1. Introduction

Energy consumption has considerably increased due to the widespread use of technology in daily life and the increase in the global population [

1]. The use of energy is still increasing, and fossil fuels are the main energy source. It has been predicted that these fossil resources will be used up in approximately 100 years [

2]. Burning fossil fuels has increased the concentration of CO

2 in the atmosphere, which has directly affected global warming [

3]. Scholars have referred to the negative environmental impacts of fossil fuels and have stated that such resources are limited and not sustainable for generating energy [

4]. Recently, researchers studying energy supply have focused on sustainable energy sources [

5]. One alternative that several studies have proposed is to substitute fossil fuels with biomass [

6].

The development of the forest sector is hardly surprising, given the increase in global demand for forestry goods over the past few decades. The global forest sector generates an estimated USD 1,600,000 million in revenue annually, or 2–3% of the GDP. Nevertheless, the current state of the economy, alterations in climate, energy, and environmental regulation and sharp shifts in demand have all contributed to the industry’s growth [

5]. A combination never seen in the contemporary history of the global economy, COVID-19 in late 2019 and early 2020 caused a global recession, a worldwide health crisis, and uncertainty that is still evolving with new virus variations at the time of publishing [

5]. Cycles of investment in the sector and consumer demand are stopped by the uncertainty the virus brings to society. Due to travel restrictions, the reduced mobility of labor, commodities, and services has impacted the mix of energy sources, resulting in a significant decrease in the usage of fossil fuels and a decrease in the industry’s need for electricity [

5].

Many countries have recently joined a movement to utilize biomass instead of fossil fuels to produce energy. According to the active proponents of this movement, biomass is the best substitute for fossil fuels, and the most important reason is its renewability as a source of energy. Biomass can generate power in various fields, from small-scale heating of stores to large-scale production of power or combined heat and power (CHP) for public places [

6]. Numerous countries, such as the United States, Malaysia, and several European countries, have recently attempted to develop innovative biomass production technologies and procedures for their commercialization [

7]. All these attempts and efforts have been made to reduce human dependence on fossil fuels by replacing them with biomass fuels. Biomass can be obtained from oil crops and materials like sugar and animal manure derived from plants [

8].

The biomass sector is important to the social and economic growth of many nations because it affects and involves certain communities and regions [

9]. The sustainability approach is a crucial idea that needs to be considered when designing supply chains. Its three primary components are the social, environmental, and economic aspects [

9]. This research aims to maximize profits, minimize environmental pollutants, maximize employment, and minimize unemployment by assessing all three aspects of supply chain management in the forest business [

9]. Therefore, researchers and industry must search for solutions to overcome difficulties in planning a sustainable biomass supply chain (BSC). Tactical, operational, and strategic levels can be considered when planning BSCs. Regarding strategic planning, researchers have proposed several mathematical programming models. Previous studies have also suggested many tactical models for designing supply chains (SCs) that consider decisions related to medium-term production planning, logistics management, and inventory control. However, operational-level models are mostly used for short-term tasks, such as transportation scheduling and routing. Zahraee et al. [

10] conducted a comprehensive literature review on this topic. They found that the mixed-integer linear programming (MILP) technique is most frequently applied to BSC problems to minimize cost. Most of the studies reviewed in the literature concentrated on developing separate operational, tactical, and strategic optimization models. To date, no study has tried to integrate different models.

Sustainable BSC is another important area where economic, environmental, and social objectives must be considered simultaneously. The economic aspect involves the maximization of profits using biofuel SCs. GHG emissions resulting from the delivery of raw materials from supply sources, pretreatment facilities, bio-refinery plants, and demand zones are the topics of environmental sustainability. From a social perspective, sustainability means maximizing social benefits through a specified investment threshold. Previous studies often focused on generating either biomass or biofuel separately. The aim of environmental optimization is to minimize three variables: (1) GHG emission volumes [

11], (2) environmental footprints [

12,

13], and (3) overall environmental factors based on the lifecycle assessment approach [

14]. Only a few studies have integrated social criteria for optimizing biofuel and bioenergy SCs. The locations of biofuel and bioenergy plants that consume residual biomass are often in remote areas; thus, building such plants can motivate community development by creating many new jobs [

15]. Therefore, labor force employment can have a significant social impact on novel biofuel and bioenergy projects [

10].

Generally, optimization techniques and algorithms deliver either exact or approximate solutions. The exact solutions can be found using commercial solvers and exact solution algorithms. However, these methods cannot handle complex optimization problems. BSC models lack multi-objective and multi-period techniques. The most well-known meta-heuristic algorithm in BSC optimization is the Genetic algorithm (GA). A special optimization algorithm applies natural evolution methods, like heredity and mutation, to approximate solutions and optimizations [

10]. Other promising approaches for solving complex optimization problems include evolutionary algorithms such as relaxation methods, decomposition, and meta-heuristics. Likewise, optimization methods have already been applied successfully in industrial logistics but are yet to be used in biomass optimization. Some examples of those algorithms are multi-objective metaheuristics and simulation-based optimization, such as non-dominated sorting genetic algorithm II (NSGA-II) and multi-objective particle swarm optimization algorithm (MOPSO) [

10].

This study aims to implement the NSGA-II and MOPSO approaches to biomass supply optimization, considering the three sustainability pillars. Specifically, this study develops a multi-objective mathematical model with the following goals:

To minimize logistics and transportation costs (the economic pillar)

To minimize environmental emissions from transportation and production (the environmental pillar)

To promote job creation (the social pillar)

Eventually, a multi-criteria decision technique to find preferences by similarity to the ideal solution (TOPSIS) was applied to determine the trade-off of the optimum design points obtained through optimization algorithm solutions with two-objective problems. The novel model developed in this paper will be tested in Malaysia’s palm oil biomass industry. It is to be noted that Malaysia is the second largest supplier of palm oil biomass in the world [

16].

The remainder of this paper is structured as follows.

Section 2 reviews previous studies on BSC and optimization methods. The same section also discusses pertinent BSC optimization techniques and sustainability pillars in BSC design and planning, encompassing tactical, operational, and strategic decision levels. The research design and methodology are discussed in

Section 3.

Section 4 discusses the creation of a multi-objective mathematical optimization model to maximize profit and reduce BSC emissions.

Section 4 also presents the model’s application to the palm oil biomass industry and discusses the findings. The final section includes recommendations for more research and the study’s conclusions, contributions, and limitations.

3. Research Methodology and Case Study

3.1. Multi-Objective Optimization Algorithms

Most real-life optimization problems involve multiple objectives that need to be accomplished, and in many cases, these objectives are conflicting. This problem is generally referred to as multi-objective optimization (MOO). Attempts to solve such problems generally lead to multiple optimal solutions that provide a trade-off among all objectives. Metaheuristic algorithms proposed in the past two decades have improved the conditions in favor of more effective solutions to MOO problems. Four key examples of such algorithms are the Genetic Algorithm (GA) [

70], particle swarm optimization (PSO) [

71], ant colony optimization [

72], and simulated annealing [

73]. Even with their high effectiveness in solving MOO problems, the application of these algorithms has faced several obstacles, such as slow convergence speed, premature convergence, complicated algorithmic structures, and the need to tune a number of parameters [

74]. As a result, it is critically important for the academic community to develop a metaheuristic algorithm with a simple structure and the ability to escape premature convergence and, concurrently, demonstrate fast convergence speed.

After the problem has been formulated, its difficulty and complexity must be measured. Because exact methods are not applicable to solving large-scale problems of multi-objective MILP, metaheuristic algorithms can be used to find effective solutions to large-scale and real-size problems. Metaheuristic algorithms are of great benefit to users. Among the most crucial aspects of such systems is their capacity to stay out of local optima when seeking workable solutions. Furthermore, these algorithms search for efficient solutions to optimization problems when the difficulty of the problem or the time constraint prevents the application of precise optimization techniques.

When designing a metaheuristic algorithm, two common issues must be considered [

75]. First, parameters that strongly influence search effectiveness and efficiency must be calibrated. Tuning the parameter could improve robustness and flexibility; nevertheless, it must be initialized cautiously. In these models, there are no obvious existing priori to be defined for setting parameters; however, obtaining optimized parameter values is greatly dependent on the search time allocated to solve the problem. It should be noted that no set of optimal parameter values can be used for every metaheuristic algorithm. Second, a fair evaluation of the metaheuristic performance is required. Three steps need to be considered in this evaluation:

Measurement (e.g., gauging the solution’s quality)

Experimental design (e.g., the factors and instances chosen; the goals of the experiments carried out)

Reporting (e.g., box plots)

