1. Introduction

In recent decades, microgrids (MGs) have emerged as pivotal technologies that enhance the sustainability and efficiency of power systems. MGs offer significant benefits to power systems and electrical consumers. These benefits include reduced network peaks and costs. Among these technologies, green microgrids stand out for their specific contribution through the use of renewable energy sources, further contributing to environmental and economic improvements. Geographically close microgrids are often linked together to leverage their combined strengths, creating multi-microgrids (MMGs). MMGs typically connect to the grid through a point of common coupling (PCC).

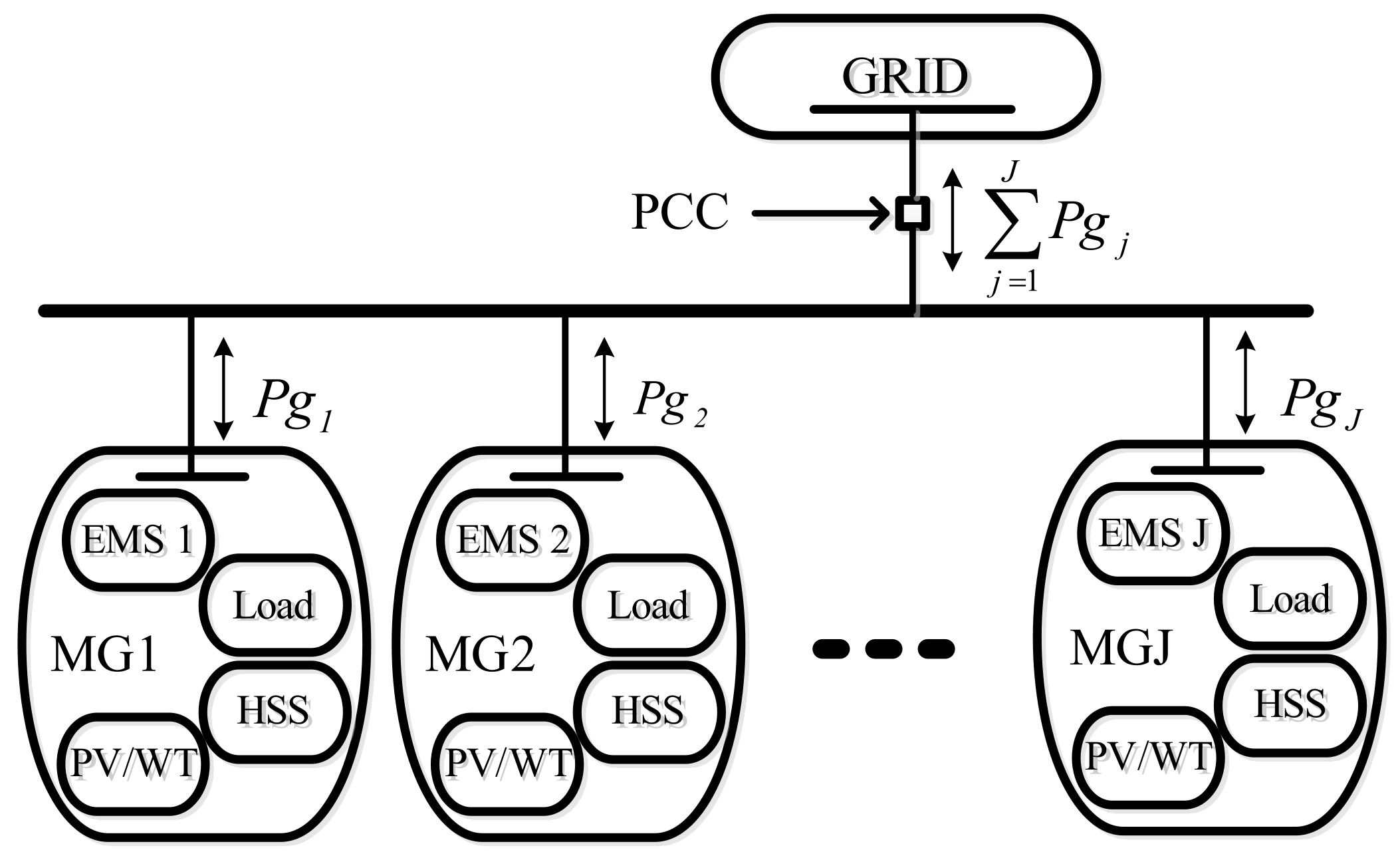

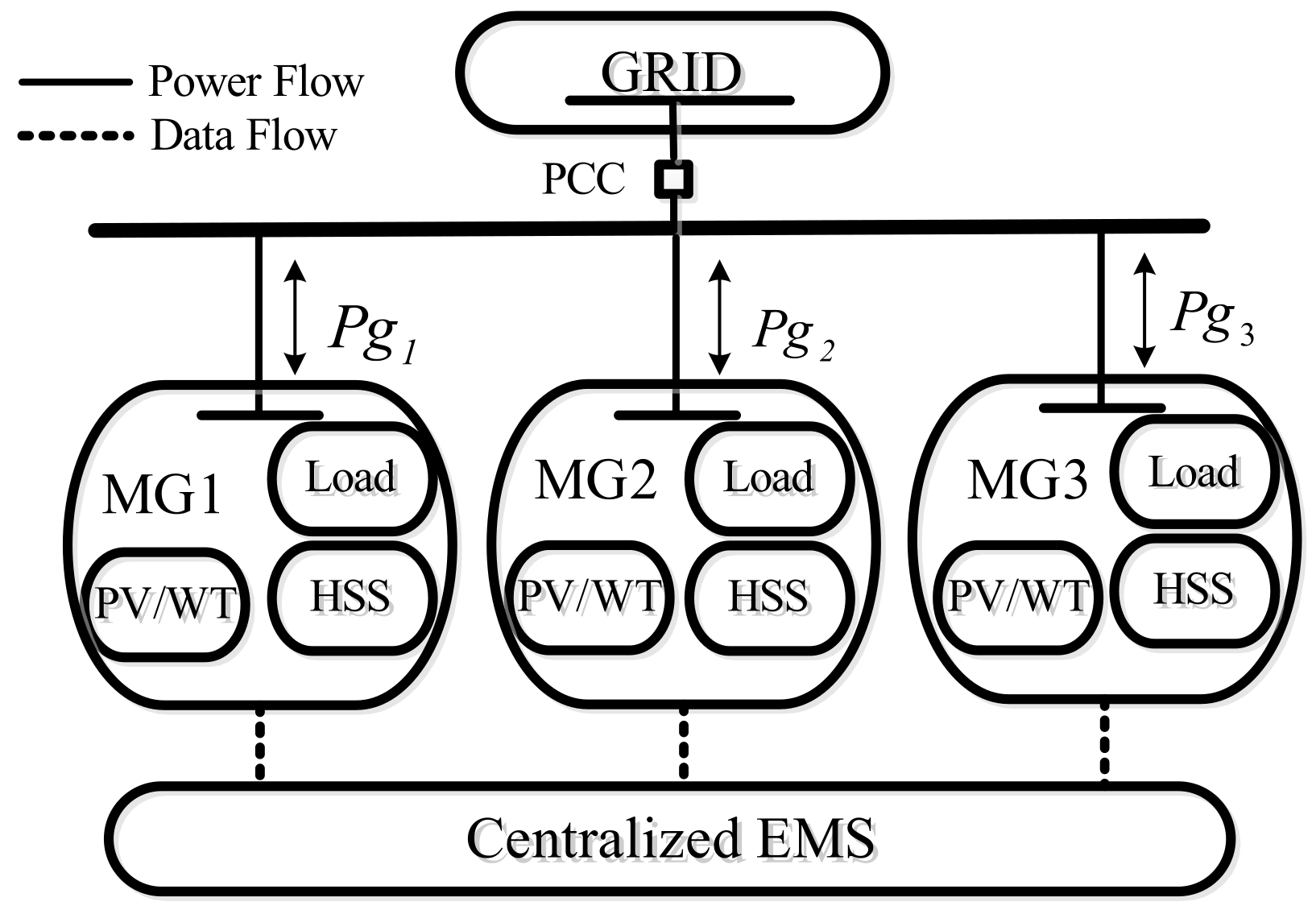

The typical configuration of multi-microgrids and the grid is shown in

Figure 1. In this figure, the MG consists of a centralized energy management system, hydrogen storage systems, electrical and hydrogen loads, photovoltaic systems, and a wind turbine, all connected to the grid through a point of common coupling. The strategic importance of energy management in MMGs cannot be overstated. It is fundamental to maximizing operational efficiency, ensuring the stability of supply, and achieving sustainable energy objectives [

1].

MMG energy management presents significant challenges and complexities [

2]. Researchers have developed various models over time to effectively manage energy in MMGs. These models are crucial for dictating the distribution, consumption, storage, and trading of energy among the microgrids, ensuring operational efficiency and sustainability. A global classification identifies two energy management system (EMS) models: centralized and decentralized [

3]. For MMGs owned by different entities, decentralized EMS models emerge as viable solutions, although they may lead to increased operational costs and excessive power trading between the microgrids and the grid. In this model, each microgrid aims to maximize its profits, seeking maximum utilization of the common line. They use a common line to connect with the grid without sharing data about their operations with neighboring microgrids. This isolation can cause power congestion on the shared line when the price of energy in the grid is low [

4]. To clarify, congestion in the power system context refers to transmission lines operating at or even exceeding their designed capacity [

5].

The need to address tie-line capacity limits in MMG studies is crucial for two main reasons. Firstly, the rapid expansion of energy storage integration has not allowed for sufficient time to strengthen and expand the transmission and distribution network. Secondly, technical constraints might lead the grid to impose restrictions on MMG connections.

