1. Introduction

Transformers have been widely used in modern power systems. Short-circuit impedance is an important parameter of a transformer, which is related to many factors of transformers, such as their capacity, copper loss, iron loss, coil material and structure. It is related to the stability of the power supply system, the quality of the power supply to the load, the safety and reliability of the transformer after parallel connection, and so on. We can calculate the maximum short-circuit current that the transformer can withstand according to the short-circuit impedance, which is an important indicator for assessing the transformer.

The short-circuit impedance of the transformer is determined by its magnetic flux leakage. Therefore, the effective calculation and control of short-circuit impedance by using magnetic flux leakage has become an important and widely discussed topic.

The calculation methods of short-circuit impedance are various, but each method has a small disadvantage. For example, the direct calculation method [

1] has a large error with the actual situation, and it is difficult to achieve wide universality. The magnetic field energy method [

2,

3,

4,

5] needs to be calculated many times in the finite element software when solving the short-circuit impedance of multiple single-to-single windings, so it increases the difficulty of solving. The field–circuit coupling method [

6,

7,

8,

9] needs to set different short-circuit conditions each time to solve the composite short-circuit impedance of a certain winding or some windings. The overall workload and working time are very long.

Reference [

10] used the direct formula method, the self-inductance and mutual inductance analysis method, and the finite element method based on ANSYS Maxwell to calculate the short-circuit impedance of the controllable reactor of the transformer. However, this method is a two-dimensional linear modeling method, and there is a large error in practical application. In reference [

11], a combined calculation method of the short-circuit impedance of a multi-winding transformer based on an equivalent single-turn inductance matrix is proposed. The error between the calculated value and the measured value is less than 5%. Reference [

12] proposed an automatic measurement technology of transformer winding short-circuit impedance based on a partial discharge ultrasonic signal, obtained the partial discharge ultrasonic signal of the transformer, and extracted the characteristics of the partial discharge ultrasonic signal of the transformer by wavelet. This method measures the short-circuit impedance error within 0.3%. Reference [

13] proposed a calculation method based on a simplified transformer finite element model. This method can quickly and accurately calculate the composite short-circuit impedance and the corresponding short-circuit circulating current of the multi-winding transformer. At present, there is a method to adjust the short-circuit impedance by changing the winding arrangement order. The literature [

14] uses the finite element method to calculate the leakage reactance of the three-phase three-column transformer, and changes the leakage reactance by adjusting the winding distribution. Reference [

15] proposed a method to adjust the short-circuit impedance of the interleaved transformer by changing the winding arrangement, and verified the accuracy of the calculation method through experimental and simulation data. However, when the transformer is manufactured, it is necessary to change the winding arrangement to adjust the short-circuit impedance. The operation is cumbersome and will destroy the structural integrity of the transformer. In the past few years, some scholars have proposed to install magnetic shunts in transformers, but their research focuses are different. The research direction mainly focuses on the influence of magnetic shunts on the electromagnetic forces of transformers [

16], the influence of magnetic shunts on eddy current loss and temperature rise [

17], and the use of magnetic shunts to reduce stray loss [

18]. The addition of magnetic shunts to increase short-circuit impedance to reduce the short-circuit current needs to be studied. It is more convenient to add magnetic shunts directly between windings, and one-by-one superposition can more accurately adjust short-circuit impedance. At present, the research on magnetic shunts is basically based on the single-phase small transformer, and there is a lack of energy efficiency research after adding magnetic shunts.

This paper is organized as follows:

Section 2 discusses the relationship between short-circuit impedance and magnetic shunts. In

Section 3, the simulation model of the transformer is established by the magnetic circuit coupling method. The accuracy of the model is verified by experiments.

Section 4 verifies the feasibility of the scheme through examples.

Section 5 studies the transformer efficiency. In

Section 6, the magnetic flux density, magnetic field strength, and relative permeability are analyzed by Altair FLUX. In

Section 7, magnetic shunts are placed in a three-phase transformer. The last part concludes the paper.