3.2. Optimization Approach

3.2.1. Non-Dominated Sorting Genetic Algorithm-II

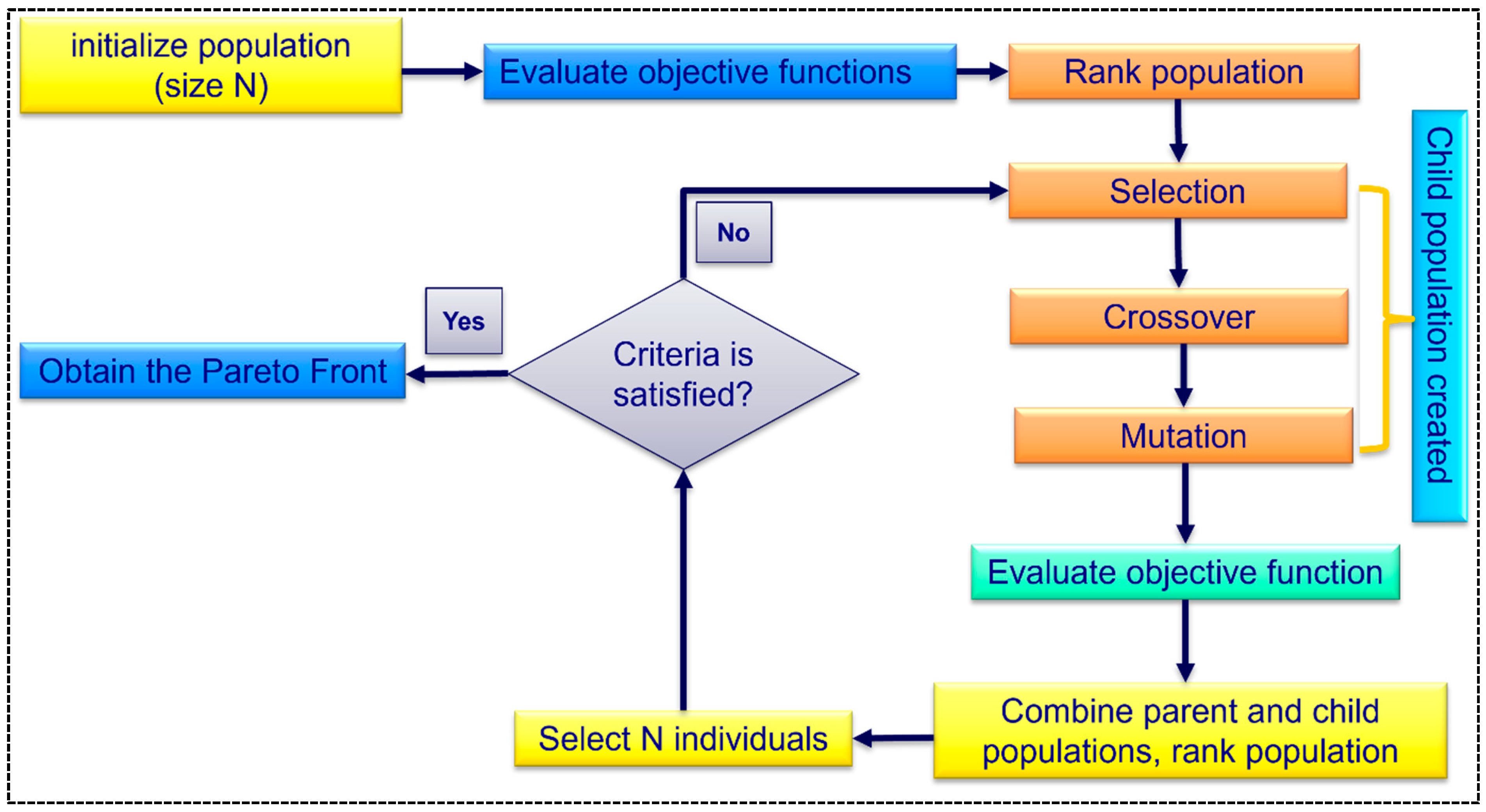

Deb et al. [

76] introduced the NSGA-II as a powerful engine that can be used to explore decision spaces based on GAs to address MOO challenges. Since its release in 2000, NSGA-II has been used by numerous researchers to address various search and optimization issues. NSGA-II is one of the most popular techniques for creating Pareto borders [

77]. The first random population of non-deterministic polynomial time (NP) chromosomes (solutions) size is generated to initiate NSGA II. The population’s objective values are then assessed over several generations using an assessment function. In the following step, The population is sorted using a non-domination sorting form to arrange several Pareto fronts of non-dominated solutions. The population being assessed is divided into groups according to the non-dominant nature of each member. The highest level is indicated by rank 1 in this ranking system, and the second-best level is indicated by rank 2, and so on. Moreover, the individuals with the lowest ranking show the first front, followed by individuals with the second lowest ranking, who show the second front, and so on.

Our testing design project is a prime example of excellence because of the carefully planned testing protocols. The selected tests are appropriate and thorough, guaranteeing that every facet of the design has been thoroughly examined. The design choice has undergone rigorous refinement to the point where it is ready for client delivery, with noticeable improvements in the version. A sorting process is applied to the newly formed population members, and a population with a precise Np size is selected. Two sortings are performed on the solutions in this process: a first sort based on the solutions’ crowding distances (descending order) and a second sort based on ranks (ascending order). The previous procedures were repeated using the new population to develop novel sequential offspring. Until the termination requirement is met, this process is repeated.

In the end, a group of Pareto-optimal, non-dominated solutions is found. For MOO, any solution is optimal.

Figure 1 outlines the NSGA II procedure. For a more detailed explanation of the use of NSGA-II, see Deb et al. [

76].

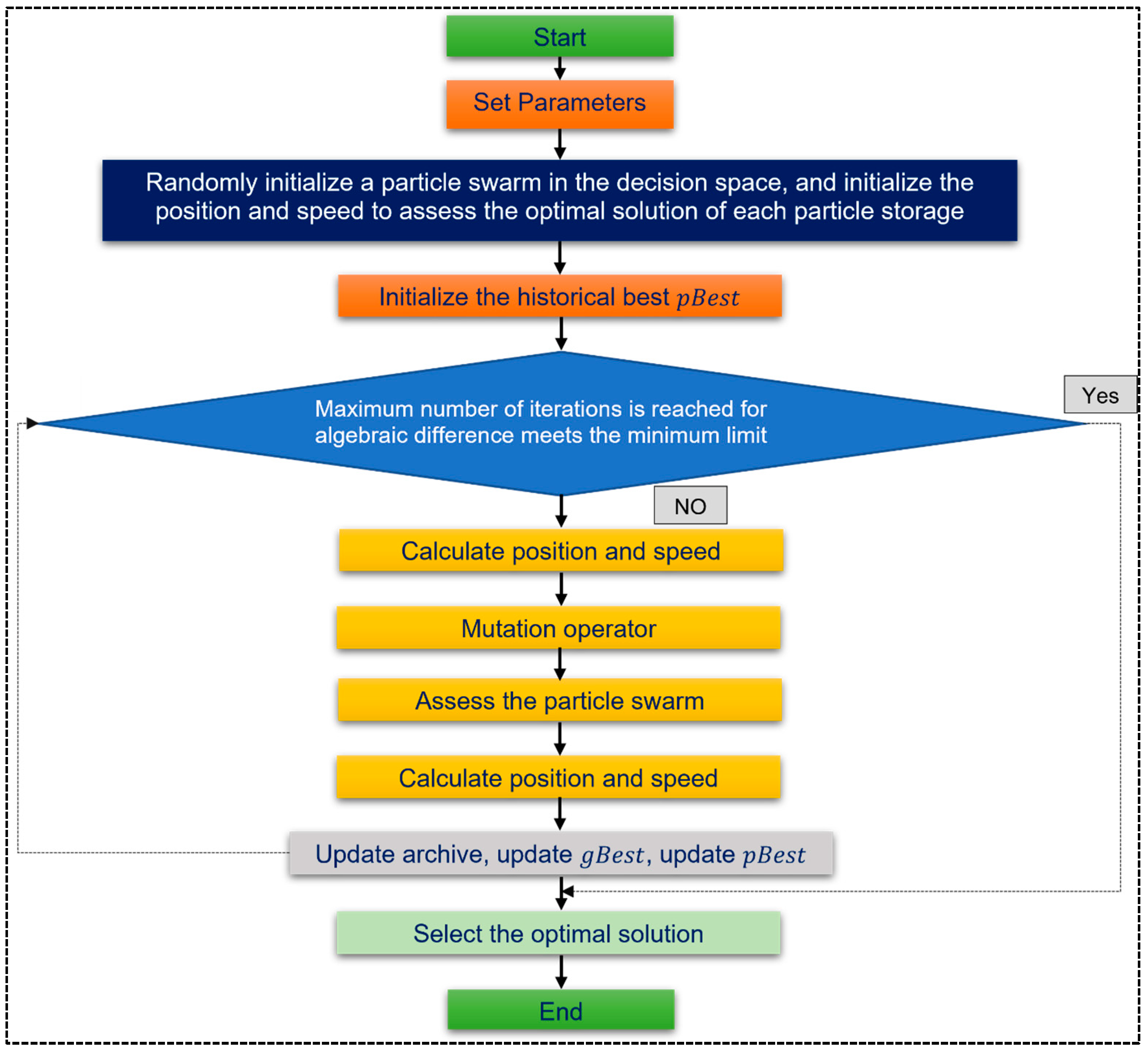

3.2.2. Multi-Objective Particle Swarm Optimization Algorithm

PSO is a widely employed metaheuristic algorithm that is primarily inspired by nature. Many researchers have applied PSO to solving single-objective and MOO problems over the past two decades [

78]. PSO was pioneered approximately a decade ago by Kennedy and Eberhart [

71] and has been employed in many global and local search strategies and learning and parameter adaptation approaches to enhance performance. These approaches often lead to an increased number of algorithmic steps and user-defined parameters, which has caused PSO to become more complex. It is, in fact, a stochastic, population-based optimization algorithm that imitates the social behaviors of a flock of birds. PSO was initially introduced to solve single-objective optimization problems. Subsequently, numerous scholars have attempted to develop it and apply it to MOO problems [

79,

80]. Moore [

81] was the first to attempt this objective using the Pareto dominance concept to generate the best solutions to guide the search. MOPSO was then developed by Coello and Lechuga [

82] using a geography-based approach and external memory to preserve diversity. Subsequently, different researchers developed multiple variants of MOPSO. Many studies have aimed to enhance the choice of optimal global and personal solutions for MOO problems. To find the best global solution from nondominated solutions, the authors of [

83] used a roulette wheel selection method. On the other hand, Liu et al. [

84] used a tournament niche strategy to determine the best global solution and then revised local optimum solutions using the Pareto dominance concept. Improving the convergence of the global Pareto-optimal front solution in objective space while maintaining sufficient diversity is a major challenge in this field.

Several studies using MOPSO [

85,

86,

87] have focused on this issue. In standard PSO, both the current global best

and the individual best

are used at iteration

. The individual best is employed to augment the diversity in quality solutions; this diversity could be simulated using randomness. Thus, the individual best must be used in cases where the optimization problem is highly nonlinear and multimodal. In comparison to PSO, once MOPSO selects the

pBest, the latter randomly selects one of them as the historical best when there is no condition for making a strict comparison to determine which one is best. To choose the

, MOPSO selects a leader in the optimal set based on the degree of congestion. To select a leader and update the archive, MOPSO employs an adaptive grid method [

78].

