Mechanical Damage to Coal and Increased Coal Permeability Caused by Water-Based Ultrasonic Cavitation

Abstract

1. Introduction

2. Methodology

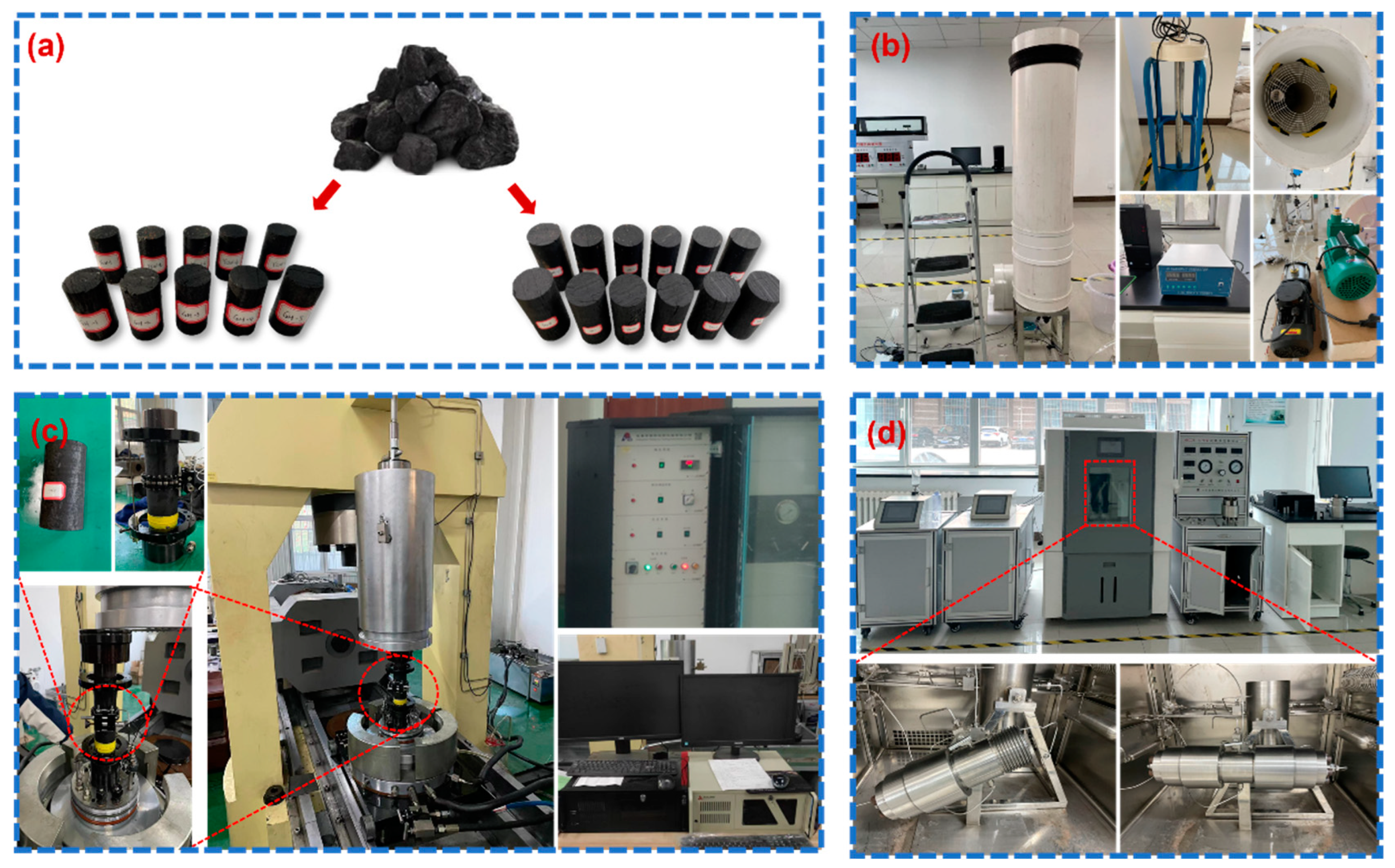

2.1. Sample Preparation

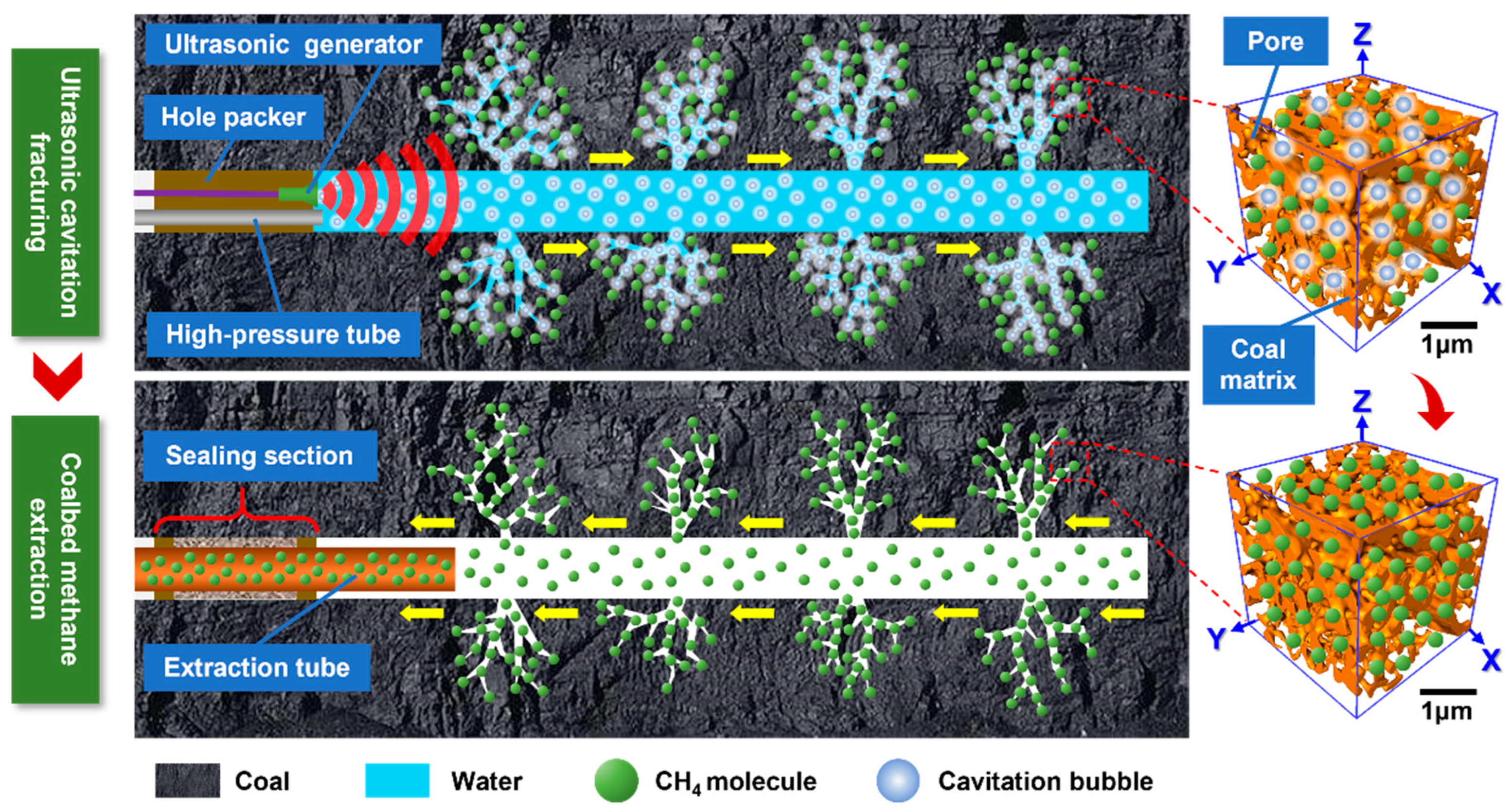

2.2. Water-Based Ultrasonic Cavitation Treatment

2.3. Uniaxial Compressive Strength Test