2. Principle of Magnetic Shunts

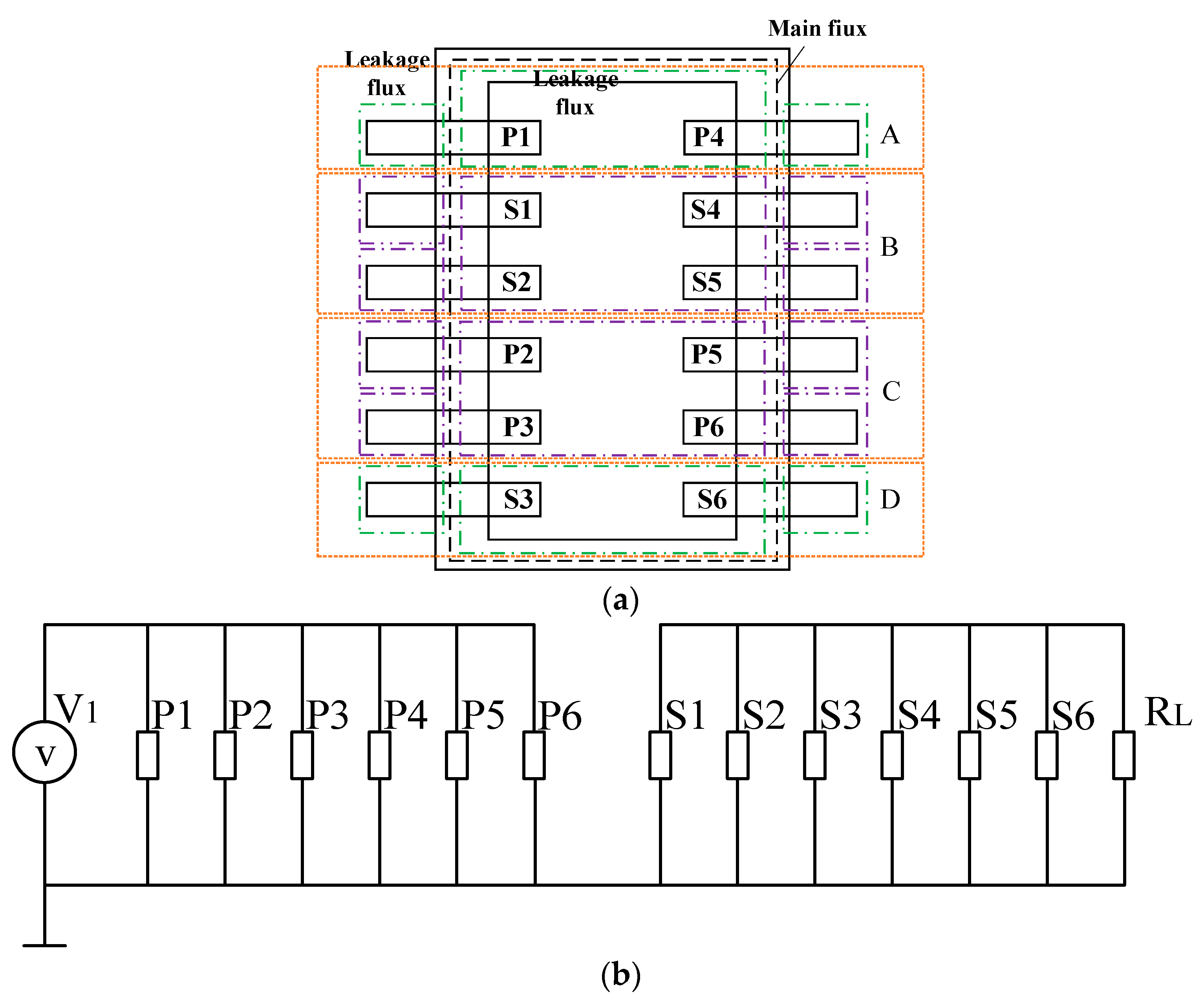

The transformer studied in this paper adopts an elliptical cylindrical winding, six windings on both sides, a symmetrical distribution, and adopts a low (P)–high (S)–high (S)–low (P)–low (P)–high (S) staggered distribution, as shown in

Figure 1a, there is sufficient insulation distance between windings. The transformer with this winding arrangement can change the leakage magnetic field and reduce the additional loss. A-D represents the four winding areas divided by the orange box. The green and purple boxes represent the simplified magnetic circuits of each area. The core adopts a UI structure, that is, there are two vertical air gaps on the transformer’s iron frame, and the core is made of a 0.35 mm silicon steel sheet. Six windings on the primary side are parallel with each other, and the voltage source is also parallel with the primary winding. Six windings on the secondary side are parallel with each other, and the load is parallel with the secondary winding. The wiring is shown in

Figure 1b.

P is the primary side winding and S is the secondary side winding. For the magnetic circuit between area A, B and B, C, the short-circuit impedance of the transformer can be adjusted by superimposing the number of magnetic shunts. The material of the magnetic shunt is the same as the magnetic core, and the B–H curve is shown in

Figure 2.

The short-circuit resistance corresponds to the equivalent resistance of the copper loss of the primary and secondary windings. Under normal circumstances, this part will not change; The short-circuit reactance reflects the equivalent parameters of the leakage flux of the primary and secondary windings. The purpose of increasing the magnetic shunt is to increase the leakage flux, so that the short-circuit impedance can be increased.

