Unmanned Aerial Vehicle (UAV)-Assisted Damage Detection of Wind Turbine Blades: A Review

Abstract

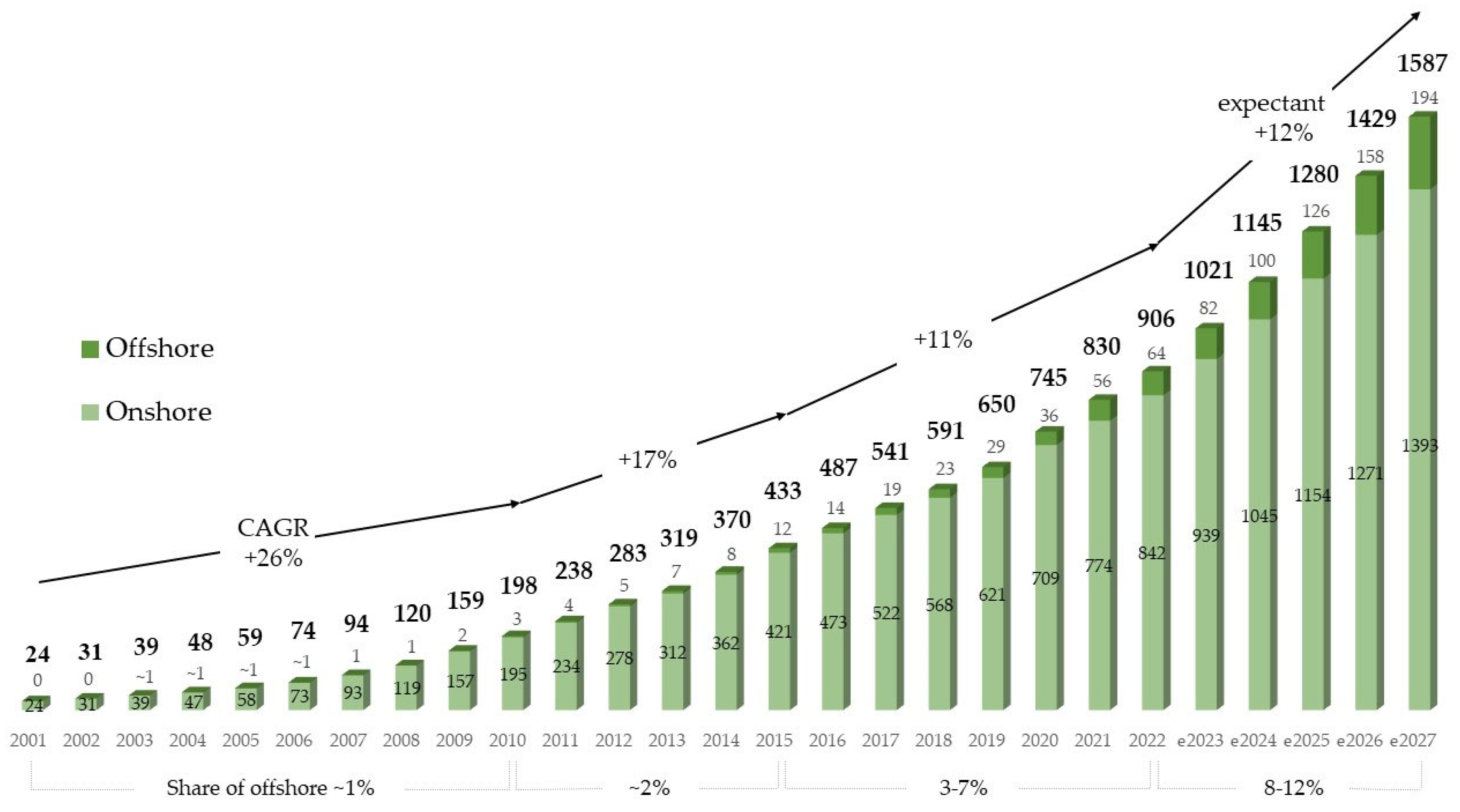

1. Introduction

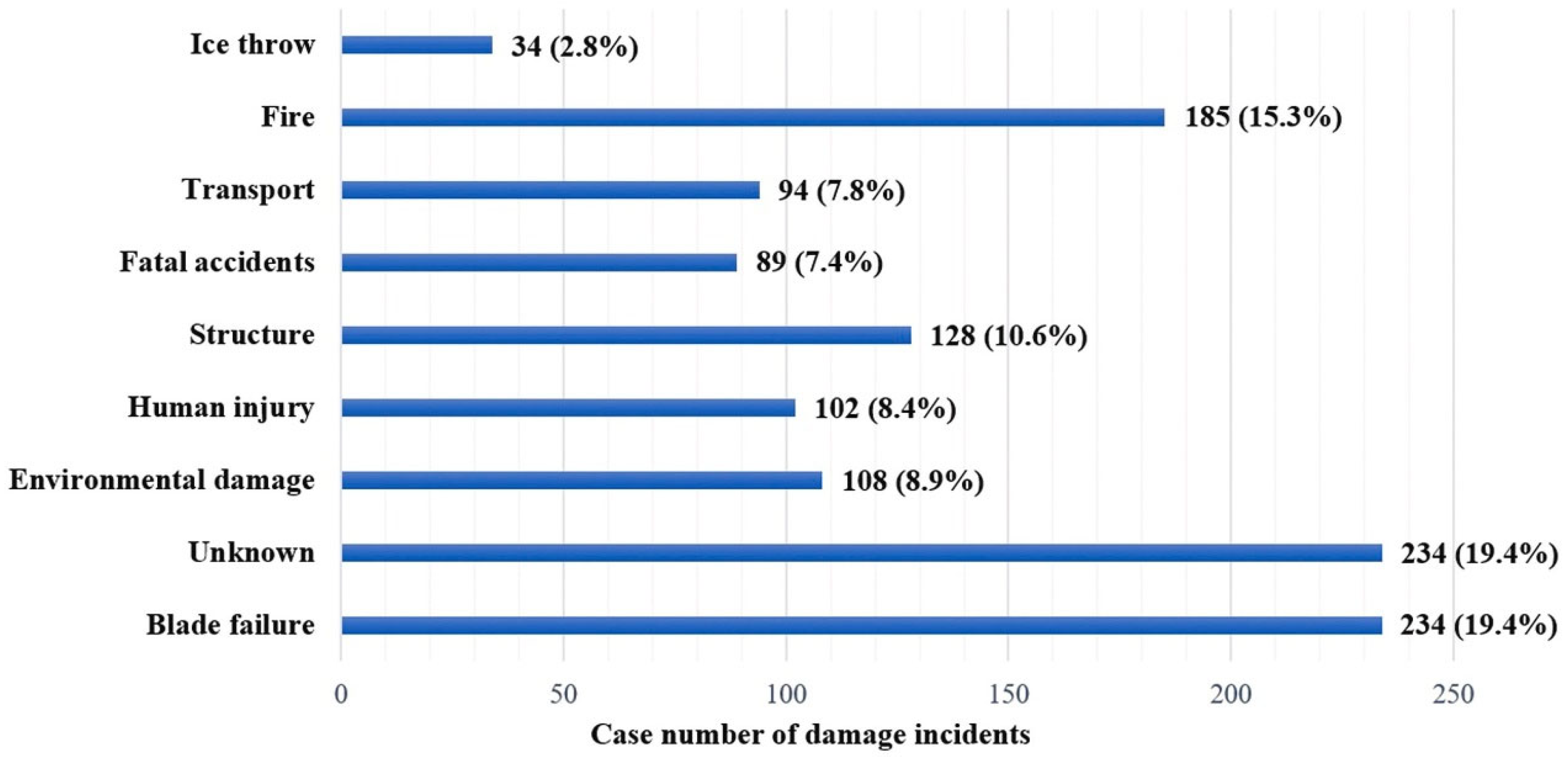

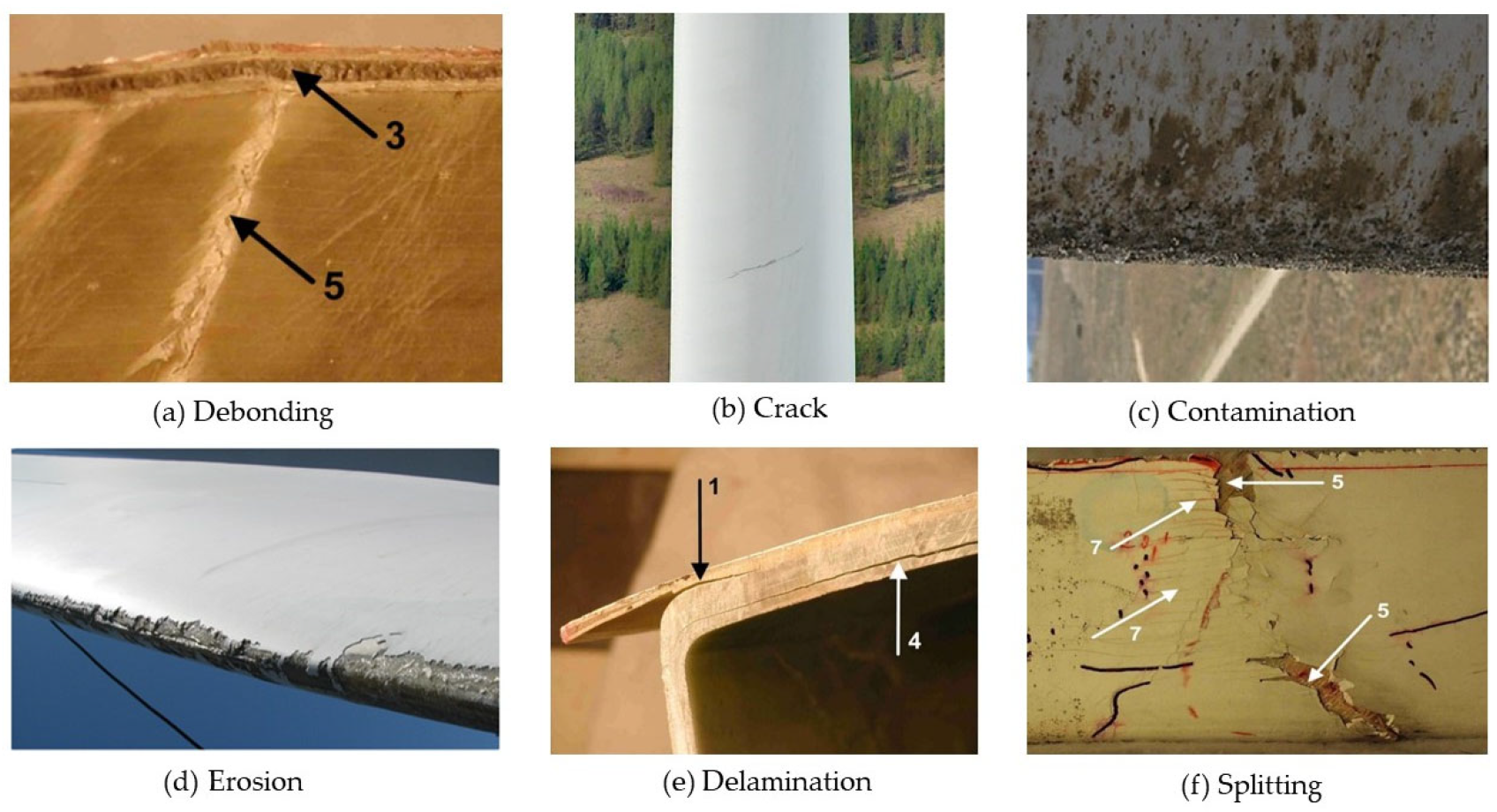

2. Damage of Wind Turbine Blades

3. Blade Damage Detection Methods

3.1. Vision

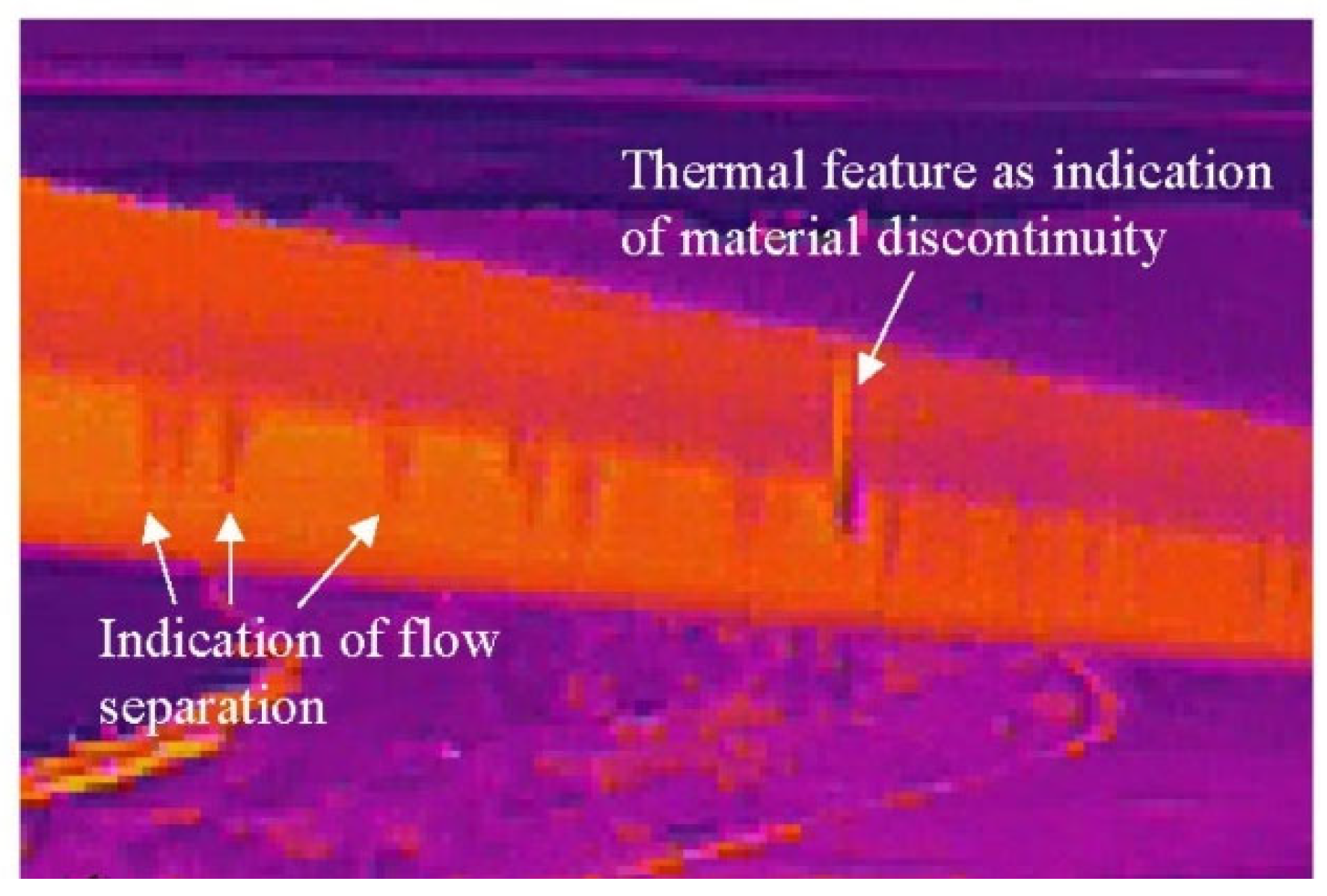

3.2. Thermography

3.3. Strain Measurement

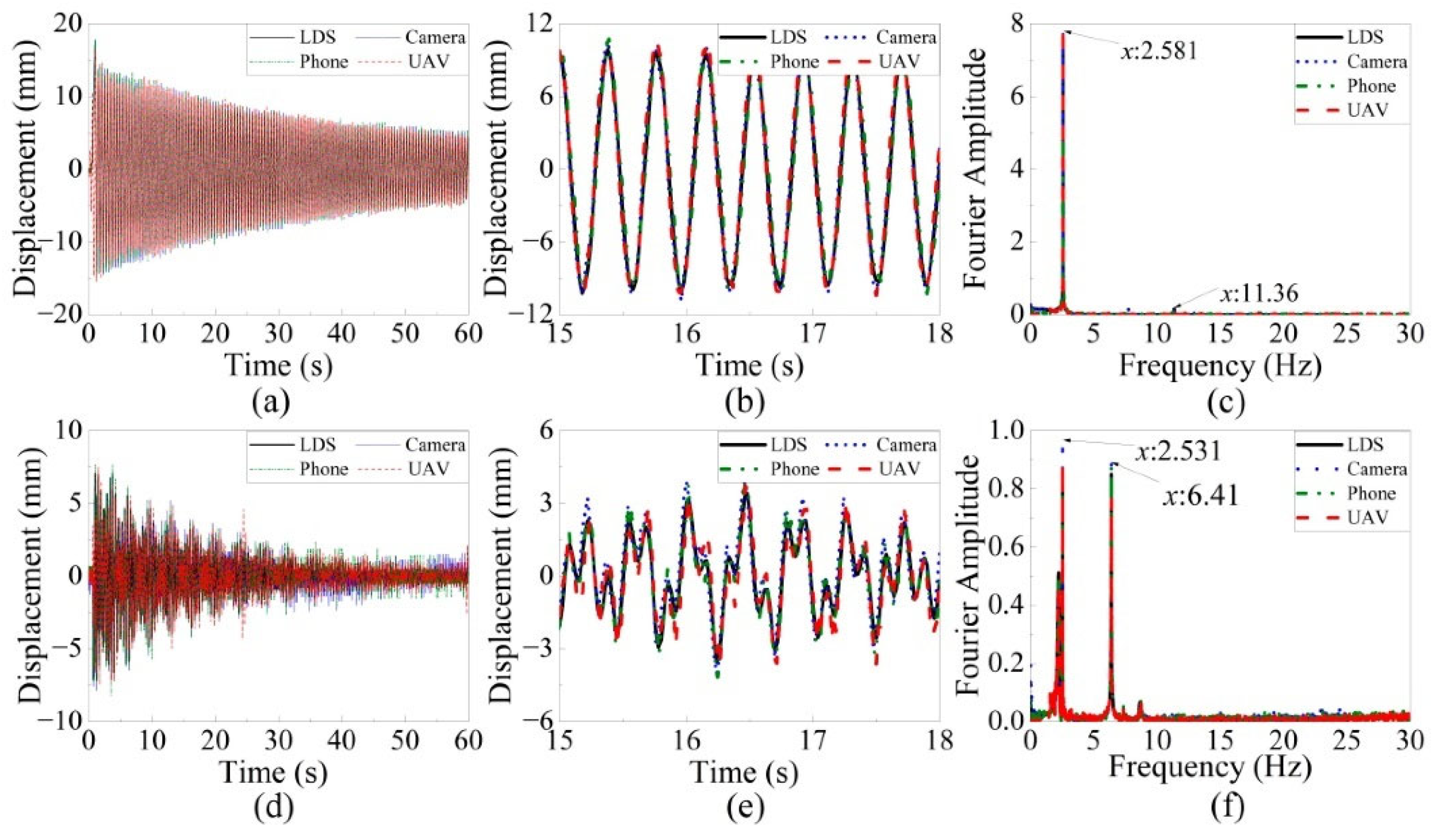

3.4. Vibration

3.5. Ultrasound

3.6. Acoustic Emission

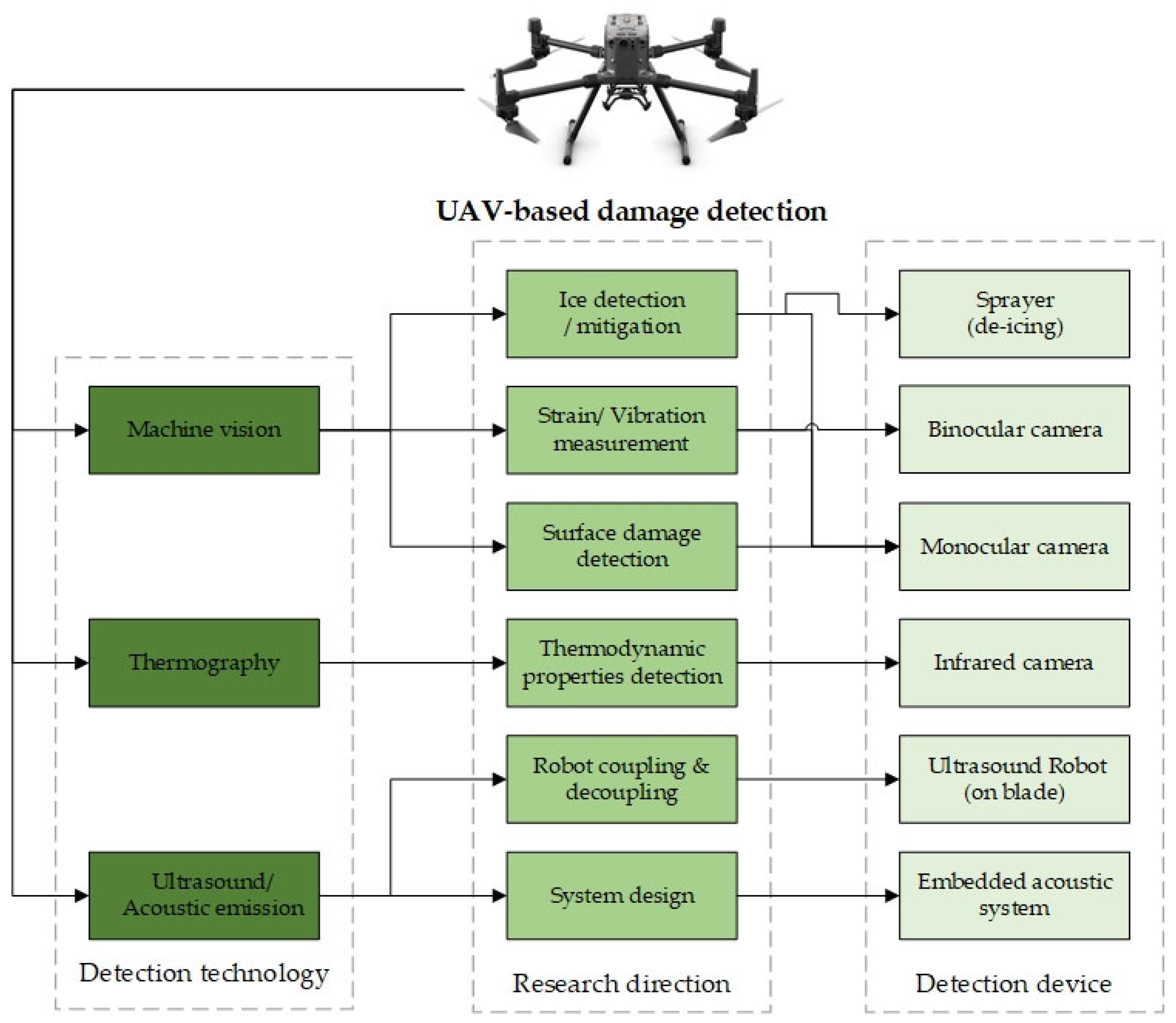

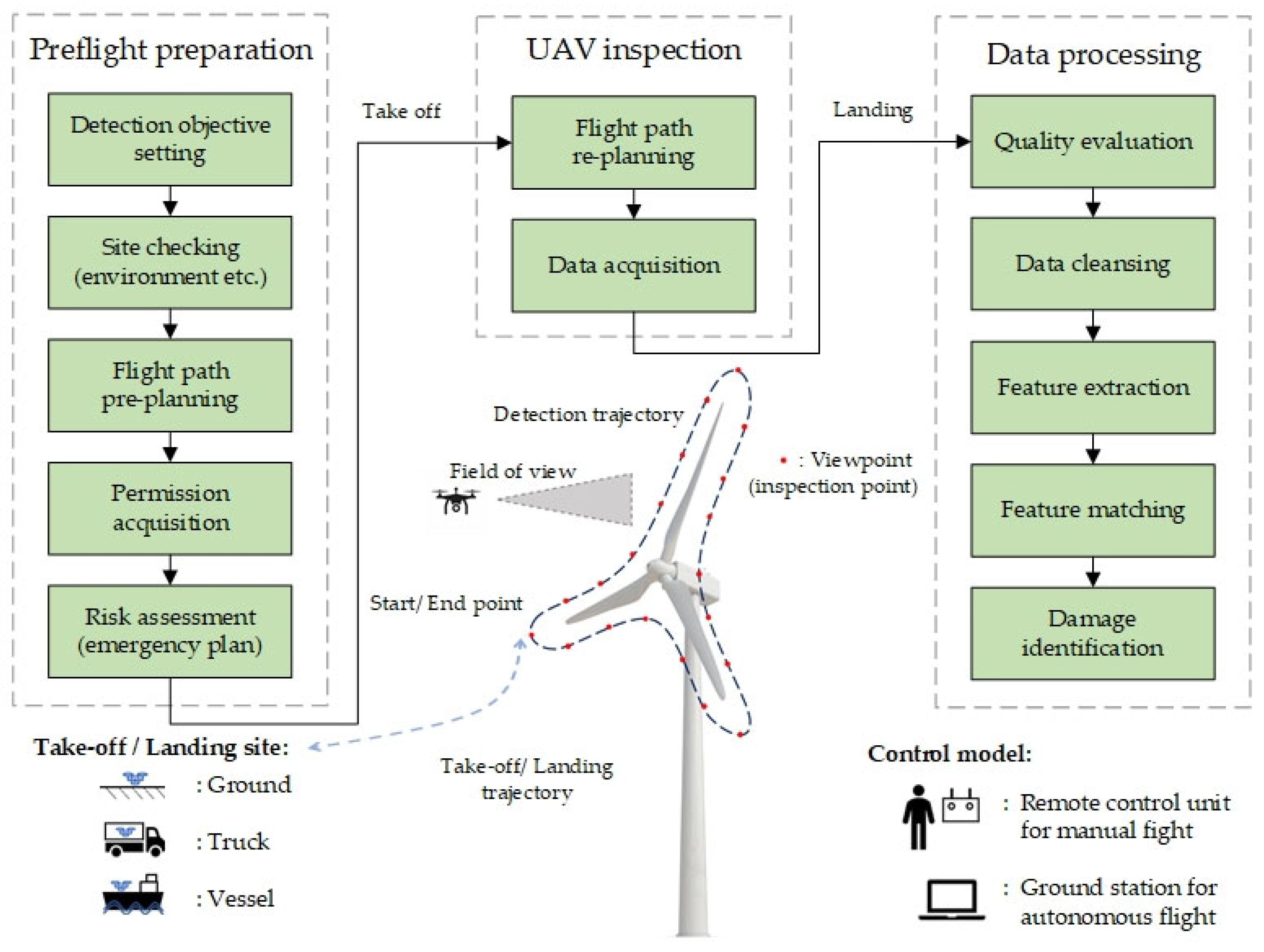

4. Blade Damage Detection Using UAVs

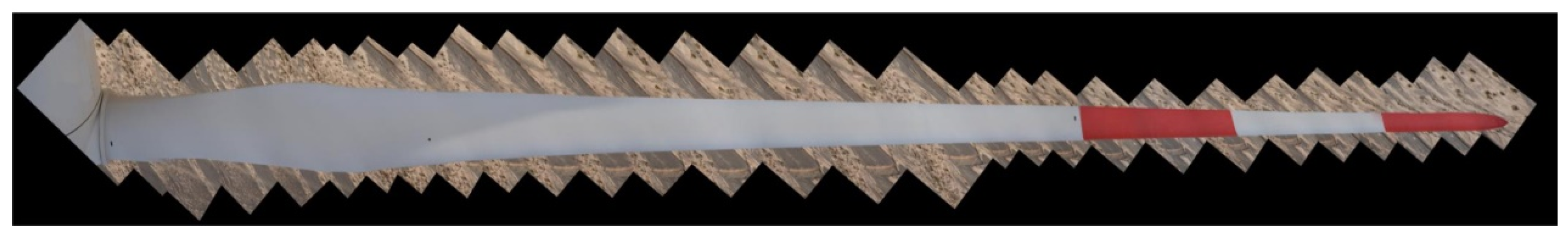

4.1. Optical-Image-Based Detection of Blade Damage

4.1.1. Elementary Image Processing Workflow

4.1.2. Frozen Blade Detection and Ice Mitigation

4.1.3. Strain and Vibration Analysis Based on Target Tracking

4.1.4. Cracks, Debonding, Erosion, and Other Damage Detection Using Deep Learning

4.2. Thermography

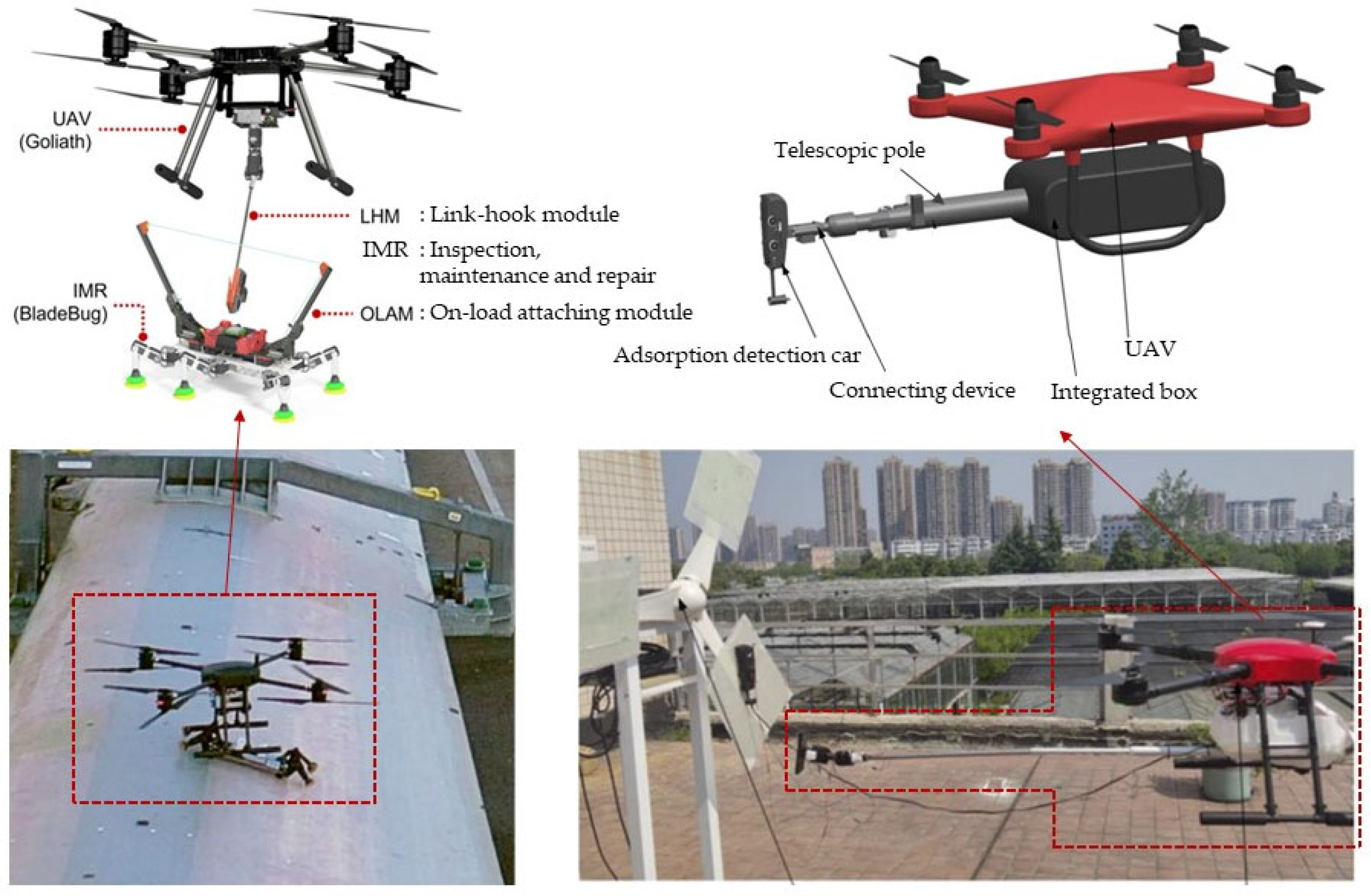

4.3. Ultrasonic Inspection Robot and Embedded Acoustic System

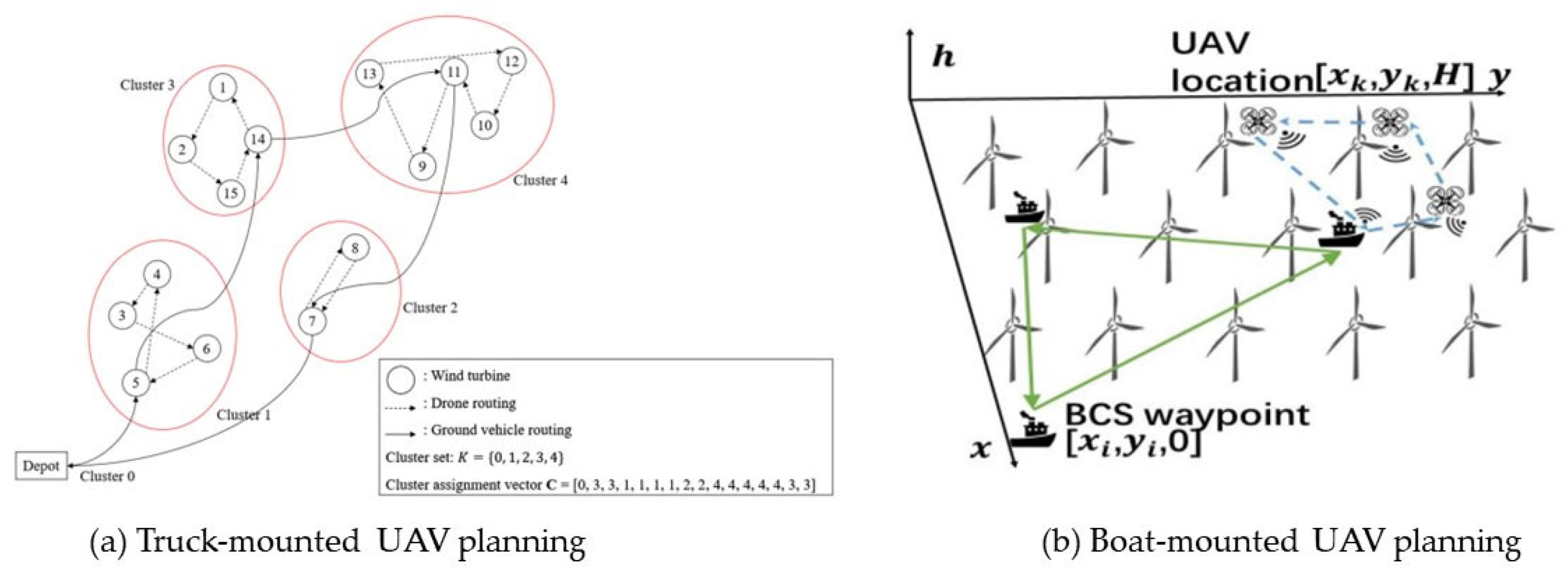

5. Autonomous UAV Flight Control for Damage Detection

5.1. Wind Turbine Localization

5.2. Distance Control between the UAV and the Wind Turbine

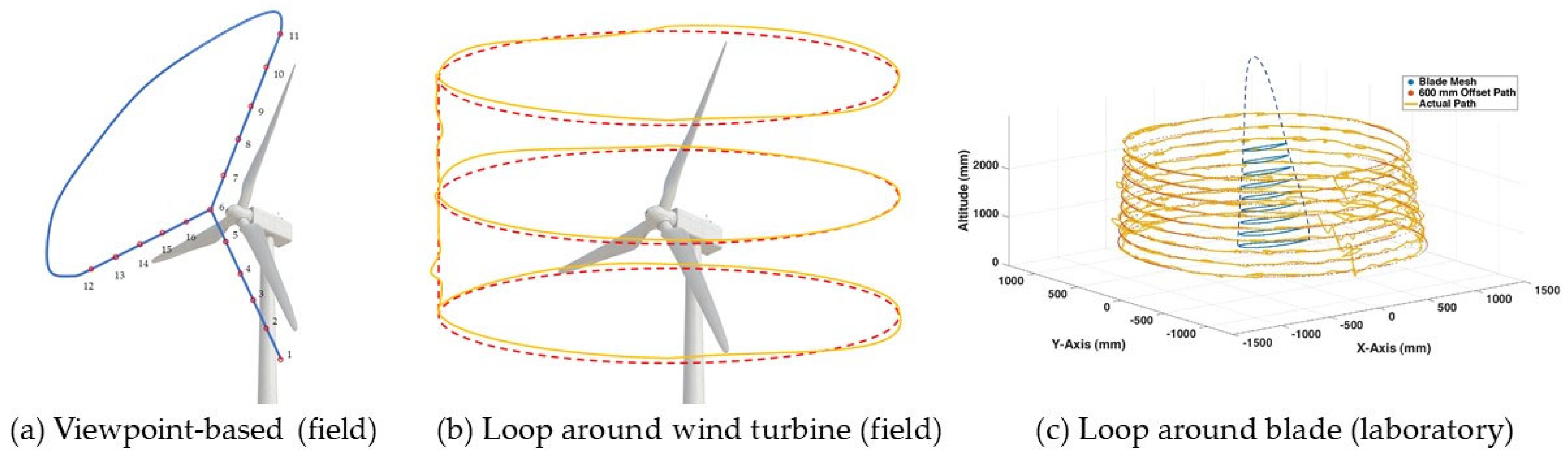

5.3. Path Planning of UAV Flight

5.4. Coupling and Decoupling of UAVs and Robots

6. Discussions

6.1. Major Challenges

- UAV performance: it is noteworthy that most UAVs reviewed in this paper are electrically powered, making them small in size with high maneuverability. However, this also introduces issues related to stability, reliability, and flight attitude requirements. The limited load capacity and space of these UAVs, often sacrificed for portability, restrict battery life and the weight and size of sensors. Furthermore, their operability in harsh environmental conditions, such as rain, snow, and strong winds, remains limited.