2.4. Gas Permeability Test

3. Analysis and Discussion

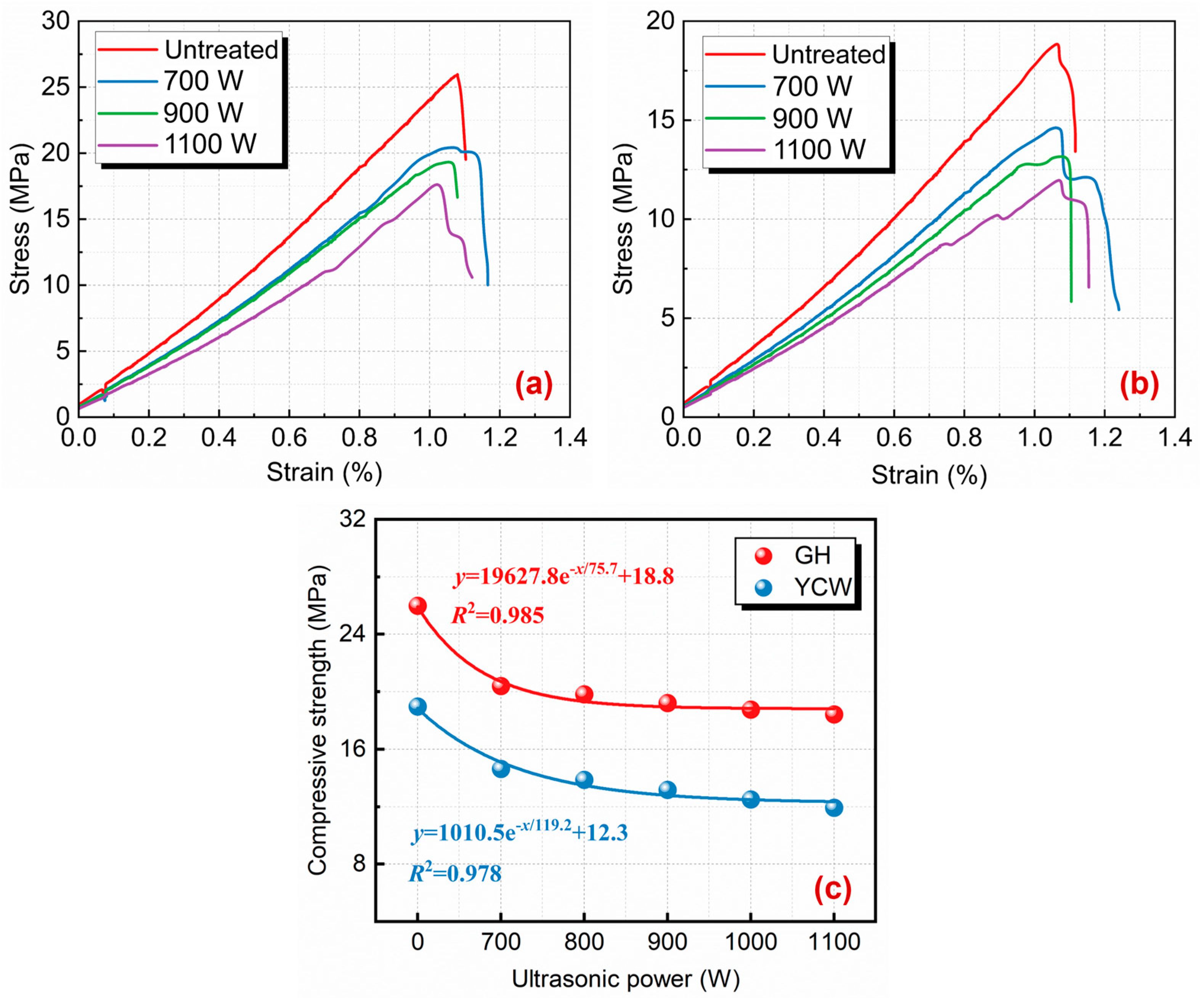

3.1. Characteristics of Coal Mechanical Damage

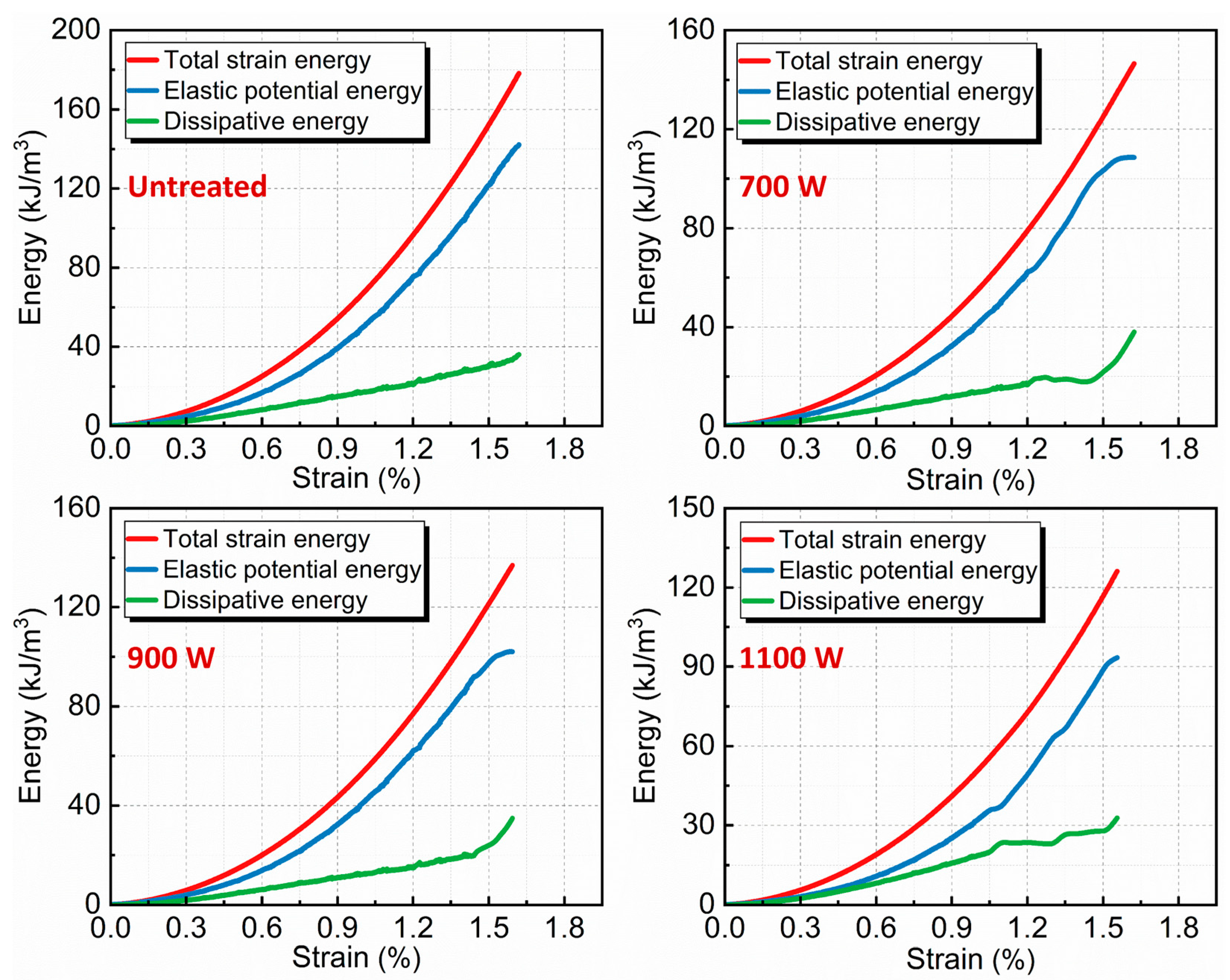

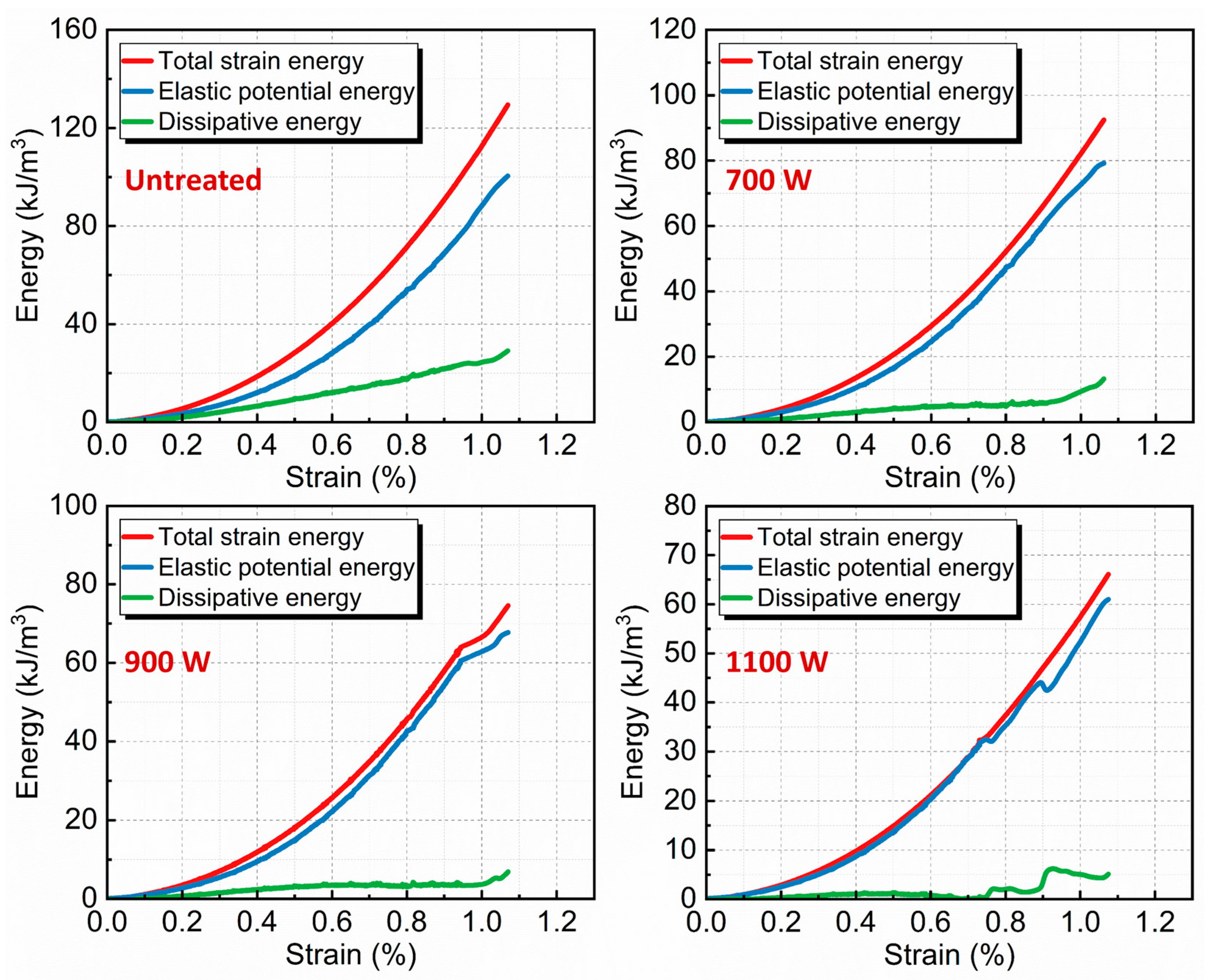

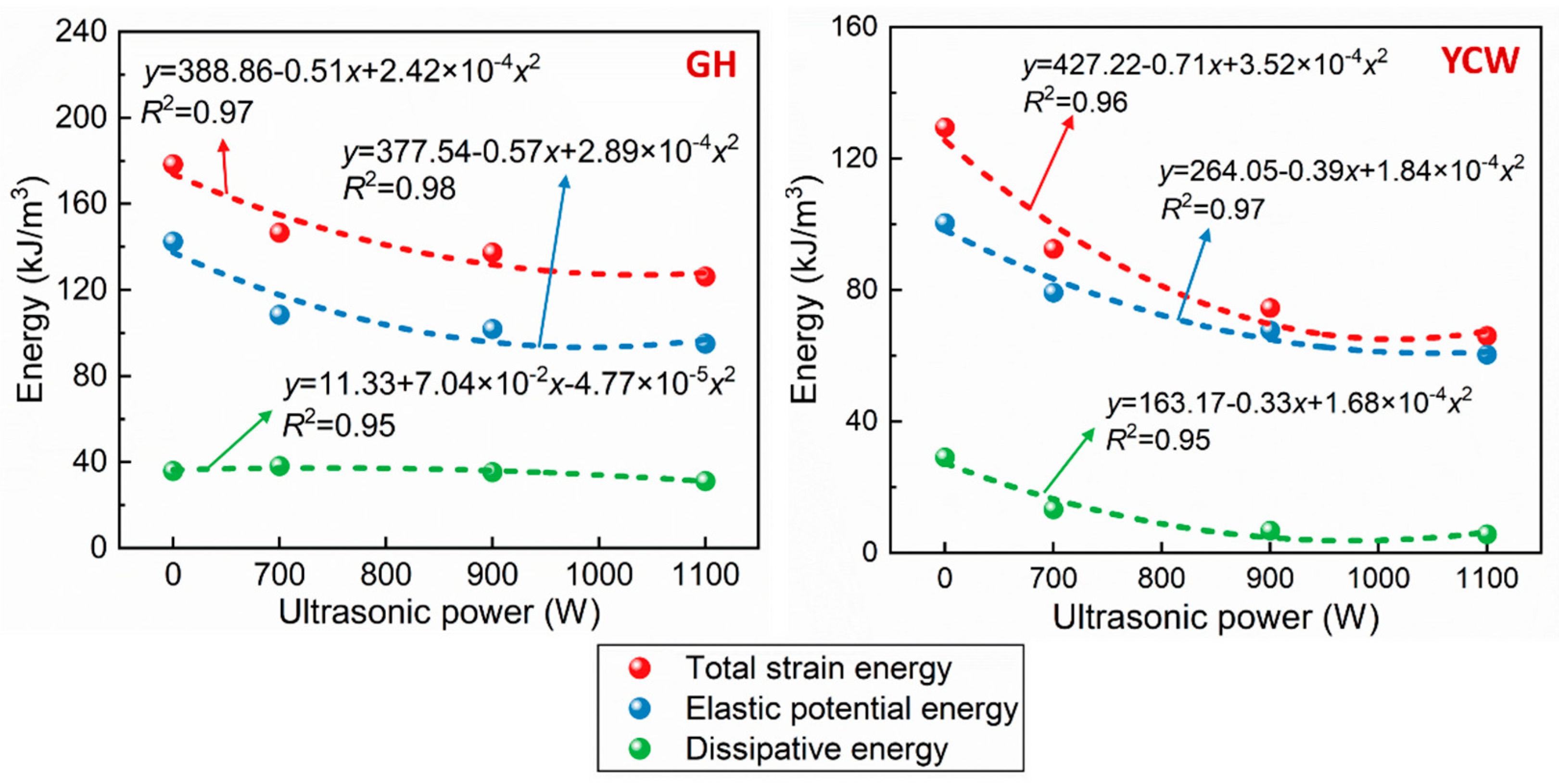

3.2. Changes in Coal Strain Energy

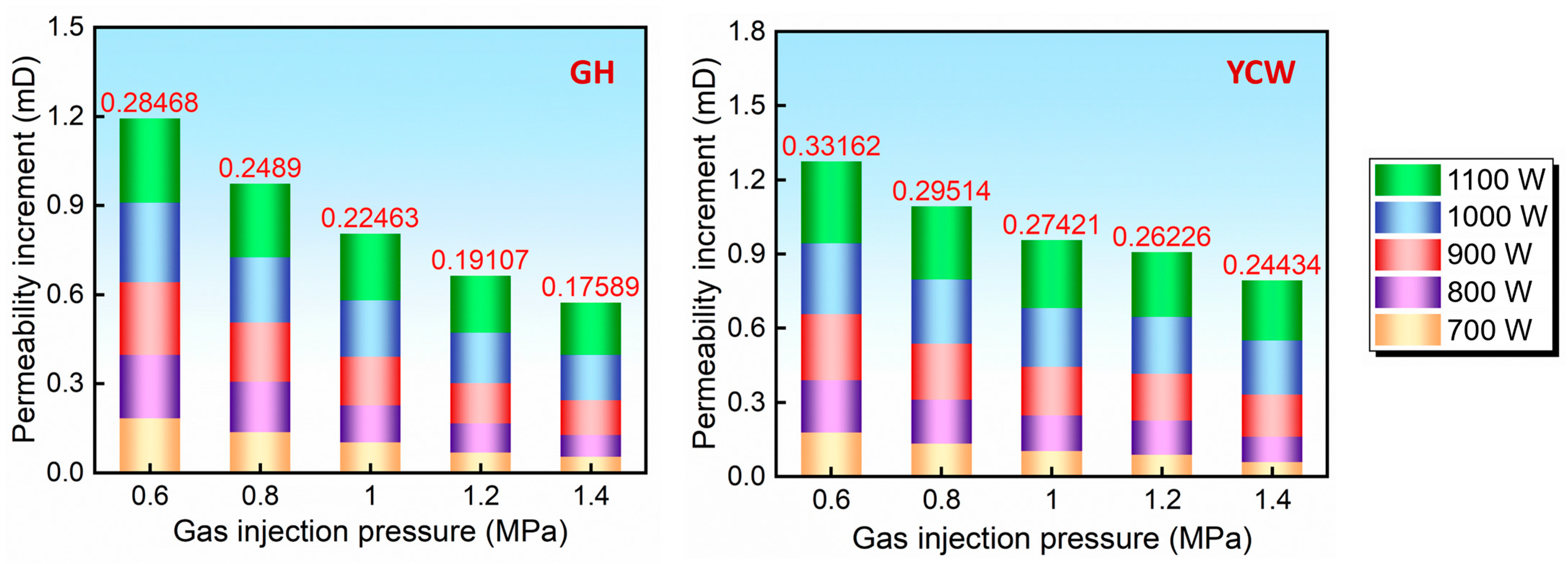

