A Review of Alternative Aviation Fuels

Abstract

1. Introduction

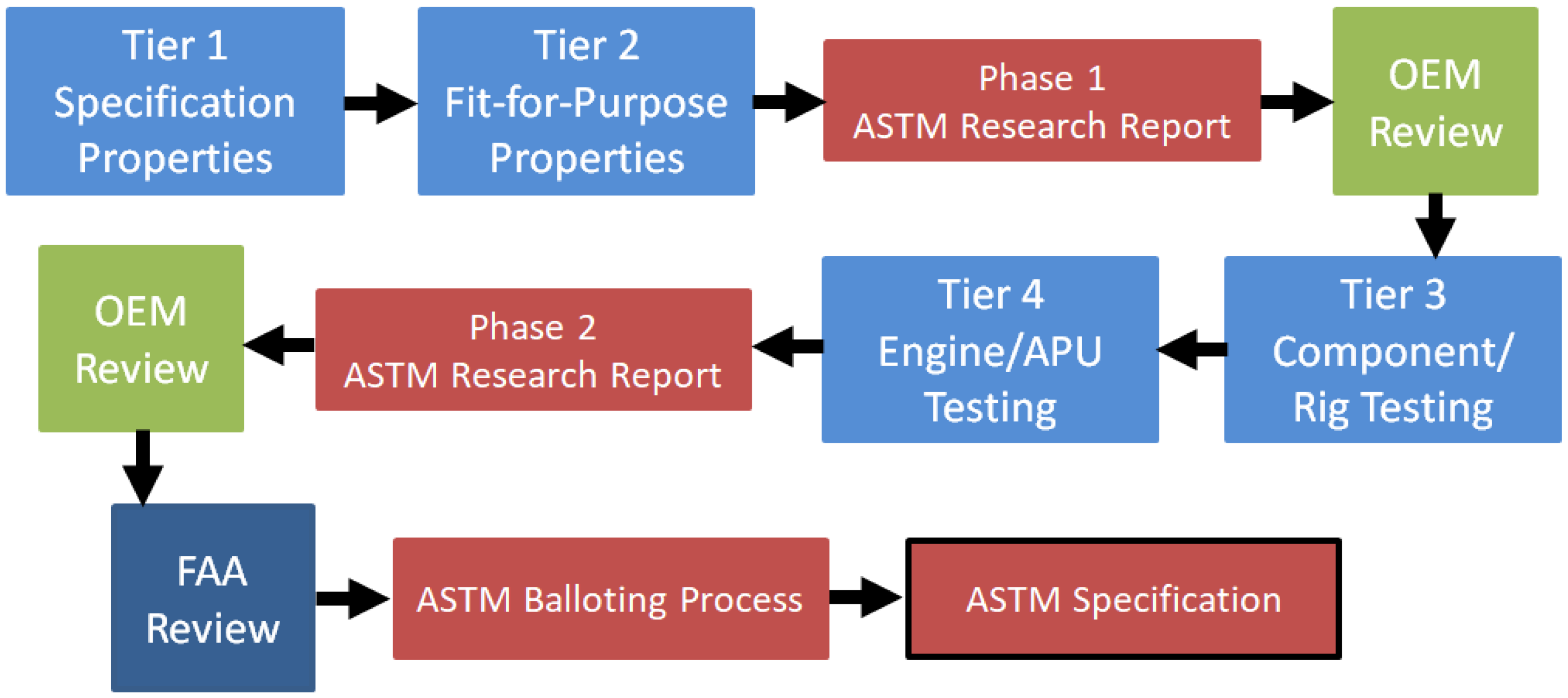

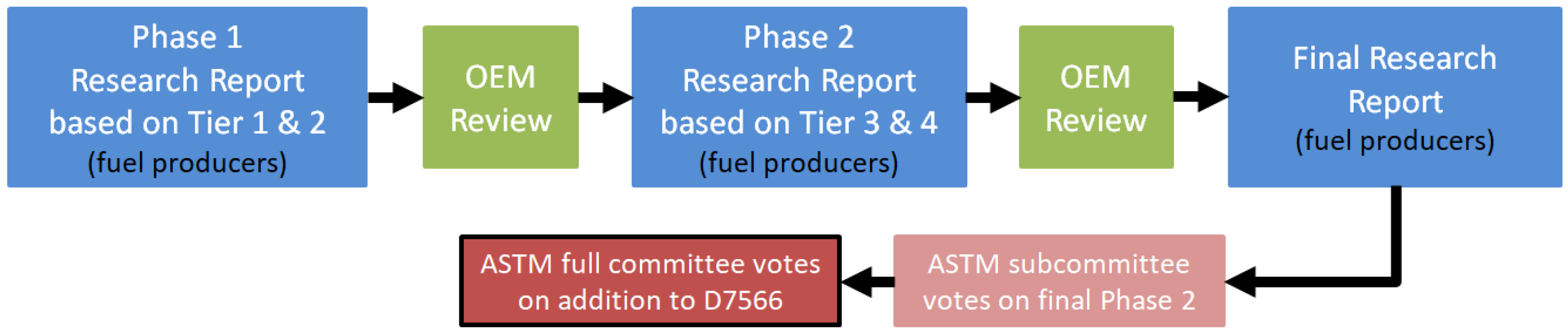

2. Certification Process

3. Certified Production Pathways

3.1. Fischer-Tropsch Synthetic Paraffinic Kerosene (FT-SPK)

3.2. Hydroprocessed Ester and Fatty Acids (HEFA-SPK)

3.3. Hydroprocessed Fermented Sugars to Synthetic Isoparaffins (HFS-SIP)

3.4. Fischer-Tropsch Synthetic Paraffinic Kerosene with Aromatics (FT-SPK/A)

3.5. Alcohol-to-Jet Synthetic Paraffinic Kerosene (ATJ-SPK)

3.6. Catalytic-Hydrothermolysis Synthesized Kerosene (CH-SK or CHJ)

3.7. Hydroprocessed Hydrocarbons, Esters and Fatty Acids Synthetic Paraffinic Kerosene (HHC-SPK or HC-HEFA-SPK)

3.8. Alcohol to Jet Synthetic Kerosene with Aromatics (ATJ-SKA)

3.9. Co-Processing

4. Physicochemical Requirements of Alternative Aviation Fuels

| Property | Unit | Limits ASTM D1655 | HEFA [28,29] | CHJ [29] | ATJ-SPK [26,28,29] | ATJ-SKA [29] | FT-SPK [28] | FT-SKA [28] | SIP [28,29] |

|---|---|---|---|---|---|---|---|---|---|

| Heat of combustion | MJ/kg | min 42.8 | 44.154 | 43.202 | 43.89 | 43.396 | - | - | 43.5 |

