563. [Google Scholar] [CrossRef] [PubMed]

- Thorpe, A.J.; Harrison, R.M.; Boulter, P.G.; McCrae, I.S. Estimation of particle resuspension source strength on a major London Road. Atmos. Environ. 2007, 41, 8007–8020. [Google Scholar] [CrossRef]

- Gustafsson, M.; Blomqvist, G.; Järlskog, I.; Lundberg, J.; Janhäll; Elmgren, M.; Johansson, C.; Norman, M.; Silvergren, S. Road dust load dynamics and influencing factors for six winter seasons in Stockholm, Sweden. Atmos. Environ. X 2019, 2, 100014. [Google Scholar] [CrossRef]

- Querol, X.; Perez, N.; Reche, C.; Ealo, M.; Ripoll, A.; Tur, J.; Pandolfi, M.; Pey, J.; Salvador, P.; Moreno, T.; et al. African dust and air quality over Spain: Is it only dust that matters? Sci. Total Environ. 2019, 686, 737–752. [Google Scholar] [CrossRef]

- Khan, R.K.; Strand, M.A. Road dust and its effect on human health: A literature review. Epidemiol. Health 2018, 40, e2018013. [Google Scholar] [CrossRef]

- USEPA. AP 42 Section 13.2.1 Paved Roads—Related Information. Emissions and Correction Parameters; US Environmental Protection Agency: Washington, DC, USA, 2003.

- Fitz, D.R.; Bumiller, K.; Etyemezian, V.; Kuhns, H.D.; Gillies, J.A.; Nikolich, G.; James, D.E.; Langston, R.; Merle, R.S. Real-time PM10 emission rates from paved roads by measurement of concentrations in the vehicle’s wake using on-board sensors Part 2. Comparison of SCAMPER, TRAKER™, flux measurements, and AP-42 silt sampling under controlled conditions. Atmos. Environ. 2021, 256, 118453. [Google Scholar] [CrossRef]

- Jancsek-Turoczi, B.; Hoffer, A.; Nyíro-Kosa, I.; Gelencser, A. Sampling and characterization of resuspended and respirable road dust. J. Aerosol Sci. 2013, 65, 69–76. [Google Scholar] [CrossRef][Green Version]

- Amato, F.; Pandolfi, M.; Viana, M.; Querol, X.; Alastuey, A.; Moreno, T. Spatial and chemical patterns of PM10 in road dust deposited in urban environment. Atmos. Environ. 2009, 43, 1650–1659. [Google Scholar] [CrossRef]

- Amato, F.; Karanasiou, A.; Moreno, T.; Alastuey, A.; Orza, J.A.G.; Lumbreras, J.; Borge, R.; Boldo, E.; Linares, C.; Querol, X. Emission factors from road dust resuspension in a Mediterranean freeway. Atmos. Environ. 2012, 61, 580–587. [Google Scholar] [CrossRef]

- Escrig, A.; Amato, F.; Pandol, M.; Monfort, E.; Querol, X.; Celades, I.; Sanfélix, V.; Alastuey, A.; Orza, J.A.G. Simple estimates of vehicle-induced resuspension rates. J. Environ. Manag. 2011, 92, 2855–2859. [Google Scholar] [CrossRef]

- Bukowiecki, N.; Lienemann, P.; Hill, M.; Furger, M.; Richard, A.; Amato, F.; Prevot, A.S.H.; Baltensperger, U.; Buchmann, B.; Gehrig, R. PM10 emission factors for non-exhaust particles generated by road traffic in an urban street canyon and along a freeway in Switzerland. Atmos. Environ. 2010, 44, 2330–2340. [Google Scholar] [CrossRef]

- Amato, F.; Nava, S.; Lucarelli, F.; Querol, X.; Alastuey, A.; Baldasano, J.M.; Pandolfi, M. A comprehensive assessment of PM emissions from paved roads: Real-world Emission Factors and intense street cleaning trials. Sci. Total Environ. 2010, 408, 4309–4318. [Google Scholar] [CrossRef] [PubMed]

- Amato, F.; Favez, O.; Pandolfi, M.; Alastuey, A.; Querol, X.; Moukhtar, S.; Bruge, B.; Verlhac, S.; Orza, J.A.G.; Bonnaire, N.; et al. Traffic induced particle resuspension in Paris: Emission factors and source contributions. Atmos. Environ. 2016, 129, 114–124. [Google Scholar] [CrossRef]

- Chen, J.; Zheng, H.; Wang, W.; Liu, H.; Lu, L.; Bao, L.; Ren, L. Resuspension method for road surface dust collection and aerodynamic size distribution characterization. China Particuology 2006, 4, 300–303. [Google Scholar] [CrossRef]

- Kasimov, N.S.; Vlasov, D.V.; Kosheleva, N.E. Enrichment of road dust particles and adjacent environments with metals and metalloids in eastern Moscow. Urban Clim. 2020, 32, 100638. [Google Scholar] [CrossRef]