3.3. The Influence of Gas Pressure on Permeability

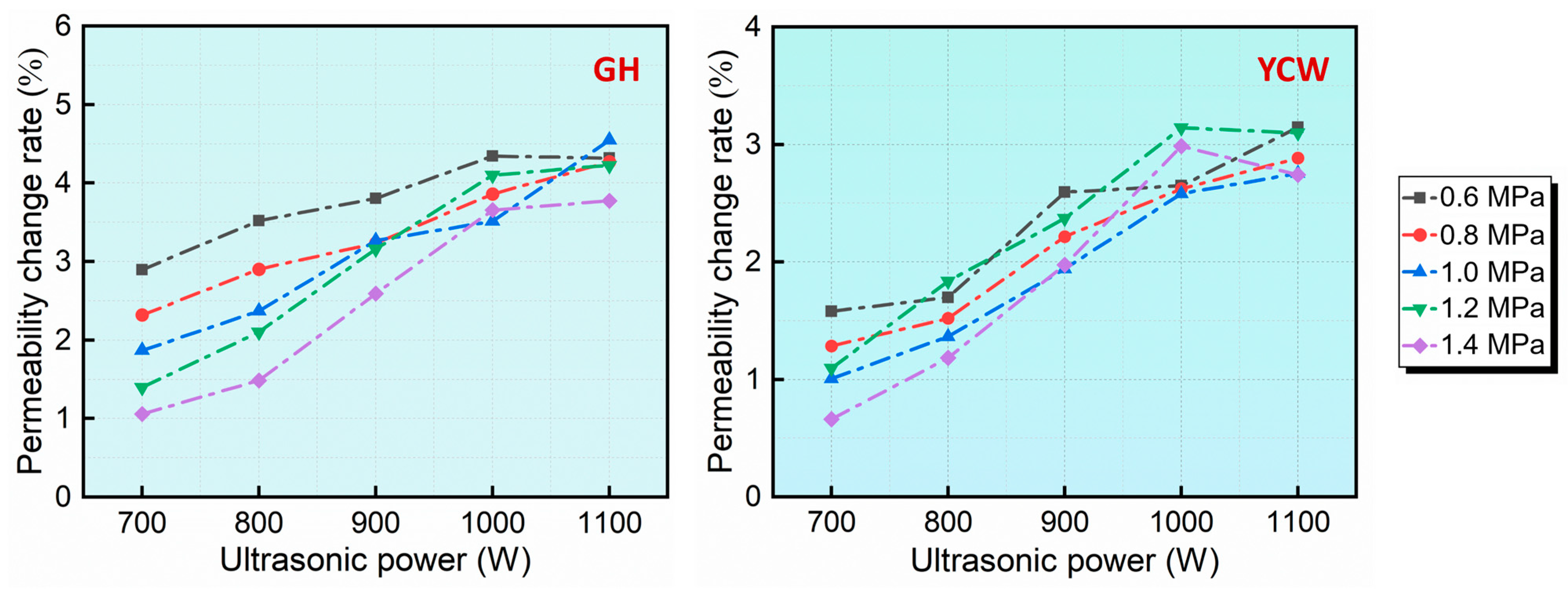

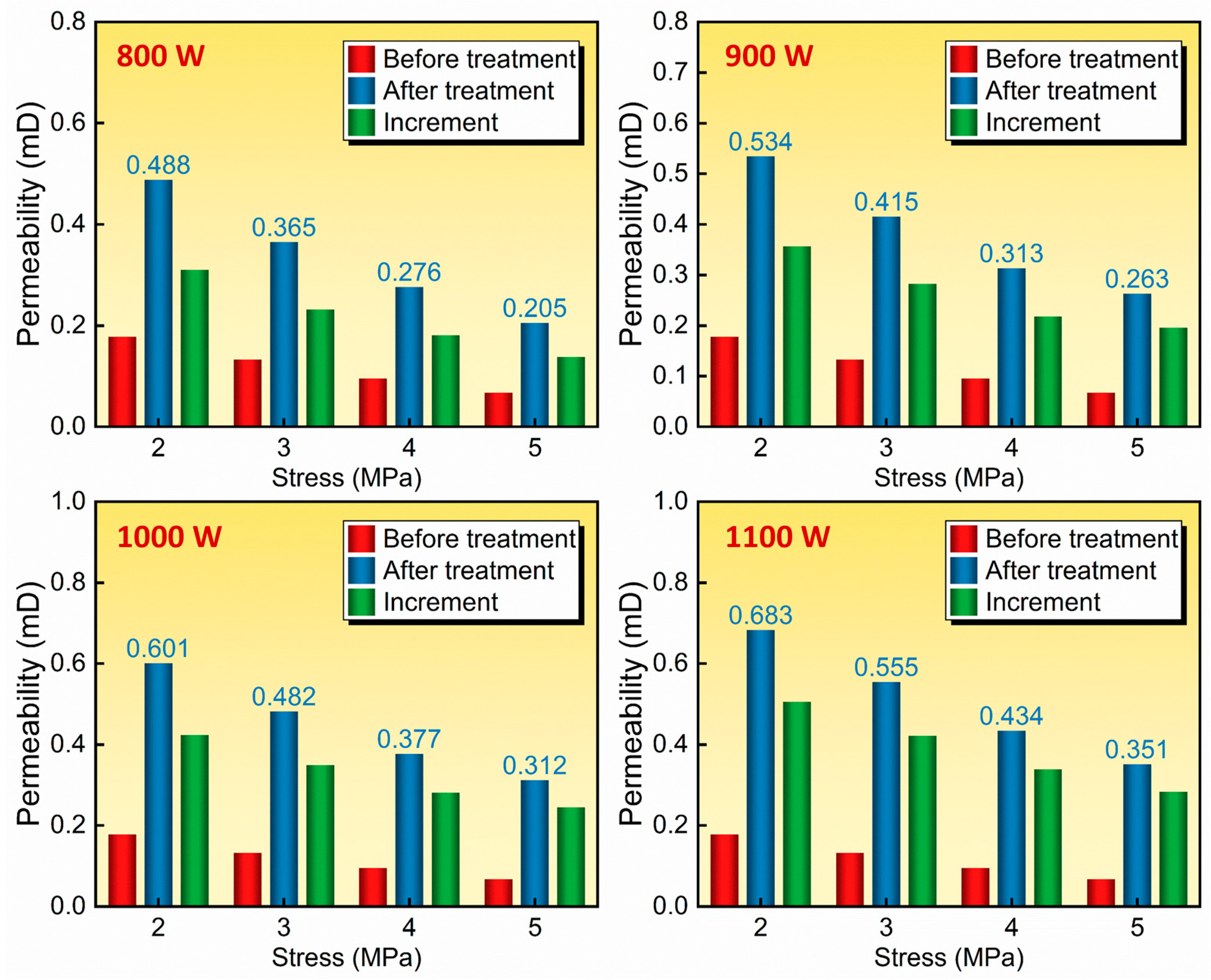

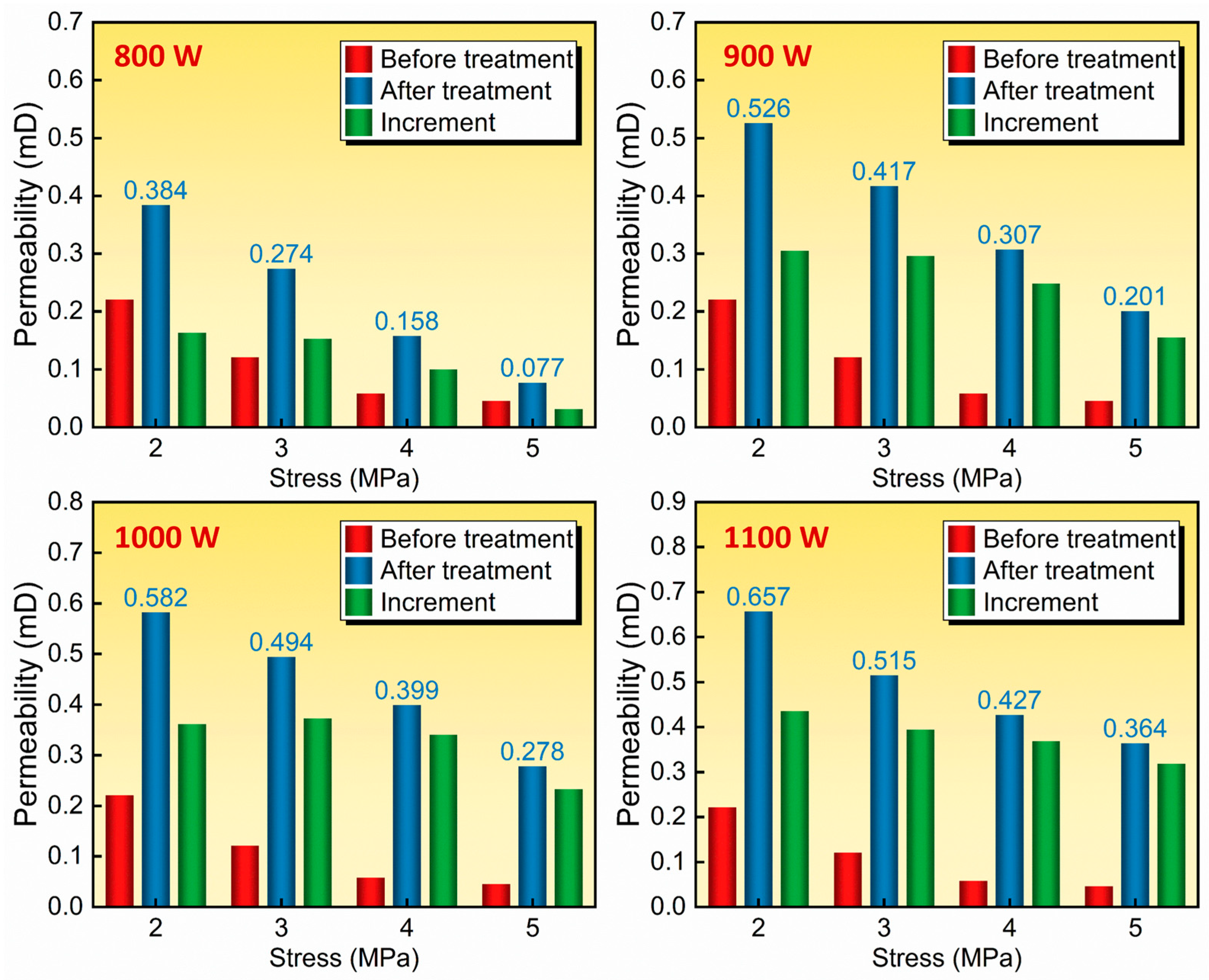

3.4. The Influence of Stress on Permeability

4. Conclusions

- (1)

- Water-based ultrasonic cavitation has the potential to significantly weaken coal’s structure and mechanical properties. For example, after 1100 W ultrasonic cavitation treatment, GH bituminous coal and YCW lignite exhibited reductions in their uniaxial compressive strengths by 31.02% and 37.03%, respectively. There was a negative exponential relationship between compressive strength and ultrasonic power, following a pattern of significant decrease, which is attributed to damage to the coal’s pore and fissure structure.

- (2)

- The damage to pores and fissures caused by ultrasonic cavitation profoundly impacts coal’s energy storage and conversion efficiency during compression. As ultrasonic power increased, dissipative energy, elastic potential energy, and total strain energy evidently decreased, particularly in YCW lignite. The possible reason is that ultrasonic cavitation altered the microstructure of coal. In an environment of 1100 W ultrasonic cavitation, the total strain energy and elastic potential energy of GH bituminous coal decreased by 29.22% and 48.96%, respectively, while those of YCW lignite decreased by 42.39% and 39.85%, respectively.