| Smoke point | mm | min 18 | - | 22.5 | 27.0 | 23.0 | - | - | - |

| Viscosity in −20 °C | mm2/s | max 8.0 | 4.801 | 3.977 | 4.779 | 3.421 | - | - | 14.13 |

| Viscosity in −40 °C | mm2/s | max 12 | - | - | 9.037 | - | - | - | - |

| Freezing point | °C | max −40 | −54.4 | −41.3 | −40 | <−80 | −40 | −40 | −60 |

| Density at 15 °C | kg/m3 | 775–840 | 730–770 | 805.2 | 730–770 | 785.9 | 730–770 | 755–800 | 765–780 |

| Flash point | °C | Min 38 | 42.0 | 42.5 | 47 | 48.5 | 38 | 38 | 107.5 |

| Distillation: | |||||||||

| 10% recovered | °C | Max 205 | 162.9 | 171.4 | - | - | 205 | 205 | - |

| 50% recovered | °C | report | 510.3 | 200.1 | - | - | - | - | - |

| 90% recovered | °C | report | 270.8 | 244.8 | - | - | - | - | - |

| Final boiling point | °C | max 300 | 148.9 | 152.1 | - | - | 300 | 300 | 247 |

| Residue | vol% | max 1.5 | 1.2 | 1.5 | - | 1.1 | - | - | - |

| Loss | vol% | max 1.5 | 1.1 | 0.9 | - | 1.1 | - | - | - |

| T50-T10 | °C | min 15 | 47.4 | 28.7 | - | - | - | - | - |

| T90-T10 | °C | min 40 | 107.9 | 73.4 | - | - | 22 | 22 | - |

| Total sulfur | m% | 0.3 | <0.001 | <0.001 | <0.001 | <0.001 | - | - | <0.001 |

| Lubricity | mm | max 0.85 | 0.906 | 0.570 | - | 0.606 | - | - | 0.562 |

| Naphthalenes | vol% | max 3.0 | - | 0.35 | - | 0.08 | - | - | - |

| Aromatics | vol% | 8–25 | - | 0.014 | 0.015 | 15.8 | 0.015 | 0.015 | 0.5 |

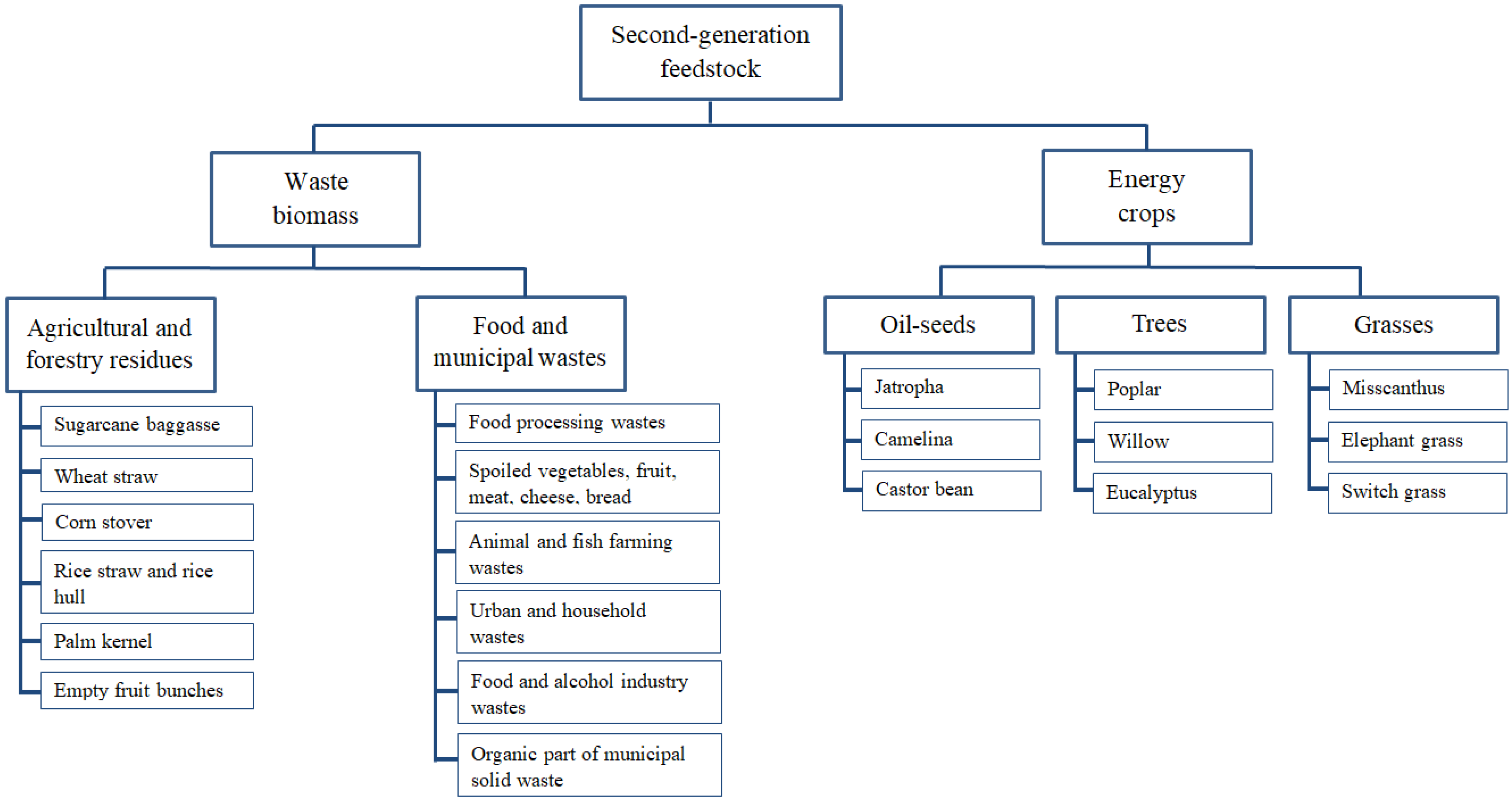

5. Feedstock Used in Production of Alternative Aviation Fuels

5.1. First Generation of Biofuels

5.2. Second Generation of Biofuels

5.3. Third Generation of Biofuels

5.4. Other Feedstock Used in SAF Production

6. CORSIA Eligible Fuels

- “CORSIA eligible fuel (CEF)—a CORSIA sustainable aviation fuel or a CORSIA lower carbon aviation fuel, which an operator may use to reduce their offsetting requirements,

- CORSIA lower carbon aviation fuel—a fossil-based aviation fuel that meets the CORSIA Sustainability Criteria under this Volume (Annex 16 ICAO, Volume IV),

- CORSIA sustainable aviation fuel—a renewable or waste-derived aviation fuel that meets the CORSIA Sustainability Criteria under this Volume” [8].