Congestion management in microgrids is critical to ensure efficient energy flow and maintain microgrid stability. Several methods have been developed to address this concern. The use of flexible AC transmission system (FACTS) devices is one such technique, offering improved control over electrical network parameters. Demand response mechanisms are also utilized, allowing for real-time adjustments to consumption patterns based on grid needs. Additionally, generator rescheduling and load shedding can be employed to balance supply and demand during peak times. The integration of energy storage systems presents another promising solution, providing buffers during high-demand periods. The rise of electric vehicles (EVs) introduces new opportunities for grid management, with their charging and discharging processes contributing to load balancing [

6]. However, with the increasing integration of renewable energy sources, microgrids face heightened levels of uncertainty. Traditional congestion management methods struggle to fully address these challenges. For instance, the inherent variability of renewable sources can lead to drastic and seasonal fluctuations in energy production.

To address congestion in feeders, Reference [

7] proposes an exclusive DC feeder system for multiple electric vehicle (EV) charging stations, connected to the grid through a grid-tie converter. Daily quotas and day-ahead schedules are set based on profit curves developed by the EV stations and evaluated by the local market operator to maximize total profit while adhering to capacity constraints. Reference [

8] investigates the use of a superconducting magnetic energy storage (SMES) device and its ability to regulate fluctuations in wind generation. A fuzzy logic controller is employed to modulate the duty cycle of the chopper circuit within the SMES, aiming to minimize the tie-line power fluctuations in the microgrid.

Congestion management has long been a pivotal issue, driving extensive research across the sector. Typically, congestion management approaches can be categorized into two models [

9]: (i) the day-ahead scheduling model, which seeks to establish the most effective set of generating units for operation to satisfy demand while adhering to the system’s security constraints; (ii) the real-time operation model, which addresses real-time congestion that might arise from variability in renewable energy sources, load shifts, and system component malfunctions. These strategies are designed to lower the costs of re-dispatching generating units and decrease the need for control actions. This research concentrates on the first model.

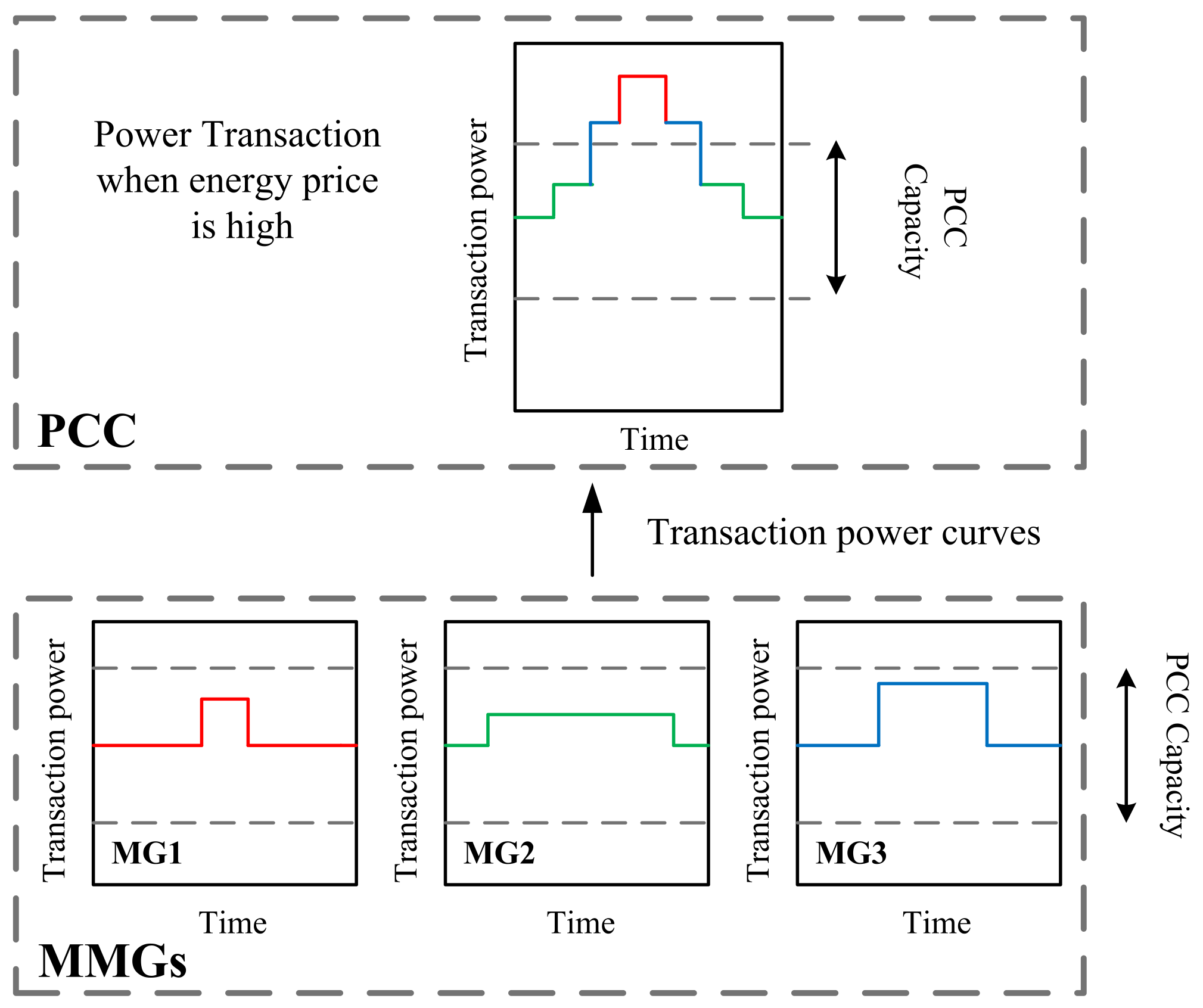

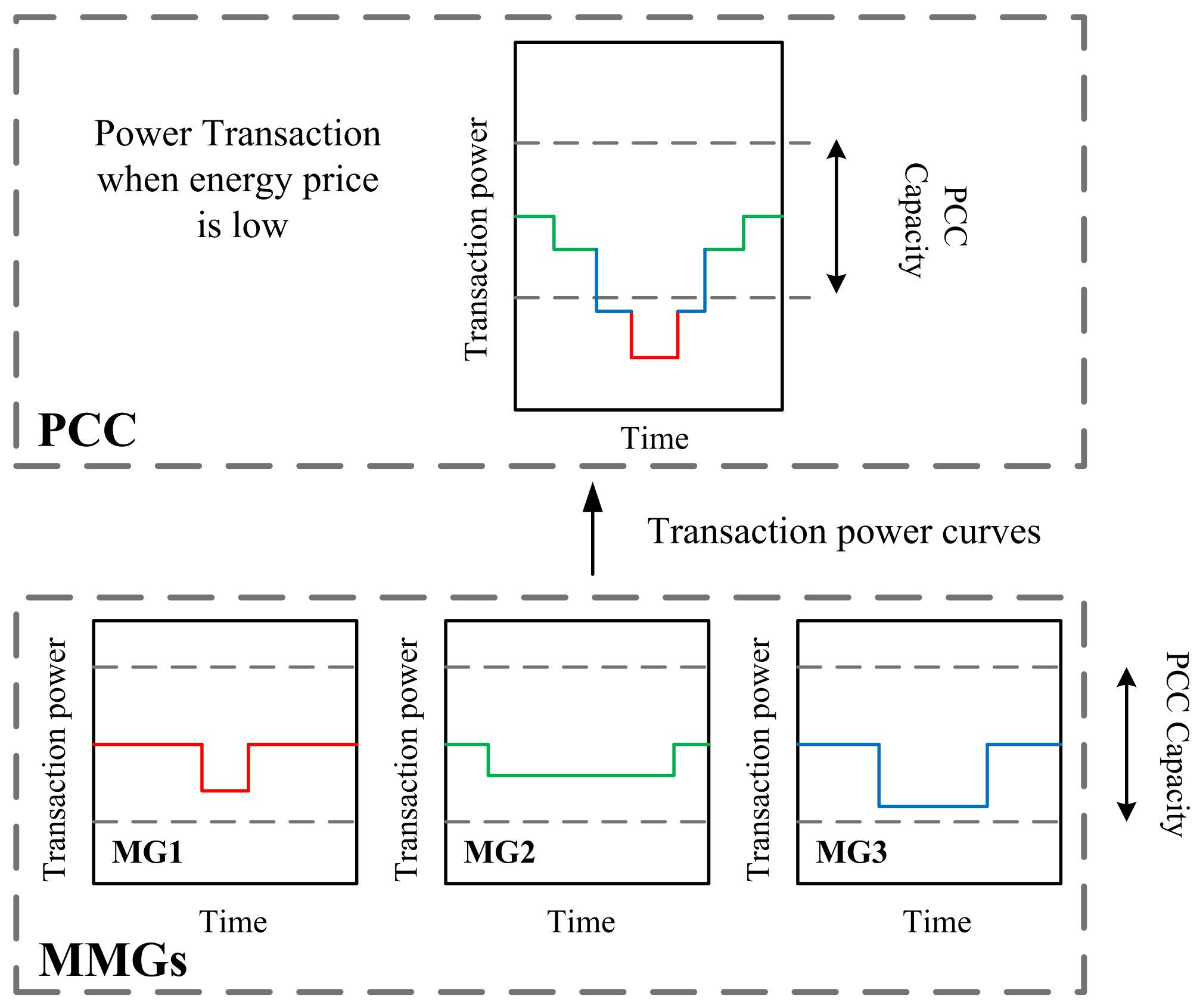

The power transactions among multi-microgrids and the grid in two different scenarios are shown in

Figure 2 and

Figure 3. In

Figure 2, the price of power is high, so the microgrids tend to sell power to the grid to increase their profit, leading to energy flows from the MMGs to the grid. In these circumstances, energy storage systems discharge their energy to sell power to the grid to maximize the profit of the MG. However, as individual microgrids lack information about their neighboring microgrids, they use the PCC capacity as their power exchange limitation. This can result in congestion at the PCC. In contrast, in

Figure 3, when the energy price is low, the energy flows from the grid to the MMGs, and energy storage systems also buy power from the grid to charge themselves to maximize the profit of the MG. Consequently, congestion may occur.