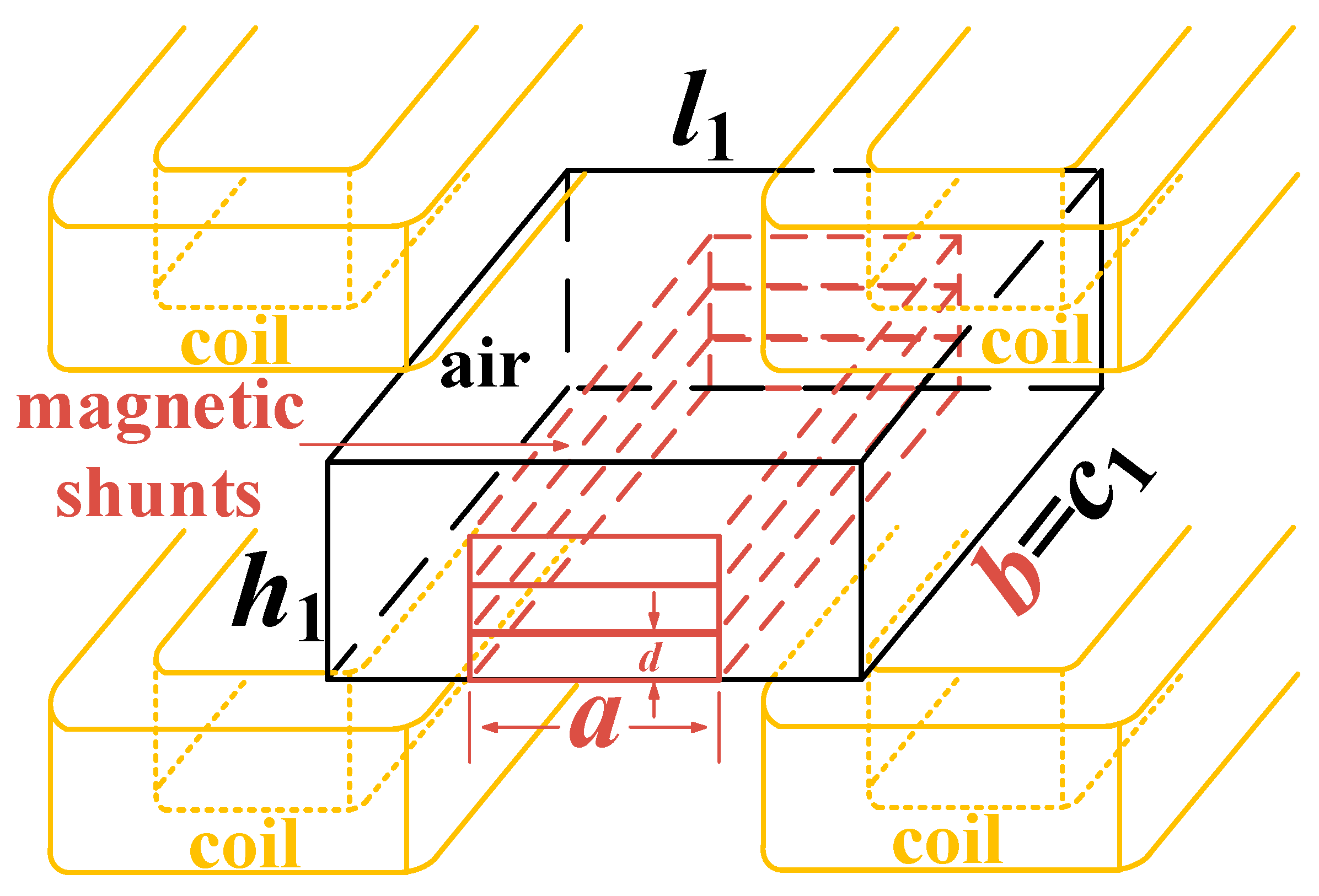

Figure 3a shows the appearance of the magnetic shunt. The thickness of a single magnetic shunt is d = 0.35 mm, the length is a = 60 mm, and the width is b = 120 mm. This section derives the case of adding a magnetic shunt at two positions, namely position 1 and position 2.

