Abstract

Organic waste-to-energy (OWtE) technologies are playing a steadily increasing role in the Green Transition, thus becoming a powerful driver in the establishment of an ever more efficient and sustainable circular economy. The advantages of OWtE processes are well known: not only do they reduce the waste volumes sent to landfills or incineration plants, but also and foremost, through the energy they yield (biogenic carbon dioxide, amongst others), they reduce dependance on fossil fuels. This article gives a complete panorama of these technologies, starting from the classical methods and ending with a review of the latest modern novelties. Advantages and disadvantages of each method are highlighted, with particular focus on the formation of by-products and the relevant treatment aimed at preventing environmental pollution. Accordingly, modern techniques for increasing waste-to-energy efficiency and integrating the concept of circular economy and substitutability are analyzed from this perspective. Along with an analysis of modern scientific achievements in this area, practical examples of the implementation of technologies in European countries are given, with an emphasis on the obvious advantages, both economic and environmental.

1. Introduction

In recent decades, there has been an increase in demand for natural resources and materials, the base of the economic system. However, natural resources are not endless. There are already shortages in some industries. The circular economy model aims to prevent negative global consequences associated with the scarcity of natural resources, the degradation of ecosystems, and climate change. Its advantage over the traditional linear economic model is that it minimizes the use of natural resources and the release of waste into the environment [1].

In this case, waste (or wastes) is unwanted or unusable materials. According to INTOSAL (Working Group on Environmental Auditing), waste is a product or substance which is no longer suited for its intended use. The Waste Framework Directive of the European Union (Article 3) formulates waste as “any substance or object which the holder discards or intends or is required to discard”.

Resource recovery from waste (RRfW) represents a transition stage toward a sustainable circular economy [2]. Not only does it use waste as an input to generate valuable products, but it also reduces the volume of natural raw material required in the production cycle. The need for landfill space is thereby reduced, and the value created from waste is optimized. The resource recovery element of RRfW results in more than just sustainable waste management; it is part of a circular economy in which the extraction of natural resources and waste generation are kept to a minimum. Resource recovery is the key to a circular economy, representing the transition to a resource recovery system from waste management alone.

Reduce, reuse, and recycle are the “three pillars” of a circular economy, but there is more to it than that. According to [3], CE is an economic system where “the value of products, materials and other resources in the economy is maintained for as long as possible, enhancing their efficient use in production and consumption, thereby reducing the environmental impact of their use, minimising waste and the release of hazardous substances at all stages of their life cycle, including through the application of the waste hierarchy”.

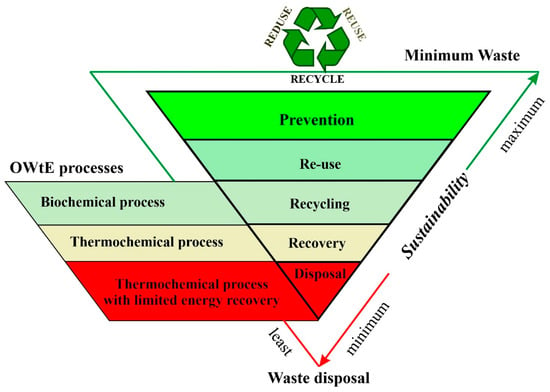

The Waste Framework Directive [4] has transformed the circular economy to a five-step “waste hierarchy”, constituting an order of preference for waste management and disposal. Preventing waste generation is the preferred option, and sending waste to landfill sites should be the last resort (Figure 1). It is evident that avoiding waste generation is the most powerful method of resource recovery. The creation of so-called waste-free (zero waste) production should be the main goal of a circular economy.

Figure 1.

The five-step “waste hierarchy” and OWtE process.

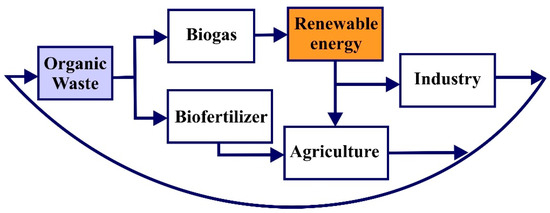

Organic waste-to-energy (OWtE) processes may involve different waste management operations, from “disposal” and “recovery” to “recycling”. In the case of the biochemical process of anaerobic digestion, resulting in biogas formation, this would be resource “recovery”. Instead, if energy is obtained from organic waste due to a thermochemical process, this would be resource recycling. In the case in which waste is incinerated with limited energy recovery, this would be “Disposal”. Figure 1 below shows the position of the organic waste-to-energy processes within the EU waste hierarchy.

New technologies, including biological processes more consistent with natural processes, are required for complex waste processing and the selective extraction of target materials with minimal energy consumption. This is especially true in the case of organic waste, a valuable asset which could be effectively recycled or used to produce energy, thereby fulfilling the worldwide goal of an increasingly waste-free and sustainable future [5].

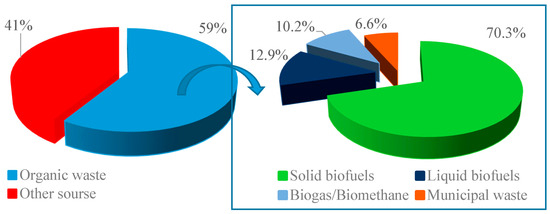

According to the Commission’s report on the sustainability of bioenergy, bioenergy produced from agricultural, forestry, and organic waste continues to be the EU’s primary source of renewable energy. In 2021, it accounted for about 59% of renewable energy consumption. According to the EU Energy Union status data for 2023, primary solid biofuels comprise the largest bioenergy share, followed by liquid biofuels, biogas/bio methane, and the renewable portion of municipal waste [6] (Figure 2).

Figure 2.

Renewable energy consumption in European Union for 2021.

Indeed, globally, despite the evident necessity of a transition to a circular economy, the share of bioenergy in the overall energy balance is small. For example, in 2016 in the Northern European countries of Switzerland, Sweden, Finland, Denmark, and Norway, more than half of all generated waste was burned to produce energy, while for the Southern and Eastern European countries of Spain, Italy, Poland, the Czech Republic, the share of waste converted into energy did not exceed an average of 15%, and in Latvia, Turkey, and Serbia, it was absent [6]. At the same time, the potential of bioenergy sources such as agricultural, forestry, and municipal waste is very high.

This study aims to analyze organic waste-to-energy (OWtE) technologies and their advantages and disadvantages.

2. Strategies for Effective and Sustainable QWtE Cycle

From a circular economy perspective, organic waste management technologies should contribute to environmental protection and sustainable development to provide a constant cycle of materials during production and consumption in which the output of waste is converted into an input of production without environmental pollution [7]. One may thereby conclude that waste-to-energy is the one of most promising technologies for resource recovery from organic waste. OWtE technologies reduce the amount of biowaste (household, forestry, and agricultural waste) going to landfills and provide low-carbon energy as a product [8].

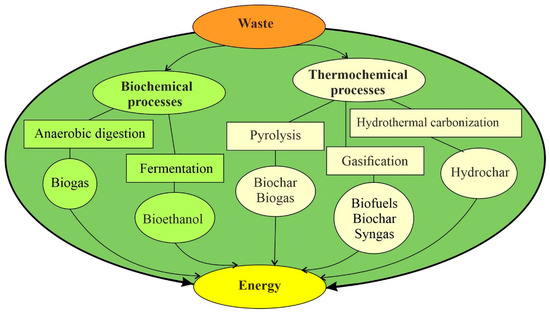

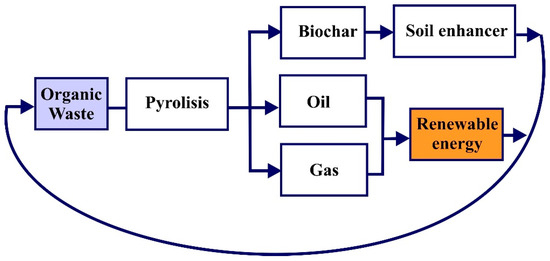

Due to population growth and enormous pressure on the demand for and consumption of fossil fuels, especially in industrialized countries, special attention is paid to energy production. Global primary energy consumption reached around 620 exajoules in 2023 [9]. Its cost is constantly increasing. Fuel extraction is associated with environmental problems. One of the most effective approaches is to reduce the consumption of fossil fuels by replacing them with a clean, sustainable, and renewable energy resource. Solid organic waste is a renewable energy resource that can be converted into any form of fuel, including solid, liquid, and gaseous (Figure 3).

Figure 3.

OWtE technologies.

Waste-to-energy (WtE) technology converts waste into electricity or heat instead of burning fossil fuels, thereby reducing greenhouse gas (GHGs) emissions [10]. The efficient conversion of agricultural organic waste (biomass) into bioenergy sources such as bioethanol, biobutanol or biomethane, and biohydrogen is possible through biochemical and thermochemical processes [11,12]. Each of them has its advantages and drawbacks (Table 1). Biochemical processes are low in energy consumption and have low capital and operational costs. Moreover, the high organic removal rate meets the requirements of the circular economy, but they have longer cycle times and a lower efficiency in breaking down complex biomass sources. Instead, thermochemical processes usually require the inclusion of solvents or catalysts, which require a significant amount of energy. Each of them has its own advantages and disadvantages (Table 1).

Table 1.

Comparative characteristics of OWtE technologies.

Typically, waste with a high moisture content (i.e., industrial wastewater, livestock manure, sewage sludge) is sent for biochemical treatment. Instead, solid waste is more suitable for thermochemical treatment.