Therefore, despite this critical oversight, only a few research studies have considered this problem. A demand response strategy discussed in [

4] is aimed at peak shaving and valley filling, although it can only redistribute a portion of the load, making it suitable primarily for minor congestion issues at the PCC. In ref. [

10], a technique based on the Lagrange function is employed to determine the equitable distribution of line capacity among the microgrids. This methodology is stringent, delineating a specific quota for each microgrid on the tie-line. A limitation of this study is its assumption based on the most adverse hourly scenario for a day, potentially reducing the total profit. Moreover, due to variations in power exchanges across different seasons, this method might not fully address congestion, increasing the possibility of load shedding and generation curtailment.

A virtual pricing model described in ref. [

11] is designed to manage the power output from micro-turbines. This regulation aids in alleviating PCC congestion. Despite its design, when renewable energy sources are highly prevalent, this method struggles to effectively handle resource generation. The advantages and disadvantages of three relevant studies, along with a comparative analysis between them and this study, are summarized in

Table 1 and

Table 2, respectively.

Energy storage is essential for maintaining the balance between supply and demand in power systems. While various energy storage options are available, including batteries, compressed air energy storage, and pumped hydro energy storage [

12], hydrogen offers distinct advantages. High energy storage capacity: Hydrogen boasts a high energy density, allowing its storage capacity to scale up to MWh or even TWh levels, whereas batteries are typically limited to kWh to MWh applications [

13]. To achieve greater a storage capacity using batteries, one would need to significantly expand the size of the installation. Long storage duration: Hydrogen’s storage duration far exceeds that of batteries. While batteries offer hourly or weekly storage, hydrogen can store energy for weeks or even months [

14]. Flexibility and volatility mitigation: Hydrogen effectively smooths out energy volatility and uncertainty, making it particularly adept at absorbing excess renewable energy generation [

15]. Energy time shift: Hydrogen facilitates the balancing of demand and supply by storing excess energy generated by renewables—particularly during periods of low demand—as hydrogen to optimize energy costs. During periods of high demand, this stored hydrogen can be converted back into electricity, thereby maximizing benefits. This energy conversion can be achieved through mechanisms like stationary fuel cells.

A limited number of studies have explored the role of hydrogen in managing congestion [

16,

17]. Ref. [

16] presents a congestion management strategy employing an energy hub that incorporates hydrogen systems, microturbines, and wind turbines in medium- and high-voltage systems. In ref. [

17], the study examines the optimal operation of virtual energy storage systems, including batteries, thermal energy storage systems, hydrogen storage systems, and electric vehicles, as well as demand response programs. The research also explores the interplay between electrical, thermal, and hydrogen markets, highlighting their potential in managing congestion.

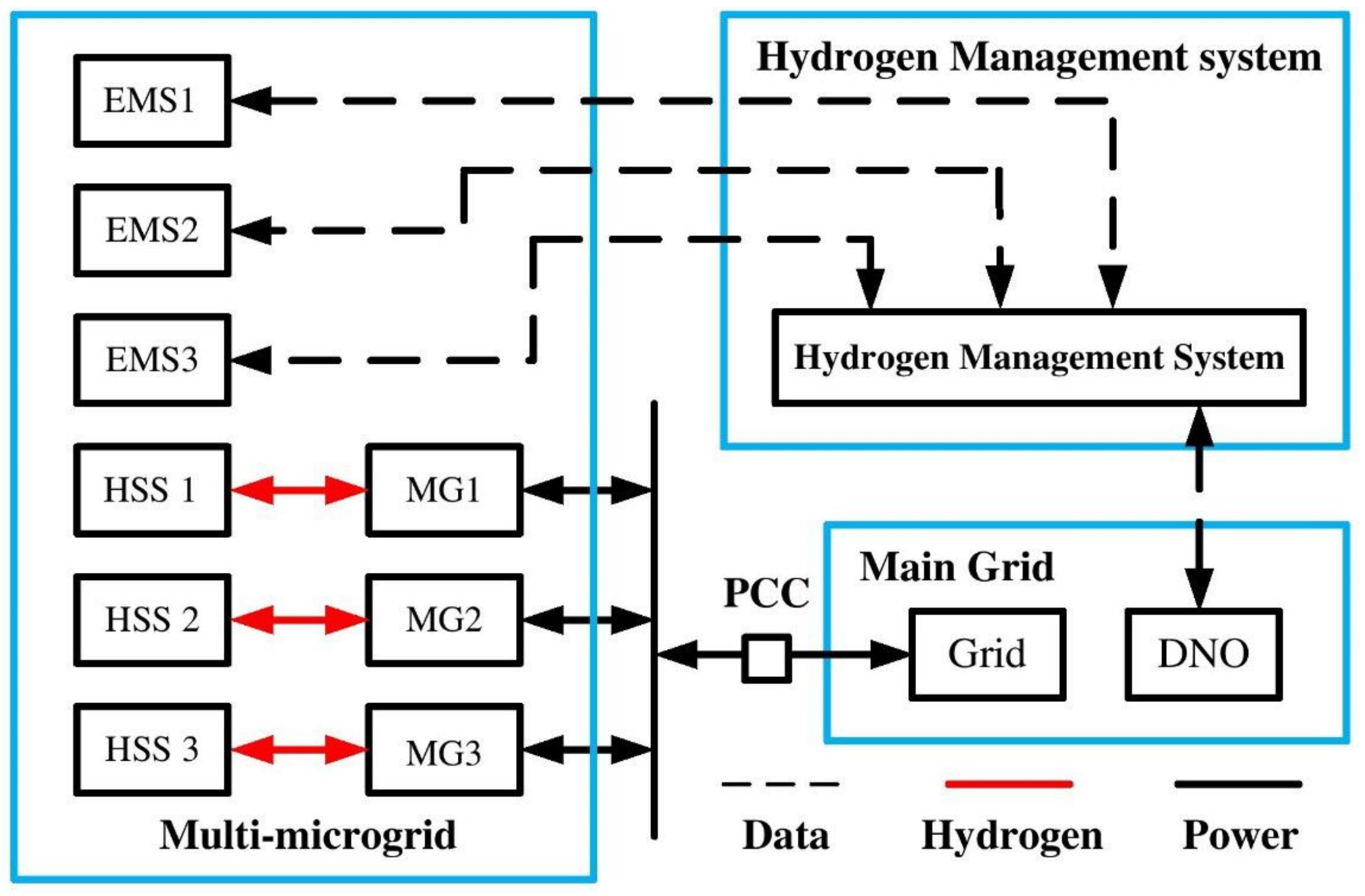

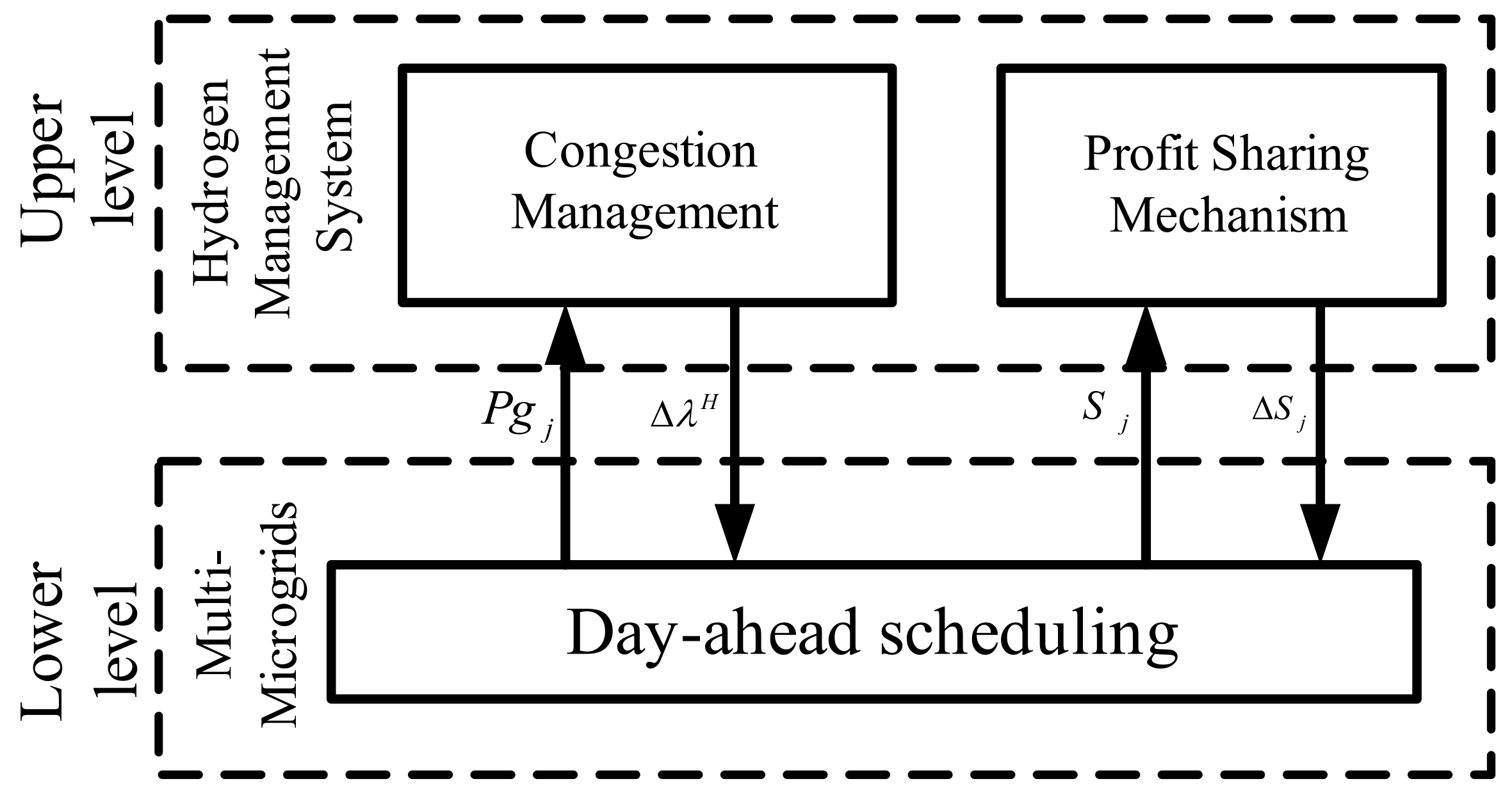

This paper introduces a bi-level hierarchical energy management system (EMS) designed to address PCC congestion within grid-connected green multi-microgrids. In the first level, each microgrid’s centralized EMS conducts day-ahead scheduling and subsequently relays any potential energy imbalances to the hydrogen management system (HMS). Notably, the HMS is composed of representatives from multiple microgrids. At the second level, the primary objective is PCC congestion management, achieved by converting surplus electrical energy into hydrogen and vice versa. Additionally, the HMS ensures that the total profit from this process is fairly allocated among the microgrids using the Shapley value method.