- Protection of Land with High Biodiversity Value or High Carbon Stock.Feedstock used in the production of CORSIA-eligible fuel shall not be acquired from land that was previously primary forest, peat lands or wetlands, and after 1 January 2008 was converted into area for biomass cultivation [58]. The first principle protects carbon reach areas (as mentioned above) as well as lands that are ecologically or culturally important or that allow the protection of threatened or vulnerable species [58].

- Environmentally, Responsible Production to Protect Soil, Water and Air.The use of the soil should be coherent with national and local laws relating to soil, but conservation of natural resources and biodiversity is also required, as well as avoidance of deterioration or damage of habitats. A few other requirements related to the principle second are: maintenance of natural vegetation areas and natural water rivers, streams and others; all highly invasive species or genetically modified plants have to be allowed to grow in specific regions or countries; and maintenance and improvement of soil fertility, prevent erosion and salinization [58].

- Safe Working Conditions.A company involved in the cultivation of raw materials and the production of alternative aviation fuel should be familiar with the local regulations regarding working conditions. Employees responsible for individual sectors related to the production of fuel should be properly trained and competent, be familiar with plant protection and hazardous substances used in cultivation, waste management, and also be qualified for hazardous or complex work, if necessary [58].

- Compliance with Human, Labour and Land Rights.This principle refers to avoiding negative environmental, economic and social impact, but also respect for a living wage and social environment. The production of biomass must not harm local food cultivation and if the prices of local food products increase due to the cultivation of biomass in the area, the company should establish mitigation measures [58]. This principle describes in detail the guidelines on basic human and worker rights in the biomass farm and the terms of employment, prohibiting discrimination and forced labour, providing legal employment.

- Compliance with Law and International Treaties.This principle requires, among others, legal ownership of used land, respect for existing land rights, and that the producer should be aware of his responsibilities according to the law [58].

- Good Management Practices and Continuous Improvement.The last principle points to economic stability, a documentation system and full compliance by subcontractors [58].