Figure 2 shows an implementation flowchart of MOPSO.

3.3. Operators of Metaheuristic Methods

3.3.1. Mutation Operator

To discover new solution spaces, a mutation operator seeks to diversify the current population relative to the new population. The evolutionary principle of adding diversity to the current population improves the algorithm significantly and enables it to find final solutions with better properties. The mutation operator of a candidate chromosome selects a few randomly selected genes. Subsequently, a predetermined mutation likelihood is used to modify their values.

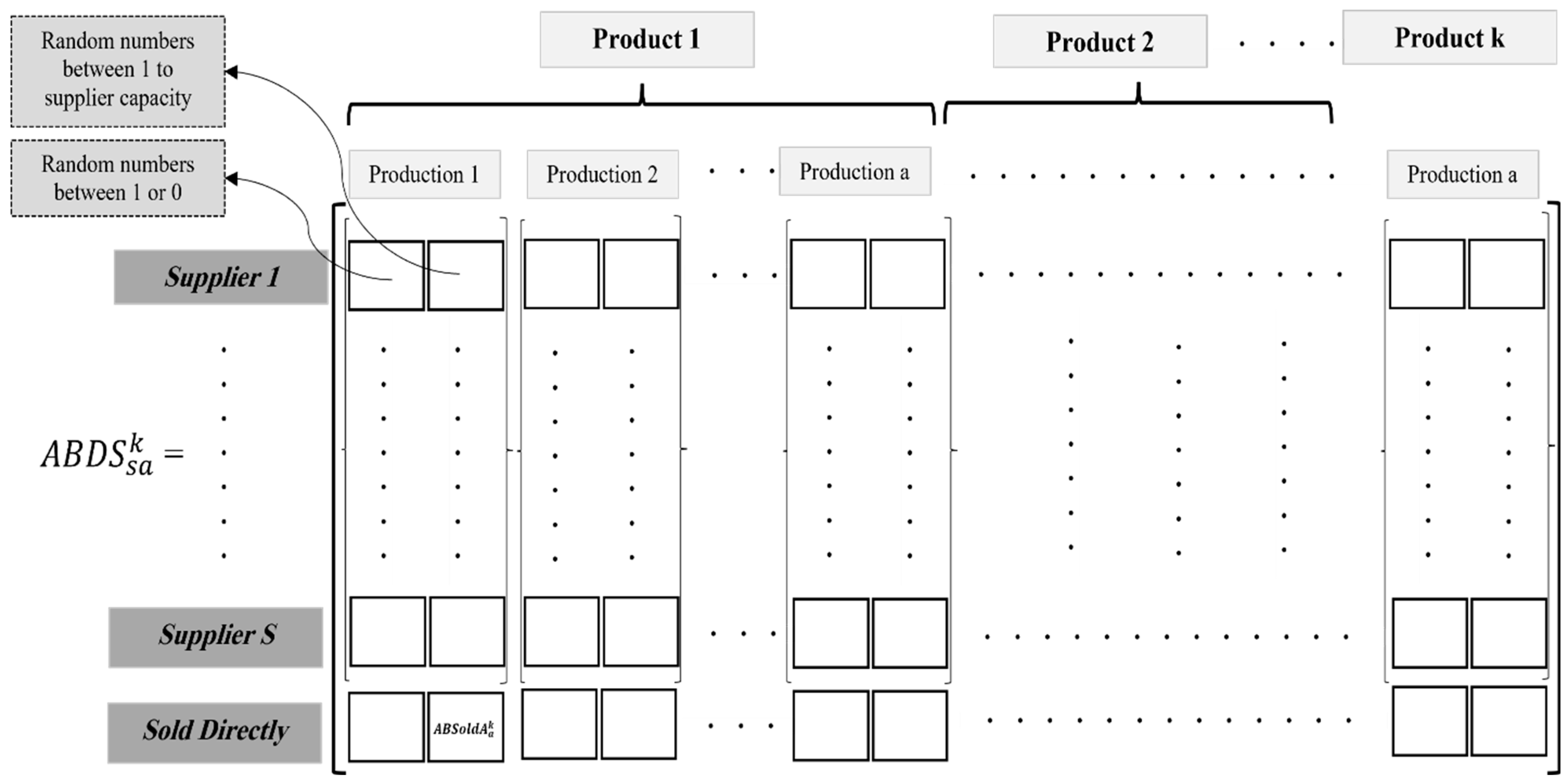

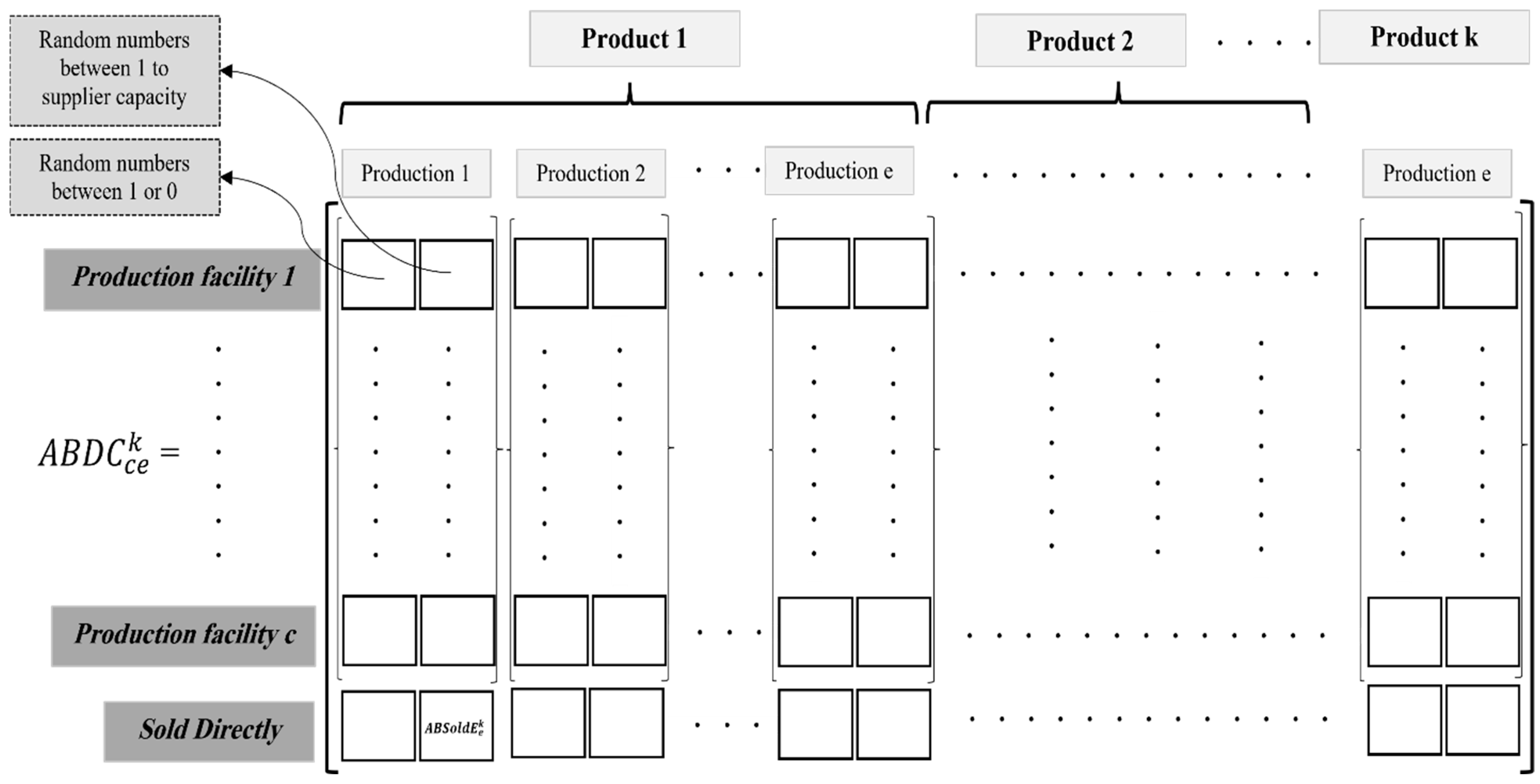

3.3.2. Generating the First Population

This section highlights the use of operators in metaheuristic methods.