To ensure data privacy within the decentralized EMS, our model adopts a strategy where each microgrid operates autonomously. This independent operation means that sensitive operational data, such as demand patterns, resource outputs, the technical data of energy storage systems, and internal load contracts, are managed locally and are not shared across the network. HMS, integral to addressing congestion at the PCC, further reinforces privacy by utilizing only aggregated, non-sensitive data from each microgrid’s EMS. These measures prevent any potential leakage of confidential information, maintaining the privacy integrity of each microgrid while enabling efficient congestion management and operational optimization through virtual hydrogen price adjustments communicated back to the microgrids. This approach not only upholds data privacy but also ensures that each microgrid can autonomously adjust its operations based on optimized data-driven insights provided by the HMS, thus balancing system-wide efficiency with stringent privacy standards.

The literature review highlights the significance of utilizing hydrogen storage systems to manage congestion in multi-microgrids with substantial penetration of renewable resources. Although extensive research has been conducted to address congestion through hydrogen storage solutions, this paper introduces, for the first time, a method for mitigating PCC congestion using hydrogen systems. Furthermore, the use of hydrogen to reduce congestion in the distribution network of green multi-microgrids has seldom been explored. The primary contributions of this study are outlined as follows:

A novel bi-level hybrid energy management system has been introduced. This design is specifically tailored to manage PCC congestion, ensuring efficient energy distribution during times of varying electrical demand or generation.

A hydrogen management system has been introduced. This system is capable of not only regulating hydrogen storage systems to mitigate congestion but also ensuring a just and equitable distribution of profits among participating microgrids.

A dynamic hydrogen pricing method is proposed for mitigating the congestion and optimizing the MMGs’ profit. This approach regulates the hydrogen price during specific hours, resulting in the self-rescheduling of MGs.

The structure of this paper is outlined as follows:

Section 2 discusses the system structure and problem formulation.

Section 3 details the simulation and numerical results obtained. This paper concludes with

Section 4, which provides the concluding remarks and future research directions.

3. Results

This study tackles the optimization problem using GAMS software (version 30.3) alongside the CPLEX solver (IBM, Armonk, NY, USA) , facilitated by the GAMS/MATLAB (version 30.3) interface for efficient input and output data transfer. The optimization process utilizes the CPLEX solver within GAMS for the mathematical programming tasks, and iterative functions are managed using MATLAB (version R2023a) . This approach ensures robust and efficient computation of solutions. The solution computations were carried out using a desktop computer equipped with a 3.9 GHz processor and 32 GB of RAM.

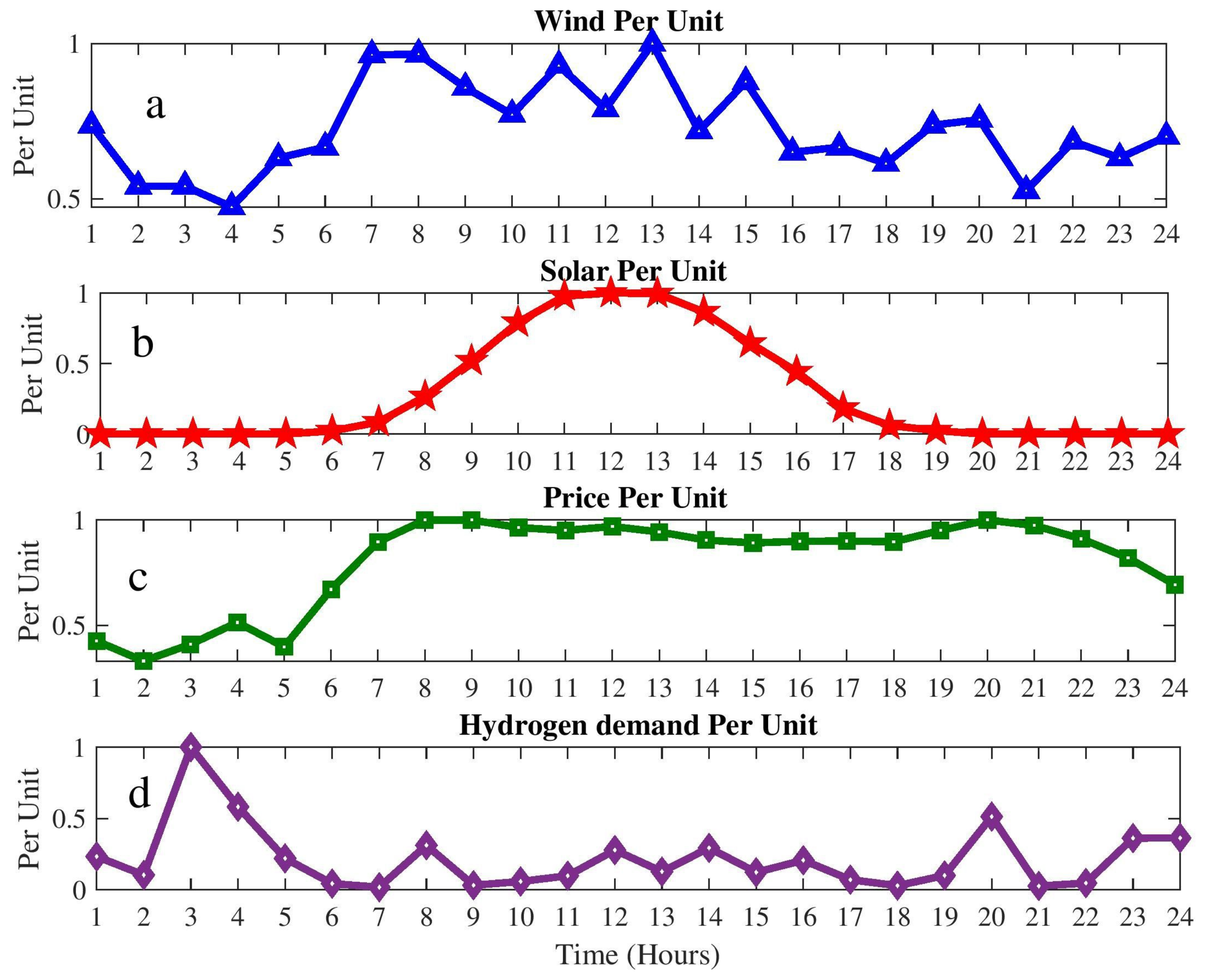

This section assesses the practicality and effectiveness of the proposed model using a case study. This study evaluates the mean scenario values for the electrical prices, PV output, WT output, and hydrogen demand profiles, as previously detailed in

Section 2 and depicted in

Figure 7 [

21]. Although this method is applicable to any microgrid, it primarily examines three specific microgrids within the MMG framework.