- Sensor performance: the performance of sensors mounted on UAVs is inherently limited by the platform’s constraints. Optical and thermal imaging cameras, although useful, cannot directly acquire three-dimensional data. While larger multi-rotor UAVs and unmanned helicopters can perform three-dimensional measurements using LiDAR, their application in wind turbine operations and maintenance remains relatively uncommon.

- Operators and governments: obtaining flight permissions for UAVs in both commercial and public wind farms poses significant challenges due to commercial sensitivity and security considerations. The lack of publicly shared wind farm data and the potential misalignment of data annotations with UAV inspection requirements further complicate this issue. Ensuring the privacy and security of wind farms necessitates strict regulations and procedures, which can hinder the efficient use of UAVs. On the other hand, the absence of standardized protocols and regulations for UAV inspections of wind turbines represents another challenge, potentially leading to inconsistencies in data collection, analysis, and interpretation, thus affecting the accuracy and reliability of inspection results. Developing standardized procedures and guidelines, along with training and certification for operators, are crucial for the widespread adoption and effective utilization of UAVs in wind turbine inspections.

6.2. Prospects

Funding

Conflicts of Interest

References

- Hutchinson, M.; Zhao, F. GWEC Global Wind Report 2023. Available online: https://gwec.net/wp-content/uploads/2023/03/GWR-2023_interactive_v2_compressed.pdf (accessed on 3 May 2024).