Since the permeability of the iron core is much larger than that of the air, that is,

μFe >>

μ0, the reluctance of the iron core can be ignored. It can be seen from

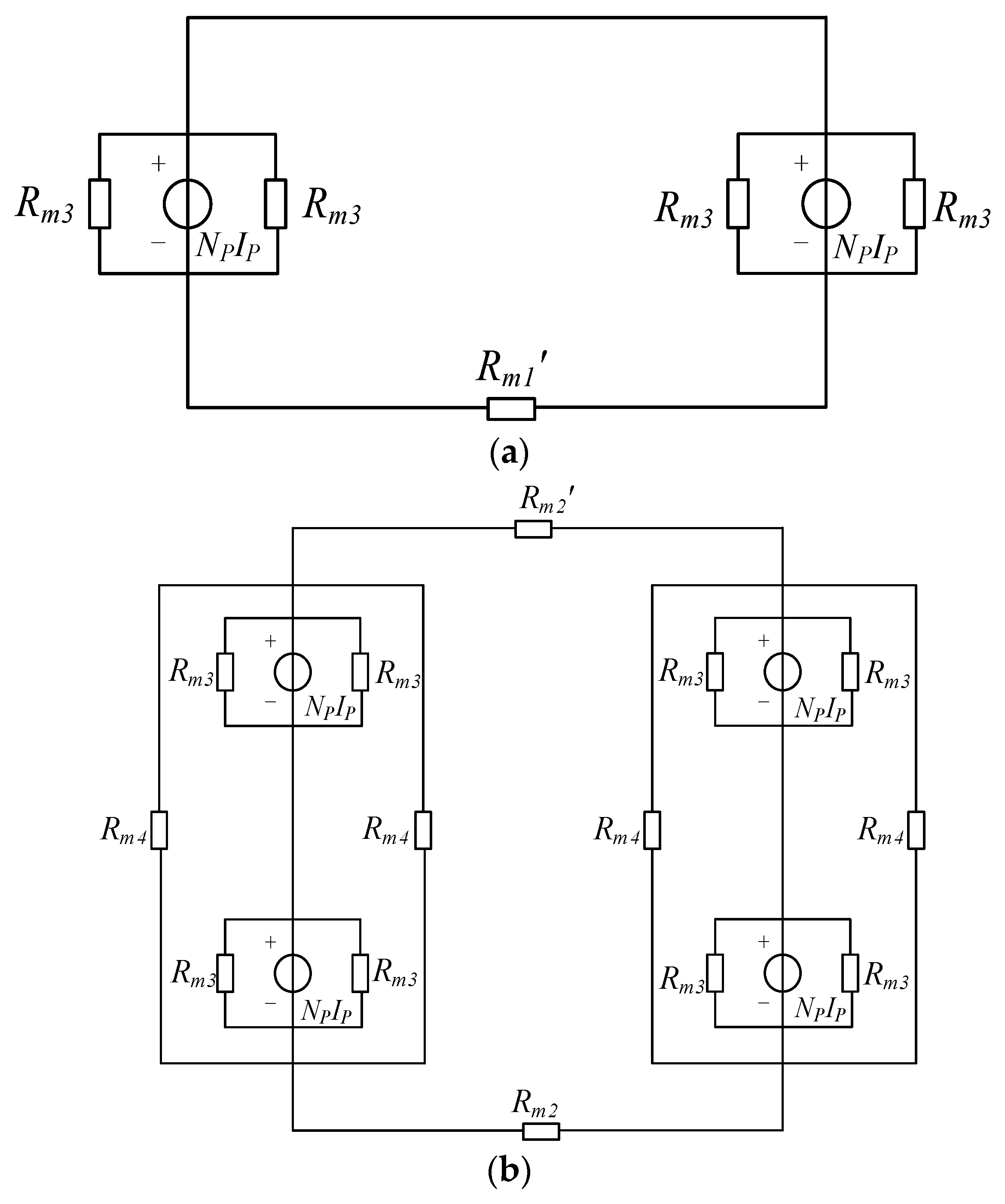

Figure 1a that the primary winding and the secondary winding structure of the transformer are the same. Therefore, when calculating the magnetic circuit parameters of the transformer, the secondary side parameters can be simplified to the primary side. By using the circuit analysis method, the primary side magnetic circuit without the magnetic shunt can be obtained, as shown in

Figure 4.

In the calculation, we ignore the skin effect and the proximity effect, and consider the core permeability as a constant. The magnetic air circuit is equivalent to multiple cuboids, and we assume that each coil on the primary side generates the same magnetic potential.

According to the calculation formula of reluctance,

where

l is the length of the magnetic circuit,

μ is the permeability, and

s is the effective cross-sectional area through which the magnetic flux passes.

According to Formula (1), the relevant reluctance expression in

Figure 4 can be calculated as follows:

where

l1 and

l3 are the length of the magnetic circuit in the A and C regions,

μ0 is the permeability,

c1 and

c3 are the width of the magnetic circuit,

h1 and

h3 are the height of the magnetic circuit.

