Exploring Performance of Pyrolysis-Derived Plastic Oils in Gas Turbine Engines

Abstract

1. Introduction

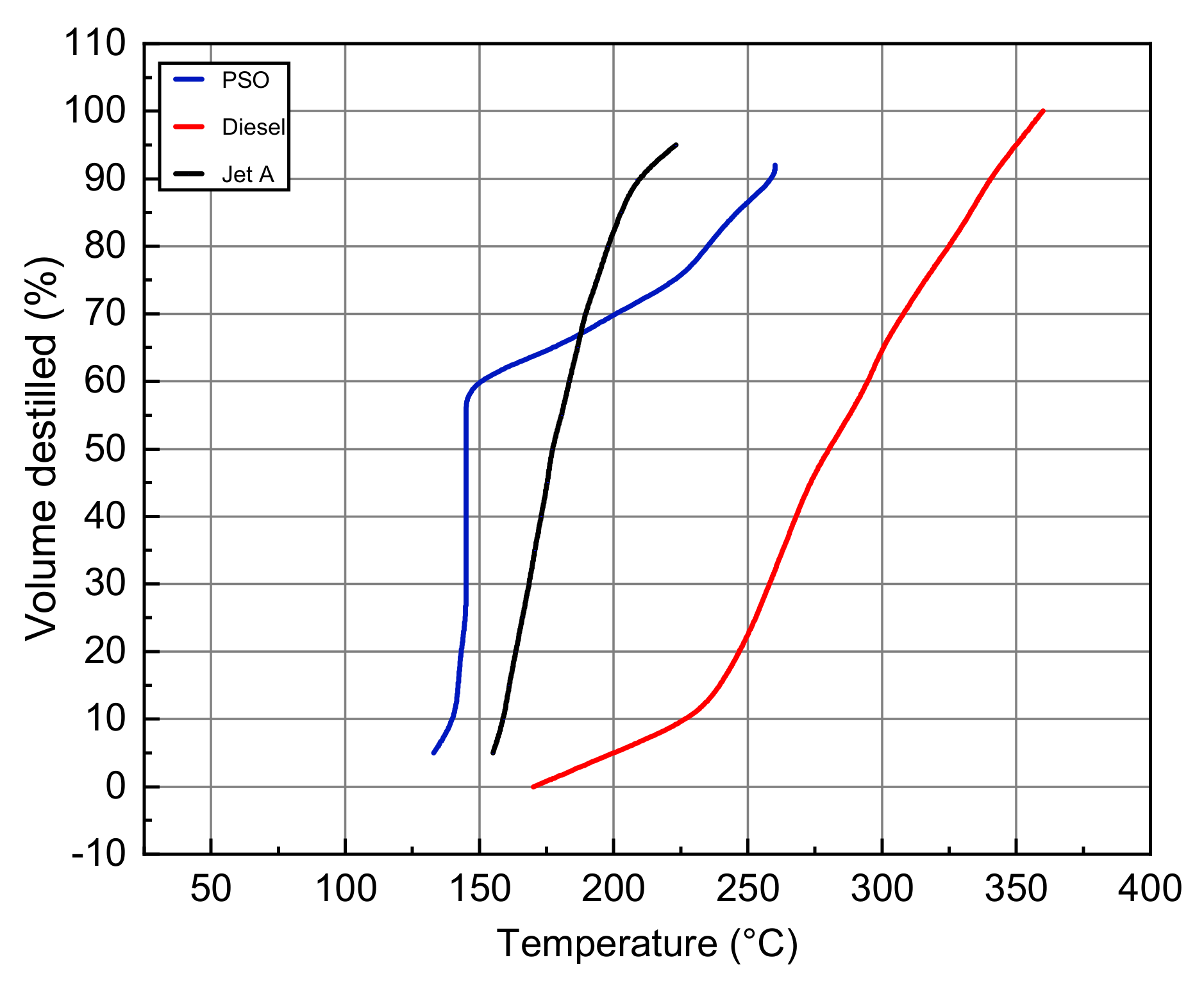

2. Fuel

3. Test Stand and Methodological Approach of GTM-140 Engine

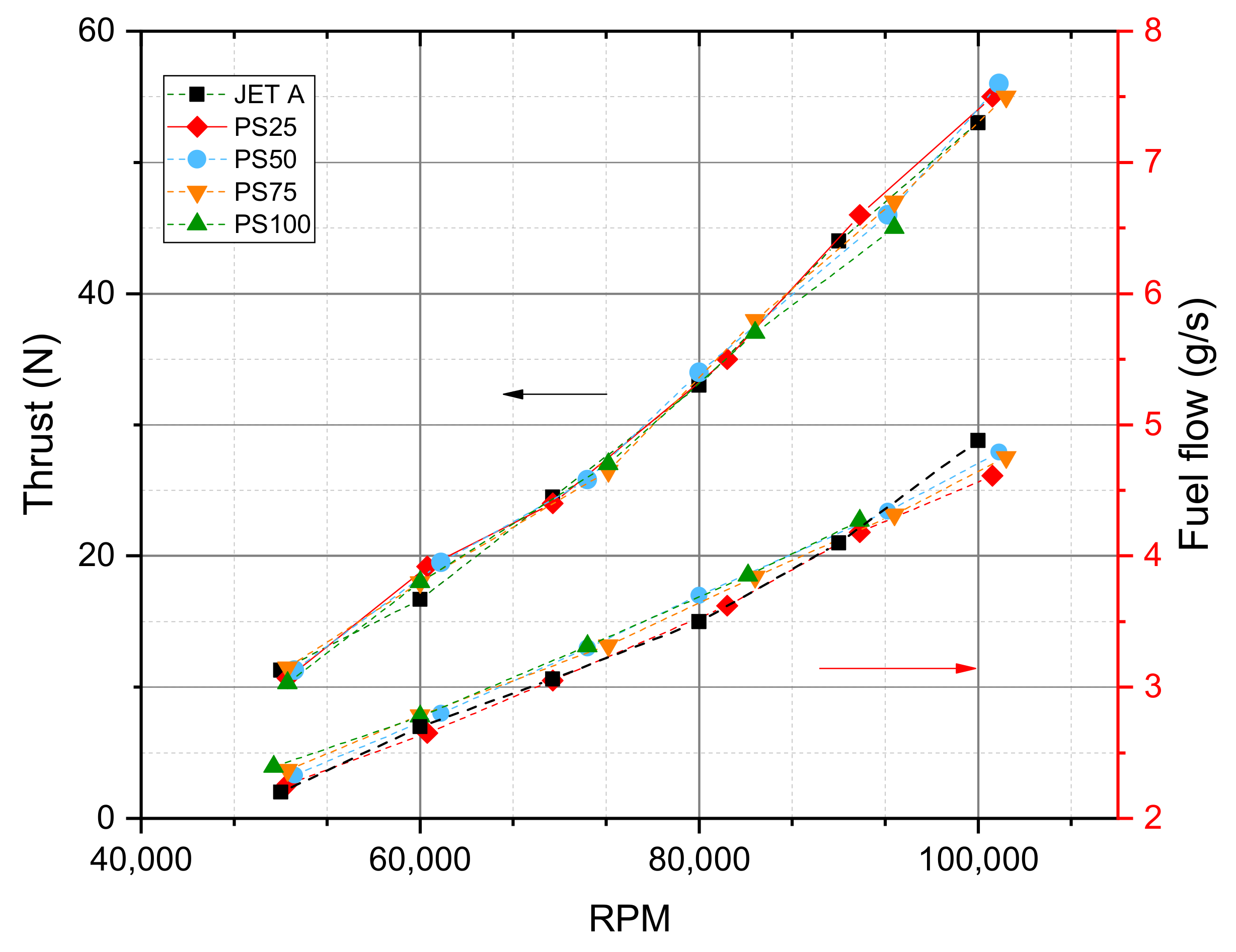

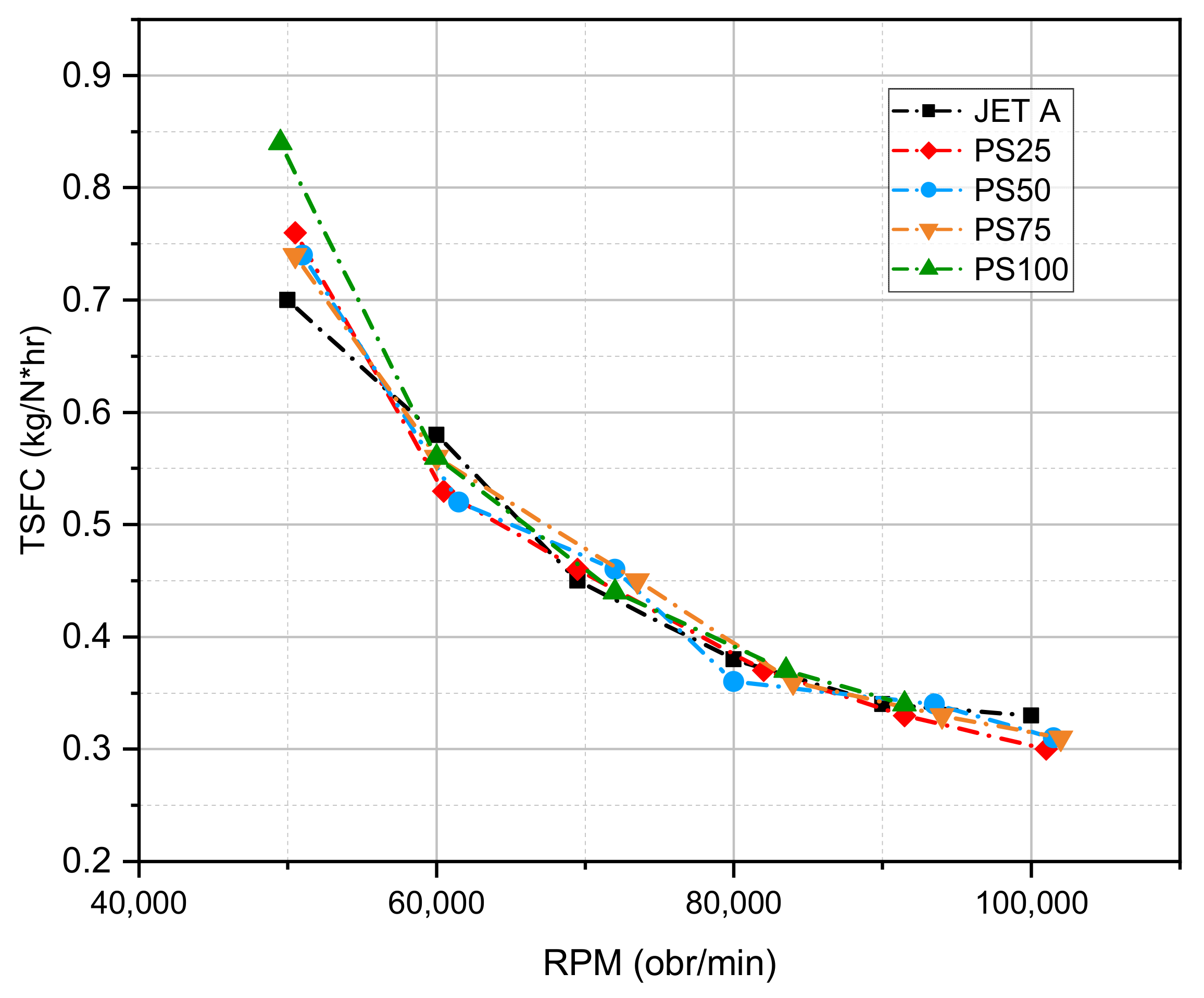

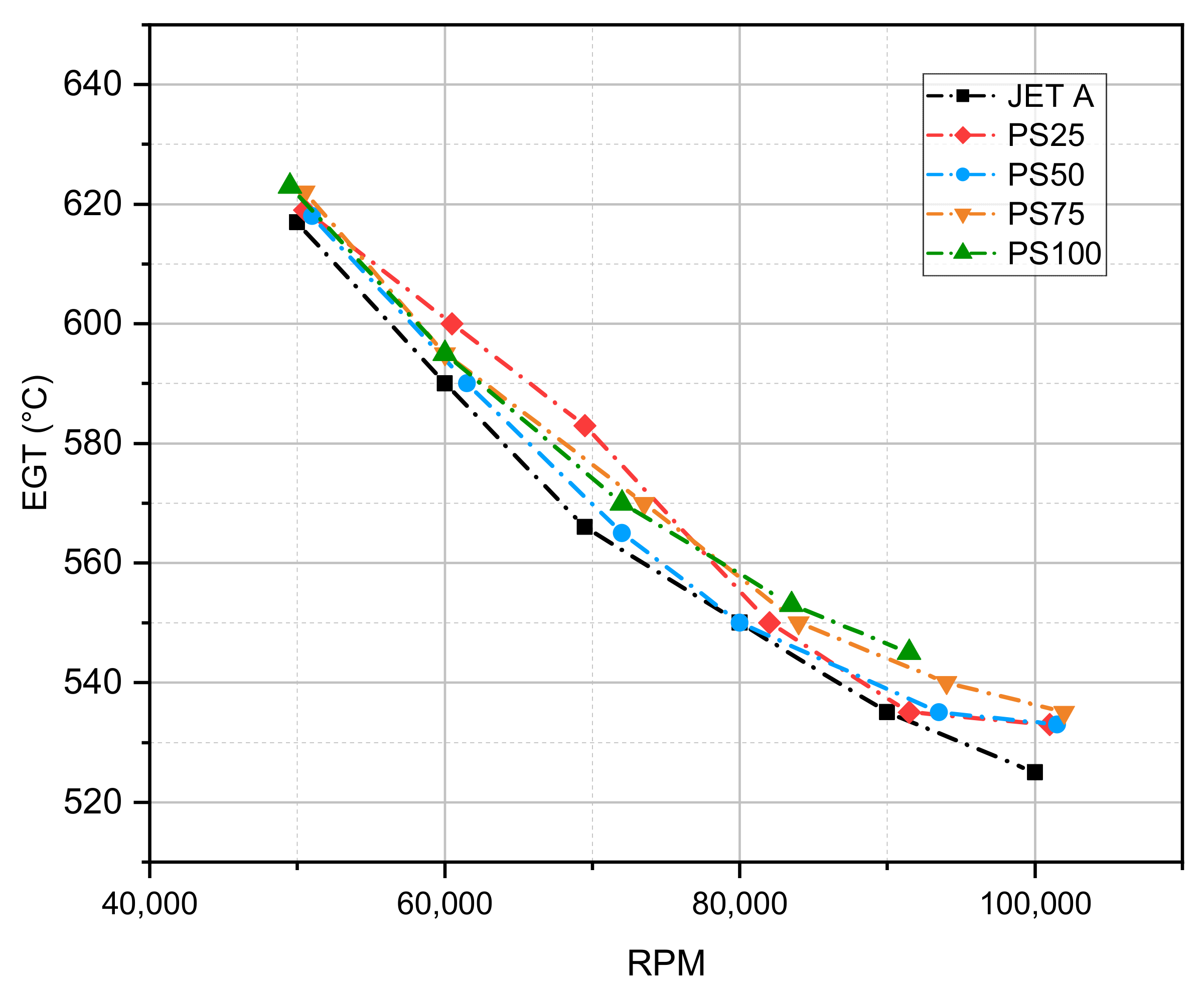

4. Performance Characteristics of the GTM-140 Engine

5. Emission Indexes of the GTM-140 Engine

6. Conclusions

- The thermal productivity of the micro gas turbine engine, as suggested by thrust-specific fuel consumption, was found to be comparable to standard fuel when operated on polystyrene oil, across a majority of the characteristics. For lower rotational speeds up to 60,000 rpm, the inclusion of more PSO in the blend with JET A resulted in an elevation in TSFC by up to 20% relative to pure JET A. However, despite a significantly lower heating value of up to 10%, the TSFC of the engine functioning on polystyrene pyrolytic oil was observed to be similar to that powered by the standard fuel for the rest of the TSFC traits.

- The exit temperatures of the gas turbine engine registered a rise by 10–15 °C for PSO/JET A blends in comparison to pure JET A.

- A pronounced escalation in the thrust-specific NOX emission index of the micro gas turbine was noticed with the introduction of polystyrene oil to the blend with JET A. This trend remained constant for all examined PSO blends across the entirety of speeds probed, with the maximum average increase being 70% for pure PSO in contrast to pure JET A.

