A Review on Recent Advances in the Energy Efficiency of Machining Processes for Sustainability

Abstract

1. Introduction

2. Scope and Objectives of the Review

3. Understanding Energy Usage in Machining Processes and Modeling

4. Strategies for Energy-Efficient Machining

4.1. Energy-Efficient Design of Machine Tools

4.2. Optimization of the Machining Process

4.2.1. Optimization of Cutting Parameters

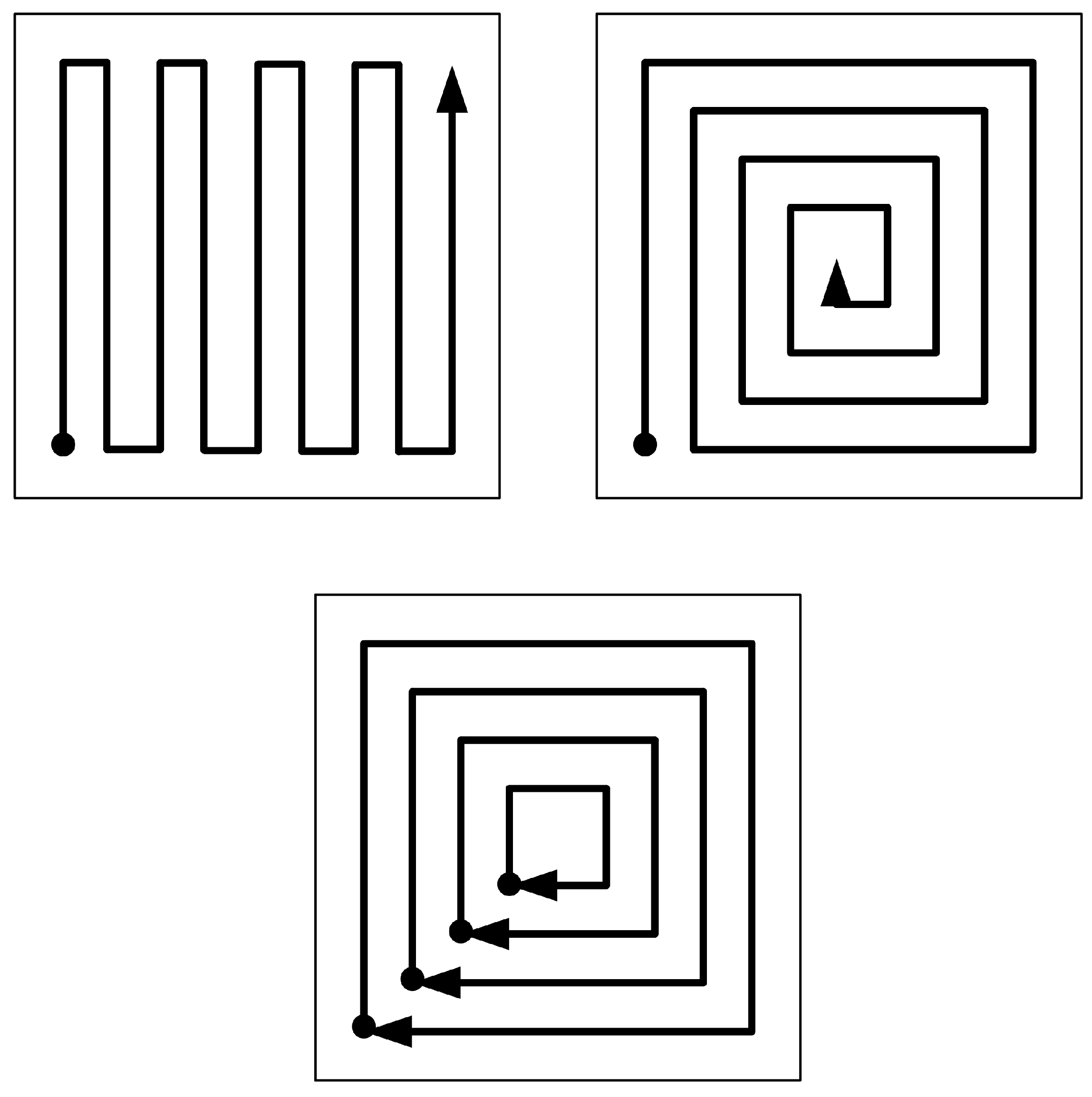

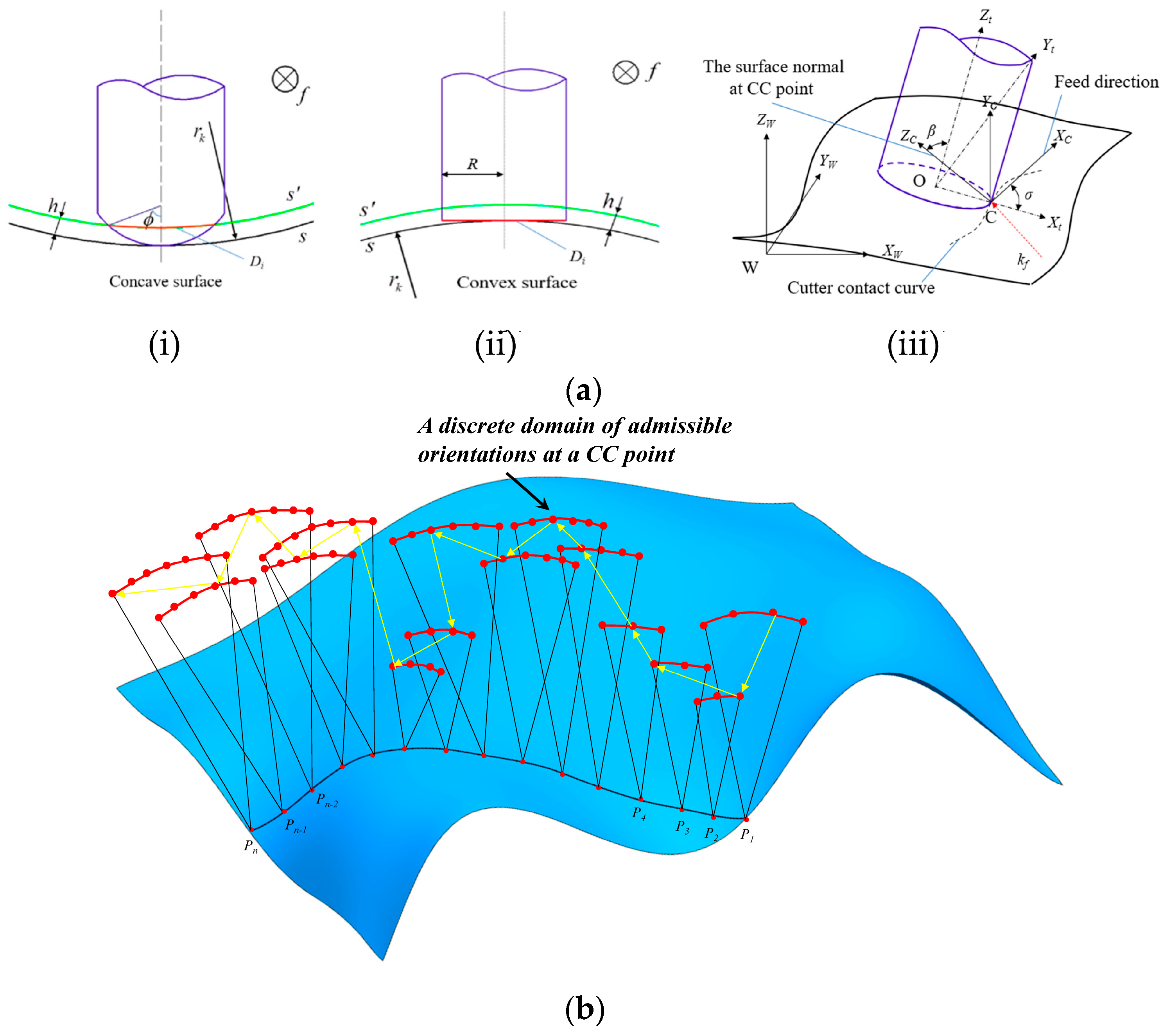

4.2.2. Toolpath Optimization