If the magnetic shunt is not added, the total reluctance of the primary side is

The transformer short-circuit inductance can be expressed as

According to the definition of short-circuit impedance

Zk, it can be simplified as

where

K is the turn ratio of the primary winding to the secondary winding group, and

Rk is the short-circuit resistance of the transformer.

After adding magnetic shunts at position 1 and position 2, the reluctance of the A and C regions in

Figure 1a will change with the increase in the number of magnetic shunts.

δ is the number of magnetic shunts. The transformer primary side magnetic circuit diagram is shown in

Figure 5.

The schematic diagram of the magnetic air circuit size between the two windings inside the core is shown in

Figure 6. We think that the magnetic circuit width

c1 is equal to the magnetic shunt width

b. The purpose of this is to facilitate the calculation. The magnetic air circuit only needs to be divided into three blocks, otherwise more is needed.

When

magnetic shunts are added at position 1, the

R’

m1 of area A is:

Due to the fact that

μFe >>

μ0, the third term can be omitted in the calculation. For ease of comparison, write

Rm1 in (2) as

It is easy to obtain

R′

m1 <

Rm1. Similarly, when

magnetic shunts are added at position 2, we can obtain the expression of

R′

m2:

The total reluctance of the primary side is

When the magnetic shunt is not added, it becomes the case of (3). Or if one of the positions is added with a magnetic shunt and the other is not added, we can freely choose the combination of , and , .

After adding the magnetic shunt, the short-circuit inductance of the transformer is

According to the definition of short-circuit impedance,

It can be concluded that increasing the thickness of the magnetic shunt can effectively adjust the short-circuit impedance of the transformer without changing the number of winding turns.

3. Experimental Model and Validation

3.1. Experimental Model

In order to shorten the design cycle of the transformer and save the cost, the transformer model is established by Altair FLUX, and an experimental test platform composed of a single-phase transformer, an oscilloscope, a multimeter, an air switch and an adjustable voltage source is established to verify the accuracy of the transformer model. The experimental platform is shown in

Figure 7.

In the steady state, the voltage and current data of the transformer no-load test, short-circuit test, and rated operation are measured. The short-circuit test of the transformer with the load is carried out under the transient condition. The rated parameters and geometric parameters of the transformer are shown in

Table 1 and

Table 2. The transformer used in the experiment is shown in

Figure 8. The simulation model is shown in

Figure 9.

The actual structure of the transformer is more complex, but in the electromagnetic simulation calculation, if there is no special consideration, it can be simplified according to the actual situation. For example: (1) The core cannot be composed of actual silicon steel sheets, but can only be replaced by the core column to make the eddy current loss of the core deviate; (2) The coil is replaced by a cylindrical conductor, resulting in errors in the calculation of magnetic flux leakage; (3) The air gap is set at the magnetic core connection. According to the actual measurement data, the finite element simulation model is established, as shown in

Figure 8. In order to improve the simulation speed and save storage space, only half of the transformer needs to be modeled.

The input of the transformer is simplified as the voltage source V1, and P1~P6 and S1~S6 are the primary winding and the secondary winding of the transformer, respectively. They are connected parallelly, and

RL is the secondary side load, as shown in

Figure 1b. By setting the resistance of

RL, the simulation data under various working conditions can be obtained. For example, when

RL = 10

8 Ω, the transformer runs without a load; when

RL =

U2N/

I2N, the transformer operates under a rated load. When

RL = 10

−8 Ω, the secondary side of the transformer is short-circuited.

3.2. Model Verification

The verification of the transformer model includes two parts:

(A) Steady-state verification involves a no-load operation experiment, a short-circuit operation experiment, and a rated load operation experiment.

In the no-load operation experiment, the voltage range of the primary side power supply of the transformer is 0~1.5

U1N, and the secondary side is open. It can be seen from reference [

15] that the maximum error between the measured value and the simulated value does not exceed 3%.

In the short-circuit operation experiment, when the secondary side of the transformer is short-circuited, the primary side inputs the voltage source. According to the experiment, when the primary side inputs 14.6 V of voltage, the secondary side winding current reaches the rated current of 58.3 A. According to the simulation, when the primary side inputs 14.1 V of voltage, the secondary side winding current reaches the rated current of 58.3 A. The error between the simulated value and the measured value of the short-circuit voltage is 3.42%.

In the rated load experiment, the primary side input voltage

U1 is 104 V, and the secondary side is connected to a pure resistive load. The results are shown in

Table 3.

Under the rated working condition, the error between the simulated value and the measured value of voltage and current is within 4%.

(B) Transient verification involves a transient short-circuit experiment.