Various currently used technologies can transform organic waste into energy, each of them negatively affecting the environment primarily because of CO2 emissions. A comparative analysis of CO2 emissions and residual waste generation pertaining to various technologies is given in Table 2 below. As it may be seen, CO2 emissions vary widely depending on the specific technology used and the nature of the waste.

Table 2.

Environmental impact and efficiency of waste-to-energy technologies.

Incineration tends to have the highest emissions, whereas anaerobic digestion has the lowest. For comparison, emissions factors quantified as the average CO2 output per unit of energy from various fossil fuel sources are 403.2 kg of CO2/MWh in the case of charcoal, 360.0 CO2/MWh for wood, and 196.5 kg/MWh for biogas [18]. Incineration, while effective at waste volume reduction, poses challenges with GHG emissions and residual waste.

The proper management of residuals is crucial to minimize environmental impacts and maximize resource recovery from waste. Bottom ash can be processed and used in construction materials like aggregate or road base material rather than being disposed of in landfills. Fly ash is typically classified as hazardous waste due to its heavy metal content and requires specialized handling and disposal methods. Depending on their characteristics, char and biochar can be used as soil amendments or activated carbon. Instead, digestate is used as a fertilizer or soil conditioner after further treatment to stabilize nutrients and reduce pathogens.

However, a proper evaluation of the true environmental impact of a given technology can be achieved if the right attention is given to the kind of CO2 emissions that are created. Indeed, not all such emissions are equal because we can distinguish between CO2 coming from the degradation or combustion of flora in the present time and fossil CO2 coming from oil. There is a basic difference between the two. Carbon dioxide emissions coming from flora degenerated or burnt in present times can be deemed to have zero polluting impact as the degenerated or burnt flora can be presumed to be replaced, in the life cycle under normal conditions, by an amount of fresh flora capable of reabsorbing them. It is obviously impossible to presume the same for CO2 coming from fossil matter, not to mention the aggravating factor of the much higher CO2 concentration in oil caused over geological eras by the pressures and temperatures that have turned organic matter into fossil oil.

Summarizing, it is clear that the role of biogenic CO2 is crucial in waste-to-energy technologies. These can in fact significantly reduce greenhouse gas emissions by capturing and utilizing biogenic methane, reducing reliance on fossil fuels, and enhancing carbon sequestration. Thus, biogenic CO2 can effectively contribute to a more sustainable and lower-carbon future.

For example, biogenic CO2 from anaerobic digestion and fermentation can be stored, used, and even earn carbon credits. Companies can use these credits, which also can be traded, to offset their emissions by funding programs that lower emissions in other places [19,20,21]. Apart from this, bio-CO2 can be successfully used as a fumigation gas for pest control in wheat grain storage [22] or converted into value-added products (short-chain fatty acids) through anaerobic fermentation and electro fermentation [23]. Various carbon-smart goods, including monomers and polymers, flavors, solvents, chemicals, and fuels, can be produced through the effective use of its gas fermentation technique [24]. In the case of CO2-assisted pyrolysis, carbon dioxide can be recycled from industrial flue gases produced at power plants in order to increase energy recovery [25].

3. Biochemical OWtE Conversion

Biochemical processes convert organic solid waste or biomass into gaseous or liquid fuels, such as biogas or bioethanol [26], using enzymes from bacteria or other microorganisms. Anaerobic fermentation and digestion are two of the most common methods for converting biomass into useful products [27]. They are environmentally friendly, clean, efficient, and do not require much energy. The process can produce a wide range of intermediate and final products depending on the choice of enzymes or microorganisms.

3.1. Anaerobic Fermentation (AF)

Anaerobic fermentation can be defined as an anaerobic bacterial redox process of an organic substrate leading to different products, e.g., the fermentation of glutamate to ammonia, CO2, acetate, butyrate, and hydrogen [28]. Under anaerobic conditions, some microorganisms grow using an ETP process with externally supplied oxidized compounds other than oxygen as the terminal electron acceptor. This type of growth is referred to as anaerobic respiration.

AF is an efficient and cost-effective method for the treatment of organic solids, from which a large number of renewable resources can be obtained [29]. The general fermentation process of ethanol, butanol, and other biofuels can be divided into four steps: (1) physical, chemical, or biological pretreatment; (2) enzymatic hydrolysis; (3) microbial fermentation; (4) separation and concentration [30].

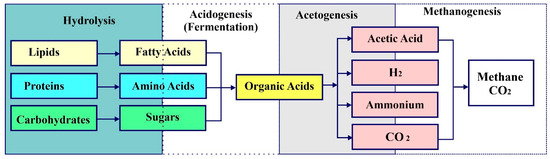

Unlike anaerobic digestion (AD), which usually includes the stages of hydrolysis, acidogenesis (fermentation), acetogenesis, and methanogenesis, AF includes only the first two stages of AD (Figure 4). Compared to AD, anaerobic fermentation allows for less energy consumption and less secondary pollution of the environment.

Figure 4.

A flow diagram of the anaerobic digestion and anaerobic fermentation process.

Both anaerobic digestion and anaerobic fermentation produce energy by processing organic waste. The difference is the end products: biogas and fertilizers in the case of AD and biofuels, hydrogen lactic acid, and volatile fatty acids (VFAs) in the case of AF [29].

AF is one way to convert organic waste into low-carbon renewable fuels, contributing to the transition to a circular economy. Integrating fuel production from organic waste into existing biofuel infrastructure can be cost-effective because the waste typically does not need to be mined or purchased [31].

Bioethanol production from waste, such as organic fraction municipal waste and agricultural waste, has consistently been one of the most popular alternative energy production pathways. In comparison to fossil fuels, bioethanol emits considerably lower levels of greenhouse gases and thus receives widespread support as a vehicle fuel source. By mixing it in with various proportions with gasoline, it transforms into gasohol, which can be used immediately in internal combustion engines without requiring further engine modifications.

Important intermediate products of anaerobic fermentation are volatile fatty acids (acetic, propionic, and butyric acids). They can be converted into the corresponding alcohols or used as materials for the production of spices, drugs, additives, and similar chemicals [32].

3.2. Anaerobic Digestion (AD)

Anaerobic digestion (AD) or the decomposition of sewage or other organic waste material by anaerobic microorganisms is a method that is widely used in the processing of animal waste (liquid and solid manure), agricultural wastes (corn stover, sugarcane residues), waste food, municipal solid waste (MSW) with water content more than 70%, sewage sludge, and industrial wastewater. Products are biogas and high-quality fertilizers (Figure 5). Biogas can be used to produce electrical and thermal energy in a cogeneration plant and/or enriched to methane, which is suitable for use as, for example, fuel for vehicles. A volume of 1 m3 of biogas is equivalent in terms of calorific value to 0.8 m3 of natural gas, 0.6 kg of gasoline, 0.7 kg of fuel oil, 1.5 kg of firewood, or 3 kg of briquetted biofuel. Biogas energy can definitely be considered an alternative renewable energy source.

Figure 5.

A flow diagram of the OWtE anaerobic digestion process as a part of the circular economy.

AD, or biomethanation, is a microbial process that breaks down organic, biodegradable material in the absence of oxygen to produce biogas and stabilize sludge. The process involves several different types of microorganisms working together to break down complex organic material in stages to produce biogas (Figure 4). The first step is hydrolysis, which involves bacteria that can convert insoluble carbohydrates, proteins, and fats into simple sugars, fatty acids, amino acids, and peptides. The second step is a fermentation process where acid-forming bacteria, also known as acidogens, convert the products of hydrolysis into simple organic acids, alcohols, carbon dioxide, and hydrogen gas. Volatile acids longer than two carbons are converted to acetate, H2, and CO2 gas by acetogenic bacteria. Finally, in the fourth step, methane-forming archaea (methanogens) produce biogas from acetic acid and H2/CO2 [33].

The effectiveness of the process depends on the number of feed formulation and process parameters, including the organic loading rate, C/N ratio, pH, temperature, moisture content, and retention duration [34].

According to data [35], when 1 ton of manure is dismissed for composting, 300–400 m3 of methane gas, ammonia, hydrogen sulfide, and carbon dioxide are released into the atmosphere. Methane (CH4) is approximately 22 times more harmful to the ozone layer than carbon dioxide (CO2). Therefore, replacing composting with anaerobic fermentation reduces emissions of harmful gases amounting to 1200 g in CO2-eq/kWh. In the case of anaerobic treatment of corn silage, the reduction in emissions is about 500 g in CO2-eq/kWh.

As a fuel, biogas is a virtually carbon-neutral form of energy production because as plants grow, carbon dioxide (CO2) from the atmosphere is absorbed by them and stored in the form of carbon-containing molecules (CO2 reduction). After combustion, the same amount of CO2 that initially came from the atmosphere is released back into the atmosphere (a CO2-neutral process).

For energy recovery by the anaerobic treatment of wastewater with high chemical oxygen demand (COD) levels, such as the in the paper and board industry, methane yields are 0.24–0.4 m3 CH4 per kg COD removed [36].

The biogas produced from anaerobic digestion can be utilized in the following ways:

- -

- It can be upgraded to 98% pure biomethane for use as a substitute fuel for natural gas. In this case, a treatment step is required: the removal of carbon dioxide and the scrubbing of toxic and corrosive H2S and other impurities.

- -

- It can be combusted directly to produce heat and power.

- -

- It can be used as row material for hydrogen, methanol, and dimethyl ether production by means of its additional processing through biomethane reforming in the presence of steam.