- Zhao, X.-G.; Ren, L.-Z. Focus on the development of offshore wind power in China: Has the golden period come? Renew. Energy 2015, 81, 644–657. [Google Scholar] [CrossRef]

- Wiser, R.; Rand, J.; Seel, J.; Beiter, P.; Fekete, E.; Gagne, S.; Gilman, P.; Lantz, E.; Smith, A.; Debruin, P.; et al. 2016 Wind Technologies Market Report; Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2016. [Google Scholar]

- International Renewable Energy Agency. Future of Wind: Deployment, Investment, Technology, Grid Integration and Socio-Economic Aspects. 2019. Available online: https://www.irena.org/publications/2019/Oct/Future-of-wind (accessed on 3 May 2024).

- Bak, C.; Zahle, F.; Bitsche, R.; Yde, A.; Henriksen, L.C.; Natarajan, A.; Hansen, M.H. The DTU 10-MW Reference Wind Turbine; Danish Wind Power Research 2013, DTU Wind Energy Report-I-0092; Technical University of Denmark: Kongens Lyngby, Denmark, 2013. [Google Scholar]

- Hau, E. Wind Turbines: Fundamentals, Technologies, Application, Economics, 3rd ed.; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Ciang, C.C.; Lee, J.-R.; Bang, H.-J. Structural health monitoring for a wind turbine system: A review of damage detection methods. Meas. Sci. Technol. 2008, 19, 122001. [Google Scholar] [CrossRef]

- Kaldellis, J.K.; Zafirakis, D. The wind energy (r) evolution: A short review of a long history. Renew. Energy 2011, 36, 1887–1901. [Google Scholar] [CrossRef]

- Thresher, R.; Robinson, M.; Veers, P. To capture the wind. IEEE Power Energy Mag. 2007, 5, 34–46. [Google Scholar] [CrossRef]

- Snyder, B.; Kaiser, M.J. Ecological and economic cost-benefit analysis of offshore wind energy. Renew. Energy 2009, 34, 1567–1578. [Google Scholar] [CrossRef]