4.2.3. Optimization/Elimination of Non-Cutting Activities

4.3. Application of Artificial Intelligence

4.3.1. Modeling Machining Energy with AI

4.3.2. AI Optimization of Machining Energy Consumption

5. Conclusions and Future Work

- -

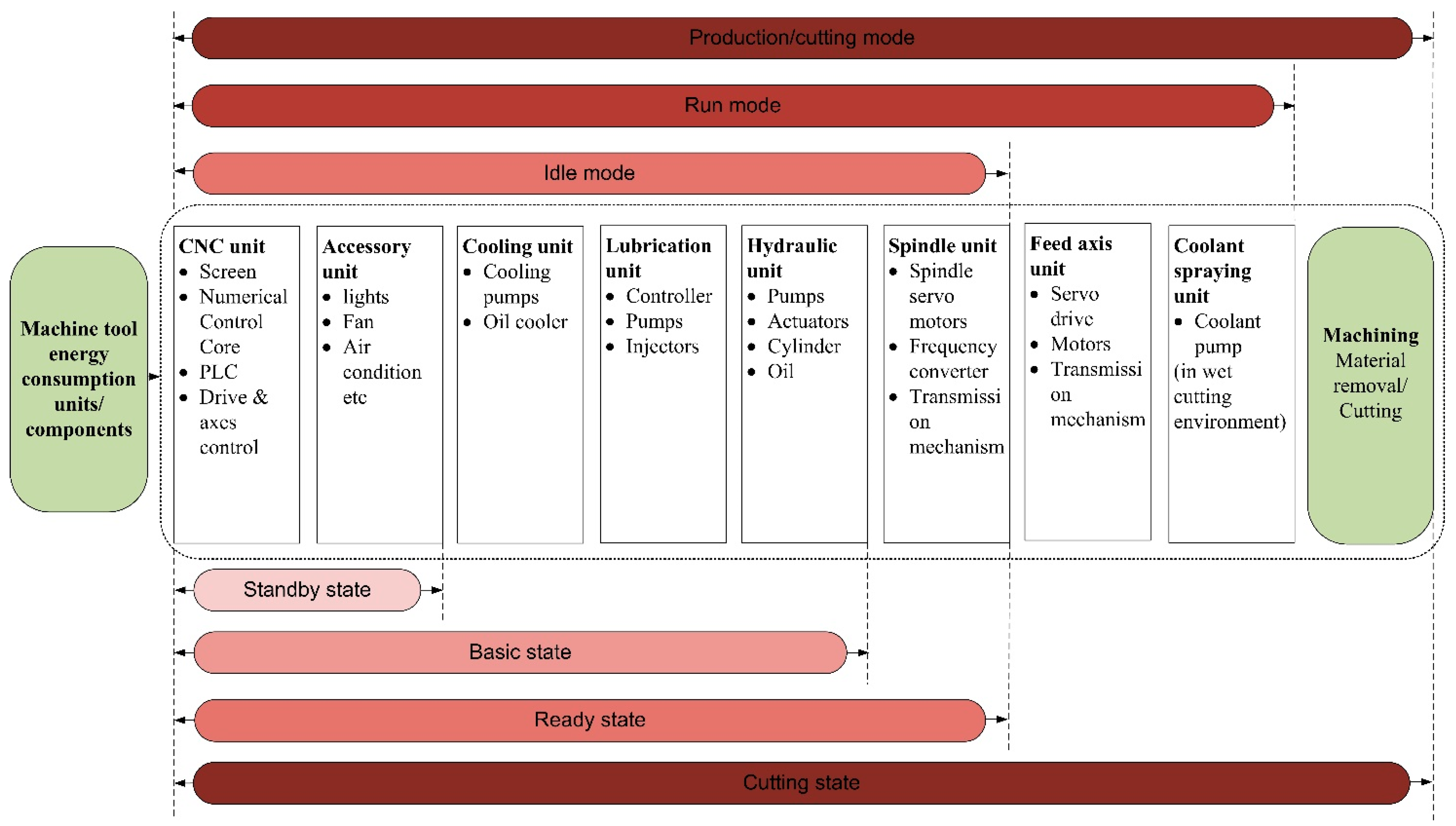

- Machine tools are one of the primary energy consumers in machining processes. Several key areas of significance include:

- ○

- The accurate modeling of machine tool energy consumption is crucial for the precise estimation of overall machining process energy consumption.