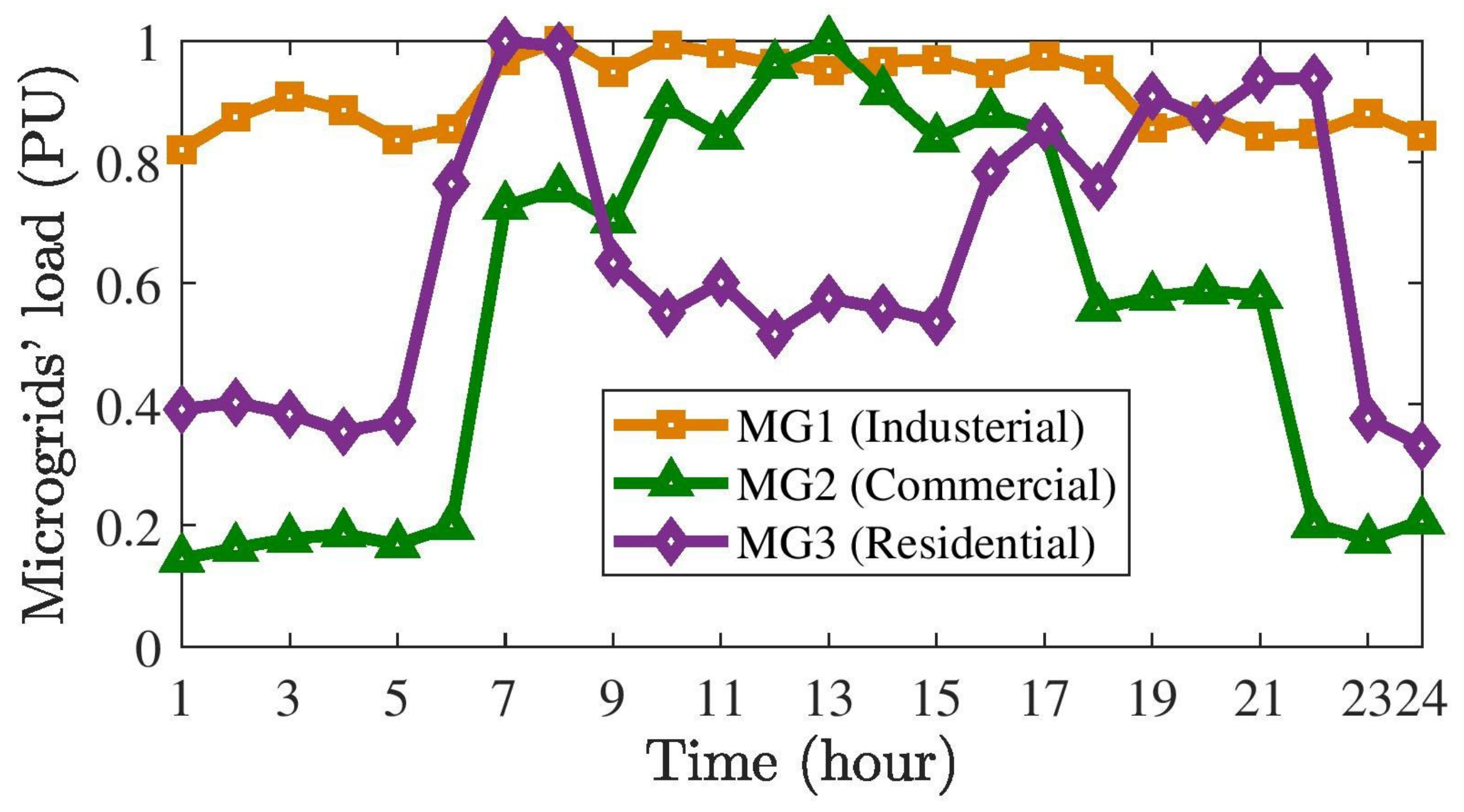

Figure 8 presents the average load scenario across three microgrids, segmented into industrial, residential, and commercial microgrids [

21]. The technical details of the HSS in these microgrids are provided in

Table 3. The highest electricity price recorded is 45.5 cents per kWh. For MG1, MG2, and MG3, the peak loads are consistently 1 MW, 0.9 MW, and 0.7 MW, respectively. In addition, across all the MGs, the peak output from the photovoltaic (PV) systems and wind turbine (WT) are 0.5 MW and 0.8 MW, respectively. Additionally, the peak hydrogen demand is 25 kg. The PCC capacity is set at 3 MW.