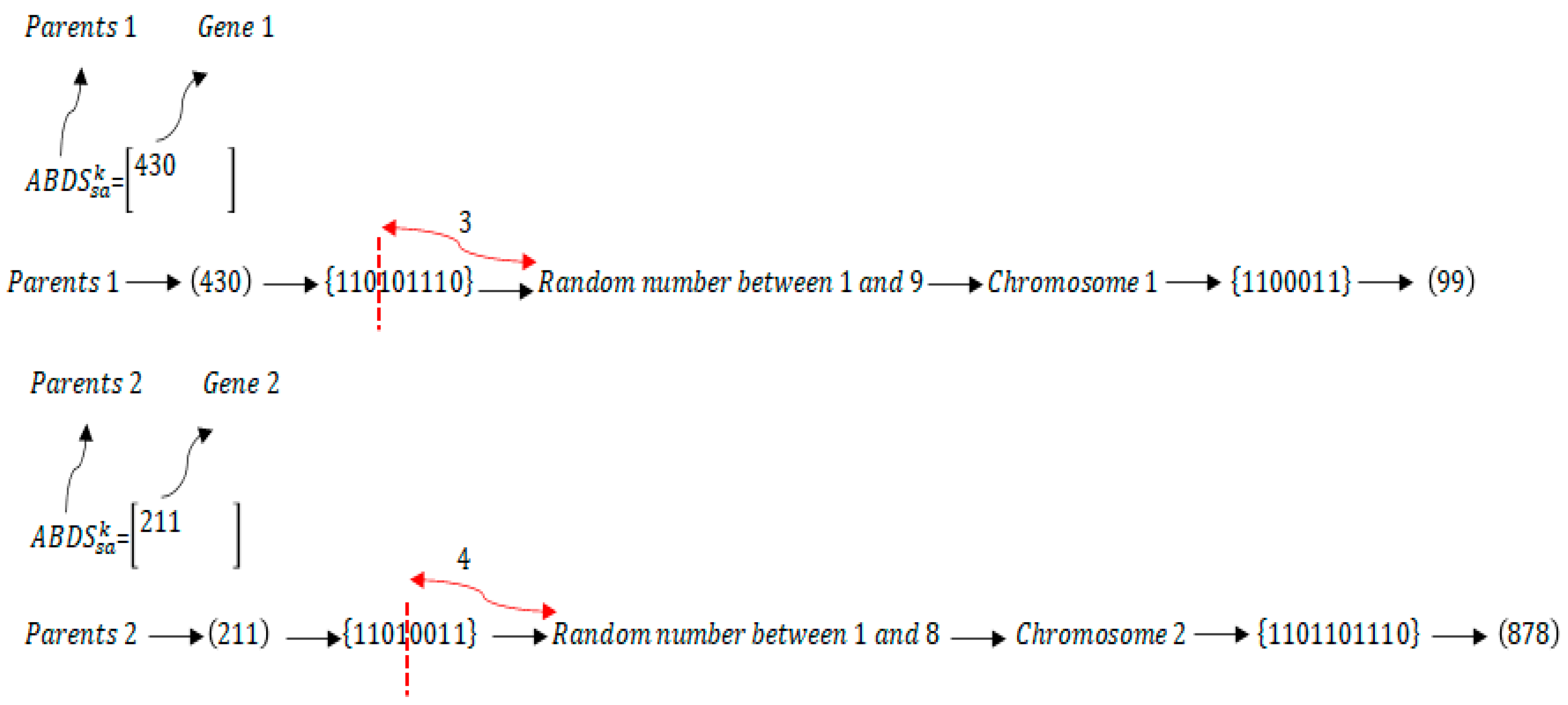

Figure 3,

Figure 4 and

Figure 5 display the graphical representation of the chromosome. There are four types of chromosomes in the developed model.

3.3.3. Crossover Operators

In addition to creating a new solution space, the crossover operator produces offspring or new solutions between chromosomal pairs that mate. Initially, a random number between 1 and 4 is generated. Next, a chromosome or chromosomes is selected.

In the present study, three distinct crossover operators were considered to mate the chromosomal pairs to prevent permutation.

Figure 6 illustrates these processes in a graphical manner, where the chromosome pairs were randomly selected with equal probability.

3.4. Case Study and Data Collection

Malaysia is a country rich in fossil fuels and renewable energy resources. In terms of fossil resources, Malaysia holds 3.7 million barrels of oil (which accounts for 0.2% of the global share) and 38.5 trillion cubic feet of natural gas (which accounts for 0.6% of the worldwide share) [

88]. Among all renewable forms, biomass is the only item that can be substituted for fossil fuels to produce different products, such as energy, materials, and chemicals. Substitution is reasonable; Malaysia’s major oil fields have experienced a significant decline in production capacity, and the country has abundant biomass resources [

89].

The primary biomass source in Malaysia is palm oil. The country has 5 million hectares of palm fields, which produce approximately 93 million tons of palm oil [

90]. Palm kernel and crude palm oil, which are critical raw materials for obtaining different basic oleochemicals and biodiesel, are generated after harvesting oil palm fruit. The palm oil industry also produces considerable amounts of agricultural waste (biomass), including palm oil trunks and fronds, palm oil mill effluent, empty fruit bunch (EFB), palm kernel shell, and palm mesocarp fiber. Zahraee et al. [

89] reported that around 230 kg of EFBs are produced from each ton of processed oil palm fresh fruit bunch.

EFBs are inexpensive biomass resources that can be used to generate various products. The Malaysian government supports the use of biomass to produce value-added products and generate bioenergy through strategies and policies, such as the National Renewable Energy Policy, the National Biomass Strategy 2020, and the “1 Malaysia Biomass Alternative Strategy” [

89]. According to the existing literature and commercialization activities, EFB is currently used to generate many different products, including briquette and pellet fuels, biogas, bio-oil, biosyngas, biohydrogen, biocomposite, biocompost, bioethanol, bioresin, activated carbon, and xylose [

89]. Providing well-optimized BSC is a key factor in realizing this potential. The generation of oil palm products needs to be considered comprehensively and simultaneously. This study focuses on modeling an optimized SC for EFBs using Peninsular Malaysia as a case study.

The necessary data was gathered from several sources, including three case studies that the authors conducted in Malaysia, which included Johor, Pahang, and Perak, as well as previously published works in the field [

89,

90,

91,

92,

93,

94]. Furthermore, the Malaysian BSC was chosen to analyze its environmental performance due to its strong ties to sustainable development goals. The analyses focused on the intricate relationships between various suppliers, accounting for multiple modes of transportation (such as trucks, trains, and pipelines) and stages of production. Supplier selection is aided by these measurements of emissions produced by raw material supply systems.

3.5. Mathematical Model Development of BSC

Figure 7 illustrates the superstructure developed in this study, including the processing and storage facilities and sequences. The assumption is that each storage point is located within its facility.

Economic, environmental, and social performance is considered when developing the mathematical model of the ideal BSC. The profit realized from product sales is less than the total cost. Therefore, as seen below, the objective function of the optimization model aims to minimize environmental emissions while maximizing overall profit using Equation (1), which is equal to the (income − costs).

Reduce emissions by minimizing total emissions from production and transportation (see Equation (2))

Costs are the total expenses for biomass raw materials, delivery, production, and emissions from delivery and production, and income is the sales of goods. Consequently,

Profit = Total sale − raw material cost − delivery cost − production cost − emission cost from delivery − emission cost from production (see Equation (1)).

The terms mentioned above, such as the production and conversion factors’ CO2 emissions, the transportation process’s CO2 emissions, and the production cost factors’ CO2 emissions, all require information or parameters. The fixed costs, which include the capital costs, and the variable costs, which include the operational costs, are constants for various modes of transportation (such as trucks and trains). To calculate transportation costs, these components are multiplied at the mass flow rate after transportation costs are stated in dollars per tonne. This study considers a truck (distance > 100 km) and a train (distance < 100 km) as the preselected vehicles for solid biomass feedstock. Conversely, pipeline transportation is used for gaseous or liquid products. When producing a single unit of goods, the production cost factor (in US dollars ($)) is calculated, which includes the equipment’s capital and operational expenses. The mass flow rate in the BSC was multiplied by the emission factors for the selected transportation mode.

Production-related CO

2 emission parameters were derived from prior research and other life cycle assessments [

89]. As a standardized international unit of measurement, the CO

2 equivalent (CO

2e) was taken into consideration for transportation and manufacturing emission factors. A cost of

$40 was allocated for each tonne of CO

2e as the cost of the emission treatment [

4]. The conversion factor in manufacturing facilities is defined as the raw material flow ratio from the inlet to the outlet. Using Google Maps and prior research, the separations between the two processing plants were measured. It should be mentioned that the cost of biomass raw material is

$6 per tonne [

84].

Table 3,

Table 4,

Table 5 and

Table 6 provide all formula definitions, parameters, variables, and indexes required for the mathematical model. Equations (1)–(34) define the mathematical model, including goal functions, variable computations, and restrictions.

Model Validation

Mathematical model validation primarily determines how a computer model accurately represents the real world from the perspective of its intended application in a certain situation. This validation was performed by comparing the values predicted by a certain model with those obtained from experiments. At the initial step of the validation process, this study considered a small size of the proposed distribution network containing two suppliers

, three production facilities level 1

, two production facilities at level 2

, two production facilities at level 3

, two production facilities at final level

with two types of products

. As explained earlier, the blending of EFBs was assumed to satisfy the supply requirements of pre-processing facilities.

Table 7 presents the parameters and values of the developed model.

To validate the proposed model, the optimization model was validated in GAMS 36.2.0 using CPLEX 20.1.0.1 as the solver. The solution was then operated on an AMD A10-4600 M APU processor, which consisted of 6 sets, 4 scalars, 8 parameters, 29 single equations, and 29 variables. It took 1.578 s to solve the problem. According to the results given in

Table 8, the proposed model was validated. For the given parameters, the minimum cost was found to be

$2560 million per year.

Table 8 shows the optimal production levels for all products, which used 3 million, 2 million, and 1.8 million tonnes per year of biomass feedstock for three suppliers. The total biomass production at each storage location is 1,690,106 and 2,400,762 tonnes per year.

4. Results and Discussion

4.1. Results of NSGA-II and MOPSO

Two distinct examples of a bi-objective sustainable BSC optimization problem were solved using the NSGA-II and MOPSO algorithms, considering the pillars of social, environmental, and economic challenges. Two examples for the chosen case study were conducted to obtain numerous Pareto Solutions (PS).

Table 9 displays the index values for each sample.