7. Emissions from Sustainable Aviation Fuels

7.1. Emission of Gaseous Exhaust Compounds

7.2. Emissions of Particulate Matter

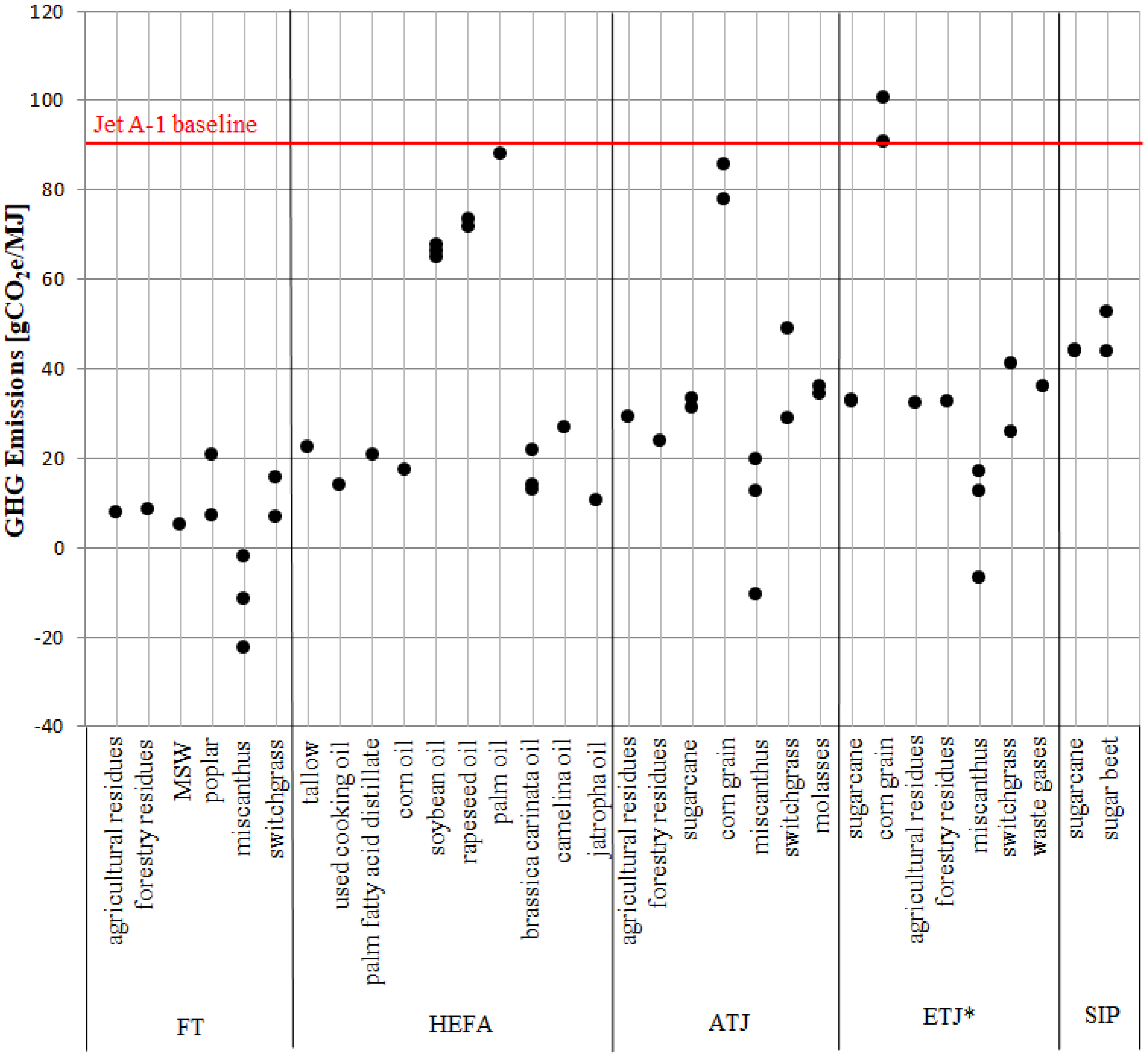

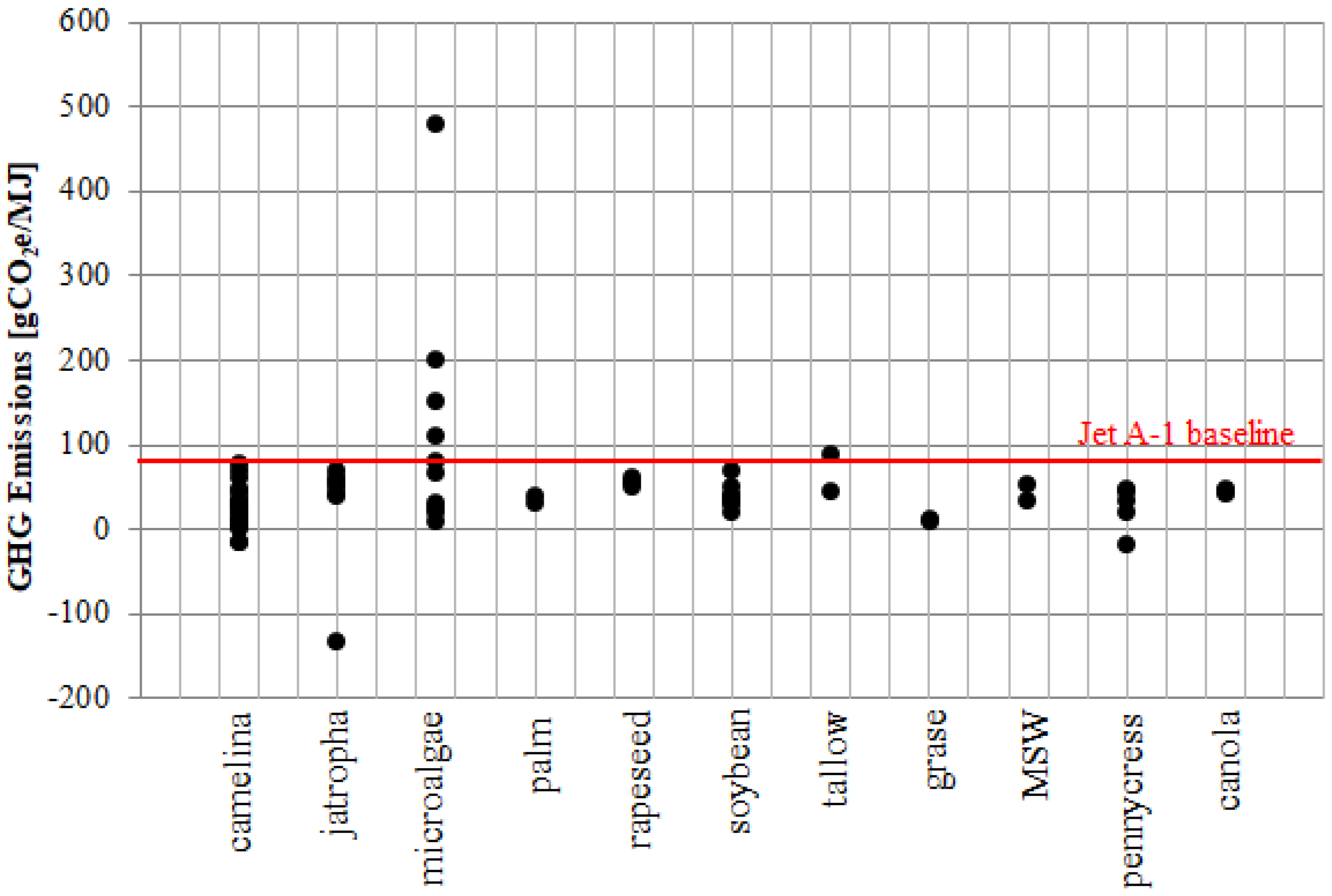

8. Life Cycle Assessment of Alternative Aviation Fuels

9. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| ASTM | American Society for Testing and Materials |

| HC | hydrocarbons |

| HC-HEFA-SPK | Hydroprocessed Hydrocarbons, Esters and Fatty Acids Synthetic Paraffinic Kerosene |

| HEFA-SPK | Hydroprocessed Ester and Fatty Acids |

| HFS-SIP | Hydroprocessed Fermented Sugars to Synthetic Isoparaffins |

| HHC-SPK | Hydroprocessed Hydrocarbons, Esters and Fatty Acids Synthetic Paraffinic Kerosene |

| HRJ | Hydroprocessed Renewable Jet |

| IH2 | Integrated hydropyrolysis and hydroconversion |

| ILUC | Induced Land Use Change |

| ISCC | International Sustainability & Carbon Certification |

| LCA | Life Cycle Assessment |

| MSW | Municipal Solid Waste |

| NOx | nitrogen oxides |

| nvPM | non-volatile particulate matter |

| OEM | Original Equipment Manufacturer |

| PM | particulate matter |

| PtL | Power-to-liquid |

| ReOIL | Pyrolysis of non-recyclable plastics |

| SAFs | Sustainable Aviation Fuels |

| SAK | Synthesized Aromatic Kerosene |

| UCO | used cooking oil |

| UHC | unburned hydrocarbons |

| ATJ-SKA | Alcohol to Jet Synthetic Kerosene with Aromatics |

| ATJ-SPK | Alcohol-to-Jet Synthetic Paraffinic Kerosene |

| CEF | CORSIA Eligible Fuel |

| CH4 | methane |

| CHJ | Catalytic-Hydrothermolysis Synthesized Kerosene |

| CH-SK | Catalytic-Hydrothermolysis Synthesized Kerosene |

| CO | carbon monoxide |

| CO2 | carbon dioxide |

| CORSIA | Carbon Offsetting and Reduction Scheme for International Aviation |

| FAA | Federal Aviation Administration |

| FGB | fourth generation biofuel |

| FT | Fischer-Tropsch |

| FT-SPK | Fischer-Tropsch Synthetic Paraffinic Kerosene |

| FT-SPK/A | Fischer-Tropsch Synthetic Paraffinic Kerosene with aromatics |

| GHG | greenhouse gas |

| GMD | geometric mean diameter |

| GSD | geometric standard deviation |

References

- Graver, B.; Rutherford, D.; Zheng, S. CO2 Emissions from Commercial Aviation 2013, 2018, and 2019; ICCT: Washington, DC, USA, 2020. [Google Scholar]

- Hoelzen, J.; Silberhorn, D.; Zill, T.; Bensmann, B.; Hanke-Rauschenbach, R. Hydrogen-powered aviation and its reliance on green hydrogen infrastructure—Review and research gaps. Int. J. Hydrogen Energy 2022, 47, 3108–3130. [Google Scholar] [CrossRef]

- Grewe, V.; Dahlmann, K.; Matthes, S.; Steinbrecht, W. Attributing ozone to NOx emissions: Implications for climate mitigation measures. Atmos. Environ. 2012, 59, 102–107. [Google Scholar] [CrossRef]

- Detsios, N.; Theodoraki, S.; Maragoudaki, L.; Atsonios, K.; Grammelis, P.; Orfanoudakis, N.G. Recent advances on alternative aviation fuels/pathways: A critical review. Energies 2023, 16, 1904. [Google Scholar] [CrossRef]