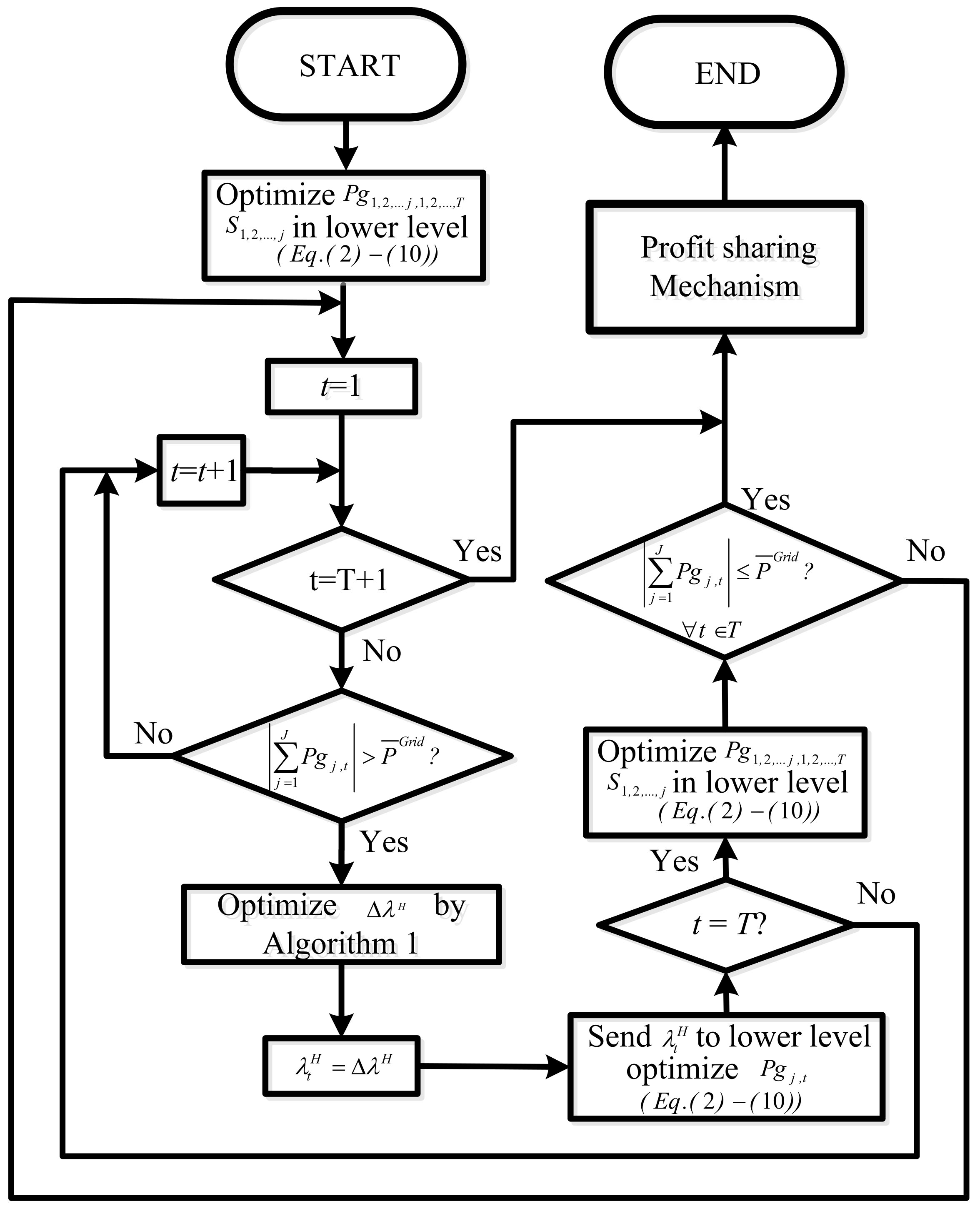

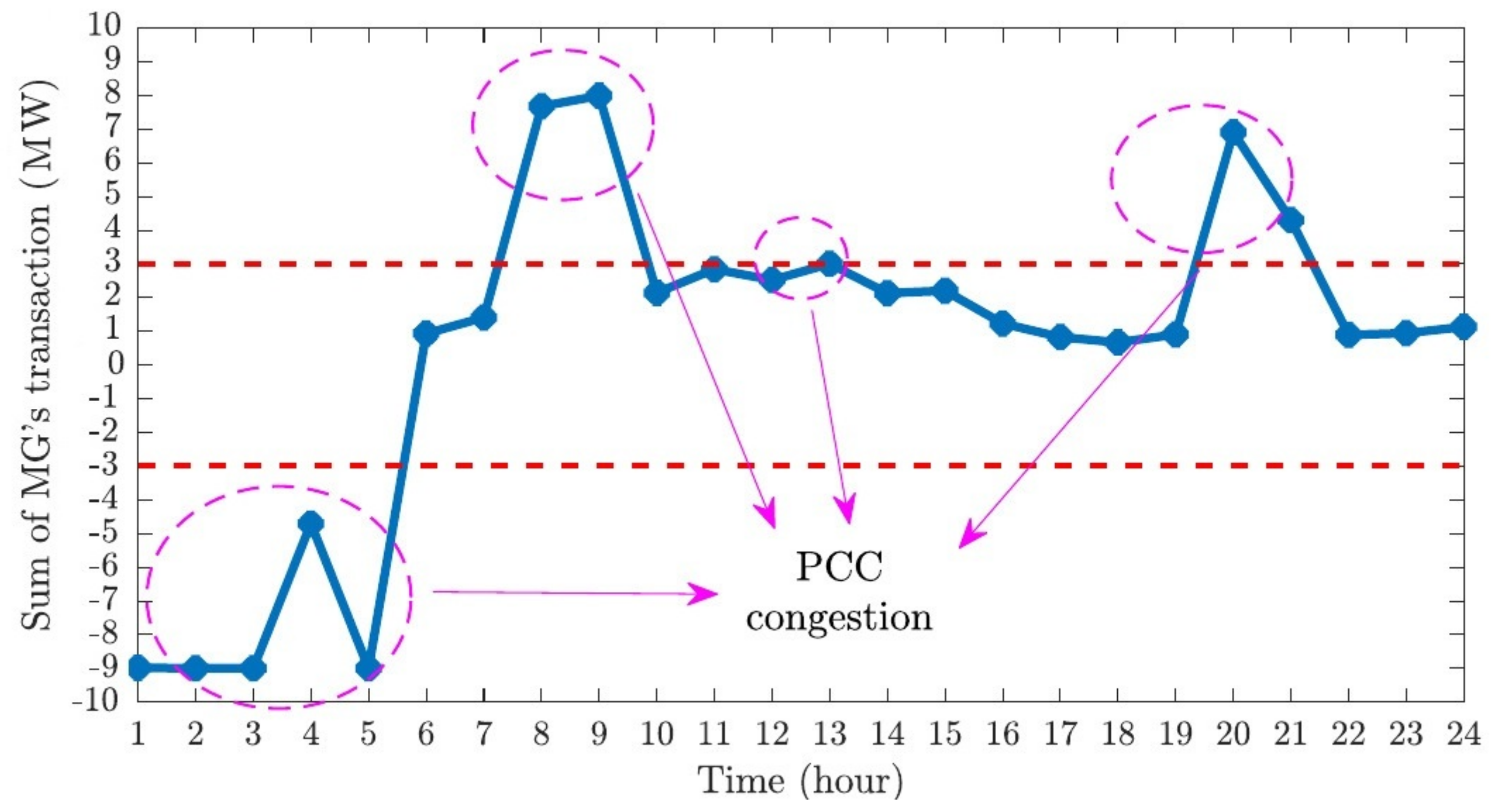

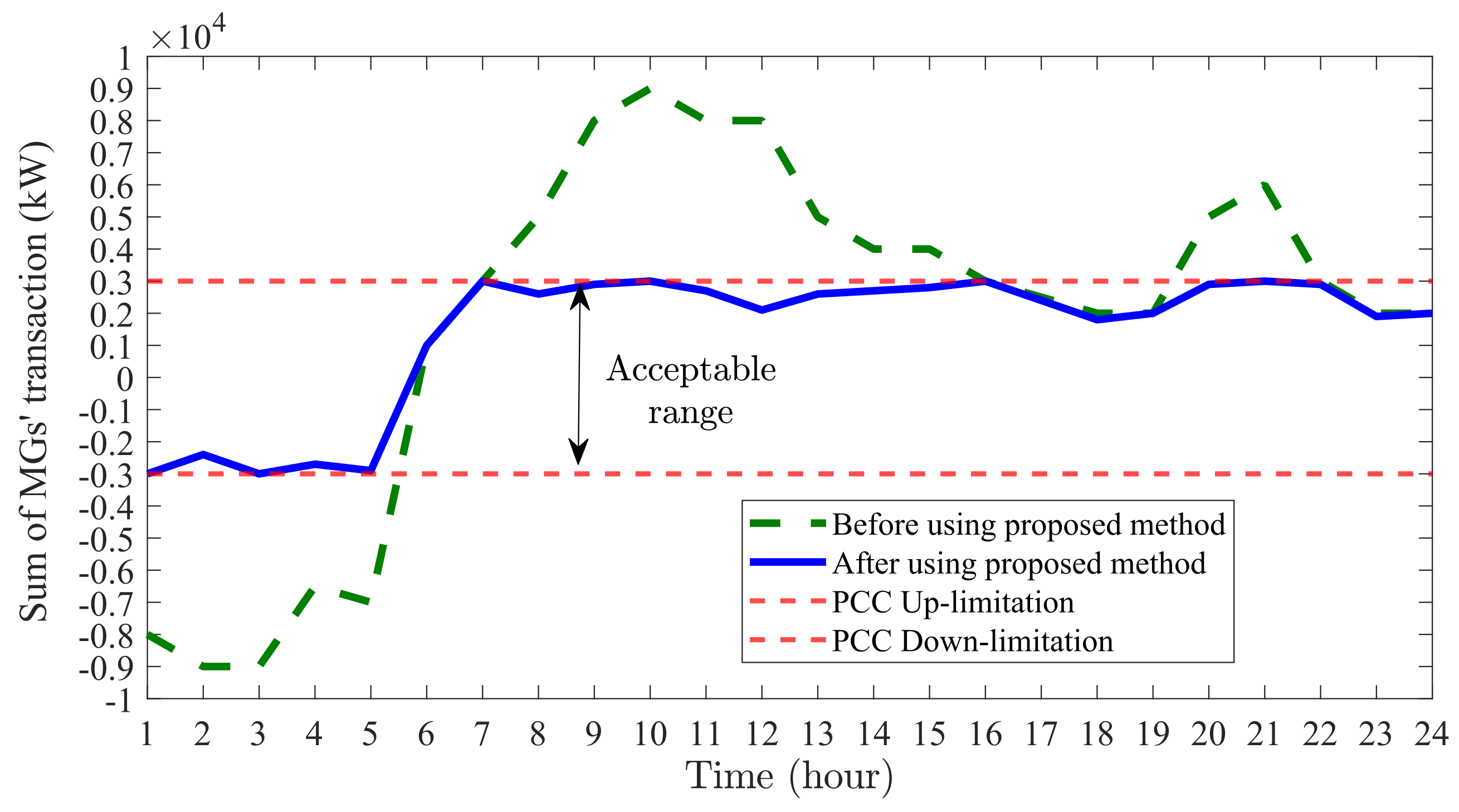

Each Microgrid transmits its power exchange profile to the HMS, which then calculates the total exchanged power by combining these profiles.

Figure 9 illustrates the sum of the average exchanged power between the MMG and the grid across all the scenarios. As indicated, the exchanged power falls outside the acceptable limits during hours 1 to 5, 8 to 9, 13, and 20 to 21.

To ensure that the trading power remains within the acceptable range, the sum of the mismatch power must be confined within the area defined by the two dotted lines in

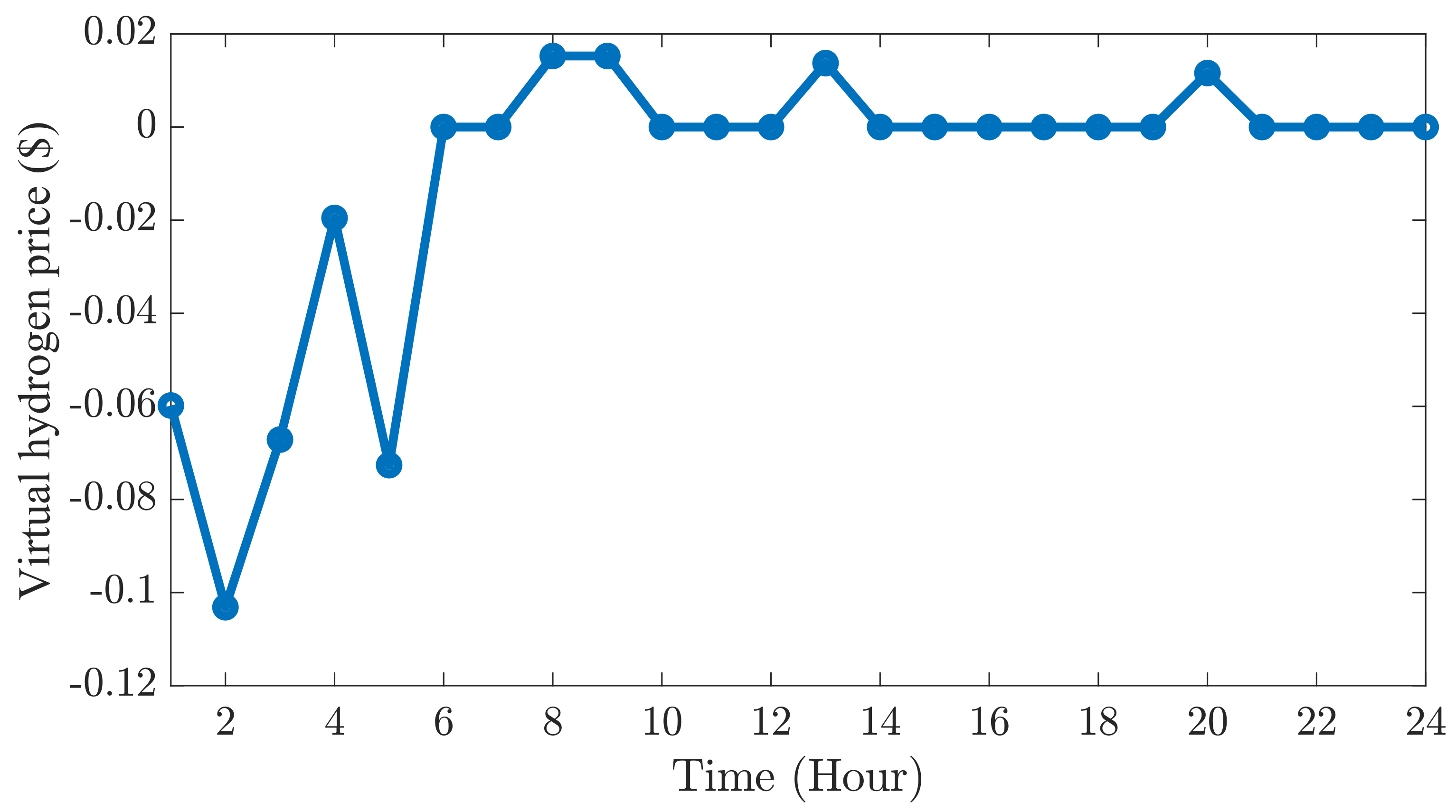

Figure 10. For this purpose, the HMS based on Algorithm 1 optimizes virtual hydrogen prices and communicates them to the microgrids. This process continues until constraint (17) is satisfied.

The optimized adjustments to virtual hydrogen prices are shown in

Figure 10. As previously mentioned, the lower energy prices during hours 1 to 5 encourage the microgrids to buy power from the grid, convert it to hydrogen, and then store the hydrogen. Specifically, the HMS optimizes the negative prices by reducing the hydrogen price from zero to negative values during these hours, leading to a decrease in hydrogen charging. Conversely, during hours 8, 9, 13, and 20, the HMS increases the virtual hydrogen prices from zero to a positive value, thus encouraging the charging of hydrogen in the hydrogen tank instead of selling power to the grid.