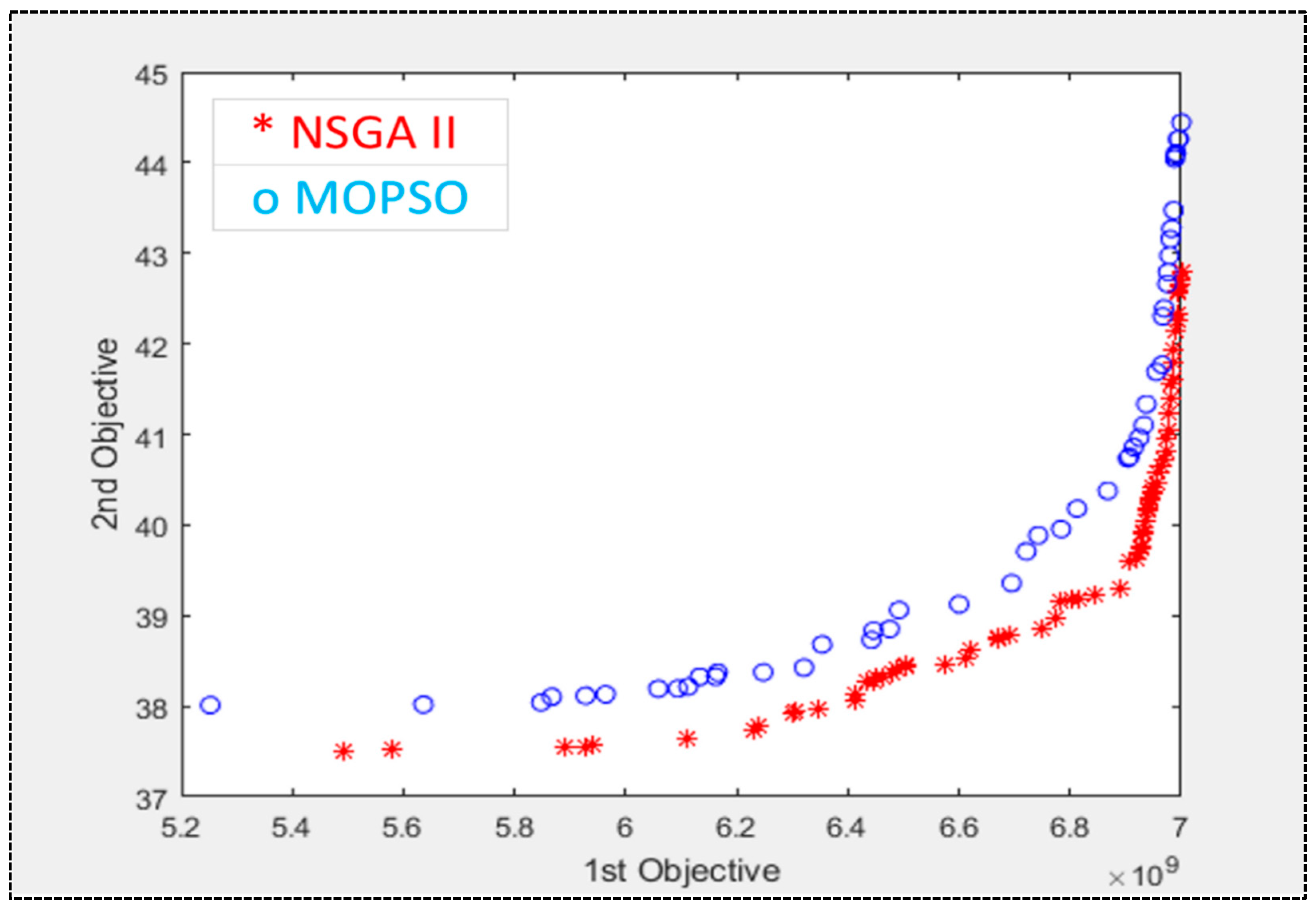

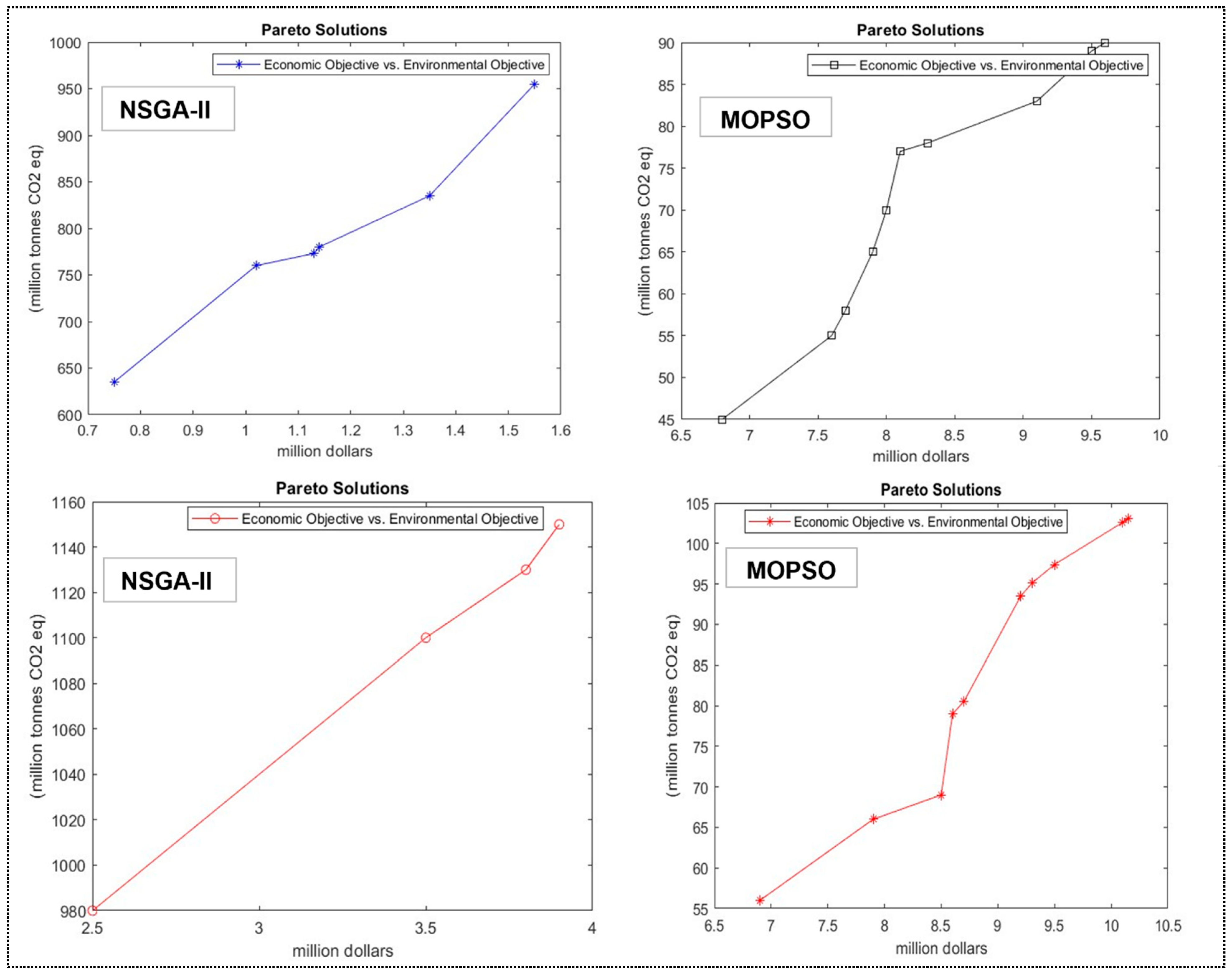

Two distinct PSs were obtained from the results after the model was run. The PSs for the two environmental and economic goals achieved using NSGA-II and MOPSO are displayed in

Figure 8. It is evident that there is a trade-off between environmental and economic goals. The largest amount of emissions is included in the maximum profit, which is equal to

$7000 million. Profit decreases by over 40% to achieve the lowest possible environmental emissions. The same scenario occurs for the second example, which includes more BSC facilities.

Figure 8 also shows the results of two algorithms: the maximum profit of BSC and the total emissions in each generation of the Pareto solution for the second example. As can be seen, the extended example achieves a better target value. Furthermore,

Figure 9 demonstrates that the maximum economic objective is equal to

$13,500 million, with the highest emissions. The environmental objective decreased to nearly 50%, thereby achieving 50% less profit. The developed model and proposed algorithms were implemented for four more examples to test the model, as shown in

Figure 10.