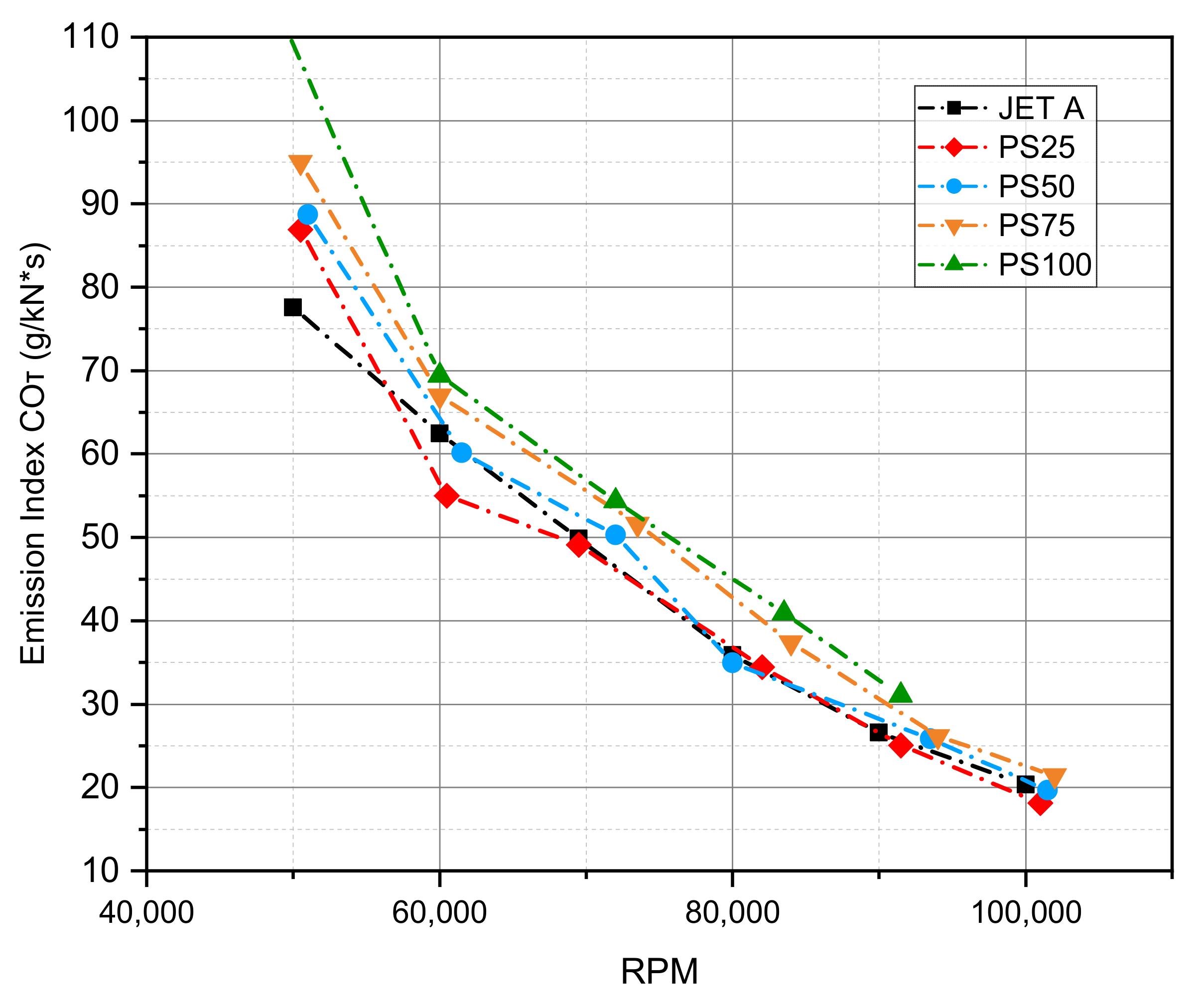

- The thrust-specific CO emission index for PSO/JET A blends was typically elevated by around 5–20% in comparison to that of JET A, contingent on the PSO content and operational range.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| CO | carbon monoxide |

| CO2 | carbon diooxide |

| NOx | nitrogen oxides |

| HHV | higher heating value |

| PS | polystyrene |

| PSO | polystyrene oil |

| PS25, PS50, PS75, PS100 | blend of PSO with JET A with 25%, 50%, 75% 100% of PSO, respectively |

| UHC | unburned hydrocarbons |

| WPPO | waste plastic pyrolysis oil |

| EGT [°C] | exhaust gas temperature |

| EIi,τ [-] | gas species (i) thrust-specific emission index |

| [kg/h] | fuel mass flow rate |

| [kg/h] | gas species (i) mass flow rate |

| MWfuel [kg/mol] | fuel molecular weight |

| MWi [kg/mol] | gas species (i) molecular weight |

| τ [N] | static thrust |

| TSFC [kg/sN] | thrust-specific fuel consumption |

| x | number of carbon atoms in the fuel molecule |

| [-] | carbon monoxide mole fraction |

| [-] | carbon dioxide mole fraction |

| [-] | gas species (i) mole fraction |

References

- Barsali, S.; De Marco, A.; Giglioli, R.; Ludovici, G.; Possenti, A. Dynamic modelling of biomass power plant using micro gas turbine. Renew. Energy 2015, 80, 806–818. [Google Scholar] [CrossRef]