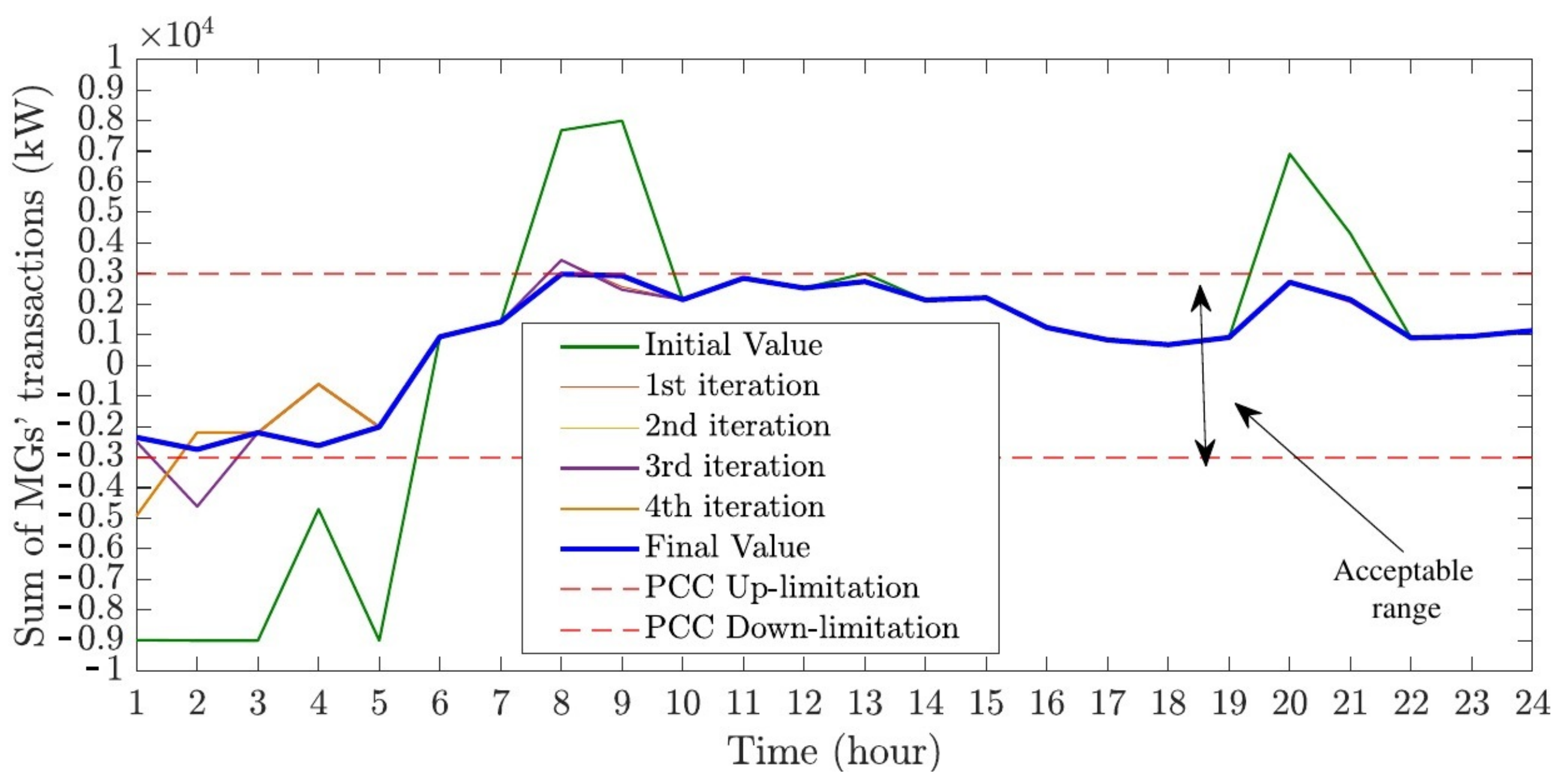

Figure 11 depicts the converge diagram of the average of transaction power between MG1, MG2, MG3, and the grid. The acceptable range for the power transactions is shown as the area between the two dashed horizontal lines. As mentioned before, initially, the exchanged power exceeds the acceptable range during hours 1 to 5, 8, 9, 13, 20 and 21. The proposed method in each iteration optimizes the virtual hydrogen prices, creating new values for power exchange. Although optimizing virtual hydrogen prices hourly using Algorithm 1 may cause violations in other hours, the proposed method iterates to ensure that the power exchange remains within the acceptable range at all times. In the case study, after five iterations, the method is converged. Although the PCC can temporarily withstand overloads, an overload approaching 300% of the rated capacity for as long as five hours represents an extreme scenario and will trigger protective systems to become active.

In this case, the HMS calculates the total profit of the microgrids at USD 19,375. This profit is subsequently allocated to the profit-sharing mechanism, which distributes it among the MGs based on the Shapley value. As a result, the earnings for MG1, MG2, and MG3 are USD 6358, USD 6558, and USD 6459, respectively. The problem reached convergence after five iterations, and the simulation time totaled approximately 691 s.

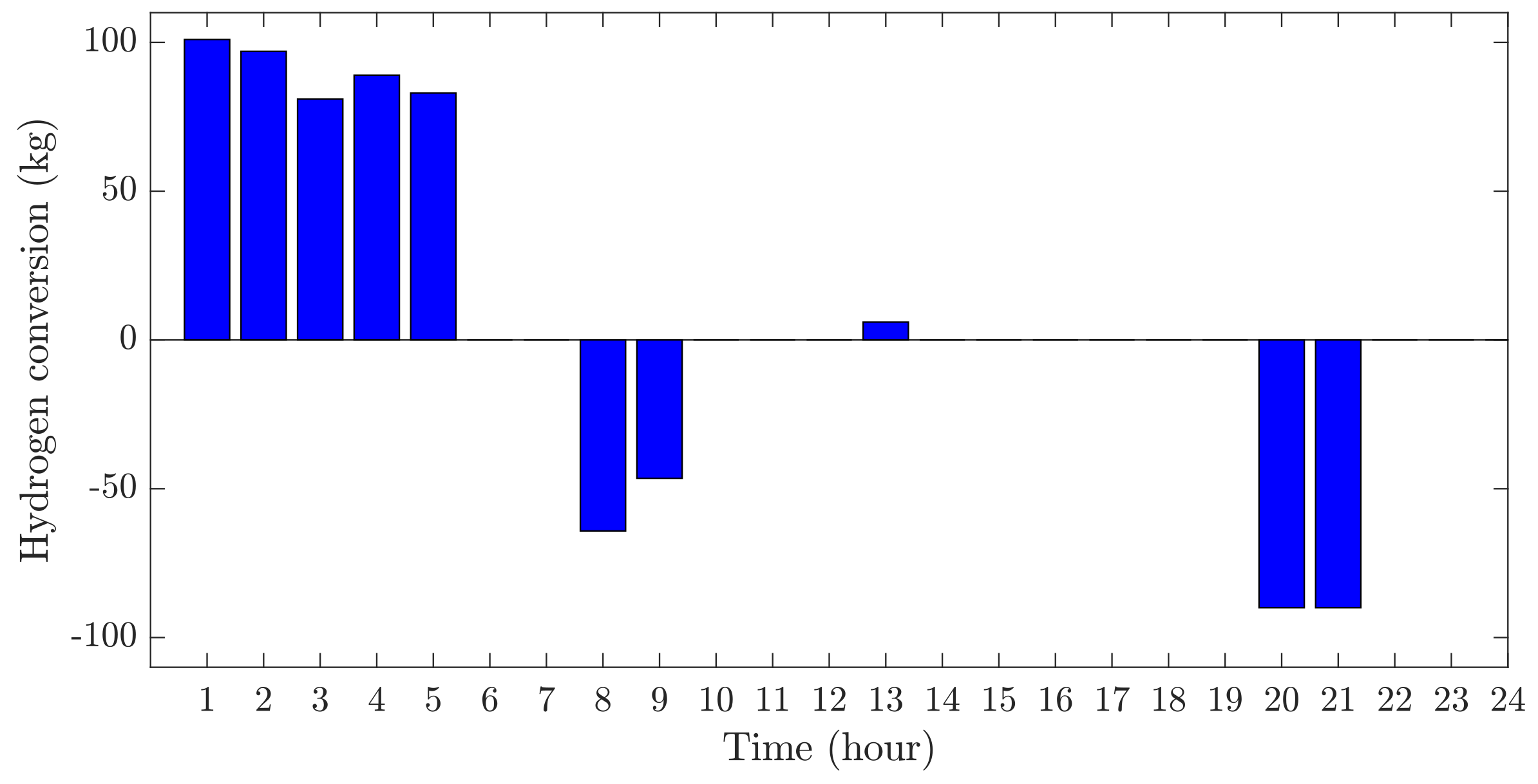

Figure 12 displays the conversion of hydrogen to power and the production of hydrogen from power over a day. As observed in

Figure 11, during the initial five hours, when electricity prices are reduced (as illustrated in

Figure 7), all the microgrids begin to charge their hydrogen storage. This activity is a primary cause of congestion at the PCC, as depicted in

Figure 11. Similarly, in hours 8, 9, 20, and 21, when electricity prices are high (also shown in

Figure 7), all the microgrids begin to discharge their hydrogen storage. The proposed algorithm optimizes the value of hydrogen conversion in these hours, optimizing the profit of the MMG and addressing the congestion in the PCC.

As shown in

Figure 12, the proposed algorithm addresses PCC congestion by readjusting the timing and amount of hydrogen transactions based on the virtual hydrogen prices (see

Figure 10), which helps to reduce congestion during peak hours. For example, during the early hours (hours 1 to 5), when electricity is cheaper and demand is low, all the microgrids charge their hydrogen storage to take advantage of the lower prices and store energy. During peak price hours—specifically at hours 8 and 9 and from hours 20 to 21—the microgrids release their stored hydrogen to benefit from higher energy prices, thus maximizing profits. Additionally, at hour 13, when energy production exceeds what the PCC can handle, the system stores the excess energy as hydrogen instead of sending it to the grid. The gaps in the data shown in

Figure 12 indicate periods when neither electrolyzers nor fuel cells are working; a strategy that maximizes the profits for the microgrids. These operational details are crucial for the efficiency of the proposed model, ensuring that the HSS is used optimally to maximize the profit with technical challenges like congestion at the PCC.