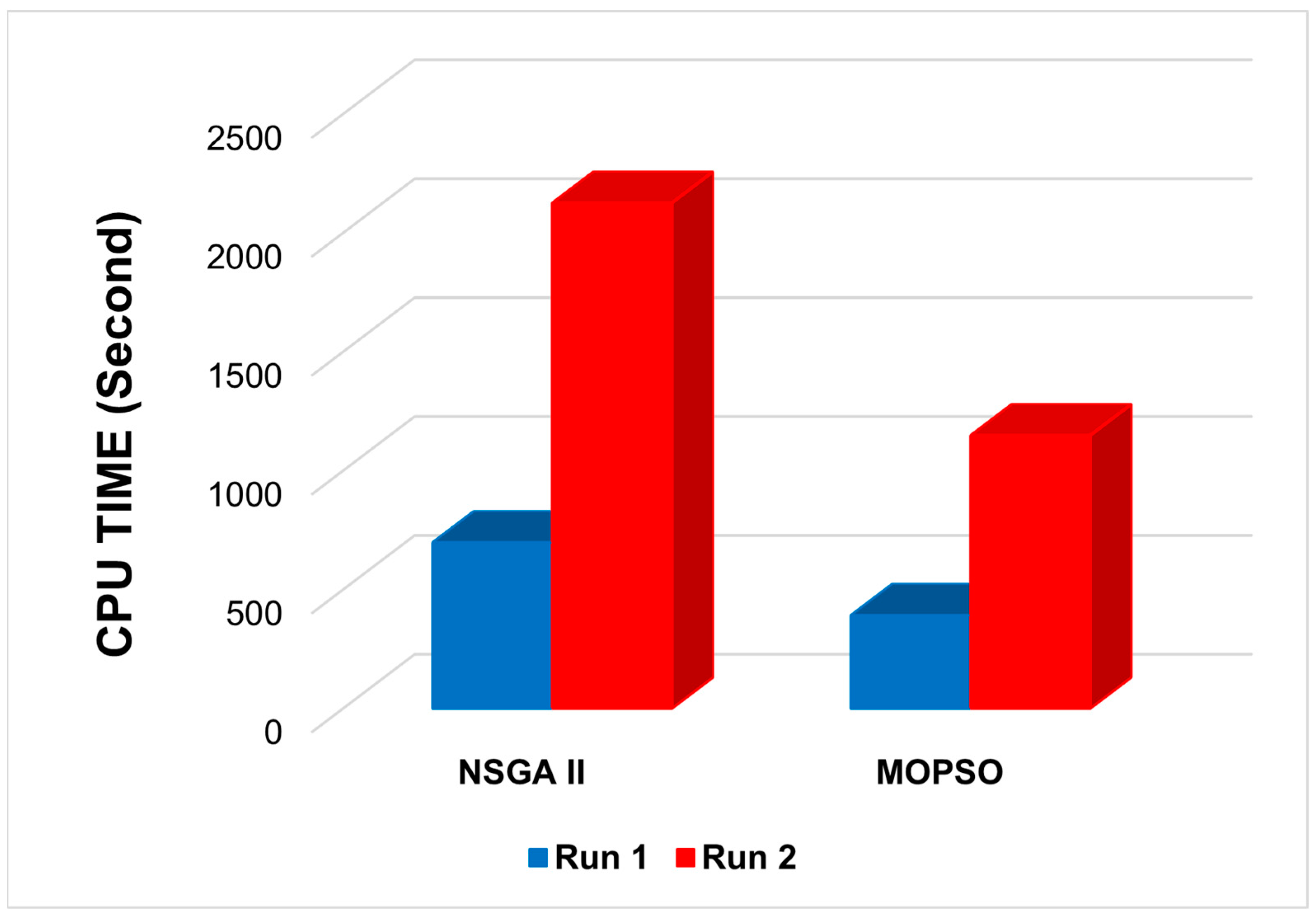

In addition, five unique responses (each showcasing a particular quality of a solution attained by NSGA-II and MOPSO) were identified and used in the experiments to assess the efficacy of both algorithms. The identified responses are as follows: (1) CPU time; (2) Number of Pareto Solutions (NPS); (3) Mean Ideal Distance (MID); (4) Spacing (S); and (5) Maximum Spread (MS) [

58]. The CPU times for the two runs of the NSGA-II results were 697.86 and 2125.90 s, and those for the MOPSO results were 391.76 and 1148.00 s, respectively. The proposed MOPSO algorithm can find a solution in less CPU time, as illustrated in

Figure 11.

In addition, five unique responses (each showcasing a particular quality of a solution attained by NSGA-II and MOPSO) were found and used in the experiments to assess the efficacy of both algorithms. The identified responses are as follows: (1) CPU time; (2) Number of Pareto Solutions (NPS); (3) Mean Ideal Distance (MID); (4) Spacing (S); and (5) Maximum Spread (MS) [

58]. The CPU times for the two runs of the NSGA-II results are equal to 697.86 and 2125.90 s, and for MOPSO results, which are 391.76 and 1148.00 s, respectively. The MOPSO algorithm can find a solution in less CPU time, as shown in

Figure 11.

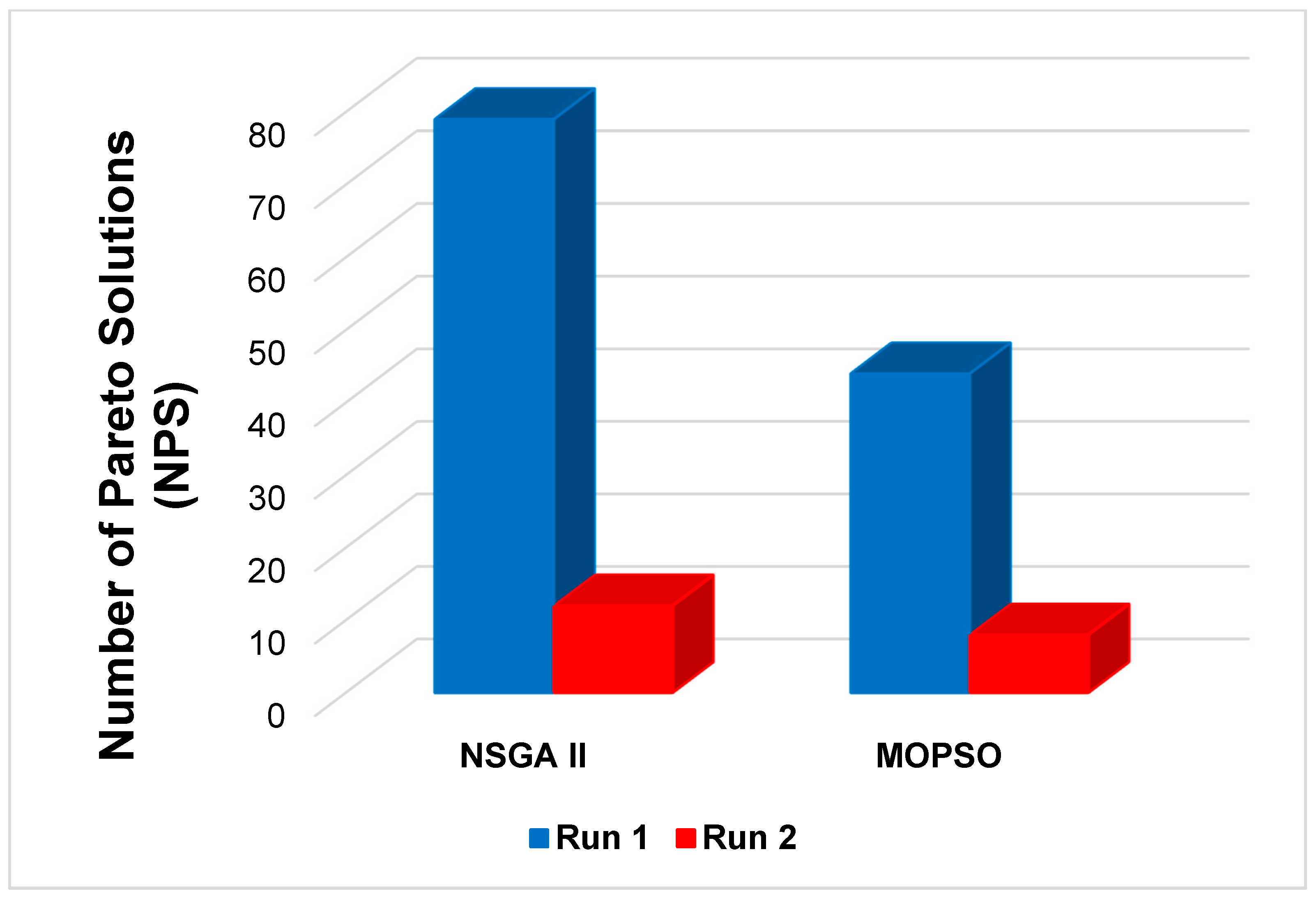

According to

Figure 12, most of the comparison results demonstrate that the NSGA-II method can find more PS for both examples, equal to 79 and 12, respectively. The proposed MOPSO algorithm generated 44 and 8 NPSs for the same examples.

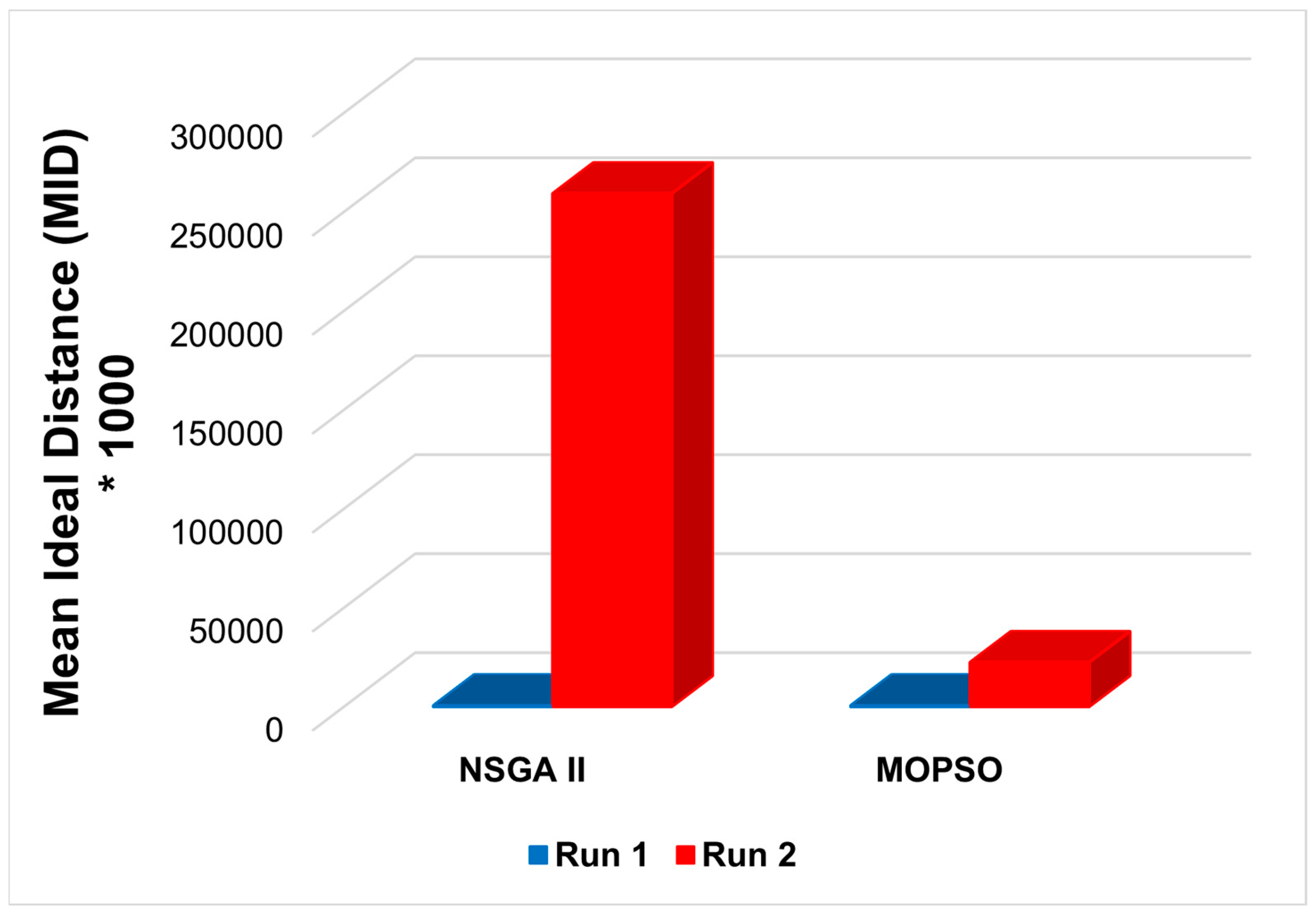

Regarding the MID parameter, the NSGA-II method has less MID, for example, run 1, with fewer types of products, production facilities, and transportation modes compared to the same condition solved by the MOPSO algorithm (