- ○

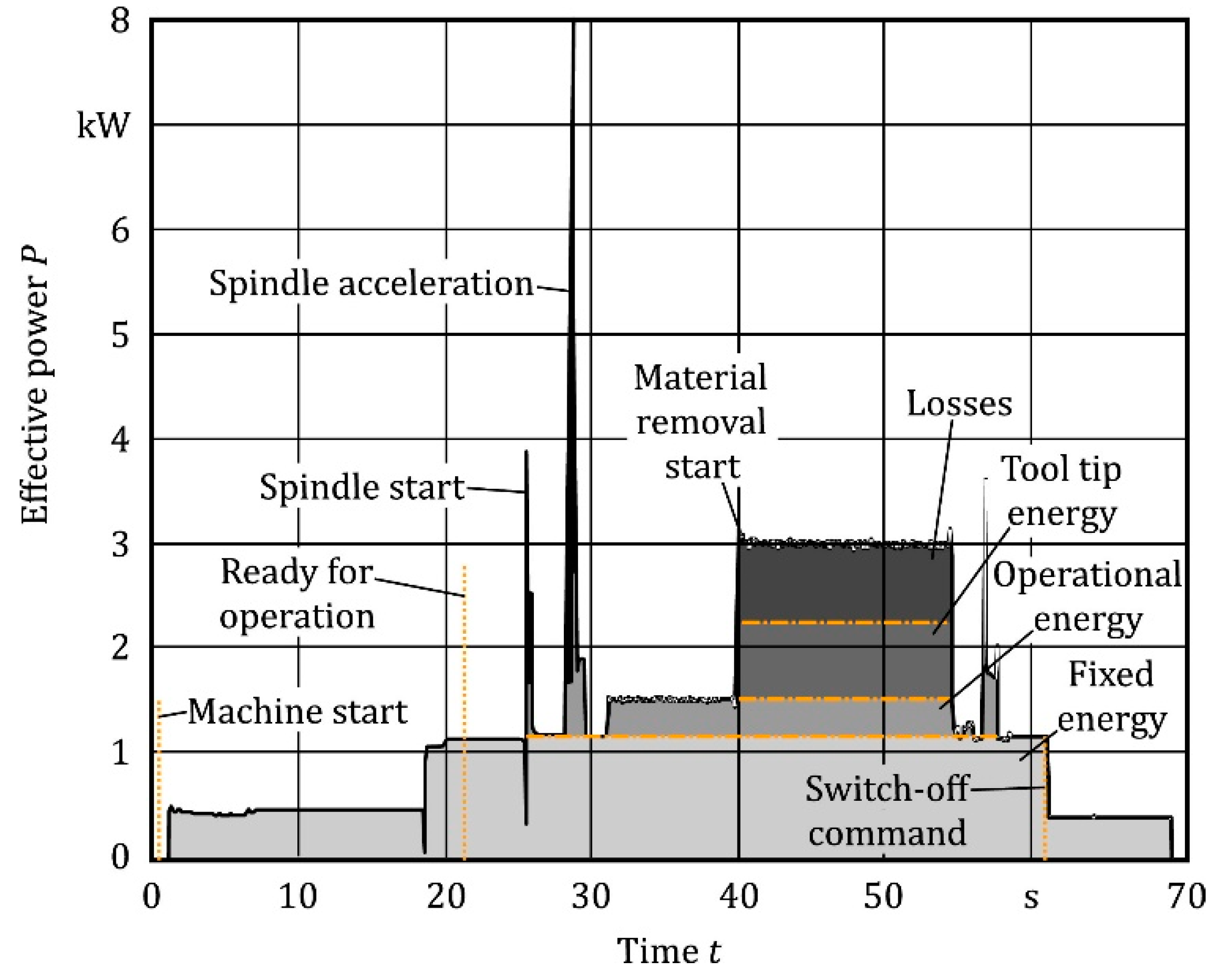

- Early studies focused primarily on energy consumption at the tool tip, providing a limited view. Contemporary models now consider factors such as startup, standby, spindle acceleration and idle state energy consumption, providing a comprehensive view of machining energy profiles.

- -

- There is still potential for improvement in machine tool energy consumption modeling, particularly in the following areas:

- ○

- Limited studies have incorporated transient state energy consumption into their models and require further investigation.

- ○

- Additional load losses, which can significantly impact energy estimation accuracy, have not been extensively studied.

- ○

- Generic energy consumption models are lacking, with most models tailored to specific machine tools and materials. Exploring and developing more generic models is necessary for the practical implementation of energy-efficient strategies.

- ○

- Energy efficiency indexing or rating systems similar to those used for other energy consumers are needed to standardize energy efficiency assessments in machining processes.

- ○

- Non-cutting activities in machining processes, such as air cut, tool path, tool change and spindle rotation speed adjustments, contribute significantly to the total energy consumption of machine tools. By optimizing these non-cutting activities, particularly through the sequencing of machining features and the adjustment of spindle rotation speeds, considerable energy savings can be achieved.

- -

- Energy-efficient design of machine tools

- ○

- Energy usage during the machining process is greatly influenced by the design of machine tools. Machine design itself can be optimized for efficiency.

- ○

- This includes incorporating high-efficiency motors (with higher-power factors) and employing lightweight designs, such as optimizing the structure of moving components like feed axes (e.g., using honeycomb structures) and utilizing lightweight materials such as Carbon Fiber Reinforced Polymer (CFRP).

- ○

- Lightweight designs of moving components of machine tools have great potential to minimize the non-cutting activities’ energy consumption.