- ICAO. Annex 16—Environmental Protection—Volume IV; ICAO: Montrea, QC, Canada, 2023. [Google Scholar]

- Colelli, L.; Segneri, V.; Bassano, C.; Vilardi, G. E-fuels, technical and economic analysis of the production of synthetic kerosene precursor as sustainable aviation fuel. Energy Convers. Manag. 2023, 288, 117165. [Google Scholar] [CrossRef]

- Deutsche Energie-Agentur GmbH (dena). Powerfuels Application Fields, Factsheets about Powerfuels Technologies and Their Areas of Application; German Energy Agency: Berlin, Germany, 2019. [Google Scholar]

- Panzone, C.; Philippe, R.; Chappaz, A.; Fongarland, P.; Bengaouer, A. Power-to-Liquid catalytic CO2 valorization into fuels and chemicals: Focus on the Fischer-Tropsch route. J. CO2 Util. 2020, 38, 314–347. [Google Scholar] [CrossRef]

- Liu, J.; Liu, Z. In-cylinder thermochemical fuel reforming for high efficiency in ammonia spark-ignited engines through hydrogen generation from fuel-rich operations. Int. J. Hydrogen Energy 2024, 54, 837–848. [Google Scholar] [CrossRef]

- Yang, R.; Liu, Z.; Liu, J. The methodology of decoupling fuel and thermal nitrogen oxides in multi-dimensional computational fluid dynamics combustion simulation of ammonia-hydrogen spark ignition engines. Int. J. Hydrogen Energy 2024, 55, 300–318. [Google Scholar] [CrossRef]

- ASTM D7566; Standard Specification for Aviation Turbine Fuel Containing Synthesized Hydrocarbons. ASTM International: West Conshohocken, PA, USA, 2024.

- U.S. Department of Energy. Sustainable Aviation Fuel: Review of Technical Pathways; Office of Energy Efficiency & Renewable Energy: Washington, DC, USA, 2020. [Google Scholar]

- ASTM D4054; Standard Practice for Evaluation of New Aviation Turbine Fuels and Fuel Additives. ASTM International: West Conshohocken, PA, USA, 2023.

- ICAO. ICAO Environment, ACT-SAF Series—SAF Production Technologies and Certification; ICAO: Montrea, QC, Canada, 2023. [Google Scholar]

- Baxter, G.; Srisaeng, P.; Wild, G. The use of aviation biofuels as an airport environmental sustainability measure: The case of Oslo Gardermoen airport. Mag. Aviat. Dev. 2020, 8, 6–17. [Google Scholar] [CrossRef]

- Yang, J.; Xin, Z.; He, Q.; Corscadden, K.; Niu, H. An overview on performance characteristics of bio-jet fuels. Fuel 2019, 237, 916–936. [Google Scholar] [CrossRef]

- Oehmichen, K.; Majer, S.; Müller-Langer, F.; Thrän, D. Comprehensive LCA of biobased sustainable aviation fuels and JET A-1 Multiblend. Appl. Sci. 2022, 12, 3372. [Google Scholar] [CrossRef]

- Tian, B.; Liu, A.; Chong, C.T.; Fan, L.; Ni, S.; Hull, A.; Rigopoulos, S.; Luo, K.; Hochgreb, S. Measurement and simulation of sooting characteristics by an ATJ-SKA biojet fuel and blends with Jet A-1 fuel in laminar non-premixed flames. Combust. Flame 2021, 233, 111582. [Google Scholar] [CrossRef]

- ASTM D1655-20b; Standard Specification for Aviation Turbine Fuels. ASTM International: West Conshohocken, PA, USA, 2020.

- Saggese, C.; Singh, A.V.; Xue, X.; Chu, C.; Kholghy, M.R.; Zhang, T.; Camacho, J.; Giaccai, J.; Miller, J.H.; Thomson, M.J.; et al. The distillation curve and sooting propensity of a typical jet fuel. Fuel 2019, 235, 350–362. [Google Scholar] [CrossRef]

- Jeyashekar, N.; Frame, E.; Wilson, G.; Hutzler, S.; O’Brien, S. Elastomer–fuel compatibility studies with alternative jet fuels for dynamic seal applications. In Proceedings of the ASME Turbo Expo 2013: Turbine Technical Conference and Exposition, San Antonio, TX, USA, 3–7 June 2013. [Google Scholar]

- Undavalli, V.; Olatunde, O.B.G.; Boylu, R.; Wei, C.; Haeker, J.; Hamilton, J.; Khandelwal, B. Recent advancements in sustainable aviation fuels. Prog. Aerosp. Sci. 2023, 136, 100876. [Google Scholar] [CrossRef]

- Aghamiri, A.R.; Lahijani, P. Catalytic conversion of biomass and plastic waste to alternative aviation fuels: A review. Biomass Bioenergy 2024, 183, 107120. [Google Scholar] [CrossRef]

- Díaz-Pérez, M.A.; Serrano-Ruiz, J.C. Catalytic production of jet fuels from biomass. Molecules 2020, 25, 802. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Wang, W.C.; Tao, L.; Markam, J.; Zhang, Y.; Tan, E.; Batan, L.; Warner, E.; Biddy, M. Review of biojet fuel conversion technologies. Renew. Sustain. Energy Rev. 2016, 53, 801–822. [Google Scholar] [CrossRef]

- Schripp, T.; Herrmann, F.; Oßwald, P.; Köhler, M.; Zschocke, A.; Weigelt, D.; Mroch, M.; Werner-Spatz, C. Particle emissions of two unblended alternative jet fuels in a full scale jet engine. Fuel 2019, 256, 115903. [Google Scholar] [CrossRef]

- Rumizen, M.A. Qualification of alternative jet fuels. Front. Energy Res. 2021, 9, 760713. [Google Scholar] [CrossRef]

- Zhang, L.; Butler, T.L.; Yang, B. Recent trends, opportunities and challenges of sustainable aviation fuel. In Green Energy to Sustainability: Strategies for Global Industries; John Wiley & Sons Ltd: Hoboken, NJ, USA, 2020; Chapter 5; pp. 85–110. [Google Scholar] [CrossRef]

- Zschocke, A.; Scheuermann, S.; Ortner, J. High Biofuel Blends in Aviation (HBBA), ENER/C2/2012/420-1 Final Report; Lufthansa & Wehrwissenschaftliches Institut für Werk- und Betriebsstoffe: Erding, Germany, 2012. [Google Scholar]

- Doliente, S.S.; Narayan, A.; Tapia, J.F.D.; Samsatli, N.J.; Zhao, Y.; Samsatli, S. Bio-aviation Fuel: A Comprehensive Review and Analysis of the Supply Chain Components. Front. Energy Res. 2020, 8, 499009. [Google Scholar] [CrossRef]