- Lundberg, J.; Gustafsson, M.; Janhäll, S.; Eriksson, O.; Blomqvist, G.; Erlingsson, S. Temporal Variation of Road Dust Load and Its Size Distribution-a Comparative Study of a Porous and a Dense Pavement. Water Air Soil Pollut. 2020, 231, 561. [Google Scholar] [CrossRef]

- Alves, C.A.; Vicente, E.D.; Vicente, A.M.P.; Rienda, I.C.; Tomé, M.; Querol, X.; Amato, F. Loadings, Chemical Patterns and Risks of Inhalable Road Dust Particles in an Atlantic City in the North of Portugal. Sci. Total Environ. 2020, 737, 139596. [Google Scholar] [CrossRef]

- Amato, F.; Pandolfi, M.; Moreno, T.; Furger, M.; Pey, J.; Alastuey, A.; Bukowiecki, N.; Prevot, A.; Baltensperger, U.; Querol, X. Sources and variability of inhalable road dust particles in three European cities. Atmos. Environ. 2011, 45, 6777–6787. [Google Scholar] [CrossRef]

- Padoan, E.; Ajmone-Marsan, F.; Querol, X.; Amato, F. An empirical model to predict road dust emissions based on pavement and traffic characteristics. Environ. Pollut. 2018, 237, 713–720. [Google Scholar] [CrossRef] [PubMed]

- Mathissen, M.; Scheer, V.; Kirchner, U.; Vogt, R.; Benter, T. Non-exhaust PM emission measurements of a light duty vehicle with a mobile trailer. Atmos. Environ. 2012, 59, 232–242. [Google Scholar] [CrossRef]

- Zhang, J.; Peng, J.; Song, C.; Ma, C.; Men, Z.; Wu, J.; Wu, L.; Wang, T.; Zhang, X.; Tao, S.; et al. Vehicular non-exhaust particulate emissions in Chinese megacities: Source profiles, real-world emission factors, and inventories. Environ. Pollut. 2020, 266, 115268. [Google Scholar] [CrossRef] [PubMed]

- Alshetty, D.; Nagendra, S. Impact of vehicular movement on road dust resuspension and spatiotemporal distribution of particulate matter during construction activities. Atmos. Pollut. Res. 2022, 13, 101256. [Google Scholar] [CrossRef]

- Rienda, I.C.; Nunes, T.; Gonçalves, C.; Vicente, A.; Amato, F.; Lucarelli, F.; Kovats, N.; Hubai, K.; Sainnokhoi, T.A.; Alves, C.A. Road dust resuspension in a coastal Atlantic intermunicipal urban area with industrial facilities: Emission factors, chemical composition and ecotoxicity. Atmos. Res. 2023, 294, 106977. [Google Scholar] [CrossRef]

- Bourliva, A.; Christophoridis, C.; Papadopoulou, L.; Giouri, K.; Papadopoulos, A.; Mitsika, E.; Fytianos, K. Characterization, heavy metal content and health risk assessment of urban road dusts from the historic center of the city of Thessaloniki, Greece. Environ. Geochem. Health 2017, 39, 611–634. [Google Scholar] [CrossRef]

- Polukarova, M.; Markiewicz, A.; Bjorklund, K.; Stromvall, A.M.; Galfi, H.; Andersson Skold, Y.; Gustafsson, M.; Järlskog, I.; Aronsson, M. Organic pollutants, nano and microparticles in street sweeping road dust and washwater. Environ. Int. 2020, 135, 105337. [Google Scholar] [CrossRef] [PubMed]

- Jarlskog, I.; Stromvall, A.M.; Magnusson, K.; Galfi, H.; Bjorklund, K.; Polukarova, M.; Garçao, R.; Markiewicz, A.; Aronsson, M.; Gustafsson, M.; et al. Traffic-related microplastic particles, metals, and organic pollutants in an urban area under reconstruction. Sci. Total Environ. 2021, 774, 145503. [Google Scholar] [CrossRef]

| Reference | Environment/Sampling System | Results |

|---|---|---|

| Woo et al., 2021 [28] | Sealed experimental chamber for brake dyno Gravimetric method closed system | 0.294 mg/km/brake per WLTC; 0.221 mg/km/brake per NEDC; 0.161 mg/km/brake per FTP; 0.251 mg/km/brake per 3h-LACT; 0.113 mg/km/brake per WLTP-B |

| Mathissen et al., 2019 [23] | Chassis dyno Semi-closed system | PN = 7 × 109 pt/km (EEPS w/o catalytic stripper); PN = 3 × 109 pt/km (CPC with catalytic stripper) |

| Zum Hagen, 2019 [20] | On road tests Semi-closed system | 1.8–2.1 mg/km/brake (cast iron disc); 1.4–1.7 mg/km/brake (cast iron disc with WC-CoCr) |

| Seo et al., 2019 [29] | Sealed experimental chamber for brake dyno closed system | 3.0 × 107–5.0 × 107 pt/cm3 (range 6 nm–10 μm) |