- ○

- The spindle is another critical moving component in machine tools, and optimizing its design is crucial for conserving energy in machine tools.

- -

- Optimization of the machining process

- ○

- A practical approach to enhancing energy efficiency in existing machine tools and production lines, requiring minimal resources and relatively straightforward implementation. The optimization has three major areas/approaches:

- ▪

- Optimization of cutting parameters,

- ▪

- Optimization of the feature sequence,

- ▪

- Tool path optimization

- ▪

- Optimization of the non-cutting activities of the machine tool

- -

- Significant advancements have been seen in the application of machine learning approaches to model and optimize the energy consumption of machining processes. Machine learning techniques have shown their reliable predictive capabilities and their adeptness at handling the inherent complexities of machining processes, thereby enhancing both modeling accuracy and optimization efficiency.

- ○

- This real-time data acquisition is crucial for developing accurate energy models that reflect the actual operational conditions of machining tools. By utilizing high-frequency energy data, the researchers were able to predict the energy consumption of a part during its design phase using machine learning algorithms

- ○

- Hybrid models leverage the predictive power of ML to inform and guide the optimization process, resulting in more efficient and effective solutions.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- U.S. EIA. International Energy Outlook with Projections to 2050; U.S. EIA: Washington, DC, USA, 2021.

- Yoon, H.S.; Kim, E.S.; Kim, M.S.; Lee, J.Y.; Lee, G.B.; Ahn, S.H. Towards Greener Machine Tools—A Review on Energy Saving Strategies and Technologies. Renew. Sustain. Energy Rev. 2015, 48, 870–891. [Google Scholar] [CrossRef]

- Campatelli, G.; Scippa, A.; Lorenzini, L.; Sato, R. Optimal Workpiece Orientation to Reduce the Energy Consumption of a Milling Process. Int. J. Precis. Eng. Manuf.—Green Technol. 2015, 2, 5–13. [Google Scholar] [CrossRef]

- IPCC. Climate Change 2007: Synthesis Report. Contribution of Working Groups I, II and III to the Fourth Assessment Report of the Intergovernmental Panel on Climate Change; Core Writing Team, Pachauri, R.K., Reisinger, A., Eds.; IPCC: Geneva, Switzerland, 2007. [Google Scholar]

- IPCC. Climate Change 2001: Synthesis Report. A Contribution of Working Groups I, II, and III to the Third Assessment Report of the Integovernmental Panel on Climate Change; Watson, R.T., the Core Writing Team, Eds.; IPCC: Geneva, Switzerland, 2001. [Google Scholar]

- IPCC. Climate Change 2014: Synthesis Report. Contribution of Working Groups I, II and III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Core Writing Team, Pachauri, R.K., Meyer, L.A., Eds.; IPCC: Geneva, Switzerland, 2014. [Google Scholar]

- Pye, S.; Broad, O.; Bataille, C.; Brockway, P.; Daly, H.E.; Freeman, R.; Gambhir, A.; Geden, O.; Rogan, F.; Sanghvi, S.; et al. Modelling Net-Zero Emissions Energy Systems Requires a Change in Approach. Clim. Policy 2021, 21, 222–231. [Google Scholar] [CrossRef]

- U.S. EIA. International Energy Outlook 2023; U.S. EIA: Washington, DC, USA, 2023.

- EPA. 2016 Climate Change Indicators in the United States. Available online: https://www.epa.gov/sites/production/files/2016-08/documents/climate_indicators_2016.pdf (accessed on 6 June 2024).

- Xie, J.; Cai, W.; Du, Y.; Tang, Y.; Tuo, J. Modelling Approach for Energy Efficiency of Machining System Based on Torque Model and Angular Velocity. J. Clean. Prod. 2021, 293, 126249. [Google Scholar] [CrossRef]

- Sihag, N.; Sangwan, K.S. A Systematic Literature Review on Machine Tool Energy Consumption. J. Clean. Prod. 2020, 275, 123125. [Google Scholar] [CrossRef]

- Zhao, G.Y.; Liu, Z.Y.; He, Y.; Cao, H.J.; Guo, Y.B. Energy Consumption in Machining: Classification, Prediction, and Reduction Strategy. Energy 2017, 133, 142–157. [Google Scholar] [CrossRef]

- Zhang, Y. Review of Recent Advances on Energy Efficiency of Machine Tools for Sustainability. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2015, 229, 2095–2108. [Google Scholar] [CrossRef]

- Lu, F.; Zhou, G.; Zhang, C.; Liu, Y.; Chang, F.; Xiao, Z. Energy-Efficient Multi-Pass Cutting Parameters Optimisation for Aviation Parts in Flank Milling with Deep Reinforcement Learning. Robot. Comput. Integr. Manuf. 2023, 81, 102488. [Google Scholar] [CrossRef]

- Pawanr, S. Modelling the Energy Consumption and Associated Carbon Emissions of Machine Tools for Machining Cylindrical Parts. Ph.D. Thesis, Birla Institute of Technology and Science Pilani, Pilani, India, 2023. [Google Scholar]

- Wang, B.; Liu, Z.; Song, Q.; Wan, Y.; Shi, Z. Proper Selection of Cutting Parameters and Cutting Tool Angle to Lower the Specific Cutting Energy during High Speed Machining of 7050-T7451 Aluminum Alloy. J. Clean. Prod. 2016, 129, 292–304. [Google Scholar] [CrossRef]

- Denkena, B.; Abele, E.; Brecher, C.; Dittrich, M.-A.; Kara, S.; Mori, M. Energy Efficient Machine Tools. CIRP Ann. 2020, 69, 646–667. [Google Scholar] [CrossRef]

- Zhou, L.; Li, J.; Li, F.; Xu, X.; Wang, L.; Wang, G.; Kong, L. An Improved Cutting Power Model of Machine Tools in Milling Process. Int. J. Adv. Manuf. Technol. 2017, 91, 2383–2400. [Google Scholar] [CrossRef]

- Dahmus, J.B.; Gutowski, T.G. An Environmental Analysis of Machining. In Proceedings of the American Society of Mechanical Engineers, Manufacturing Engineering Division, MED, Anaheim, CA, USA, 13–19 November 2004; Volume 15, pp. 643–652. [Google Scholar]