- Moioli, E.; Salvati, F.; Chiesa, M.; Siecha, R.T.; Manenti, F.; Laio, F.; Rulli, M.C. Analysis of the current world biofuel production under a water–food–energy nexus perspective. Adv. Water Resour. 2018, 121, 22–31. [Google Scholar] [CrossRef]

- Lee, R.A.; Lavoi, J.M. From first- to third-generation biofuels: Challenges of producing a commodity from a biomass of increasing complexity. Anim. Front. 2013, 3, 6–11. [Google Scholar] [CrossRef]

- O’Connell, A.; Kousoulidou, M.; Lonza, L.; Weindorf, W. Considerations on GHG emissions and energy balances of promising aviation biofuel pathways. Renew. Sustain. Energy Rev. 2019, 101, 504–515. [Google Scholar] [CrossRef]

- Abdullah, B.; Syed Muhammad, S.A.F.; Shokravi, Z.; Ismail, S.; Kassim, K.A.; Mahmood, A.N.; Aziz, M.M.A. Fourth generation biofuel: A review on risks and mitigation strategies. Renew. Sustain. Energy Rev. 2019, 107, 37–50. [Google Scholar] [CrossRef]

- Hari, T.H.; Yaakob, Z.; Binitha, N.N. Aviation biofuel from renewable resources: Routes, opportunities and challenges. Renew. Sustain. Energy Rev. 2015, 42, 1234–1244. [Google Scholar] [CrossRef]

- Achten, W.M.J.; Verchot, L.; Franken, Y.J.; Mathijs, E.; Singh, V.P.; Aerts, R.; Muys, B. Jatropha bio-diesel production and use. Biomass Bioenergy 2008, 32, 1063–1084. [Google Scholar] [CrossRef]

- ATAG. Beginner’s Guide to Sustainable Aviation Fuel; Air Transport Action Group: Geneva, Switzerland, 2017. [Google Scholar]

- The Network of African Science Academies (NASAC). Jatropha curcas-derived biofuel industry in Africa. In Proceedings of the Conference Proceedings, Nairobi, Kenya, 22–23 February 2010.

- Kostova, B. Current Status of Alternative Aviation Fuels; U.S. Department of Energy: Washington, DC, USA, 2017. [Google Scholar]

- Woods, J. Sustainable Biofuels: Prospects and Challenges—Policy Document 01/08; The Royal Society: London, UK, 2008. [Google Scholar]

- Shonnard, D.A.; Williams, L.; Kalnesc, T.N. Camelina-derived jet fuel and diesel: Sustainable advanced biofuels. Environ. Prog. Sustain. Energy 2010, 29, 382–392. [Google Scholar] [CrossRef]

- Yilmaz, N.; Atmanli, A. Sustainable alternative fuels in aviation. Energy 2017, 140, 1378–1386. [Google Scholar] [CrossRef]

- ATAG. Beginner’s Guide to Sustainable Aviation Fuel; Air Transport Action Group: Geneva, Switzerland, 2009. [Google Scholar]

- Carrino, L.; Visconti, D.; Fiorentino, N.; Fagnano, M. Biofuel production with castor bean: A win–win strategy for marginal land. Agronomy 2020, 10, 1690. [Google Scholar] [CrossRef]

- Heaton, E.A.; Dohleman, F.G.; Miguez, A.F.; Juvik, J.A.; Lozovaya, V.; Widholm, J.; Zabotina, O.A.; Mcisaac, G.F.; David, M.B.; Voigt, T.B.; et al. Miscanthus: A promising biomass crop. Adv. Bot. Res. 2010, 56, 75–137. [Google Scholar] [CrossRef]

- Scagline-Mellor, S.; Griggs, T.; Skousen, J.; Wolfrum, E.; Holásková, I. Switchgrass and giant miscanthus biomass and theoretical ethanol production from reclaimed mine lands. Bioenergy Res. 2018, 11, 562–573. [Google Scholar] [CrossRef]

- Rödl, A. Lignocellulosic Biomass. In Biokerosene: Status and Prospects; Kaltschmitt, M., Neuling, U., Eds.; Springer: Berlin/Heidelberg, Germany, 2018; pp. 189–220. [Google Scholar]

- Mathioudakis, V.; Gerbens-Leenes, P.W.; van der Meer, T.H.; and Hoekstra, A.Y. The water footprint of second-generation bioenergy: A comparison of biomass feedstocks and conversion. J. Clean. Prod. 2017, 148, 571–582. [Google Scholar] [CrossRef]

- de Corato, U.; de Bari, I.; Viola, E.; Pugliese, M. Assessing the main opportunities of integrated biorefining from agro-bioenergy co/by-products and agroindustrial residues into high-value added products associated to some emerging markets: A review. Renew. Sustain. Energy Rev. 2018, 88, 326–346. [Google Scholar] [CrossRef]

- Karmee, S.K. Fuel not food—Towards sustainable utilization of gutter oil. Biofuels 2017, 8, 339–346. [Google Scholar] [CrossRef]

- Popov, S.; Kumar, S. Renewable fuels via catalytic hydrodeoxygenation of lipid-based feedstocks. Biofuels 2013, 4, 219–239. [Google Scholar] [CrossRef]

- Markou, G.; Wang, L.; Ye, J.; Unc, A. Using agro-industrial wastes for the cultivation of microalgae and duckweeds: Contamination risks and biomass safety concerns. Biotechnol. Adv. 2018, 36, 1238–1254. [Google Scholar] [CrossRef] [PubMed]

- Gilmour, D.J. Microalgae for biofuel production. Adv. Appl. Microbiol. 2019, 109, 1–30. [Google Scholar] [CrossRef] [PubMed]

- Elmoraghy, M. Production of Bio-Jet Fuel from Microalgae. Master’s Thesis, University of New Hampshire, Durham, NH, USA, 2013. [Google Scholar]

- Leong, W.-H.; Lim, J.-W.; Lam, M.-K.; Uemura, Y.; Ho, Y.-C. Third generation biofuels: A nutritional perspective in enhancing microbial lipid production. Renew. Sustain. Energy Rev. 2018, 91, 950–961. [Google Scholar] [CrossRef]

- Tandon, P.; Jin, Q. Microalgae culture enhancement through key microbial approaches. Renew. Sustain. Energy Rev. 2017, 80, 1089–1099. [Google Scholar] [CrossRef]

- Seah, C.C.; Tan, C.H.; Arifin, N.A.; Hafriz, R.S.R.M.; Salmiaton, A.; Nomanbhay, S.; Shamsuddin, A.H. Co-pyrolysis of biomass and plastic: Circularity of wastes and comprehensive review of synergistic mechanism. Results Eng. 2023, 17, 100989. [Google Scholar] [CrossRef]