- Dinwoodie, I.; McMillan, D.; Revie, M.; Lazakis, I.; Dalgic, Y. Development of a combined operational and strategic decision support model for offshore wind. Energy Procedia 2015, 80, 7–14. [Google Scholar] [CrossRef]

- Chou, J.-S.; Chiu, C.-K.; Huang, I.-K.; Chi, K.-N. Failure analysis of wind turbine blade under critical wind loads. Eng. Fail. Anal. 2013, 27, 99–118. [Google Scholar] [CrossRef]

- Jureczko, M.; Pawlak, M.; Mężyk, A. Optimisation of wind turbine blades. J. Mater. Process. Technol. 2005, 167, 463–471. [Google Scholar] [CrossRef]

- Kaewniam, P.; Cao, M.; Alkayem, N.F.; Li, D.; Manoach, E. Recent advances in damage detection of wind turbine blades: A state-of-the-art review. Renew. Sustain. Energy Rev. 2022, 167, 112723. [Google Scholar] [CrossRef]

- Hameed, Z.; Hong, Y.; Cho, Y.; Ahn, S.; Song, C. Condition monitoring and fault detection of wind turbines and related algorithms: A review. Renew. Sustain. Energy Rev. 2009, 13, 1–39. [Google Scholar] [CrossRef]

- Reder, M.D.; Gonzalez, E.; Melero, J.J. Wind turbine failures—Tackling current problems in failure data analysis. J. Phys. Conf. Ser. 2016, 753, 072027. [Google Scholar] [CrossRef]

- Yang, W.; Court, R.; Jiang, J. Wind turbine condition monitoring by the approach of SCADA data analysis. Renew. Energy 2014, 53, 365–376. [Google Scholar] [CrossRef]

- Brøndsted, P.; Lilholt, H.; Lystrup, A. Composite materials for wind power turbine blades. Annu. Rev. Mater. Res. 2005, 35, 505–538. [Google Scholar] [CrossRef]

- Cooperman, A.; Eberle, A.; Lantz, E. Wind turbine blade material in the United States: Quantities, costs, and end-of-life options. Resour. Conserv. Recycl. 2021, 168, 105439. [Google Scholar] [CrossRef]

- Mishnaevsky Jr, L.; Branner, K.; Petersen, H.N.; Beauson, J.; McGugan, M.; Sørensen, B.F. Materials for wind turbine blades: An overview. Materials 2017, 10, 1285. [Google Scholar] [CrossRef]