- Kellens, K.; Dewulf, W.; Overcash, M.; Hauschild, M.Z.; Duflou, J.R. Methodology for Systematic Analysis and Improvement of Manufacturing Unit Process Life Cycle Inventory (UPLCI) CO2PE! Initiative (Cooperative Effort on Process Emissions in Manufacturing). Part 2: Case Studies. Int. J. Life Cycle Assess 2012, 17, 242–251. [Google Scholar] [CrossRef]

- Balogun, V.A.; Mativenga, P.T. Modelling of Direct Energy Requirements in Mechanical Machining Processes. J. Clean. Prod. 2013, 41, 179–186. [Google Scholar] [CrossRef]

- Schudeleit, T.; Züst, S.; Weiss, L.; Wegener, K. The Total Energy Efficiency Index for Machine Tools. Energy 2016, 102, 682–693. [Google Scholar] [CrossRef]

- Lv, J.; Tang, R.; Jia, S.; Liu, Y. Experimental Study on Energy Consumption of Computer Numerical Control Machine Tools. J. Clean. Prod. 2016, 112, 3864–3874. [Google Scholar] [CrossRef]

- Edem, I.F.; Mativenga, P.T. Modelling of Energy Demand from Computer Numerical Control (CNC) Toolpaths. J. Clean. Prod. 2017, 157, 310–321. [Google Scholar] [CrossRef]

- Edem, I.F.; Mativenga, P.T. Impact of Feed Axis on Electrical Energy Demand in Mechanical Machining Processes. J. Clean. Prod. 2016, 137, 230–240. [Google Scholar] [CrossRef]

- Lv, J.; Tang, R.; Jia, S. Therblig-Based Energy Supply Modeling of Computer Numerical Control Machine Tools. J. Clean. Prod. 2014, 65, 168–177. [Google Scholar] [CrossRef]

- Liu, F.; Xie, J.; Liu, S. A Method for Predicting the Energy Consumption of the Main Driving System of a Machine Tool in a Machining Process. J. Clean. Prod. 2015, 105, 171–177. [Google Scholar] [CrossRef]

- Kim, S.-Y.; Shin, Y.-J.; Kim, M.-S.; Lee, J.-Y.; Kim, E.-S.; Ahn, S.-H.; Yoon, H.-S.; Yoon, Y.-C.; Min, S. A Simplified Machine-Tool Power-Consumption Measurement Procedure and Methodology for Estimating Total Energy Consumption. J. Manuf. Sci. Eng. 2015, 138, 051004. [Google Scholar] [CrossRef]

- Yoon, H.S.; Singh, E.; Min, S. Empirical Power Consumption Model for Rotational Axes in Machine Tools. J. Clean. Prod. 2018, 196, 370–381. [Google Scholar] [CrossRef]

- Feng, M.; Hua, Z.; Qingshan, G.; Hon, K.K.B. A Novel Energy Evaluation Approach of Machining Processes Based on Data Analysis. Energy Sources Part A Recover. Util. Environ. Eff. 2019, 45, 4789–4803. [Google Scholar] [CrossRef]

- Pan, J.; Li, C.; Tang, Y.; Li, W.; Li, X. Energy Consumption Prediction of a CNC Machining Process with Incomplete Data. IEEE/CAA J. Autom. Sin. 2021, 8, 987–1000. [Google Scholar] [CrossRef]

- Pawanr, S.; Garg, G.K.; Routroy, S. A Novel Approach to Model the Energy Consumption of Machine Tools for Machining Cylindrical Parts. J. Manuf. Process. 2022, 84, 28–42. [Google Scholar] [CrossRef]

- Brillinger, M.; Wuwer, M.; Smajic, B.; Abdul Hadi, M.; Trabesinger, S.; Oberegger, B.; Jäger, M. Novel Method to Predict the Energy Consumption of Machined Parts in the Design Phase to Attain Sustainability Goals. J. Manuf. Process. 2023, 101, 1046–1054. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, L.; Liu, W.; Li, L.; Gao, Y.; Cai, W.; Sutherland, J.W. Dynamics Analysis and Energy Consumption Modelling Based on Bond Graph: Taking the Spindle System as an Example. J. Manuf. Syst. 2022, 62, 539–549. [Google Scholar] [CrossRef]

- DMG Mori Seiki Co., Ltd. Press Release DMG MORI Going Green with New Energy-Saving Functions; DMG Mori Seiki Co., Ltd.: Tokyo, Japan, 2014; Volume 81. [Google Scholar]

- Ji, Q.; Li, C.; Zhu, D.; Jin, Y.; Lv, Y.; He, J. Structural Design Optimization of Moving Component in CNC Machine Tool for Energy Saving. J. Clean. Prod. 2020, 246, 118976. [Google Scholar] [CrossRef]

- Wang, J.; Niu, W.; Ma, Y.; Xue, L.; Cun, H.; Nie, Y.; Zhang, D. A CAD/CAE-Integrated Structural Design Framework for Machine Tools. Int. J. Adv. Manuf. Technol. 2017, 91, 545–568. [Google Scholar] [CrossRef]

- Li, W.; Li, C.; Wang, N.; Li, J.; Zhang, J. Energy Saving Design Optimization of CNC Machine Tool Feed System: A Data-Model Hybrid Driven Approach. IEEE Trans. Autom. Sci. Eng. 2022, 19, 3809–3820. [Google Scholar] [CrossRef]

- Triebe, M.J.; Zhao, F.; Sutherland, J.W. Genetic Optimization for the Design of a Machine Tool Slide Table for Reduced Energy Consumption. J. Manuf. Sci. Eng. Trans. ASME 2021, 143, 101003. [Google Scholar] [CrossRef]

- Hu, L.; Zha, J.; Kan, F.; Long, H.; Chen, Y. Research on a Five-Axis Machining Center Worktable with Bionic Honeycomb Lightweight Structure. Materials 2021, 14, 74. [Google Scholar] [CrossRef] [PubMed]