In the transient short-circuit experiment, the primary side inputs sine wave voltage:

where α is the initial phase angle of the input voltage when

t = 0.

Figure 10 is the transient short-circuit experimental circuit diagram.

According to the short-circuit time measured by the transient short-circuit experiment, the simulation is set to close the switch when the short-circuit is

t = 0.594 s at the same time. The measured value of the primary side current and the simulated value over time are shown in

Figure 11.

According to the simulation results, it can be found that when t = 0.615 s, the primary side current reaches the maximum value, and the error between the simulation value and the measured value is 3.4%.

In other words, by comparing the simulated value of the transformer with the measured value, it is concluded that the error of each working condition is less than 5% within the allowable range of the project. Therefore, the simulation model can be used for further research.

4. Illustrative Example

As shown in

Figure 12, magnetic shunts are added between the first set of P and S windings.

When the magnetic shunts are added, according to (2), (6)–(9), (16) and (17) can be obtained:

The parameter values of (16) and (17) are shown in

Table 4.

By changing the number of magnetic shunts, the secondary side is short-circuited. When the current passing through the secondary side is a rated current, the simulation value, calculated value, and experimental value of the short-circuit impedance in

Table 5 are compared. SV means the simulation value, CV means the calculated value, and EV means the measured value. The short-circuit impedance in the following Table is the actual value rather than the percentage.

As shown in

Figure 13, the short-circuit impedance change corresponding to the maximum short-circuit current is as follows:

(A) As the thickness of the magnetic shunt increases, it gradually increases, thereby reducing the maximum short-circuit current.

(B) As the thickness of the magnetic shunt increases, the short-circuit impedance curve tends to be gentle and the growth rate decreases. Therefore, considering the economic benefits, increasing the number of magnetic shunts at the same position is not a case of more being better.

The calculated value in the curve is close to the experimental value, and the simulation value has a relatively large error. The reason for this is that the actual situation is simplified during the simulation. For example, the magnetic core cannot be modeled by a piece of a silicon steel sheet, but by a complete magnetic core column; the coil is replaced by a cylindrical conductor, resulting in small errors in the calculation of the leakage of the magnetic field, and so on.

The short-circuit resistance corresponds to the equivalent resistance of the copper loss of the primary and secondary windings. In large transformers, the resistance component accounts for a small proportion of the short-circuit impedance. For 220 V transformers, the DC resistance is generally very small, between tens to hundreds of milliohms. The single-phase transformer used in this paper has 42 turns of primary winding. The resistance of each winding on the primary side is only 73.2 mΩ, the secondary winding is 97 turns, and the resistance of each winding on the secondary side is only 400 mΩ. But in the method of increasing the short-circuit impedance by the magnetic shunt proposed in this paper, when the number of magnetic shunts is increased to 5, the short-circuit impedance has increased by 27 mΩ, and as the number increases, the short-circuit impedance continues to increase.

In addition, we change the winding material from copper wire to aluminum wire, and the wire resistance increases. The resistance of each winding on the primary side becomes 118.3 mΩ, and the resistance of each winding on the secondary side becomes 646.8 mΩ. When the number of magnetic shunts increases to 10, the short-circuit impedance increases by 53.3 mΩ, and as the number increases, the short-circuit impedance continues to increase. The results are shown in

Table 6.

Therefore, it is a convenient and effective method to increase the short-circuit impedance by increasing number of magnetic shunts on some occasions.

5. Research on Efficiency of the Single-Phase Transformer

In this section, the efficiency of a single-phase transformer is simulated, and the efficiency of no magnetic shunt and adding 1, 2, 3, 7 and 10 magnetic shunts under a rated load is discussed. The input and output power are compared directly, as shown in the following

Table 7.

The secondary voltage and efficiency in

Table 7 are converted into

Figure 14. It can be seen that the change trend is consistent. As the number of magnetic shunts increases, the secondary voltage and efficiency decrease slightly. When 10 magnetic shunts are added, the voltage decreases by 0.866% and the efficiency decreases by 1.75%. However, combined with the short-circuit impedance simulation data in

Table 5, the short-circuit impedance increases by 22.378%. Therefore, we can conclude that the short-circuit impedance can be greatly increased by adding a magnetic shunt at the expense of a very small part of the output voltage and efficiency.

It is worth noting that the position of the added magnetic shunts discussed in this paper is not necessarily optimal. If the positions and shapes of the magnetic shunts are optimized, it is believed that the efficiency and the secondary side voltage drop will be smaller.