The use of biogas helps to mitigate the effects of global warming by also changing the consumption of fossil fuels for energy production and motor fuel, and it thus significantly reduces CO2, CH4, and N2O emissions into the atmosphere. On the other hand, the development and application of renewable energy sources contributes to the more efficient use of domestic energy production potential, a reduction in imports of fossil fuels, the development of local industry, and the creation of new jobs. For example, in Sweden, there are 138 anaerobic digesters in sewage treatment WWTPs, which produce 727 GWh of biogas, and 36 co-digestion plants, which produce 963 GWh of biogas annually [34].

Biogas technologies are promising for the development of renewable energy. The advantages and disadvantages of anaerobic digestion in terms of waste-to-energy processes are presented in Table 3.

Table 3.

The advantages and disadvantages of biogas production as a source of renewable energy.

As can be seen from the above, the use of biogas as an energy source has several advantages:

- Biogas, or biomethane obtained from it, is a renewable energy source.

- The use of biogas can reduce the cost of energy production since it is a cheap and easily accessible source.

- The use of biogas makes it possible to reduce dependence on oil and gas, which cause emissions of greenhouse gases and other harmful substances.

Considering the advantages and shortcomings of this process, we can conclude that anaerobic decomposition is a promising direction in converting organic waste into energy as part of the transition to a circular economy.

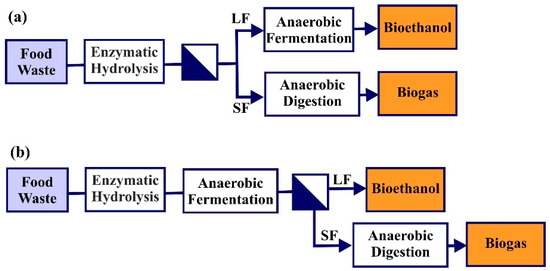

3.3. Joint AD/AF Process

The case of joint AD/AF producing bioethanol and biomethane from food waste was proposed by Jarunglumlert et al. [20]. Two possible scenarios were examined. In the first scenario, (Figure 6a), the liquid fraction of the hydrolysate is separated after hydrolysis by the enzyme and sent for processing to produce ethanol while the solid fraction is subjected to anaerobic digestion to produce biogas. Instead, in the second case (Figure 6b), the hydrolysate is used in ethanol fermentation, followed by the extraction of fermented solid residues for additional anaerobic digestion. The outcome demonstrates that the co-production of bioethanol and biomethane from food waste is an extremely efficient method for increasing gross energy output when compared to producing either product alone, with a gross energy output of 8.37 and 9.57 GJ/ton, respectively.

Figure 6.

Co-production of bioethanol and biomethane from food waste. (a) scenario 1 and (b) scenario 2.

4. Thermochemical OWtE Technologies

Thermochemical processes such as pyrolysis, incineration, gasification, and hydrothermal carbonization are considered effective methods for recycling organic waste through a waste-to-energy pathway into value-added products. Compared to biochemical technologies, thermochemical ones are energy efficient and require short processing times.

For example, in the case of pyrolysis, the application of heat above 650–800 K leads to the dissociation of a complex molecule into simpler compounds. The result is the production of a liquid product, solid charcoal, and gaseous compounds from biomass [37].

Indeed, most thermochemical processes can only process dry waste. Their effectiveness in the case of wet waste rich in organic matter is significantly reduced. This problem can be resolved by hydrothermal carbonization (HTC), in which waste is treated in the presence of subcritical water [38].

HTC is a biomass pre-treatment thermochemical process with high moisture content with hot compressed water in the temperature range of 180–280 °C, under pressure (2–6 MPa) for 5–240 min. The primary product of hydrothermal carbonation is a coal-like product called hydro-char. Its by-products are:

- -

- solid (ash), which can be used as a plant nutrient enhancer due to its phosphorus content;

- -

- aqueous (nutrient-rich), which can be used to water plants because it is rich in potassium;

- -

- gas phases (mostly CO2).

In recent years, thermochemical waste-to-energy processes have been considered a very important tool for the development of sustainable energy production and environmental management.

4.1. Incineration

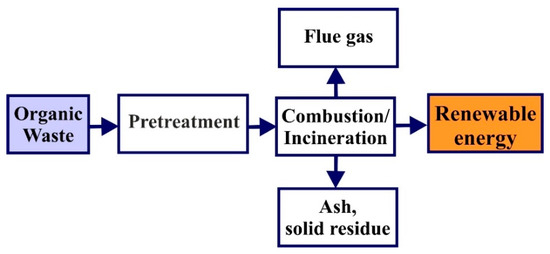

Incineration is a thermal waste treatment technique that can be understood as a controlled combustion process with the primary objective of volume reduction and energy recovery from the waste stream. It is the thermal oxidation of combustible matter with oxygen (from air) at sufficient temperatures to ignite the waste.

Incineration is an important technique in waste management systems and the waste hierarchy from the point of view of waste-to-energy (WtE) processes. It is used to treat approximately 63% of the waste in European countries [39].

Typically, the purpose of recycling waste by incineration is to reduce its mass and volume, which would otherwise require disposal in landfills. For example, when 49.4 kg of household waste is burned, only 1.3 kg remains in the form of ash [40]. Another important reason is the detoxification of waste, as it may contain pathogenic, infectious, or toxic materials. Thus, waste incineration is also used to prevent pollution and the spread of disease.

The incineration process is separated into three main parts: pretreatment, incineration, energy recovery and conversion, and flue gas cleaning (Figure 7).

Figure 7.

Flow diagram of incineration process.

Pretreatment is an important step because during combustion, the waste must be evaporated, which requires energy and reduces the temperature of the flue gases. Organic waste bio-residue should be deeply dewatered before incineration [41]. The moisture content of the waste should be >45%.

During the combustion process, the amount of heat generated directly depends on the degree of flammability of the substances contained in the waste. The higher the content of flammable substances in the waste, the more air is needed for combustion. For example, if more volatile substances are released into the gas phase when there is a lack of oxygen, then more ash remains in the solid waste after the release of volatile particles. The air pollutants are gaseous (NOx, SO2, CO, CO2, O2, HCl), heavy metals, and toxic chemicals. Ash consists of residues left in the combustion chamber (bottom ash) and in their pollution treatment devices (fly ash). Modern waste incineration plants differ in technical solutions, but in all cases, emissions are kept within legal limits, regardless of the composition of the waste being burned [40]. All have multi-stage air purification, bag filtration, and selective and non-selective catalytic reduction to combat nitrogen and sulfur oxides, HCl, HF, and most heavy metals [42].

The heat produced from combustion can be recovered and converted to electric power [43]. Heat generated from waste is used to produce steam in the boiler. Then, the steam drives the turbine to generate electricity [44].

Maintaining the right combustion temperature and effective post-combustion treatments is critical for operating waste-to-energy plants, balancing efficient energy recovery with environmental protection. Temperatures above 850 °C are generally required to ensure the complete combustion of the waste, breaking down organic compounds and reducing the formation of harmful emissions like dioxins and furans. Indeed, emissions from waste incineration facilities are typically lower than from traditional coal or oil-fired power stations, especially when modern emission control and adequate clean-up systems of the flue gas are employed [40].

Waste moisture content can also affect combustion efficiency, energy recovery, and emissions. Waste with a high moisture content needs more energy to evaporate the water. That reduces the net energy available for combustion, lowering overall combustion temperatures and resulting in incomplete combustion. Mechanical or thermal pre-treatment steps can be applied before incineration to address this issue.

Moreover, an incineration plant requires significant investment and generates high operating costs.

4.2. Gasification

Gasification is a thermochemical process in which biomass is processed at elevated temperatures in various gasifying media (oxygen, steam, air, CO2, etc.) to form synthesis gas, which can be further processed into more valuable chemicals and biofuels [45,46]. Air, due to its availability and low cost, is the most common gasifying medium. The advantage of steam is that the resulting gas contains a higher H/C ratio [47]. A mixture of air and steam gives a high hydrogen yield and calorific value [48].

Biomass gasification plants are different from the large-scale gasification processes typically used in large industrial facilities such as power plants, oil refineries, and chemical plants. Biomass typically contains a high percentage of moisture, carbohydrates, and sugar. The presence of high levels of moisture in the biomass reduces the temperature inside the gasifier, so it must be dried before it is fed into the gasifier. In addition, the biomass must be processed to a uniform size or shape to enter the gasifier at a constant rate and ensure that as much of the biomass as possible is gasified.

Typically, the gasification process involves four different stages, such as the drying of raw materials, pyrolysis (decomposition), oxidation (combustion), and reduction (gasification) (Figure 8).

Figure 8.

Flow diagram of biomass gasification process.

Biomass with a moisture content of more than 20% usually requires a drying step (endothermic evaporation) before it can be used for gasification. At this stage, bound water turns into steam (at a temperature of 100–200 °C).

In the pyrolysis zone (thermochemical breakdown of biomass), large molecular groups are converted into smaller hydrocarbons to form biochar, liquid products, and gaseous molecules in an oxygen-free environment at temperatures ranging from 125 to 500 °C [49].

Chemical reactions occurring inside the combustion zone occur with the release of heat (exothermic), which leads to an increase in temperature ranging from 1100 to 1500 °C [50]. CO, CO2, H2, and H2O are formed as a result, and generated heat is used for drying pyrolysis processes.

The main product of the gasification process is synthesis gas, consisting of H2, CO, CO2, and CH4 [46]. It should be noted that in order to produce high-quality synthesis gas, a synthesis gas purification stage is necessary. By-products of the gasification process include coals, oils, ash, and resins.

The biochar produced during gasification is an important sustainable product of the gasification process. It has the capacity to absorb pollutants from aqueous waste streams owing to its complex porous structures [51].