- Yi, Q.; Li, C.; Ji, Q.; Zhu, D.; Jin, Y.; Li, L. Design Optimization of Lathe Spindle System for Optimum Energy Efficiency. J. Clean. Prod. 2020, 250, 119536. [Google Scholar] [CrossRef]

- Lv, Y.; Li, C.; Jin, Y.; He, J.; Li, J. Energy Saving Design of the Spindle of CNC Lathe by Structural Optimization. Int. J. Adv. Manuf. Technol. 2021, 114, 541–562. [Google Scholar] [CrossRef]

- Denkena, B.; Helmecke, P.; Hülsemeyer, L. Energy Efficient Machining of Ti-6Al-4V. CIRP Ann.—Manuf. Technol. 2015, 64, 61–64. [Google Scholar] [CrossRef]

- Zhao, L.; Fang, Y.; Lou, P.; Yan, J.; Xiao, A. Cutting Parameter Optimization for Reducing Carbon Emissions Using Digital Twin. Int. J. Precis. Eng. Manuf. 2021, 22, 933–949. [Google Scholar] [CrossRef]

- Wu, P.; He, Y.; Li, Y.; He, J.; Liu, X.; Wang, Y. Multi-Objective Optimisation of Machining Process Parameters Using Deep Learning-Based Data-Driven Genetic Algorithm and TOPSIS. J. Manuf. Syst. 2022, 64, 40–52. [Google Scholar] [CrossRef]

- Bagaber, S.A.; Yusoff, A.R. Energy and Cost Integration for Multi-Objective Optimisation in a Sustainable Turning Process. Measurement 2019, 136, 795–810. [Google Scholar] [CrossRef]

- Bousnina, K.; Hamza, A.; Ben Yahia, N. A Combination of PSO-ANN Hybrid Algorithm and Genetic Algorithm to Optimize Technological Parameters during Milling 2017A Alloy. J. Ind. Prod. Eng. 2023, 40, 554–571. [Google Scholar] [CrossRef]

- Edem, I.F.; Balogun, V.A.; Mativenga, P.T. An Investigation on the Impact of Toolpath Strategies and Machine Tool Axes Configurations on Electrical Energy Demand in Mechanical Machining. Int. J. Adv. Manuf. Technol. 2017, 92, 2503–2509. [Google Scholar] [CrossRef]

- Luan, X.; Zhang, S.; Li, J.; Li, G.; Chen, J.; Mendis, G. Comprehensive Effects of Tool Paths on Energy Consumption, Machining Efficiency, and Surface Integrity in the Milling of Alloy Cast Iron. Int. J. Adv. Manuf. Technol. 2018, 98, 1847–1860. [Google Scholar] [CrossRef]

- Feng, C.; Chen, X.; Zhang, J.; Huang, Y.; Qu, Z. Minimizing the Energy Consumption of Hole Machining Integrating the Optimization of Tool Path and Cutting Parameters on CNC Machines. Int. J. Adv. Manuf. Technol. 2022, 121, 215–228. [Google Scholar] [CrossRef]

- Lu, F.; Zhou, G.; Zhang, C.; Liu, Y.; Chang, F.; Lu, Q.; Xiao, Z.; Zhang, B.C. Energy-Efficient Tool Path Generation and Expansion Optimisation for Five-Axis Flank Milling with Meta-Reinforcement Learning. J. Intell. Manuf. 2024, 2024, 1–25. [Google Scholar] [CrossRef]

- Gao, Y.; Mi, S.; Zheng, H.; Wang, Q.; Wei, Z. An Energy Efficiency Tool Path Optimization Method Using a Discrete Energy Consumption Path Model. Machines 2022, 10, 348. [Google Scholar] [CrossRef]

- Trifunović, M.; Madić, M.; Radovanović, M. Pareto Optimization of Multi-Pass Turning of Grey Cast Iron with Practical Constraints Using a Deterministic Approach. Int. J. Adv. Manuf. Technol. 2020, 110, 1893–1909. [Google Scholar] [CrossRef]

- Zhou, L.; Li, F.; Wang, Y.; Wang, L.; Wang, G. A New Empirical Standby Power and Auxiliary Power Model of CNC Machine Tools. Int. J. Adv. Manuf. Technol. 2022, 120, 3995–4010. [Google Scholar] [CrossRef]

- Luan, X.; Zhang, S.; Chen, J.; Li, G. Energy Modelling and Energy Saving Strategy Analysis of a Machine Tool during Non-Cutting Status. Int. J. Prod. Res. 2019, 57, 4451–4467. [Google Scholar] [CrossRef]

- Sihag, N.; Sangwan, K.S. An Improved Micro Analysis-Based Energy Consumption and Carbon Emissions Modeling Approach for a Milling Center. Int. J. Adv. Manuf. Technol. 2019, 104, 705–721. [Google Scholar] [CrossRef]

- Hu, L.; Liu, Y.; Lohse, N.; Tang, R.; Lv, J.; Peng, C.; Evans, S. Sequencing the Features to Minimise the Non-Cutting Energy Consumption in Machining Considering the Change of Spindle Rotation Speed. Energy 2017, 139, 935–946. [Google Scholar] [CrossRef]

- Feng, C.; Huang, Y.; Wu, Y.; Zhang, J. Feature-Based Optimization Method Integrating Sequencing and Cutting Parameters for Minimizing Energy Consumption of CNC Machine Tools. Int. J. Adv. Manuf. Technol. 2022, 121, 503–515. [Google Scholar] [CrossRef]

- Soori, M.; Arezoo, B.; Dastres, R. Machine Learning and Artificial Intelligence in CNC Machine Tools, A Review. Sustain. Manuf. Serv. Econ. 2023, 2, 100009. [Google Scholar] [CrossRef]

- Bhinge, R.; Park, J.; Law, K.H.; Dornfeld, D.A.; Helu, M.; Rachuri, S. Toward a Generalized Energy Prediction Model for Machine Tools. J. Manuf. Sci. Eng. Trans. ASME 2017, 139, 041013. [Google Scholar] [CrossRef] [PubMed]