Figure 13). However, with the highest number of products, manufacturers, and transportation types, MOPSO has a lower and better MID than NSGA-II. In contrast,

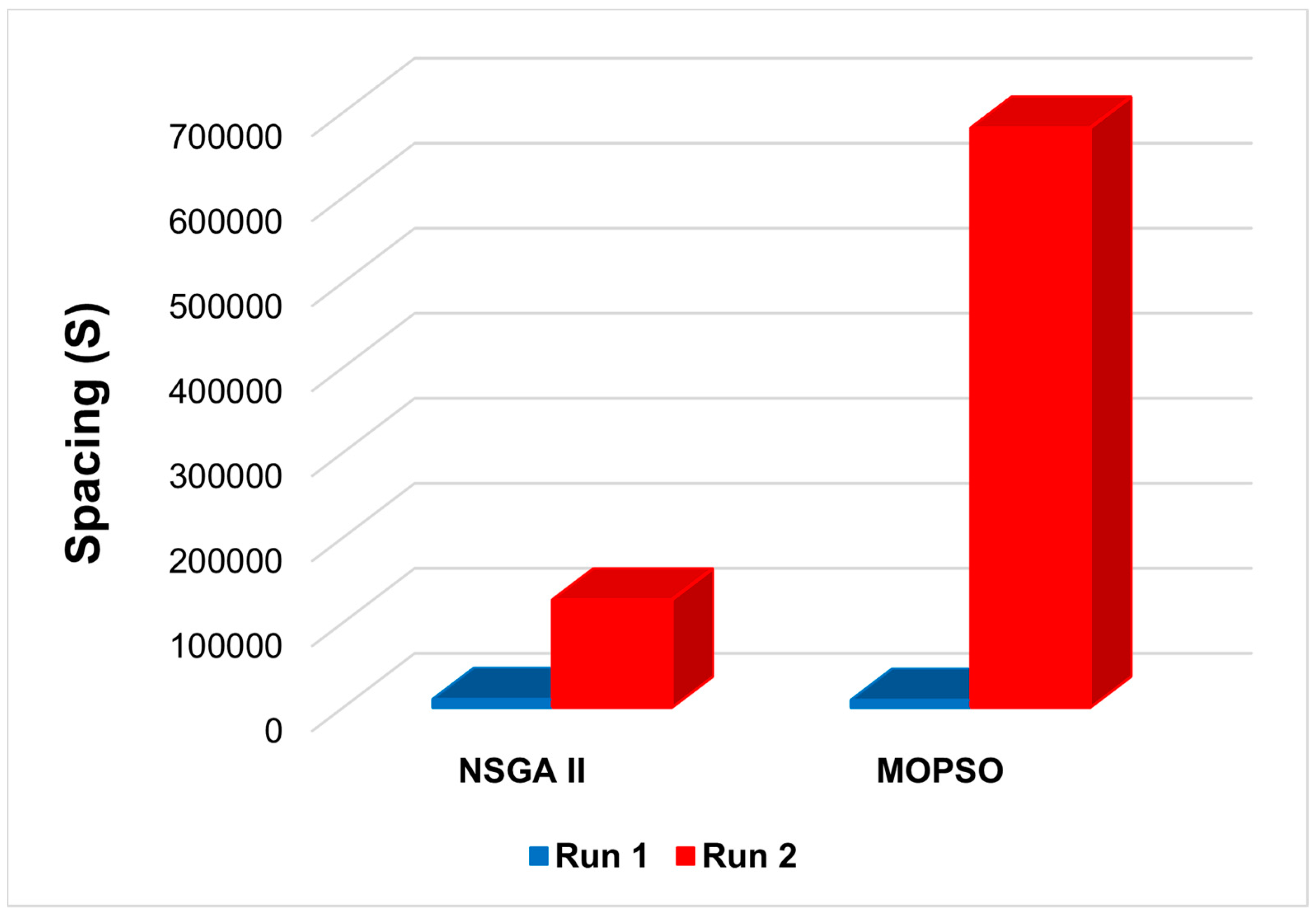

Figure 14 shows that NSGA-II, with the highest number of indexes, has less S (126,839) than MOPSO (681,860), as shown in Example 2. However, MOPSO delivers better S results—for example, 1.

The MS parameter of the MOPSO algorithm is higher than that of NSGA-II in the second example, as shown in

Figure 15. This can prove MOPSO’s aptitude for solving models with higher indexes. For the first case, the MS parameters were 454,540 for MOPSO and 487,960 for NSGA-II. Considering these findings, TOPSIS was used in the following phase to compare the parameters and select the superior algorithm by applying the TOPSIS criteria.

4.2. Implementation of the TOPSIS Method

The two-objective optimization results and TOPSIS are used to identify the optimal trade-off solutions. First, the two-objective optimization problems were solved to examine the optimum output under various variable conditions. This helps find the trade-off optimum design points from the standpoint of all the two objective functions simultaneously.

Table 10 and

Table 11 show the values and means of the performance parameters for each sample obtained using NSGA-II and MOPSO.

In the next step, TOPSIS is applied to rank the given alternatives of PS obtained from NSGA-II and MOPSO developed by Hwang and Yoon [

95]. In general, TOPSIS explores the positive ideal solution (

) and the negative ideal solution (

). Then, it searches the Pareto set to identify the best compromise solution, which is the closest to

and the farthest from

, based on the objective weights allocated by the decision-maker. One of the most important steps in TOPSIS analysis is determining the. Several approaches can be used to calculate these weights, including the analytical hierarchy process (AHP), RANking COMparison (RANCOM), and direct expert assignment. The advantage of the AHP is that it can systematically derive weights via pairwise comparisons, which captures the relative importance of criteria. On the other hand, it requires careful judgment and consensus among decision-makers, which can be subjective and time-consuming [

96]. In contrast, the RANCOM method provides an alternate weight determination method. To reduce subjectivity and bias in weight assignment, RANCOM employs randomization techniques to generate weights using random numbers. This approach is useful when determining the importance of the objective criteria is challenging or when resource limitations or a lack of agreement make traditional approaches like AHP impracticable. Ultimately, the method of choice should fit the particular context and objectives of the decision-making process, striking a balance between the necessity of systematic analysis and the useful factors of solution robustness and weight determination [

91]. In this study, the weights were derived from expert knowledge.

In the following, the steps taken by TOPSIS to determine the best compromise solution are briefly described:

- (1)

Input matrix , where the element is the objective value of the ith alternative (i.e., A is composed of the Pareto solutions).

- (2)

Calculating the normalized rating

according to the Equation (35). The vector normalization method is used in this method. The data processing logic is based on the Euclidean distance (second-order torque), so the vector method (Euclidean norm) is used. The vector method, unlike the simple linear normalization method, is performed as follows:

Equations (36)–(40) are used to calculate the

as follows:

- (3)

Constructing the weighted normalized values using the following Equation (41):

where

is the weight value of the jth attribute and must satisfy:

Table 12 summarizes the values for

and

.

In the next step, Equations (43)–(47) are used to calculate the

as follows:

- (4)

Equations (48) and (49) are used to find and as follows, where stands for a set of benefit attributes; note that larger values indicate better performance—for instance, the amount of production for a factory. signifies a set of cost attributes; remember that smaller values here indicate better performance, for example, the number of employees in a factory.

Table 13 shows the results of

and

for NSGA-II and MOPSO for two examples.

- (5)

Equations (50) and (51) are used to define the distance measure over each criterion to both ideal () and nadir (). Equations (52)–(55) demonstrate the calculations for and for NSGA-II and MOPSO.

- (6)

In the last step of the calculations, Equation (56) is used to measure relative closeness

for each Pareto solution as follows:

Equations (57) and (58) show the value of

for NSGA_II and MOPSO as follows:

- (7)

Finally, the best compromise solution whose relative closeness is the closest to 1 is selected.

According to the results, the MOPSO algorithm is closer to 1, demonstrating the MOPSO’s superiority compared with the NSGA-II algorithm. However, the NSGA-II algorithm could find more PS values when solving the BSC problem.