- Chiaramonti, D.; Goumas, T. Impacts on industrial-scale market deployment of advanced biofuels and recycled carbon fuels from the EU Renewable Energy Directive II. Appl. Energy 2019, 251, 113351. [Google Scholar] [CrossRef]

- PlasticsEurope Market Research Group (PEMRG); Conversio Market & Strategy GmbH. Plastics—The Facts 2019: An Analysis of European Plastics Production, Demand and Waste Data; PlasticsEurope: Brussels, Belgium, 2019. [Google Scholar]

- Plastic Europe Plastics—The Facts 2020. Available online: https://plasticseurope.org/knowledge-hub/plastics-the-facts-2020/ (accessed on 1 June 2023).

- Hopewell, J.; Dvorak, R.; Kosior, E. Plastics recycling: Challenges and opportunities. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 2115–2126. [Google Scholar] [CrossRef]

- Bridgwater, A.V. Review of fast pyrolysis of biomass and product upgrading. Biomass Bioenergy 2012, 38, 68–94. [Google Scholar] [CrossRef]

- Wang, S.; Rodriguez Alejandro, D.A.; Kim, H.; Kim, J.Y.; Lee, Y.R.; Nabgan, W.; Hwang, B.W.; Lee, D.; Nam, H.; Ryu, H.J. Experimental investigation of plastic waste pyrolysis fuel and diesel blends combustion and its flue gas emission analysis in a 5 kW heater. Energy 2022, 247, 123408. [Google Scholar] [CrossRef]

- Dobó, Z.; Jakab, Z.; Nagy, G.; Koós, T.; Szemmelveisz, K.; Muránszky, G. Transportation fuel from plastic wastes: Production, purification and SI engine tests. Energy 2019, 189, 116353. [Google Scholar] [CrossRef]

- Rajak, U.; Panchal, M.; Veza, I.; Ağbulut, Ü.; Nath Verma, T.; Sarıdemir, S.; Shende, V. Experimental investigation of performance, combustion and emission characteristics of a variable compression ratio engine using low-density plastic pyrolyzed oil and diesel fuel blends. Fuel 2022, 319, 123720. [Google Scholar] [CrossRef]

- van der Westhuizen, S.; Collard, F.X.; Görgens, J. Pyrolysis of waste polystyrene into transportation fuel: Effect of contamination on oil yield and production at pilot scale. J. Anal. Appl. Pyrolysis 2022, 161, 105407. [Google Scholar] [CrossRef]

- Nisar, J.; Ali, G.; Shah, A.; Farooqi, Z.H.; Iqbal, M.; Khan, S.; Sherazi, S.T.H.; Sirajuddin. Production of fuel oil and combustible gases from pyrolysis of polystyrene waste: Kinetics and thermodynamics interpretation. Environ. Technol. Innov. 2021, 24, 101996. [Google Scholar] [CrossRef]

- Januszewicz, K.; Hunicz, J.; Kazimierski, P.; Rybak, A.; Suchocki, T.; Duda, K.; Mikulski, M. An experimental assessment on a diesel engine powered by blends of waste-plastic-derived pyrolysis oil with diesel. Energy 2023, 281, 128330. [Google Scholar] [CrossRef]

- Kumar, S.; Prakash, R.; Murugan, S.; Singh, R.K. Performance and emission analysis of blends of waste plastic oil obtained by catalytic pyrolysis of waste HDPE with diesel in a CI engine. Energy Convers. Manag. 2013, 74, 323–331. [Google Scholar] [CrossRef]

- Das, A.K.; Hansdah, D.; Mohapatra, A.K.; Panda, A.K. Energy, exergy and emission analysis on a DI single cylinder diesel engine using pyrolytic waste plastic oil diesel blend. J. Energy Inst. 2020, 93, 1624–1633. [Google Scholar] [CrossRef]