- ISCC. CORSIA 202 Sustainability Requirements; ISCC: Köln, Germany, 2020. [Google Scholar]

- Kurzawska-Pietrowicz, P.; Maciejewska, M.; Jasiński, R. Exhaust emissions from a jet engine powered by sustainable aviation fuel calculated at various cruising altitudes. Combust. Engines 2024. [Google Scholar] [CrossRef]

- Corporan, E.; Edwards, T.; Shafer, L.; DeWitt, M.J.; Klingshirn, C.; Zabarnick, S.; West, Z.; Striebich, R.; Graham, J.; Klein, J. Chemical, thermal stability, seal swell, and emissions studies of alternative jet fuels. Energy Fuels 2011, 25, 955–966. [Google Scholar] [CrossRef]

- Przysowa, R.; Gawron, B.; Białecki, T.; Łęgowik, A.; Merkisz, J.; Jasiński, R. Performance and emissions of a microturbine and turbofan powered by alternative fuels. Aerospace 2021, 8, 25. [Google Scholar] [CrossRef]

- Gawron, B.; Białecki, T.; Janicka, A.; Suchocki, T. Combustion and emissions characteristics of the turbine engine fueled with HEFA blends from different feedstocks. Energies 2020, 13, 1277. [Google Scholar] [CrossRef]

- Oliveira, J.; Brojo, F. Simulation of the combustion of bio-derived fuels in a CFM56-3 combustor. In Proceedings of the 2nd International Conference Sustainable and Renewable Energy Engineering (ICSREE), Hiroshima, Japan, 10–12 May 2017. [Google Scholar] [CrossRef]

- Pawlak, M.; Kuzniar, M. The effects of the use of algae and jatropha biofuels on aircraft engine exhaust emissions in cruise phase. Sustainability 2022, 14, 6488. [Google Scholar] [CrossRef]

- Lobo, P.; Hagen, D.E.; Whitefield, P.D. Comparison of PM emissions from a commercial jet engine burning conventional, biomass, and Fischer-Tropsch fuels. Environ. Sci. Technol. 2011, 45, 10744–10749. [Google Scholar] [CrossRef] [PubMed]

- Moore, R.H.; Thornhill, K.L.; Weinzierl, B.; Sauer, D.; D’Ascoli, E.; Kim, J.; Lichtenstern, M.; Scheibe, M.; Beaton, B.; Beyersdorf, A.J.; et al. Biofuel blending reduces particle emissions from aircraft engines at cruise conditions. Nature 2017, 543, 411–415. [Google Scholar] [CrossRef]

- Jasiński, R.; Kurzawska, P.; Przysowa, R. Characterization of particle emissions from a DGEN 380 small turbofan fueled with ATJ blends. Energies 2021, 14, 3368. [Google Scholar] [CrossRef]

- Timko, M.T.; Herndon, S.C.; de la Rosa Blanco, E.; Wood, E.C.; Yu, Z.; Miake-Lye, R.C.; Corporan, E. Combustion products of petroleum jet fuel, a Fischer-Tropsch synthetic fuel, and a biomass fatty acid methyl ester fuel for a gas turbine engine. Combust. Sci. Technol. 2011, 183, 1039–1068. [Google Scholar] [CrossRef]

- Durdina, L.; Brem, B.T.; Elser, M.; Schönenberger, D.; Siegerist, F.; Anet, J.G. Reduction of nonvolatile particulate matter emissions of a commercial turbofan engine at the ground level from the use of a sustainable aviation fuel blend. Environ. Sci. Technol. 2021, 55, 14576–14585. [Google Scholar] [CrossRef]

- Chan, T.W.; Chishty, W.A.; Canteenwalla, P.; Buote, D.; Davison, C.R. Characterization of emissions from the use of alternative aviation fuels. J. Eng. Gas. Turbine Power 2016, 138, 011506. [Google Scholar] [CrossRef]

- Lobo, P. Impact of Alternative Fuels on the PM Emissions Characteristics of Gas Turbine Engines. Ph.D. Thesis, Manchester Metropolitan University, Manchester, UK, 2015. [Google Scholar]

- Braun-Unkhoff, M.; Riedel, U. Alternative fuels in aviation. CEAS Aeronaut. J. 2015, 6, 83–93. [Google Scholar] [CrossRef]

- Braun-Unkhoff, M.; Kathrotia, T.; Rauch, B.; Riedel, U. About the interaction between composition and performance of alternative jet fuels. CEAS Aeronaut. J. 2016, 7, 83–94. [Google Scholar]

- Link, D.D.; Gormley, R.J.; Baltrus, J.P.; Anderson, R.R.; Zandhuis, P.H. Potential additives to promote seal swell in synthetic fuels and their effect on thermal stability. Energy Fuels 2008, 22, 1115–1120. [Google Scholar] [CrossRef]

- ICAO. ICAO Document, CORSIA Sustainability Criteria for CORSIA Eligible Fuels; ICAO: Montreal, QC, Canada, 2022. [Google Scholar]

- ICAO. CORSIA Supporting Document, CORSIA Eligible Fuels—Life Cycle Assessment Methodology; ICAO: Montreal, QC, Canada, 2022. [Google Scholar]

- ICAO. ICAO Document, CORSIA Methodology for Calculating Actual Life Cycle Emissions Values; ICAO: Montreal, QC, Canada, 2022. [Google Scholar]

- Seber, G.; Escobar, N.; Valin, H.; Malina, R. Uncertainty in life cycle greenhouse gas emissions of sustainable aviation fuels from vegetable oils. Renew. Sustain. Energy Rev. 2022, 170, 112945. [Google Scholar] [CrossRef]

- ICAO. ICAO Document, CORSIA Default Life Cycle Emissions Values for CORSIA Eligible Fuels; ICAO: Montreal, QC, Canada, 2022. [Google Scholar]

- Kurzawska-Pietrowicz, P. Life Cycle emission of selected sustainable aviation fuels—A review. Transp. Res. Procedia 2023, 75, 77–85. [Google Scholar] [CrossRef]

- Capaz, R.S.; Seabra, J.E.A. Life Cycle Assessment of Biojet Fuels. In Biofuels for Aviation; Elsevier: Amsterdam, The Netherlands, 2016; pp. 279–294. [Google Scholar] [CrossRef]

- Stratton, R.W.; Wong, H.M.; Hileman, J.I. Quantifying variability in life cycle greenhouse gas inventories of alternative middle distillate transportation fuels. Environ. Sci. Technol. 2011, 45, 4637–4644. [Google Scholar] [CrossRef] [PubMed]

- ICAO. Sustainable Aviation Fuels Guide: ICAO Environment; ICAO: Montreal, QC, Canada, 2017. [Google Scholar]