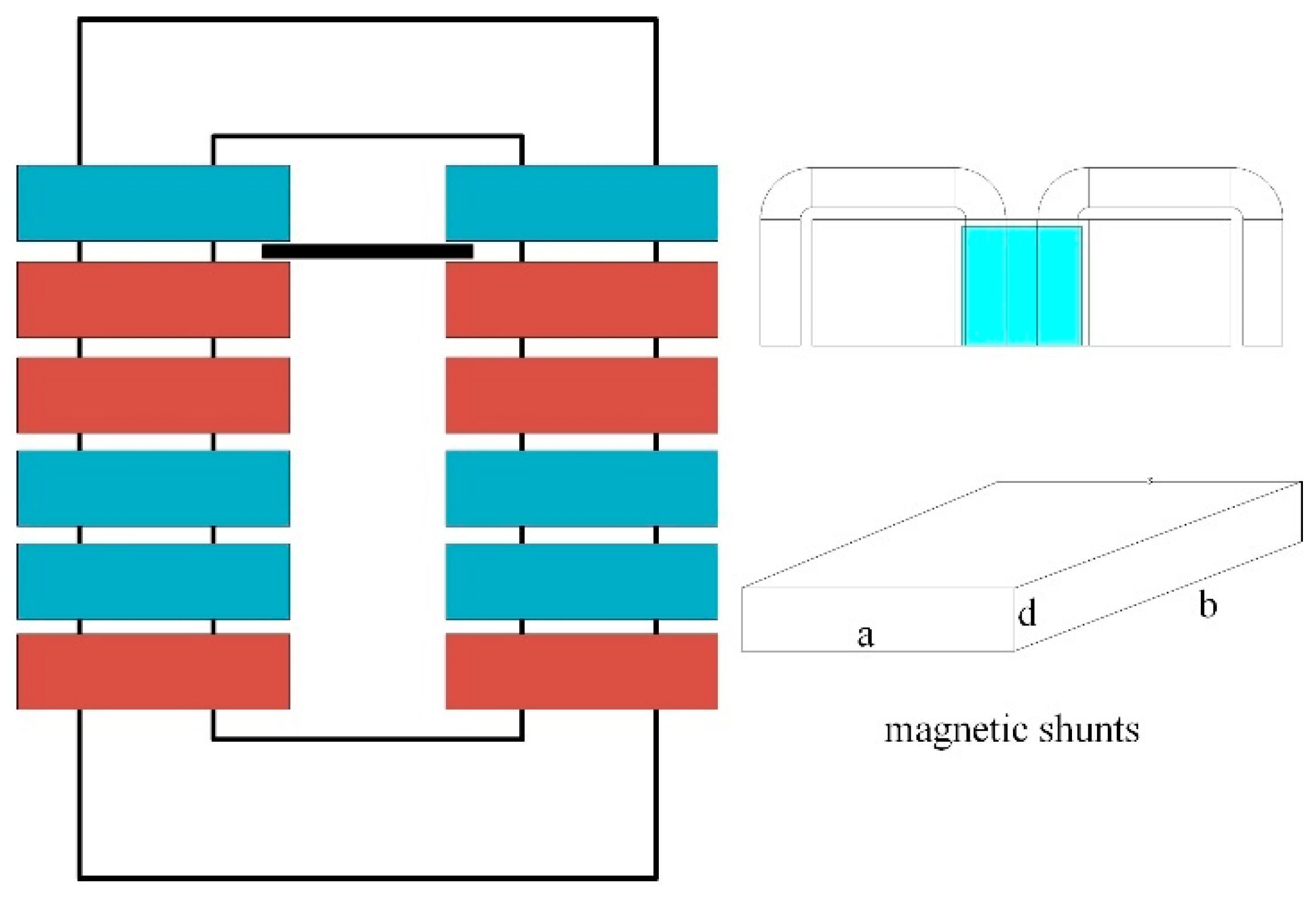

7. The Case of Adding Magnetic Shunts to Three-Phase Transformers

At present, the three-phase transformer is widely used, so this section introduces magnetic shunts into three-phase transformers. Firstly, the three-phase transformer model is established according to the technical parameters provided by the manufacturer, as shown in

Figure 18. The red box represents the three-phase input connector on the primary side. The three-phase transformer is verified with reference to the single-phase transformer model verification process. The error is less than 10%. Three-phase transformer wiring is shown in

Figure 19. The rated parameters are shown in

Table 8.