- Shokrieh, M.M.; Rafiee, R. Simulation of fatigue failure in a full composite wind turbine blade. Compos. Struct. 2006, 74, 332–342. [Google Scholar] [CrossRef]

- Tong, W. Wind Power Generation and Wind Turbine Design; WIT Press: Southampton, UK, 2010. [Google Scholar]

- Li, D.; Ho, S.-C.M.; Song, G.; Ren, L.; Li, H. A review of damage detection methods for wind turbine blades. Smart Mater. Struct. 2015, 24, 033001. [Google Scholar] [CrossRef]

- Lu, B.; Li, Y.; Wu, X.; Yang, Z. A review of recent advances in wind turbine condition monitoring and fault diagnosis. In Proceedings of the 2009 IEEE Power Electronics and Machines in Wind Applications, Lincoln, NE, USA, 24–26 June 2009; pp. 1–7. [Google Scholar]

- Du, Y.; Zhou, S.; Jing, X.; Peng, Y.; Wu, H.; Kwok, N. Damage detection techniques for wind turbine blades: A review. Mech. Syst. Signal Process. 2020, 141, 106445. [Google Scholar] [CrossRef]

- Overgaard, L.; Lund, E. Structural collapse of a wind turbine blade. Part B: Progressive interlaminar failure models. Compos. Part A Appl. Sci. Manuf. 2010, 41, 271–283. [Google Scholar] [CrossRef]

- Davis, N.N.; Byrkjedal, Ø.; Hahmann, A.N.; Clausen, N.E.; Žagar, M. Ice detection on wind turbines using the observed power curve. Wind Energy 2016, 19, 999–1010. [Google Scholar] [CrossRef]

- Jaunet, V.; Braud, C. Experiments on lift dynamics and feedback control of a wind turbine blade section. Renew. Energy 2018, 126, 65–78. [Google Scholar] [CrossRef]

- Jiménez, A.A.; Márquez, F.P.G.; Moraleda, V.B.; Muñoz, C.Q.G. Linear and nonlinear features and machine learning for wind turbine blade ice detection and diagnosis. Renew. Energy 2019, 132, 1034–1048. [Google Scholar] [CrossRef]

- Rahimi, H.; Schepers, J.G.; Shen, W.Z.; García, N.R.; Schneider, M.; Micallef, D.; Simao Ferreira, C.J.; Jost, E.; Klein, L.; Herráez, I. Evaluation of different methods for determining the angle of attack on wind turbine blades with CFD results under axial inflow conditions. Renew. Energy 2018, 125, 866–876. [Google Scholar] [CrossRef]

- Haselbach, P.U.; Bitsche, R.D.; Branner, K. The effect of delaminations on local buckling in wind turbine blades. Renew. Energy 2016, 85, 295–305. [Google Scholar] [CrossRef]

- Lee, J.-K.; Park, J.-Y.; Oh, K.-Y.; Ju, S.-H.; Lee, J.-S. Transformation algorithm of wind turbine blade moment signals for blade condition monitoring. Renew. Energy 2015, 79, 209–218. [Google Scholar] [CrossRef]

- Beganovic, N.; Söffker, D. Structural health management utilization for lifetime prognosis and advanced control strategy deployment of wind turbines: An overview and outlook concerning actual methods, tools, and obtained results. Renew. Sustain. Energy Rev. 2016, 64, 68–83. [Google Scholar] [CrossRef]

- Ji, Y.M.; Han, K. Fracture mechanics approach for failure of adhesive joints in wind turbine blades. Renew. Energy 2014, 65, 23–28. [Google Scholar] [CrossRef]

- Sørensen, B.F.; Joergensen, E.; Debel, C.P.; Jensen, H.M.; Jacobsen, T.K.; Halling, K.M. Improved Design of Large Wind Turbine Blade of Fibre Composites Based on Studies of Scale Effects (Phase 1). Summary Report. 2004. Available online: https://www.osti.gov/etdeweb/servlets/purl/20553530 (accessed on 3 May 2024).

- Kim, S.; Adams, D.E.; Sohn, H.; Rodriguez-Rivera, G.; Myrent, N.; Bond, R.; Vitek, J.; Carr, S.; Grama, A.; Meyer, J.J. Crack detection technique for operating wind turbine blades using Vibro-Acoustic Modulation. Struct. Health Monit. 2014, 13, 660–670. [Google Scholar] [CrossRef]

- Cao, Z.; Li, S.; Li, C.; Li, P.; Ko, T.J. Formation mechanism and detection and evaluation methods as well as repair technology of crack damage in fiber-reinforced composite wind turbine blade: A review. Int. J. Adv. Manuf. Technol. 2022, 120, 5649–5672. [Google Scholar] [CrossRef]

- Xiaoxun, Z.; Xinyu, H.; Xiaoxia, G.; Xing, Y.; Zixu, X.; Yu, W.; Huaxin, L. Research on crack detection method of wind turbine blade based on a deep learning method. Appl. Energy 2022, 328, 120241. [Google Scholar] [CrossRef]

- Han, W.; Kim, J.; Kim, B. Effects of contamination and erosion at the leading edge of blade tip airfoils on the annual energy production of wind turbines. Renew. Energy 2018, 115, 817–823. [Google Scholar] [CrossRef]

- Soltani, M.R.; Birjandi, A.H.; Moorani, M.S. Effect of surface contamination on the performance of a section of a wind turbine blade. Sci. Iran. 2011, 18, 349–357. [Google Scholar] [CrossRef]

- Gaudern, N. A practical study of the aerodynamic impact of wind turbine blade leading edge erosion. J. Phys. Conf. Ser. 2014, 524, 012031. [Google Scholar] [CrossRef]

- Keegan, M.H.; Nash, D.; Stack, M. On erosion issues associated with the leading edge of wind turbine blades. J. Phys. D Appl. Phys. 2013, 46, 383001. [Google Scholar] [CrossRef]

- Mishnaevsky, L., Jr.; Hasager, C.B.; Bak, C.; Tilg, A.-M.; Bech, J.I.; Rad, S.D.; Fæster, S. Leading edge erosion of wind turbine blades: Understanding, prevention and protection. Renew. Energy 2021, 169, 953–969. [Google Scholar] [CrossRef]

- Sareen, A.; Sapre, C.A.; Selig, M.S. Effects of leading edge erosion on wind turbine blade performance. Wind Energy 2014, 17, 1531–1542. [Google Scholar] [CrossRef]

- Amenabar, I.; Mendikute, A.; López-Arraiza, A.; Lizaranzu, M.; Aurrekoetxea, J. Comparison and analysis of non-destructive testing techniques suitable for delamination inspection in wind turbine blades. Compos. Part B Eng. 2011, 42, 1298–1305. [Google Scholar] [CrossRef]

- Gómez Muñoz, C.Q.; García Márquez, F.P.; Hernández Crespo, B.; Makaya, K. Structural health monitoring for delamination detection and location in wind turbine blades employing guided waves. Wind Energy 2019, 22, 698–711. [Google Scholar] [CrossRef]

- Garolera, A.C.; Madsen, S.F.; Nissim, M.; Myers, J.D.; Holboell, J. Lightning damage to wind turbine blades from wind farms in the US. IEEE Trans. Power Deliv. 2014, 31, 1043–1049. [Google Scholar] [CrossRef]

- Rachidi, F.; Rubinstein, M.; Montanya, J.; Bermudez, J.-L.; Sola, R.R.; Sola, G.; Korovkin, N. A review of current issues in lightning protection of new-generation wind-turbine blades. IEEE Trans. Ind. Electron. 2008, 55, 2489–2496. [Google Scholar] [CrossRef]

- Sun, S.; Wang, T.; Chu, F. In-situ condition monitoring of wind turbine blades: A critical and systematic review of techniques, challenges, and futures. Renew. Sustain. Energy Rev. 2022, 160, 112326. [Google Scholar] [CrossRef]

- Rempel, L. Rotor blade leading edge erosion-real life experiences. Wind Syst. Mag. 2012, 11, 22–24. [Google Scholar]

- Yang, C.; Liu, X.; Zhou, H.; Ke, Y.; See, J. Towards accurate image stitching for drone-based wind turbine blade inspection. Renew. Energy 2023, 203, 267–279. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, Y.; Lv, W.; Wang, D. Image recognition of wind turbine blade damage based on a deep learning model with transfer learning and an ensemble learning classifier. Renew. Energy 2021, 163, 386–397. [Google Scholar] [CrossRef]

- Ochieng, F.X.; Hancock, C.M.; Roberts, G.W.; Le Kernec, J. A review of ground-based radar as a noncontact sensor for structural health monitoring of in-field wind turbines blades. Wind Energy 2018, 21, 1435–1449. [Google Scholar] [CrossRef]

- Yan, Y.; Cheng, L.; Wu, Z.; Yam, L. Development in vibration-based structural damage detection technique. Mech. Syst. Signal Process. 2007, 21, 2198–2211. [Google Scholar] [CrossRef]

- Yang, W.; Tavner, P.J.; Crabtree, C.J.; Feng, Y.; Qiu, Y. Wind turbine condition monitoring: Technical and commercial challenges. Wind Energy 2014, 17, 673–693. [Google Scholar] [CrossRef]

- Qiao, W.; Lu, D. A survey on wind turbine condition monitoring and fault diagnosis—Part I: Components and subsystems. IEEE Trans. Ind. Electron. 2015, 62, 6536–6545. [Google Scholar] [CrossRef]

- Ren, Z.; Verma, A.S.; Li, Y.; Teuwen, J.J.E.; Jiang, Z. Offshore wind turbine operations and maintenance: A state-of-the-art review. Renew. Sustain. Energy Rev. 2021, 144, 110886. [Google Scholar] [CrossRef]

- Carnero, A.; Martín, C.; Díaz, M. Portable motorized telescope system for wind turbine blades damage detection. Eng. Rep. 2023, e12618. [Google Scholar] [CrossRef]

- Ozbek, M.; Rixen, D.J.; Erne, O.; Sanow, G. Feasibility of monitoring large wind turbines using photogrammetry. Energy 2010, 35, 4802–4811. [Google Scholar] [CrossRef]

- Zhou, H.; Dou, H.; Qin, L.; Chen, Y.; Ni, Y.; Ko, J. A review of full-scale structural testing of wind turbine blades. Renew. Sustain. Energy Rev. 2014, 33, 177–187. [Google Scholar] [CrossRef]

- Naderhirn, M.; Langthaler, P. Method and System for Inspecting a Surface Area for Material Defects. U.S. Patent 10,656,096, 19 May 2020. [Google Scholar]

- Yang, J.; Peng, C.; Xiao, J.; Zeng, J.; Yuan, Y. Application of videometric technique to deformation measurement for large-scale composite wind turbine blade. Appl. Energy 2012, 98, 292–300. [Google Scholar] [CrossRef]

- Feng, D.; Feng, M.Q. Computer vision for SHM of civil infrastructure: From dynamic response measurement to damage detection–A review. Eng. Struct. 2018, 156, 105–117. [Google Scholar] [CrossRef]