The relative concentration of gasification products depends on the composition of the starting substrate and process parameters. For example, at high temperatures, the formation of H2 and CO2 tends to dominate, while at low temperatures, the production of CO and CH4 prevails [52]. The characteristics of the organic waste (lignin content, mineral content, volatile substance, moisture, ash content, and size) affect gasification efficiency. For example, the content of inorganic substances in biomass may have a significant impact on the reactivity of the gasification process. The higher ash content of raw materials contributes to the efficiency of gasification. In addition, an increase in moisture content promotes the processes of supercritical gasification of water and the gas conversion reaction, which increases the H2 content [53].

Syngas can be used for energy production by feeding it into a gas turbine providing power, and syngas generated from biomass gasification (after cleaning) may be used in heat- and steam-generating boilers or in electricity generation by direct burning.

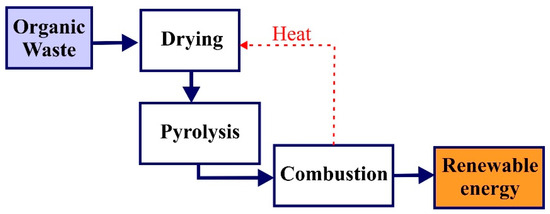

4.3. Pyrolysis

Pyrolysis is the chemical decomposition of organic materials through the application of heat. Chemical reactions occurring at temperatures from 100 °C to 300 °C are usually called thermal decomposition. Instead, decomposition that usually occurs at temperatures between 300 °C and 800 °C is called pyrolysis. The rate of pyrolysis increases with temperature. In industrial applications, the temperatures used are often 430 °C (about 800 °F) or higher.

Pyrolysis, which is also the first step in gasification and combustion, occurs in the absence or near absence of oxygen, and it is thus distinct from combustion (burning), which can take place only if sufficient oxygen is present.

In the case of waste recycling, pyrolysis involves the heat treatment of waste—without access to oxygen—and its consequent decomposition into simple substances, resulting in the release of useful energy. It converts low energy material into high-energy-density biofuel [54]. This technology is suitable for working with organic and inorganic substances. As all stages of pyrolysis are completed, heavy elements break down into lighter ones with a low molecular weight.

With simple combustion, chemical substances are rapidly oxidized to form water, which immediately evaporates, along with carbon dioxide. Since there is no contact with oxygen during pyrolysis, no harmful emissions into the air are observed.

The process itself takes place sequentially in four stages:

- Placing waste in a special chamber and drying it;

- The dry distillation of waste;

- The combustion of solid residues;

- The formation of gas, coal, and oil (end products of pyrolysis).

In the case of organic waste, pyrolysis is the thermal decomposition in the absence of oxygen, resulting in the formation of three primary products, coal, oil, and gas, in varying proportions. However, by changing the process conditions, you can increase the yield of one or another product [55]. Currently, there are three categories of pyrolysis: slow, fast, and flash pyrolysis (Table 4) [56,57,58,59,60].

Table 4.

Comparative characteristics of thermochemical processes OWtE.

The shortage of natural resources, especially so-called non-renewable energy resources, is a problem in modern society. From the point of view of the circular economy, recycling already generates organic waste, and converting these into useful resources is one of the ways to alleviate such constraints (Figure 9). In this case, so-called closed-loop recycling (reusing and recycling used items to produce energy through pyrolysis) can be classified as closed-loop energy [63].

Figure 9.

Flow diagram of pyrolysis as closed-loop recycling.

Pyrolysis results in the formation of three main products: a carbon-rich solid product (biochar), volatile matter which can further be partially condensed to a liquid phase (bio-oil), and the remaining so-called “non-condensable” gases, like CO, CO2, CH4, and H2 [8]. “Biochar” is a recently invented term for renewable fuels, soil reclamation, and carbon sequestration. It includes coal and charcoal produced by the partial combustion of organic materials, excluding fossil fuel products.

Biochar is produced by biomass heating at high temperature in the absence or limited supply of oxygen. It can be produced from various types of biomass and waste [64]. For example, agricultural wastes such as wood waste, peanut shells, hazelnuts, and wheat straw can be used to produce biochar through slow pyrolysis (300–900 °C in an anoxic environment). Moreover, gases and other by-products formed during this reaction can be used as energy sources to produce heat and electricity. On the other hand, the pyrolysis of wood-based feedstock such as olive husks and dates results in a hardier and coarser biochar with a carbon content of up to 80% by weight.

Pyrolysis is effective in organic waste treatment, but the effectiveness of the process is strongly dependent on waste composition. The treatment of mixtures of food waste with this method has thus far received limited attention due to the high variability of the composition of this waste.

4.4. Hydrothermal Carbonization (HTC)

Hydrothermal carbonization is a thermochemical process that uses heat and pressure to convert biomass and organic waste. The process produces three products: hydrocarbon (solid), liquid, and gas. Compared to pyrolysis or gasification, the energy required for the HTC process is significantly lower. In addition, this process improves the dewatering and hydrophobicity of waste and improves the fuel properties of solid products [65].

In recent years, there has been increasing interest in the thermochemical treatment of organic waste using the process of hydrothermal carbonization of biomass [66]. Several factors drive this process:

- -

- The waste can be wet, which avoids the previous stage of dehydration;

- -

- Relatively low temperatures compared to other thermochemical processes, thereby reducing energy costs;

- -

- Higher product yield in the case of solid product (coke) compared to other thermochemical methods—20–80% with hydrothermal carbonization versus 12–35% with pyrolysis;

- -

- The resulting liquid and gas phases can be valorized after further processing.

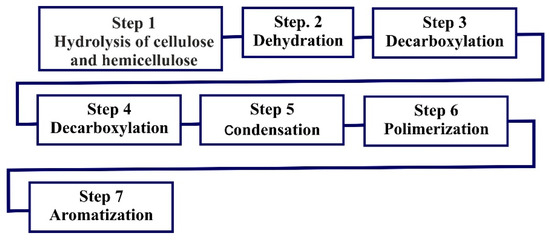

The hydrothermal conditioning process takes place in a humid environment at temperatures from 180 to 260 °C, resulting in the degradation of lignin, cellulose, and hemicellulose. The ingredients are then condensed back into a solid product [67]. The mechanism of the HTP can be divided into several stages (Figure 10). The final products will largely depend on the composition of the raw materials, residual moisture, and water quality.

Figure 10.

The mechanism of the hydrothermal conditioning process.

As a result of the process, solid and liquid products are formed. The solid product can be used to produce solid fuels with high energy density. The liquid product is a composition of commercially valuable chemicals, acids and phenols, and therefore their extraction from the liquid phase can become economically feasible. The gaseous product typically consists of approximately 90% CO2. Other gases, such as CO, CH4, or H2, may also be present in the gas, but in small quantities [68].

The hydrothermal treatment process mainly depends on treatment time, water content, pH, and the temperature of the process. Other factors include the pressure, thermodynamic equilibrium, feedstock destruction, intensity of reaction, amount of obtained product, particle size, and stability.

For example, higher temperatures accelerate the degradation and polymerization of organic waste, while lower temperatures activate the depolymerization (product fragmentation) process [69]. At temperatures above 100 °C, waste is disinfected; temperatures around 200 °C significantly accelerate decomposition and polymerization. Finally, temperatures above 250 °C can promote the production of oil or gas instead of hydrocoal [68]. With an increase in temperature to above 260 °C, the hydrothermal process is further refined into two techniques: (i) hydrothermal liquefaction (HTL) and (ii) hydrothermal gasification (HTG) [70].

The process of hydrothermal carbonization be influenced not only by higher temperatures but also by changing the pressure in the reactor. The increased efficiency created by higher temperatures may be further enhanced by greater pressure [71].

Higher water content accelerates hydrothermal carbonization reactions, through its effect on the decarboxylation and hydrolysis process [72].

The chemical composition of the hydrochar (end solid product after HTC) changes significantly. Carbonization not only results in an increase in carbon content but also in a decrease in hydrogen, oxygen, and nitrogen [73]. The hydrochar, in addition to biofuel, can be used to improve soil health, as well as for sequestration to reduce greenhouse gas emissions [74].

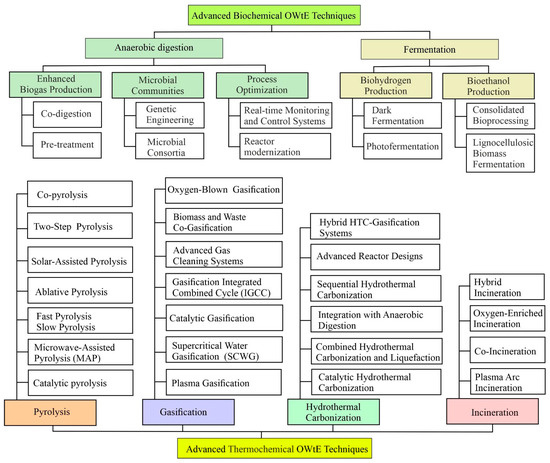

5. Advanced OWtE Techniques

Recent times have seen considerable advances in organic waste-to-energy technology, driven by an ever-increasing demand for sustainable waste management and the generation of renewable energy with processes optimized in terms of (i) efficiency, (ii) stability, and (iii) biogas output. Figure 11 below offers an overview of the different advanced techniques for converting organic waste to energy, enhancing efficiency, optimizing resource utilization, reducing environmental impact, and improving the economic viability of waste-to-energy (WTE) processes.

Figure 11.

Flow chart. Advanced OWtE techniques.