- Agusdinata, D.B.; Zhao, F.; Ileleji, K.; DeLaurentis, D. Life cycle assessment of potential biojet fuel production in the United States. Environ. Sci. Technol. 2011, 45, 9133–9143. [Google Scholar] [CrossRef] [PubMed]

- Han, J.; Elgowainy, A.; Cai, H.; Wang, M.Q. Life-cycle analysis of bio-based aviation fuels. Bioresour. Technol. 2013, 150, 447–456. [Google Scholar] [CrossRef] [PubMed]

- Lokesh, K.; Sethi, V.; Nikolaidis, T.; Goodger, E.; Nalianda, D. Life cycle greenhouse gas analysis of biojet fuels with a technical investigation into their impact on jet engine performance. Biomass Bioenergy 2015, 77, 26–44. [Google Scholar] [CrossRef]

- Sieverding, H.L.; Zhao, X.; Wei, L.; Stone, J.J. Life-cycle assessment of oilseeds for biojet production using localized cold-press extraction. J. Environ. Qual. 2016, 45, 967–976. [Google Scholar] [CrossRef]

- Suresh, P.; Malina, R.; Staples, M.; Lizin, S.; Olcay, H.; Blazy, D.; Barrett, S.R.H. Life cycle greenhouse gas emissions and costs of production of diesel and jet fuel from municipal solid waste. Environ. Sci. Technol. 2018, 52, 12055–12065. [Google Scholar] [CrossRef] [PubMed]

- de Jong, S.; Antonissen, K.; Hoefnagels, R.; Lonza, L.; Wang, M.; Faaij, A.; Junginger, M. Lifecycle analysis of greenhouse gas emissions from renewable jet fuel production. Biotechnol. Biofuels 2017, 10, 1–18. [Google Scholar] [CrossRef] [PubMed]

- Fan, J.; Shonnard, D.R.; Kalnes, T.N.; Johnsen, P.B.; Rao, S. A life cycle assessment of pennycress (Thlaspi arvense L.)-derived jet fuel and diesel. Biomass Bioenergy 2013, 55, 87–100. [Google Scholar] [CrossRef]

- Li, X.; Mupondwa, E. Life cycle assessment of camelina oil derived biodiesel and jet fuel in the Canadian Prairies. Sci. Total Environ. 2014, 481, 17–26. [Google Scholar] [CrossRef]

- Ukaew, S.; Beck, E.; Meki, M.N.; Shonnard, D.R. Application of the roundtable on sustainable biofuels method to regional differences in nitrous oxide emissions for the rapeseed hydrotreated renewable jet life cycle. J. Clean. Prod. 2014, 83, 220–227. [Google Scholar] [CrossRef]

- Wong, H.M. Life-Cycle Assessment of Greenhouse Gas Emissions from Alternative Jet Fuel. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2008. [Google Scholar]

- IRENA Biofuels for Aviation: Technology Brief; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2017.

- Manzo, R. CORSIA and Sustainable Aviation Fuel—Legal Brief: Perspectives for SAF Producers: An Analysis of International Legal Frameworks Impacting Emissions Trading; CISDL: Montreal, QC, USA, 2022. [Google Scholar]

| Research | Tested Engine | Tested Fuel | Emission Change in Relation to Conventional Aviation Fuel |

|---|---|---|---|

| [60] | T63-A-700 | 100% FT-SPK | CO2 and NOx similar |

| UHC reduction by 20–30% | |||

| CO reduction by 10–25% | |||

| PM reduction | |||

| [61] | GTM 140 | 50%, 100% ATJ | CO rise |

| CO2 slight reduction | |||

| HC reduction for thrust over 50% and rise for thrust below 50% | |||

| 5%, 20%, 30% HEFA | CO and NOx rise | ||

| HC reduction | |||

| DGEN 380 | 5%, 20%, 30% ATJ | CO rise | |

| CO2 slight reduction | |||

| 5%, 20%, 30% HEFA | CO and CO2 rise | ||

| [62] | GTM 140 | 50% HEFA | CO and CO2 reduction |

| NOx rise | |||

| [63] | CFM 56-3 (CFD simulation) | 100% Jatropha biofuel | CO2 reduction by 20% |

| UHC rise | |||

| 100% Algae biofuel | NOx reduction | ||

| CO2 and NOx reduction | |||

| 100% Sunflower biofuel | UHC reduction for thrust below 80% | ||

| CO2, UHC, NOx reduction | |||

| [64] | CFM56-5C (calculations) | Algae biofuel | CO2 reduction by 6% |

| NOx reduction by 44% | |||

| HC reduction by 32% | |||

| CO reduction by 49% | |||

| Jatropha biofuel | CO2 reduction by 9% | ||

| NOx reduction by 6% | |||

| HC similar | |||

| CO increase by 132% | |||

| [65] | CFM56-7B | 100% FT-SPK | PM number reduction by 52% |

| PM mass reduction by 62% | |||

| 50% FT-SPK | PM number reduction by 34% | ||

| PM mass reduction by 39% | |||

| [66] | CFM56-2-C1 | 50% HEFA | PM number and mass reduction by 50–70% |

| [67] | GTM 120 | 30% ATJ | PM number reduced by 51% |

| PM mass reduced by 53% | |||

| [26] | CFM56-5C4 | CHJ | PM increase |

| 100% ATJ | PM reduced by 70% | ||

| [68] | CFM56-7 | 100% FT-SPK | CO reduction by 20% |

| NOx reduction by 10% | |||

| PM number reduction by 70% | |||

| [69] | CFM56-7B | 32% HEFA | PM GMD and GSD reduction |

| nvPM number reduction by 60% (idle) | |||

| nvPM mass reduction by 70% | |||

| nvPM number reduction by 10% (take-off) | |||

| [70] | GE CF-700-2D-2 | 100% CH-SKA | PM reduction by 7–25% |

| 50% HEFA | PM reduction by 40–60% | ||

| 100% FT-SPK | PM reduction by 70–95% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kurzawska-Pietrowicz, P.; Jasiński, R. A Review of Alternative Aviation Fuels. Energies 2024, 17, 3890. https://doi.org/10.3390/en17163890

Kurzawska-Pietrowicz P, Jasiński R. A Review of Alternative Aviation Fuels. Energies. 2024; 17(16):3890. https://doi.org/10.3390/en17163890

Chicago/Turabian StyleKurzawska-Pietrowicz, Paula, and Remigiusz Jasiński. 2024. "A Review of Alternative Aviation Fuels" Energies 17, no. 16: 3890. https://doi.org/10.3390/en17163890

APA StyleKurzawska-Pietrowicz, P., & Jasiński, R. (2024). A Review of Alternative Aviation Fuels. Energies, 17(16), 3890. https://doi.org/10.3390/en17163890