- Shihavuddin, A.; Chen, X.; Fedorov, V.; Nymark Christensen, A.; Andre Brogaard Riis, N.; Branner, K.; Bjorholm Dahl, A.; Reinhold Paulsen, R. Wind Turbine Surface Damage Detection by Deep Learning Aided Drone Inspection Analysis. Energies 2019, 12, 676. [Google Scholar] [CrossRef]

- Guo, J.; Liu, C.; Cao, J.; Jiang, D. Damage identification of wind turbine blades with deep convolutional neural networks. Renew. Energy 2021, 174, 122–133. [Google Scholar] [CrossRef]

- Liu, L.; Li, P.; Wang, D.; Zhu, S. A wind turbine damage detection algorithm designed based on YOLOv8. Appl. Soft Comput. 2024, 154, 111364. [Google Scholar] [CrossRef]

- Du, Y.; Wu, H.; Cava, D.G. A motion-blurred restoration method for surface damage detection of wind turbine blades. Measurement 2023, 217, 113031. [Google Scholar] [CrossRef]

- Peng, Y.; Wang, W.; Tang, Z.; Cao, G.; Zhou, S. Non-uniform illumination image enhancement for surface damage detection of wind turbine blades. Mech. Syst. Signal Process. 2022, 170, 108797. [Google Scholar] [CrossRef]

- Yang, B.; Sun, D. Testing, inspecting and monitoring technologies for wind turbine blades: A survey. Renew. Sustain. Energy Rev. 2013, 22, 515–526. [Google Scholar] [CrossRef]

- Katnam, K.; Comer, A.; Roy, D.; Da Silva, L.; Young, T. Composite repair in wind turbine blades: An overview. J. Adhes. 2015, 91, 113–139. [Google Scholar] [CrossRef]

- Tchakoua, P.; Wamkeue, R.; Ouhrouche, M.; Slaoui-Hasnaoui, F.; Tameghe, T.A.; Ekemb, G. Wind turbine condition monitoring: State-of-the-art review, new trends, and future challenges. Energies 2014, 7, 2595–2630. [Google Scholar] [CrossRef]

- Schubel, P.; Crossley, R.; Boateng, E.; Hutchinson, J. Review of structural health and cure monitoring techniques for large wind turbine blades. Renew. Energy 2013, 51, 113–123. [Google Scholar] [CrossRef]

- Ye, X.; Su, Y.; Han, J. Structural health monitoring of civil infrastructure using optical fiber sensing technology: A comprehensive review. Sci. World J. 2014, 2014, 652329. [Google Scholar] [CrossRef] [PubMed]

- Ramakrishnan, M.; Rajan, G.; Semenova, Y.; Farrell, G. Overview of fiber optic sensor technologies for strain/temperature sensing applications in composite materials. Sensors 2016, 16, 99. [Google Scholar] [CrossRef] [PubMed]

- Alian, H.; Konforty, S.; Ben-Simon, U.; Klein, R.; Tur, M.; Bortman, J. Bearing fault detection and fault size estimation using fiber-optic sensors. Mech. Syst. Signal Process. 2019, 120, 392–407. [Google Scholar] [CrossRef]

- Ozbek, M.; Rixen, D.J. Operational modal analysis of a 2.5 MW wind turbine using optical measurement techniques and strain gauges. Wind Energy 2013, 16, 367–381. [Google Scholar] [CrossRef]

- Li, Y.; Wang, X.; Liu, Z.; Liang, X.; Si, S. The entropy algorithm and its variants in the fault diagnosis of rotating machinery: A review. IEEE Access 2018, 6, 66723–66741. [Google Scholar] [CrossRef]

- Qiao, W.; Lu, D. A survey on wind turbine condition monitoring and fault diagnosis—Part II: Signals and signal processing methods. IEEE Trans. Ind. Electron. 2015, 62, 6546–6557. [Google Scholar] [CrossRef]

- Yan, R.; Gao, R.X.; Chen, X. Wavelets for fault diagnosis of rotary machines: A review with applications. Signal Process. 2014, 96, 1–15. [Google Scholar] [CrossRef]

- Popescu, T.D.; Aiordachioaie, D. Fault detection of rolling element bearings using optimal segmentation of vibrating signals. Mech. Syst. Signal Process. 2019, 116, 370–391. [Google Scholar] [CrossRef]

- Amezquita-Sanchez, J.P.; Adeli, H. Signal processing techniques for vibration-based health monitoring of smart structures. Arch. Comput. Methods Eng. 2016, 23, 1–15. [Google Scholar] [CrossRef]

- Wang, H.; Jing, X. Vibration signal–based fault diagnosis in complex structures: A beam-like structure approach. Struct. Health Monit. 2018, 17, 472–493. [Google Scholar] [CrossRef]

- Gómez Muñoz, C.Q.; Arcos Jiménez, A.; García Márquez, F.P.; Kogia, M.; Cheng, L.; Mohimi, A.; Papaelias, M. Cracks and welds detection approach in solar receiver tubes employing electromagnetic acoustic transducers. Struct. Health Monit. 2018, 17, 1046–1055. [Google Scholar] [CrossRef]

- Habibi, H.; Cheng, L.; Zheng, H.; Kappatos, V.; Selcuk, C.; Gan, T.-H. A dual de-icing system for wind turbine blades combining high-power ultrasonic guided waves and low-frequency forced vibrations. Renew. Energy 2015, 83, 859–870. [Google Scholar] [CrossRef]

- Yin, C.; Zhang, Z.; Wang, Z.; Guo, H. Numerical simulation and experimental validation of ultrasonic de-icing system for wind turbine blade. Appl. Acoust. 2016, 114, 19–26. [Google Scholar] [CrossRef]

- Park, B.; An, Y.-K.; Sohn, H. Visualization of hidden delamination and debonding in composites through noncontact laser ultrasonic scanning. Compos. Sci. Technol. 2014, 100, 10–18. [Google Scholar] [CrossRef]

- Sohn, H.; Dutta, D.; Yang, J.; DeSimio, M.; Olson, S.; Swenson, E. Automated detection of delamination and disbond from wavefield images obtained using a scanning laser vibrometer. Smart Mater. Struct. 2011, 20, 045017. [Google Scholar] [CrossRef]

- Nair, A.; Cai, C. Acoustic emission monitoring of bridges: Review and case studies. Eng. Struct. 2010, 32, 1704–1714. [Google Scholar] [CrossRef]

- Glowacz, A. Fault diagnosis of single-phase induction motor based on acoustic signals. Mech. Syst. Signal Process. 2019, 117, 65–80. [Google Scholar] [CrossRef]

- Li, X.; Yang, Z.; Chen, X. Quantitative damage detection and sparse sensor array optimization of carbon fiber reinforced resin composite laminates for wind turbine blade structural health monitoring. Sensors 2014, 14, 7312–7331. [Google Scholar] [CrossRef]

- Márquez, F.P.G.; Tobias, A.M.; Pérez, J.M.P.; Papaelias, M. Condition monitoring of wind turbines: Techniques and methods. Renew. Energy 2012, 46, 169–178. [Google Scholar] [CrossRef]

- Fontanes, P.; Montanya, J.; Arcanjo, M.; Urbani, M.; Asensio, C.; Guerra-Garcia, C. On the induced currents to wind turbines by the Earth’s atmospheric electric potential: Experiments with drones. IEEE Access 2022, 10, 21277–21290. [Google Scholar] [CrossRef]

- Fontanes, P.; Montanyà, J.; Arcanjo, M.; Guerra-Garcia, C.; Tobella, G. Experimental investigation of the electrification of wind turbine blades in fair-weather and artificial charge-compensation to mitigate the effects. J. Electrost. 2022, 115, 103669. [Google Scholar] [CrossRef]

- Peng, L.; Liu, J. Detection and analysis of large-scale WT blade surface cracks based on UAV-taken images. IET Image Process. 2018, 12, 2059–2064. [Google Scholar] [CrossRef]

- Sarkar, D.; Gunturi, S.K. Wind turbine blade structural state evaluation by hybrid object detector relying on deep learning models. J. Ambient Intell. Humaniz. Comput. 2020, 12, 8535–8548. [Google Scholar] [CrossRef]

- Peng, Y.; Tang, Z.; Zhao, G.; Cao, G.; Wu, C. Motion Blur Removal for Uav-Based Wind Turbine Blade Images Using Synthetic Datasets. Remote Sens. 2021, 14, 87. [Google Scholar] [CrossRef]

- Stokkeland, M.; Klausen, K.; Johansen, T.A. Autonomous visual navigation of Unmanned Aerial Vehicle for wind turbine inspection. In Proceedings of the 2015 International Conference on Unmanned Aircraft Systems (ICUAS), Denver, CO, USA, 9–12 June 2015. [Google Scholar]

- Wang, L.; Yang, J.; Huang, C.; Luo, X. An Improved U-Net Model for Segmenting Wind Turbines from UAV-Taken Images. IEEE Sens. Lett. 2022, 6, 1–4. [Google Scholar] [CrossRef]

- Gohar, I.; Halimi, A.; See, J.; Yew, W.K.; Yang, C. Slice-Aided Defect Detection in Ultra High-Resolution Wind Turbine Blade Images. Machines 2023, 11, 953. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, Z. Automatic Detection of Wind Turbine Blade Surface Cracks Based on UAV-Taken Images. IEEE Trans. Ind. Electron. 2017, 64, 7293–7303. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, Z.; Luo, X. A Two-Stage Data-Driven Approach for Image-Based Wind Turbine Blade Crack Inspections. IEEE/ASME Trans. Mechatron. 2019, 24, 1271–1281. [Google Scholar] [CrossRef]

- Deng, L.; Guo, Y.; Chai, B. Defect Detection on a Wind Turbine Blade Based on Digital Image Processing. Processes 2021, 9, 1452. [Google Scholar] [CrossRef]

- Gao, L.; Hu, H. Wind turbine icing characteristics and icing-induced power losses to utility-scale wind turbines. Proc. Natl. Acad. Sci. USA 2021, 118, e2111461118. [Google Scholar] [CrossRef]

- Fakorede, O.; Feger, Z.; Ibrahim, H.; Ilinca, A.; Perron, J.; Masson, C. Ice protection systems for wind turbines in cold climate: Characteristics, comparisons and analysis. Renew. Sustain. Energy Rev. 2016, 65, 662–675. [Google Scholar] [CrossRef]

- Madi, E.; Pope, K.; Huang, W.; Iqbal, T. A review of integrating ice detection and mitigation for wind turbine blades. Renew. Sustain. Energy Rev. 2019, 103, 269–281. [Google Scholar] [CrossRef]

- Parent, O.; Ilinca, A. Anti-icing and de-icing techniques for wind turbines: Critical review. Cold Reg. Sci. Technol. 2011, 65, 88–96. [Google Scholar] [CrossRef]

- Wei, K.; Yang, Y.; Zuo, H.; Zhong, D. A review on ice detection technology and ice elimination technology for wind turbine. Wind Energy 2020, 23, 433–457. [Google Scholar] [CrossRef]

- Icing on Drones and Wind Turbines. 2019. Available online: https://folk.ntnu.no/richahan/Publications/2019_WindTech_postprint.pdf (accessed on 3 May 2024).