- (3)

- The ultrasonic cavitation effect effectively enhanced coal’s permeability, with GH bituminous coal’s and YCW lignite’s permeability increasing by 4.32 and 3.14 times, respectively, in a 1000 W ultrasonic cavitation environment. This enhancement resulted from seepage structural damage, topological degradation, and throat dredging, which facilitate gas diffusion and migration within coal. Additionally, with increasing ultrasonic power, coal permeability and its rate of change also increased. However, as circumferential stress intensified, the permeability and its increment gradually declined. As gas injection pressure rose, permeability initially decreased but eventually stabilized. Therefore, in practical applications of WUC-ECBM, increasing ultrasonic power is a potential optimization method, but the impact of ground stress on this approach should be carefully analyzed.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| CBM | Coalbed methane; |

| WUC-ECBM | Water-based ultrasonic cavitation-enhanced coalbed methane recovery. |

References

- Wang, K.; Zhang, X. Current Status and Prospects of CMM Drainage Technologies in China. China Coalbed Methane 2006, 3, 13–16. [Google Scholar] [CrossRef]

- Kong, S.; Feng, G.; Liu, Y.; Li, K. Potential of dimethyl ether as an additive in CO2 for shale oil recovery. Fuel 2021, 296, 120643. [Google Scholar] [CrossRef]

- Zhang, D.; Zhu, J.; Zhao, X.; Gao, X.; Geng, M.; Chen, G.; Jiao, J.; Liu, S. Dynamic assessment of coalbed methane resources and availability in China. J. China Coal Soc. 2018, 43, 1598–1604. [Google Scholar] [CrossRef]

- Xu, F.; Hou, W.; Xiong, X.; Xu, B.; Wu, P.; Wang, H.; Feng, K.; Yun, J.; Li, S.; Zhang, L.; et al. The status and development strategy of coalbed methane industry in China. Pet. Explor. Dev. 2023, 50, 669–682. [Google Scholar] [CrossRef]

- Yuan, L. Key Technique of Safe Mining in Low Permeability and Methane-Rich Seam Group. Chin. J. Rock Mech. Eng. 2008, 27, 1370–1379. [Google Scholar] [CrossRef]

- Cheng, Y.; Yu, Q. Development of Regional Gas Control Technology for Chinese Coalmines. J. Min. Saf. Eng. 2007, 24, 383–390. [Google Scholar] [CrossRef]

- Wang, Y.; He, X.; Wang, E.; Li, Y. Research progress and development tendency of the hydraulic technology for increasing the permeability of coal seams. J. China Coal Soc. 2014, 39, 1945–1955. [Google Scholar] [CrossRef]

- Li, X.; Wang, X.; Kang, Y.; Yuan, B.; Fang, Z.; Li, D.; Hu, Y. Energy characteristic and dissipation in transient process of hydraulic cutting seams system in coal seam. J. China Coal Soc. 2014, 39, 1404–1408. [Google Scholar] [CrossRef]

- Zhang, R. Research on the Stress Relief and Permeability Increase Mechanism and High-Efficiency Gas Drainage Method on a Composite Coal Seam. Ph.D. Thesis, China University of Mining and Technology, Xuzhou, China, 2019. [Google Scholar]

- Sun, J. Applied Research on Permeability Increasing by Liquid Carbon Dioxide Phase Transition Blasting based on Different Initiating Condition. Ph.D. Thesis, China University of Mining and Technology, Xuzhou, China, 2015. [Google Scholar]

- Liao, R.; Xu, Y.; Hu, X. Damage to Low-Permeability Reservoir by Water Locking Effect and Its Inhibiting and Removing Method. Nat. Gas Ind. 2002, 22, 87–89. [Google Scholar] [CrossRef]

- Zhao, Y.; Wan, Z.; Zhang, Y.; Zhang, N.; Feng, Z.; Dong, F.; Wu, J.; Qu, F. Experimental Study of Related Laws of Rock Thermal Cracking and Permeability. Chin. J. Rock Mech. Eng. 2010, 29, 1970–1976. [Google Scholar]

- Gao, J.; Fang, Y.; Liu, J.; Lu, F.; Hu, J. Influence of multi-component acid acidification on anti-reflection effect of high-rank coal in Zhongmacun Mine. J. Saf. Environ. 2022, 22, 3111–3126. [Google Scholar] [CrossRef]

- Guo, J. Research on Characteristics and its Mechanism of Intensifying Gas Desorption and Seepage of Anthracite by Electrochemical Method. Ph.D. Thesis, Taiyuan University of Technology, Taiyuan, China, 2015. [Google Scholar]

- Lin, H.; Wang, P.; Li, S.; Li, B.; Luo, R.; Qin, L. Evolution law and model of coal permeability under liquid nitrogen cycle freezing and thawing. J. Min. Saf. Eng. 2023, 40, 1067–1077. [Google Scholar] [CrossRef]

- Zhang, L.; Guo, X.; Liu, Y.; Deng, C.; Song, L.; Zhou, Q.; Shi, J.; Zhou, Y. Controlled mechanism of dynamic behavior of water-based ultrasonic cavitation in coal pore microstructure. Fuel 2024, 358 Pt B, 130003. [Google Scholar] [CrossRef]

- Cao, L.; Guo, X.; Song, L.; Deng, C.; Zhang, Y.; Mu, Y.L.; Liu, F.; Xu, J. Spatial evolution mechanism of coal structure damage and gas permeability under water-based ultrasonic treatment. Environ. Earth Sci. 2024, 83, 299. [Google Scholar] [CrossRef]

- Van Wijngaarden, L. Mechanics of collapsing cavitation bubbles. Ultrason. Sonochem. 2016, 29, 524–527. [Google Scholar] [CrossRef] [PubMed]

- Shen, Y. Theoretical & Experimental Study of a Single Bubble Cavitation and Population of Cavitation Bubble s in Ultrasound Field. Ph.D. Thesis, Northeastern University, Shenyang, China, 2019. [Google Scholar]

- Xian, X. The present situation of coal-bed methane mining and utilization in our country and looking forward to its industrialization. J. Chongqing Univ. (Nat. Sci. Ed.) 2000, 15, 1–5. [Google Scholar] [CrossRef]

- Nie, B.; He, X.; Wang, E.; Zhang, L.; Feng, Z.; Xue, E. The effect of power sound wave on storage and motion of coalbed methane. Coal Geol. Explor. 2004, 32, 23–26. [Google Scholar] [CrossRef]

- Yao, Y.; Liu, D.; Xie, S. Quantitative characterization of methane adsorption on coal using a low-field-NMR relaxation method. Int. J. Coal Geol. 2014, 131, 32–40. [Google Scholar] [CrossRef]

- Lu, Y.; Ding, H.; Ge, Z.; Xia, B.; Cheng, L. Experiment study of effect of coal permeability under thermal effect of cavitation water jets. Rock Soil Mech. 2014, 35, 1247–1254. [Google Scholar] [CrossRef]

- Jiang, Y.; Song, C.; Wang, S.; Kang, Z.; Wang, P.; Huang, K. Study on desorption and diffusion characteristics of coalbed methane under ultrasonic excitation. Coal Sci. Technol. 2020, 48, 174–179. [Google Scholar] [CrossRef]

- Ma, H.; Zhai, C.; Xu, J.; Sun, Y. Effect of NMR technology-based ultrasonic frequency on stimulated cracking of coal. Coal Geol. Explor. 2019, 47, 38–44. [Google Scholar] [CrossRef]