It has been seen that combining different types of organic waste (so called co-digestion) can lead to improved biogas yields while reducing chemical consumption and operational costs. For instance, an optimal C/N ratio in a substrate provides bacteria with the nutrients they need to produce the highest amount of methane [75]. Typically, food waste, animal manure, and sewage sludge are N-rich materials (C/N = 10–20), while lignocellulosic biomass is rich in carbon (C/N > 50). For example, co-digesting sewage sludge (FW) [76,77] co-digesting cattle [64] or chicken manure [78] and food waste (FW) produces higher methane yield than the AD of FW alone.

Furthermore, pre-treatment methods have been developed that help breaking down complex organic materials, making them more accessible for microbial digestion. They include the following:

- -

- Applying high temperature and pressure to hydrolyze complex organic compounds into simpler molecules is called thermal hydrolysis [79,80]. Furthermore, thermal hydrolysis destroys pathogens; enhances the solubility of organic molecules, making them more accessible to microbial action; and reduces raw material viscosity, which improves mixing and reduces energy consumption during the breakdown process. As a result, this produces excellent biogas yields.

- -

- Using ultrasonic waves to disrupt cell walls and increase the surface area for microbial action is called ultrasonic pre-treatment [81,82].

- -

- Adding chemicals (e.g., acids, alkalis) to solubilize organic matter is called chemical pre-treatment.

Innovative processes that use natural or synthetic microbial communities to produce liquid biofuels (microbial oils, ethanol, etc.), biogas, biohydrogen, and electricity integrate biotransformation with other processes to improve biodegradability and energy recovery. Genetic engineering is used to develop specific consortia of microorganisms that can enhance their metabolic pathways for better substrate degradation and methane production [83].

Finally, process optimization plays an important role. Advanced computational models and simulation tools are called to predict and optimize the anaerobic digestion process. These models can simulate different scenarios and help in decision-making for process improvements by implementing advanced sensors and control algorithms to monitor parameters such as pH, temperature, and volatile fatty acids in real time, allowing for immediate adjustments [84].

Hydrogen is one of the end products obtained from the fermentation of organic waste. It has a high energy density and releases no greenhouse gases when it burns. As an alternative to classic anaerobic fermentation, dark fermentation involves anaerobic microorganisms in darkness, produces a higher concentration of bio H2, and has a shorter doubling time for microorganisms [85]. On the other hand, photo-fermentative hydrogen production employs light to transfer electrons and protons from organic compound oxidation into hydrogen molecules in anaerobic, nitrogen-controlled environments. Adding photogenerated electrons from the photo-nano-catalyst accelerates the fermentative mechanism and increases biohydrogen production [86].

In the case of bioethanol production, consolidated bioprocessing combines the production of saccharolytic enzymes, pretreatment, saccharification, and fermentation steps in a single reactor and mediates the process using a single microorganism or microbial consortium [87,88]. This potentially reduces the operational costs and achieves higher process efficiency.

Bioethanol production from lignocellulosic biomass is an advanced process that converts plant-based materials into ethanol, a renewable fuel. Lignocellulosic biomass, such as agricultural residues (corn stover, wheat straw), forestry residues, and dedicated energy crops (switchgrass, miscanthus), is abundant and does not compete with food crops. In recent decades, bioethanol production from lignocellulosic biomass has been gaining attention due to its high availability, positive environmental impact, and economic potential, thanks to its high organic content including hemicellulose, cellulose, and lignin [89]. The process involves pretreatment followed by enzymatic hydrolysis, fermentation by microbes (bacteria and yeast), and bioethanol distillation [90].

Advanced techniques in pyrolysis for OWtE include catalytic pyrolysis, microwave-assisted pyrolysis (MAP), two-step pyrolysis, co-pyrolysis, etc. (Figure 11). CO2-assisted pyrolysis, as an alternative to conventional pyrolysis, is perfect for treating organic waste materials like plant biomass, animal manure, and household and municipal wastes. It uses CO2 to help materials decompose and prevent the formation of many dangerous chemicals. Adding CO2 produces more stable bio-oil and higher-quality pyrogas, which has a considerably favorable impact on product composition. In addition, it valorizes organic wastes like plant biomass, animal dung, algae, food, textiles, plastics, and other materials. Another advantage of CO2 pyrolysis is reducing the emission of hazardous chemical species, including polycyclic aromatic hydrocarbons (PAHs) and benzene derivatives [91]. Microwave-assisted pyrolysis uses microwave energy to heat the biomass, providing uniform and rapid heating. It has faster heating rates, better control over process conditions, and potentially higher efficiency. The MAV is suitable for a wide range of organic wastes, including food waste, plastics, and agricultural residues [92]. Fast pyrolysis is characterized by rapid heating rates and short residence times (seconds) at 450 °C and 600 °C, resulting in bio-oil with smaller amounts of biochar and syngas. Instead, slow pyrolysis involves slower heating rates and longer residence times (hours) at lower temperatures (between 300 °C and 500 °C), increasing biochar yield, with bio-oil and syngas as by-products [93]. Ablative pyrolysis mechanically forces the biomass against a hot surface, causing thermal decomposition. It has high heat transfer rates and is suitable for large biomass particles, producing bio-oil, biochar, and syngas with high energy efficiency [94]. Solar-assisted pyrolysis uses concentrated solar power to provide the necessary heat for the pyrolysis process, reducing reliance on fossil fuels and greenhouse gas emissions. Indeed, it requires efficient solar concentrators and reliable sunlight availability [95]. Co-pyrolysis involves the simultaneous pyrolysis of multiple feedstocks to enhance the process efficiency and product quality. Synergistic effects can improve bio-oil quality, increase liquid yields, and reduce overall process costs [96].

Advanced gasification techniques offer promising solutions for converting organic waste into valuable energy products, contributing to sustainable waste management and renewable energy production. Plasma gasification uses plasma torches to create extremely high temperatures (up to 5000 °C), breaking organic waste into syngas with minimal residue. It has high efficiency and the ability to handle a wide variety of wastes, including hazardous materials. The by-product of the process, vitrified slag, can be used in construction, showcasing its versatility. It is a potential technology that is compatible with circular economy principles, especially the one about “keeping materials in use for as long as possible.” [97]. Supercritical water gasification operates at temperatures and pressures above the critical point of water (374 °C and 221 bar), efficiently converting wet biomass into hydrogen-rich syngas. It has high hydrogen yield and is effective for wet biomass and organic waste, but it requires high pressure and temperature-resistant materials [98]. Catalytic gasification involves the use of catalysts to lower the gasification temperature and improve the quality of the syngas produced. Catalytic biomass gasification offers many benefits over conventional biomass gasification techniques, including increased hydrocarbon conversion and catalytic yield (higher production of syngas) [99]. Oxygen-blown gasification uses pure oxygen instead of air for gasification, reducing nitrogen content in the syngas and increasing its calorific value. Indeed, it requires an oxygen supply system, which can be costly [100]. The Integrated Gasification Combined Cycle (IGCC) combines gasification with a combined cycle power plant, utilizing both the syngas and the heat produced for electricity generation. It has several benefits: high efficiency, low emissions, and the ability to create power and chemical products suitable for large-scale power generation from organic waste [101]. Co-gasification involves gasifying biomass with other organic wastes, such as plastics or municipal solid waste, to improve process efficiency and syngas quality. Synergistic effects improve overall gasification performance and increase flexibility in feedstock utilization. However, managing feedstock variability and optimizing process parameters can be challenging.

Advanced Hydrothermal Carbonization (HTC) techniques called for enhanced energy conversion efficiency and higher yields with improved hydrochar properties, with the ability to handle a wide range of organic waste materials, making it more suitable as a fuel or soil amendment. Additionally, it can reduce greenhouse gas emissions with better waste management and the potential for nutrient recovery. The shortcomings include high capital and operational costs, the necessity of consistent supply, and feedstock quality. Catalytic HTC involves catalysts to enhance the reaction rates and improve the quality of hydrochar [102]. Combined HTC and hydrothermal liquefaction (HTL) integrate both processes to maximize the energy recovery from organic waste. HTC pre-treats the biomass to produce hydrochar, which is then subjected to HTL to produce bio-crude oil, optimizing the utilization of both solid and liquid fractions of the waste, improving overall energy yield [103]. HTC integration with anaerobic digestion involves pre-treating biomass with HTC to improve the digestibility of the remaining organics. It enhances biogas production, improves waste management, and reduces processing time [104]. Hybrid HTC–gasification systems combine the benefits of HTC and gasification to produce solid and gaseous fuels. Hydrochar produced from HTC is further gasified to produce syngas, enhancing the overall energy recovery [105].

Waste-to-energy (WtE) incineration is a viable solution to both municipal solid waste management and renewable energy concerns [106]. Although incineration has several advantages, it has the problem of associated environmental pollution due to flue gas emissions, contaminated fly ash, as well as the challenge of combustion instability. Advanced oxyfuel combustion (OFC) and oxygen-enriched combustion (OEC) reduce secondary gas emissions. In the first scenario, air is substituted by high-quality oxygen (95%) for fuel combustion, resulting in high flame temperatures, and exhaust gas is recycled to dilute the oxygen stream provided to the incinerator. In the second scenario, OFC can enrich CO2 concentration in the flue gas to 90–95% by volume, significantly reducing the total flue gas quantity. However, the high expense of pure oxygen makes the technology unfeasible economically. OEC has thus gained popularity as a method for reducing secondary emissions in waste-to-energy (WTE) facilities [14,107,108].

Advanced techniques for organic waste-to-energy are crucial for achieving sustainable waste management and renewable energy goals. Ongoing research, development, and collaboration among industry, government, and academia will be essential for overcoming challenges and realizing the full potential of these technologies.