4.3. Sensitivity Analysis

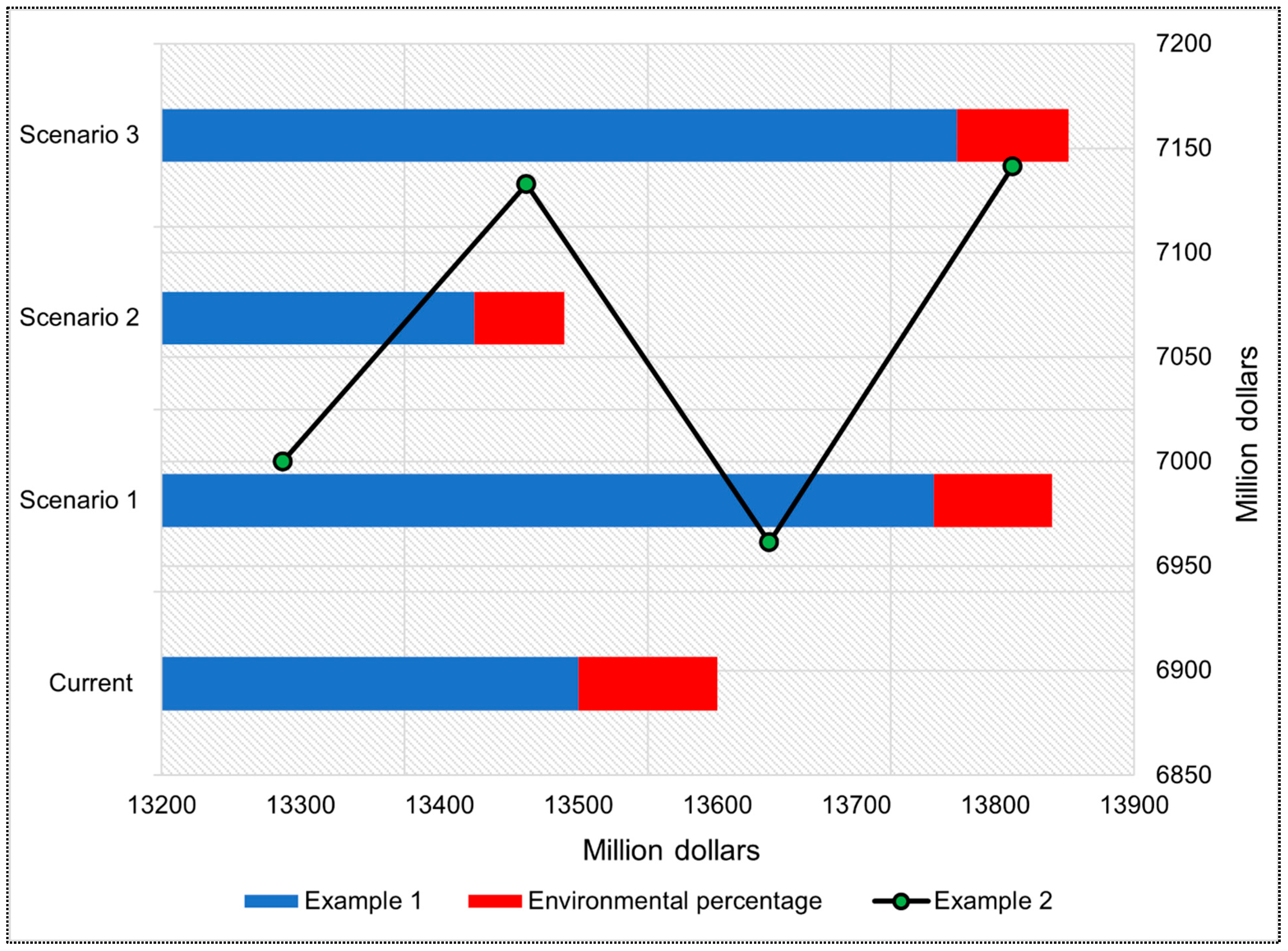

A sensitivity analysis was performed to assess the uncertainties. Selling price, production cost, and demand were selected for the sensitivity analysis. The changes in these parameters were calculated by classifying them into three scenarios (

Table 14). Both the original selling price and production cost factor were increased to 50%, and demand was set until a 10% increase. The first scenario shows that by increasing 10% of the selling price and cost by 2% demand, profit will increase, and the environmental objective will decrease by 15% (

Figure 16). However, in the second scenario, profit will be reduced by 0.5%, and environmental objectives will be reduced by 35%.

Figure 16 also shows that there should be a 10–30% increase in sales and cost to meet 2–8% demand.

4.4. Discussion

Assessing the financial viability of using oil palm EFB as a renewable feedstock for the production of materials, chemicals, and energy can be made easier using an ideal BSC. The prerequisite steps that should be taken to achieve the optimum BSC are presented; that is, steps that can be applied to various types of biomass feedstock and products. Three sustainability factors—economic, environmental, and social variables—were incorporated into the suggested model for use in tactical, operational, and strategic decision-making. It also helps determine optimal assignments for transportation modes by classifying processing routes and products according to their states (liquid, solid, or gas). Furthermore, the model considered environmental emissions and emissions costs from transportation and production activities.

Numerous significant trade-off points between objective functions were discovered due to this optimization. Such a MOO of profit and emissions could reveal significant design trade-offs between competing objective functions, which is difficult to find in any other way. The optimization results also consider the trade-off between profit and emissions considering economic and environmental concerns.

Note that the key advantage of the models proposed in this paper is that they can integrate strategic and tactical planning while considering the dynamic nature and operational limitations of SCs. Moreover, the developed models simultaneously considered the three pillars of sustainability. The MOO model presented in this study is the first application of BSCs that has combined simulation modeling and mathematical programming to address the complex problems typically associated with SCs. The developed multi-objective mathematical optimization model is also the first model that simultaneously integrates the economic, environmental, and social sustainability pillars of the BSC. Implementing two main evolutionary algorithms (NSGA-II and MOPSO) using the TOPSIS approach is another significant contribution that has not previously received attention in the BSC-planning literature. The mathematical optimization and simulation components of the proposed models were developed independently in the current paper. In addition, they are applied to similar case studies individually or together. Based on biomass and product types, adaptations to the simulation and optimization models may be needed. However, the general structure of the mathematical and dynamic simulation models is applicable to other cases without limitations. The case studies included substantial amounts of data regarding both bioenergy and biofuel production’s technical and economic aspects. Future research can use these data efficiently and effectively.

According to examples 1 and 2, the maximum profits are $13,500 million and $7000 million, respectively, which includes the most significant emissions. The optimization approach’s outcomes showed. The expanded example reduces 40% in profit to obtain the lowest possible emissions from manufacturing and transportation in BSC, which results in a better goal value. Furthermore, the performance of both methods was evaluated using five performance parameters. In comparison to NSGA-II, the nest CPU time associated with the MOPSO algorithm was 697.86 and 2125.90 s for each sample, respectively. Furthermore, the results demonstrate that compared to the MOPSO algorithm, the NSGA-II algorithm generated more Pareto solutions. Finally, several trade-off optimal design points were identified and subsequently presented using the TOPSIS approach to analyze the optimization algorithm solutions derived from the two objective problems. The outcomes demonstrated that MOPSO was better than NSGA-II; nevertheless, NSGA-II had a greater PS. These engine map points can be used by designers to improve performance.

Nevertheless, the PSO approach and NSGA-II are evolutionary algorithms that can result in nonconvergent, excessively high computational costs and suboptimal solutions. Further research could be conducted in this area to develop generation-algorithm-based multiobjective solution methods that are effective in reducing operating costs and gas emissions, such as the weighted sum technique and the ε-constraint method [

97]. Researchers can run extensive simulations using (a Python library for multi-criteria decision-making (PYMCDM) to examine how SPOTIS functions in various weighting scenarios, particularly emphasizing how well it can reduce or eliminate rank reversal effects. In a similar vein, decision-making software platforms are interactive. It offers intuitive user interfaces for sensitivity testing and decision outcome visualization, which can improve the dependability and transparency of comparison studies between SPOTIS and alternative techniques.

In conclusion, incorporating interactive decision-making software and PYMCDM into research would make it easier to thoroughly explore the potential benefits of preventing rank reversal and improving our knowledge of and ability to use SPOTIS in real-world decision-making situations.

5. Conclusions

To take into account the social, environmental, and economic pillars of sustainability, this study simultaneously addresses sustainable BSC optimization. Initially, the economic principle is examined to optimize revenue and reduce the environmental impact of production and transportation within the BSC. To tackle these problems, a single multi-objective mathematical model was created using MATLAB software (R2024a) and evolutionary algorithms—specifically, NSGA-II and MOPSO. The TOPSIS method was proposed and employed as a multi-criteria decision analysis tool to compare, investigate, and rank a set of alternative solutions based on pre-specified criteria between the NSGA-II and MOPSO algorithms. The developed model was tested using two examples for the Malaysian Palm Oil case study. GAMES validated and verified the mathematical model using a simple case study example to compare the results. According to examples 1 and 2, the maximum profits are $13,500 million and $7000 million, respectively, which includes the greatest emissions, the optimization approach’s outcomes show. The expanded example reduces 40% of profits to obtain the lowest possible emissions from manufacturing and transportation in BSC, which results in a better goal value. In addition, five performance parameters were used to evaluate the performance of both algorithms. The nest CPU time is related to the MOPSO algorithm and is equal to 697.86 and 2125.90 s for each example, respectively, compared to NSGA-II. The results also demonstrate that the NSGA-II algorithm produced more Pareto solutions than the MOPSO algorithm. Some trade-off optimum design points were finally specified and presented by applying TOPSIS to the optimization algorithm solutions obtained from the two objective problems. In addition, MOPSO was found to be more successful than NSGA-II, while the latter had a higher PS value. Designers can use the same points on the engine map to improve performance.

Several uncertainty sources, including biomass availability, transportation times, and bulk density, were incorporated into the model proposed in this study. In addition, despite being highly variable in real-life situations, biomass quality attributes (e.g., ash content and moisture content) were assumed to be fixed in this research. This can significantly influence the final results because variations in biomass quality can result in significant financial losses.

The following are some ways in which future research can resolve the uncertainty in other model parameters that were mentioned in this study:

There is room to account for equipment failure, repair timeframes, biomass quality, product costs, and demand. To do so, it is essential to estimate the probability distribution functions for uncertain parameters and incorporate them into the developed model. This is particularly important when considering seasonality in biomass supply and demand.

Biomass must be stored and appropriately inventoried to avoid disruption to production processes due to variations in biomass demand and supply. Despite the challenge that uncertainty often creates for the economic viability of forest-based BSCs, most studies on bioenergy and biofuel SC planning have concentrated on deterministic models, and only a few researchers have integrated uncertainties into their models. An important reason for this is the intricacy of commonly used techniques (e.g., stochastic programming) when incorporating uncertainties into modeling. Such methods usually result in designing models requiring considerable computational effort to solve complex problems, such as models incorporating different planning levels.

Future studies should extend the proposed model by considering the stochastic behavior of the economic, environmental, and social planning associated with BSC. Eventually, the proposed model can be used together with inventory management and technological risks for each processing route in the SC model to estimate performance measures accurately. In addition, future investigations are suggested for advances in the field of sensitivity analysis, providing a new perspective on the simultaneous influence of changes in multiple values on the robustness of the MCDM result.