| Perricone et al., 2019 [8] | Sealed experimental chamber for brake dyno | PN = 1010 pt/block (cold) PN = 108 pt/block (warm) |

| Lyu et al., 2020 [30] | pin-on-disc system closed system | 0.75 mg/m3 (Cu-full); 0.9–1.2 mg/m3 (Cu-free) |

| Kim et al., 2021 [31] | Sealed experimental chamber for brake dyno closed system | 4.37–14.41 mg/kg/vehicle |

| Oroumiyeh et al., 2021 [25] | On road tests open system | Heaviest vehicle: 950–8420 μg/m3 per PM10 520–4280 μg/m3 per PM2.5 Lightest vehicle: 430–3890 μg/m3 per PM10 250–2440 μg/m3 per PM2.5 |

| Zhang et al., 2024 [32] | Sealed experimental chamber for brake dyno On-road acquisition of the 6-wheel forces, GPS, accelerometer and brake temperature | PM10: 61–72% in mass loss 2.66 mg/km PM2.5 11.65 mg/km PM10 |

| Reference | Environment/Sampling System | Results |

|---|---|---|

| Charbouillot et al., 2023 [44] | Track Isokinetic sampling behind the driving wheel with 3 vertically aligned nozzles | PM10: 1.1–4.1% (on mass loss) PM2.5: 0.1–0.2% (on mass loss) |

| Zhang et al., 2024 [32] | On-road acquisition of the 6 wheel forces, laboratory reproduction with a wheel dynamometer Constant volume sampling at the tire-ring contact point. System enclosed in a semi-open chamber | 0.21 mg/km PM2.5 1.27 mg/km PM10 |

| Grigoratos et al., 2018 [60] | Laboratory tests Circular road simulator, cooled (max speed 70 km/h) | Mass losses between 55 and 214 mg/km_veh PM10 20–50 microg/m3 (50% PM2.5) |

| Guo et al., 2023 [35] | On-road acquisition of speed and wheel forces, laboratory reproduction with a wheel dynamometer | Silicon: PM2.5 7%w Zn: PM2.5 0.7%w The main component is organic carbon, followed by inorganic elements and water-soluble ions. Pyrene is the dominant polycyclic aromatic |

| Yan et al., 2021 [47] | Laboratory tests. Wheel dyno. System enclosed in a flow-controlled chamber | 0:040–0.1040 mg/km |

| Tonegawa, Sasaki, 2021 [51] | On-road tests | Tire wear: 3.7 mg/km-veh (of which 3–4%w consists of PM10 and PM2.5) PM10: 0.4–1.7 mg/km |

| Park et al., 2018 [45] | Laboratory tests. Wheel dyno. System enclosed in a flow-controlled chamber | PM10: 0.055–0.222 mg/km PM2.5: 0.029–0.051 mg/km |

| Kim et al., 2018 [52] | Laboratory tests. Wheel dyno. System enclosed in a flow-controlled chamber | PM10: 0.0002–0.066 mg/km PM2.5: 0.0001–0.036 mg/km |

| Pirjola et al., 2009 [50] | On-road tests. Isokinetic sampling at constant volume | PM10: 0.060–5.3 mg/m3 |

| Woo et al., 2022 [46] | Laboratory tests. Wheel dyno; On-road tests. Isokinetic sampling at constant volume | 0.91–1.34 mg/vkm PM10 0.1–0.38 mg/vkm PM2.5 3.12–3.95 × 1013 pt/vkm 45–95 mg/km a 110 km/h on track (resuspended particulates included) 2–4% of that is attributable to tires (7–16 µg/m3 PM10 1.4–2.8 µg/m3 PM2.5) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Costagliola, M.A.; Marchitto, L.; Giuzio, R.; Casadei, S.; Rossi, T.; Lixi, S.; Faedo, D. Non-Exhaust Particulate Emissions from Road Transport Vehicles. Energies 2024, 17, 4079. https://doi.org/10.3390/en17164079

Costagliola MA, Marchitto L, Giuzio R, Casadei S, Rossi T, Lixi S, Faedo D. Non-Exhaust Particulate Emissions from Road Transport Vehicles. Energies. 2024; 17(16):4079. https://doi.org/10.3390/en17164079

Chicago/Turabian StyleCostagliola, Maria Antonietta, Luca Marchitto, Rocco Giuzio, Simone Casadei, Tommaso Rossi, Simone Lixi, and Davide Faedo. 2024. "Non-Exhaust Particulate Emissions from Road Transport Vehicles" Energies 17, no. 16: 4079. https://doi.org/10.3390/en17164079

APA StyleCostagliola, M. A., Marchitto, L., Giuzio, R., Casadei, S., Rossi, T., Lixi, S., & Faedo, D. (2024). Non-Exhaust Particulate Emissions from Road Transport Vehicles. Energies, 17(16), 4079. https://doi.org/10.3390/en17164079