6. OWtE Technologies, Practical Application in EU

The European Union (EU) has implemented various policies and initiatives to promote the conversion of organic waste to energy as part of its broader goals of waste reduction, renewable energy production, and climate change mitigation.

According to CEWEP (Confederation of European Waste-to-Energy Plants), incineration includes about 500 plants from 23 countries [109]. Instead, biological treatment waste plants in the EU count more than 4500 units [104] with a capacity of more than 45 million tons of bio-waste per year.

Bioenergy produced from agricultural, forestry, and organic waste feedstock continues to be the main source of renewable energy in the EU, accounting for about 59% of renewable energy consumption in 2021. Primary solid biofuels (70.3%) represent the largest share of bioenergy, followed by liquid biofuels (12.9%), biogas/bio-methane (10.1%), and the renewable share of municipal waste (6.6%) [6]. Here are some notable cases demonstrating the application of these technologies across different European countries.

One of the most advanced waste-to-energy complexes in Europe, Högdalenverket (Sweeden), uses combustible domestic and industrial waste, including organic waste, to generate heat and power. It is a crucial part of Stockholm’s southern district heating network. The Högdalen incinerator facility can handle about 700,000 tons of garbage annually. The town of Stockholm and the power company Fortum jointly own Stockholm Exergi, the facility’s owner. Stockholm Exergi operates several waste and biofuel incinerators in Stockholm. The facilities owned by Stockholm Exergi generate 2138 GWh of energy (heat and electricity) annually, and the environment and the city of Stockholm both profit from this recycled energy [110].

Biogas and fertilizers are produced from organic waste at a biorefinery in Linköping, Sweden. The plant processes 100,000 tonnes of organic waste from the food industry and households every year, converting it to biogas and biofertilizer, which return essential nutrients such as phosphorus and nitrogen to neighboring fields. The biogas is utilized as fuel for automobiles, particularly the city’s public transportation system, once it is converted to biomethane. The Tekniska verken Group made the decision to build a facility in 2023 to handle the biogenic carbon dioxide that is created when food waste, slaughterhouse waste, and other wastes are digested and subsequently removed during the biogas generation process. The system will be installed at Svensk Biogas, Tekniska verken’s biogas facility in Linköping, and it will purify and liquefy the carbon dioxide (CO2) from the biogas output. By next summer, in 2025, the factory should be completed and producing 20,000 tons of food-grade quality bioCO2 annually [111].

In Germany, agricultural residue is transformed into bioenergy by biomass gasification. Agricultural organic waste such as straw and corn stover are converted into syngas through gasification. The syngas is then used to generate electricity and heat. Farmers benefit from an additional revenue stream by selling agricultural residues and using the bioenergy produced for their operations. In Germany, about 400 biomass gasification plants provide approximately 35 MWe of electricity. This initiative promotes sustainable agricultural practices, reduces waste, and supports Germany’s renewable energy targets. The largest German DFB (Dual Fluidized Bed) gasification plant currently in operation in Europe is Neu-Ulm. This infrastructure presents a thermal input load of 15.1 MWth and an output of 4.6 MWe and provides power for 21,000 inhabitants of Neu-Ulm [112].

The Ecotricity Green Gas Mill, located in Gloucestershire, UK, focuses on converting grass and other organic materials into renewable biogas. Using anaerobic digestion, the mill processes grass and other organic materials to produce biogas. This biogas is then purified and injected into the national gas grid, while a natural fertilizer produced as a by-product will go back onto farmland. The plant can generate enough green gas to power approximately 6000 homes annually [113]. It demonstrates a sustainable alternative to fossil fuels, reducing reliance on natural gas and contributing to energy security.

The Kymijärvi II power plant is a unique energy production facility in Lahti, Finland. It is the world’s first gasification power plant to use waste-based solid recovered fuel (SRF) and waste wood to generate electricity and district heat. The fuel is made from plastic, wood, and paper waste collected from industrial, commercial, and household sources. The 160 MW plant has the capacity for up to 250,000 tonnes of SRF and waste wood per year, which amounts to about 170,000 tonnes of coal and produces about 280–300 GWh of electricity as well as 680–700 GWh of heat annually. Kymijärvi II produces 110,000 tonnes of carbon dioxide annually, whereas the same amount of energy generated with coal would produce 410,000 tonnes more [114]. Kymijärvi II processes 250,000 tons of waste annually, producing electricity for 50,000 homes and district heating for 30,000 homes. It represents an advanced and efficient method of waste management and energy production [115].

Another promising direction is reconverting existing oil refineries into Hydrotreated Vegetable Oil (HVO) biorefineries, using sustainable feedstock in their operations in the near future to comply as biofuel in the EU. In Italy, ENI has converted its Venice and Sicily refineries to Hydrotreated Vegetable Oil (HVO) production. The Venice plant will be producing 420,000 tonnes/y in 2024, while the Sicily refinery aims to use feedstock not in competition with the food chain. Today, ENI has a total processing capacity of 1.1 million tonnes per year, with a goal of doubling its total capacity by 2024, reaching 5–6 million tonnes by 2050. “HVOlution” is already available in 50 Eni Live Stations in Italy and expected to be available in 150. Produced from waste raw materials and plant residues, and from oils generated from crops not in competition with the food supply chain, it can already be used by approved engines [116].

Ingelia, Valencia (Spain), has designed and built a hydrothermal carbonization plant for biomass, producing a solid carbon-based biomaterial (hydrochar). Hydrochar can be used as a raw material for industry, substituting fossil fuels, and as a biofuel with a high GCV (gross calorific value), low humidity, high performance on combustion, and without CO2 emissions [117].

To sum up, it should be noted that in the EU in 2021, biomass fuels and bioliquids were used for the production of 17.3 mtoe of gross heat: solid biomass (76.0%), renewable municipal waste (18.1%), and biogases (5.0%). In the electricity sector, 45.6 mtoe of biomass fuels and bioliquids were used to produce 14.6 mtoe of gross electricity. That is, 74% of gross electricity from biomass was produced in combined heat and power plants, mainly from solid biomass (54.8%), biogases (31.1%), and renewable municipal waste (11.6%) [118].

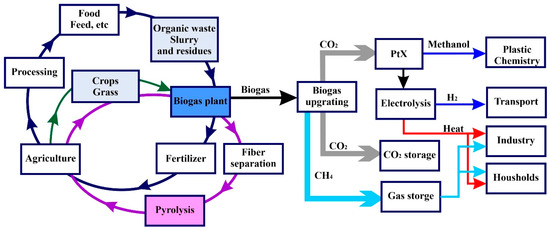

One of the most evident examples of converting organic waste into energy in full accordance with the concept of a circular economy is biogas technology in Denmark (Figure 12). The energy content of the biomass (livestock waste and residues from households, industry, and agriculture) is employed to generate biogas, an alternative to fossil fuels. Instead, the waste and residues are extracted and utilized as fertilizer in agriculture. After all, before biomethane is introduced into the gas system, biogenic CO2 is extracted and used to produce Power-to-X fuels and store CO2 [119].

Figure 12.

An example biogas plant as circular economy in practice (Denmark).

These examples demonstrate Europe’s diverse and innovative approaches to converting organic waste into valuable energy, contributing to sustainability and reducing reliance on fossil fuels. The overall transformation of organic waste to value-added bioproducts enhances the circular economy approach.

The Confederation of European Waste-to-Energy Plants (CEWEP) represents over 400 plants from 23 countries. Its mission is to contribute to European environmental and energy legislation and participate in ongoing studies with international organizations like the UNEP, OECD, and EU [120]. This legislation defines EfW as an industrial activity that must comply with stringent industrial emission levels and report monthly to the relevant authorities while maintaining ongoing pollution management.

Each EU Member State has devised its plan to achieve these shared goals while adhering to the Directives. EU countries have frequently utilized strong regulatory leverages, such as landfill bans or taxes. The EU has increased the efficiency of energy recovery.

7. Conclusions

Reducing dependence on fossil fuels and reducing environmental pollution are the main trends forcing humanity to look for new energy sources. This paper summarizes the current OWtE technologies as a part of the sustainable resource recovery process. We started with classical methods and concluded with discussing the most recent innovations. The merits and disadvantages of each process were discussed, with a particular emphasis on the generation of by-products and the appropriate treatment to prevent environmental harm. As a result, new strategies for enhancing waste-to-energy efficiency and incorporating it into the principles of a circular economy and substitutability have been examined from this perspective. Along with a review of recent scientific breakthroughs in this field, practical examples of technology application in European countries were given, focusing on the clear economic and environmental benefits.

Author Contributions

Conceptualization, S.Z.; methodology, F.F. and V.C.; validation, PIN, formal analysis, F.F.; investigation and data curation, S.Z.; writing—original draft preparation, S.Z.; writing, review and editing, S.Z.; visualization, V.C.; editing and review, F.F.; supervision, management, editing, and review, F.V. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data are available upon reasonable request.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| CE | Circular economy |

| OWtE | Organic waste-to-energy |

| WtE | Waste-to-energy |

| GHGs | Greenhouse gasses |

| RRfW | Resource recovery from waste |

| OSW | Organic solid waste |

| AF | Anaerobic fermentation |

| ETP | Electron transport phosphorylation |

| AD | Anaerobic digestion |

| VFAs | Volatile fatty acids |

| MSW | Municipal solid waste |

| COD | Chemical oxygen demand |

| HTC | Hydrothermal carbonization |

| HTL | Hydrothermal liquefaction |

| HTV | Hydrothermal vaporization |

| HTG | Hydrothermal gasification |

| DCWG | Super critical water gasification |

References

- Velenturf, A.; Purnell, P. Principles for a Sustainable Circular Economy. Sustain. Prod. Consum. 2021, 27, 1437–1457. [Google Scholar] [CrossRef]

- Lag-Brotons, A.J.; Velenturf, A.P.M.; Crane, R.; Head, I.M.; Purnell, P.; Semple, K.T. Editorial: Resource Recovery From Waste. Front. Environ. Sci. Sec. Microbiol. Chem. Geomicrobiol. 2020, 8, 35. [Google Scholar] [CrossRef]

- Regulation (EU) 2020/852 of the European Parliament and of the Council of 18 June 2020 on the Establishment of a Framework to Facilitate Sustainable Investment, and Amending Regulation (EU) 2019/2088. 2020. Available online: http://data.europa.eu/eli/reg/2020/852/oj (accessed on 10 April 2024).