- Singh, R.K.; Ruj, B.; Sadhukhan, A.K.; Gupta, P.; Tigga, V.P. Waste plastic to pyrolytic oil and its utilization in CI engine: Performance analysis and combustion characteristics. Fuel 2020, 262, 116539. [Google Scholar] [CrossRef]

- Kalargaris, I.; Tian, G.; Gu, S. Combustion, performance and emission analysis of a DI diesel engine using plastic pyrolysis oil. Fuel Process. Technol. 2017, 157, 108–115. [Google Scholar] [CrossRef]

- Mariappan, M.; Panithasan, M.S.; Venkadesan, G. Pyrolysis plastic oil production and optimisation followed by maximum possible replacement of diesel with bio-oil/methanol blends in a CRDI engine. J. Clean. Prod. 2021, 312, 127687. [Google Scholar] [CrossRef]

- ASTM D1298; Standard Test Method for Density, Relative Density (Specific Gravity), or API Gravity of Crude Petroleum and Liquid Petroleum Products by Hydrometer Method. ASTM International: West Conshohocken, PA, USA, 2012.

- ASTM D445; Standard Test Method for Kinematic Viscosity of Transparent and Opaque Liquids (and Calculation of Dynamic Viscosity). ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM D4809-95; Standard Test Method for Heat of Combustion of Liquid Hydrocarbon Fuels by Bomb Calorimeter (Precision Method). ASTM International: West Conshohocken, PA, USA, 1995.

- ASTM D92; Standard Test Method for Flash and Fire Points by Cleveland Open Cup Tester. ASTM International: West Conshohocken, PA, USA, 2011.

- Buffi, M.; Seljak, T.; Cappelletti, A.; Bettucci, L.; Valera-Medina, A.; Katrašnik, T.; Chiaramonti, D. Performance and emissions of liquefied wood as fuel for a small scale gas turbine. Appl. Energy 2018, 230, 1193–1204. [Google Scholar] [CrossRef]

- Krakos, A.; Janicka, A.; Molska, J.; Zawiślak, M.; Lizanets, D.; Białecki, T.; Gawron, B.; Suchocki, T. Microfluidic-assisted toxicity studies of jet fuels on environmental microorganisms—Towards new lab-on-a-chip sensing applications. Meas. J. Int. Meas. Confed. 2022, 204, 112037. [Google Scholar] [CrossRef]

- Chmielewski, M.; Niszczota, P.; Gieras, M. Combustion efficiency of fuel-water emulsion in a small gas turbine. Energy 2020, 211, 118961. [Google Scholar] [CrossRef]

- Habib, Z.; Parthasarathy, R.; Gollahalli, S. Performance and emission characteristics of biofuel in a small-scale gas turbine engine. Appl. Energy 2010, 87, 1701–1709. [Google Scholar] [CrossRef]

- Kazimierski, P.; Hercel, P.; Suchocki, T.; Smoliński, J.; Pladzyk, A.; Kardaś, D.; Łuczak, J.; Januszewicz, K. Pyrolysis of pruning residues from various types of orchards and pretreatment for energetic use of biochar. Materials 2021, 14, 2969. [Google Scholar] [CrossRef]

- Suchocki, T.; Kazimierski, P.; Lampart, P.; Januszewicz, K.; Białecki, T.; Gawron, B.; Janicka, A. A comparative study of pentanol (C5 alcohol) and kerosene blends in terms of gas turbine engine performance and exhaust gas emission. Fuel 2023, 334 Pt 2, 126741. [Google Scholar] [CrossRef]

- Mendez, C.; Parthasarathy, R.; Gollahalli, S. Performance and Emission Characteristics of a Small-Scale Gas Turbine Engine Fueled with Ethanol/Jet A Blends. In Proceedings of the 50th AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, Nashville, TN, USA, 9–12 January 2012; American Institute of Aeronautics and Astronautics: Reston, VI, USA, 2012; pp. 1359–1370. [Google Scholar]

- Gawron, B.; Białecki, T.; Janicka, A.; Suchocki, T. Combustion and emissions characteristics of the turbine engine fueled with HeFA blends from different feedstocks. Energies 2020, 13, 1277. [Google Scholar] [CrossRef]