- Yu, G.; Zhai, C.; Qin, L.; Tang, Z.; Wu, S.; Xu, J. Changes to coal pores by ultrasonic wave excitation of different power. J. China Univ. Min. Technol. 2018, 47, 264–270+322. [Google Scholar] [CrossRef]

- Wang, S.; Shi, Q.; Wang, S.; Shen, Y.; Sun, Q.; Cai, Y. Resource property and exploitation concepts with green and low-carbon of tar-rich coal as coal-based oil and gas. J. China Coal Soc. 2021, 46, 1365–1377. [Google Scholar] [CrossRef]

- Hu, G.; Zhu, Y.; Xu, J.; Qin, W. Mechanism of the controlled microwave field enhancing gas desorption and diffusion in coal. J. China Univ. Min. Technol. 2017, 46, 480–492. [Google Scholar] [CrossRef]

- Xiong, J.; Wan, Y.; Liu, X.; Liang, L.; Shen, L. Experimental Device Design for Enhancing Desorption of Shale Gas by Ultrasonic Wave. Res. Explor. Lab. 2020, 39, 77–79+97. [Google Scholar] [CrossRef]

- Kozmus, G.; Zevnik, J.; Hočevar, M.; Dular, M.; Petkovšek, M. Characterization of cavitation under ultrasonic horn tip—Proposition of an acoustic cavitation parameter. Ultrason. Sonochem. 2022, 89, 106159. [Google Scholar] [CrossRef] [PubMed]

- An, Y. Nonlinear bubble dynamics of cavitation. Phys. Rev. E 2012, 85, 016305. [Google Scholar] [CrossRef] [PubMed]

- Sieber, A.B.; Preso, D.B.; Farhat, M. Cavitation bubble dynamics and microjet atomization near tissue-mimicking materials. Phys. Fluids 2023, 35, 027101. [Google Scholar] [CrossRef]

- Kong, S.; Huang, X.; Li, K.; Song, X. Adsorption/desorption isotherms of CH4 and C2H6 on typical shale samples. Fuel 2019, 255, 115632. [Google Scholar] [CrossRef]

- Yang, H.; Wang, W.; Lu, K.; Chen, Z. Cavitation reduction of a flapper-nozzle pilot valve using continuous microjets. Int. J. Heat Mass Transf. 2019, 133, 1099–1109. [Google Scholar] [CrossRef]

- Wen, Z.; Wang, Q.; Yang, Y.; Si, L. Pore structure characteristics and evolution law of different-rank coal samples. Geofluids 2021, 2021, 1505306. [Google Scholar] [CrossRef]

- Chen, Y.; Xie, G.; Chang, J.; Grundy, J.; Liu, Q. A study of coal aggregation by standing-wave ultrasound. Fuel 2019, 248, 38–46. [Google Scholar] [CrossRef]

- Zhao, Z.; Liu, P.; Li, Q.; Nie, B.; Zhao, K.; Zhao, Y.; Liu, X.; Bao, G.; Song, J.; Gao, Y. Evaluating coal pore structure and gas sorption-diffusion behavior alteration induced by ultrasound stimulation using sorbing tests and matrix diffusion modeling. Geoenergy Sci. Eng. 2024, 234, 212642. [Google Scholar] [CrossRef]

- Zhang, R.; Hao, C. Research on the Development of Hydraulic Flushing Caverning Technology and Equipment for Gas Extraction in Soft and Low Permeability Tectonic Coal Seams in China. ACS Omega 2022, 7, 21615–21623. [Google Scholar] [CrossRef] [PubMed]

- Zou, Q.; Zhang, T.; Ma, T.; Tian, S.; Jia, X.; Jiang, Z. Effect of water-based SiO2 nanofluid on surface wettability of raw coal. Energy 2022, 254, 124228. [Google Scholar] [CrossRef]

- Zou, Q.; Chen, Z.; Cheng, Z.; Liang, Y.; Xu, W.; Wen, P.; Zhang, B.; Liu, H.; Kong, F. Evaluation and intelligent deployment of coal and coalbed methane coupling coordinated exploitation based On Bayesian network and cuckoo search. Int. J. Min. Sci. Technol. 2022, 32, 1315–1328. [Google Scholar] [CrossRef]

- Khachatryan, A.; Aloyan, S.; May, P.; Sargsyan, R.; Khachatryan, V.; Baghdasaryan, V. Graphite-to-diamond transformation induced by ultrasound cavitation. Diam. Relat. Mater. 2008, 17, 931–936. [Google Scholar] [CrossRef]

- Chen, J.; Cheng, W.; Wang, G.; Li, H. Correlation mechanism between the law of ultrasonic propagation in coal samples and the migration of water. Fuel 2021, 310 Pt A, 122264. [Google Scholar] [CrossRef]

| Coal Samples | Type | Maceral Proportion (%) | Ro,max (%) | Mad (%) | Aad (%) | Vdaf (%) | FCad (%) | |||

|---|---|---|---|---|---|---|---|---|---|---|

| Vitrinite | Inertinite | Exinite | Mineral | |||||||

| GH | Bituminous coal | 57.81 | 32.19 | 2.50 | 7.50 | 1.18 | 3.09 | 13.72 | 22.65 | 60.54 |

| YCW | Lignite | 42.67 | 55.68 | 0.00 | 1.65 | 0.73 | 8.08 | 3.26 | 30.06 | 58.60 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, X.; Liu, Y.; Li, Y.; Deng, C.; Zhang, L.; Zhang, Y. Mechanical Damage to Coal and Increased Coal Permeability Caused by Water-Based Ultrasonic Cavitation. Energies 2024, 17, 3626. https://doi.org/10.3390/en17153626

Guo X, Liu Y, Li Y, Deng C, Zhang L, Zhang Y. Mechanical Damage to Coal and Increased Coal Permeability Caused by Water-Based Ultrasonic Cavitation. Energies. 2024; 17(15):3626. https://doi.org/10.3390/en17153626

Chicago/Turabian StyleGuo, Xiaoyang, Yijia Liu, Yanfeng Li, Cunbao Deng, Lemei Zhang, and Yu Zhang. 2024. "Mechanical Damage to Coal and Increased Coal Permeability Caused by Water-Based Ultrasonic Cavitation" Energies 17, no. 15: 3626. https://doi.org/10.3390/en17153626

APA StyleGuo, X., Liu, Y., Li, Y., Deng, C., Zhang, L., & Zhang, Y. (2024). Mechanical Damage to Coal and Increased Coal Permeability Caused by Water-Based Ultrasonic Cavitation. Energies, 17(15), 3626. https://doi.org/10.3390/en17153626