- Waste Framework Directive. Available online: https://environment.ec.europa.eu/topics/waste-and-recycling/waste-framework-directive_en#ref-2023-amendment-to-the-waste-framework-directive (accessed on 10 March 2024).

- Bakan, B.; Bernet, N.; Bouchez, T. Circular Economy Applied to Organic Residues and Wastewater: Research Challenges. Waste Biomass-Valorization 2022, 13, 1267–1276. [Google Scholar] [CrossRef]

- Bioenergy Report Outlines Progress Being Made across the EU. Available online: https://energy.ec.europa.eu/news/bioenergy-report-outlines-progress-being-made-across-eu-2023-10-27_en (accessed on 10 March 2024).

- Silva-Martínez, R.D.; Sanches-Pereira, A.; Ortiz, W.; Gómez Galindo, M.F.; Coelho, S.T. The state-of-the-art of organic waste to energy in Latin America and the Caribbean: Challenges and opportunities Renew. Energy 2020, 156, 509–525. [Google Scholar] [CrossRef]

- Wainaina, S.; Awasthi, M.K.; Sarsaiya, S.; Chen, H.; Singh, E.; Kumar, A.; Ravindran, B.; Awasthi, S.K.; Liu, T.; Duan, Y.; et al. Resource recovery and circular economy from organic solid waste using aerobic and anaerobic digestion technologies. Bioresour. Technol. 2020, 301, 122778. [Google Scholar] [CrossRef] [PubMed]

- Primary Energy—Global Consumption 2023. Statista. Available online: https://www.statista.com/statistics/265598/consumption-of-primary-energy-worldwide/ (accessed on 15 July 2024).

- Kalair, A.R.; Seyedmahmoudian, M.; Stojcevski, A.; Abas, N.; Khan, N. Waste to energy conversion for a sustainable future. Heliyon 2021, 7, e08155. [Google Scholar] [CrossRef]

- Kataya, G.; Cornu, D.; Bechelany, M.; Hijazi, A.; Issa, M. Biomass Waste Conversion Technologies and Its Application for Sustainable Environmental Development—A Review. Agronomy 2023, 13, 2833. [Google Scholar] [CrossRef]

- Elalami, D.; Barakat, A. State of the art of energy production from agricultural residues using thermochemical and biological processes. In Clean Energy and Resources Recovery; Volume 1; Elsevier: Amsterdam, The Netherlands, 2021; pp. 1–24. [Google Scholar]

- Zhang, J.; Du, Z.; Fu, L.; Han, Y.; Zheng, W.; Yu, F.; Chen, H.; Feng, L.; Li, Y.; Ping, W. Novel Anaerobic Digestion and Carbon Dioxide Emissions Efficiency Analysis of Food Waste Treatment Based on SBM-DEA Model. J. Clean. Prod. 2021, 328, 129591. [Google Scholar] [CrossRef]

- Unegg, M.C.; Steininger, K.W.; Ramsauer, C.; Rivera-Aguilar, M. Assessing the Environmental Impact of Waste Management: A Comparative Study of CO2 Emissions with a Focus on Recycling and Incineration. J. Clean. Prod. 2023, 415, 137745. [Google Scholar] [CrossRef]

- Integrated Gasification Combined-Cycle|Climate Technology Centre & Network|1181699. Available online: https://www.ctc-n.org/technology-library/production-efficiency/integrated-gasification-combined-cycle (accessed on 27 June 2024).

- Schwartz, N.R.; Paulsen, A.D.; Blaise, M.J.; Wagner, A.L.; Yelvington, P.E. Analysis of Emissions from Combusting Pyrolysis Products. Fuel 2020, 274, 117863. [Google Scholar] [CrossRef]

- Yu, S.; He, J.; Zhang, Z.; Sun, Z.; Xie, M.; Xu, Y.; Bie, X.; Li, Q.; Zhang, Y.; Sevilla, M.; et al. Towards Negative Emissions: Hydrothermal Carbonization of Biomass for Sustainable Carbon Materials (Adv. Mater. 18/2024). Adv. Mater. 2024, 36, 2470139. [Google Scholar] [CrossRef]

- Carbon Dioxide Emissions Factor, kg CO2 per MWh. Our World in Data. Available online: https://ourworldindata.org/grapher/carbon-dioxide-emissions-factor (accessed on 27 June 2024).

- Vikjær-Andresen, E. How Can Biogenic CO2 Be Used to Address the Climate Crisis? World Economic Forum. Available online: https://www.weforum.org/agenda/2023/10/biogenic-co2-climate-green-hydrogen/ (accessed on 11 July 2024).

- Jarunglumlert, T.; Bampenrat, A.; Sukkathanyawat, H.; Prommuak, C. Enhanced Energy Recovery from Food Waste by Co-Production of Bioethanol and Biomethane Process. Fermentation 2021, 7, 265. [Google Scholar] [CrossRef]

- Kumar, H.; Vijay, V.K.; Subbarao, P.M.; Chandra, R. Studies on the Application of Bio-Carbon Dioxide as Controlled Atmosphere on Pest Management in Wheat Grain Storage. J. Stored Prod. Res. 2022, 95, 101911. [Google Scholar] [CrossRef]

- Intergovernmental Panel on Climate Change (IPCC) Emission Factor Database (EFDB). Available online: https://www.ipcc-nggip.iges.or.jp/EFDB/ (accessed on 27 October 2023).

- Lanza, L.J. Tech’s Bacteria Carbon Capture Tech. Carbon Credits. Available online: https://carboncredits.com/lanzatech-capture-carbon/ (accessed on 24 June 2024).

- Velvizhi, G.; Sarkar, O.; Rovira-Alsina, L.; Puig, S.; Mohan, S.V. Conversion of Carbon Dioxide to Value Added Products through Anaerobic Fermentation and Electro Fermentation: A Comparative Approach. Int. J. Hydrogen Energy 2022, 47, 15442–15455. [Google Scholar] [CrossRef]

- Kwon, E.E.; Kim, S.; Lee, J. Pyrolysis of Waste Feedstocks in CO2 for Effective Energy Recovery and Waste Treatment. J. CO2 Util. 2019, 31, 173–180. [Google Scholar] [CrossRef]

- Williams, C.L.; Dahiya, A.; Porter, P. Introduction to bioenergy and waste to energy. In Bioenergy, 2nd ed.; Cambridge University Press: Cambridge, UK, 2020; pp. 5–44. [Google Scholar]

- Manikandan, S.; Vickram, S.; Sirohi, R.; Subbaiya, R.; Krishnan, R.Y.; Karmegam, N.; Sumathijones, C.; Rajagopal, R.; Chang, S.W.; Ravindran, B.; et al. Critical review of biochemical pathways to transformation of waste and biomass into bioenergy. Bioresour. Technol. 2023, 372, 128679. [Google Scholar] [CrossRef] [PubMed]

- Buckel, W. Energy Conservation in Fermentations of Anaerobic. Bacteria. Front. Microbiol. 2021, 12, 703525. [Google Scholar]

- Zhang, Y.; Wang, X.; Zhu, W.; Zhao, Y.; Wang, N.; Gao, M.; Wang, Q. Anaerobic fermentation of organic solid waste: Recent updates in substrates, products, and the process with multiple products co-production. Environ. Res. 2023, 233, 116444. [Google Scholar] [CrossRef]

- Lin, J.; Zhang, Y.; Song, T.; Su, H. Waste Fermentation for Energy Recovery. In Waste-to-Energy: Recent Developments and Future Perspectives towards Circular Economy; Springer: Cham, Switzerland, 2022; pp. 207–225. [Google Scholar]

- Hegde, S.; Trabold, T.A. Sustainable Waste-to-Energy Technologies: Fermentation. In Sustainable Food Waste-To-Energy Systems; Chapter 5; Academic Press: Cambridge, MA, USA, 2018; pp. 69–88. [Google Scholar]

- Fan, Y.X.; Zhang, J.Z.; Zhang, Q.; Ma, X.Q.; Liu, Z.Y.; Lu, M.; Qiao, K.; Li, F.L. Biofuel and chemical production from carbon one industry flux gas by acetogenic bacteria. In Advances in Applied Microbiology; Chapter 1; Academic Press: Cambridge, MA, USA, 2021; Volume 117, pp. 1–34. [Google Scholar]

- Zueva, S.; Kovalev, A.A.; Litti, Y.V.; Ippolito, N.M.; Innocenzi, V.; De Michelis, I. Environmental and Economic Aspects of Biomethane Production from Organic Waste in Russia. Energies 2021, 14, 5244. [Google Scholar] [CrossRef]

- Yan, J.; Salman, C.A. Waste-to-energy (WtE): Current technologies and their future potential. In Waste Biorefineries; Elsevier: Amsterdam, The Netherlands, 2023; pp. 83–97. [Google Scholar]

- Dong, H.; Mangino, J.; Mcallister, T.A.; Hatfield, J.L.; Johnson, D.E.; Bartram, D.; Gibb, D. Emissions from Livestock and Manure Management. 2006. Available online: http://www.ipcc-nggip.iges.or.jp/public/2006gl/pdf/4_Volume4/V4_10_Ch10_Livestock.pdf (accessed on 16 July 2024).