- Garg, A.; Lam, J.S.L.; Gao, L. Power Consumption and Tool Life Models for the Production Process. J. Clean. Prod. 2016, 131, 754–764. [Google Scholar] [CrossRef]

- Garg, A.; Lam, J.S.L.; Gao, L. Energy Conservation in Manufacturing Operations: Modelling the Milling Process by a New Complexity-Based Evolutionary Approach. J. Clean. Prod. 2015, 108, 34–45. [Google Scholar] [CrossRef]

- Iqbal, A.; Zhang, H.C.; Kong, L.L.; Hussain, G. A Rule-Based System for Trade-off among Energy Consumption, Tool Life, and Productivity in Machining Process. J. Intell. Manuf. 2015, 26, 1217–1232. [Google Scholar] [CrossRef]

- Nguyen, T.T. An Energy-Efficient Optimization of the Hard Turning Using Rotary Tool. Neural Comput. Appl. 2021, 33, 2621–2644. [Google Scholar] [CrossRef]

- ANSI/MTC1.4-2018; MTConnect Standard Version 1.4.0. MTConnect Institute: McLean, VA, USA, 2018. Available online: https://www.mtconnect.org/s/ANSI_MTC1_4-2018.pdf (accessed on 6 June 2024).

- Brillinger, M.; Wuwer, M.; Abdul Hadi, M.; Haas, F. Energy Prediction for CNC Machining with Machine Learning. CIRP J. Manuf. Sci. Technol. 2021, 35, 715–723. [Google Scholar] [CrossRef]

- Jiang, W.; Lv, L.; Xiao, Y.; Fu, X.; Deng, Z.; Yue, W. A Multi-Objective Modeling and Optimization Method for High Efficiency, Low Energy, and Economy. Int. J. Adv. Manuf. Technol. 2023, 128, 2483–2498. [Google Scholar] [CrossRef]

- Xi, L.; Li, L.; Li, L.; Zhao, J.; Sutherland, J.W. Parameter Optimization of Titanium Alloy Considering Energy Efficiency and Tool Wear Based on RBFNN-MOPSO Algorithm in Milling. J. Manuf. Process. 2024, 122, 97–111. [Google Scholar] [CrossRef]

- Wang, H.; Liu, G.; Zhang, Q.; Mu, W.L. Developing an Energy-Efficient Process Planning System for Prismatic Parts via STEP-NC. Int. J. Adv. Manuf. Technol. 2019, 103, 3557–3573. [Google Scholar] [CrossRef]

- Zhao, X.; Li, C.; Tang, Y.; Li, X.; Chen, X. Reinforcement Learning-Based Cutting Parameter Dynamic Decision Method Considering Tool Wear for a Turning Machining Process. Int. J. Precis. Eng. Manuf.—Green Technol. 2024, 11, 1053–1070. [Google Scholar] [CrossRef]

- Srinidhi, N.N.; Dilip Kumar, S.M.; Venugopal, K.R. Network Optimizations in the Internet of Things: A Review. Eng. Sci. Technol. Int. J. 2019, 22, 1–21. [Google Scholar] [CrossRef]

- Li, C.; Chen, X.; Tang, Y.; Li, L. Selection of Optimum Parameters in Multi-Pass Face Milling for Maximum Energy Efficiency and Minimum Production Cost. J. Clean. Prod. 2017, 140, 1805–1818. [Google Scholar] [CrossRef]

- ISO14649-1; Industrial Automation Systems and Integration-Physical Device Control-Data Model for Computerized Numerical Controllers—Part 1: Overview and Fundamental Principles. International Organization for Standardization: Geneva, Switzerland, 2003.

- Wang, J.; Tian, Y.; Hu, X.; Li, Y.; Zhang, K.; Liu, Y. Predictive Modelling and Pareto Optimization for Energy Efficient Grinding Based on AANN-Embedded NSGA II Algorithm. J. Clean. Prod. 2021, 327, 129479. [Google Scholar] [CrossRef]

- Chen, X.; Li, C.; Yang, Q.; Tang, Y.; Li, L.; Zhao, X. Toward Energy Footprint Reduction of a Machining Process. IEEE Trans. Autom. Sci. Eng. 2022, 19, 772–787. [Google Scholar] [CrossRef]

- Ross, N.S.; Mashinini, P.M.; Sherin Shibi, C.; Kumar Gupta, M.; Erdi Korkmaz, M.; Krolczyk, G.M.; Sharma, V.S. A New Intelligent Approach of Surface Roughness Measurement in Sustainable Machining of AM-316L Stainless Steel with Deep Learning Models. Meas. J. Int. Meas. Confed. 2024, 230, 114515. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, W.; Zhang, S.; Zhang, Y.; Zhou, J.; Wang, Z.; Huang, B.; Huang, R. A Novel Method Based on Deep Reinforcement Learning for Machining Process Route Planning. Robot. Comput. Integr. Manuf. 2024, 86, 102688. [Google Scholar] [CrossRef]