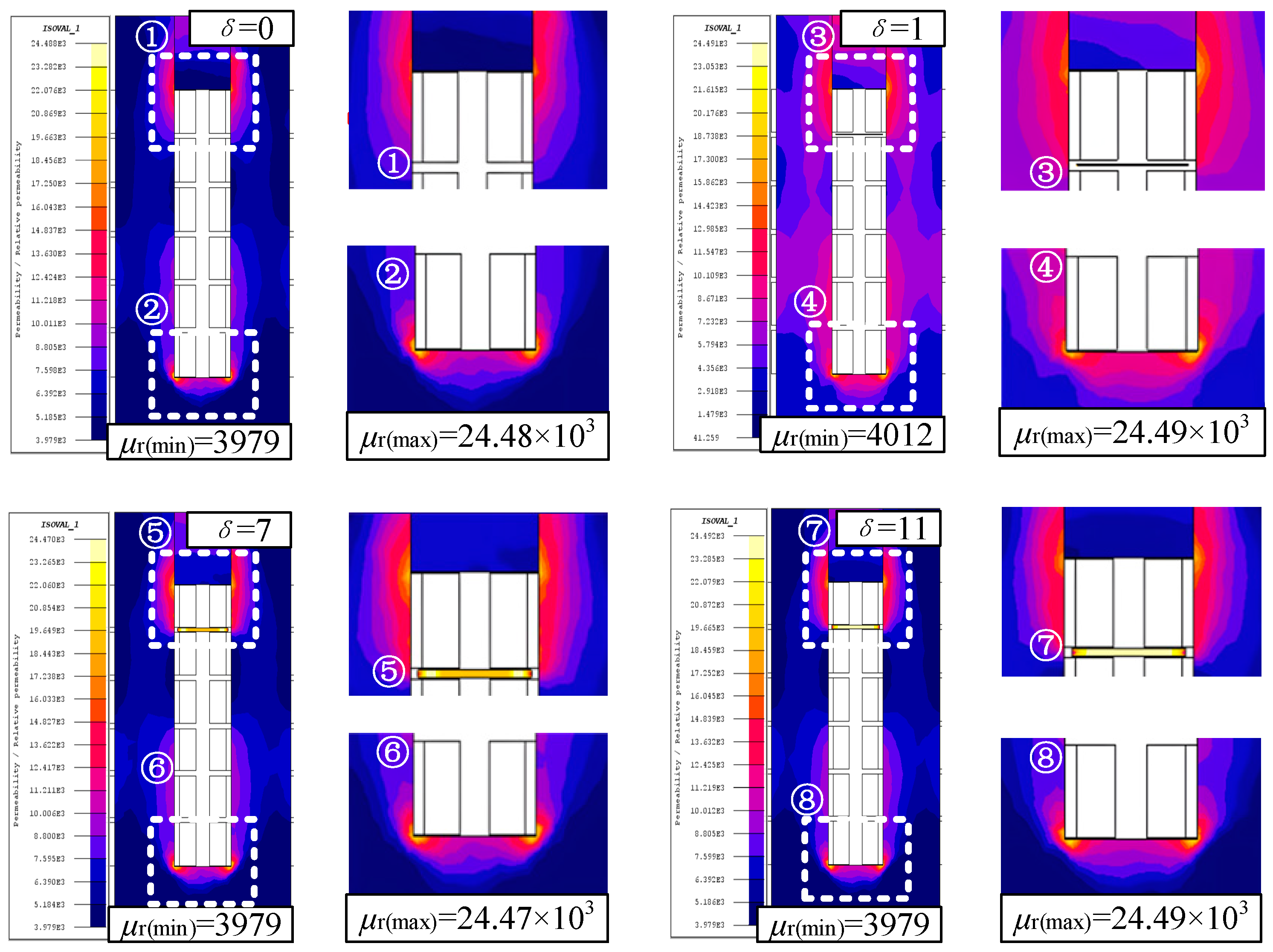

Firstly, the distribution of the magnetic field intensity vectors during normal operation is simulated. It is shown in

Figure 20a. It is found that the magnetic field intensity is the strongest at the position between the windings, so the number of magnetic separators can be saved to the greatest extent by placing them between the windings. Magnetic shunts are placed in position 1 and position 2 between the B and C phase windings shown in

Figure 20b, and the size of the magnetic shunts is adjusted appropriately.

The three-phase winding of the secondary side is short-circuited. The primary side is powered by three sinusoidal current sources with an effective value of 7.6 A, a frequency of 50 Hz, and a phase difference of 120°. The circuit diagram is shown in

Figure 21.

First, add one, two, four, five, and eight magnetic shunts at position 1, and then add eight magnetic shunts at position 2. The results are as follows.

It can be seen from

Table 9 that when eight magnetic shunts are added at position 1, the C-phase short-circuit impedance increases by 6%. However, when eight magnetic shunts are added at position 2, the C-phase short-circuit impedance increases by 21.7%. It can be concluded that in addition to the number of magnetic shunts, the position of the magnetic shunts also has an important influence on the short-circuit impedance.