- Gopal, P.M.; Sivaram, N.M.; Barik, D. Paper Industry Wastes and Energy Generation From Wastes. In Energy from Toxic Organic Waste for Heat and Power Generation; Woodhead Publishing Series in Energy; Chapter 7; Woodhead Publishing: Sawston, UK, 2019; pp. 83–97. [Google Scholar]

- Singh, V.; Das, D. Chapter 3. Potential of Hydrogen Production From Biomass. In Science and Engineering of Hydrogen-Based Energy Technologies; Academic Press: Cambridge, MA, USA, 2019; pp. 123–164. [Google Scholar]

- Sharma, H.B.; Venna, S.; Dubey, B.K. Resource recovery and circular economy approach in organic waste management using hydrothermal carbonization. In Clean Energy and Resources Recovery; Chapter 13; Elsevier: Amsterdam, The Netherlands, 2021; pp. 313–326. [Google Scholar]

- Thabit, Q.; Nassour, A.; Nelles, M. Flue Gas Composition and Treatment Potential of a Waste Incineration Plant. Appl. Sci. 2022, 12, 5236. [Google Scholar] [CrossRef]

- Alao, M.A.; Popoola, O.M.; Ayodele, T.R. Waste-To-Energy Nexus: An Overview of Technologies and Implementation for Sustainable Development. Clean. Energy Syst. 2022, 3, 100034. [Google Scholar] [CrossRef]

- Wei, R.; Zhang, R.; Song, L. Incineration disposal of organic waste bio-residue via a deep dewatering process using refuse incineration bottom ash: Moisture transfer and low calorific value improvement. Environ. Sci. Pollut. Res. 2022, 29, 78107–78119. [Google Scholar] [CrossRef] [PubMed]

- Dal Pozzo, A.; Antonioni, G.; Guglielmi, D.; Stramigioli, C.; Cozzani, V. Comparison of alternative flue gas dry treatment technologies in waste-to-energy processes. Waste Manag. 2016, 51, 81–90. [Google Scholar] [CrossRef] [PubMed]

- Moharir, R.V.; Gautam, P.; Kumar, S. Waste Treatment Processes/Technologies for Energy Recovery. In Current Developments in Biotechnology and Bioengineering; Chapter 4; Elsevier: Amsterdam, The Netherlands, 2019; pp. 53–77. [Google Scholar]

- Lam, C.H.K.; Ip, A.W.M.; Barford, J.P.; McKay, G. Use of Incineration MSW Ash: A Review. Sustainability 2010, 2, 1943–1968. [Google Scholar] [CrossRef]

- Murugesan, P.; Raja, V.; Dutta, S.; Moses, J.A.; Anandharamakrishnan, C. Food waste valorisation via gasification. A review on emerging concepts, prospects and challenges. Sci. Total Environ. 2022, 851, 157955. [Google Scholar] [CrossRef] [PubMed]

- Mishra, S.; Upadhyay, R.K. Review on biomass gasification: Gasifiers, gasifying mediums, and operational parameters. Mater. Sci. Energy Technol. 2021, 4, 329–340. [Google Scholar] [CrossRef]

- Yang, H.; Chen, H. Biomass gasification for synthetic liquid fuel production. In Gasification for Synthetic Fuel Production; Woodhead Publishing: Sawston, UK, 2015; pp. 241–275. [Google Scholar]

- McCaffrey, Z.; Thy, P.; Long, M.; Oliveira, M.; Wang, L.; Torres, L.; Aktas, T.; Chiou, B.S.; Orts, W.; Jenkins, B.M. Air and steam gasification of almond biomass. Front. Energy Res. 2019, 7, 84. [Google Scholar] [CrossRef]

- Tezer, Ö.; Karabağ, N.; Öngen, N.; Çolpan, C.Ö.; Ayol, A. Biomass gasification for sustainable energy production: A review. Int. J. Hydrogen Energy 2022, 47, 15419–15433. [Google Scholar] [CrossRef]

- Sansaniwal, S.K.; Pal, K.; Rosen, M.A.; Tyagi, S.K. Recent advances in the development of biomass gasification technology: A comprehensive review. Renew. Sustain. Energy Rev. 2017, 72, 363–384. [Google Scholar] [CrossRef]

- Kane, S.; Ulrich, R.; Harrington, A.; Stadie, N.P.; Ryan, C. Physical and chemical mechanisms that influence the electrical conductivity of lignin-derived biochar. Carbon Trends. 2021, 5, 100088. [Google Scholar] [CrossRef]

- Su, H.; Hantoko, D.; Yan, M.; Cai, Y.; Kanchanatip, E.; Liu, J.; Zhou, X.; Zhang, S. Evaluation of catalytic subcritical water gasification of food waste for hydrogen production: Effect of process conditions and different types of catalyst loading. Int. J. Hydrogen Energy 2019, 44, 21451–21463. [Google Scholar] [CrossRef]

- Su, H.; Liao, W.; Wang, J.; Hantoko, D.; Zhou, Z.; Feng, H.; Jiang, J.; Yan, M. Assessment of supercritical water gasification of food waste under the background of waste sorting: Influences of plastic waste contents. Int. J. Hydrogen Energy 2020, 45, 21138–21147. [Google Scholar] [CrossRef]

- Czajczyńska, D.; Anguilano, L.; Ghazal, H.; Krzyżyńska, R.; Reynolds, A.J.; Spencer, N.; Jouhara, H. Potential of pyrolysis processes in the waste management sector. Therm. Sci. Eng. Prog. 2017, 3, 171–197. [Google Scholar] [CrossRef]

- Shahbaz, M.; AlNouss, A.; Parthasarathy, P.; Abdelaal, A.H.; Mackey, H.; McKay, G. Investigation of biomass components on the slow pyrolysis products yield using Aspenlus for techno-economic analysis. Biomass Conv. Bioref. 2020, 12, 669–681. [Google Scholar] [CrossRef]

- Chen, W.H.; Farooq, W.; Shahbaz, M.; Naqvi, S.R.; Ali, I.; Al-Ansari, T. Current status of biohydrogen production from lignocellulosic biomass, technical challenges and commercial potential through pyrolysis process. Energy 2021, 226, 120433. [Google Scholar] [CrossRef]

- Venderbosch, R.H.; Prins, W. Fast pyrolysis technology development. Biofuels Bioprod. Biorefining 2010, 4, 178–208. [Google Scholar] [CrossRef]

- Uddin, M.N.; Techato, K.; Taweekun, J.; Rahman, M.M.; Rasul, M.G.; Mahlia, T.M.I. An overview of recent developments in biomass pyrolysis technologies. Energies 2018, 11, 3115. [Google Scholar] [CrossRef]

- Amenaghawon, N.; Anyalewechi, C.L.; Okieimen, C.O.; Kusuma, H.S. Biomass pyrolysis technologies for value-added products: A state-of-the-art review. Environ. Dev. Sustain. 2021, 23, 14324–14378. [Google Scholar] [CrossRef]

- Al-Rumaihi, A.; Shahbaz, M.; Mckay, G.; Mackey, H.; Al-Ansari, T. A review of pyrolysis technologies and feedstock: A blending approach for plastic and biomass towards optimum biochar yield. Renew. Sustain. Energy 2022, 167, 112715. [Google Scholar] [CrossRef]

- Liu, W.J.; Jiang, H.; Yu, H.Q. Development of biochar-based functional materials: Toward a sustainable platform carbon material. Chem. Rev. 2015, 115, 12251–12285. [Google Scholar] [CrossRef]

- Onay, O.; Kockar, O.M. Slow, fast and flash pyrolysis of rapeseed Renew. Energy 2003, 28, 2417–2433. [Google Scholar]

- Andooz, A.; Eqbalpour, M.; Kowsari, E.; Ramakrishna, S.; Cheshmeh, Z.A. A comprehensive review on pyrolysis from the circular economy point of view and its environmental and social effects. J. Clean. Prod. 2023, 388, 136021. [Google Scholar] [CrossRef]

- Fang, J.; Zhan, L.; Ok, Y.S.; Gao, B. Minireview of potential applications of hydrochar derived from hydrothermal carbonization of biomass. J. Ind. Eng. Chem. 2018, 57, 15–21. [Google Scholar] [CrossRef]

- Czerwińska, K.; Śliz, M.; Wilk, M. Hydrothermal carbonization process: Fundamentals, main parameter characteristics and possible applications including an effective method of SARS-CoV-2 mitigation in sewage sludge. A review. Renew. Sustain. Energy Rev. 2022, 154, 111873. [Google Scholar] [CrossRef]

- González-Arias, J.; Sánchez, M.E.; Cara-Jiménez, J. Hydrothermal carbonization of biomass and waste: A review. Environ. Chem. Lett. 2022, 20, 211–221. [Google Scholar] [CrossRef]

- Parshetti, G.K.; Liu, Z.; Jain, A.; Srinivasan, M.P.; Balasubramanian, R. Hydrothermal carbonization of sewage sludge for energy production with coal. Fuel 2013, 111, 201–210. [Google Scholar] [CrossRef]