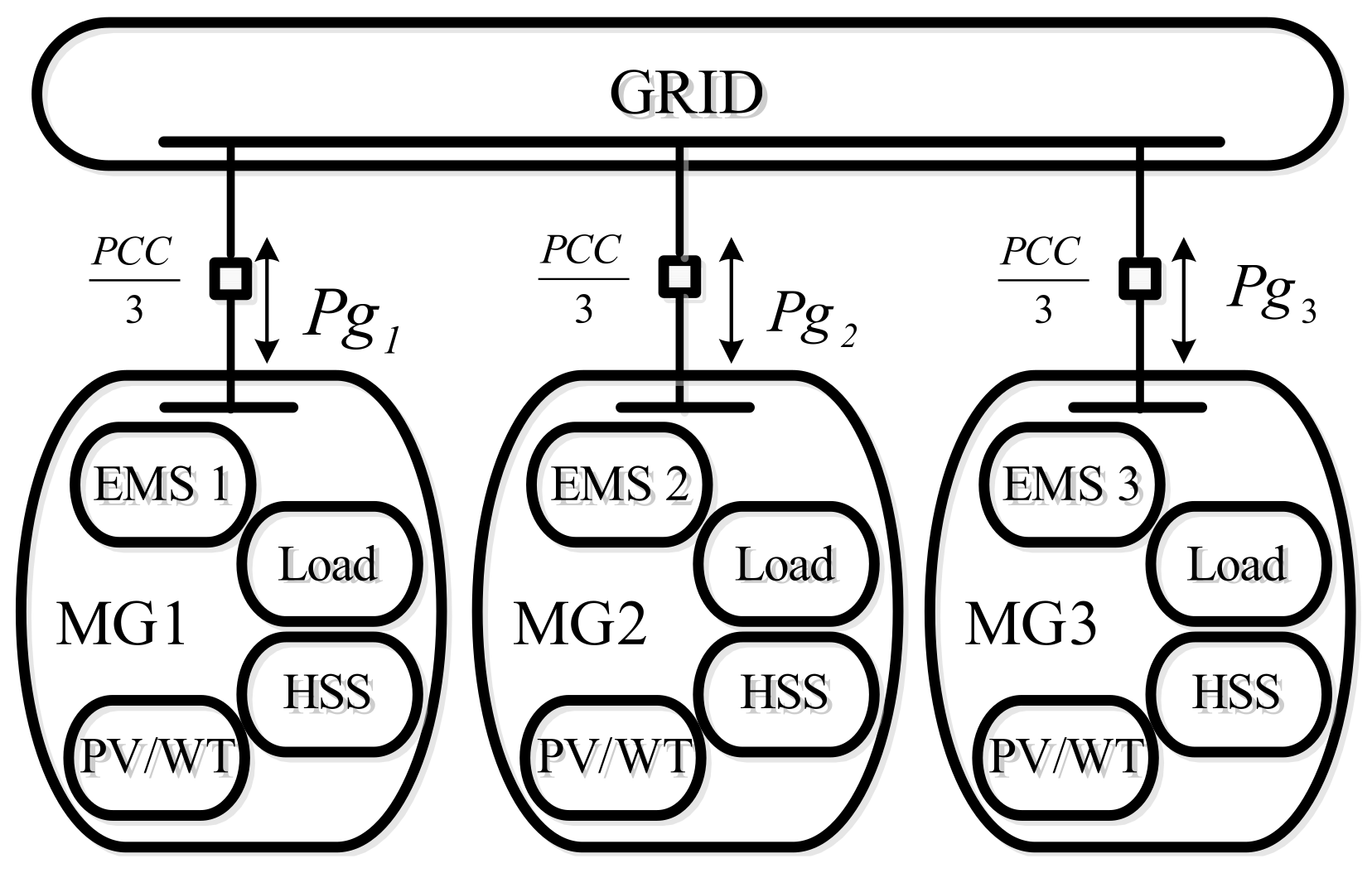

The proposed hybrid energy management systems, while preserving customer privacy, might decrease profits by potentially trapping solutions at local optimum points. To achieve global optimization, a centralized EMS (

Figure 13) should be considered that schedules all the microgrids. The profit of the centralized model is obtained using (19):

subject to the constraints of (20), which defines the PCC capacity.

Optimizing (19), considering (20) and the previous constraints, sharing all the data through the centralized EMS leads to the total profit of the MMG increasing by USD 20,324, indicating that although our proposed method preserves the privacy of the MGs, the total profit decreases by 4.9 % compared with the global solution.

Another possible solution to preserve privacy among the MGs involves dividing the PCC capacity among them, meaning that each MG receives an equal share of the PCC capacity (

Figure 14). In this solution, constraint (4), which defines the PCC capacity, is modified by (21).

Optimizing (1) and considering (21) and the previous constraints of approach, the total profit of the microgrids amounts to USD 18,193. Consequently, the profits for MG1, MG2, and MG3 are USD 5902, USD 6210, and USD 6081, respectively. This method, while less burdensome, results in a total profit decrease of 6.1 % compared with the proposed method and 11.3 % compared with the global solution.

To validate the proposed method, the results were compared with those of previous studies. The findings in ref. [

4] indicate that this method increases the MMG’s profit more effectively than the methods in refs [

10,

11]. Therefore, this study compares the proposed method with ref. [

4]. Similar to the approach in ref. [

4], for comparison, the demand response (DR) program based on the data from [

4] has been incorporated into the proposed method for comparison with ref. [

4]. The comparison between the results of the proposed method, ref. [

4], and the global optimization solution is presented in

Table 4.

The proposed method, which includes the DR program, increases the total profit of the microgrids by approximately 0.65% compared to ref. [

4]. However, the global optimization solution yields a higher profit, surpassing the proposed method by approximately 8.97%. This demonstrates that the efficiency of the proposed method is comparable to that of ref. [

4]. Consequently, it can increase the microgrids’ profit more than the profits reported in refs. [

10,

11].

The proposed method was tested in two distinct scenarios: (i) summer (on the 14th day of the second month) and (ii) winter (on the 14th day of the second month). During the summer scenario, due to the increased output from photovoltaic systems, the microgrids tended to sell power back to the grid to maximize their profits. This often resulted in them exceeding the upper limit of the PCC capacity, particularly between hours 7 to 16, as shown in

Figure 15. The proposed model enabled the individual microgrids to manage their energy transactions effectively, thereby resolving congestion at the PCC. Notably, during the early hours of the day, the microgrids tended to purchase electricity at lower prices to charge their hydrogen storage systems, which occasionally led to them exceeding the lower PCC limit.

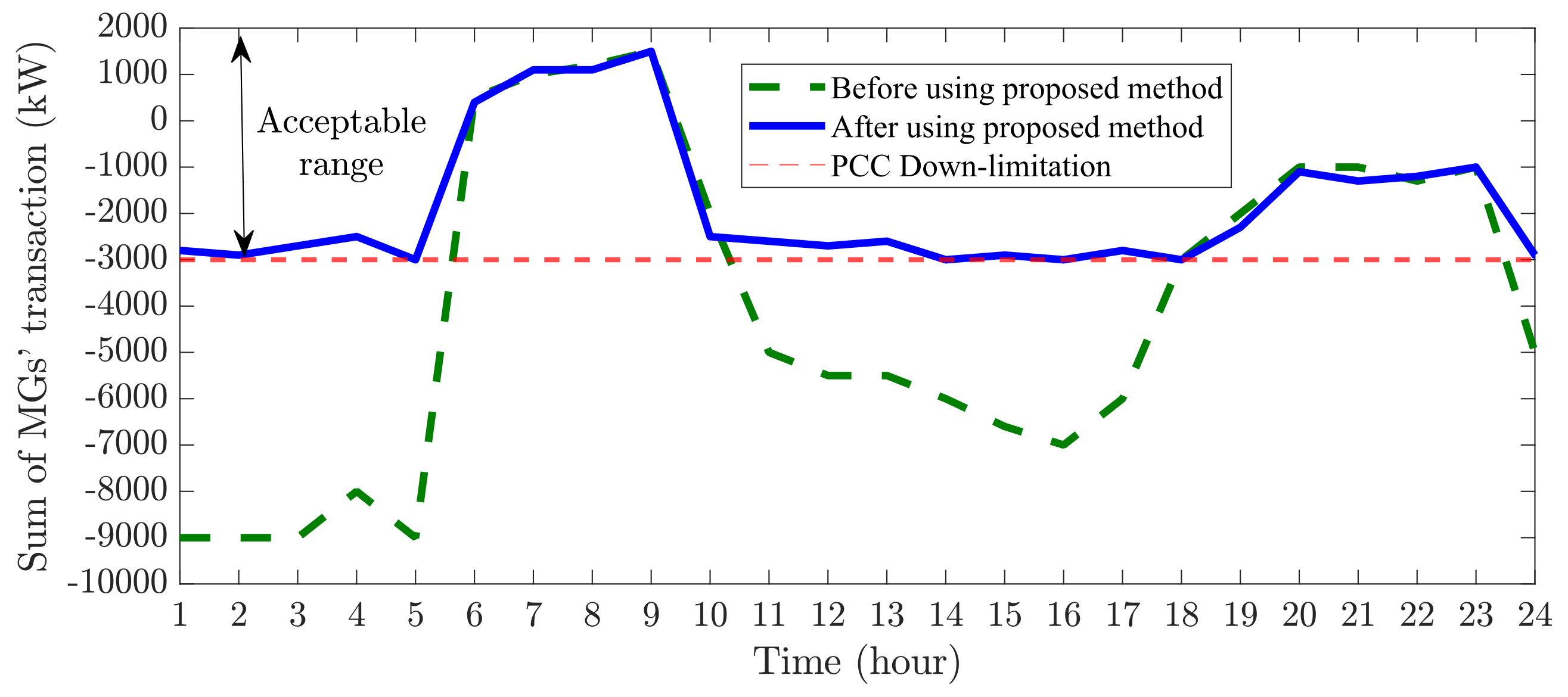

Conversely, the winter scenario, depicted in

Figure 16, presented different challenges due to decreased solar energy availability and increased heating demands, leading to frequent exceedances of the lower PCC limit. The proposed method adeptly managed PCC congestion through the flexible operation of hydrogen storage systems, which balanced the energy supply, especially when renewable generation was insufficient. This scenario underscores the versatility and effectiveness of our model in handling seasonal fluctuations in energy demand and generation, affirming the proposed method as a reliable solution for PCC congestion across diverse environmental conditions.