| Reference | Model | Remark |

|---|---|---|

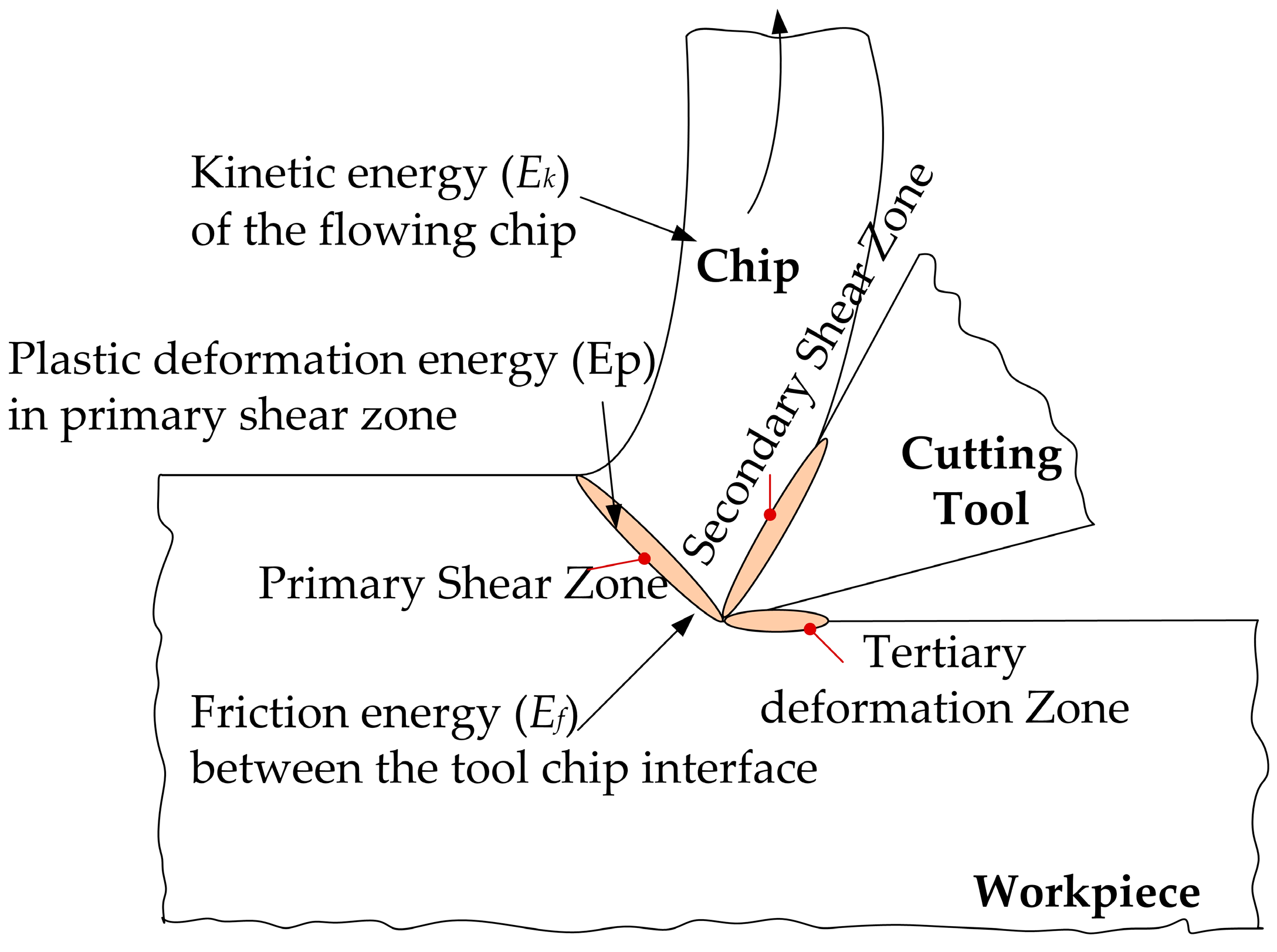

| Wang et al. [16] | where , and the energies associated with the primary shear zone, frictional forces and kinetic energy of the chips flow, respectively. | Focused only on tool-tip energy consumption |

| Dahmus and Gutowski [19] | is a constant | One of the primary models and studies which investigated the machine tools energy consumption |

| Kellens et al. [20] | (cutting state) are energy consumptions | Proposed a machining state-based approach for machine tool energy consumption modeling |

| Balogun and Mativenga [21] | (basic state), (ready state) and (cutting state) are energy consumptions | Introduced a ready state of machine tools for the modeling of the energy consumption |

| Lv et al. [26] | (total) and (standby), (coolant pump), (cutting) are power consumptions | A Therblig-based approach to evaluating and investigating the machine tools’ energy consumption |

| Liu et al. [27] | (cutting) are energy consumptions | Focused on one of the machine tools’ primary energy-intensive spindle system energy consumption |

| Kim et al. [28] | (cutting) are power consumptions | Revealed that the actual cutting process itself requires a consistent amount of energy regardless of the specific machine tool. The difference in energy use stems primarily from the power demands during idle states and spindle operation |

| Schudeleit et al. [22] | (cutting) are energy consumptions | Proposed a new metric for rating machine tool designs for energy efficiency, considering individual components and their interaction. This fills a gap in ISO standards for eco-design |

| Edem and Mativenga [25] | Investigated the impact of the feed axis weight and workpiece weight on the total energy consumption of the machine tool | |

| Edem and Mativenga [24] | (coolant pump) energy consumptions | Proposed a Numerical code-based energy modeling for machine tools |

| Yoon et al. [29] | (cutting power). | A component-level energy consumption model for machine tools focusing on the feed drive and rotational axes |

| Feng et al. [30] | represent the coefficients | Workpiece hardness, cutting tool edge, material removal rate and spindle speed were added as influential factors under this data-driven power consumption model |

| Pan et al. [31] | (additional loss) (cutting time) | A machine learning (ML) model for machine tool energy consumption prediction, leveraging data to compensate for missing information |

| Pawanr et al. [32] | (variable MRR machining) energy consumptions | Proposed a new model for machine tool energy consumption considering both constant and variable material removal rates |

| Brillinger et al. [33] | (removed volume of material) | Proposed prediction technique for energy consumption during the design phase, allowing designers to make eco-friendly choices upfront. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pawanr, S.; Gupta, K. A Review on Recent Advances in the Energy Efficiency of Machining Processes for Sustainability. Energies 2024, 17, 3659. https://doi.org/10.3390/en17153659

Pawanr S, Gupta K. A Review on Recent Advances in the Energy Efficiency of Machining Processes for Sustainability. Energies. 2024; 17(15):3659. https://doi.org/10.3390/en17153659

Chicago/Turabian StylePawanr, Shailendra, and Kapil Gupta. 2024. "A Review on Recent Advances in the Energy Efficiency of Machining Processes for Sustainability" Energies 17, no. 15: 3659. https://doi.org/10.3390/en17153659

APA StylePawanr, S., & Gupta, K. (2024). A Review on Recent Advances in the Energy Efficiency of Machining Processes for Sustainability. Energies, 17(15), 3659. https://doi.org/10.3390/en17153659