- Turns, S.R. An Introduction to Combustion—Concepts and Applications; McGraw-Hill: New York, NY, USA, 2012; ISBN 9780073380193. [Google Scholar]

- Suchocki, T.K.; Kazimierski, P.; Januszewicz, K.; Lampart, P.; Zaniewski, D.; Klimaszewski, P.; Witanowski, Ł. Pyrolysis-derived waste polypropylene oils in gas turbine engines: A comprehensive performance and emission study. Arch. Thermodyn. 2023, 44, 157–183. [Google Scholar] [CrossRef]

| ASTM Standard | Unit | Property | Method |

|---|---|---|---|

| D1298 [18] | kg/m3 | Density | density meters with U-tube oscillators (U-tube) |

| D445 [19] | m2/s | Kinematic Viscosity | Rheometer |

| D4809-95 [20] | MJ/kg | Calorific value | Calorimeter |

| D92 [21] | °C | Flash point | Persky–Martens flash point test |

| Property | JET A | PSO | Diesel [16] |

|---|---|---|---|

| Molecular weight [kg/kmol] | 142 | 117.8 | - |

| Chemical formula | C10H22 | C9,51H9,66 | |

| Density [kg/m3] | 821 (at 15 °C) | 943.5 | 840 |

| Viscosity [cP] | 1.5–2.6 (at 20 °C) | 1.012 | 2.62 (at 40 °C) |

| HHV [MJ/kg] | 43.28 | 40.5 | 42.9 |

| Flash point [°C] | 42 | >24 | 59.5 |

| Sulfur [wt%] | 0.3 | - | 0.00135 |

| C content [wt%] | 86.15 | 92 | 86.57 |

| H2 content [wt%] | 13.85 | 8 | 13.38 |

| O2 content [wt%] | 0.10 | - | 0.05 |

| Aromatic content [wt%] | 26 | 98 | 29.6 |

| Measured Parameter | Range | Unit | Device/Sensor Type | Resolution | Uncertainty |

|---|---|---|---|---|---|

| Temperatures of inlet/exit compressor/turbine sector (T1–T4) | 0–1100 °C | °C | Thermocouple K-Type | 1 °C | ±1 °C |

| Pressure of inlet/exit compressor and turbine sector (P1–P4) | P1 0–0.98 bar(a) P2–P4 0–9.8 bar(a) | bar | Digital pressure transducers | 0.01 bar | ±1.0% |

| Static Thrust | 0:200 | N | Strain gauges | 1 N | 1 mV/V |

| Fuel volumetric flow | 0.5–100 | LPH | Oval-gear flowmeter | 0.01 LPH | ±0.5% |

| Rotational speed | 0:200,000 | rpm | Rotational speed sensor—magnetic pick-up | 1 rpm | ±0.5% |

| Gas Emissions | Range | Unit | Device/Sensor Type | Resolution | Uncertainty |

| Oxygen | 0:20.95 | % | Electrochemical | 0.01% | ±0.2% absolute |

| or 5% rel. | |||||

| Carbon monoxide | 0:5000 | ppm | Electrochemical | 1 ppm | ±5 ppm absolute |

| or 5% rel. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suchocki, T.; Kazimierski, P.; Januszewicz, K.; Lampart, P.; Gawron, B.; Białecki, T. Exploring Performance of Pyrolysis-Derived Plastic Oils in Gas Turbine Engines. Energies 2024, 17, 3903. https://doi.org/10.3390/en17163903

Suchocki T, Kazimierski P, Januszewicz K, Lampart P, Gawron B, Białecki T. Exploring Performance of Pyrolysis-Derived Plastic Oils in Gas Turbine Engines. Energies. 2024; 17(16):3903. https://doi.org/10.3390/en17163903

Chicago/Turabian StyleSuchocki, Tomasz, Paweł Kazimierski, Katarzyna Januszewicz, Piotr Lampart, Bartosz Gawron, and Tomasz Białecki. 2024. "Exploring Performance of Pyrolysis-Derived Plastic Oils in Gas Turbine Engines" Energies 17, no. 16: 3903. https://doi.org/10.3390/en17163903

APA StyleSuchocki, T., Kazimierski, P., Januszewicz, K., Lampart, P., Gawron, B., & Białecki, T. (2024). Exploring Performance of Pyrolysis-Derived Plastic Oils in Gas Turbine Engines. Energies, 17(16), 3903. https://doi.org/10.3390/en17163903