- Gao, L.; Tao, T.; Liu, Y.; Hu, H. A field study of ice accretion and its effects on the power production of utility-scale wind turbines. Renew. Energy 2021, 167, 917–928. [Google Scholar] [CrossRef]

- Gidinceanu, C. De-Icing and Maintenance of Wind Turbines with Drones. Master’s Thesis, Aalborg University, Aalborg, Denmark, 2019. [Google Scholar]

- Khadka, A.; Afshar, A.; Zadeh, M.; Baqersad, J. Strain monitoring of wind turbines using a semi-autonomous drone. Wind Eng. 2021, 46, 296–307. [Google Scholar] [CrossRef]

- Khadka, A.; Fick, B.; Afshar, A.; Tavakoli, M.; Baqersad, J. Non-contact vibration monitoring of rotating wind turbines using a semi-autonomous UAV. Mech. Syst. Signal Process. 2020, 138, 106446. [Google Scholar] [CrossRef]

- Li, W.; Zhao, W.; Gu, J.; Fan, B.; Du, Y. Dynamic Characteristics Monitoring of Large Wind Turbine Blades Based on Target-Free DSST Vision Algorithm and UAV. Remote Sens. 2022, 14, 3113. [Google Scholar] [CrossRef]

- Zhang, R.; Wen, C. SOD-YOLO: A Small Target Defect Detection Algorithm for Wind Turbine Blades Based on Improved YOLOv5. Adv. Theory Simul. 2022, 5, 2100631. [Google Scholar] [CrossRef]

- Ran, X.; Zhang, S.; Wang, H.; Zhang, Z. An Improved Algorithm for Wind Turbine Blade Defect Detection. IEEE Access 2022, 10, 122171–122181. [Google Scholar] [CrossRef]

- Xu, Y.; Luo, X.; Yuan, M.; Huang, B.; Malof, J.M. Soft-masks guided faster region-based convolutional neural network for domain adaptation in wind turbine detection. Front. Energy Res. 2023, 10, 1083005. [Google Scholar] [CrossRef]

- Nikolov, I.; Madsen, C. Wind Turbine Blade SfM Image Capturing Setups. 2020. Available online: https://data.mendeley.com/datasets/fptxw8cynv/1 (accessed on 3 May 2024).

- Nikolov, I.; Nielsen, M.; Garnæs, J.; Madsen, C. Wind Turbine Blade Surfaces. 2020. Available online: https://data.mendeley.com/datasets/jrmm82m4mv/1 (accessed on 3 May 2024).

- Shihavuddin, A.S.M.; Mohammad Rifat Ahmmad, R.; Xiao, C.; Md Hasan, M.; Mohammad Asif, U.L.H.; Muhammad Abul, H.; Ahmed Al, M. Replication Data for Remote Damage Detection of Power Plants Using Deep Learning Based Drone Image Analysis. 2020. Available online: https://dataverse.harvard.edu/dataset.xhtml?persistentId=doi:10.7910/DVN/GFYPQW (accessed on 3 May 2024).

- Shihavuddin, A.; Rashid, M.R.A.; Maruf, M.H.; Hasan, M.A.; ul Haq, M.A.; Ashique, R.H.; Al Mansur, A. Image based surface damage detection of renewable energy installations using a unified deep learning approach. Energy Rep. 2021, 7, 4566–4576. [Google Scholar] [CrossRef]

- Wang, Y.; Yoshihashi, R.; Kawakami, R.; You, S.; Harano, T.; Ito, M.; Komagome, K.; Iida, M.; Naemura, T. Unsupervised anomaly detection with compact deep features for wind turbine blade images taken by a drone. IPSJ Trans. Comput. Vis. Appl. 2019, 11, 3. [Google Scholar] [CrossRef]

- Diaz, P.M.; Tittus, P. Fast detection of wind turbine blade damage using Cascade Mask R-DSCNN-aided drone inspection analysis. Signal Image Video Process. 2023, 17, 2333–2341. [Google Scholar] [CrossRef]

- Zhang, C.; Yang, T.; Yang, J. Image Recognition of Wind Turbine Blade Defects Using Attention-Based MobileNetv1-YOLOv4 and Transfer Learning. Sensors 2022, 22, 6009. [Google Scholar] [CrossRef]

- Reddy, A.; Indragandhi, V.; Ravi, L.; Subramaniyaswamy, V. Detection of Cracks and damage in wind turbine blades using artificial intelligence-based image analytics. Measurement 2019, 147, 106823. [Google Scholar] [CrossRef]

- Xu, D.; Wen, C.; Liu, J. Wind turbine blade surface inspection based on deep learning and UAV-taken images. J. Renew. Sustain. Energy 2019, 11, 053305. [Google Scholar] [CrossRef]

- Zhao, X.-Y.; Dong, C.-Y.; Zhou, P.; Zhu, M.-J.; Ren, J.-W.; Chen, X.-Y. Detecting Surface Defects of Wind Tubine Blades Using an Alexnet Deep Learning Algorithm. IEICE Trans. Fundam. Electron. Commun. Comput. Sci. 2019, E102.A, 1817–1824. [Google Scholar] [CrossRef]

- Masita, K.; Hasan, A.; Shongwe, T. Defects Detection on 110 MW AC Wind Farm’s Turbine Generator Blades Using Drone-Based Laser and RGB Images with Res-CNN3 Detector. Appl. Sci. 2023, 13, 13046. [Google Scholar] [CrossRef]

- Galleguillos, C.; Zorrilla, A.; Jimenez, A.; Diaz, L.; Montiano, Á.L.; Barroso, M.; Viguria, A.; Lasagni, F. Thermographic non-destructive inspection of wind turbine blades using unmanned aerial systems. Plast. Rubber Compos. 2015, 44, 98–103. [Google Scholar] [CrossRef]

- Chen, X.; Sheiati, S.; Shihavuddin, A.S.M. AQUADA PLUS: Automated damage inspection of cyclic-loaded large-scale composite structures using thermal imagery and computer vision. Compos. Struct. 2023, 318, 117085. [Google Scholar] [CrossRef]

- Yu, J.; He, Y.; Zhang, F.; Sun, G.; Hou, Y.; Liu, H.; Wang, H. An Infrared Image Stitching Method for Wind Turbine Blade Using UAV Flight Data and U-Net. IEEE Sens. J. 2023, 23, 8727–8736. [Google Scholar] [CrossRef]

- Jiang, Z.; Jovan, F.; Moradi, P.; Richardson, T.; Bernardini, S.; Watson, S.; Weightman, A.; Hine, D. A multirobot system for autonomous deployment and recovery of a blade crawler for operations and maintenance of offshore wind turbine blades. J. Field Robot. 2022, 40, 73–93. [Google Scholar] [CrossRef]

- Sun, X.; Wu, W.; Wang, J.; Xu, L.; Jiang, R.; Sun, Y.; Fang, L. Optimization design of negative pressure adsorption car for internal defect detection of wind turbine blades on UAV. AIP Adv. 2023, 13, 025133. [Google Scholar] [CrossRef]

- García Márquez, F.P.; Bernalte Sánchez, P.J.; Segovia Ramírez, I. Acoustic inspection system with unmanned aerial vehicles for wind turbines structure health monitoring. Struct. Health Monit. 2021, 21, 485–500. [Google Scholar] [CrossRef]

- Gu, W.; Hu, D.; Cheng, L.; Cao, Y.; Rizzo, A.; Valavanis, K.P. Autonomous Wind Turbine Inspection using a Quadrotor. In Proceedings of the 2020 International Conference on Unmanned Aircraft Systems (ICUAS), Athens, Greece, 1–4 September 2020. [Google Scholar]

- Kanellakis, C.; Fresk, E.; Sharif Mansouri, S.; Kominiak, D.; Nikolakopoulos, G. Autonomous visual inspection of large-scale infrastructures using aerial robots. arXiv 2019, arXiv:1901.05510. [Google Scholar]

- Stokkeland, M. A Computer Vision Approach for Autonomous Wind Turbine Inspection Using a Multicopter; Institutt for Teknisk Kybernetikk: Trondheim, Norway, 2014. [Google Scholar]

- Parlange, R.; Martinez-Carranza, J.; Sucar, L.; Ren, B.; Watkins, S. Vision-based autonomous navigation for wind turbine inspection using an unmanned aerial vehicle. In Proceedings of the 10th International Micro-Air Vehicles Conference, Melbourne, Australia, 22–23 November 2018. [Google Scholar]

- Guo, H.; Cui, Q.; Wang, J.; Fang, X.; Yang, W.; Li, Z. Detecting and Positioning of Wind Turbine Blade Tips for UAV-Based Automatic Inspection. In Proceedings of the IGARSS 2019—2019 IEEE International Geoscience and Remote Sensing Symposium, Yokohama, Japan, 28 July–2 August 2019. [Google Scholar]

- Parlange, R.; Martinez-Carranza, J. Leveraging single-shot detection and random sample consensus for wind turbine blade inspection. Intell. Serv. Robot. 2021, 14, 611–628. [Google Scholar] [CrossRef]

- Ma, Y.; Wang, S.; Yu, D.; Zhu, K. Robust visual-inertial odometry with point and line features for blade inspection UAV. Ind. Robot: Int. J. Robot. Res. Appl. 2021, 48, 179–188. [Google Scholar] [CrossRef]

- Zhang, D.; Watson, R.; Dobie, G.; MacLeod, C.; Khan, A.; Pierce, G. Quantifying impacts on remote photogrammetric inspection using unmanned aerial vehicles. Eng. Struct. 2020, 209, 109940. [Google Scholar] [CrossRef]

- Durdevic, P.; Ortiz-Arroyo, D. A Deep Neural Network Sensor for Visual Servoing in 3D Spaces. Sensors 2020, 20, 1437. [Google Scholar] [CrossRef] [PubMed]

- Car, M.; Markovic, L.; Ivanovic, A.; Orsag, M.; Bogdan, S. Autonomous Wind-Turbine Blade Inspection Using LiDAR-Equipped Unmanned Aerial Vehicle. IEEE Access 2020, 8, 131380–131387. [Google Scholar] [CrossRef]

- Høglund, S. Autonomous Inspection of Wind Turbines and Buildings Using an UAV; Institutt for Teknisk Kybernetikk: Trondheim, Norway, 2014. [Google Scholar]

- Schafer, B.E.; Picchi, D.; Engelhardt, T.; Abel, D. Multicopter unmanned aerial vehicle for automated inspection of wind turbines. In Proceedings of the 2016 24th Mediterranean Conference on Control and Automation (MED), Athens, Greece, 21–24 June 2016. [Google Scholar]

- Chung, H.-M.; Maharjan, S.; Zhang, Y.; Eliassen, F.; Strunz, K. Placement and Routing Optimization for Automated Inspection with Unmanned Aerial Vehicles: A Study in Offshore Wind Farm. IEEE Trans. Ind. Inform. 2021, 17, 3032–3043. [Google Scholar] [CrossRef]

- Cao, P.; Liu, Y.; Yang, C.; Xie, S.; Xie, K. MEC-Driven UAV-Enabled Routine Inspection Scheme in Wind Farm under Wind Influence. IEEE Access 2019, 7, 179252–179265. [Google Scholar] [CrossRef]

- Ivić, S.; Crnković, B.; Grbčić, L.; Matleković, L. Multi-UAV trajectory planning for 3D visual inspection of complex structures. Autom. Constr. 2023, 147, 104709. [Google Scholar] [CrossRef]

- Baik, H.; Valenzuela, J. An optimization drone routing model for inspecting wind farms. Soft Comput. 2020, 25, 2483–2498. [Google Scholar] [CrossRef]

- Huang, X.; Wang, G.; Lu, Y.; Jia, Z. Study on a Boat-Assisted Drone Inspection Scheme for the Modern Large-Scale Offshore Wind Farm. IEEE Syst. J. 2023, 17, 4509–4520. [Google Scholar] [CrossRef]

- Nordin, M.; Sharma, S.; Khan, A.; Gianni, M.; Rajendran, S.; Sutton, R. Collaborative Unmanned Vehicles for Inspection, Maintenance, and Repairs of Offshore Wind Turbines. Drones 2022, 6, 137. [Google Scholar] [CrossRef]

- Banaszak, Z.; Radzki, G.; Nielsen, I.; Frederiksen, R.; Bocewicz, G. Proactive Mission Planning of Unmanned Aerial Vehicle Fleets Used in Offshore Wind Farm Maintenance. Appl. Sci. 2023, 13, 8449. [Google Scholar] [CrossRef]

| Damage Type | Details of Typical Damage Types | Internal/Outer |

|---|---|---|

| Debonding 1 | Skin/adhesive or main spar/adhesive layer debonding | Outer |

| Debonding 2 | Adhesive joint failure between skins | Outer |

| Debonding 3 | Sandwich panel face/core debonding | Outer |

| Debonding 6 | Skin/adhesive debonding induced by buckling | Outer |

| Debonding | Coating debonding, such as gelcoat off | Outer |

| Crack | Crack in split crack 5, gelcoat 7, early crack | Outer |

| Contamination | Dirt, oil dirt, insect contamination | Outer |

| Erosion/corrosion | Edge erosion, leading edge erosion/rust, pitting | Outer |

| Delamination | Delamination driven by a tensional or a buckling load 4 | Internal/outer |

| Splitting | Fiber failure in tension, laminate failure in compression 5 | Internal/outer |

| Technology | Sensors | Indicators | Arrangement | Precision |

|---|---|---|---|---|

| Vision | Binoculars, eyes, professional tools | / | On ground/hanging basket/climber on wind turbine | / |

| Camera | Image feature | On ground | ≈1 mm | |

| UAV | / | |||

| Thermography | Thermal/infrared camera | Temperature Thermal energy Thermal responses | On ground | 3–5 mm |

| UAV | / | |||

| Strain measurement | Strain gauges, FBGs | Strain Peak strain Strain rate Deflection | On wind turbine | ≈1 cm |

| Camera | UAV | / | ||

| Vibration | Displacement sensors/velocity sensors/accelerometers | Frequency–response Amplitude Mode shape Strain energy Spectral kurtosis | On wind turbine | <1 mm |

| Radar | On ground | <1 mm | ||

| Camera | UAV | / | ||

| Ultrasound | Piezoceramic material sensors | Frequency Amplitude Time-of-flight Reflection energy | On wind turbine | ≈1 cm |

| Robots | UAV | / | ||

| Acoustic emission | AE sensors/macro-fiber composite sensors/piezoceramic material sensors | Acoustic emission signals Waveform characteristics Acoustic energy RMS | On wind turbine | <1 cm |

| Embedded acoustic emission sensors | UAV | / |

| Technology | Advantages | Limitations | Damage Types | Principle |

|---|---|---|---|---|

| Vision | Low cost; independence from system complexity; visuality | Heavy computation; poor explanation; susceptible to environment | Surface damage: crack, debonding, erosion, etc. | Based on real or similar human vision |

| Thermography | Full field measurement; visuality; fast detection | Unable to detect early damages; susceptible to environment | Fatigue, delamination, etc. | Focus on thermodynamic property variations |

| Strain measurement | Continuous monitoring; external-incentive-free; wide sampling rates | Accuracy subjected to selected area; one sensor for one point; low fatigue resistance | Minute changes in length or deformation | Strain gauges: resistance change detection according to grid variation |

| Vibration | High sensitivity; easy deployment | Unable to detect early damages; susceptible to environmental disturbances | Frequency response, modal parameters, etc. | Focus on vibration representing dynamic properties |

| Ultrasound | Available for location, size, and depth of inner damage | Complicated data processing; time-consuming | Inner structural damage: Delamination, debonding, etc. | Wave reflection detection according to differences in the material and its damage |

| Acoustic emission | Continuous monitoring; high sampling frequencies; high sensitivity | High cost; high sensor deployment requirement; complicated data processing | Damage initiation, crack propagation, plastic deformation | Transient elastic wave detection through rapid release of energy from local sources |

| Methodology | Type | Effectiveness | Cost | Roughness Increase | External Energy | Stage |

|---|---|---|---|---|---|---|

| Black paint | Anti-icing | Limited | Low | Low | None | Prototype |

| Coating | Anti-icing | Limited | Low | Medium | None | Prototype |

| Microwave/infrared/ultrasonic | De-icing | Effective | Medium | Almost none | Low | Experimental |

| Pneumatic/expulsive | De-icing | Effective | High | High | Low | Operational (aeronautics) |

| Chemicals | Both | Momentaneous and degrading | Low | Medium | Low | Experimental |

| Hot air | Both | Effective | High | None | High | Operational |

| Inside resistive heaters | Both | Effective | Medium–high | None | Low–medium | Experimental |

| Dataset | Purpose | Images | Environment | Source | Description |

|---|---|---|---|---|---|

| Blade-SfM [117] | Blade reconstruction | 531 | 1 | Outdoor laboratory shooting | Different distance 2/4/6 m; horizontal image overlap; vertical image angle change |

| Blade-Surface [118] | Blade reconstruction, damage detection, and roughness quantization | 299 | 2 | Indoor and outdoor laboratory shooting | Contain ground truth microscopy data Small blade segment with sand blasted |

| DTU [64] | Damage detection | 701 | 1 | UAV field measurement | The same wind turbine inspection images of two years |

| RDF [119] | Damage detection | 431 | 1 | UAV field measurement | Some of images being collected from DTU |

| Blade30 [51] | Blade reconstruction, defect detection, segmentation, classification, and deduplication | 1302 | 6 | UAV field measurement | Contain more regions, more weather, more environments, and more utility |

| Model | Pre-Training Dataset | Training Samples | Testing Samples | Detective Types | Accuracy (%) | Supplement |

|---|---|---|---|---|---|---|

| VGG16+PCA [121] | ImageNet | 73,918 | 21,085 | Damage or not | 55.5F1 | Manually remove background; unsupervised anomaly detection through One-Class Support Vector Machine; model compression through Principal Component Analysis |

| AlexNet-tl-rf [52] | ImageNet | 900 | 450 | Damage or not | 98.49AA | Otsu threshold segmentation; random-forest-based ensemble learning classifier |

| Cascade Mask R-DSCNN [122] | COCO | 650 | 51 | Broken, crack, erosion, lighting damage, corrosion 1, VGMT | 82.42MAP | Regular augmentations: flip, zoom, shearing; depth-wise separable convolution-based Resnet 50 and feature pyramid network |

| MobileNetv1-YOLOv4 [123] | PASCAL VOC | 976 | 586 (390 validation samples) | Contamination, corrosion 2, crack, spalling | 88.61MAP | 15 kinds of augmentation operations; attention-based feature optimization using SENet: 92.94MAP, ECANet: 91.90MAP, and CBAM: 90.29MAP |

| Model | Training Samples | Validation Samples | Testing Samples | Detective Types | Accuracy (%) | Supplement |

|---|---|---|---|---|---|---|

| CNN [124] | 1150 | 248 | 247 | Damage or not, | 94.94A | Augmentation through Keras neural network library containing flip, zoom, and shearing |

| 9505 | 3471 | / | crack, erosion, lightning damage, mechanical damage, tip open | 90.6A | ||

| Deep CNN [65] | 5400 | / | 600 | coating defect, crack, debonding 1, erosion, fiber defect | 97A 97F1 | Extended Haar-like feature extract; region proposals through Adaboost cascade classifier |

| VGG-11+ADMM [125] | 20,422 | / | 5351 | Contamination 2, debonding 2,3, erosion | 92.8F1 | Model compression through alternating direction method of multipliers |

| AlexNet [126] | 10,000 | / | 6 × 350 | Crack, sand holes | 99.001AA | Test using 6-turn 350 images |

| Res-CNN3 [127] | 1552 | / | 681 | Crack, delamination, erosion, fatigue damage | 80.6MAP | Res-Net; temporal channel complexity simplification; region proposals through selective search |

| Faster R-CNN [64] | 726 | / | 433 | Erosion, DLR, VGMT | 81.10MAP | Augmentation through multi-scale pyramid, patching scheme, and regular; architecture: Inception-ResNet-v2 |

| YOLOv3 [95] | 600 | / | 146 | Crack, erosion, DLR, VGMT | 96MAP | Deblurring through super-resolution CNN |

| AFB-YOLOv5 [115] | 2396 | / | 599 | Damage, contamination 1 | 82.7F1 83.7MAP | Segmentation through random cropping; weighted bidirectional feature pyramid network; coordinate attention module; EIoU replace CIoU |

| SOD-YOLOv5 [114] | 15,920 | 4549 | 2274 | Contamination 2, corrosion, debonding 2,3 | 95.1MAP | Segmentation through Grab Cut and Hough transform; add a micro-scale detection layer; convolutional block attention module; computation reduction through channel pruning algorithm |

| MI-YOLOv5 [38] | 819 | 102 | 102 | Early crack | 93.2MAP | Augmentation through slice transposition and reconstruction; architecture: Mobilenetv3, Ghostnet and Alpha-IOU; C3TR replace C3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Shu, Z. Unmanned Aerial Vehicle (UAV)-Assisted Damage Detection of Wind Turbine Blades: A Review. Energies 2024, 17, 3731. https://doi.org/10.3390/en17153731

Zhang Z, Shu Z. Unmanned Aerial Vehicle (UAV)-Assisted Damage Detection of Wind Turbine Blades: A Review. Energies. 2024; 17(15):3731. https://doi.org/10.3390/en17153731

Chicago/Turabian StyleZhang, Zengyi, and Zhenru Shu. 2024. "Unmanned Aerial Vehicle (UAV)-Assisted Damage Detection of Wind Turbine Blades: A Review" Energies 17, no. 15: 3731. https://doi.org/10.3390/en17153731

APA StyleZhang, Z., & Shu, Z. (2024). Unmanned Aerial Vehicle (UAV)-Assisted Damage Detection of Wind Turbine Blades: A Review. Energies, 17(15), 3731. https://doi.org/10.3390/en17153731